Page 1

To: Farnell InOne

Issue No. : CE-AAKX-CEM-1

Date of Issue : 12 December, 2006

ENGINEERING DRAFT

Product Description

Customer Part Number

Product Part Number

Country of Origin

Marking of the Origin

Applications

Term of Validity

・ These specifications are temporary specifications. Ask factory for technical specifications before purchase

and / or use.

Capacitor Business Unit

Panasonic Electronic Devices Co.,Ltd.

25.Kohata-nishinaka..Uji City,

Kyoto, 611-8585, Japan

Phone (774)32-1111

Phone :+81-774-33-3209

Fax :+81-774-33-4251

No.3726636

: Aluminum Electrolytic Capacitor

:

: Radial lead type (JIS:04 type) AK series X type

: Japan, Malaysia

: Printed on the packaging label

: AUDIO

: November 9, 2007 from the date issue

:

Engineering Group

Aluminum Engineering Team

:

Haruhiko Handa

: Engineer

:

Hisao Nagara

: Manager

(Direct)

Prepared by

Contact Person

Signature

Name(Print)

Title

Authorized by

Signature

Name(Print)

Title

Page 2

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

Contents

Notice matter

Scope

Parts Number

Parts Lists

Can Size Table

Dimensions and Appearance

Constructions

Marking

Lot No. System

Standard Rating

Performance Characteristics

Other Characteristics

Dimensions

(Snap-in lead formed type)

Taping Shape and Dimensions

Taping Specifications

Package Amount and Shape

Notes in using Radial lead type

Aluminum Electrolytic Capacitor

Page No.

Contents

P. 1

P. 2

P. 2

P. 3

P. 4

P. 5

P. 6

P. 6

P.7 ~ P.8

P. 9

P.10 ~ P.12

P.13

P.14

P.15 ~ P.18

P.19 ~ P.21

P.22 ~ P.24

P.25 ~ P.28

Panasonic Electronic Devices Co.,Ltd.

Page 3

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

Notice matter

◆ Law and regulation which are applied

・This product complies with the RoHS Directive (Restriction of the use of certain Hazardous

Substances in electrical and electronic equipment (DIRECTIVE 2002/95/EC).

・No Ozone Depleting Chemicals(ODC's), controlled under the Montreal Protocol Agreement,

are used in producing this product.

・ We do not PBBs or PBDEs as brominated flame retardants.

・ All the materials that are used for this product are registered as "Known Chemicals" in the Japanese act

"Law Concerning the Examination and Regulation of Manufacture, etc. of Chemical Substances".

・ Export procedure which followed export related regulations, such as foreign exchange and a foreign

trade method, on the occasion of export of this product .Thank you for your consideration.

◆ Limitation of a use

・ This capacitor is designed to be used for electronics circuits such as audio/visual equipment,

home appliances, computers and other office equipment, optical equipment, measuring equipment

and industrial robots.

High reliability and safety are required [ be / a possibility that incorrect operation of this product may do harm

to a human life or property ] more. When use is considered by the use, the delivery specifications which

suited the use separately need to be exchanged.

◆ Unless otherwise specified, the product shall conform to JIS 5101-4-1

◆ Country of origin : JAPAN,MALAYSIA

◆ Manufacturing factory : Panasonic Electronic Devices Yamaguchi Co.,Ltd.

1285, Aza-Sakutaguchi, Oaza-Asada,Yamaguchi City, Yamaguchi

Panasonic Electronic Devices Malaysia Sdn.Bhd.

No.1 Jalan Jemuju 16/13,40200 Shah Alam,Selangor Darul Ehsan, MALAYSIA

753-8536 Japan

1

Panasonic Electronic Devices Co.,Ltd.

Page 4

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

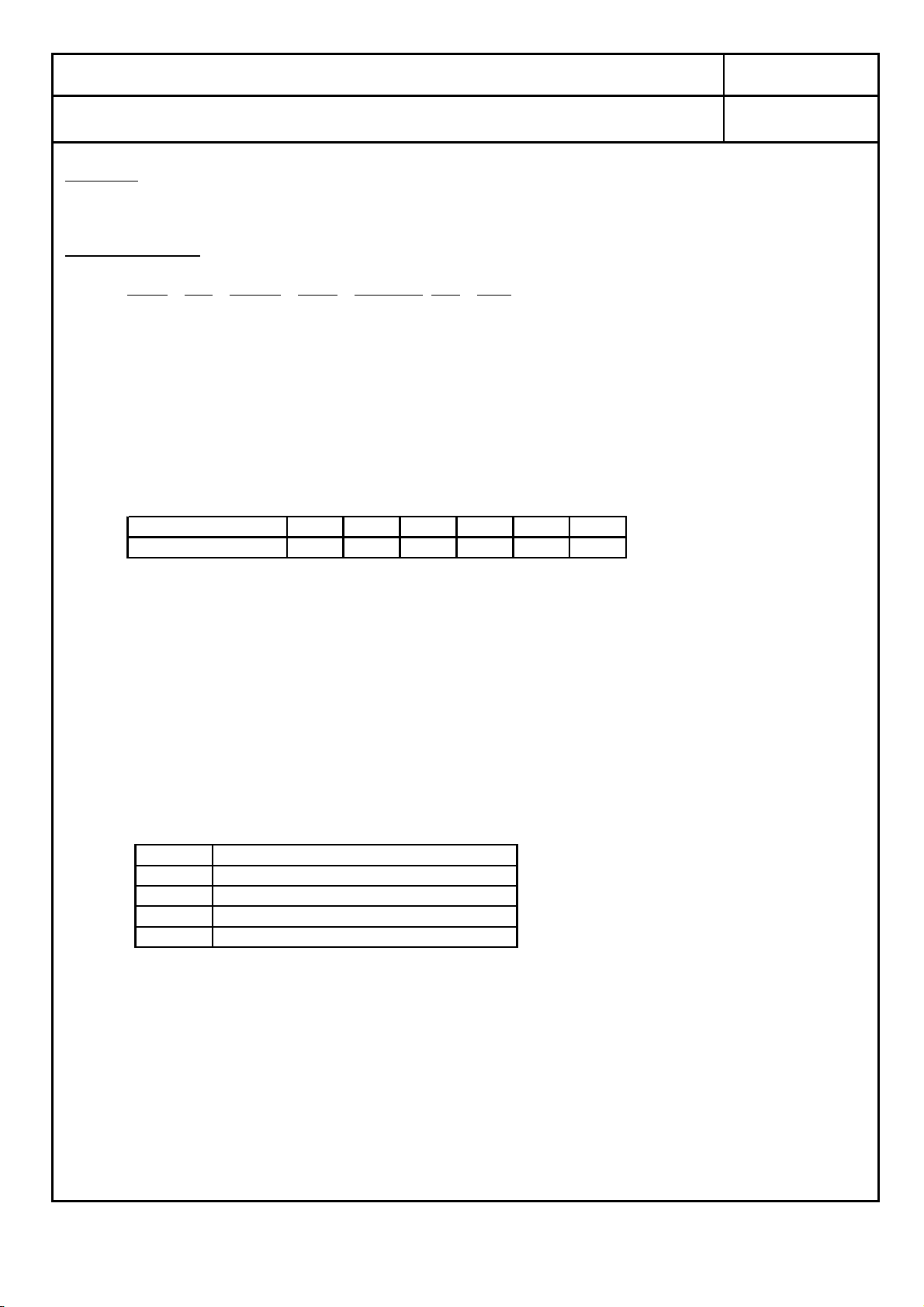

1. Scope

Fixed capacitors for use in electronic equipment, Aluminum electrolytic capacitors with non-solid electrolyte.

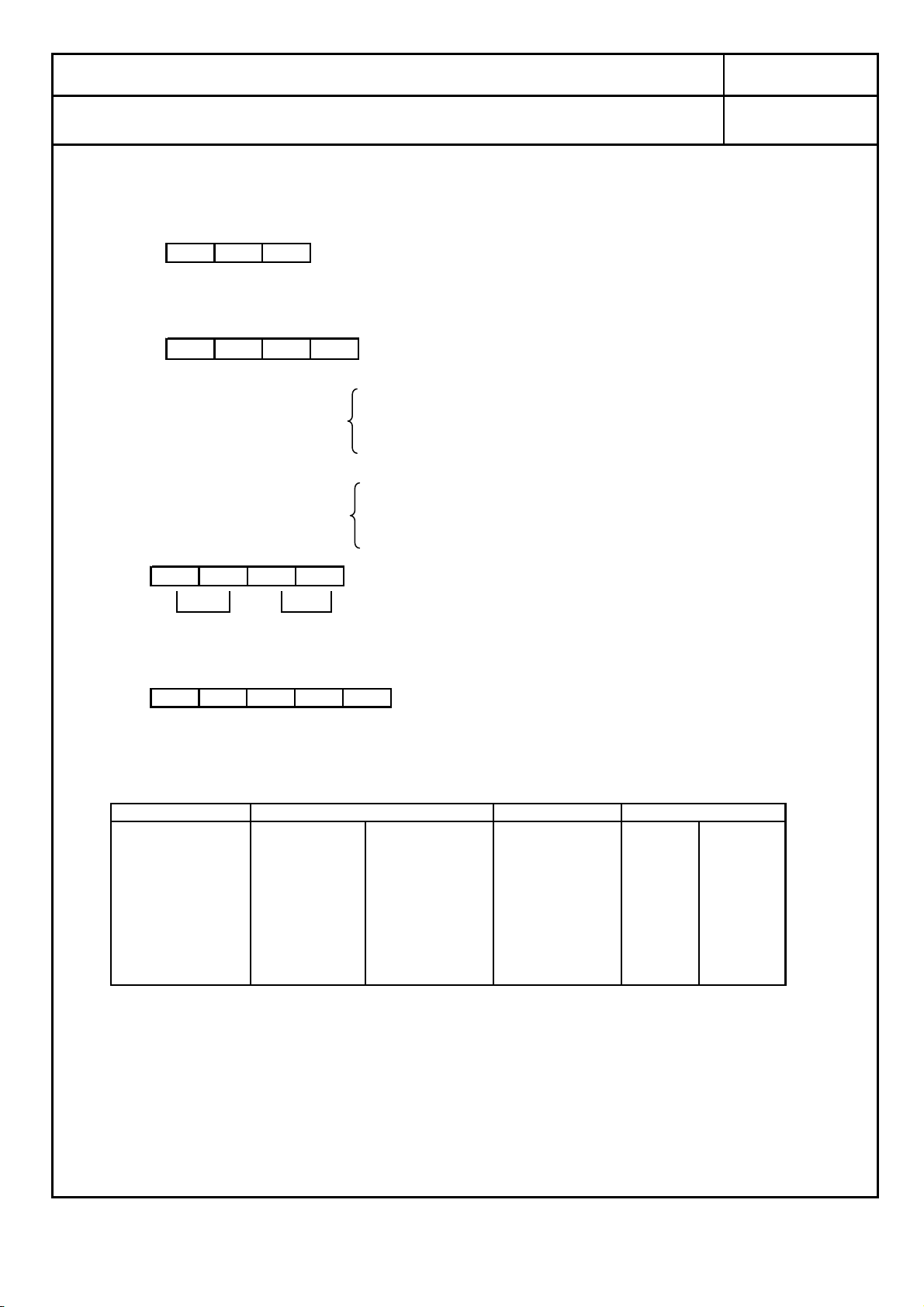

2. Parts Number

2-1 2-2 2-3 2-4 2-5 2-4 2-6

2-1 Aluminum Electrolytic Capacitor

2-2 Type : Radial lead type ( JIS : 04 type )

2-3 Rated Voltage Code

2-4 AK series X type

2-5 Capacitance Code : Indicating capacitance in uF by 3 letters.

The first 2 figures are actual values and the third

denotes the number of zeros.

"R" denotes the decimal point and all figures are the

actual number with "R".

For example, 1uF is expressed as 1R0 in this case.

ex. 0. 1µF → 0R1 , 10µF → 100 , 1000µF → 102

2-6 Suffix Code for Appearance : Special Code for Appearance

Item 9 for snap-in lead,

Item 10 for lead taping dimensions,

Item 11 and Item 12 for lead taping specifications.

EC A ○○ AK ○○○ X □

Voltage Code 0J 1A 1C 1E 1V 1H

Rated Voktage (V.DC) 6.3 10 16 25 35 50

Blank Standard Long Lead

E Snap-in lead

i Lead taping (2.5mm pitch)

B Lead taping (5.0mm pitch)

Q Lead taping (5.0mm pitch:For φ8×7 only)

2

Panasonic Electronic Devices Co.,Ltd.

Page 5

Engineering Draft

CE-AAKX-CEM-1

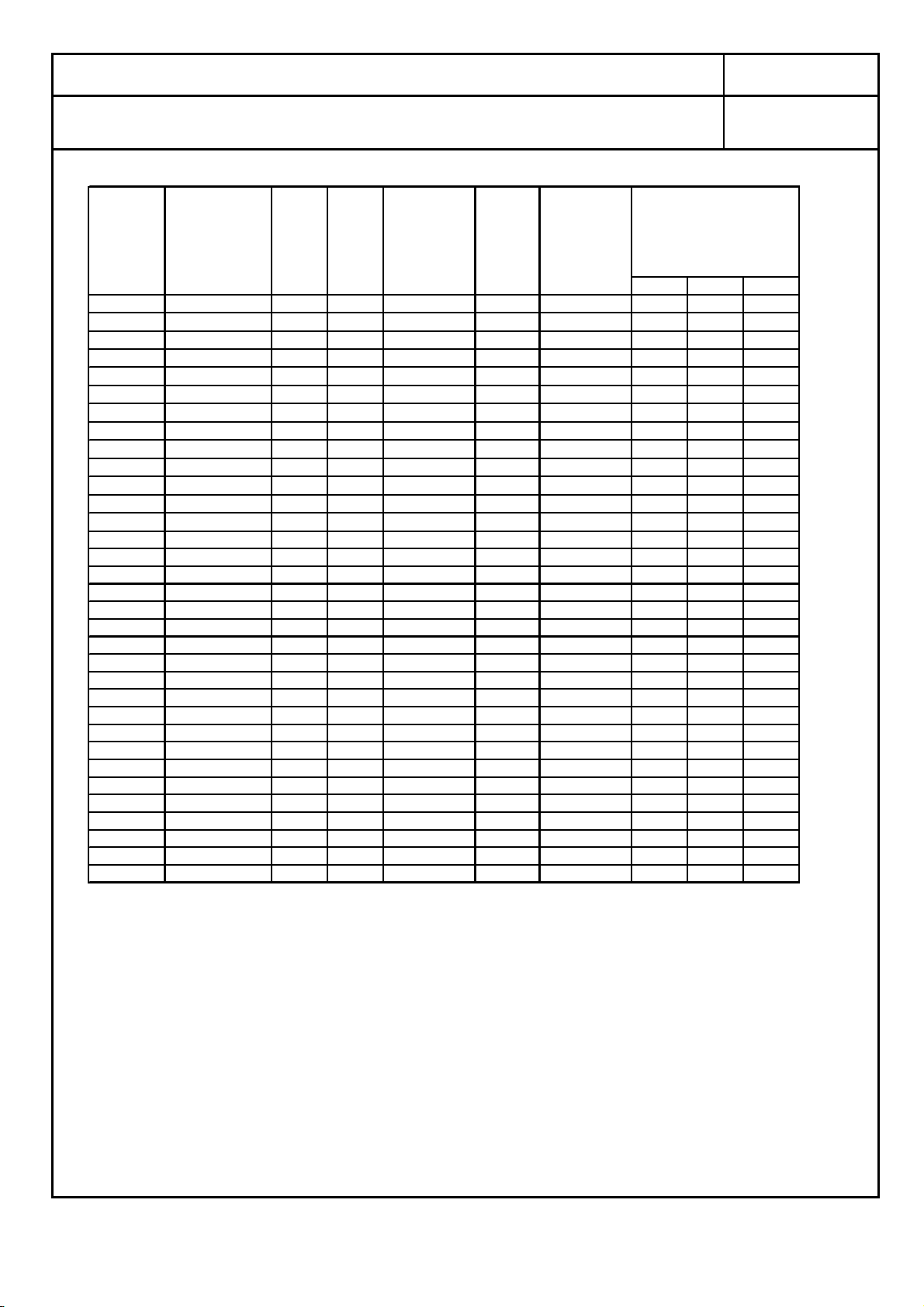

Parts Lists

A type AK series X type

Tangent

Part No. W.V. Cap. of loss

[V.DC] [µF] angle [µA] [mA rms]

max. max. max.

(120Hz) (120Hz) (After (120Hz)

(20℃)(20℃) 2 min.) (85℃) φDLφd

ECA0JAK470X 6.3 47 0.33 3.0 46 4 7 0.45

ECA0JAK101X 6.3 100 0.33 6.3 71 5 7 0.45

ECA0JAK221X 6.3 220 0.33 13.8 103 6.3 7 0.45

ECA0JAK331X 6.3 330 0.33 20.7 130 8 7 0.45

ECA1AAK330X 10 33 0.25 3.3 43 4 7 0.45

ECA1AAK221X 10 220 0.25 22 120 8 7 0.45

ECA1CAK220X 16 22 0.20 3.5 39 4 7 0.45

ECA1CAK330X 16 33 0.20 5.2 60 5 7 0.45

ECA1CAK470X 16 47 0.20 7.5 70 5 7 0.45

ECA1CAK101X 16 100 0.20 16.0 91 6.3 7 0.45

ECA1EAK100X 25 10 0.15 3.0 28 4 7 0.45

ECA1EAK220X 25 22 0.15 5.5 55 5 7 0.45

ECA1EAK470X 25 47 0.15 11.7 70 6.3 7 0.45

Leakage

Current

Rated Ripple

Current

Dim.[mm

]

3

ECA1VAK330X 35 33 0.12 11.5 65 6.3 7 0.45

ECA1VAK470X 35 47 0.12 16.4 85 8 7 0.45

ECA1HAK0R1X 50 0.1 0.10 3.0 1 4 7 0.45

ECA1HAKR22X 50 0.22 0.10 3.0 2 4 7 0.45

ECA1HAKR33X 50 0.33 0.10 3.0 3 4 7 0.45

ECA1HAKR47X 50 0.47 0.10 3.0 5 4 7 0.45

ECA1HAKR68X 50 0.68 0.10 3.0 7 4 7 0.45

ECA1HAK010X 50 1 0.10 3.0 10 4 7 0.45

ECA1HAK2R2X 50 2.2 0.10 3.0 16 4 7 0.45

ECA1HAK3R3X 50 3.3 0.10 3.0 16 4 7 0.45

ECA1HAK4R7X 50 4.7 0.10 3.0 23 4 7 0.45

ECA1HAK100X 50 10 0.10 5.0 35 5 7 0.45

ECA1HAK220X 50 22 0.10 11.0 60 6.3 7 0.45

ECA1HAK330X 50 33 0.10 16.5 75 8 7 0.45

Panasonic Electronic Devices Co.,Ltd.

Page 6

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

4

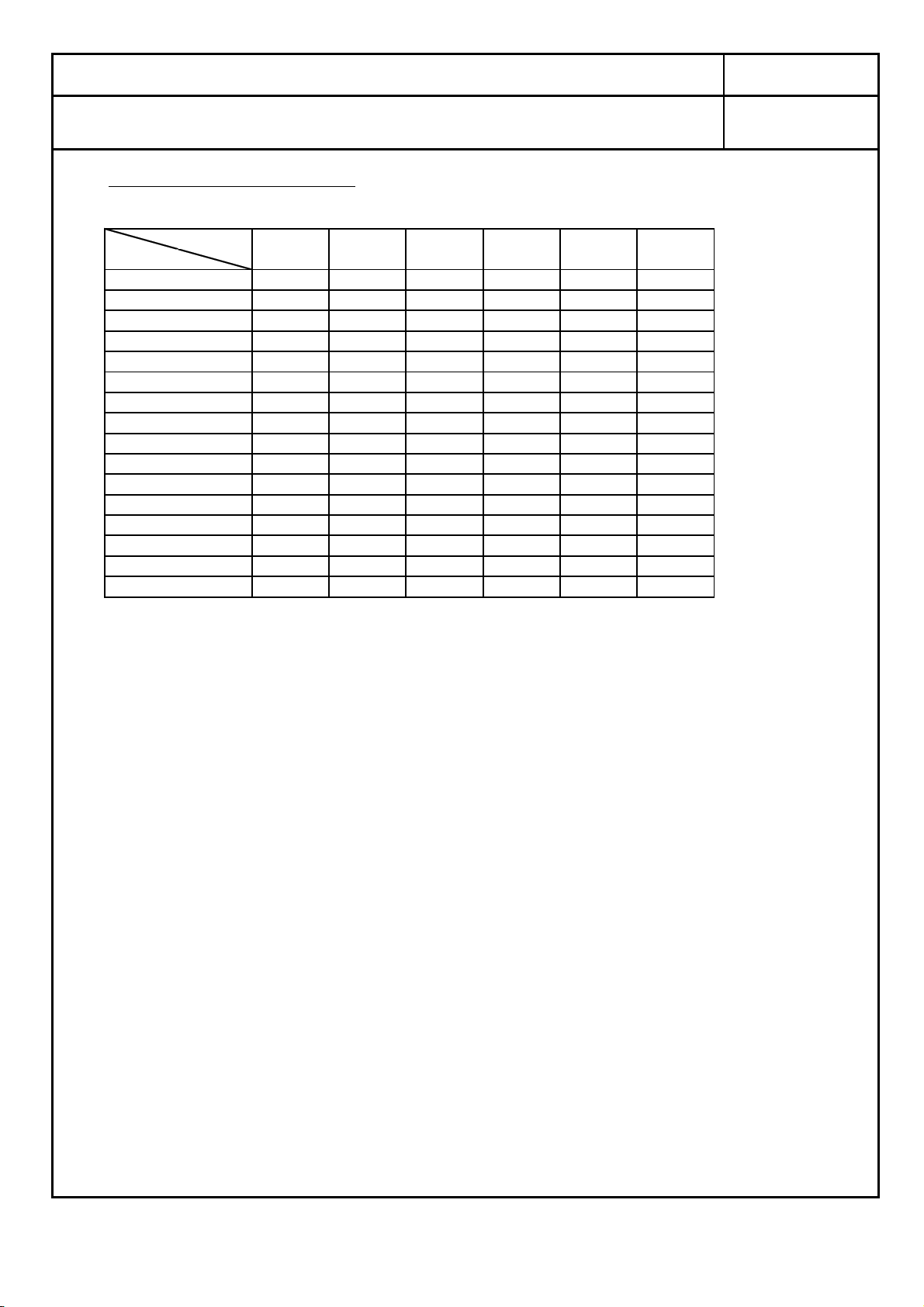

Capacitance and Can Size Table

φDxL[mm]

4x7

4x7

4x7

4x7

4x7

4x7

4x7

4x7

4x7

4x7

Can Size(φD×L

0.1

0.22

0.33

0.47

0.68

1

2.2

3.3

4.7

10

22

33

47

100

220

330

V.DC

)

4x7 4x7 5x7 6.3x7

4x7

5x7

→

→

5x7

5x7 6.3x7 8x7

6.3x7 8x7 6.3x7

8x7

256.3 10 16

35 50

4x7 5x7

→

6.3x7 8x7

Please refer to a high-ranking voltage for "→".

Panasonic Electronic Devices Co.,Ltd.

Page 7

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

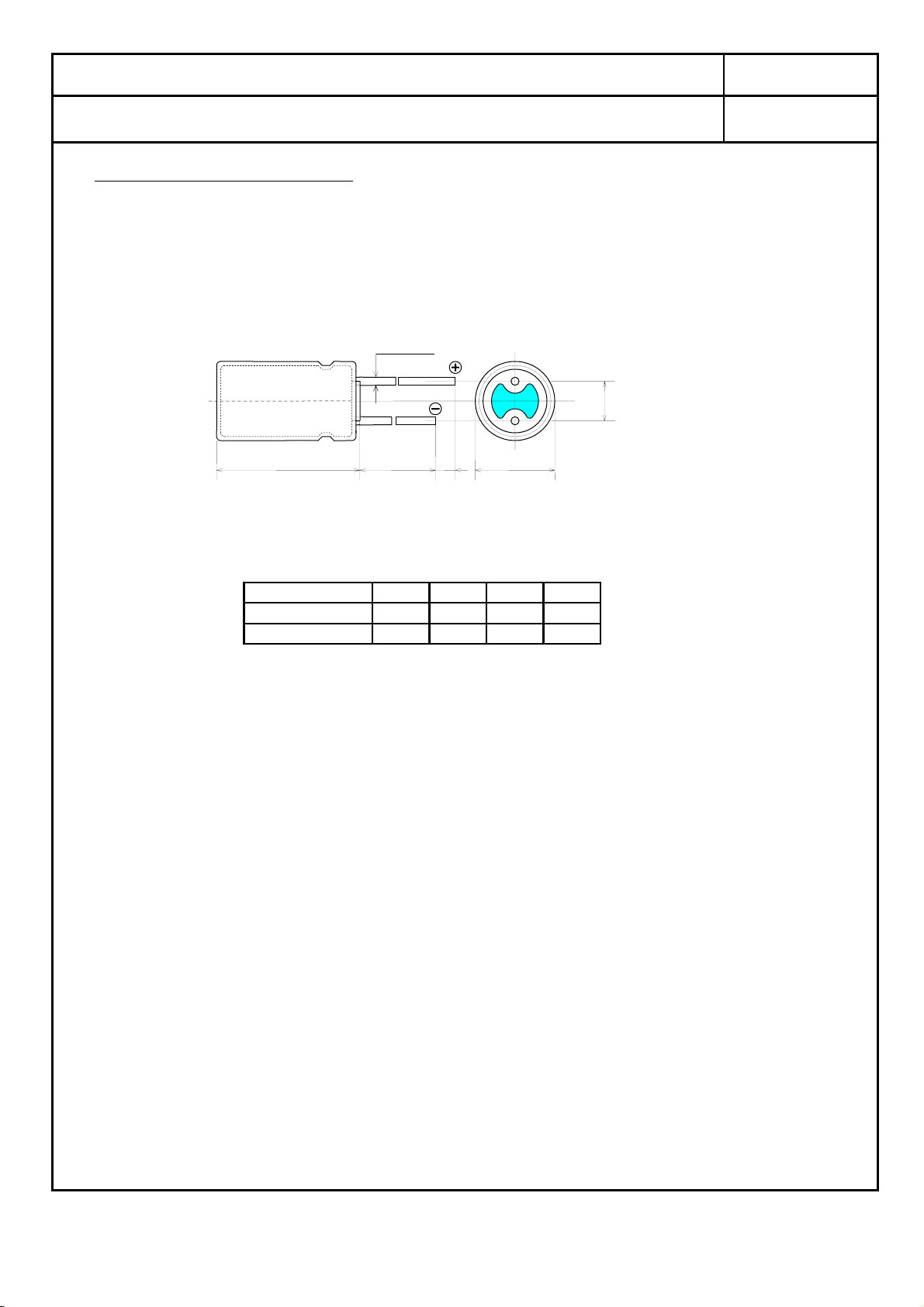

3. Dimensions and Appearance

Body Color ( Clear Blue) , Marking ( White )

Standard Long Lead (Suffix : Blank)

φd±0.05

L±1.0

14min

3

min.

φD±0.5

Body Dia. φD456.38

Lead Space F 1.5 2.0 2.5 2.5

Lead Dia. φd 0.450.450.450.45

Please refer to L dimension on the parts number lists table.

[mm]

F±0.5

[mm]

5

Panasonic Electronic Devices Co.,Ltd.

Page 8

Engineering Draft

A

CE-AAKX-CEM-1

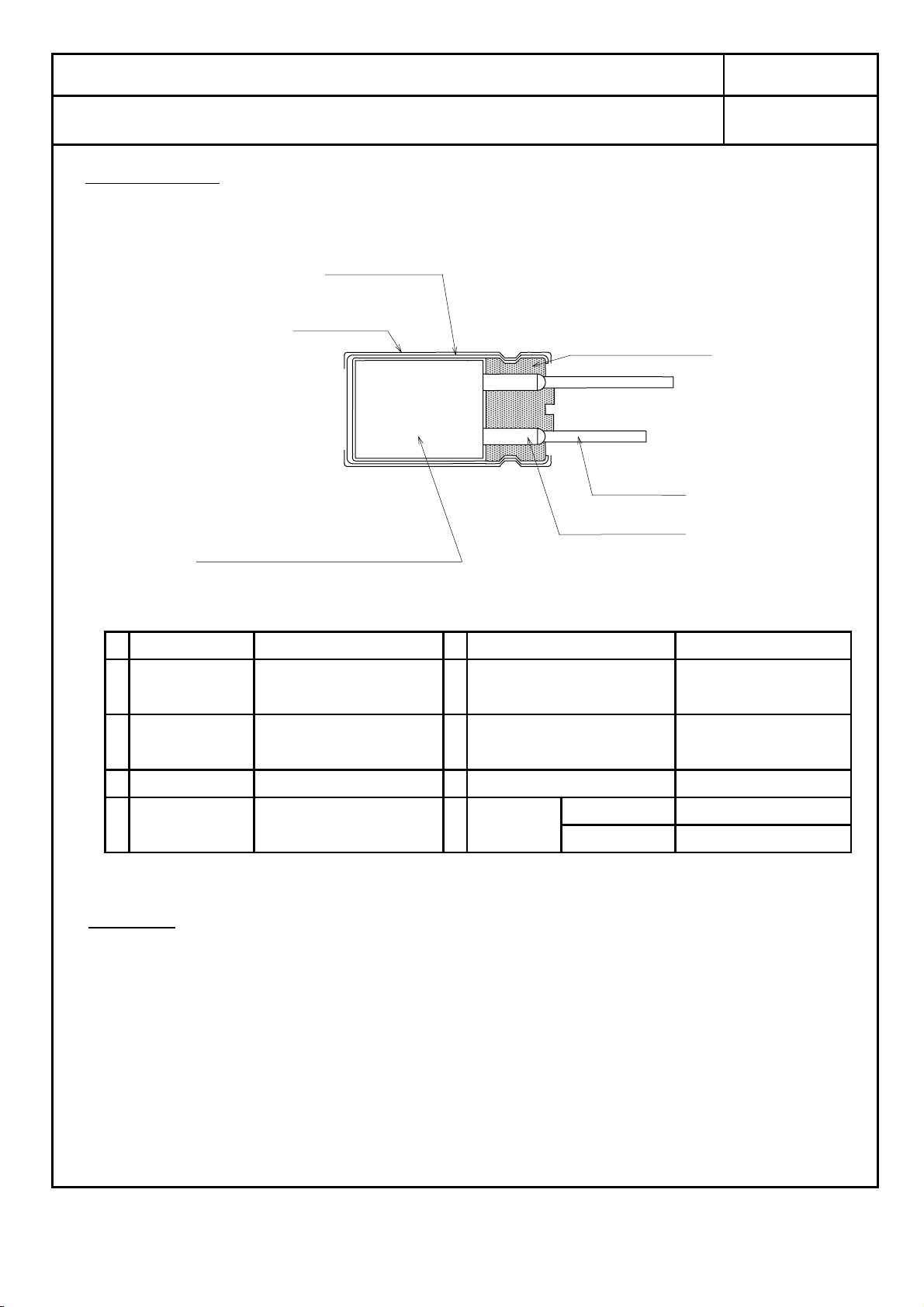

4. Constructions

4-1 Inside Construction

4-2 Construction Parts

Inside uni

(5 Separator、6・7Anode and、

Cathode foil、8 Electrolyte)

Parts Materials Materials

A type AK series X type

3 Aluminum can

2 Sleeve

t

6

4 Sealing rubber

1 Lead wire

luminum Lead

Parts

1 Lead Wire Solid tinned copper weld 5 Separator Manila hemp

steel wire

2 Sleeve Thermoplastic Resin 6 Anode Foil High purity

3 Aluminum Can Aluminum 7 Cathode Foil Aluminum foil

4 Sealing Rubber Synthetic rubber 8 Electrolyte Main Solvent

(EPT/IIR) Main Solute

5. Marking

Markings indicated on the products :

a ) Rated Voltage.

b ) Capacitance

c ) Negative Polarity

d ) Manufacturer’s Trademark

e ) Upper Category Temperature

f ) Lot No. (It indicates to Lot No. System)

Aluminum foil

Ethlene glycol

Ammonium salt

Panasonic Electronic Devices Co.,Ltd.

Page 9

Engineering Draft

A

A

CE-AAKX-CEM-1

Radial lead type Lot No. System 7

・JAPAN PRODUCTS

Lot number is indicated on a sleeve in following manner.

eg. For 04 type, expressed in 3 figures, 4 figures, or 5 figures.

(a) (b) (c)

(a)sequential alphabet for each lot

(b)month (1 to 9 and O for October, N for November, D for December)

(c)sequential alphabet for

(a) (b) (c) (d)

As for the display contents of 4 figures, there are 2 kinds

(1) (a) last number of year

(b) month (1 to 9 and O for October, N for November, D for December)

(c) week (1 to 5 and A to E)

(d) line code in alphabet (A to Z)

(2) (a) last number of year

(b) month (1 to 9 and O for October, N for November, D for December)

(c) line code in alphabet (A to Z)

(d) production date

(a) (b)

(a) last 2 digit of year

(b) numerical indication of week (ninth week of 1992=09)

(a) (b) (c) (d) -

(a) last number of year

(b) month (1 to 9 and O for October, N for November, D for December)

(c) week (1 to 5 and A to E)

(d) line code

production year production week

1:2001 1:January 7:July

2:2002 2:February 8:August B,2:second week B=2 2=28

3:2003 3:March 9:September C,3: third week C=3 3=29

4:2004 4:April O:October D,4: forth week

~

Indicating with the 6:June D:December Z=26

last digit or the

last 2 digits of a

year.

* Lot number can be written in both horizontal and vertical directions.

* Manufacturing country for certain products may not be indicated.

and shifts operation.

※ Letters and marks are also used to distinguish different lines, machines

production month production date

,1: first week

5:May N:November E,5: fifth week Y=25 5=31

=1 date 1=27 date

~

4=30

Panasonic Electronic Devices Co.,Ltd.

Page 10

Engineering Draft

r

A

r

r

r

A

Radial lead type Lot No. System 8

・MALAYSIA PRODUCTS

Lot number is indicated on a sleeve in following manner.

eg. For 04 type, expressed in 4 figures, or 5 figures.

(a) (b) (c) (c)

(a) last number of year

(b) month (1 to 9 and O for October, N for November, D for December)

(c) line code in alphabet (A to Z)

(a) (b) (b) (a)

(a) last number of year and line code in alphabet (A to Z)

(b) month (1 to 9 and O for October, N for November, D for December)

and production date

(a) (b) (c) (d) (d)

(a) last number of year

(b) month (1 to 9 and O for October, N for November, D for December)

(c) week (Greece number)

(d) line code

(a) (b) (c)

(d) (d)

(a) last number of year

(b) month (1 to 9 and O for October, N for November, D for December)

(c) week (Greece number)

(d) line code

production yea

1:2001 1:January 7:July

2:2002 2:February 8:August

3:2003 3:March 9:Septembe

4:2004 4:April O:Octobe

~ 5:May N:Novembe

Indicating with the 6:June D:December

Ⅰ: first week

Ⅱ:second week

Ⅲ: third week

: forth week

Ⅳ

Ⅴ: fifth week

,1: first week 1:1date B:11date

B,2:second week 2:2date C:12date

C,3: third week 3:3date

D,4: forth week

E,5: fifth week 9:9date V:31date

CE-AAKX-CEM-1

production date production month production week

~

U:30date

:10date

~

last digit or the

last 2 digits of a

year.

Panasonic Electronic Devices Co.,Ltd.

Page 11

Engineering Draft

CE-AAKX-CEM-1

6. Standard Ratings

No.

1 Category Temperature Range -40℃ ~ +85

2 Rated Voltage Range 6.3 V.DC ~ 50 V.DC

3 Capacitance Range 0.1 µF ~ 330 µF (120Hz 20℃)

4 Capacitance Tolerance ± 20% (120Hz 20℃)

5 Surge Voltage R.V. 6.3 10 16 25 35 50

(V.DC) S.V. 8 1320324463

6 Rated Ripple Current Parts Lists and Table3

A type AK series X type

Item Ratings

9

℃

Panasonic Electronic Devices Co.,Ltd.

Page 12

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

7. Performance Characteristics

No Item Performance Characteristics Test

1 Leakage Current ≦ I = 0. 01CV or 3µA, whichever is

greater.

I : Leakage current C : Capacitance

V : Rated voltage

2 Capacitance Within the specified capacitance

tolerance.

3 Tangent of Loss Less than the table 1 value of item 8.

Angle

(tanδ)

4 Characteristics at Step 2

High and Low Impedance Ratio :

Temperature Ratio for the value in step 1 shall

be less than the value from table 2

in item 8. *

Step 4

Leakage Current :

500% of the value of item 7. 1. *

≦

Capacitance Change : Impedance should be measured at the frequency

Within ±25% of the value in step 1 of 120 Hz±10%.

Tangent of Loss Angle (tanδ):

the value of item 7. 3.

≦

5 Surge Leakage Current : Test Temperature : 15℃ ~ 35

the value of item 7.1.

≦

Capacitance Change : Series Protectiv e Resistance :

Within ±15% of the initially

measured value.

Tangent of Loss Angle (tanδ): R = Series protective resistance (kΩ)

the value of item 7. 3. C =Capacitance (µF)

≦

Appearance : Test Voltage : Surge voltage item 6. 5

No significant change can be Applied Voltage : 1000 cycles of 30s±5s

observed.

Series Resistor : 1000Ω±10Ω

Applied Voltage : Rated voltage

Measuring : After 2 minutes

Measuring Frequency

Measuring Circuit

Measuring Voltage

Measuring Frequency

Measuring Circuit

Measuring Voltage

Test Temperature (℃)Step

1

3

4

5

* Capacitors should be stored at each

temperature until measured impedance or

capacitance is stabilized.

: 120 Hz±20%

: Equiv alent series circuit

: +1. 5V. DC ~ +2 V. DC

( ≦0.5V for AC.)

: 120 Hz±20%

: Equiv alent series circuit

: +1. 5V. DC ~ +2 V. DC

( ≦0.5V for AC.)

20± 2

-40±32

20±

2

85± 2

20± 2

℃

100 ± 50

R =

C

“ON” and 5 min. 30 s "OFF"

10

Time

15 minutes

2 hours

Panasonic Electronic Devices Co.,Ltd.

Page 13

Engineering Draft

g

y

g

g

CE-AAKX-CEM-1

A type AK series X type

No Item Performance Characteristics Test

6 Robustness of

Terminations Diameter [mm] Pull Strength

Tensile φ0.45 5 N

There is no damage or breakage after Applied above steady pull axially for a 10s±1s

Bending test.

Diameter [mm ] Static Load

φ0.45 2.5 N

At first, a capacitor is placed in vertical position

with the weight specified above being applied to

one of leads. Then the capacitor is slowly

rotated 90°to horizontal position and

subsequently returned to vertical position.

The above bendin

An additional bending is done in the opposite

direction.

7 Vibration Capacitance : Frequency

Measured value is to be stabilized (1 minute per cycle.)

during test. (Measured several Total Amplitude : 1. 5 mm

times within 30 min. Direction and Duration of Vibration :

before completion of test) It is done in the X, Y, Z axis direction for 2

Appearance : hours each, with a total of 6 hours.

No significant change can be Mounting Method :

observed. The capacitor shall be fixed with its lead wires

Capacitance Change : at the point of 4 mm from the bottom of

W ithin ±5% of the initiall

measured value.

capacitor body.

11

procedure takes for 2s ~3s

: 10 Hz ~55 Hz

8 Solderability M ore than 3/4 of the term inal surface Solder Type : H60A, H60S, or H63A (JIS Z3282)

shall be covered with new solder. Solder Temperature

Immersing Time : 2s±0. 5s

Immersing Depth

Flux : Approx. 25% rosin (JIS K5902)

9 Resistance to Leakage Current : Solder Type : H60A, H60S, or H63A (JIS Z3282)

Soldering Heat

≦ the value of item 7.1.

Capacitance Chan

W ithin ±10% of the initially Im m ersing Depth

measured value.

Tangent of Loss Angle (tanδ):

≦

the value of item 7. 3.

Appearance :

nificant change can be

No si

observed.

e : Immersing Time : 10s±1s

Solder Temperature

: 235℃±5

: 1. 5mm ~ 2. 0mm from the root.

in ETHANOL (JIS K8101)

: 260℃±5℃

: 1. 5mm ~ 2. 0mm from the root.

℃

Panasonic Electronic Devices Co.,Ltd.

Page 14

Engineering Draft

p

CE-AAKX-CEM-1

A type AK series X type

No Item Performance Characteristics Test

10

Solvent There shall be no damage and legible Class of Reagent : Isopropyl Alcohol

Resistance of marking. Marking can be easily Test Temperature : 20℃ ~ 25℃

Marking comprehended. Immersing Time : 30s±5s

11 Damp Heat Leakage Current : Test Temperature : 40℃±2℃

(Steady state)

12 Endurance Leakage Current : Test Temperature : 85℃±2

13 Shelf Life Leakage Current : Test Temperature : 85℃±2℃

* Voltage treatment :

resistors (1000Ω±10Ω), for 30 minutes as a posttest treatment (performing discharge).

the value of item 7.1. Relative Humidity : 90% ~ 95%

≦

Capacitance Change : Test Duration : 240hours ±8hours

Within ±20% of the initially

measured value. After subjected to the test, capacitors shall

Tangent of Loss Angle (tanδ): be left for 2 hours at room temperature and

≦ 120% the value of item 7. 3. room humidity prior to the measurement.

Appearance :

No significant change can be

observed.

℃

the value of item 7.1. Test Duration

≦

Capacitance Change : Applied Voltage : Rated Voltage .

Within ±20% of the initially

measured value. After subjected to the test, capacitors shall be left at

Tangent of Loss Angle (tanδ): room temperature and room humidity for 2 hours prior

200% of the value of item 7. 3. to the measurement.

≦

Appearance :

No significant change can be

observed.

the value of item 7.1. Test Duration

≦

Capacitance Change :

Within ±20% of the initially

measured value. After subjected to the test with no voltage applied,

Tangent of Loss Angle (tanδ):

≦ 200% of the value of item 7. 3. be left for 2 hours at room temperature and

Appearance : humidity prior to the measurement.

No significant change can be

observed.

acitors shall undergo voltage treatment*and

ca

: 1000

: 500

+48

hours

0

+48

The rated voltage shall be applied to the capacitors, which are connected to series protective

hours

0

12

Panasonic Electronic Devices Co.,Ltd.

Page 15

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

8. Other Characteristics

■ Table 1. Tangent of Loss Angle(tanδ)

V.DC 6.31016253550

D.F. 0.33 0.25 0.20 0.15 0.12 0.10

■ Table 2.Characteristics at low temperature Impedance ratio (at 120 Hz)

V.DC 6.31016253550

Z(-40℃)/Z(20℃)864433

■ Table 3.Frequency Correction Factor of Rated Ripple Current

50,60 120 1k 10k

Coefficient 0.7 1 1.3 1.7

13

Frequency (Hz)

~

Panasonic Electronic Devices Co.,Ltd.

Page 16

Engineering Draft

φ

CE-AAKX-CEM-1

A type AK series X type

14

9. Snap-In Lead Formed Type ( Part No. Suffix : E )

φ4~φ8

[mm]

H2

F

P

E

φD±0.5

[mm]

φ t

d

H3

H1

* Direction of bending is random.

φD H1±0.5 H2 H3±0.3 F±0.5 P E max. φd±0.05 P.W .B

4 4.5 2.7 1.5 5.0 0.95 1.0 0.45 0.9 1.6

5 4.5 2.7 1.5 5.0 0.95 1.0 0.45 0.9 1.6

6.3 4.5 2.7 1.5 5.0 0.95 1.0 0.45 0.9 1.6

8 4.5 2.7 1.5 5.0 0.95 1.0 0.45 0.9 1.6

*The lead forming dimensions above shall only be subjected to our outgoing inspection and

not to the customer's incoming inspection.

Due to the application of mechanical stress during transportation, actual dimensions might

not meet the specification.

Panasonic Electronic Devices Co.,Ltd.

Page 17

Engineering Draft

∆

CE-AAKX-CEM-1

A type AK series X type

15

10.Lead Taping

10-1. Lead Taping ( Body Diameter φ4 ~φ6. 3 ) The Suffix of Taping Part Number : i

1) Applicable Range

This specification is applied to products, which are Aluminum Electrolytic Capacitors (JIS04 type)

that taped with single tape.

2) Taping Shape & Dimensions

φ4 ,φ.5 φ6.3

∆P

P2

P

φD

h

∆P

P2

φD

P

∆h

L

L

W2

W0

w

F

P1

W1

H

W

W2

W0

P1

F

H

W1

P0

φd

φD0

t

P0

φd

φD0

t

[mm]

Item Symbol Dimensions Tolerance Remarks

Body diameter

Body length

Lead wire diameter

Body pitch

Feed hole pitch *1

Hole center to lead

Feed hole center

to product center

Lead to lead distance

Mount tape

Adhesive tape

Hole position

Adhesive tape slipping

Height of product

from the center

Feed hole diameter

Inclination of body

Inclination of body

Total tape thickness

φD456.3±0.5

L ---

7.0

φd 0.45 ±0.05

P 12.7 ±1.0

P0 12.7 ±0.2

P1

5.1

±0.5

P2 6.35 ±1.00

F

2.5

±0.5

W 18.0 ±0.5

W0 6.0

≦

W1 9.0 ±0.5

W2 0 ~1.5 ---

H 18.50

+0.75

-0.50

φD0 4.0 ±0.2

h1.0 ≧---

△

P1.0 ≧---

△

t0.6±0.3

Specified by the contact surface between

tape & lead

ditto

---

Specified at the top of the body

ditto

CP wire is excluded

*1 Cumulative deviation of “feed hole pitch” shall be less than 1 mm in 20 sections.

Panasonic Electronic Devices Co.,Ltd.

Page 18

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

16

10-2. Lead Taping ( Body Diameter φ8 ) The Suffix of Taping Part Number : i

1) Applicable Range

This specification is applied to products, which are Aluminum Electrolytic Capacitors (JIS04 type)

that taped with single tape.

2) Taping Shape & Dimensions

∆P

P2

W

W2

W0

P1

F

P0

Item Symbol Dimensions Tolerance Remarks

Body diameter

Body length

Lead wire diameter

Body pitch

Feed hole pitch *1

Hole center to lead

Feed hole center

to product center

Lead to lead distance

Mount tape

Adhesive tape

Hole position

Adhesive tape slipping

Height of product

from the center

Feed hole diameter

Inclination of body △

Inclination of body

Total tape thickness

φD8±0.5

L 7.0 ---

φd 0.45 ±0.05

P 12.7 ±1.0

P0 12.7 ±0.2

P1

P2 6.35

F

W 18.0 ±0.5

W0 6.0

W1 9.0 ±0.5

W2 0 ~1.5 ---

H18.50

φD0 4.0 ±0.2

h1.0 ≧--P1.0 ≧---

△

t 0.6 ±0.3

*1 Cumulative deviation of “feed hole pitch” shall be less than 1 mm in 20 sections.

P

5.1

2.5

≦

φD

φd

∆h

L

H

W1

φD0

±0.5

±1.00

±0.5

Specified by the contact surface between

tape & lead

ditto

t

---

+0.75

-0.50

Specified at the top of the body

ditto

CP wire is excluded

[mm]

Panasonic Electronic Devices Co.,Ltd.

Page 19

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

17

10-3 Lead Taping ( Body Diameter φ4 ~φ6. 3 ) The Suffix of Taping Part Number : B

1) Applicable Range

This specification is applied to products, which are Aluminum Electrolytic Capacitors (JIS04 type)

that taped with single tape.

2) Taping Shape & Dimensions

∆P

P2 P

φD

∆h

L

W2

W0

W

F

P1

H0

H

W1

P0

φd φD0

t

[mm]

Item Symbol Dimensions Tolerance Remarks

Body diameter

Body length

Lead wire diameter

Body pitch

Feed hole pitch *1

Hole center to lead

Feed hole center

to product center

Lead to lead distance

Mount tape

Adhesive tape

Hole position

Adhesive tape slipping

Height of product

from the center

Lead wire clinch height

Feed hole diameter

Inclination of body △

Inclination of body

Total tape thickness

φD 4 5 6.3 ±0.5

φd0.45±0.05

P0 12.7 ±0.2

P1

P2 6.35 ±1.00

W0 6.0

W1 9.0 ±0.5

W2 0 ~1.5 ---

H0 16.0

φD0 4.0 ±0.2

△

L7.0---

P 12.7 ±1.0

3.85

F

5.0

±0.5

+0.8

W 18.0 ±0.5

≦

H 17.50

+0.75

-0.20

±0.5

h1.0 ≧--P1.0 ≧---

t 0.6 ±0.3

Specified by the contact surface between

tape & lead

ditto

-0.2

---

Specified at the top of the body

ditto

CP wire is excluded

*1 Cumulative deviation of “feed hole pitch” shall be less than 1 mm in 20 sections.

*2 Lead forming angle

A=90°min

A

Panasonic Electronic Devices Co.,Ltd.

Page 20

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

10-4. Lead Taping ( Body Diameter φ8 ) The Suffix of Taping Part Number : Q

1) Applicable Range

This specification is applied to products, which are Aluminum Electrolytic Capacitors (JIS04 type)

that taped with single tape.

2) Taping Shape & Dimensions

∆P

P2

W

W2

W0

P1

F

P0

Item Symbol Dimensions Tolerance Remarks

Body diameter

Body length

Lead wire diameter

Body pitch

Feed hole pitch *1

Hole center to lead

Feed hole center

to product center

Lead to lead distance

Mount tape

Adhesive tape

Hole position

Adhesive tape slipping

Height of product

from the center

Lead wire clinch height

Feed hole diameter

Inclination of body △

Inclination of body

Total tape thickness

φD8±0.5

L 7.0 ---

φd 0.45 ±0.05

P 12.7 ±1.0

P0 12.7 ±0.2

P1

P2

3.85

F

W 18.0 ±0.5

W0 6.0

W1 9.0 ±0.5

W2 0 ~1.5 ---

H

18.5

H0 16.0

φD0 4.0 ±0.2

h1.0 ≧--P1.0 ≧---

△

t 0.6 ±0.3

*1 Cumulative deviation of “feed hole pitch” shall be less than 1 mm in 20 sections.

*2 Lead forming angle

A=90°min

P

5.0

≦

φD

6.35

φd

∆h

L

H

W1

φD0

±1.00

±0.5

+0.8

Specified by the contact surface between

tape & lead

ditto

t

-0.2

---

+0.75

-0.50

±0.5

Specified at the top of the body

ditto

CP wire is excluded

18

[mm]

A

Panasonic Electronic Devices Co.,Ltd.

Page 21

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

19

11. Taping Method

11-1 The capacitors shall be placed vertically on the base tape, and their lead wires are fixed with

the adhesive tape. In addition, the direction of polarity is standardized as the base tape

is situated underneath of an adhesive tape, and lead wires with the same polarity are placed on

the right hand side (the direction of polarity for bipolar products is not specified).

(Examples)

*Polarity direction

φ4 ~ φ8: Negative polarity on the right.

11-2 After taping, there shall be no more than three blank spaces without lead wires on the base tape.

The number of blank spaces within a packing unit (an inner carton) is not restricted, however,

the specified packing quantity must be satisfied.

11 - 3 The connection method is as follows. The portion shall meet the general taping specification.

The position of connection shall not be restricted.

Base tapes shall not be connected with each other by using staples.

Adhesive tape

Note ) When connecting two base tapes, they shall not be piled on top of each other.

Connecting point

Base

Connect with the

adhesive tape

Panasonic Electronic Devices Co.,Ltd.

Page 22

Engineering Draft

CE-AAKX-CEM-1

A type AK series X type

11-4 In case of removing the products after taping, lead wires shall be cut or the capacitor

shall be pulled out.

The length of remaining lead wire shall be less than 2.0 mm from the upper edge of

the base tape.

2mm max.

11-5 Tensile strength of lead wire after taping (specified for the positive lead wire only) :

Fix the tape as below and pull the positive lead wire to the vertical direction by using the

push pull scale.

The tensile strength shall be greater than 2. 94 N.

After continuously storing in an atmosphere of 40℃±2℃ and 90% ~ 98% for 250 hours,

the taped products shall meet the specification above, and there shall be no inclination

of the capacitors or covering of holes with the adhesive.

Lead wire

Base

Push pull scale

Lead wire

Fixed

Adhesive tape

20

Panasonic Electronic Devices Co.,Ltd.

Page 23

Engineering Draft

(a)

CE-AAKX-CEM-1

A type AK series X type

21

12. Packing Method

12-1 Taped products shall be packed in an inner carton ( the smallest packing unit ) in the zigzag pattern.

In an inner carton, the lead wires with positive polarity are not to be placed on the top of lead wires

with negative polarity and vice versa (however, the last sentence does not apply to bipolar products).

(Examples)

Inner packing

case

φ4~φ8

φ10

~

φ18

12-2 Polarity identifications on an inner carton shall match the polarity of products situated inside

the inner carton.

12-3 Inner cartons shall be handled as follows.

* No more than 10 inner cartons shall be piled on top of each other.

* In case of situating cartons in upright position, the indication of polarity shall be faced upward.

* The products shall be handled with care.

<Right> <Wrong>

○ ○

×

12-4 The inner cartons shall be packed in a cardboard box for transportation.

Products with various part numbers can be packed in an outer carton upon request.

However, each inner carton (the smallest packing unit) shall only contain products

with the same part number.

12-5 The shape & dimensions of inner cartons shall be as follows.

(b)

Can size

φDL

φ4 ~φ8 7 340 55 320

Note : The dimensions listed above are subject to

(c)

change without notice, depending on the

auto-insert machine.

No unit at

The corner.

×

(a) (b) (c)

[mm]

Panasonic Electronic Devices Co.,Ltd.

Page 24

Engineering Draft

(5) φ

CE-AAKX-CEM-1

Radial lead type Package Amount and Shape

Label information on the packing box. Package Label Example

The label has following information in English Long lead , Lead formed Outer Box

a ) Rated Voltage, Capacitance

b ) Manufacturer’s Trademark

c ) Part Number

d ) Packing Quantity

e ) Serial No.

f ) Manufacturer’s Name

g ) Country of Origin

Long lead , Lead formed (Unit:pcs)

Long lead Lead formed

Can size

φ4x7 200 10000 200 10000

φ5x7 200 10000 200 10000

φ6.3x7 200 10000 200 10000

φ8x7 200 4000 200 4000

Package Material

Inner Vinyl bag

Outer Card board

Packaging Packaging Packaging Packaging

Quantity Quantity per box Quantity Quantity per box

Long lead

Lead formed

Contents of label description

(1) Customer Part No.

(2) Quantity

(3) Rated Capacitance

(4) Voltage

(5) Can Size

(6) Product Part No.

<JAPAN PRODUCTS>

Customer Part No.

(1)

(3N)1 (1) (2)

(3N)2 Y5201R41A001 108010

FIXED ALUMINIUM ELECTROLYTIC CAPACITOR

(6)

(2)

Serial No. Y5201R41A001

Panasonic Electronic Devices Co.,Ltd.

M

(3) uF (4) V

MADE IN JAPAN EIAJ C-3 001

G

22

× L

<MALAYSIA PRODUCTS>

Customer Part No.

(1)

(3N)1 (1) (2)

(3N)2 D0002R03D428 108010

FIXED ALUMINIUM ELECTROLYTIC CAPACITOR

(6)

Panasonic Electronic Devices (M) Sdn. Bhd.

M

EIAJ-C3 PEDMA(SA) Made in Malaysia

Production month

Panasonic Electronic Devices Co.,Ltd.

(5) φ X L

Serial No.

D0002R03D428

G

(3) uF

(4) V

(2)

PCS

.

Page 25

Engineering Draft

(5) φ

CE-AAKX-CEM-1

Radial lead type Package Amount and Shape

Label information on the packing box.

The label has following information in English

a ) Rated Voltage, Capacitance

b ) Manufacturer’s Trademark

c ) Part Number

d ) Packing Quantity

e ) Serial No.

f ) Manufacturer’s Name

g ) Country of Origin

Taping (Unit:pcs)

Box

Can size

φ4 2000 10000

φ5 2000 10000

φ6.3 2000 10000

φ8 1000 5000

Packaging Packaging

Quantity Quantity per box

Package Label Example Taping Outer Box

Contents of label description

(1) Customer Part No.

(2) Quantity

or

(3) Rated Capacitance

(4) Voltage

(5) Can Size

(6) Product Part No.

<JAPAN PRODUCTS> <MALAYSIA PRODUCTS>

Customer Part No.

(1)

(3N)1 (1) (2)

(3N)2 Y5201R41A001 108010

FIXED ALUMINIUM ELECTROLYTIC CAPACITOR

(6)

(2)

Serial No. Y5201R41A001

Panasonic Electronic Devices Co.,Ltd.

MADE IN JAPAN EIAJ C-3 001

M

G

(3) uF (4) V

× L

Customer Part No.

(1)

(3N)1 (1) (2)

(3N)2 D0002R03D428 108010

FIXED ALUMINIUM ELECTROLYTIC CAPACITOR

(6)

Panasonic Electronic Devices (M) Sdn. Bhd.

M

EIAJ-C3 PEDMA(SA) Made in Malaysia

Production month

(5) φ X L

Serial No.

D0002R03D428

Package Material

Taping

Inner Card board

Outer Card board

23

G

(3) uF

(4) V

(2)

PCS

.

Panasonic Electronic Devices Co.,Ltd.

Page 26

Engineering Draft

(5) φ

CE-AAKX-CEM-1

Radial lead type Package Amount and Shape

24

Taping Inner Box

Contents of label description

(1) Customer Part No.

(2) Quantity

(3) Rated Capacitance

(4) Voltage

(5) Can Size

(6) Product Part No.

<JAPAN PRODUCTS> <MALAYSIA PRODUCTS>

Customer Part No.

(1)

(3N)1 (1) (2)

(3N)2 Y5201R41A001 108010

FIXED ALUMINIUM ELECTROLYTIC CAPACITORS

Panasonic Electronic Devices Co.,Ltd. EIAJ C-3 MADE IN JAPAN 001

M

G

(6)

(3) uF (4) V

× L

Serial No. Y5201R41A001

(2) PCS.

Customer Part No.

(1)

(3N)1 (1) (2)

(3N)2 D0002R03D428 108010

FIXED ALUMINIUM ELECTROLYTIC CAPACITOR

(6)

Panasonic Electronic Devices (M) Sdn. Bhd.

M

EIAJ-C3 PEDMA(SA) Made in Malaysia

Production month

(5) φ X L

Serial No.

D0002R03D428

Storage

1. With respect to the handling method, follow Item 12-3 in this specification.

2. Products shall be out of direct sun light. In addition, the temperature and humidity shall be normal.

Minimum order quantity

The order shall be placed with a multiple of the inner carton quantity.

Examples : φ4 ~ φ6. 3 : minimum 2000 pcs

φ8 : minimum 1000 pcs

G

(3) uF

(4) V

(2)

PCS

.

Panasonic Electronic Devices Co.,Ltd.

Page 27

Engineering Draft

CE-AAKX-CEM-1

Application Guidelines

* This specification guarantees the quality and performance of the product as individual components.

Before use, check and evaluate their compatibility with installed in your products.

* Do not use the products beyond the specifications described in this document.

* Install the following systems for a failsafe design to ensure safety if these products are to be used in equipment where a defect in these

products may cause the loss of human life or other signification damage, such as damage to vehicles (automobile, train, vessel), traffic

lights, medical equipment, aerospace equipment, electric heating appliances, combustion/ gas equipment, rotating equipment, and

disaster/crime prevention equipment.

・The system is equipped with a protection circuit and protection device.

・The system is equipped with a redundant circuit or other system to prevent an unsafe status in the event of a single fault.

* Before using the products, carefully check the effects on their quality and performance, and determined whether or not they can be used.

These products are designed and manufactured for general-purpose and standard use in general electronic equipment.

These products are not intended for use in the following special conditions.

1. In liquid, such as Water, Oil, Chemicals, or Organic solvent

2. In direct sunlight, outdoors, or in dust

3. In vapor, such as dew condensation water of resistive element, or water leakage, salty air, or air with a high concentration corrosive

1. Circuit Design

1.1 Operating Temperature and Frequency

Electrical parameters for electrolytic capacitors are normally specified at 20℃ temperature and 120 Hz frequency.

These parameters vary with changes in temperature and frequency. Circuit designers should take these changes into consideration.

(1) Effects of operating temperature on electrical parameters

(2) Effects of frequency on electrical parameters

b) At lower frequencies, heat generated by ripple current will rise due to an increase in equivalent series resistance (ESR).

1.2 Operating Temperature and Life Expectancy

Check for the maximum capacitor operating temperatures including ambient temperature, internal capacitor temperature rise due to

Avoid placing components, which could conduct heat to the capacitor from the back side of the circuit board.

(3) The formula for calculating expected life at lower operating temperatures is as follows ;

L

L

T

T

gas, such as Cl2, H2S, NH3, SO2, or NO2

4. In an environment where strong static electricity or electromagnetic waves exist

5. Mounting or placing heat-generating components or inflammables, such as vinyl-coated wires, near these products

6. Sealing or coating of these products or a printed circuit board on which these products are mounted, with resin and other material

7. Using resolvent, water or water-soluble cleaner for flux cleaning agent after soldering.

(In particular, when using water or a water-soluble cleaning agent, be careful not to leave water residues)

* Please arrange circuit design for preventing impulse or transitional voltage.

Do not apply voltage, which exceeds the full rated voltage when the capacitors receive impulse voltage, instantaneous high voltage,

high pulse voltage etc.

* Electrolyte is used in the products. Therefore, misuse can result in rapid deterioration of characteristics and functions of each product.

Electrolyte leakage damages printed circuit and affects performance, characteristics, and functions of customer system.

a) At higher temperatures, leakage current and capacitance increase while equivalent series resistance (ESR) decreases.

b) At lower temperatures, leakage current and capacitance decrease while equivalent series resistance (ESR) increases.

a) At higher frequencies, capacitance and impedance decrease while tanδ increases.

(1) Expected life is affected by operating temperature. Generally, each 10 ℃ reduction in temperature will double the expected life.

Use capacitors at the lowest possible temperature below the upper category temperature.

(2) If operating temperatures exceed the upper category limit, rapid deterioration of electrical parameter will occur and irreversible damage

will result.

ripple current, and the effects of radiated heat from power transistors, IC's or resistors.

T1-T

2

L2=L1x2

: Guaranteed life (h) at temperature, T1 ℃

1

: Expected life (h) at temperature, T2 ℃

2

: Upper category temperature (℃)

1

: Actual operating temperature, ambient temperature + temperature rise due to ripple current heating(℃)

2

10

25

(4) Please use according to the lifetime as noted in this specification. Using products beyond end of the lifetime may change characteristics rapidly,

short-circuit, operate pressure relief vent, or leak electrolyte.

Panasonic Electronic Devices Co.,Ltd.

Page 28

Engineering Draft

CE-AAKX-CEM-1

Application Guidelines

1.3 Common Application Conditions to Avoid

The following misapplication load conditions will cause rapid deterioration of a capacitor’s electrical parameters.

In addition, rapid heating and gas generation within the capacitor can occur, causing the pressure relief vent to operate and resultant leakage

of electrolyte. Under extreme conditions, explosion and fire ignition could result.

The leaked electrolyte is combustible and electrically conductive.

(1) Reverse Voltage

DC capacitors have polarity. Verify correct polarity before insertion. For circuits with changing or uncertain polarity, use DC bipolar

capacitors. DC bipolar capacitors are not suitable for use in AC circuits.

(2) Charge / Discharge Applications

Standard capacitors are not suitable for use in repeating charge/discharge applications. For charge/ discharge applications, consult us

with your actual application condition.

(3) Over voltage

Do not apply voltages exceeding the maximum specified rated voltage. Voltages up to the surge voltage rating are acceptable for

short periods of time.

Ensure that the sum of the DC voltage and the superimposed AC ripple voltage does not exceed the rated voltage.

(4) Ripple Current

Do not apply ripple currents exceeding the maximum specified value. For high ripple current applications, use a capacitor designed for

high ripple currents. In addition, consult us if the applied ripple current is to be higher than the maximum specified value.

Ensure that rated ripple currents that superimposed on low DC bias voltages do not cause reverse voltage conditions.

1.4 Using Two or More Capacitors in Series or Parallel

(1) Capacitors Connected in Parallel

The circuit resistance can closely approximate the series resistance of the capacitor, causing an imbalance of ripple current loads within

the capacitors. Careful wiring methods can minimize the possible application of an excessive ripple current to a capacitor.

(2) Capacitors Connected in Series

Differences in normal DC leakage current among capacitors can cause voltage imbalances.

The use of voltage divider shunt resistors with consideration to leakage currents can prevent capacitor voltage imbalances.

1.5 Capacitor Mounting Considerations

(1) Double-Sided Circuit Boards

Avoid wiring pattern runs, which pass between the mounted capacitor and the circuit board. When dipping into a solder bath,

an excess solder may deposit under the capacitor by capillary action, causing short circuit between anode and cathode terminals.

(2) Circuit Board Hole Positioning

The vinyl sleeve of the capacitor can be damaged if solder passes through a lead hole into the subsequently processed parts.

Special care when locating hole positions in proximity to capacitors is recommended.

(3) Circuit Board Hole Spacing

The spacing of circuit board holes should match the lead wire spacing of capacitors within the specified tolerances.

Incorrect spacing can cause an excessive lead wire stress during the insertion process.

This may result in premature capacitor failure due to the short or open circuit, increased leakage current, or electrolyte leakage.

(4) Clearance for Case Mounted Pressure Relief

Capacitors with case mounted pressure relief require sufficient clearance to allow proper pressure relief operation.

The minimum clearances are dependent of capacitor diameters as follows.

Dia. 6. 3 mm ~Dia. 16 mm : 2 mm minimum, Dia. 18 mm ~Dia. 35 mm : 3 mm minimum, Dia 40 mm or greater : 5 mm minimum.

(5) Clearance for Seal Mounted Pressure Relief

Provide a hole on a circuit board to relieve gas when a pressure relief of a capacitor is situated underneath of the circuit board.

(6) Wiring Near the Pressure Relief

Avoid locating high voltage, high current wiring, or circuit board paths above the pressure relief .

Flammable, high temperature gas that exceeds 100 ℃ may be released and could dissolve the wire insulation and ignite.

(7) Circuit Board Patterns Under the Capacitor

Avoid circuit board runs underneath the capacitor, as an electrical short can occur due to an electrolyte leakage.

(8) Screw Terminal Capacitor Mounting

Do not orient the capacitor with the screw terminal side of the capacitor facing downward.

Tighten the terminal and mounting bracket screws within the torque range specified in the specification.

1.6 Electrical Isolation of the Capacitor

Completely isolate the capacitor as follows.

(1) Between the cathode and the case (except for axially leaded B types) and between the anode terminal and other circuit paths.

(2) Between the extra mounting terminals (on T types) and the anode terminal, cathode terminal, and other circuit paths.

1.7 Capacitor Sleeve

The vinyl sleeve or laminate coating is intended for marking and identification purposes and is not meant to electrically insulate the capacitor.

26

The sleeve may split or crack if immersed into solvents such as toluene or xylene and then subsequently exposed to high temperatures.

Panasonic Electronic Devices Co.,Ltd.

Page 29

Engineering Draft

CE-AAKX-CEM-1

Application Guidelines

27

2. Capacitor Handling Techniques

2.1 Considerations Before Using

(1) Capacitors have a finite life. Do not reuse or recycle capacitors from used equipment.

(2) Transient recovery voltage may be generated in the capacitor due to dielectric absorption.

If required, this voltage can be discharged with a resistor with a value of about 1kΩ.

(3) Capacitors stored for a long period of time may exhibit an increase in leakage current.

This can be corrected by gradually applying rated voltage in series with a resistor of approximately 1kΩ.

(4) If capacitors are dropped, they can be damaged mechanically or electrically. Avoid using dropped capacitors.

(5) Dented or crushed capacitors should not be used. The seal integrity can be damaged and loss of electrolyte/shortened life can result.

2.2 Capacitor Insertion

(1) Verify the correct capacitance and rated voltage of the capacitor.

(2) Verify the correct polarity of the capacitor before insertion.

(3) Verify the correct hole spacing before insertion (land pattern size on chip type) to avoid stress on the terminals.

(4) Ensure that the lead clinching operation done by auto insertion equipments does not stress the capacitor leads where they enter the seal of

the capacitor.

For chip type capacitors, excessive mounting pressure can cause high leakage current, short circuit, or disconnection.

2.3 Manual Soldering

(1) Apply soldering conditions (temperature and time) based on the specification, or do not exceed temperature of 350 ℃ for 3

seconds or less.

(2) If lead wires must be modified to meet terminal board hole spacing, avoid stress on the lead wire where it enters the capacitor seal.

(3) If a soldered capacitor must be removed and reinserted, avoid excessive stress on the capacitor leads.

(4) Avoid physical contacts between the tip of the soldering iron and capacitors to prevent melting of the vinyl sleeve.

2.4 Flow Soldering

(1) Do not immerse the capacitor body into the solder bath as excessive internal pressure could result.

(2) Apply proper soldering conditions (temperature, time, etc.). Do not exceed the specified limits.

(3) Do not allow other parts or components to touch the capacitor during soldering.

2.5 Other Soldering Considerations

Rapid temperature rise during the preheat operation and resin bonding operation can cause cracking of the capacitor’s vinyl sleeve.

For heat curing, do not exceed 150 ℃ for the maximum time of 2 minutes.

2.6 Capacitor Handling after Soldering

(1) Avoid moving the capacitor after soldering to prevent excessive stress on the lead wires where they enter the seal.

(2) Do not use the capacitor as a handle when moving the circuit board assembly.

(3) Avoid striking the capacitor after assembly to prevent failure due to excessive shock.

2.7 Circuit Board Cleaning

(1) Circuit boards can be immersed or ultrasonically cleaned using suitable cleaning solvents for up to 5 minutes

and up to 60 ℃ maximum temperatures. The boards should be thoroughly rinsed and dried.

The use of ozone depleting cleaning agents is not recommended for the purpose of protecting our environment.

(2) Avoid using the following solvent groups unless specifically allowed in the specification ;

・ Halogenated cleaning solvents : except for solvent resistant capacitor types, halogenated solvents can permeate the seal and cause

internal capacitor corrosion and failure.

For solvent resistant capacitors, carefully follow the temperature and time requirements based on the

・ Alkaline solvents : could react and dissolve the aluminum case.

・ Petroleum based solvents : deterioration of the rubber seal could result.

・ Xylene : deterioration of the rubber seal could result.

・ Acetone : removal of the ink markings on the vinyl sleeve could result.

(3) A thorough drying after cleaning is required to remove residual cleaning solvents that may be trapped between the capacitor and the circuit

board. Avoid drying temperatures, which exceed the Upper category temperature of the capacitor.

(4) Monitor the contamination levels of the cleaning solvents during use in terms of electrical conductivity, pH, specific gravity, or water content.

Chlorine levels can rise with contamination and adversely affect the performance of the capacitor.

(5) Depending on the cleaning method, the marking on a capacitor may be erased or blurred.

Please consult us if you are not certain about acceptable cleaning solvents or cleaning methods.

2.8 Mounting Adhesives and Coating Agents

When using mounting adhesives or coating agents to control humidity, avoid using materials containing halogenated solvents.

Also, avoid the use of chloroprene based polymers.

Harden on dry adhesive or coating agents well lest the solvent should be left.

After applying adhesives or coatings, dry thoroughly to prevent residual solvents from being trapped between the capacitor and the circuit

board.

2.9 Fumigation

In exporting electronic appliances with aluminum electrolytic capacitors, in some cases fumigation treatment using such halogen

compound as methyl bromide is conducted for wooden boxes.

If such boxes are not dried well, the halogen left in the box is dispersed while transported and enters in the capacitors inside.

This possibly causes electrical corrosion of the capacitors. Therefore, after performing fumigation and drying make sure that no halogen

is left.

Don’t perform fumigation treatment to the whole electronic appliances packed in a box.

specification. 1-1-1 trichloroethane should never be used on any aluminum electrolytic capacitor.

Panasonic Electronic Devices Co.,Ltd.

Page 30

Engineering Draft

CE-AAKX-CEM-1

Application Guidelines

3. Precautions for using capacitors

3.1 Environmental Conditions

Capacitors should not be stored or used in the following environments.

(1) Exposure to temperatures above the upper category or below the lower category temperature of the capacitor.

(2) Direct contact with water, salt water, or oil.

(3) High humidity conditions where water could condense on the capacitor.

(4) Exposure to toxic gases such as hydrogen sulfide, sulfuric acid, nitric acid, chlorine, Chlorine compound, Bromine, Bromine compound or

ammonia.

(5) Exposure to ozone, radiation, or ultraviolet rays.

(6) Vibration and shock conditions exceeding specified requirements.

3.2 Electrical Precautions

(1) Avoid touching the terminals of a capacitor as a possible electric shock could result. The exposed aluminum case is not insulated and

could also cause electric shock if touched.

(2) Avoid short circuiting the area between the capacitor terminals with conductive materials including liquids such as acids or alkaline solutions.

4. Emergency Procedures

(1) If the pressure relief of the capacitor operates, immediately turn off the equipment and disconnect from the power source.

This will minimize an additional damage caused by the vaporizing electrolyte.

(2) Avoid contact with the escaping electrolyte gas, which can exceed 100 ℃ temperatures.

If electrolyte or gas enters the eye, immediately flush the eye with large amounts of water.

If electrolyte or gas is ingested by mouth, gargle with water.

If electrolyte contacts the skin, wash with soap and water.

5. Long Term Storage

Leakage current of a capacitor increases with long storage times. The aluminum oxide film deteriorates as a function of temperature and time.

If used without reconditioning, an abnormally high current will be required to restore the oxide film.

This surge current could cause the circuit or the capacitor to fail. After one year, a capacitor should be reconditioned by applying the rated

voltage in series with a 1000 Ω current limiting resistor for a time period of 30 minutes.

5.1 Environmental Conditions

(1) Exposure to temperatures above the upper category or below the lower category temperature of the capacitor.

(2) Direct contact with water, salt water, or oil.

(3) High humidity conditions where water could condense on the capacitor.

(4) Exposure to toxic gases such as hydrogen sulfide, sulfuric acid, nitric acid, chlorine, Chlorine compound, Bromine, Bromine compound or

ammonia.

(5) Exposure to ozone, radiation, or ultraviolet rays.

(6) Vibration and shock conditions exceeding specified requirements.

6. Capacitor Disposal

When disposing capacitors, use one of the following methods.

(1) Incinerate after crushing the capacitor or puncturing the can wall (to prevent explosion due to internal pressure rise).

(2) Dispose as solid waste.

NOTE : Local laws may have specific disposal requirements which must be followed.

28

Panasonic Electronic Devices Co.,Ltd.

Loading...

Loading...