Page 1

ORDER NO. CPD0606050C1

Wireless Display

CF-08TX1A1M

This is the Service Manual for

the following areas.

M …for U.S.A.

© 2006 Matsushita Electric Industrial Co., Ltd. All rights

reserved. Unauthorized copying and distribution is a violation

Page 2

1

Page 3

2

Page 4

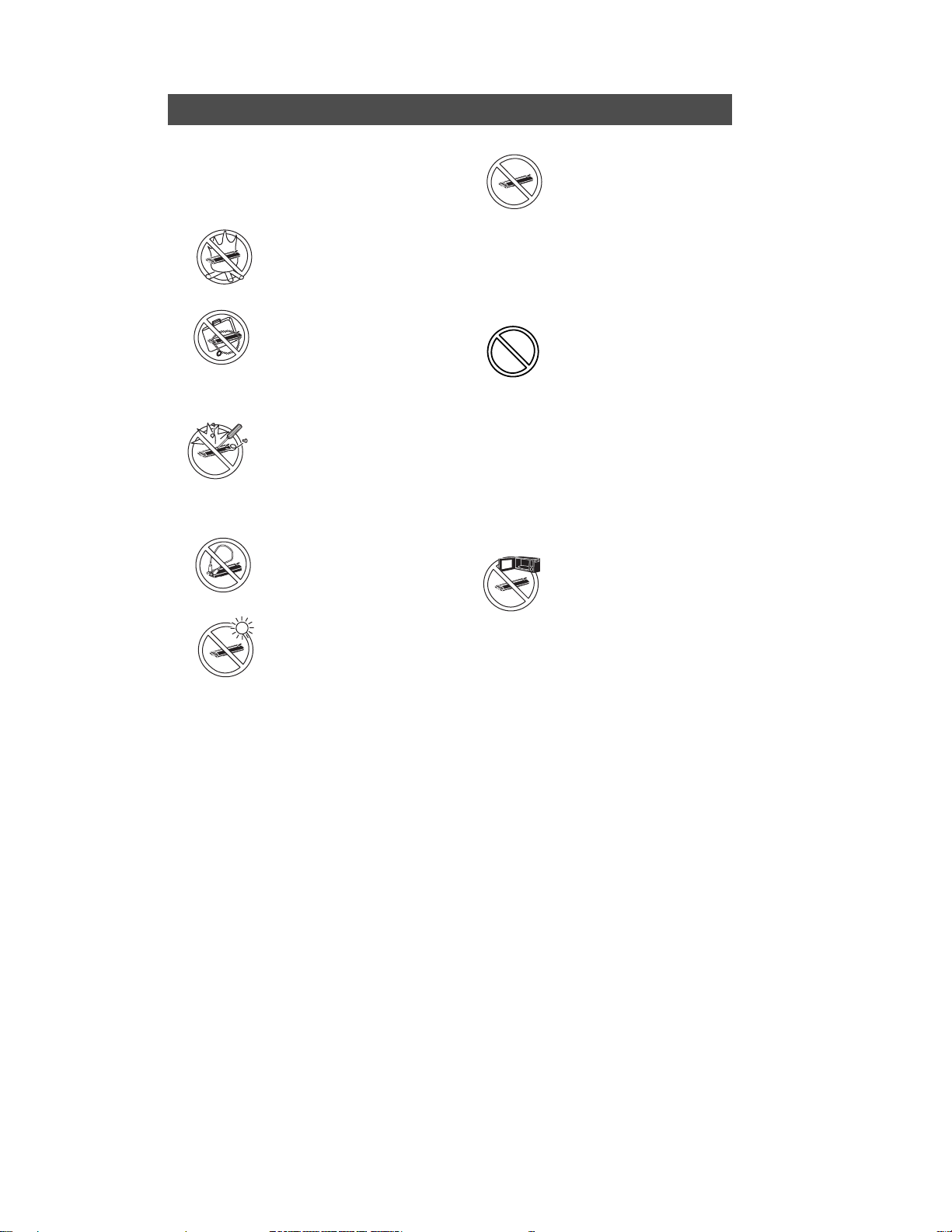

Precautions

Battery Pack

Care should be exercised with

regard to the following in order to

avoid the possibility of overheating,

fire or damage.

Avoid Heat

Do not throw the battery

pack into a fire or expose

it to excessive heat.

Keep Articles Away

Do not place the battery

pack together with articles such as necklaces

or hairpins when carrying or storing.

Do Not Disassemble

Do not insert sharp

objects into the battery

pack, expose it to bumps

or shocks, deform, disassemble, or modify it.

Do Not Short

Do not short the positive

(+) and negative (-) contacts.

Avoid Extreme Heat,

Cold and Direct Sunlight

Do not charge, use or

leave the battery pack for

extended periods where

it will be exposed to

direct sunlight, in a hot

place (in a car on a

sunny day, for example),

or in a cold place.

Do Not Use With Any

Other Equipment

The battery pack is

rechargeable and was

intended for the specified equipment. Do not

use it with any equipment

other than the one for

which it was designed.

Do Not Use This Wireless Display with a Battery Pack Other Than

the One Specified

Use only the specified

Panasonic battery pack

(CF-VZSU44U) with your

CF-08. Use of batteries

other than those manufactured and supplied by

Panasonic may represent a safety hazard.

Do Not Put into a Microwave

Do not put the battery

pack into a microwave

oven or a pressurized

chamber.

3

Page 5

Stop Using

Should the battery emit

an abnormal odor,

become hot to the touch,

become discolored,

change shape, or

become in any way different from normal,

remove it from the wireless display and stop

using it.

Do not touch the terminals on the

battery pack. The battery pack may

no longer function properly if the

contacts are dirty or damaged.

Do not expose the battery pack to

water, or allow it to become wet.

If the battery pack will not be used

for a long period of time (a month or

more), charge or discharge (use) the

battery pack until the remaining battery level becomes 30% to 40% and

store it in a cool, dry place.

This wireless display prevents overcharging of the battery by recharging

only when the remaining power is

less than approx. 95% of capacity.

The battery pack is not charged

when the wireless display is first purchased. Be sure to charge it before

using it for the first time. When the

AC adaptor is connected to the wireless display, charging begins automatically.

Should the battery leak and the fluid

get into your eyes, do not rub your

eyes. Immediately flush your eyes

with clear water and see a doctor for

medical treatment as soon as possible.

NOTENOTE

The battery pack may become warm

during recharging or normal use.

This is completely normal.

Recharging will not commence if

internal temperature of the battery

pack is outside of the allowable temperature range (0 °C to 45 °C {32°F

to 122°F}). Once the allowable range

requirement is satisfied, charging

begins automatically. Note that the

recharging time varies based on the

usage conditions. (Recharging takes

longer than usual when the temperature is 10 °C {50°F} or below.)

If the temperature is low, the operating time is shortened. Only use the

equipment within the allowable temperature range.

The battery pack is a consumable

item. If the amount of time the equipment can be run by using a particular

battery pack becomes dramatically

shorter and repeated recharging

does not restore its performance, the

battery pack should be replaced with

a new one.

When transporting a spare battery

inside a package, briefcase, etc., it is

recommended that it be placed in a

plastic bag so that its contacts are

protected.

Always power off the equipment

when it is not in use. Leaving the

equipment on when the AC adaptor

is not connected will exhaust the

remaining battery capacity.

4

Page 6

CONTENTS

1. Specifications ··················································································································1-1

2. Introduction······················································································································2-1

3. Description of parts ·········································································································3-1

4. Starting up/Shutting Down·······························································································4-1

5. Diagnosis & Repair··········································································································5-1

6. Troubleshooting···············································································································6-1

7. Block Diagram ·················································································································7-1

8. Wiring Connection Diagram ····························································································8-1

9. Disassembly/Reassembly ·····························································································9-1

10. Exploded View·············································································································10-1

11. Replacement Parts List ·······························································································11-1

Page 7

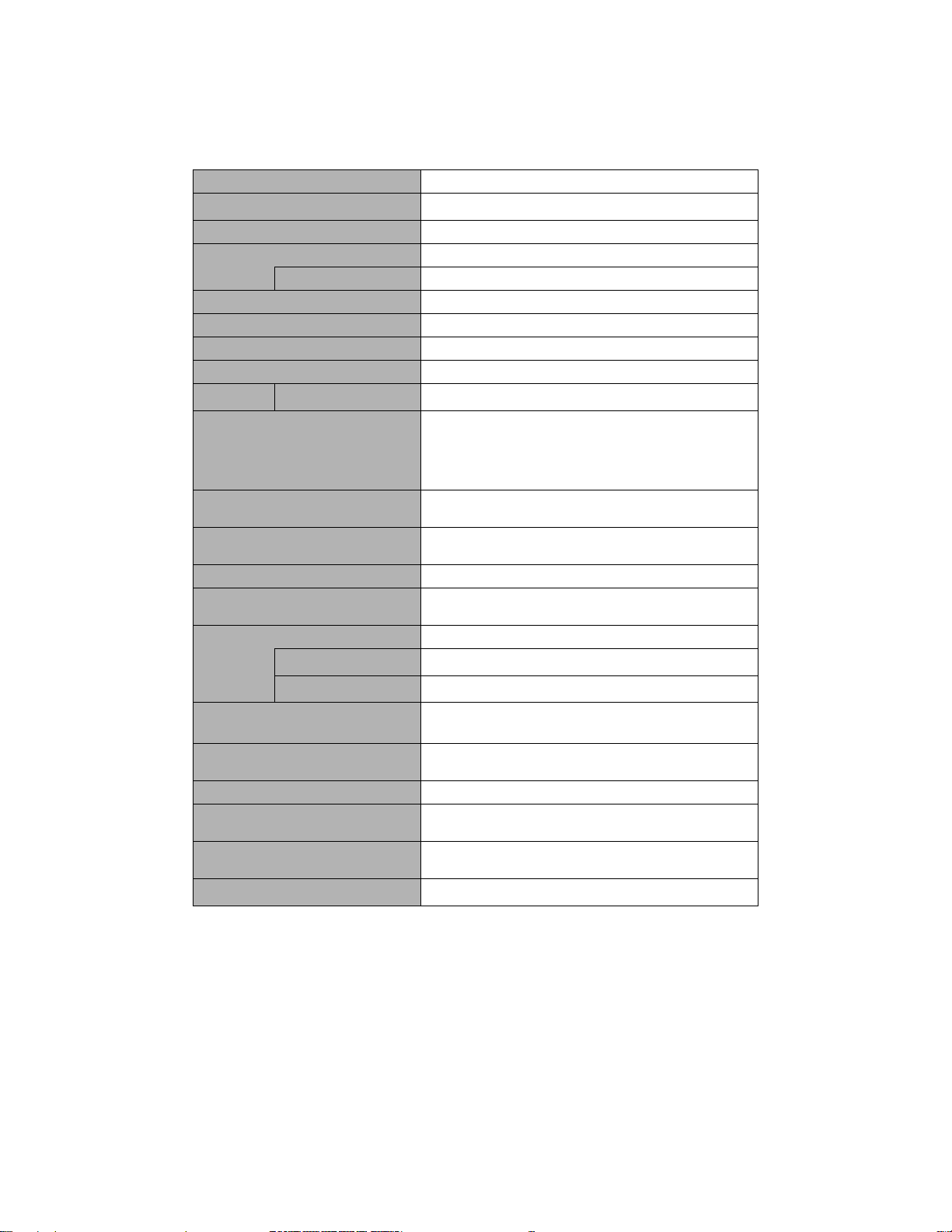

1 Specifications

Main Specifications

Model No. CF-08TX1A1M

CPU

Memory (ROM/RAM) 32 MB (Flash) /64 MB

Display Method 10.4 XGA type

Internal LCD Display 65,536 colors (1024 × 768 pixels)

Wireless LAN Built-in

Bluetooth Built-in

LAN IEEE 802.3 10Base-T, IEEE 802.3u 100Base-TX

Sound WAVE playback, Monaural speaker

Card Slot

Interface USB Port × 1 (USB1.1), LAN Port (RJ-45), Expan-

Button Power button, USER button, Keyboard button,

Pointing Device Touchscreen (Anti-Reflection, Stylus (included)

Power Supply AC adaptor or Battery pack

AC Adaptor

Battery Pack Li-ion 7.4 V, 5.2 Ah

Power Consumption

Physical Dimensions (W × H × D) 267 mm × 208 mm × 36 mm (excluding protrusion)

Weight Approx. 1.2 kg {Approx. 2.6 lb.}

Operation Environment Temperature: 5 °C to 35 °C {41 °F to 95 °F}

Storage Environment Temperature: -20 °C to 60 °C {-4 °F to 140 °F}

Operating System

SD Memory Card

*3

Operating Time

Charging Time

Intel® PXA270 Processor 312 MHz

*1

× 1, Data transfer rate=4.8 MB per second

sion Bus Connector (Dedicated 16-pin), Microphone

Jack (Miniature jack, 3.5 DIA, Monaural), Headphone Jack (Miniature jack, 3.5 DIA, Impedance

32 , Output Power 4 mW × 2)

Cursor control button (with Enter key)

touch capable)

Input: 100 V to 240 V AC, 50 Hz/60 Hz

Output: 16.0 V DC, 2.5 A

*4

*4

*7

Approx. 4.5 hours to 14 hours*5 (Approx. 7 hours)

Approx. 4 hours

Approx. 10 W *8/ Approx. 30 W (Maximum when

recharging in the ON state)

{10.5 ’’ × 8.2 ’’ × 1.4 ’’}

Humidity: 30% to 80% RH (No condensation)

Humidity: 30% to 90% RH (No condensation)

Microsoft® Windows® CE 5.0 Professional

*2

*6

1-1

Page 8

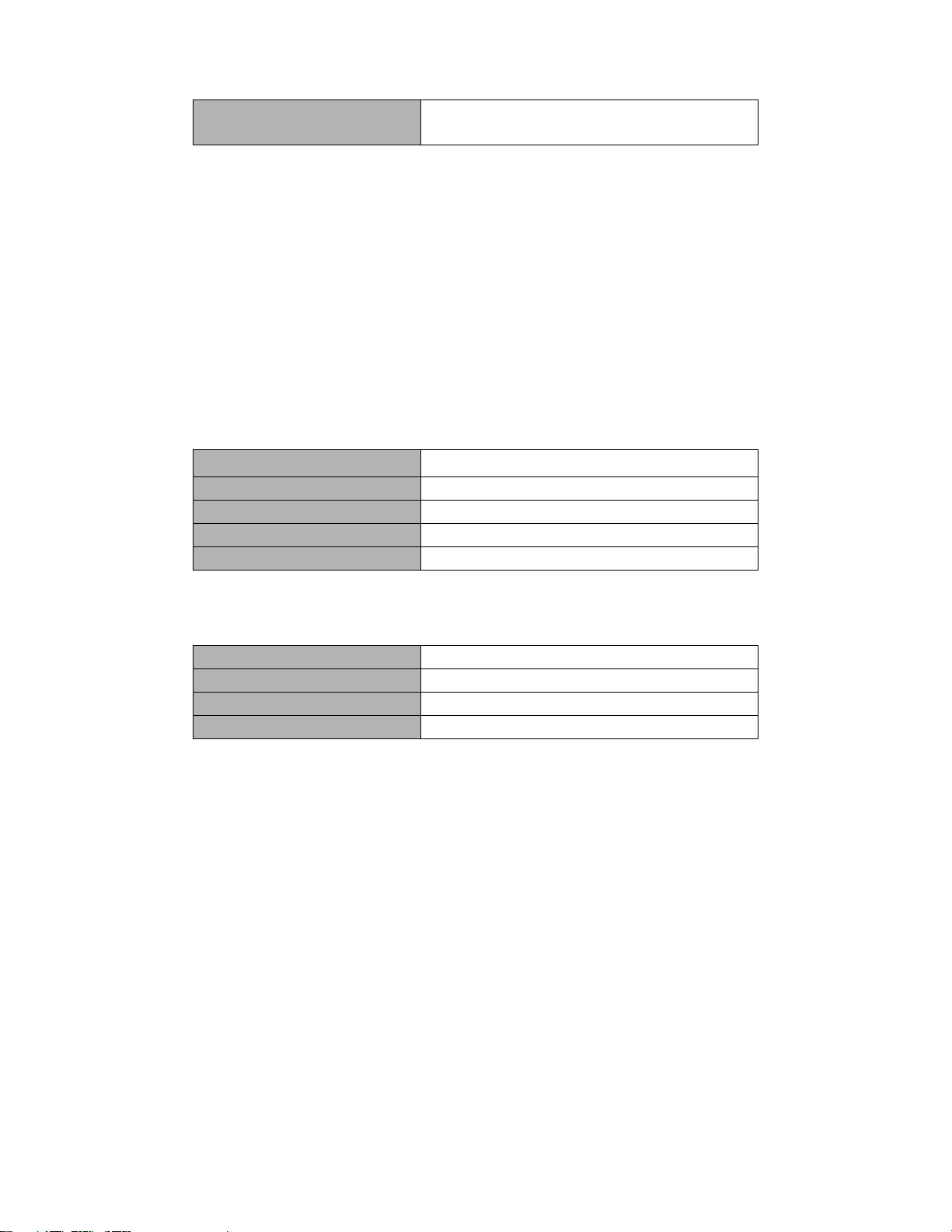

Software

Microsoft

®

Remote Desktop Connection, Citrix®

ICA® Client, Microsoft® Internet Explorer 6.0

*1

This slot does not support the MultiMedia card.

Operation has been confirmed for Panasonic SD Memory Cards with up to 2 GB capacity.

*2

Theoretical value and not the actual speed. The transfer rate does not become higher

even if you use a card that supports the higher transfer rate.

*3

<Only for North America>

The AC adaptor is compatible with power sources up to 240 V AC adaptor. The wireless

display is supplied with a 125 V AC compatible AC cord.

*4

Varies depending on the usage conditions.

*5

Measured using BatteryMark™ Version 4.0.1 (LCD brightness: Maximum - Minimum)

*6

Measured using MobileMark™ 2002 (LCD brightness: 150 cd/m2)

*7

Approx. 0.9 W when the battery pack is fully charged (or not being charged) and the

wireless display is OFF.

*8

Rated power consumption

Wireless LAN

Data transfer rates

*9

11/5.5/2/1 Mbps (automatically switched)

Standards supported IEEE802.11b

Transmission method OFDM system, DS-SS system

Wireless channels used Channels 1 to 11

RF frequency band 2412-2462 MHz

*9

These are speeds specified in IEEE802.11b standards. Actual speeds may differ.

Bluetooth™

Bluetooth Version 1.2

Transmission Method FHSS system

Wireless Channels Used Channels 1 to 79

RF Frequency Band 2.402-2.48 GHz

1-2

Page 9

2 Introduction

Copyright

This manual is copyrighted by Matsushita Electric Industrial Co., Ltd. with all rights

reserved. No part of this manual may be reproduced in any form without the prior

written permission of Matsushita Electric Industrial Co., Ltd.

No patent liability is assumed with respect to the use of the information contained

herein.

© 2006 Matsushita Electric Industrial Co., Ltd. All Rights Reserved.

Disclaimer

Wireless display specifications and manuals are subject to change without notice.

Matsushita Electric Industrial Co., Ltd. assumes no liability for damage incurred

directly or indirectly from errors, omissions or discrepancies between the wireless

display and the manuals.

Trademarks

Microsoft

Microsoft Corporation of the United States and/or other countries.

SD Logo is a trademark.

Citrix

Bluetooth™ is a trademark owned by Bluetooth SIG, Inc., U.S.A. and licensed to

Matsushita Electric Industrial Co., Ltd.

Panasonic® is a registered trademark of Matsushita Electric Industrial Co., Ltd.

Names of products, brands, etc., appearing in this manual are trademarks or registered trademarks of their respective own companies.

®

, Windows® and the Windows logo are registered trademarks of

®

and ICA® protocol are registered trademarks of Citrix Systems, Inc.

2-1

Page 10

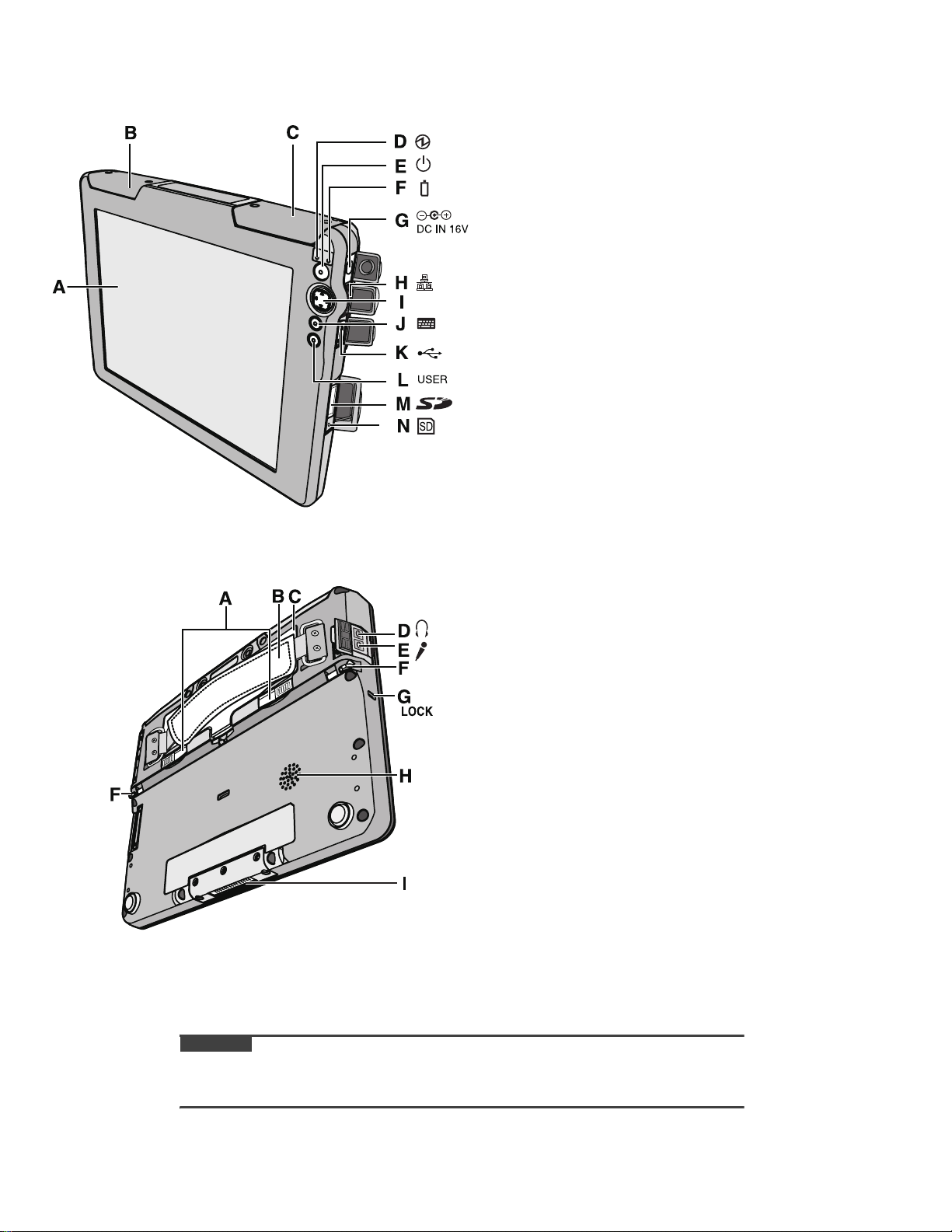

3 Description of parts

A. LCD (Touchscreen)

B. Wireless LAN antenna

C. Bluetooth antenna

D. Power status

E. Power button

F. Battery status

G. DC- IN j ac k

A. Battery cover latch

B. Hand strap

Adjust the length of the belt so that

the wireless display does not fall

by mistake, and firmly hold the

wireless display when using it.

C. Battery pack

D. Headphone jack

You can connect headphones or

amplified speakers. When they are

connected, audio from the internal

speakers is not heard.

E. Microphone jack

Use only monaural condenser

microphone (miniature jack). Connecting another type of microphone may interrupt audio input or

may cause a malfunction.

F. Stylus holder

G. Security lock

You can connect a Kensington

cable. Refer to the instruction

manual of the cable.

H. Speaker

I. Expansion bus connector

H. LAN port

I. Cursor control button

J. Keyboard button

K. USB port

L. USER button

M. SD Memory Card slot

N. SD Memory Card status

CAUTION

Do not put metallic objects or magnetic media close to the speaker.

Do not touch the expansion bus connector. The wireless display may no longer

function properly if the connector is dirty or damaged.

3-1

Page 11

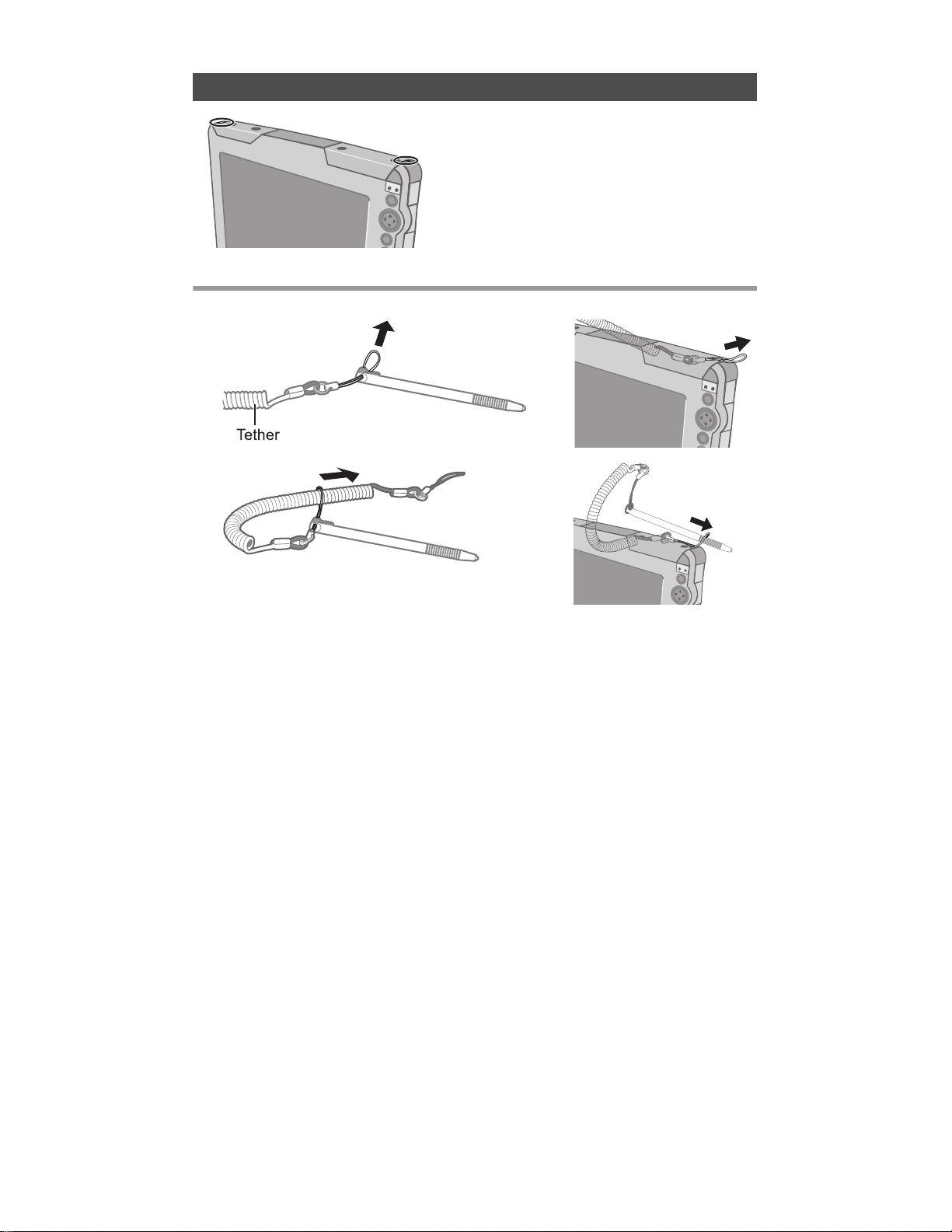

Using the Tether

Attaching the Tether

The tether can be attached to the upper right

or upper left corner of the display. It prevents

the pen (included) from falling accidentally.

1

2

3

4

3-2

Page 12

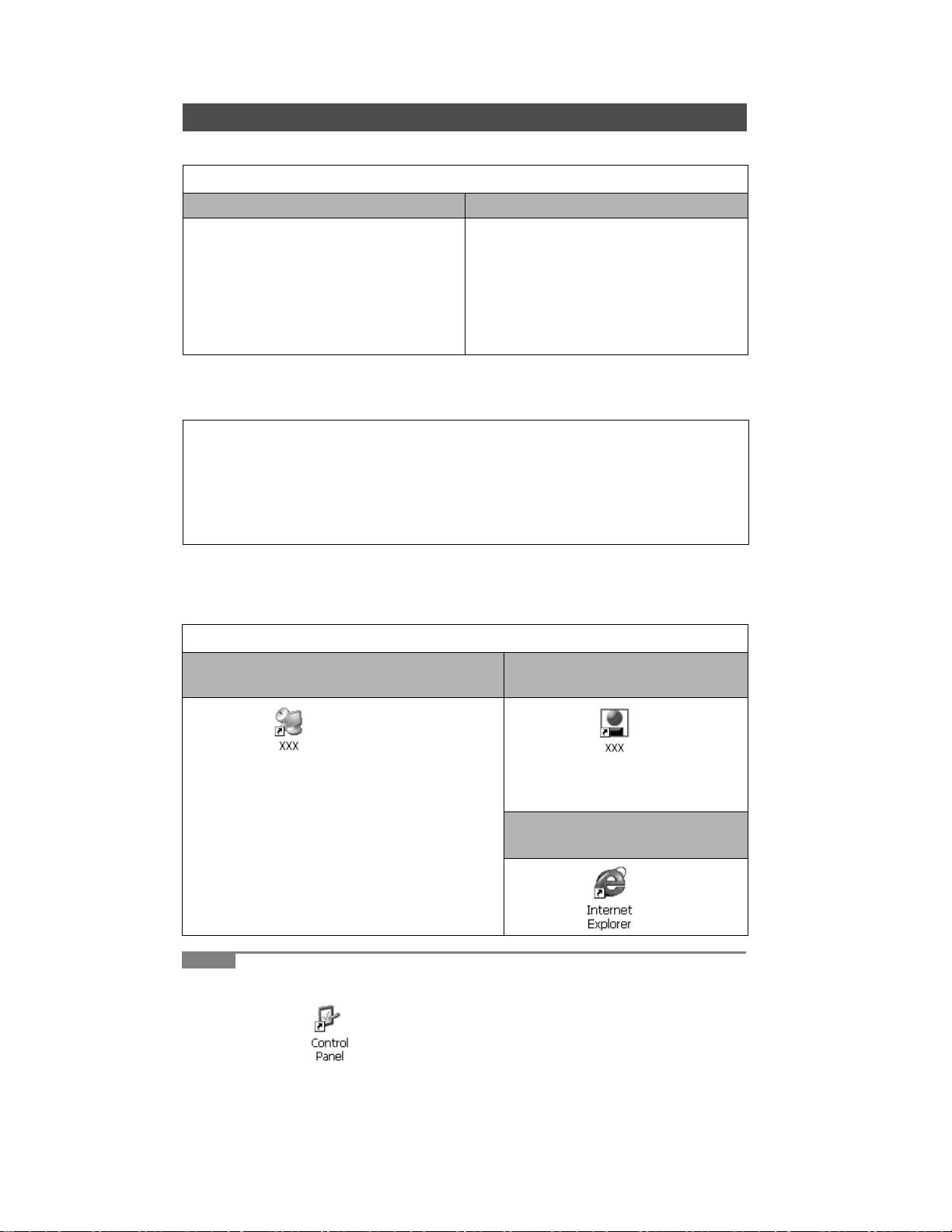

4 Starting up/Shutting Down

Starting Up

1 Turn on the wireless display.

When you log on as a Supervisor When you log on as a User

Press the power button with the USER

button pressed.

• If you do not do so, even when

you set enter the Supervisor

Password, the wireless display

will run in the User operating

environment.

2 When the [Enter Password] screen appears, enter the

password, and then tap [OK].

When you log on as a User

When the check mark is added for [Skip Password Dialog] of the [User]

tab in [Security (Supervisor)], the [Enter Password] screen is not displayed.

Press the power button.

3 Connect to the server.

When making connections with Microsoft®

Remote Desktop Connection

Double-tap

The server desktop screen will appear.

*1

The file name entered when making the

server setting will appear instead of “XXX”.

• When you do not add the check mark

for [Save my password] in “When making connections with Microsoft® Remote

Desktop Connection” step C of “Firsttime Operation” step 7

Enter the password, and then tap [OK].

NOTENOTE

When logged on as a User, the security setting screen can be displayed using

the following procedure.

① Double-tap on the desktop.

② Double-tap [Security (User)].

The following screen will appear.

*1

on the desktop.

When making connections with

Citrix® ICA® Client

*2

Double-tap

*2

The file name entered when making the server setting will appear

instead of “XXX”.

When making connections with

Microsoft

Double-tap on the desktop.

®

Internet Explorer

the desktop.

4-1

Page 13

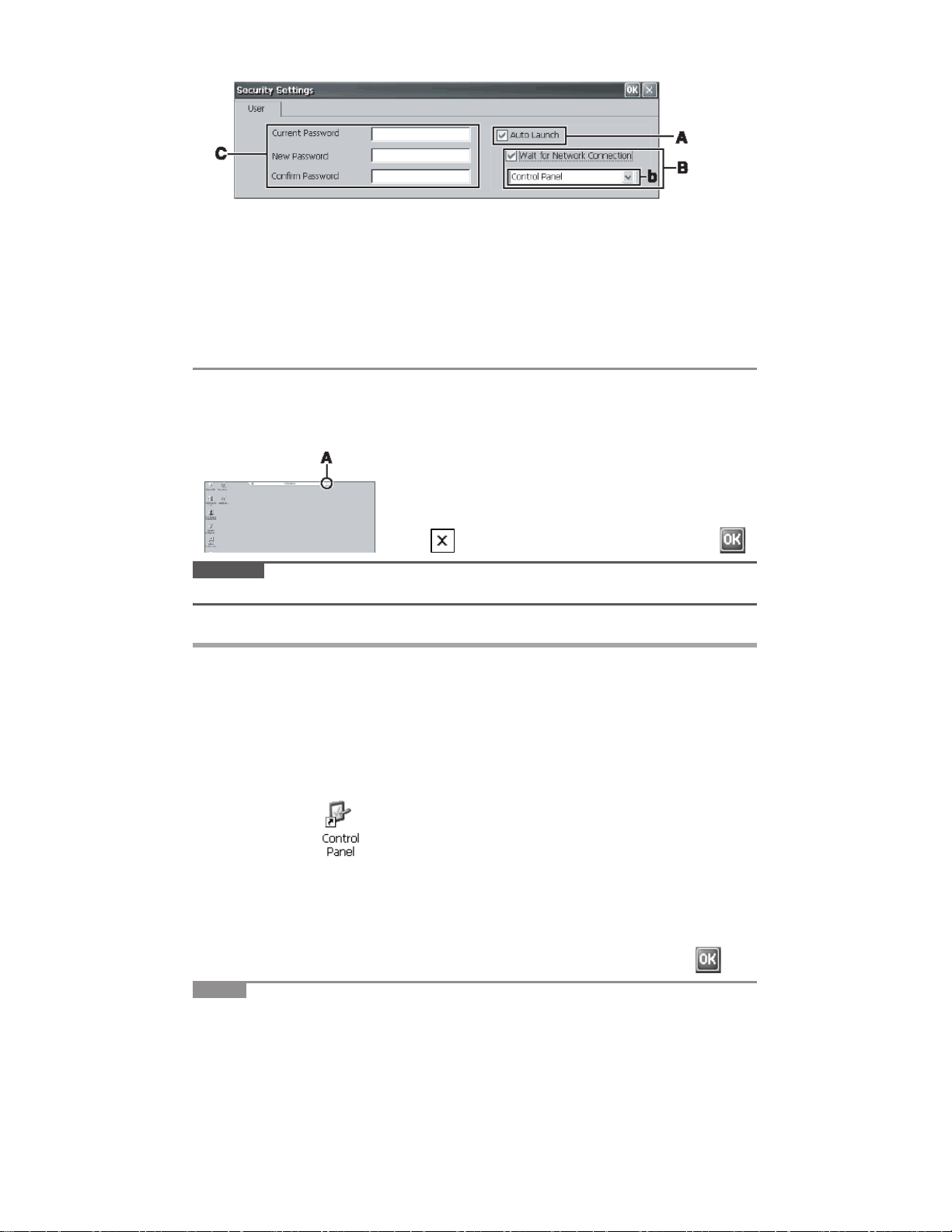

A. Auto Launch

B. Wait for Network Connection

• When the Supervisor does not

add the check mark for [Allow

Change Auto Launch] in the

[User] tab of the [Security Settings (Supervisor)] screen, [Auto

Launch] and [Wait for Network

Connection] cannot be set here.

C. Password

To set the password

• If a User Password has been set in the

[User] tab of [Security (Supervisor)]

screen, User cannot delete a password.

• If a User Password has not been set in

the [User] tab of [Security (Supervisor)]

screen, User cannot create a new

password.

When terminating the connection

Perform the following operation.

Tap [Start] - [Log Off] - [Log Off].

<Only when making connections with Microsoft

Remote Desktop Connection>

You can terminate the connection using the following

operation.

Tap (A), and when the message appears, tap .

CAUTION

If you tap [Start] - [Shut Down], the power for the server itself will be turned off.

Make the settings (only for the Supervisor)

®

When settings have been changed

Before turning off the wireless display, save (back up) the settings making reference to step

9 in “First-time Operation” .

When deleting settings

Perform the following procedure.

AADouble-tap on the desktop and double-tap [Flash Delete].

B Connect your wireless display to a power outlet.

C Tap [Delete Backup].

When the confirmation message appears, tap [Yes].

Deleting data will start.

D When the message “Backup data has been deleted.” appears, tap .

NOTENOTE

When you turn on the wireless display next time, the calibration screen will

appear.

4-2

Page 14

When returning the wireless display to its condition at the time of shipment

Perform the following procedure while the wireless display is turned off.

A Connect your wireless display to a power outlet.

B Press the power button with the keyboard button and USER button

pressed until the message “Reset the device to factory default...” appears.

When the [Enter Password] screen appears, enter the Supervisor Password and tap [OK].

C Select [Yes].

NOTENOTE

When you turn on the wireless display next time, the calibration screen will

appear.

Shutting Down (power off the wireless display)

1 Press the power button for one or two seconds until the

message “Preparing to Power off…” appears.

When shutting down forcefully, press the power button for four seconds

or longer.

4-3

Page 15

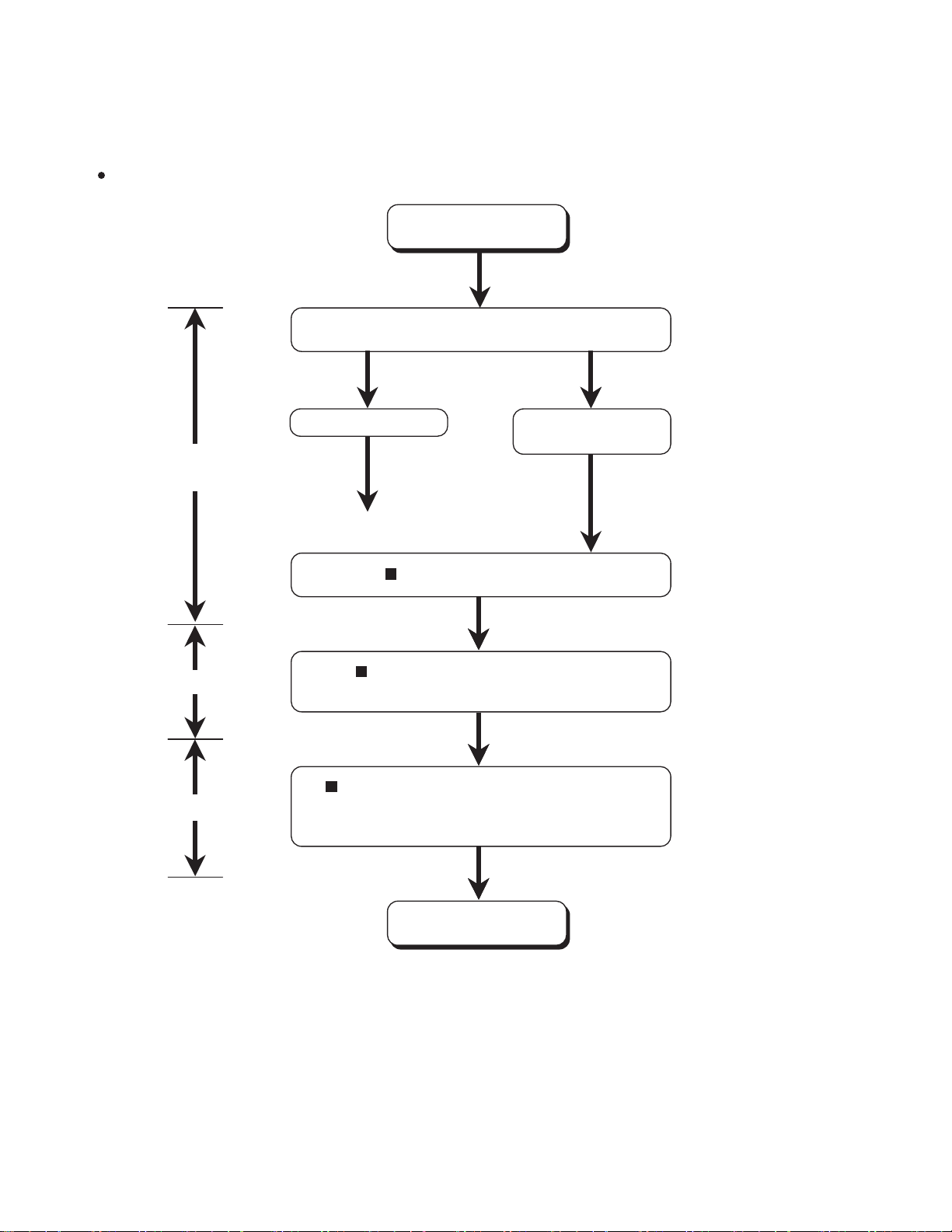

5 Diagnosis & Repair

5.1. Basic Procedures

The basic procedures for diagnosis, disassembly, and test of defective parts of a set to be repaired are summarized below.

For details, refer to relevant pages in the Service Manual.

Flow Chart

OCCURRENCE OF

TROUBLE

Insert the AC plug.

Press the Power button,

Self Test Program

Self Test Program start up.

while pressing the USER button

and the Cursor control button

at the same time.

DEFECTIVE PARTS

SORTING

REPAIR WORK

INSPECTION

NORMAL FINISH

ERROR

OCCURRENCE

OK

TROUBLESHOOTING

DISASSEMBLY PROCEDURE

Replace defective parts.

Self Test Program

After repair, make sure that the repaired

set operates properly.

TEST OK

FAULT

END OF

REPAIR WORK

5-1

Page 16

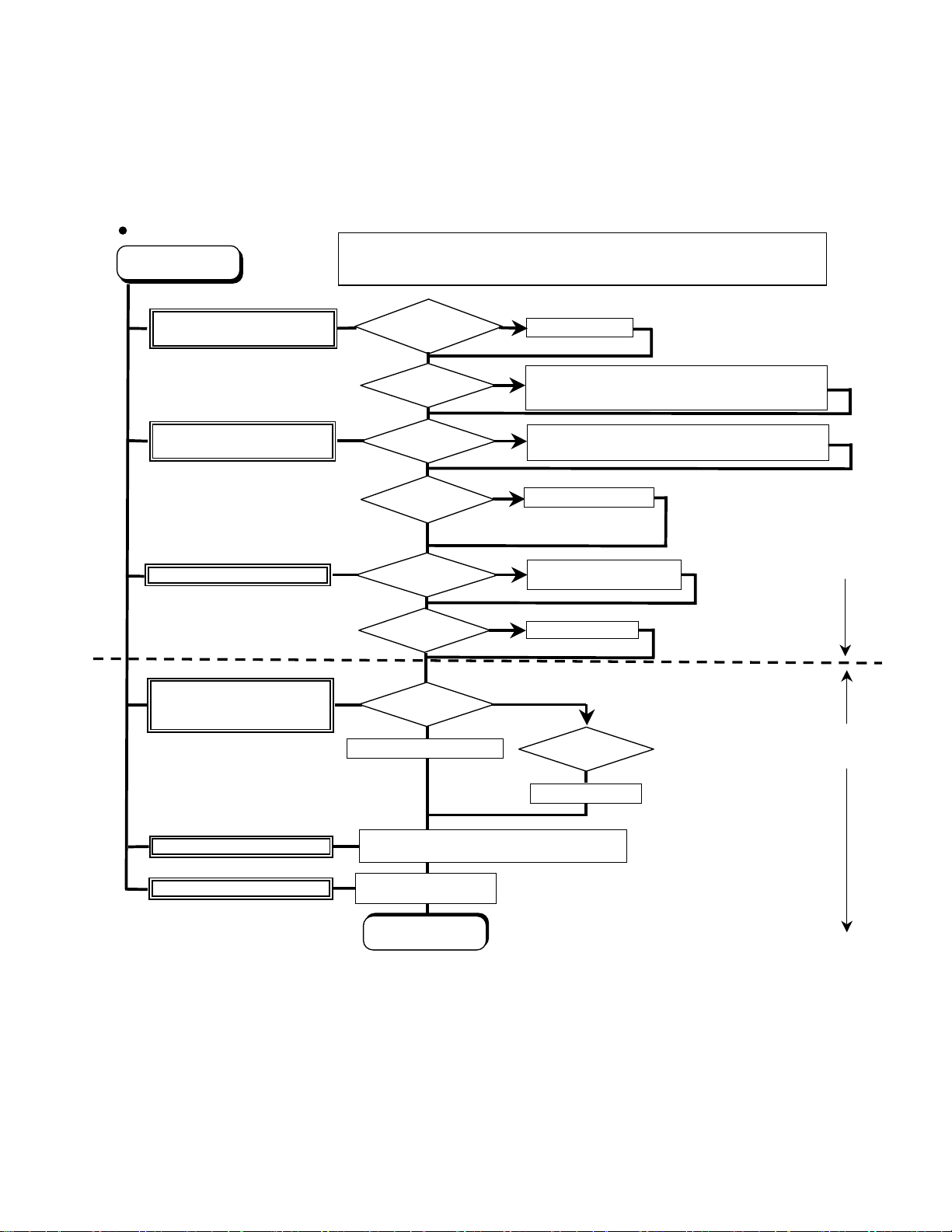

5.2. Troubleshooting

f defective.

Please take note of the following two points with regard to troubleshooting:

1. Know-how of diagnosis upon occurrence of heavy troubles, e.g. ‘Set cannot be turned ON’, ‘Set fails to start’, ‘No display on

screen’, etc.

2. Explanation of each trouble, mainly symptom of trouble in operation.

Flow Chart

START

START

Set cannot be supplied with current.

Power lamp fails to light up.

Dark display on screen.

Screen fails to display.

Failure in starting

Lines appearing on screen.

Part of block displayed

Properly on screen.

Touch screen cannot be input.

Starts but operates unstably.

Pay attention to the following points when in pursuit of the cause of a troubleshooting.

1. Peripheral apparatus connected with the set should all be removed before operation check.

2. Make sure that cables, boards, etc. are not coming off, and recheck the contact condition.

Power unit

Output voltage

NG

Replace power unit.

OK

NO

Power lamp

Board input/output

LCD back

light lighting

check

Inverter

voltage

YES

OK

Check contact condition of power input terminal. Replace i

Check SW cable continuity. Replace if defective.

Check SW board connection and contact. Replace if defective.

NG

Replace inverter board. (Check if fuse is broken).

Check inverter cable continuity. Replace if defective

NO

Replace LCD back light.

YES

operating check

NO

Replace main board

(Check fuse at power source).

YES

Result of

Selt Test Program

NG

Replace main board.

OK

LCD Unit for trial.

Replace LVDS board and cable.

Replace

OK

NG

Replace

main board

for trial.

OK

Replace main board.

Make sure of contact of Touch screen connector in use.

Replace Touch screen or main board. .

Reinstall firmware/software.

Replace main board.

Heavy trouble e.g.,

‘Set cannot be turned

ON’, ‘Set fails to start’,

‘No display on

screen’, etc.

Each kind of

trouble in

operation.

START

END

5-2

Page 17

5.3. Self Test Program

1. Introduction

This description explains Self-Test Program of this Test.

2. How to Start-up

(1) Connect the AC adaptor. ( Unless you connect the AC adaptor, the Self-Test Program

does not start. )

(2) Connect the AC adaptor. Press the USER button and Cursor Control button at the same

time, then press the Power button to turn on the computer. Self-Test Program starts

automatically.

3. Self-Test

This test is to check if the device is disconnected.

3.1. Test Items

Condut the device test in the following order.

(1) CPU Type check

(2) SDRAM march test

(3) Test register check for the source microcomputer

(4) ID check and frame buffer test for 2700G(GRAPHIC)

(5) Test register and chip ID test for LAN9118

(6) Card detection pin check and tuple information check for PCMCIA

3.1.1. CPU Type check

Check if the CPU is mounted with Intel PXA270 C5 Stepping.

3.1.2. SDRAM march test

Conduct the march test for the main-64MB and 2700G-VRAM8MB.

5-3

Page 18

3.1.3. Test register check for the source microcomputer.

Check the test register of the source microcomputer

3.1.4. ID check for 2700G

Confirm the ID of 2700G.

3.1.5. Chip ID check for LAN9118

Check the test register and chip ID of LAN9118.

3.1.6. Card detection pin check and tuple information check for PCMCIA

When you cannot obtain the tuple information, wait 0.5 second, then try to obtain the

information by calling for API. Repeat this up to 10 times. (The maximum time required: 5

seconds.)

3.2. Display during the test

The following charactors are shown during the Self-Test.

*** SELF TEST ***

Now Testing...

3.3. Test Result

When the Self Test ends normally, each test result is shown on the display. The same result

as Overall Result is shown underneath.

5-4

Page 19

If the results of all items are OK, the following display appears.

*** SELF TEST ***

CPU Type : OK

SDRAM March Test : OK

Embedded Controller : OK

2700G : OK

LAN9118 : OK

PCMCIA : OK

Overall Result : OK

If only the PCMCIA result is NG, the following display appears.

*** SELF TEST ***

CPU Type : OK

SDRAM March Test : OK

Embedded Controller : OK

2700G : OK

LAN9118 : OK

PCMCIA : NG

Overall Result : NG

After the test result is shown on the display, the program hangs.

4. How to Restart

To restart the computer, either disconnect the AC adaptor, or press and hold the power

button more than 4 seconds.

5-5

Page 20

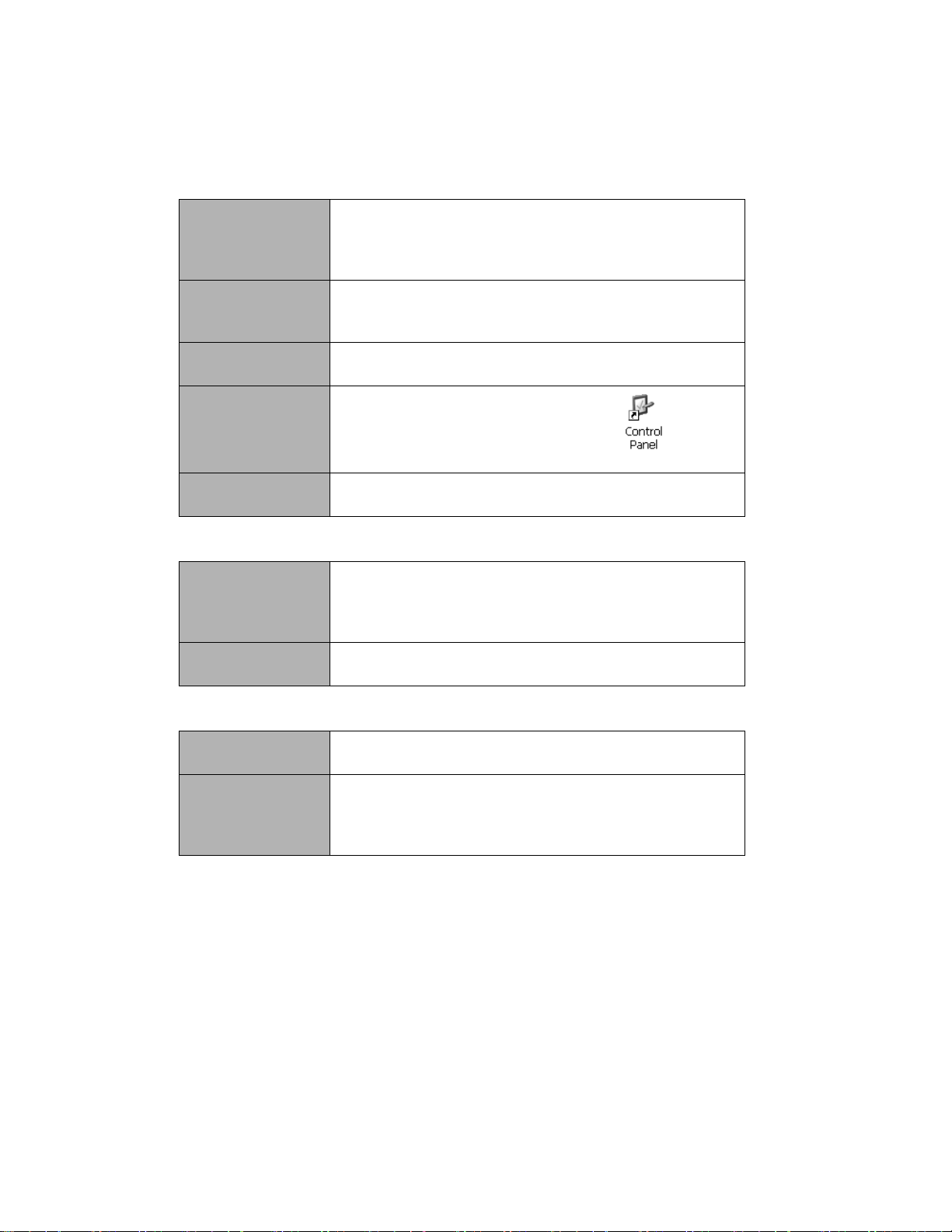

6 Troubleshooting

Follow the instructions below when a problem has occurred. For a software problem, refer to the software’s instruction manual. If the problem persists, contact

your technical support office.

Starting Up

Cannot start up.

The power indicator or battery indicator is not lit.

Cannot turn on the

wireless display.

You have forgotten

the password.

The date and time

are incorrect.

Other startup problems.

Display

No display. The display is turned off by the power-saving function.

The screen is dark. Adjust the brightness. As you increase the brightness,

Connect the AC adaptor.

Insert a fully charged battery.

Remove the battery pack and the AC adaptor, then connect them again.

Leave it in an environment of 5 °C {41 °F} or higher

temperature for about an hour, then turn on the power

once more.

Supervisor Password or User Password: Contact your

technical support office.

Make the correct settings. Double-tap on the

desktop, and double-tap [Date/Time].

Remove all peripheral devices.

To resume, touch the LCD.

The wireless display powers off by the power-saving

function. To power on, press the power button.

battery consumption increases.

Touchscreen

The cursor does not

work.

Cannot point the

correct position

using the included

stylus.

When using the external mouse, connect it correctly.

Perform the touchscreen calibration .

6-1

Page 21

Shut Down

Cannot shut down. Press the power button for four seconds or longer to

shut down the wireless display.

Sound

No sound. Confirm the volume for [Quick Menu] or [Volume &

Sounds] in Control Panel.

Unable to hear

sound in stereo.

Wireless Communication

Playback conditions vary depending on the server.

• If you are connecting through Microsoft® Remote

Desktop Connection or a web server, you will hear

monaural sound even if the original sound is stereo.

• For playback conditions when connecting through Cit-

®

rix

Presentation Server 4.0, refer to the Citrix man-

ual for details.

Cannot connect to

network.

Connecting Peripherals

The connected keyboard and mouse

do not work.

The device connected to the serial

port does not work.

Cannot print. Check the printer connection.

Others

Check the network settings.

You may experience interference with other wireless

LAN access points.

Verify that each wireless LAN access point is set to a

different channel.

Check the keyboard and mouse connection.

Check the connection.

The device driver may not work. Refer to the instruction

manual of the device.

Do not connect two mouse devices simultaneously.

Turn on the printer.

The printer is not online.

No paper is in the printer tray or there is a paper jam.

Turn on the printer and connect it to the wireless display, and then turn on the wireless display.

No response. The screen content may not display correctly due to

poor signal quality. In such case, move to a place where

signal quality is good then make a connection.

Press the power button for four seconds or longer to

shut down the wireless display, and then press the

power button to turn it on.

6-2

Page 22

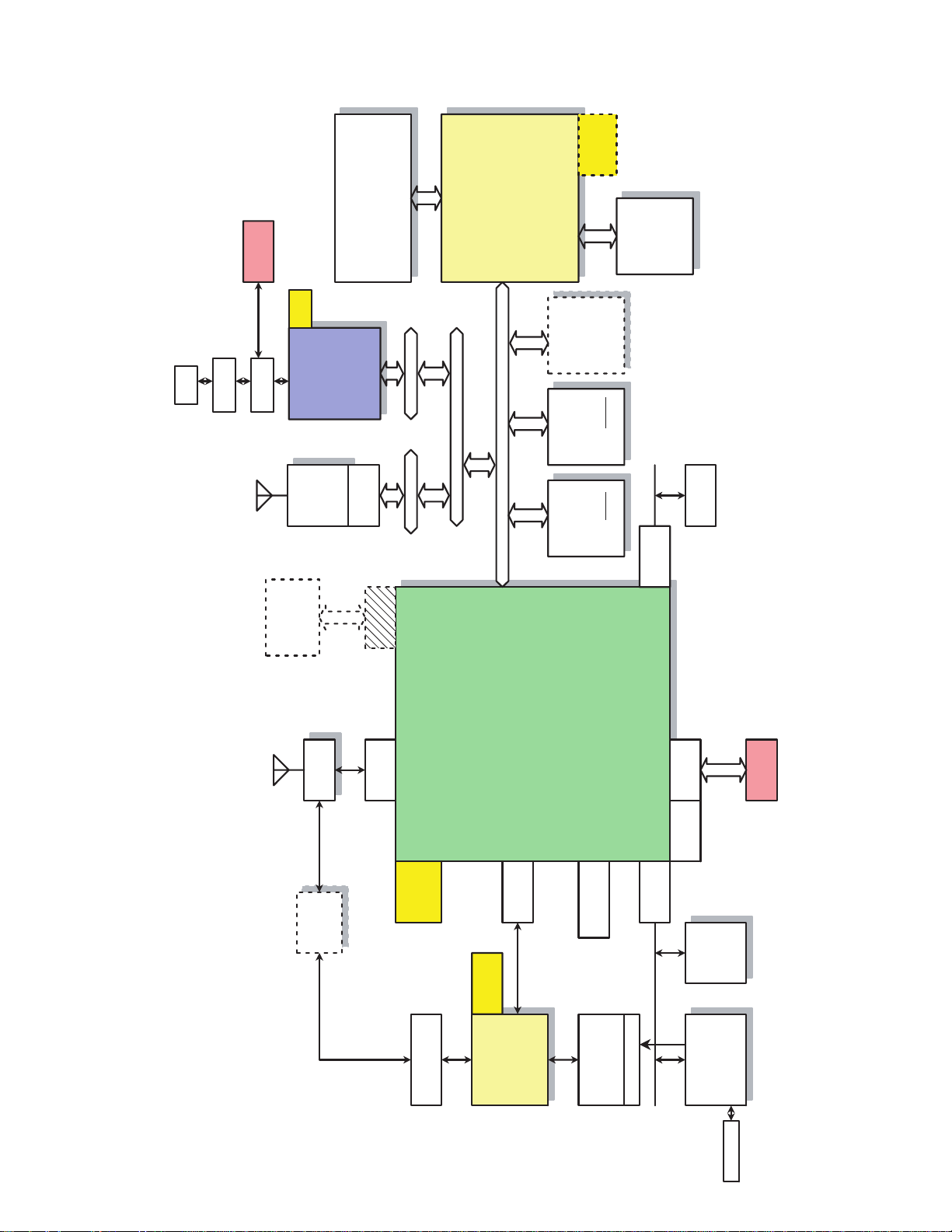

7 Block Diagram

Crystal

13.000MHz

LAN

with

10.4 inches XGA

Cradle I/F

Crystal

25MHz

FingerChip

SMSC

LAN9118

LAN

Wireless

802.11b/g

Switch

Magnetics

TachPanel and CCFL Backlight

I/O 3.3V

10/100 Base-T

CF Slot 0

16bits Bus(3.3V)

16bits Bus(3.3V)

Intel 2700G3

SN74AVCB164245

16bits Bus(3.3V)

Multimedia Accelerator

Non Stack / 384kB SRAM

32bits Bus(1.8V)

I/O 1.8V

Core 1.2V

Analog 2.5V

(1Chip)

Mobile

DiskOnChip

1.8V

(2Chip)

SDRAM

1.8V

Flash

(1Chip)

8MB

(1Chip)

x32/1.8V

SDRAM

64MB/128MB

64MB/128MB

EEPROM

S-24C04B

32MB/64MB

I2C I/F

Standard

Block Diagram

CF-08

I/O 1.8V

Bulverde

24.576MHz

with Touch screen

AC97 I/F

WM9712

controller

Microprocessor

DC-DC

MAX1586

M16C28

Battery Monitor

Battery CN

Cradle I/F

13MHz-312MHz,Core 0.85-1.3V

SD/MMC/SDIO

(Wolfson)

FL BackLight

Touch Screen

on LCD Panel

Power-MG

USB Host2

USB Host1

I2C I/F

POWER

PWM

PMC

Intel PXA270 C5

ALPS

Bluetooth

Codec

Motorola

MC145483

Serial(BT) Serial(FF )

Crystal

32.786KHz

13.000MHz

Mic/Amp/Speaker

Crystal

AC97 Codec

7-1

Page 23

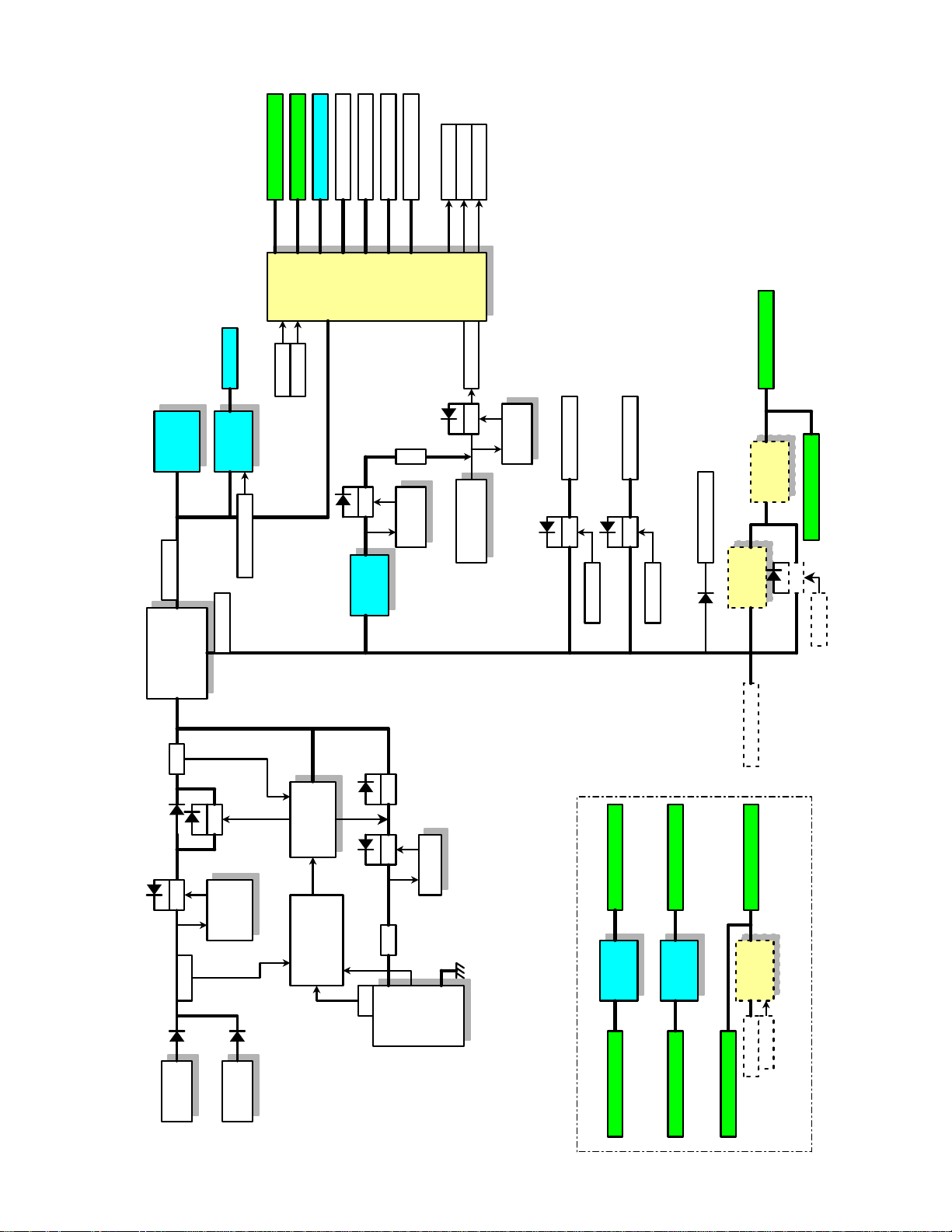

VCC_IO(3.3V)

VA3

VA3

VCC_PLL(1.3V)

VCC_MEM(1.8V)

VCC_CORE(0.8-1.3V)

VCC_USIM(3.0V)

VCC_SRAM(1.1V)

LDO

Main

DC/DC

(MAX1586)

RESET#

VCC_BATT(3.3V)

VDD_FAULT#

BATT_FAULT#

VAMP

SYS_EN

PWR_EN

LCD

Inverter

Back light

VCC_5P0V

DC/DC

(LTC3728)

R

3.3V

Voltage

Regulator

FET

AC97PWR_EN#

Voltage

VCC_3P3V

R

Voltage

Detector

3.4V

Regulator

FET

BKBT(VBK3)

FET

Voltage

Detector

WLVCC(3.3V)

Connector

Sub Battery

FET

VLAN(3.3V)

FET

CFPWR_EN

VLPWR_EN

VCC_BATT(3.3V)

BAK_1P8V(SDRAM) SYS_EN

DC/DC

(LTC3406)

VCC_MEM(1.8V)

FET

(LTC4411)

PowerPath

PWR_EN

VCC_BATT(3.3V)

FET

FET

Voltage

& OVP#

Detector

ACIN

(16V/2.5A)

AC Adapter

(16V/2.5A)

Cradle Con

Charger

(LTC4008)

FET

OVP#

V2700_Core(1.2V)

PMC

M16C28

Battery Monitor

R

Voltage

Regulator

NTC

7.4V

Battery

5200mAh

VCC_MEM(1.8V)

V2700_PLL(2.5V)

1.2V

2.5V

Voltage

Regulator

VCC_IO(3.3V)

V2700_LM(1.8V/2.5V)

DC/DC

VCC_3P3V

VCC_MEM(1.8V)

2700G Power

(LTC3406)

7-2

Page 24

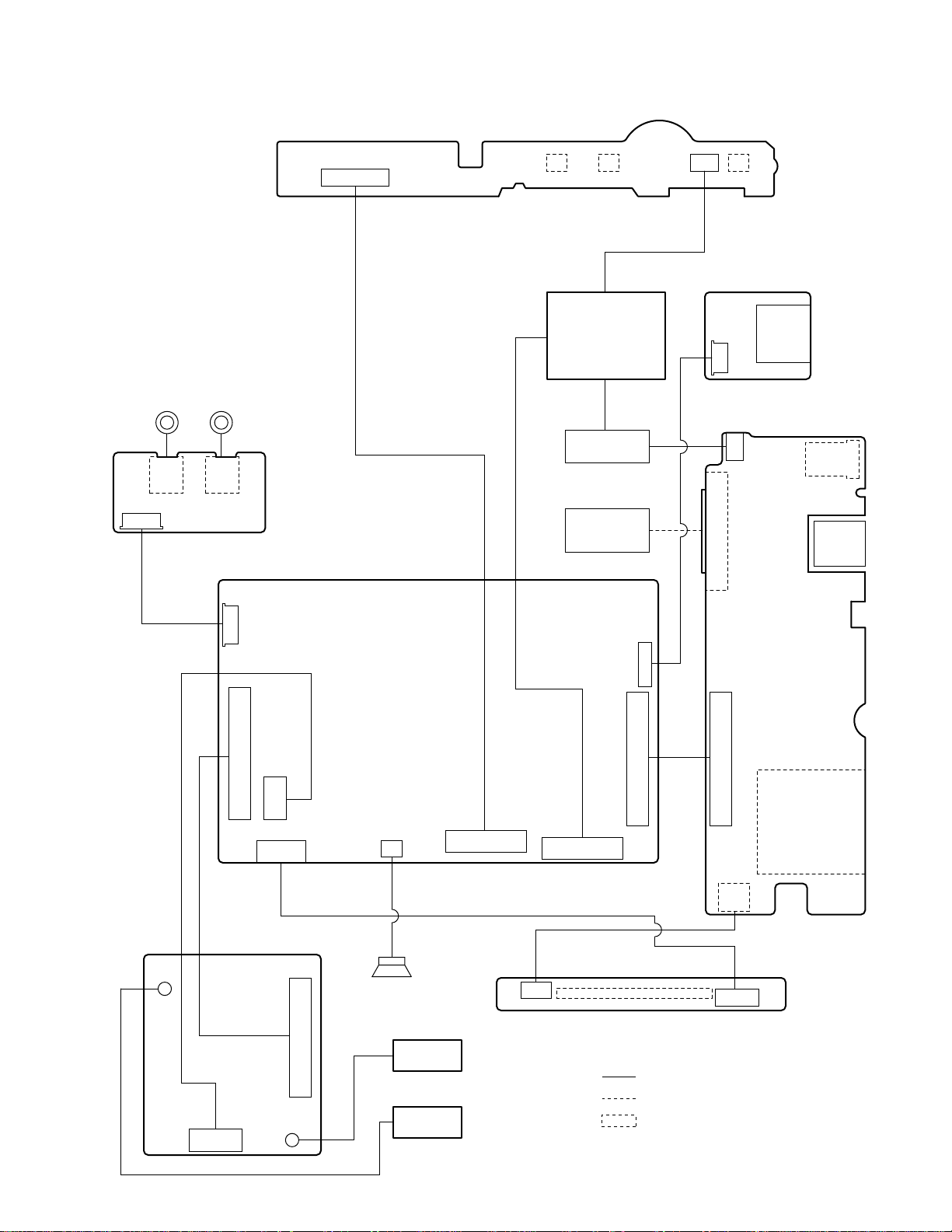

8 Wiring Connection Diagram

SW LED PCB

CN501 SW500

Microphone

CN302 CN301

CN300

AUDIO CON PCB

Headphone

CN500

SW502 SW501

LCD

INVERTER

BATTERY

PACK

USB PCB

CN400

CN401

IO POWER PCB

CN6

CN9

USB

CN7

DC-IN

CN4

LAN

CN7

WLAN PCB

CN2

CN3

CN13

CN4

CN3

CN1

MAIN PCB

CN9

SPEAKER

ANTENNA

PCB R

ANTENNA

PCB L

CN6

CN2

DOCK CON PCB

CN601

EXPANSION BUS

CN12

CN10

CN602

Connector by Cable

Direct connection by Connectors

Parts on Bottom Side

CN1

CN8

SD CARD SLOT

CN600

8-1

Page 25

9 Disassembly/Reassembly

Note:

Power off the computer. Do not shut down to the Suspend or hibernation mode.

Do not add peripherals while the computer is in the Suspend or hibernation mode; abnormal operation may result.

9.1. Disassembly Instructions

9.1.1. Preparation

Be sure to make the following preparations before disassembling.

• Shut down Windows and turn off the power.

• Disconnect the AC adaptor.

• Remove other devices if they are connected.

Attention:

• Please execute writing BIOS ID when you exchange the

Main Board.

• Parts (Sheet and rubber) etc. related various the Conductive

Cloth and Heat Spreader cannot be recycled. Use new parts.

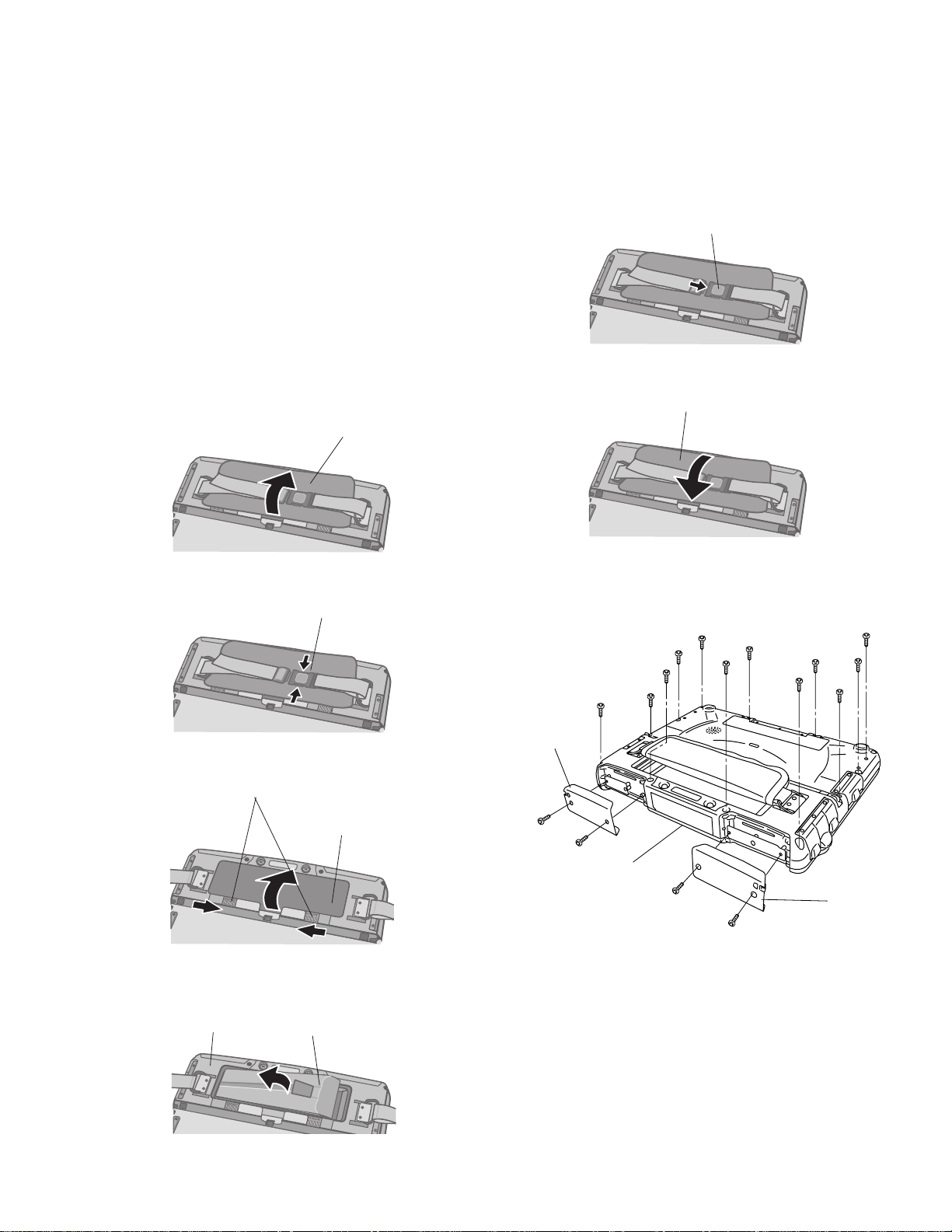

9.1.2. Removing the Battery Pack

hand strap cover

1. Open the hand strap cover.

hand strap

5. Pull the tab of the Battery Pack and remove it from the

wireless display.

hand strap

6. Attach the hand strap.

hand strap cover

7. Close the hand strap cover.

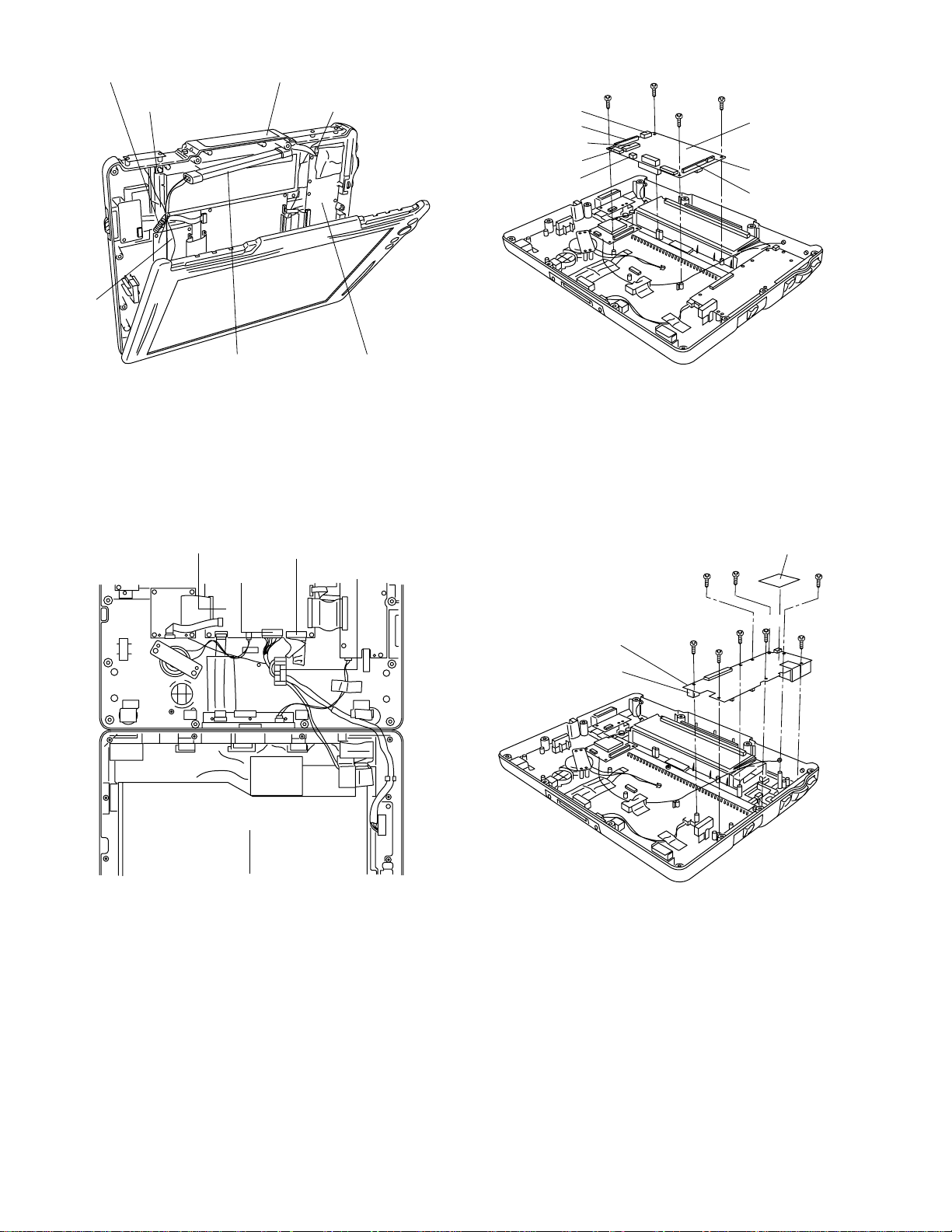

9.1.3. Removing the Display Unit

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

2. Remove the hand strap.

battery cover latch

battery cover

3. Slide the Battery cover latch.

4. Open and remove the Battery cover.

wireless display

battery pack

Antenna

Cover L

<N4>

<N4>

Rear Cabinet

<N4>

<N4>

Antenna

Cover R

1. Remove the two Screws <N4> and the Antenna Cover L.

2. Remove the two Screws <N4> and the Antenna Cover R.

9-1

Page 26

3. Remove the 12 Screws <N6>.

9.1.4. Removing the Main PCB

Lamp Cable Spring

Cable Holder Sheet

Cable

Rear Cabinet

Inverter

Connector(CN6)

IO Power P.C.B.

4. Remove the Cable Hold Sheet while opening the Rear

Cabinet ASS'Y slowly.

5. Remove the Cable hooked on the Lamp Cable Spring.

6. Remove both the Inverter and the Inverter Case.

7. Remove the Connector (CN6) connected to the IO Power

PCB.

8. Open the Rear Cabinet.

Main P.C.B.

Connector

(CN6)

Connector

(CN2)

Clamper

<N1>

<N1>

Connector(CN7)

Connector(CN3)

Connector(CN13)

Connector(CN4)

Connector(CN9)

<N1>

<N1>

Main P.C.B.

Connector(CN12)

Connector(CN10)

1. Disconnect the seven Cables from the Connectors

(CN3,CN4,CN7,CN9,CN10,CN12,CN13).

2. Remove the four Screws <N1>.

3. Remove the Main PCB.

Screws <N1>: XSB2+4FNL

9.1.5. Removing IO Power PCB

Edge Sheet

<N1>

<N1>

<N1>

Display

Unit

9. Remove the Clamper and the Connectors (CN2, CN6)

connected to the Main PCB.

10. Remove the Display Unit.

Screws <N4>:DXSB2+6FNL

Screws <N6>:DXYN26+J6FNL

IO Power P.C.B.

Connector(CN8)

<N1>

<N1>

<N1>

<N1>

1. Disconnect the Cable from the Connector (CN8).

2. Remove the Edge Sheet.

3. Remove the eight Screws <N1>.

4. Remove the IO Power PCB.

Screws <N1>:XSB2+4FNL

<N1>

9-2

Page 27

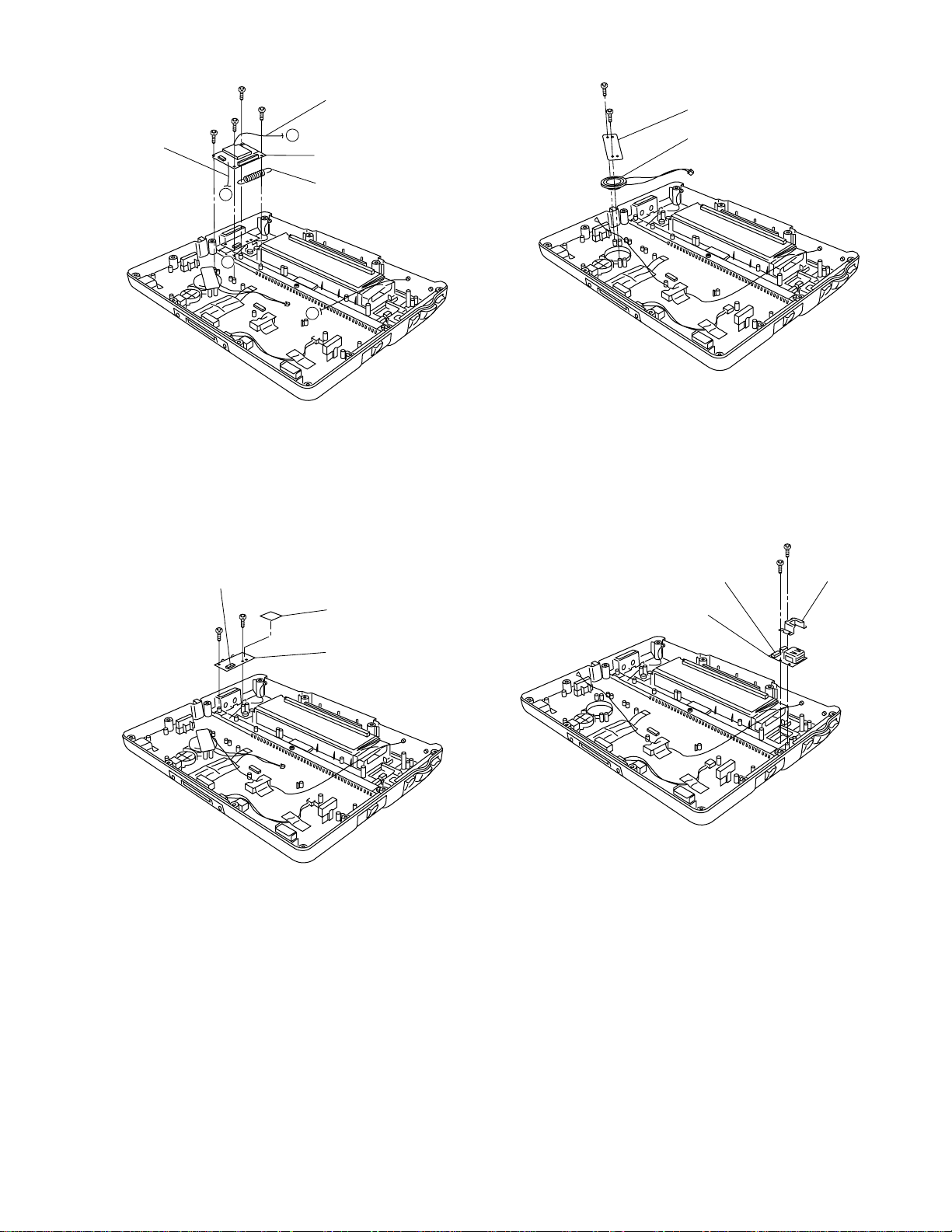

9.1.6. Removing the WLAN PCB

9.1.8. Removing the Speaker

Antenna Cable

<N1>

<N1>

<N1>

<N1>

A

B

Antenna Cable

B

WLAN P.C.B.

Lamp Cable Spring

A

1. Remove the two Antenna Cables.

2. Remove the four Screws <N1>.

3. Remove the Lamp Cable Spring.

4. Remove the WLAN PCB.

Screws <N1>:XSB2+4FNL

9.1.7. Removing the Audio Con PCB

Connector(CN300)

<N1>

<N1>

Edge Sheet

<K1-1-2>

<K1-1-2>

Speaker Hold Sheet

Speaker

1. Remove the two Screws <K1-1-2>.

2. Remove the Speaker Hold Sheet.

3. Remove the Speaker fixed with the two-sided tape.

Screws <K1-1-2>:XSB2+4FNL

9.1.9. Removing the USB PCB

<N1>

<N1>

Connector(CN400)

USB P.C.B.

USB Hold Plate

Audio Con P.C.B.

1. Disconnect the Cable from the Connector (CN300).

2. Remove the Edge Sheet.

3. Remove the two Screws <N1>.

4. Remove the Audio Con PCB.

Screws <N1>:XSB2+4FNL

1. Remove the two Screws <N1>.

2. Disconnect the Cable from the Connector (CN400).

3. Remove the USB Hold Plate and the USB PCB.

Screws <N1>:XSB2+4FNL

9-3

Page 28

9.1.10. Removing the WLAN L PCB

Insulation Sheet

(CN600,CN601).

Antenna Cable

WLAN L P.C.B.

<N7>

1. Remove the Insulation Sheet.

2. Remove the Screw <N7>.

3. Remove both the Antenna Cable and the WLAN L PCB.

Screw <N7>:DFHE5025XA

9.1.11. Removing the Bluetooth WLAN R

PCB

Tape

Antenna

Cable

<N3> <N3>

<N3>

<N3>

Dock Con P.C.B.

Docking P.C.B. Sheet

Base Joint Cover

<N3>

3. Remove the five screws <N3>.

4. Remove the Base Joint Cover, the Docking PCB Sheet

and the Dock Con PCB.

Screws <N3>:DXQT26+D5FNL

9.1.13. Removing the SW LED PCB

Connector(CN500)

<N2>

<N2>

SW Board Stopper Plate

<N2>

SW LED P.C.B.

Connector(CN501)

Blue tooth

<N7>

WLAN R P.C.B.

1. Remove the two tapes.

2. Remove the Screw <N7>.

3. Remove both the Antenna Cable and the Bluetooth

WLAN R PCB.

Screw <N7>:DFHE5025XA

9.1.12. Removing the Dock Con PCB

Dock Con P.C.B.

Connector(CN601)

1. Remove the FFC Hold Cushion.

2. Disconnect the two Cables from the Connectors

FFC Hold Cushion

Connector(CN600)

1. Remove the three Screws <N2>.

2. Remove the SW Board Stopper Plate.

3. Disconnect the two Cables from the Connectors

(CN500,CN501).

4. Remove the SW LED PCB.

Screws <N2>:DRSB2+5FKL

9-4

Page 29

9.1.14. Removing the LCD Unit and the

Inverter

Pet Tape

Inverter Case

1. Disconnect the Cable from the Inverter Connector.

2. Remove the Inverter with the Inverter Case.

3. Remove the Pet Tape.

TS Noise Tape

Inverter

Inverter

Connector

LCD Unit

LCD Unit

4. Remove the TS Noise Tape.

5. Remove the Cable from the Clamper.

6. Remove the LCD Unit.

Cable

Clamper

9-5

Page 30

9.2. Reassembly Instructions

9.2.1. Attention when CF-08 series is repaired

• Please execute writing BIOS ID when you exchange the Main Board.

• Parts (Sheet and rubber) etc. related various the Conductive Cloth and Heat Spreader cannot be recycled. Use new parts.

9.2.2. Setting the LCD Unit and the Inverter

1. Attach the LCD Unit.

2. Attach the TS Noise Tape.

3. Put the Cable into the Clamper.

TS Noise Tape

LCD Unit

Clamper

Cable

4. Attach the Pet Tape.

5. Connect the Cable to the Inverter connector.

Pet Tape

Inverter Case

Inverter

Inverter

Connector

LCD Unit

9-6

Page 31

■ Preparations for backlight

wide side

For appearance standard information of the LCD process,

refer to the "Common Assembly Instruction Manual".

LCD Prism Sheet

Remove the protection films. (both sides)

Handle with care.

(Avoid fingerprints or scores.)

Holder Sheet

LCD

Prism Sheet

Holder Sheet

0~0.5mm

1

Attach two sheets.

Insert into the inside the ribs.

(4 places in total)

LCD

Panel Frame

Attach in the same way as 3.

Symmetric shape

*Do not run over to the display side.

LCD

Prism Sheet

Light Guide Panel

Protection films is torn off.

(both side)

narrow side

Adhesive Tape S

Insert into the inside the ribs.

(4 places in total)

LCD Panel Frame

Do not push or press the pull base.

Reinforce Plate

Handle with care.

(Avoid fingerprints or scores.)

CCFL

narrow side

A

Insert into the inside the Hooks.

(both sides)

Safety Working

Avoid any stress when handling.

Refrecter

(Handle with care not to break.)

B

Details of "A"

0~0.5mm

Avoid

running

over the

wall.

0~0.5mm

Avoid running over the rib.

(both sides)

Do not fix the Cable at this point.

(Note) Handle with care not to damage

the light guide plate by using the Cable.

thin line: white

Avoid running over the rib

of the LCD Frame.

Reinforce Plate

thick line: pink

Tape

LCD FRAME

DBEFD Sheet

Light Guide Panel

Prism Sheet

After attaching to the light

guide plate, put pressure of

20 to 30N(2.0 to 3.0 Kgf)

on the Frame.

A

wide side

Details of "A"

Attach

Adhesive

here.

Tape L

PET Tape

0~0.5mm

*Avoid running over the display side.

(Handle 4 in the same way.)

(black side)

9-7

Insert into the inside

the Hooks.

(both sides)

Details of "B"

Insert between 5

and LCD Frame on

the opposite side

(6) as well..

Page 32

LCD Refrection Sheet

Insert after attaching 1.

Make the silver side inside.

Insert into the inside the ribs.

(4 places in total)

To avoid deflection,

do not attach 2 too

close to the Frame.

LCD

FRAME

LCD Refrection

Sheet

Holder Sheet

Positional Relation Chart for 1 and 2

LCD Refrection

Sheet

Avoid running over the rib.

(both sides)

(Running over causes moire.)

0~0.5mm

Holder Sheet

■ Assembly of the LCD

Safety Working

Notes for removing the Protection Films.

<To prevent damage to DBEF layer and

static electricity generation>

When removing the back side (inside)

Protection Film,keep the wind from the

ion-blower to the peeled side of LCD.

Then remove the Film slowly spending

more than five seconds, from LCD TAB

side on the left bottom toward along the

arrow direction.

LIGT GUIDE

PANEL

Prism Sheet

Details for attachment

0.50

~0mm

Light

Shield

Sheet A

*Remove it parallel to LCD.

OK

ionblower

NG

ionblower

Before reattaching the peeled

Protection Film to the LCD,

remove electricity.

0.5~0mm

Protection Film

LCD

Protection Film

LCD

Light Shield Sheet A

Do not bend in the

arrow direction.

*Absolutely avoid any

stress on FPC.

Handle with care.

Insert into the inside the Hooks.

(both sides)

Avoid running over AR SHEET.

Light Shield Sheet A

LCD FRAME

0~0.3mm

AR SHEET

MODULE

After removing the four sheets of the

Release Paper of the two-sided tape

on the LCD frame, then attach 1.

LCD Module

Light Shield Sheet A

Remove the Protection Films. (both sides)

Peeled Laminate Film is electric-charged.

Before reusing the Film, remove electricity.

9-8

Page 33

LCD PWB Sheet

Parts for electricity removing work

Refrect Tape

Press the Sheet along the

edge of the Reflector (Avoid floating.).

0~0.5mm

Attach here.

Lengthwise: Match to the top end of the Reflector.

Crosswise: Match to the rib of the Frame.

Standard attaching position of 1

Match to the PWC outline.

CN

Run over the end of the CN metal

(0.5 to 1 mm)

Match to the Kapton side

and attach to the Reflector

side.(Do not remove the

Release Paper other than

the Paper of the attaching

part.)

TS Noise Tape

0~1mm

Bend to the lateral side.

Pet Tape 1

A

View from A direction

LCD PWB SPACER ASSY

Insert between Board and LCD Frame.

LCD PWB SPACER ASSY

Spacer

LCD PWB Spacer

Sheet

Asymmetric shape

The form of the left and

the right isn’t symmetrical.

Holder sheet

edge standard: +0.5 mm

Spacer Sheet

Screw

0~1mm

Holder sheet

-

edge standard: +0.5 mm

-

Screw

9-9

Page 34

■ Preparations for Touchscreen

Attachment

Standard

Front Case Assy

TS Tape

Attachment

Standard

Attachment

Standard

■ Assembly of the Touchscreen

(Note)

Apply the load 20 to 30N (2.0 to 3.0 Kgf) to the Cushions.

TOUCH SCREEN ASSY

Attach the surface to the LCD Front.

TOUCH SCREEN ASSY

*Remove it parallel to the T/S.

OK

Laminate

Film

Attachment

Standard

Attachment

Standard

Attach to the center

of the display surface.

(Using the jig)

T/S

NG

Laminate

Film

T/S

<tentative measure>

After attaching the Protection Film

using jig (auto-attachment machine),

lift the film from both sides.

(like trash-catch)

Protect

Sheet

Dimensional

tolerance: +0.2

-

Fit to the stand wall and

attach to the undersurface.

LCD Side Cushion T5

edge standard:

+1mm

-

1 to 1.5 mm from

the Front Frame

TS Spacer A

2~4mm

Ensure TS spacer A, TS side

spacer and LCD FPC spacer

doesnot run over the display side.

Ensure TS side spacer does

not runover both edges of

TS glass.

TS Side Spacer

Turn the notch of the

Sheet to outside.

0.5 to 1 mm from

the Front Frame

A

Details of "A"

25–1mm

Touch Screen

LCD Side Cushion T2

Attach to

the wall.

LCD Side Cushion T5

2 to 3 mm from

the Front Frame

1 to 1.5 mm from

the Front Frame

TS Side Spacer

LCD FPC Spacer

stiffening

plate side

TS FPC

Spacer

0~0.5mm

Fit to the stand

wall and attach

to the undersurface.

Fit to the stand

wall and attach

to the undersurface.

LCD Side

Cushion T8

edge standard

+1 mm

Fit to the stand

wall and attach

to the undersurface.

LCD Side

Cushion T8

edge standard

+1 mm

9-10

Page 35

■ Assembly of the LCD Block

Shield Tape

Safety Working

0~1mm

LCD Signal Cable

edge standard: +0.5 mm

Put inside

the rib.

Match to the edge of the

Connector.

Busterade

1~3mm

0~1mm

LCD Side

Cushion T8

Attach to the

undersurface.

Frame edge

standard

+0.5mm

-

Board edge

standard

+0.5mm

-

Put inside

the rib.

edge standard: +1mm

-

Pet Tape 1

Shield Tape

LCD Block

5~6mm

Caution High

Voltage Label

LCD Side

Cushion T5

0~1mm

Attach the Conductive Cloth

to the Mg side.

(Remove the Release Paper

only of the attaching part.)

Pet Tape 1

0~3mm

Note

Caution to High Voltage

0~3mm

5~6mm 5~6mm

LCD Side Cushion Thin

After the liquid crystal block is set, attach LCD

side cushion TS and LCD side cushion thin with

their gluing sides facing downward.

1~3mm

Safety Working

When the Cable is close to the edge

(more than 4 mm than the standard position),

ensure that the Cable is not wound in other parts.

Pet Tape 1

0~3mm

5~6mm

Shield Tape

Frame edge

standard

+0.5mm

-

Board edge

standard

+0.5mm

within the rib

-

LCD Side Cushion T5

9.2.3. Setting the SW LED PCB

1. Connect the Cable to the connector (CN501) of the SW

LED PCB.

2. Attach the tape.

3. Fix the SW LED PCB and SW Board Stopper Plate using

three Screws <N2>. No1 to No3

4. Put the Cable into the Clamper.

Note:

Tighten the Screws in the numbered order (No1 to No3).

Screws <N2>:DRSB2+5FKL

Connector(CN500)

No.2

<N2>

No.3

<N2>

SW Board Stopper Plate

No.1

<N2>

SW LED P.C.B.

Connector(CN501)

9-11

Page 36

■ Assembly of the SW LED PCB

Power Button

Scroll Button

User Button

Safety Working

Lamp CN

Inverter CN Tape

Match the end.

LED Lens

Power

Button

Sheet

Attach.

Scroll

Button

Sheet

Asymmetric shape

SW Rubber

Ensure it is attached

in the notch.

Note)Avoid any stress on

the transformer of the

Inverter and the coil.

Important Parts for Safety

Inverter

Press the scroll button.

(3.0 to 4.0 Kgf)

SW

Board

in FPC direction

Place the stiffening

plate downward.

After attaching FPC, put the

Tape

Board and fix it with a tape:

CN edge standard.

SW Card Cable

Ensure the Cable does

not run over the LCD Frame.

Order of fixing

Screw-1->Screw-3

SW

Board

Stopper

Plate

Screw-2

Screw-3

Clamper

Safety Working

Pass it through

the clamper.

Screw-1

0~1mm

Lamp CN

Tape

1~2mm

0 to 1 mm

from the line

Inverter Case

After passing the case

through, attach to the back

side of the Board.

Remove the Release

Paper on the back

side and attach it,

matching it to the edge

of the case.

Match.

0 to 1 mm

from the line

Inverter

Fix Tape

Inverter

Cable

Safety Working

Pass the Cable between

the Board and rib.

Clamper

Safety Working

Pass it through the clamper.

Wrap around the Conductive Cloth on this side.

9-12

Page 37

9.2.4. Setting the Dock Con PCB

1. Fix the Docking PCB Sheet, the Base Joint Cover and the

Dock Con PCB using five Screws <N3>. No1 to No5

No.3No.4

<N3> <N3>

<N3>

No.5

Dock Con P.C.B.

Docking P.C.B. Sheet

Base Joint Cover

2. Connect the two Cables to the two connectors (CN600,

CN601) of the Dock Con PCB.

3. Attach the FFC Hold Cushion.

Note:

Tighten the Screws in the numbered order (No1 to

No5).

Screws <N3>:DXQT26+D5FNL

<N3>

No.1

Dock Con P.C.B.

Connector(CN601)

<N3>

No.2

FFC Hold Cushion

Connector(CN600)

9-13

Page 38

■ Assembly of the DOCK CON PCB

Order of fixing

Screw-1->Screw-5

Screw-4

Screw-3

Screw-5

Screw-1

Attach the Hook firmly.Ensure

the Connector Terminals of the

Sheet ( Docking PCB sheet) do

not run over.

(Attach in the arrow direction

horizontally.)

Screw-2

Match to the end of the

Connector. (0 to 1 mm)

Caption Tape

Match to the center of

Mg square hole. (– 1 mm)

Ensure the

direction is right.

Check Insert/Lock.

stiffening plate side

Cradle

Relay Card

Base Joint Cover

Docking PCB Sheet

Attach.

0~1mm

FFC Hold Cushion

Attach to the

top side of CN.

FFC

(Docking Card)

Busterade

10+1mm

Docking

PCB side

Rear Case Assy

Docking Cover Sheet

Asymmetric shape

9-14

Page 39

9.2.5. Setting the Bluetooth WLAN R PCB

1. Fix the Antenna Cable and the Bluetooth WLAN R PCB

using one Screw <N7>.

2. Fix the Antenna Cables with the two tapes.

Tape

Screw <N7>:DFHE5025XA

9.2.6. Setting the WLAN L PCB

1. Fix the Antenna Cable and the WLAN L PCB using one

Screw <N7>.

2. Fix the Antenna Cable with the Insulation Sheet.

Screw <N7>:DFHE5025XA

Antenna

Cable

<N7>

Blue tooth

WLAN R P.C.B.

Insulation Sheet

■ Assembly of the Antenna PCB

ANT Cable Packing

Press fit.

Insert until it reaches

the brim.

Screw

Antenna PCB(BT)

Screw

Antenna PCB(WLAN)

Antenna Cable

WLAN L P.C.B.

Press fit.

Insert until it reaches

the brim.

<N7>

9-15

Page 40

9.2.7. Setting the USB PCB

1. Fix the USB Hold Plate and the USB PCB using two

Screws <N1>.

2. Attach the Edge Sheet.

Screws <N1>:XSB2+4FNL

9.2.8. Setting the Speaker

1. Attach the Speaker.

2. Fix the Speaker Hold Sheet using two Screws <K1-1-2>.

Screws <K1-1-2>:XSB2+4FNL

<K1-1-2>

<K1-1-2>

<N1>

Connector(CN400)

USB P.C.B.

Speaker Hold Sheet

Speaker

<N1>

USB Hold Plate

9.2.9. Setting the Audio Con PCB

1. Connect the Cable to the Connector (CN300) of the Audio

Con PCB.

2. Fix the Audio Con PCB using two Screws <N1>.

3. Attach the Edge Sheet.

Screws <N1>:XSB2+4FNL

Connector(CN300)

<N1>

<N1>

Edge Sheet

Audio Con P.C.B.

9-16

Page 41

9.2.10. Setting the WLAN PCB

1. Fix the WLAN PCB and the lamp Cable Spring using four

Screws <N1>.

2. Fix the two Antenna Cables.

Screws <N1>:XSB2+4FNL

Antenna Cable

<N1>

<N1>

<N1>

<N1>

Antenna Cable

B

WLAN P.C.B.

9.2.11. Setting the IO Power PCB

1. Fix the IO Power PCB using eight Screws <N1>. No1 to

No8

2. Connect the Cable to the Connector (CN8) of the IO

Power PCB.

3. Attach the Edge Sheet.

Note:

Tighten the Screws in the numbered order (No1 to No8).

Screws <N1>:XSB2+4FNL

A

IO Power P.C.B.

Connector(CN8)

Lamp Cable Spring

B

A

No.3

<N1>

No.6

<N1>

No.7

<N1>

No.8

<N1>

No.2

<N1>

No.5

<N1>

Edge Sheet

No.1

<N1>

No.4

<N1>

9-17

Page 42

9.2.12. Setting the Main PCB

1. Connect the Cable to the Connector (CN7) of the Main

PCB.

2. Fix the Main PCB using four Screws <N1>. No1 to No4

3. Connect the Cables to the six Connectors

(CN3,CN4,CN9,CN10,CN12,CN13) of the Main PCB.

Note:

Tighten the Screws in the numbered order (No1 to No4).

Screws <N1>:XSB2+4FNL

Connector(CN7)

Connector(CN3)

Connector(CN13)

Connector(CN4)

Connector(CN9)

No.4

<N1>

No.2

<N1>

No.1

<N1>

No.3

<N1>

Main P.C.B.

Connector(CN12)

Connector(CN10)

9-18

Page 43

■ Assembly of the USB PCB, Audio Con PCB, WLAN PCB, IO Power PCB, and Main PCB

Attachment

Standard

Attach to the lateral side

in the order of a to b.

BATT CN Cover Sheet

edge –0.5mm

Screw x8

Order of fixing

Screw-1->Screw-8

Audio Con PCB

Screw

x2

Hook on the boss and tighten

together with the Board. (Fix

the short hand of the Hook.)

Direction; left opening

Lamp Cable

Spring

1~2mm

Screw

x4

WLAN PCB

1~2mm

4

Edge

Sheet

b

1

2

4

3

2

3

a

5

6

IO Power PCB

1

7

8

Screw

x4

Order of fixing

Screw-1->Screw-4

USB PCB

stiffening plate side

FFC(USB)

Check Insert/Lock.

Main PCB Hold Sheet

VGA Damper

Main PCB

Match to the

silk position.

0~1mm

within the Connector GND

Keep more than 1 mm

between the edge of FFC

folding point and the boss.

Edge Sheet

End of the CN

standard –0.5mm

USB Hold Plate

Screw

end of FFC

standard

–0.5mm

9-19

Page 44

FFC(Audio Card)

Attachment

Standard

–0.5(Board edge)

0.5mm

1

Edge Sheet

Match to the center. Match to the center.

Shield Tape

0~0.5mm

Shield Tape

FFC

(Wireless Card)

Remove half of the Release

Paper and wrap around one loop.

FFC(Audio Card)

Safety Working

Check Insert/Lock.

0~0.5mm

Busterade

Safety Working

Check Insert/Lock.

FFC

(Wireless Card)

Connect.

Ensure the correct order.

ANT Cable→FFC→Spring

BT FFC

b

Connect.

Safety Working

Check Insert/Lock.

Tape

Safety Working

Check Insert/Lock.

Connect.

Ensure the Cable does not lean to the CN

side. (Avoid coming over the A line edge

to keep the inserting room for CN. )

End of the CN

0 to 0.5 mm

Edge

Sheet

A

Attachment

Standard

–0.5(Board edge)

a

c

1~3mm

Connect.

Safety Working

Check Insert/Lock.

0~1mm

Match to the center. (–2)

*Note

Apply the load to attach. 20 to 30N (2.0 to 3.0 Kgf)

Paste Sheets firmly. 20~30N(2.0~3.0Kgf)

*

4–2mm

a

Shield

Tape

Loosen slightly not to strain.

Shield Tape

10–5mm

0~1mm

Ant.Cable

Handle FFC carefully.

Hold down the arrow

point of FFC lightly.

Tape

Remove the

Release Paper and

attach to the wall.

Power Cable

1~3mm

bc

9-20

Page 45

9.2.13. Setting the Display Unit

1. Connect the Cables to the connectors (CN2, CN6) of the

Main PCB.

2. Put the two Cables into the Clamper.

Main P.C.B.

Connector

(CN6)

Display

Unit

Connector

(CN2)

Clamper

3. Connect the Inverter Cable to the connector (CN6) of the

Power PCB as closing the Rear Cabinet.

4. Attach both the Inverter Case and the Inverter.

5. Hook the Cable on the lamp Cable Spring.

6. Attach the Cable Hold Sheet.

7. Set the LCD Unit with its face down and then close the

Rear Cabinet.

Lamp Cable Spring

Cable Holder Sheet

Cable

Rear Cabinet

Connector(CN6)

IO Power P.C.B.Inverter

9-21

Page 46

8. Fix the Rear Case ASS'Y using 12 Screws <N6>. No1 to

No12

9. Fix the Antenna Cover R using two Screws <N4>.

10. Fix the Antenna Cover L using two Screws <N4>.

Note:

Tighten the Screws in the numbered order (No1 to No12).

No.1

<N6>

No.5

<N6>

No.9

<N6>

No.12

<N6>

No.4

<N6>

No.7

<N6>

No.8

<N6>

No.6

<N6>

No.3

<N6>

No.10

<N6>

No.11

<N6>

No.2

<N6>

Screws <N4>:DXSB2+6FNL

Screws <N6>:DXYN26+J6FNL

■ Assembly of the Display unit

Safety Working

U-turn using the

pin as a guide.

Antenna

Cover L

<N4>

<N4>

Rear Cabinet

<N4>

Connect.

<N4>

Antenna

Cover R

Tape

Inside the

Pin standard

Fix with Tape not to

strain the right edge.

4~6mm

Safety Working

Safety Working

Clamper Lock

Clamp at the foot

of the Clamper.

9-22

Page 47

*Note

Ensure the Cable does not run over the Cushions (a,b,c).

Note

Avoid any stress on the transformer

and the coil.

Insert position

shape of the A boss

A

Connect.

Safety Working

Insert the cable.

Safety Working

Insert the cushions on the both sides with the "Caution to High

Voltage" label facing front until they reach the bottom while

matching the cushions to the A boss and the rib..(Top of the A boss

and the cushions on the both sides must be on the same line.)

front side

Pass between

the Pins.

A

B

Cable Hold Sheet

Safety Working

Hook the FL Cable.

Hook the Spring Hook over the cable.

Note)

Do not strain the Cable on the both

edges when removing the Inverter for

repairment.

Attach cable hold sheet to the Pin after fixing the Cable.

(B side and 1 must be on the same line oroverlaps.)

b

c

a

9-23

Page 48

9.2.14. Setting the Battery Pack

hand strap cover

battery cover latch

battery cover

battery cover latch

1. Open the hand strap cover.

hand strap

2. Remove the hand strap.

battery cover latch

battery cover

3. Slide the Battery cover latch.

4. Open and remove the Battery cover.

battery pack

6. Fit the battery cover, and then close the battery cover.

7. Slide the battery cover latch.

hand strap

8. Attach the hand strap.

hand strap cover

9. Attach the hand strap cover.

5. Firmly attach the battery pack to the connector.

9-24

Page 49

■ Assembly of the Battery Pack

*Reuse the bag used on delivery.

Battery Pack

Do not remove

through the whole

process.

Pen

Important Parts for Safety

Slide the knob to the

outside and lock firmly.

Battery Cover Assy

guide to match

the end –2 mm

Important Parts for Safety

Information Label

Allowable

displacement:

max. 1 mm

Coa Label(Win Ce)

10~15mm

Model Label

Serial Label

9-25

Page 50

Screw

Ensure the direction is right.

The side with fewer stitches is placed on the surface.

Turn the metal clasp on

both sides to the inside.

Hand Strap

Slide the knob to the

outside and lock firmly.

Screw

9-26

Page 51

10 Exploded View

N7

N7

N7

N3

N3

K8

K51

K53

E6

K42

K29

K45

E14

E16

E16

K26

K9

K10

K10

K43

K50

K18

K20

K19

K22

K7

K28

K48

K6

K5

K21

K16

E7

N7

N7

N6

N6

N6

N6

N6

N6

N6

N6

N6

N6

N7

N7

N3

N3

E8

N7

E5

E17

K15

K49

K12

N4

E2

E1

K24

K36

K46

E9

E4

K15

K15

K3

K44

K11

K39

N1

N1

N1

N1

N4

N1

E11

K11

N1

N1

N1

E18

N1

N1

N1

N1

N1

N1

K35

K23

K52

E15

K25

K26

K41

K47

K40

K23

K4

K34

N5

N5

N1

N1

K11

N1

N1

K54

K54

E7-1

E8-1

Screw tightening torque

0.2 _ 0.02N m

(2.0 _ 0.2kgf cm)

0.3 _ 0.03N m

(3.0 _ 0.3kgf cm)

0.45 _ 0.05N m

(4.5 _ 0.5kgf cm)

0.8_0.08N m

(8.0 _0.8kgf cm)

A

B

C

D

+

+

+

+

+

+

+

A

A

A

A

A

A

A

A

A

A

A

A

A

A

C

C

C

B

N3

B

B

A

C

C

C

C

C

C

D

A

A

C

A

A

A

D

B

A

A

A

A

A

A

C

CF-08TX1A1M

10-1

Page 52

K1

K1-3

K1-7

K1-8

K1-6

K1-1

K1-2

K1-9

K1-1-1

A

K1-1-2

K1-1-5

K1-1-7

Capton tape

(10 25)

K1-1-4

K1-1-6

K1-3

K1-10

K1-5

K1-4

K1-1-13

K1-6

Capton tape

(10 25)

K1-7

K1-3

K1-7

K1-8

K1-1-12

K1-1-3

K1-1-8

K1-1-14

K1-1-12

K1-1-10

K1-1-9

K1-1-11

Screw tightening torque

A

0.2 _ 0.02N m

+

(2.0 _ 0.2kgf cm)

+

CF-08TX1A1M

10-2

Page 53

K200-1

K200-4

K200-3

K200-2

K200-2-6-1

K200-6

K200-3

K200-4

K37

K200-4

K200-5

K200-3

K37

K200-2-1

K200-4

K200-3

K200-2-6

K200

K31

K32

K17

E3

A

A

K11

A

E13

K33

K30

K2

N2N2

A

K38

K200-2-5

E19-1

K201

K200-2-4

E19-1-3

E19-3

K201

E19-1-2

E20

K200-2-5

K200-2-2

E19-2

E19

K200-2-3

E19-1-1

Screw tightening torque

A

0.2 _ 0.02N m

+

(2.0 _ 0.2kgf cm)

+

K14

E10

K13

K27

E12

10-3

CF-08TX1A1M

Page 54

11 Replacement Parts List

Note: Important Safety Notice

Components identified by mark have special characteristics important for safety.

When replacing any of these components, use only manufacturer's specified parts.

CF-08TX1A1M

REF.NO. and AREA PART NO. DESCRIPTION Q'TY

Main Block Unit

E1 DL3UP1486AAA PCB, MAIN RTL 1

E2 DL3U11487AAA PCB, IO POWER RTL 1

E3 DL3U21487AAA PCB, SW LED RTL 1

E4 DL3U31487AAA PCB, AUDIO CON RTL 1

E5 DL3U41487AAA PCB, USB RTL 1

E6 DL3U51487AAA PCB, DOCK CON RTL 1

E7 DL3U11489AAA PCB, BLUETOOTH WLAN R RTL 1

E7-1 DFJS1016ZA WLAN/BT CABLE R 1

E8 DL3U21489AAA PCB, WLAN L RTL 1

E8-1 DFJS899ZA ANTENNA CABLE L 1

E9 DL3UP1488AAA PCB, WLAN RTL 1

E10 N0GB1J000018 INVERTER 1

E11 DFJS1012ZA POWER CABLE 1

E12 DFJS1014ZA INVERTER CABLE 1

E13 DFJS1015YA SWITCH CABLE 1

E14 DFJK10T068DB FP FFC 1

E15 DFJK16T078DB DOCKING FFC 1

E16 DFJK50T043DB LAN/POWER FFC 2

E17 DFJK9015ZA USB FFC 1

E18 DFJK9019ZA BT FFC 1

E19 DFWV08A0085 LCD ASS'Y 1

E19-1 DL3DW0181AAA LCD ASS'Y 1

E19-1-1 A2CA00000066 BACK LIGHT 1

E19-1-2 DFHM0290ZA REFLECTION ANGLE 1

E19-1-3 DFQT9863ZA LCD ATTENTION LABEL 1

E19-2 DFHE0995YA TS NOISE SHEET 1

E19-3 DFHE0646ZA BUSTERADE 1

E20 DFJS1011ZA LCD CABLE 1

Accessories

A1 CF-AA1623AM6 AC ADAPTOR 1

A2 N4HULSA00003 BATTERY PACK 1

A3 K2CG3DR00003 AC CABLE 1

A4 DFQX5591ZA MANUAL 1

A5 DFME0148ZA TETHER 1

A6 DFHS9017ZA TOUCH PANEL CLOTH ASS'Y 1

Packing Material

P1 DFPK1187ZA PACKING CASE 1

P2 DFPN0828ZB CUSHION B 2

P3 DFPN0832ZA CUSHION T 2

P4 DFPK1037YA ACCESSORY BOX 1

P5 DFPE0830ZA HOLDER 1

Mechanical Parts

K1 DFWV80C0505 REAR CABINET ASS'Y 1

K1-1 DFKE9081YA-0 REAR CASE ASS'Y 1

K1-1-1 L0AA02A00069 SPEAKER 1

K1-1-2 XSB2+4FNL SCREW 2

K1-1-3 DFHG898ZA BATTERY SPACER 1

K1-1-4 DFHP7230ZA SPEAKER BASE SHEET UPPER 1

K1-1-5 DFHP7258ZA SPEAKER TAPE 1

K1-1-6 DFHR3C72ZA SPEAKER BASE LOWER SHEET 1

11-1

Page 55

K1-1-7 DFHR3C73ZA SPEAKER HOLD SHEET 1

K1-1-8 DFHR3C75ZA BATTERY BOTTOM BLIND SHEET 1

K1-1-9 DFHR3C76YA USB SHEET 1

K1-1-10 DFHR3C78ZA LAN SHEET 1

K1-1-11 DFHR3C79ZA SD SHEET 1

K1-1-12 DFHR3C80ZA PEN HOLD SHEET 2

K1-1-13 DFHR3C82ZA MAIN PCB INS. SHEET 1

K1-1-14 DFQT9976ZA-0 SD LED SIGN LABEL 1

K1-2 DFMD1197ZA KENSINGTON PLATE 1

K1-3 DFMC0867ZA EMI CLOTH 3

K1-4 DFMY3232ZA HEAT RADIATION PLATE 1

K1-5 DFHG894XA LCD REAR CUSHION T3L 1

K1-6 DFHG895ZA LCD REAR CUSHION T3S 2

K1-7 DFHG896ZA LCD REAR CUSHION T6L 3

K1-8 DFHG897ZA LCD REAR CUSHION T6M 2

K1-9 DRQT2+I35FKL SCREW 1

K1-10 DFHR1108ZA LCD REAR CLAMPER 1

K2 DFMD2179ZA SW BOARD PLATE 1

K3 DFMD3126ZA USB HOLD PLATE 1

K4 DFMD4061ZA-0 CARD READER BLIND PLATE 1

K5 DFMD4062ZA-0 AUDIO COVER PLATE 1

K6 DFMD4063ZA-0 DC/USB COVER PLATE 1

K7 DFMD4064ZA-0 SD COVER PLATE 1

K8 DFMD4065ZA BATTERY MAGNET COVER PLATE 1

K9 DFMC0866ZA AUDIO EMI SHEET 1

K10 DFMC0867ZA EMI CLOTH 2

K11 DFMX0734ZA PROTECT SHEET 5

K12 DFMX1236ZA IO BOARD EDGE SHEET 1

K13 DFMX1237YA CN FIX TAPE 2

K14 DFMX9011ZA INVERTER CASE ASS'Y 1

K15 DFHG1331ZA SHIELD SHEET(LAN JACK) 3

K16 DFHG1714ZA ANT CABLE PACKING 1

K17 DFHG1841XA SW BOARD RUBBER 1

K18 DFHG1842ZA-0 DC COVER 1

K19 DFHG1843ZA-0 USB COVER 1

K20 DFHG1844ZA-0 LAN COVER 1

K21 DFHG1845ZA-0 AUDIO COVER 1

K22 DFHG1846ZA-0 SD COVER 1

K23 DFHG370ZA-1 FOOT RUBBER 2

K24 DFHG900ZA VGA DAMPER 1

K25 DFHE0465ZA EMI SHEET 5 1

K26 DFHE0646ZA BUSTERADE 2

K27 DFHP7168ZA INVERTER TAPE 1

K28 DFKH1019ZA-0 HANDY STRAP 1

K29 DFKE9085ZA-0 BATTERY COVER ASS'Y 1

K30 DFGL0152ZA-0 LED LENS 1

K31 DFBC0317ZA-0 POWER BUTTON 1

K32 DFBC0318ZA-0 USER BUTTON 2

K33 DFBC0319ZA-0 SCROLL BUTTON 1

K34 DFBD9007ZA-0 BATTERY LOCK ASS'Y R 1

K35 DFBD9008ZA-0 BATTERY LOCK ASS'Y L 1

K36 DFHR1109ZA LAMP CABLE SPRING 1

K37 DFHR1110ZA LCD SW CABLE CLAMPER 2

K38 DFHR3159ZA TOP CASE SHEET 1

K39 DFHR3636ZA CABLE HOLD SHEET 1

K40 DFHR3741ZA FFC CN STOPPER 1

K41 DFHR3C41YA DOCKING PCB SHEET 1

K42 DFHR3C42YA DOCKING COVER SHEET 1

11-2

Page 56

K43 DFHR3C43ZA-0 CARD BLIND SHEET 1

K44 DFHR3C74ZA BATTERY CN COVER SHEET 1

K45 DFHR3C77YA AUDIO SHEET 1

K46 DFHR3C81YA MAIN PCB HOLD SHEET 1

K47 DFHR3E39ZA CAPTON TAPE 1

K48 DFHR6207ZA PEN 1

K49 DFHR6224ZA-0 ANTENNA COVER L 1

K50 DFHR6225ZA-0 ANTENNA COVER R 1

K51 DFHR6226ZA-0 PEN COVER 1

K52 DFHR6227ZA-0 BASE JOINT COVER 1

K53 DFGT1079ZA-0 INFORMATION LABEL 1

K54 DFHG1714XA ANT CABLE PACKING 2

K200 DFWV80A0359 FRONT CABINET ASS'Y 1

K200-1 DFKF9032ZA-0 FRONT CASE ASS'Y 1

K200-2 DFWV84A0270 TOUCH SCREEN PANEL KIT 1

K200-2-1 DFHP7229ZA TS TAPE 1

K200-2-2 DFHR3476ZA TS SPACER A 1

K200-2-3 DFHR3630ZA TS FPC SPACER 1

K200-2-4 DFHR3D66ZA TS SPACER L 1

K200-2-5 DFHR3D70ZA TS SIDE SPACER 2

K200-2-6 DL3DV0181AAA TS PANEL ASS'Y 1

K200-2-6-1 N2BAAYY00007 TOUCH SCREEN 1

K200-3 DFHG891YA LCD SIDE CUSHION T8 4

K200-4 DFHG892YA LCD SIDE CUSHION T5 4

K200-5 DFHG893ZA LCD SIDE CUSHION T2 1

K200-6 DFHG899ZA LCD SIDE DAMPER THIN 2

K201 DFMC0867ZA EMI CLOTH 3

N1 XSB2+4FNL SCREW 24

N2 DRSB2+5FKL SCREW 3

N3 DXQT26+D5FNL SCREW 9

N4 DXSB2+6FNL SCREW 4

N5 DXSN4+6FNL SCREW 2

N6 DXYN26+J6FNL SCREW 12

N7 DFHE5025XA SCREW 13

11-3

Page 57

Replacement Parts List

A

Note: Important Safety Notice

Components identified by mark have special characteristics important for safety.

When replacing any of these components use only manufacturer's specified parts.

CF-08TX1A1M

REF. NO and ARE

MAIN PCB

C 1 F1G1E103A062 CAPACITOR, 25V, 0.01µF 25

C10

C50

C 150

C 151

C 164

C 169

C 171

C 187

C 188

C 207

C 245

C 247

C 250

C 266

C 278

C 279

C 280

C 311

C 312

C 313

C 314

C 324

C 325

C 326

C 5 F1G1H1R0A543 CAPACITOR, 50V, 1pF 1

C 7 F1G1A104A014 CAPACITOR, 10V, 0.1µF 152

C8

C9

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

PART NO. DESCRIPTION

Q'TY

11-4

Page 58

C27

C28

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

C40

C41

C42

C43

C44

C49

C52

C53

C55

C56

C57

C65

C66

C67

C68

C69

C70

C71

C74

C75

C81

C82

C83

C84

C85

C86

C87

C88

C89

C90

C91

C92

C93

C94

C95

C96

C97

11-5

Page 59

C98

C 102

C 103

C 104

C 105

C 106

C 107

C 108

C 109

C 110

C 111

C 112

C 113

C 114

C 115

C 116

C 117

C 118

C 119

C 120

C 121

C 122

C 125

C 126

C 127

C 138

C 139

C 140

C 141

C 142

C 147

C 148

C 152

C 163

C 170

C 172

C 173

C 175

C 176

C 177

C 178

C 179

C 180

C 181

C 182

C 184

C 186

C 215

C 226

C 230

11-6

Page 60

C 232

C 233

C 234

C 239

C 241

C 265

C 274

C 276

C 277

C 281

C 282

C 283

C 284

C 285

C 286

C 287

C 288

C 293

C 294

C 295

C 296

C 297

C 298

C 299

C 300

C 301

C 303

C 304

C 306

C 310

C 315

C 316

C 317

C 318

C 319

C 320

C 323

C 11 F1G1H102A496 CAPACITOR, 50V, 1000pF 3

C 216

C 217

C 45 F1G1H680A451 CAPACITOR, 50V, 68pF 4

C46

C47

C48

C 54 F1H1A1050015 CAPACITOR, 10V, 1µF 17

C 129

C 131

C 132

C 133

C 220

11-7

Page 61

C 221

C 229

C 231

C 235

C 257

C 258

C 259

C 262

C 263

C 268

C 308

C 100 F1J0J1060004 CAPACITOR, 6.3V, 10µF 23

C 101

C 124

C 135

C 137

C 149

C 174

C 183

C 190

C 191

C 236

C 237

C 238

C 242

C 246

C 248

C 252

C 254

C 255

C 256

C 302

C 305

C 307

C 165 F1G1H8R0A452 CAPACITOR, 50V, 8pF 2

C 166

C 167 F1G1E682A062 CAPACITOR, 25V, 6800pF 2

C 168

C 189 F1G1C223A004 CAPACITOR, 16V, 0.022µF 1

C 193 F1H0J1050022 CAPACITOR, 6.3V, 1µF 3

C 194

C 222

C 210 F1G0J224A001 CAPACITOR, 6.3V, 0.22µF 5

C 211

C 214

C 244

C 249

C 223 EEFCD0J470ER CAPACITOR, 6.3V, 47µF 5

C 224

C 225

11-8

Page 62

C 240

C 243

C 227 F1G1H100A452 CAPACITOR, 50V, 10pF 2

C 228

C 251 F1J0J226A048 CAPACITOR, 6.3V, 22µF 6

C 253

C 269

C 336

C 337

C 338

C 260 F1G1H331A450 CAPACITOR, 50V, 330pF 3

C 261

C 264

C 267 F1G1H332A496 CAPACITOR, 50V, 3300pF 1

C 270 EEFUD0J101ER CAPACITOR, 6.3V, 100µF 2

C 271

C 330 F1L1H100A072 CAPACITOR, 50V, 10pF 2

C 331

CN 1 K1KA10BA0014 CONNECTOR 1

CN 2 K1KA14BA0098 CONNECTOR 1

CN 3 K1MN50AA0018 CONNECTOR 2

CN 10

CN 4 K1MN16BA0059 CONNECTOR 1

CN 6 K1KA30BA0060 CONNECTOR 1

CN 7 K1MN10B00146 CONNECTOR 1

CN 9 K1KA02BA0085 CONNECTOR 1

CN 12 K1MN08AA0068 CONNECTOR 1

CN 13 K1MN12AA0018 CONNECTOR 1

D 1 B0KB00000044 DIODE 5

D2

D7

D8

D9

D 5 B0JCMD000014 DIODE 2

D6

FL 1 J0MAB0000169 FILTER 2

FL 2

FL 3 J0MAB0000116 FILTER 2

FL 4

IC 1 C2GBC0000268 IC, CPU 1

IC 4 C0EBE0000459 IC 2

IC 36

IC 5 C0EBD0000313 IC 1

IC 6 C0JBAZ002067 IC, LOGIC 2

IC 53

IC 8 C1CB00002385 IC, CONTROLLER 1

IC 9 C0JBAB000619 IC, GATE LOGIC 3

IC 21

IC 29

IC 10 C3ABRY000010 IC, SDRAM 2

11-9

Page 63

IC 11

IC 15 C3FBRY000001 IC, FLASH MEMORY 1

IC 16 C3ABPY000009 IC, SDRAM 1

IC 19 C0CBCAC00161 IC 1

IC 22 C0JBCZ000523 IC 1

IC 23 C0JBAZ002770 IC, LOGIC 1

IC 26 C0JBAZ002758 IC, LOGIC 1

IC 27 C0JBAZ002239 IC, GATE LOGIC 4

IC 34

IC 35

IC 37

IC 28 C0ZBZ0001023 IC 2

IC 30

IC 31 C0JBAA000350 IC, LOGIC 1

IC 32 C0JBAC000338 IC, GATE LOGIC 1

IC 39 C1CB00002054 IC, LAN CONTROLLER 1

IC 42 C1BB00000895 IC, AC97 CODEC 1

IC 43 C0CBCBC00130 IC, REGURATOR 1

IC 44 C1BB00000873 IC, AUDIO AMP 1

IC 45 C0DBAGG00014 IC 1

IC 49 C1CB00002478 IC, LAN SWITCH 1

IC 50 C0CBAAC00163 IC 1

IC 51 C3EBEC000061 IC, EEPROM 1

L 1 J0JDC0000045 INDUCTOR 4

L2

L14

L15

L 3 J0JHC0000074 INDUCTOR 3

L5

L6

L 12 DDB5Z024E-L INDUCTOR 1

L 13 J0MAB0000174 INDUCTOR 1

L 16 G1C3R3MA0077 INDUCTOR 2

L18

L 17 G1C4R7MA0077 INDUCTOR 1

Q 1 B1CFGD000004 TRANSISTOR 4

Q3

Q4

Q26

Q 8 B1DHDC000028 TRANSISTOR 6

Q10

Q22

Q24

Q28

Q29

Q 9 UNR9213J0L TRANSISTOR 6

Q23

Q25

Q30

Q31

11-10

Page 64

Q44

Q 27 UNR9113J0L TRANSISTOR 3

Q33

Q36

Q 34 XP0421300L TRANSISTOR 3

Q35

Q38

R 1 ERJ2GEJ473X RESISTOR, 1/16W, 47KΩ 21

R28

R29

R30

R31

R32

R33

R36

R38

R 168

R 171

R 177

R 178

R 179

R 310

R 311

R 312

R 353

R 354

R 355

R 356

R 2 ERJ2GEJ102X RESISTOR, 1/16W, 1K Ω 9

R62

R 172

R 174

R 241

R 242

R 307

R 308

R 309

R 5 ERJ2GE0R00X RESISTOR, 1/16W, 0Ω 22

R6

R50

R51

R72

R 115

R 116

R 118

R 119

R 120

R 180

R 200

R 234

11-11

Page 65

R 265

R 275

R 277

R 279

R 283

R 284

R 292

R 325

R 327

R 7 ERJ2GEJ103X RESISTOR, 1/16W, 10KΩ 11

R8

R9

R24

R37

R43

R 243

R 244

R 253

R 255

R 256