User's Manual

http://www.nais-e.com/vision/

Panasonic...the new name for

Matsushita Electric Works, Ltd.

Before Reading This Manual

Thank you for purchasing the LightPixAE20.

In this manual, information on the hardware (installation, wiring, etc.) and the software (functions, setting

procedures, etc.) is described. Read this User’s Manual carefully before use.

Safety Precautions

To ensure that you use this product correctly, read this User’s Manual thoroughly before use. Make sure that

you fully understand the product and information on safe.

Conventions used in the Safety Precautions

Symbols:

The following symbols used in Safety Precautions.

Symbol Explanation:

WARNING

This indicates the existence of a hazard that could result in death of or serious damage to the operator, if

the safety instruction is not observed.

CAUTION

This indicates the existence of a hazard that could result in serious bodily injury or property damage, if the

safety instruction is not observed.

WARNING

• Do not use the product in the environment where combustible gas presents. This might cause

explosion.

• Never attempt to disassemble or alter the product. Failure to do so might result in an electric shock and

physical damage.

CAUTION

• Be sure to ground the product. Failure to do so might result in an electric shock.

• Do not touch the terminals while the power is on. This might result in an electric shock.

• Do not place heavy objects on the product. Do not use a heater near the product. This may result in

smoke coming from the product.

• Do not allow metallic objects or other flammable foreign matter inside the product. This might cause a

fire, electric shock or product damage.

• Use the product following the specifications. Failure to do so might result in abnormal heat and smoke

coming from the product.

• If you want to use the product for the purposes that are expected to lead to physical damage or serious

loss, safety measures, such as the installation of fail-safe systems, should be taken.

Table of Contents

Precautions before Use .................................................................................. iv

1. Overview of Light Pix AE20...................................................................... 1

1.1 Overview ...........................................................................................................2

1.2 Product Configuration........................................................................................ 3

1.3 Inspection Applications...................................................................................... 4

2. Names and Functions of Parts................................................................. 5

2.1 About the Main Unit........................................................................................... 6

2.2 Operation Unit ...................................................................................................7

2.2.1 Operation Unit...........................................................................................................7

2.2.2 Texts Displayed on the LCD Monitor of the Operation Unit....................................... 8

2.2.3 Lock Function............................................................................................................ 9

2.3 Finder Unit.......................................................................................................10

3. Installation and Wiring............................................................................ 11

3.1 A List of Connectable Units and Devices......................................................... 12

3.2 Connection between the Units......................................................................... 13

3.2.1 Connection the Main Unit to the Operation Unit......................................................13

3.2.2 Connection of the Operation and Finder Units ........................................................ 14

3.3 Fixing and Removing the Main Unit................................................................. 15

3.3.1 Main Unit ................................................................................................................. 15

3.3.2 Operation Unit......................................................................................................... 18

3.3.3 Finder Unit...............................................................................................................19

3.3.4 Installation Environment.......................................................................................... 20

3.4 Input/Output Cables for Connecting Power Supply Unit or External Devices ..21

3.4.1 Sequence of Input/Output Signals...........................................................................21

3.4.2 Input Signal .............................................................................................................22

3.4.3 Output Signal ..........................................................................................................23

3.4.4 Power Supply Unit and the Wiring...........................................................................24

3.4.5 Grounding the Main Unit .........................................................................................25

3.4.6 Comformity to the EMC standard............................................................................ 25

3.5 Serial (RS-232C) Port...................................................................................... 26

3.5.1 Connecting to the External Devices ........................................................................26

3.5.2 Wiring Method......................................................................................................... 27

4. Inspection Applications.......................................................................... 29

4.1 Overview .........................................................................................................30

4.1.1 Inspection Applications............................................................................................30

4.1.2 Inspection Time....................................................................................................... 31

i

4.2 Color Area and Color Judgement.................................................................... 32

4.2.1 Overview of Color Area........................................................................................... 32

4.2.2 Overview of Color Judgement................................................................................. 33

4.2.3 Setting Procedures and Modes............................................................................... 34

4.2.4 Setting up the LightPixAE20 in CONFIGURATION Mode....................................... 35

4.2.5 Teaching in TEACHING Mode................................................................................ 37

4.2.6 Setting Judgement Criteria in JUDGEMENT CRITERIA SETTING mode ..............41

4.2.7 Inspection Execution............................................................................................... 42

4.3 Color Pattern Matching.................................................................................... 44

4.3.1 Overview of Color Pattern Matching ....................................................................... 44

4.3.2 Setting Procedure and Modes................................................................................. 48

4.3.3 CONFIGURATION mode........................................................................................ 49

4.3.4 Teaching in TEACHING Mode................................................................................ 52

4.3.5 Setting Judgement Criteria in JUDGEMENT CRITERIA SETTING Mode ..............56

4.3.6 Inspection Execution............................................................................................... 57

4.4 Edge Detection................................................................................................ 59

4.4.1 Overview of Edge Detection....................................................................................59

4.4.2 Setting Procedure and Modes................................................................................. 61

4.4.3 Setting Up the LightPixAE20 in CONFIGURATION Mode...................................... 62

4.4.4 Executing a Teaching in TEACHING Mode ............................................................64

4.4.5 Setting Up the Judgement Criteria in JUDGEMENT CRITERIA SETTING mode... 68

4.4.6 Inspection Execution............................................................................................... 69

4.5 Peak Detection ................................................................................................70

4.5.1 Overview of Peak Detection.................................................................................... 70

4.5.2 Setting Procedure and Modes................................................................................. 72

4.5.3 Setting Up the LightPixAE20 in CONFIGURATION................................................ 73

4.5.4 Teaching in TEACHING Mode................................................................................ 75

4.5.5 Setting Up the Judgement Criteria in JUDGEMENT CRITERIA SETTING Mode... 79

4.5.6 Inspection Execution............................................................................................... 80

4.6 Measurement .................................................................................................. 81

4.6.1 Overview of Length Measurement.......................................................................... 81

4.6.2 Setting Procedure and Modes................................................................................. 84

4.6.3 Setting Up the LightPixAE20 in CONFIGURATION Mode...................................... 85

4.6.4 Setting a Minimum Value for a Mesurement Object................................................ 87

4.6.5 Teaching in TEACHING mode................................................................................ 88

4.6.6 Setting Up Judgement Criteria in JUDGEMENT CRITERIA and MEASUREMENT

OBJECT MIN. SETTING modes............................................................................. 92

4.6.7 Measurement Execution .........................................................................................93

4.7 Detailed Functions in CONFIGURATION Mode.............................................. 95

5. Parallel Communication..........................................................................99

5.1 Operations through Parallel Communication................................................. 100

5.1.1 Using Input Signals from External Devices........................................................... 100

5.1.2 Output Signals from the LightPix........................................................................... 100

5.2 Input/Output Timing....................................................................................... 102

ii

5.2.1 Performing a Reading Operation (Internal Trigger: OFF)......................................102

5.2.2 Switching Product Types.......................................................................................103

5.2.3 Swtiching to TEACHING Mode .............................................................................103

5.2.4 Teaching ...............................................................................................................104

6. RS-232C Communication ..................................................................... 107

6.1 Overview .......................................................................................................108

6.2 Command Format .........................................................................................110

6.2.1 Reading Data Area: RD ........................................................................................110

6.2.2 Writing in the Data Area: WD ................................................................................ 111

6.2.3 Notation Sytem for Data in Command/Response Messages ................................112

6.2.4 A List of Error Codes.............................................................................................113

6.3 Communication Conditions............................................................................ 114

6.4 A List of Data Registers for Each Application ................................................116

6.4.1 Color Area/Judgement ..........................................................................................116

6.4.2 Color Pattern Matching..........................................................................................119

6.4.3 Edge Detection......................................................................................................122

6.4.4 Peak Detection...................................................................................................... 125

6.4.5 Measurement ........................................................................................................128

7. About AETOOL and GT11 .................................................................... 133

7.1 AETOOL........................................................................................................ 134

7.1.1 Overview of AETOOL............................................................................................134

7.1.2 Obtaining and Installing the AETOOL ...................................................................135

7.1.3 Connecting to a Computer ....................................................................................135

7.2 GT11 136

7.2.1 Functions of GT11.................................................................................................136

7.2.2 Sample Data for GT11 ..........................................................................................136

7.2.3 Connection to the GT11 ........................................................................................ 137

8. General Specifications, Product Numbers and Dimensions............. 139

8.1 General Specifications................................................................................... 140

8.2 A List of Product Numbers.............................................................................142

8.3 Dimensions....................................................................................................143

Record of Changes ...................................................................................... 146

iii

Precautions before Use

Installation Environment

Avoid installing the LightPixAE20 in the following locations:

Locations with direct sunlight or environmental temperatures exceeding a range of 0ºC to +40ºC.

Locations with a relative humidity exceeding a range of 35%RH to 85%RH (without dew condensation

at 25ºC)

Locations with a lot of fine particles, iron filings, salt, oily smoke or conductive dusts.

Locations with an atmosphere containing corrosive gases or flammable gases.

Locations where the product can contact oil or chemicals.

Locations near organic solvents (such as benzene, paint thinner, and alcohol) or strongly alkaline

materials (such as ammonia and caustic soda)

Locations within 100mm of high-voltage wires (or devices), power-driven lines (or devices), radios,

transmitters and devices generating large switching surge (be sure to keep more than 100mm space

between the LightPixAE20 and these devices)

Power Supply

Take care not to generate excessive static electricity from the LightPixAE20.

When supplying power to the LightPixAE20, do not commonly use the power source for powering the

device and be sure to install a protection circuit such as a fuse.

Use an insulated power supply unit with a built-in protection circuit. The LightPixAE20 power supply

unit is a non-insulated circuit. Therefore, applying an abnormal voltage might damage the internal

circuit. If you use a power supply unit without a protection circuit, supply power through a protective

device such as a fuse.

About grounding

Do not commonly use the ground with other devices.

Grounding should be as close as the main unit as possible, and keep the distance short.

Noise Countermeasure

Do not bundle the optional cable connecting between the main unit and the operation unit, and input

/output signal cables connecting to the main unit together with motor or power cables. Ensure that they

are at least 100m apart. Keep the signal cables as short as possible.

If the external devices connected to the main unit are connected with directive conduction load (a motor

or relay), equip noise absorption elements such as noise killers at the load side.

Lighting equipment for image process generates signal of extremely high noise level due to high

frequency lighting. If you use external lighting, arrange the wiring of power transmission and signal

cables carefully.

Before Turning on the LightPixAE20

Pay attentions to the followings when turning on the LightPixAE20 for the first time;

Confirm no wiring waste or especially any conductive substance coming from installation is on the

printed circuit board

Confirm that the power voltage, power wiring and input/output wiring is correct.

Confirm that the fixing and terminal screws are securely tightened.

Do not turn the LightPixAE20 on within 10 minutes after turning the main unit off. This may result in

malfunction.

iv

General Cautions

Do not connect Ethernet to the connector on the operation unit for connecting the optional cable or the

port for connecting the operation unit.

Use the operation unit and finder unit of a product number specified by Matsushita Electric Works, Ltd.

A breakdown, damage or destruction by using any other than the specified will not be covered by our

guarantee.

Do not disassemble and remodel the LightPixAE20 or change its internal settings. A breakdown,

damage or destruction caused by disassembling, remodeling the LightPixAE20 or not following the

instructions described in the manuals will not be covered by our guarantee.

Do not change or set items that should not be as described in the manual or the specification.

Breakdown, damage or destruction resulting from changing or setting them will not be covered by our

guarantee.

To USA Customer

Products sold by Seller are covered by the warranty and patent indemnification provisions in its Terms

and Conditions of Sale only.

v

Chapter 1

Overview of Light Pix AE20

1

1.1 Overview

LightPixAE20 (hereinafter called “the LightPixAE20”) is a device that is integrated with CPU, camera, lens

and lighting equipment. With AETOOL software for the LightPixAE20 (free), you can download one of the

inspection applications to the main unit, check scanning conditions or images and document the images

stored in the main unit (or save them as bmp file).

In addition, with the operation unit and finder unit, you can check the current image or modify the scanning

conditions, and with our programmable display GT11, you can change settings or control start of code read.

The operating instructions mainly for the operation unit and finder unit are described in this manual.

Refer to the AETOOL help files (available after installation) for further details of the AETOOL.

About the AETOOL: Page 134

2

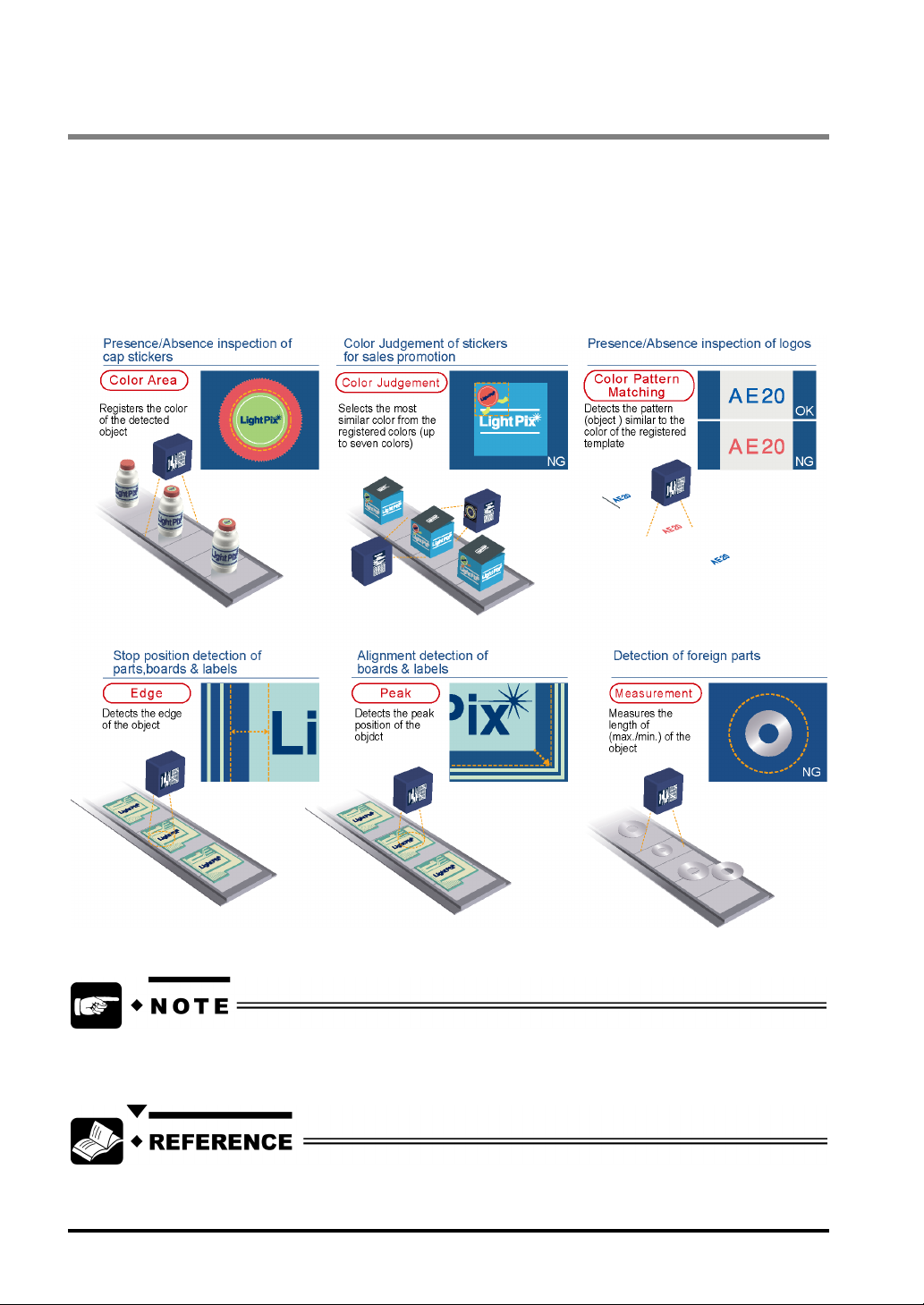

1.2 Product Configuration

Main Unit

The LightPixAE20 is a device that is integrated with CPU, a camera and lighting

equipment. Inspections can be performed by using the main unit only. You can

download one of the inspection applications to the AETOOL. The LightPixAE20

has parallel I/O and serial RS-232C ports for communication with external

devices.

Operation unit

The operation unit has eight buttons and a display area (7-segment

negative/positive LCD display). With these buttons, you can make various

settings. In the display area, setting items and options are displayed. If the

device is connected to the main unit with the provided cable while scanning

codes, the detected data, results, and operation status of the main unit are

displayed in this area.

Finder Unit

The finder unit is a device that displays the images captured with the main unit.

Mount the device onto the operation unit before use. Do not directly connect the

finder unit to the main unit.

AETOOL*

The AETOOL is software exclusively for LightPixAE20. Before using this software, install it to the PC

connected to the LightPixAE20 with USB cable (AB type). The key features of this software are shown in

the table below.

Features Description

Transferring the inspection

application to the main unit

Setting up inspection conditions Carries out all of the operations you can perform with both the operation

Backing up configuration data

and downloading backup

configuration data

Documenting configuration data Writes out the backup configuration data in the CSV format.

You can freely download this software from our website.

"http://www.nais-j.com/vision/uacs"

Switches the applications for LightPixAE20

unit and the finder unit.

Backups the configuration data, saves files on PC and downloads the data

to the main unit. Thus, if you use multiple main units under the same

reading conditions, you can copy and use the data in individual main units.

3

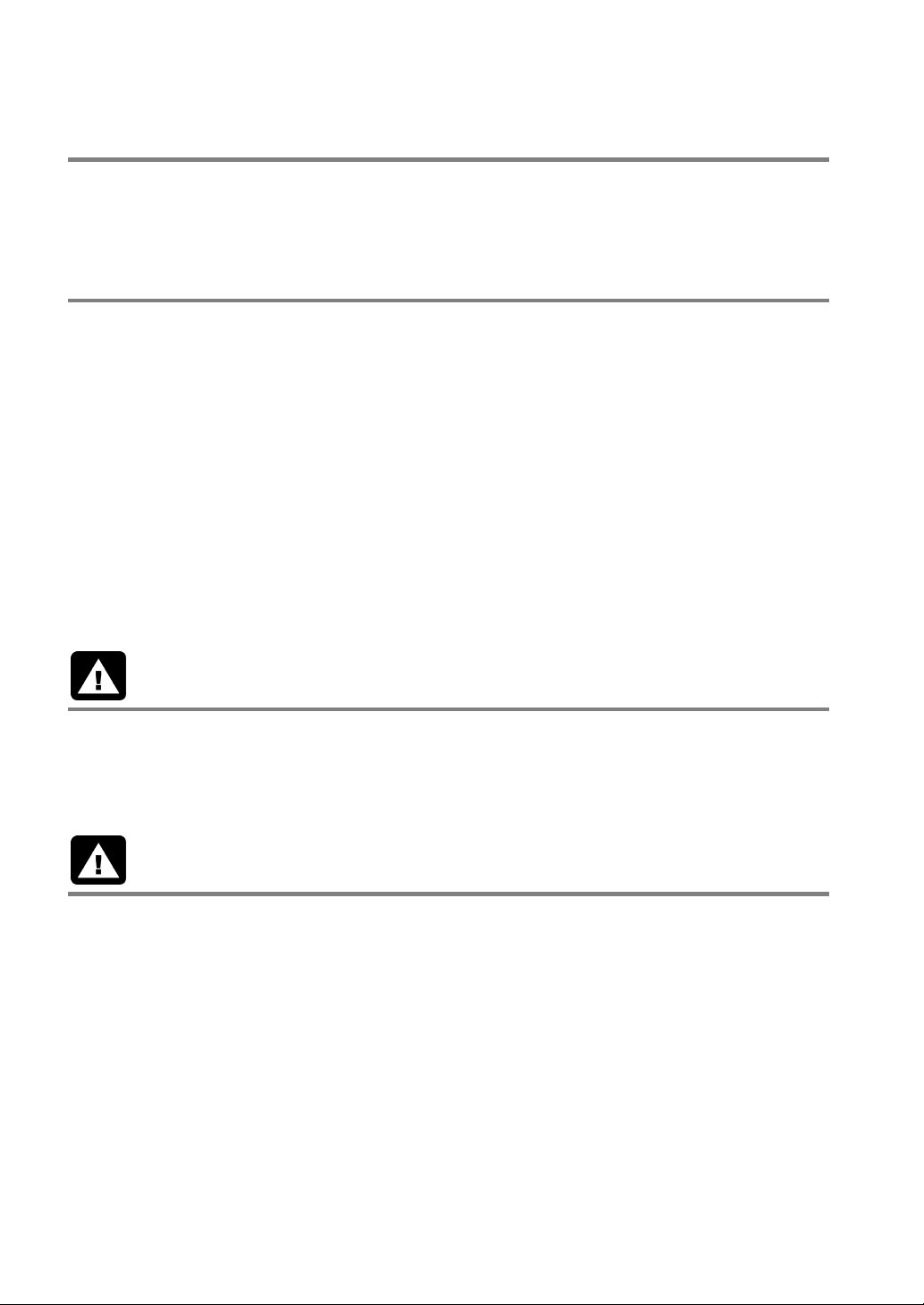

1.3 Inspection Applications

There are six kinds of inspection applications available on the LightPixAE20. You can download one of the

following inspection applications to the main unit before use.

Inspection Applications

Type Overview

Color Area Measures the registered color area

Color Judgement Selects the color of the object from maximum seven registered

Color Pattern

Matching

Edge Checks whether or not the detected edges of the object move from the

Peak Finds out whether or not the detected vertices of the object move from the

Measurement Finds out whether or not the measured max./min. values in the horizontal and

The number of inspection applications that you can download is only one.

Refer to section 4, “Inspection Applications“(page 30) for the details of each inspection application.

In a color extraction image, detects the same image as the saved base image

(template)

registered base position

register base position

vertical directions are equal to the registered base size

4

Chapter 2

Names and Functions of Parts

5

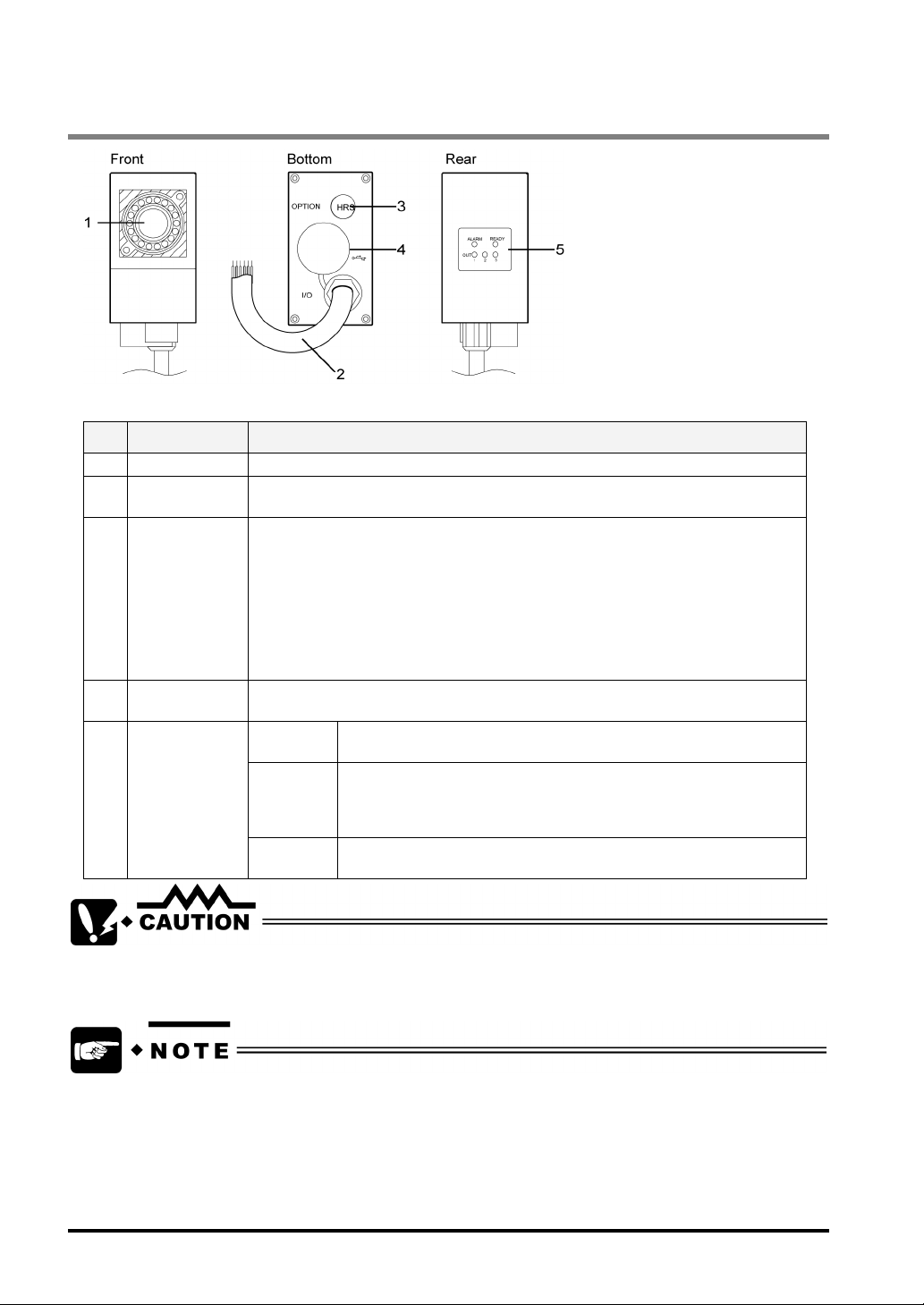

2.1 About the Main Unit

Designations and Descriptions of Each Part

No. Name Description

1 Capture part Camera for capturing images, lens and white LED are built in this part.

2 I/O cable This external input/output cable used for supplying 24 VDC, inputting scan start

3 Optional cable

connector

(for connection

to the operation

unit and for

RS232C)

4 USB port This port is used for connecting to the PC in which AETOOL is installed. Use a AB

5 LED indicators

TRIGGER signal and outputting inspection result signal.

Port used for connecting to the operation unit and to external devices such as PLC,

our programmable display GT11, etc. through RS-232C communication.

Select a proper optional cable for your connecting equipment.

• When connecting to operation unit (plus finder unit), use the optional cable

ANE2813.

• When connecting to external devices through RS-232C communication,

use the optional cable ANE2803.

• In the both cases above, use the optional cable ANE2823.

type cable for USB2.0 or 1.1 (max. cable length: 5m)

OUT1 - 3 Output state of inspection results. The OUT1-3 LEDs goes on when

each signal is output.

READY The READY LED goes on when the main unit performs no process.

The LightPixAE20 can receive inspection start signal (TRIGGER

signal in RUN or RUN VIEW mode) from the external devices only

while the READY signal is being output.

ALARM The ALARM LED goes on when the LightPixAE20 could not finish

teaching properly.

Use only the specified cable and device for the optional cable connector and USB port respectively.

Failure to do so may result in product damage.

• If the ALRAM signal is output when teaching is finished properly, reboot the LightPixAE20.

In the case of frequent output of the ALARM signal, the LightPixAE20 may be broken. Please

contact us.

• Expected service life of the white LED built in the main unit is 30,000 hours. (Light intensity drops

to 50 % under the conditions of high-speed operation at 25ºC while internal trigger is ON.) It is

advisable to make regular adjustment for light intensity and carry out a re-teaching, because

lower light intensity may negatively affect the measurement results.

6

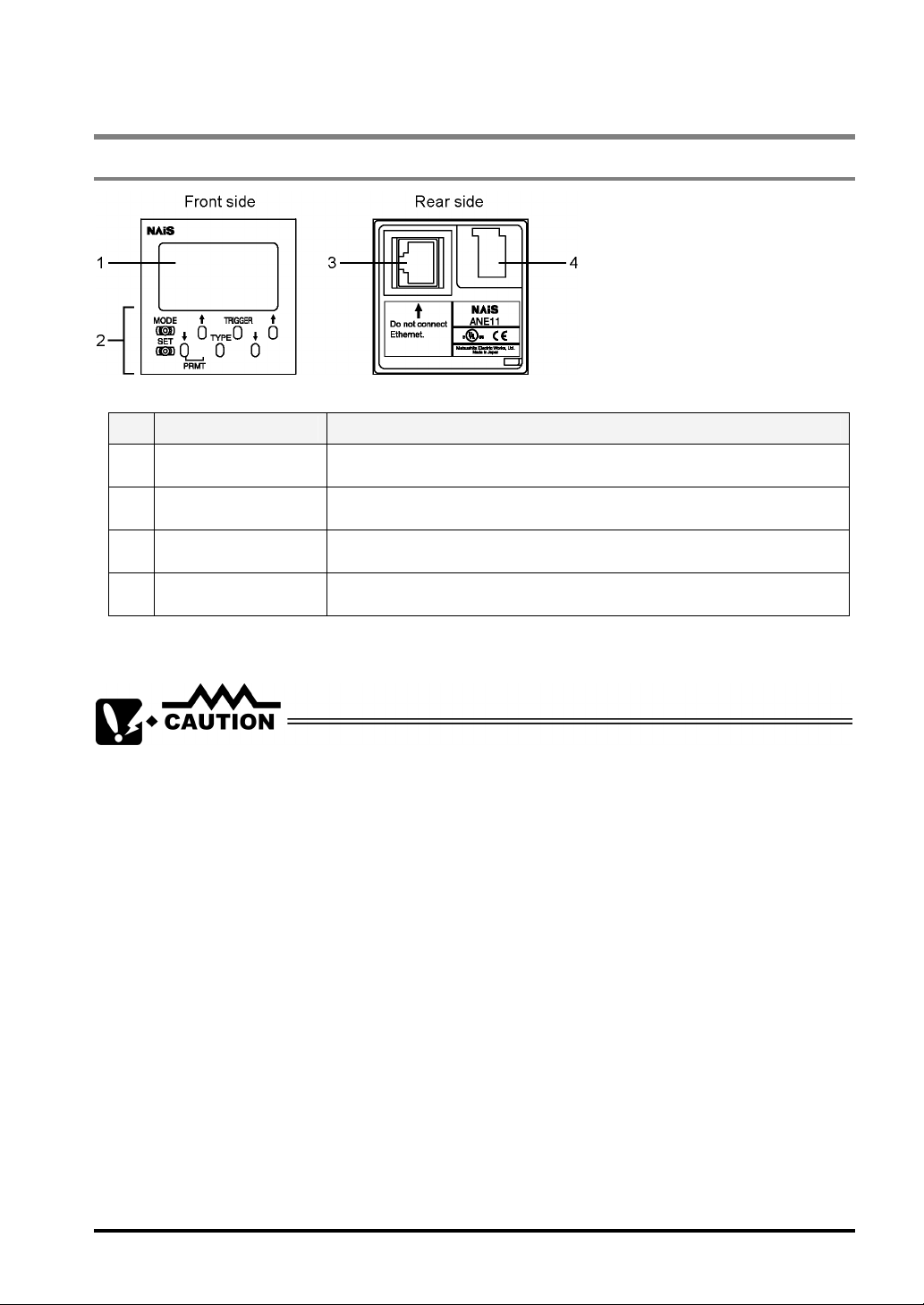

2.2 Operation Unit

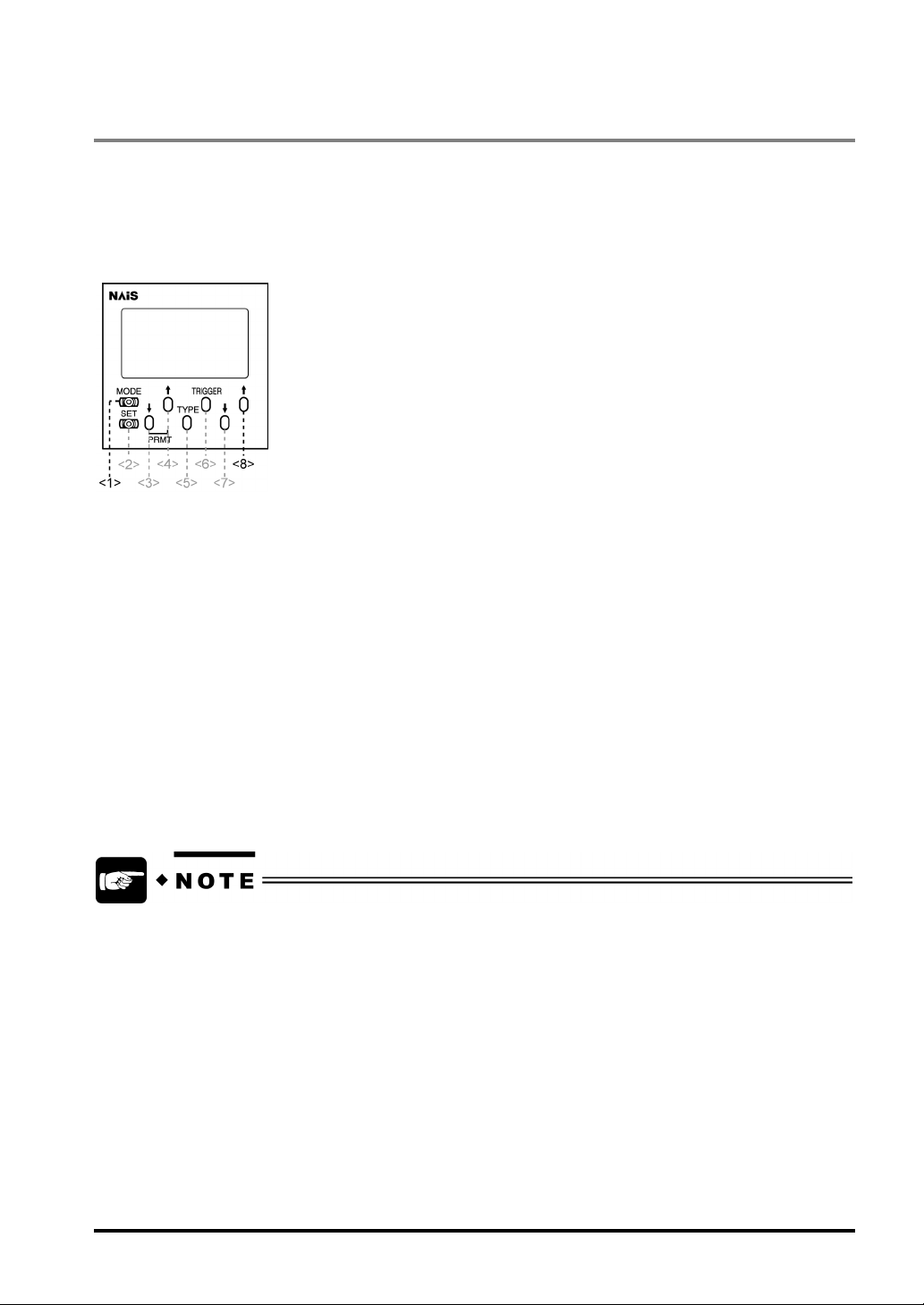

2.2.1 Operation Unit

Designations and Descriptions of Each Part

No. Name Description

1 Display area Operation status of main unit, modes, inspection results and setting items are

2 Operating buttons Used for operating the main unit. There are eight operating buttons.

displayed in the display area. Refer to the next page for further details.

3 Port for connecting to

the main unit

4 Connector for finder

unit

Do not connect any other device to the port for the main unit. Failure to do so may result in product

damage.

Used for connecting to the main unit. Use the cable ANE2813 or ANE2823 to

connect to the main unit.

Used for connecting to the finder unit

7

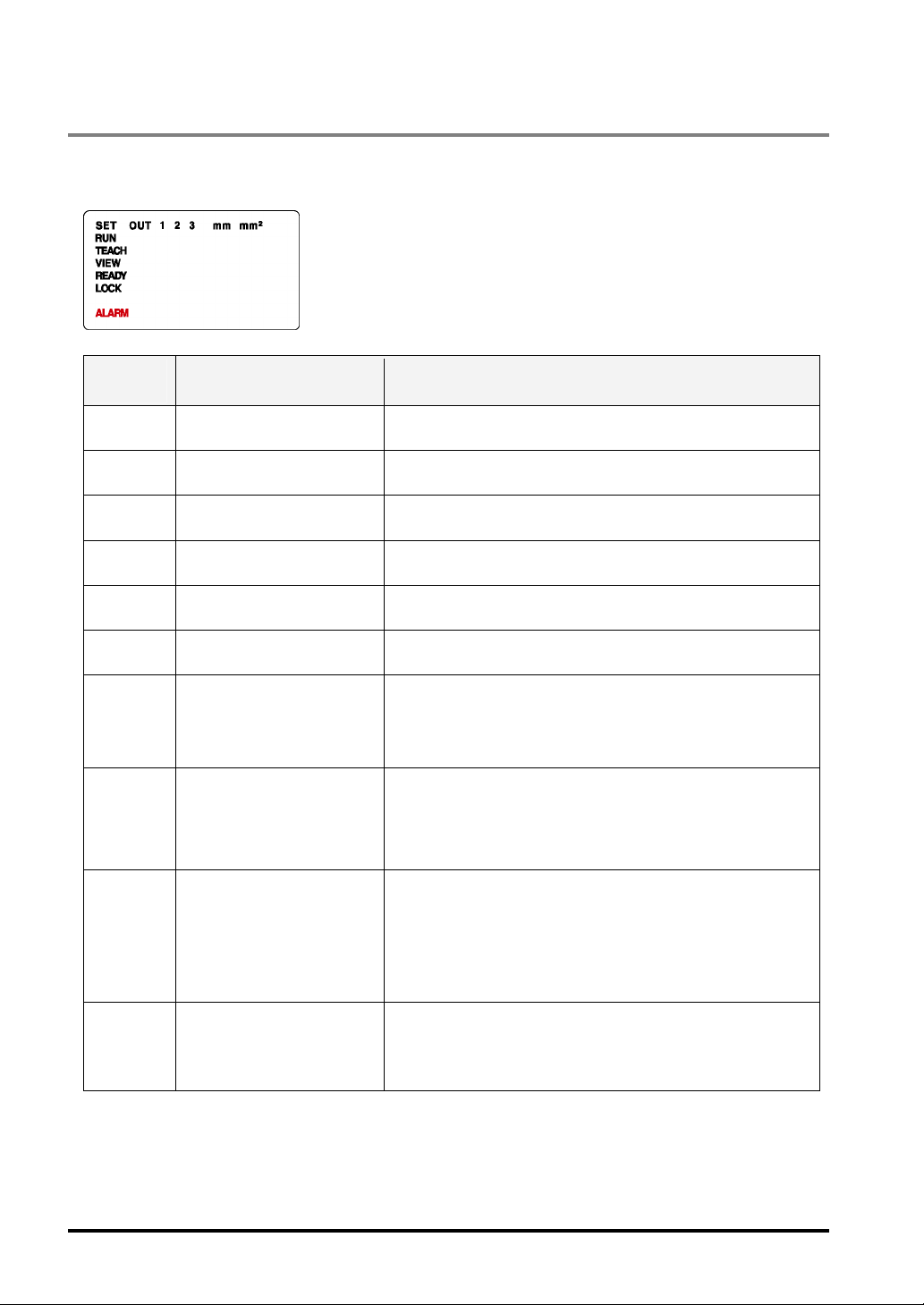

2.2.2 Texts Displayed on the LCD Monitor of the Operation Unit

The display area of the operation unit displays measurement data and setting values and operating status of

the LightPixAE20 as a text string.

Displayed

text

SET CONFIGURATION mode Indicates the LightPixAE20 is in CONFIGURATION mode

RUN RUN (RUN VIEW) mode Indicates the LightPixAE20 is in RUN mode.

TEACH TEACHING mode Indicates the LightPixAE20 is in TEACHING mode.

Mode Description

VIEW RUN VIEW mode Indicates the LightPixAE20 is RUNVIEW mode. In this mode,

READY RUN (RUN VIEW) mode

LOCK RUN (VIEW) mode Means the lock function is activated. In this mode, you cannot

ALARM

(Red)

OUT1-3 RUN (RUN VIEW) mode Represents output state of parallel output signals OUT1-3. The

mm RUN (RUN VIEW) mode Indicates the unit for the measured data is millimeter. You can

mm2 RUN (RUN VIEW) mode Indicates the unit for the measured data is square millimeter.

TEACHING mode

RUN (VIEW) mode

TEACHING mode

(May be displayed when the

device is in the other

modes.)

captured images are displayed on the finder unit.

Displayed when parallel output signal “READY” is ON.

operate the LightPixAE20.

Displayed when the parallel output signal “ALARM” is ON.

signals that are turned on are displayed.

For example,

• OUT 1 2: OUT1 and OUT2 signals are on.

check it only if you are using the following applications:

• Color Pattern Matching

• Edge

• Peak

• Measurement

You can check it only if you are using the following applications:

• Color Area

• Color Judgement

8

2.2.3 Lock Function

The LightPixAE20 comes with a built-in Lock function that helps you avoid accidental operation of the

operation unit (if connected). As long as this function is activated, the current operation mode and settings of

the LightPixAE20 are not changed even if the operating buttons are accidentally pressed.

Buttons to be used for setting the Lock function

To lock the operation unit:

1. Press the buttons 1 and 8 on the operation unit at the same time for approximately three

seconds.

The word “Lock” appears on the LCD display (refer to the previous page for details of displayed texts).

To unlock the operation unit:

1. Press the buttons 1 and 8 on the operation unit at the same time for approximately three

seconds.

The word “Lock” disappears.

Even when locking the operation unit, you can input signals from AETOOL or external devices, or

change settings and switch modes via RS-232C communication.

9

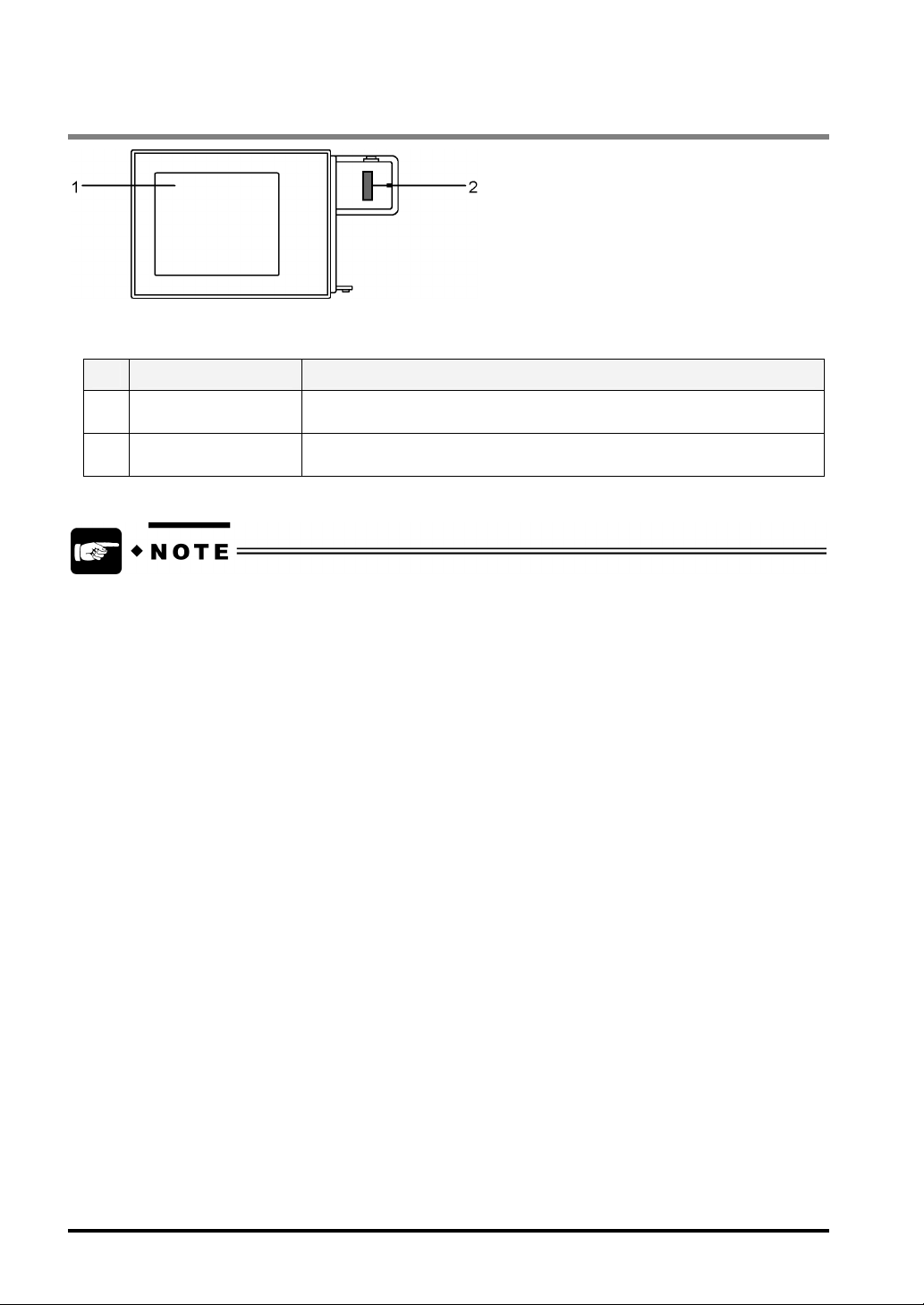

2.3 Finder Unit

Designations and Descriptions of Each Part

No. Name Description

1 Image display area A captured image is displayed when the LightPixAE20 is in RUN-VIEW

mode. (Images are not displayed in RUN mode.)

2 Connecting connector Used for connecting the operation unit.

Expected service life of the backlight is approx. 40,000hours (at operating ambient temperature

25ºC). The LightPixAE20 comes with a built-in Backlight OFF-TIMER function. This function would

be helpful if you want to turn the device off in 10, 30 or 60 minutes. Refer to Section 4.7, “Detailed

Functions in CONFIGURATION Mode” for more details of Backlight OFF-TIMER function.

10

Chapter 3

Installation and Wiring

11

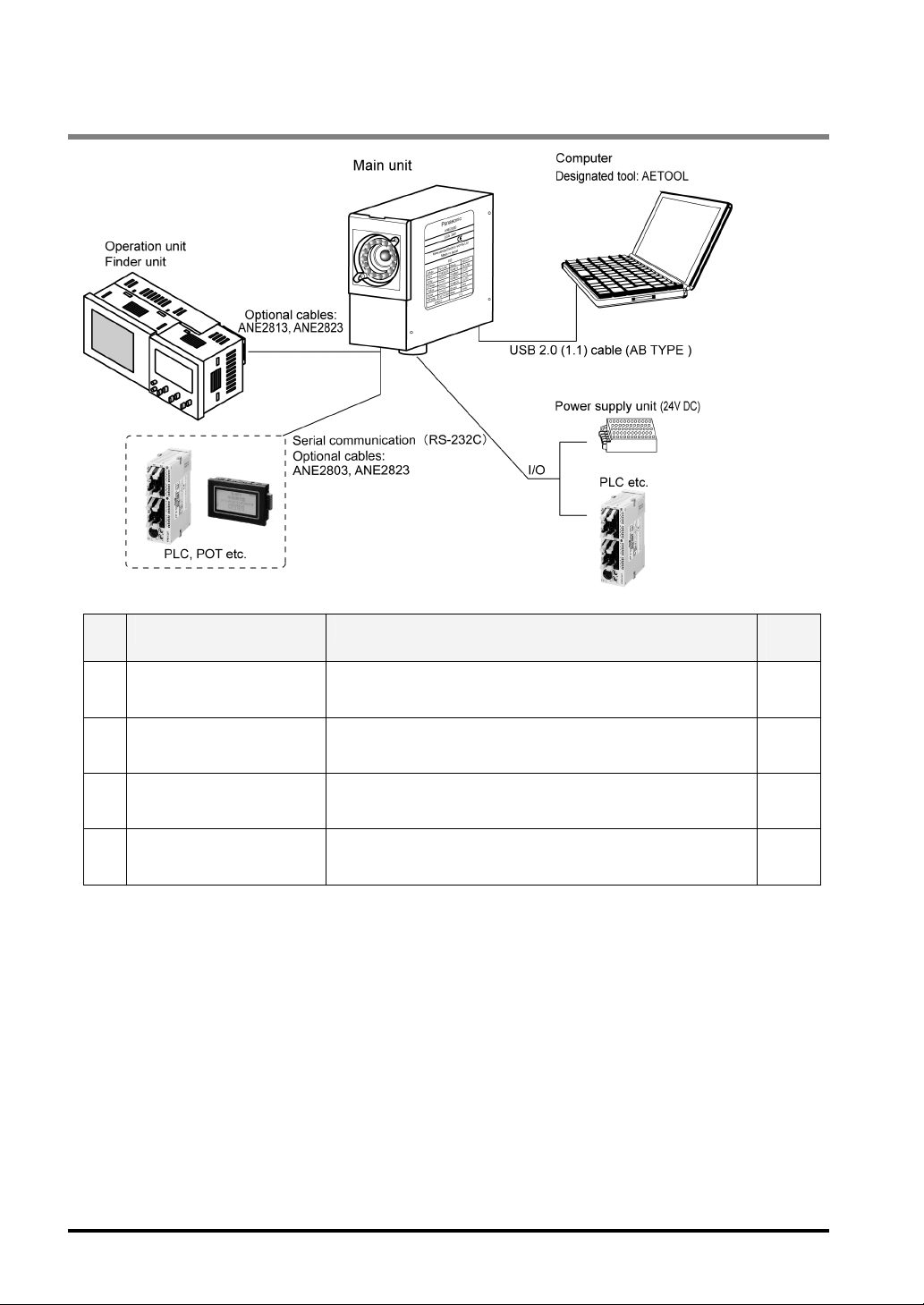

3.1 A List of Connectable Units and Devices

No. Connectable unit/device Purpose

1 Operation unit and finder

unit

To set inspection conditions and display images 13

Ref.

Page

2 I/O – power supply unit and

PLC

3 Serial (RS232C) – PLC,

POT, etc.

4 AETOOL installed PC To perform all operations without using the operation unit and

To control the LightPixAE20 with external devices such as

power supply unit and PLC and import measurement results.

To receive inspection results, control the LightPixAE20 by

sending commands from external devices and import

measurement results.

finder unit.

12

15

26

135

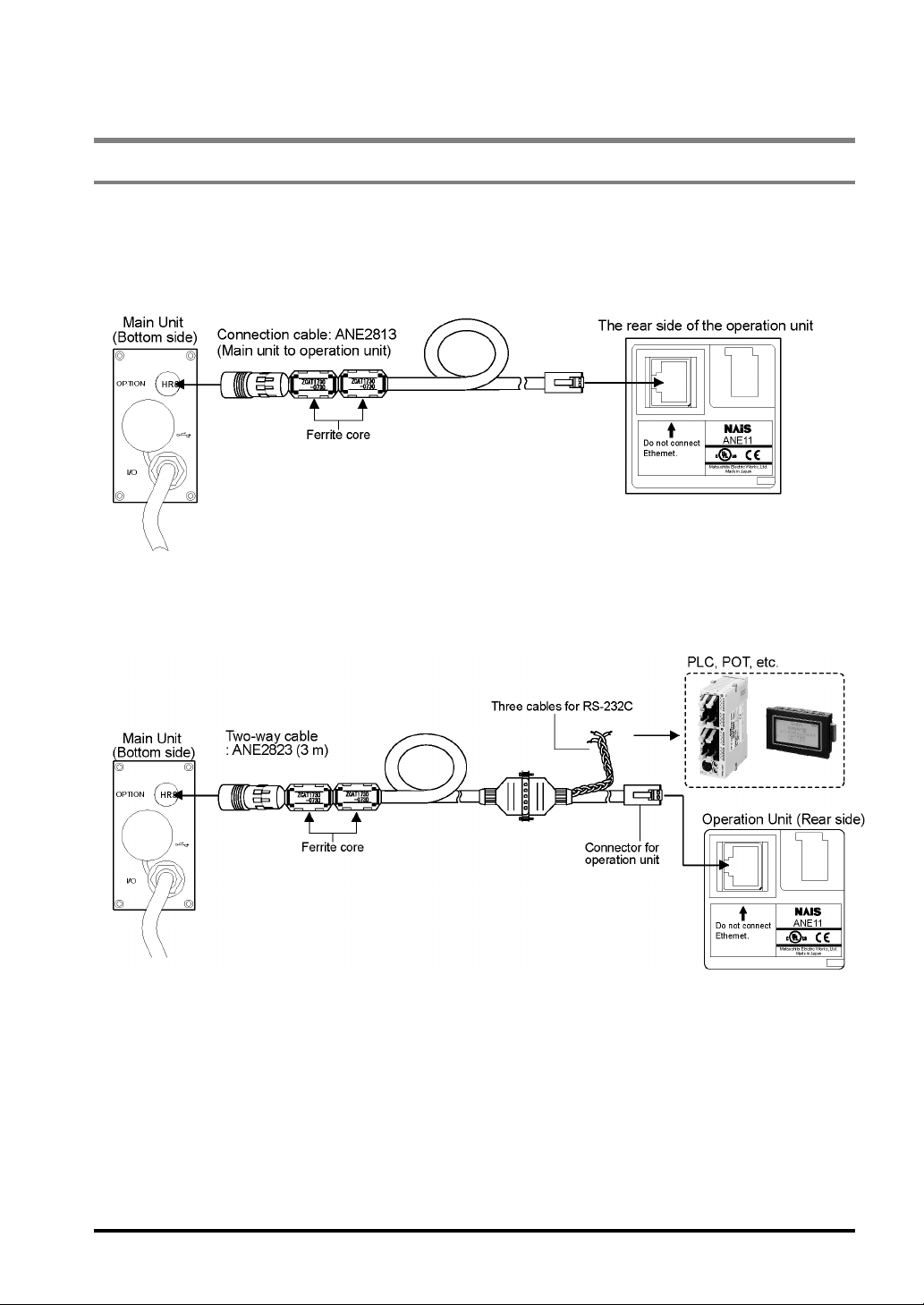

3.2 Connection between the Units

3.2.1 Connection the Main Unit to the Operation Unit

Use only the specified cable ANE2813 (cable length: 3m) or ANE2823 (cable length: 3m) to connect the main

unit to the operation unit.

When connecting to only the operation unit (with the finder unit)

When connecting the main unit to the operation unit (with the finder unit) and to the

external devices such as PLC and POT via RS-232C

13

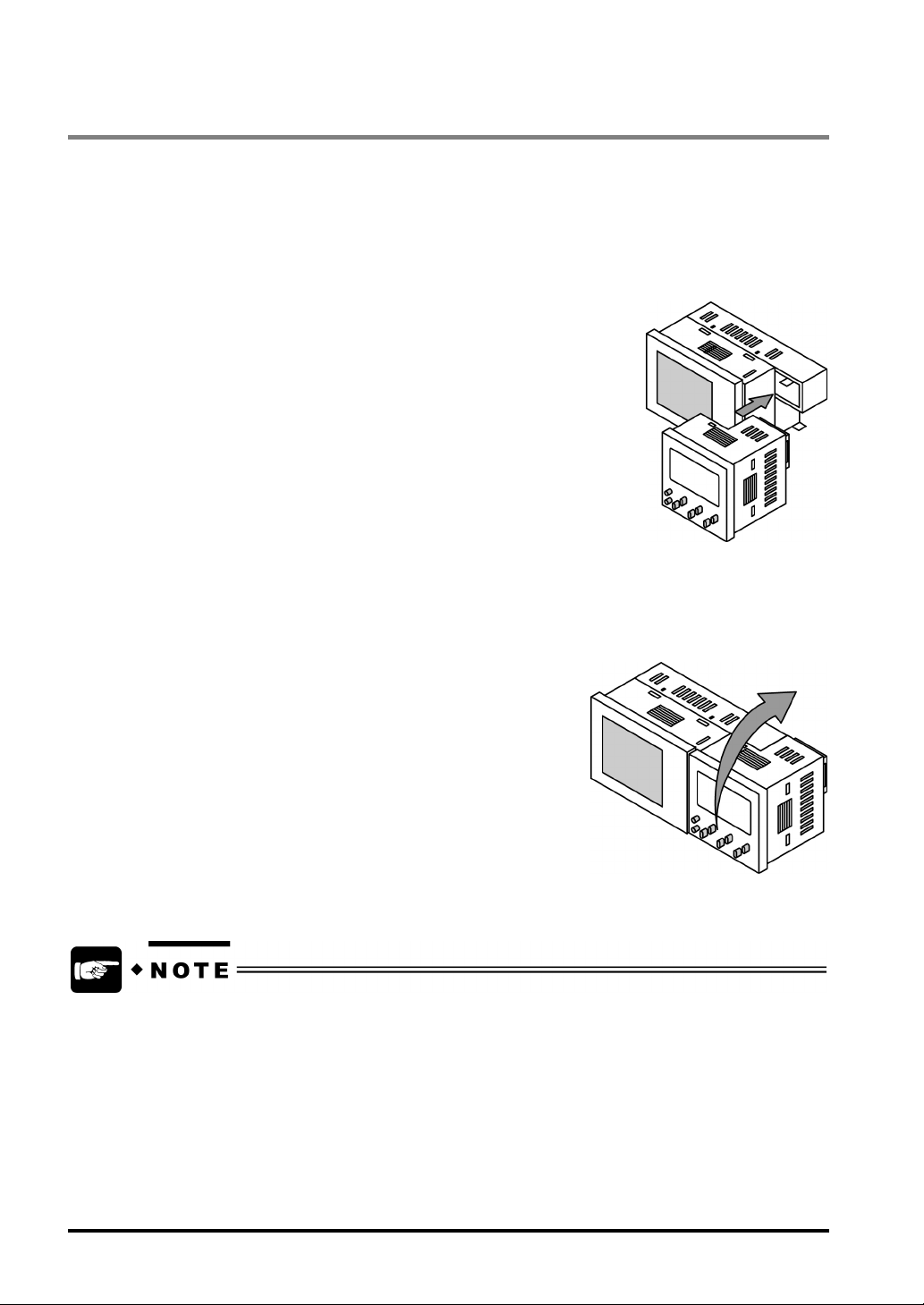

3.2.2 Connection of the Operation and Finder Units

You can mount the finder unit on the operation unit without using any cables. Use the connector for

connecting the operation unit or finder unit on each unit.

To mount the operation unit on the finder unit:

1. Insert the operation unit into the finder unit until it clicks.

To remove the operation unit from the finder unit:

1. Hold the finder unit with one hand.

2. Hold the operation unit with the other hand and lift the operation unit in the arrow direction.

• When using the finder unit, mount the operation unit on the finder unit first and connect the

devices with the optional cable for connecting to the main unit

• Do not mount the operation unit on the finder unit while the operation unit is running. Failure to do

so may result in the product damage.

14

3.3 Fixing and Removing the Main Unit

3.3.1 Main Unit

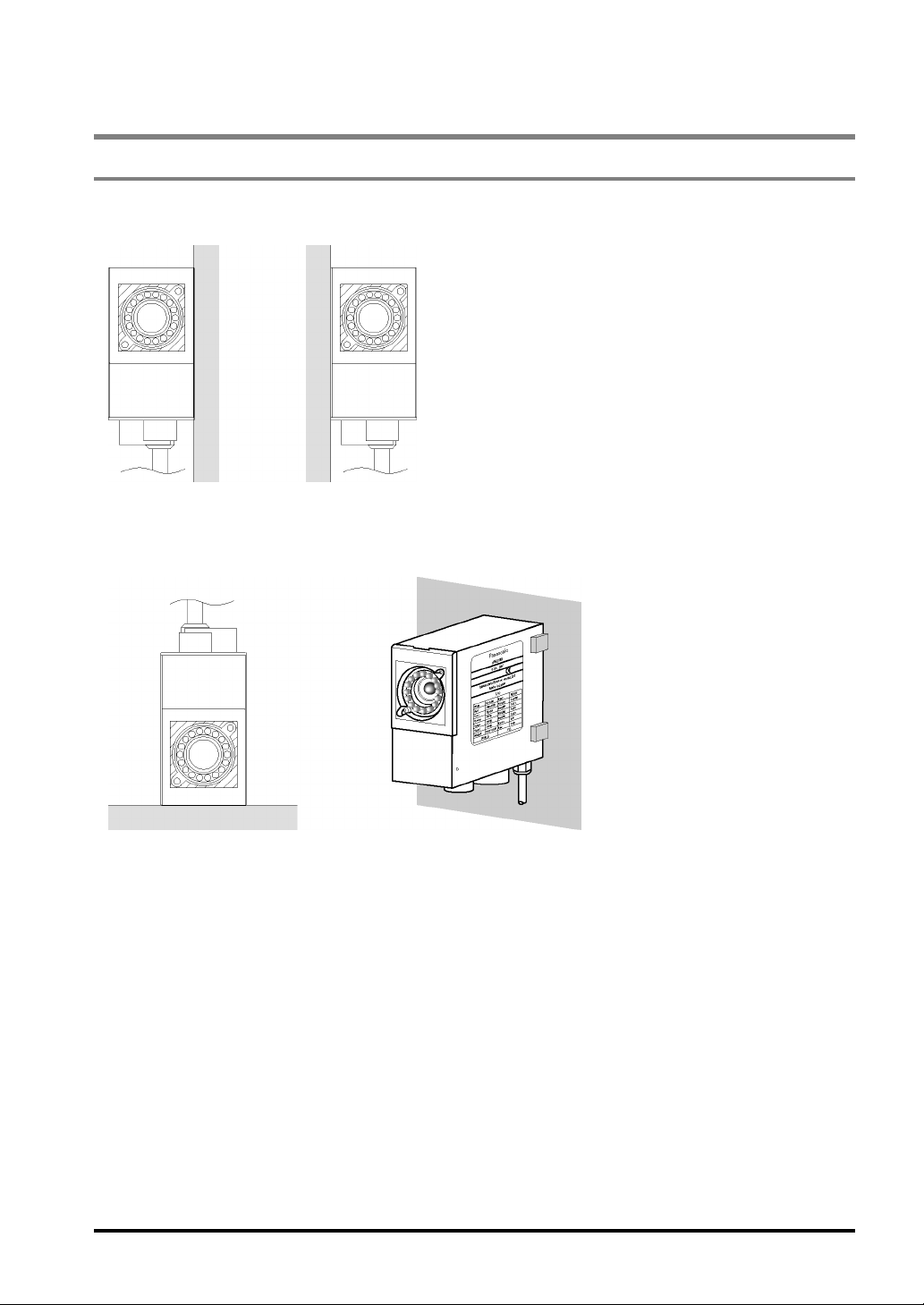

Fixing the main unit on a wall

Use the three holes on a side of the main unit to fix it on a wall.

Avoid installing the main unit as the following figures shown below.

Wrong Examples

15

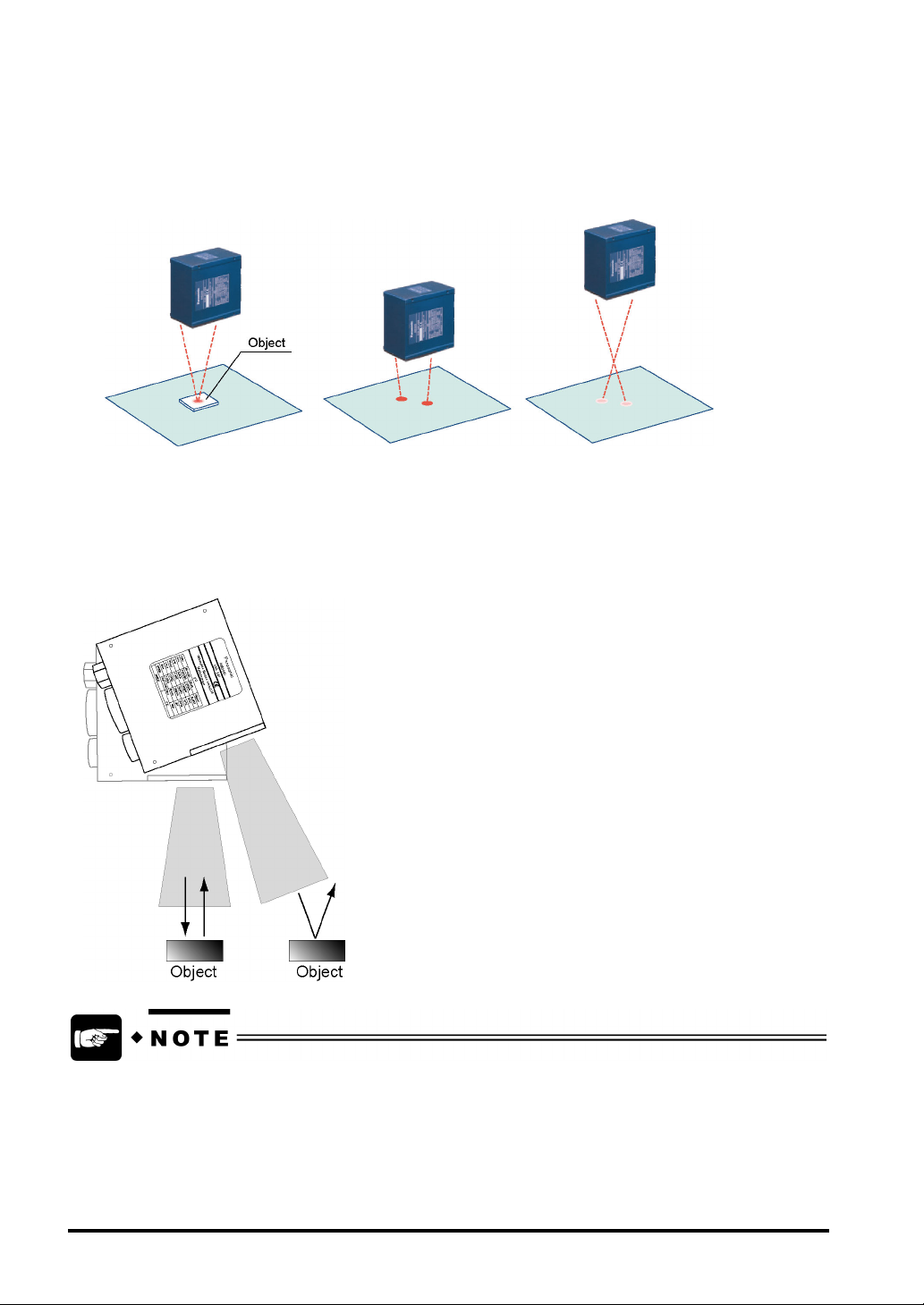

Installation distance between the main unit and the inspection object

Keep 15 to 220 mm space between the object and the main unit, but the space varies depending on the

product number of the main unit. Since light guides (two red LED lights) are emitted from the LightPixAE20

to the area around the object, adjust the position of the main unit so that the two lights are close (or overlap)

each other.

Proper Too close Too far

(Dim light guides)

Installation angle

If you want to capture a shiny object, the light emitted from white LED may interfere with the object due to

the mirror reflection from it, so slant the main unit.

16

• Disturbance light, of which illumination intensity varies at the time of measurement, negatively

affects the measurement results. Shield the device from any disturbance light.

• The larger the installation angle, the greater the warp generated in the captured mages. This will

lead to mixed measurement results depending on the position of the object within the field of

view. Determine the installation angle of the main unit after actually checking the image.

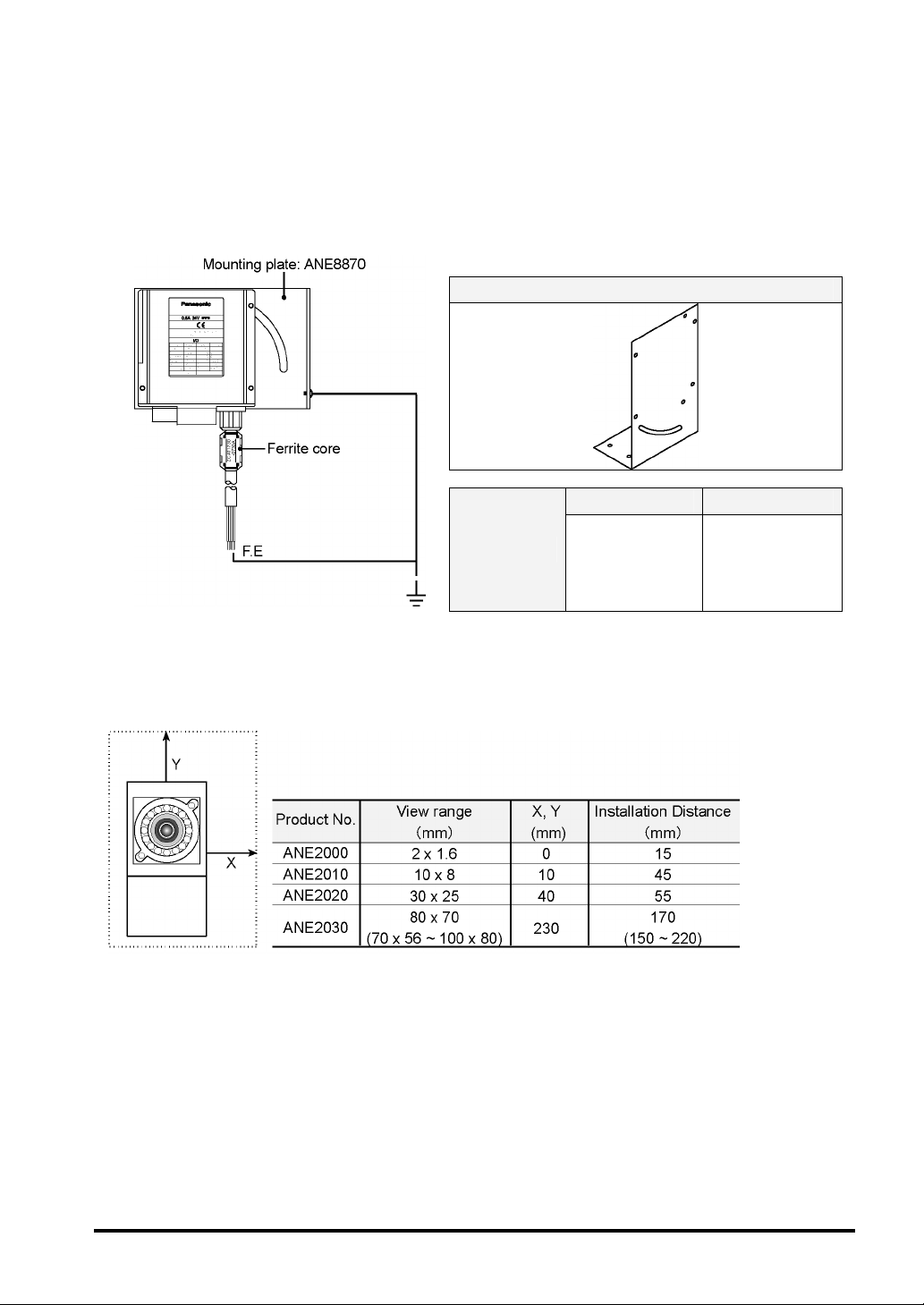

Conformity to the EMC standard

The AE20 will comply with the EMC standards (EN61000-6-4, EN61000-6-2) in EMC Directive (EMC

Directive 89/336/EEC). The product must fulfill the following conditions:

1. No USB communication

2. Ferrite core must be used for the wirings as the figures shown below.

3. Mounting plate ANE8870 (separately sold) must be used for grounding.

Mount Plate - Product No. ANE8870

Manufacturer Product No.

Ferrite Core

TDK CO., LTD. ZCAT1730-0730A

Installation space between the multiple units

Keep the enough space between the units to prevent the lights emitted from each unit from interfering with

each other (see the table below).

17

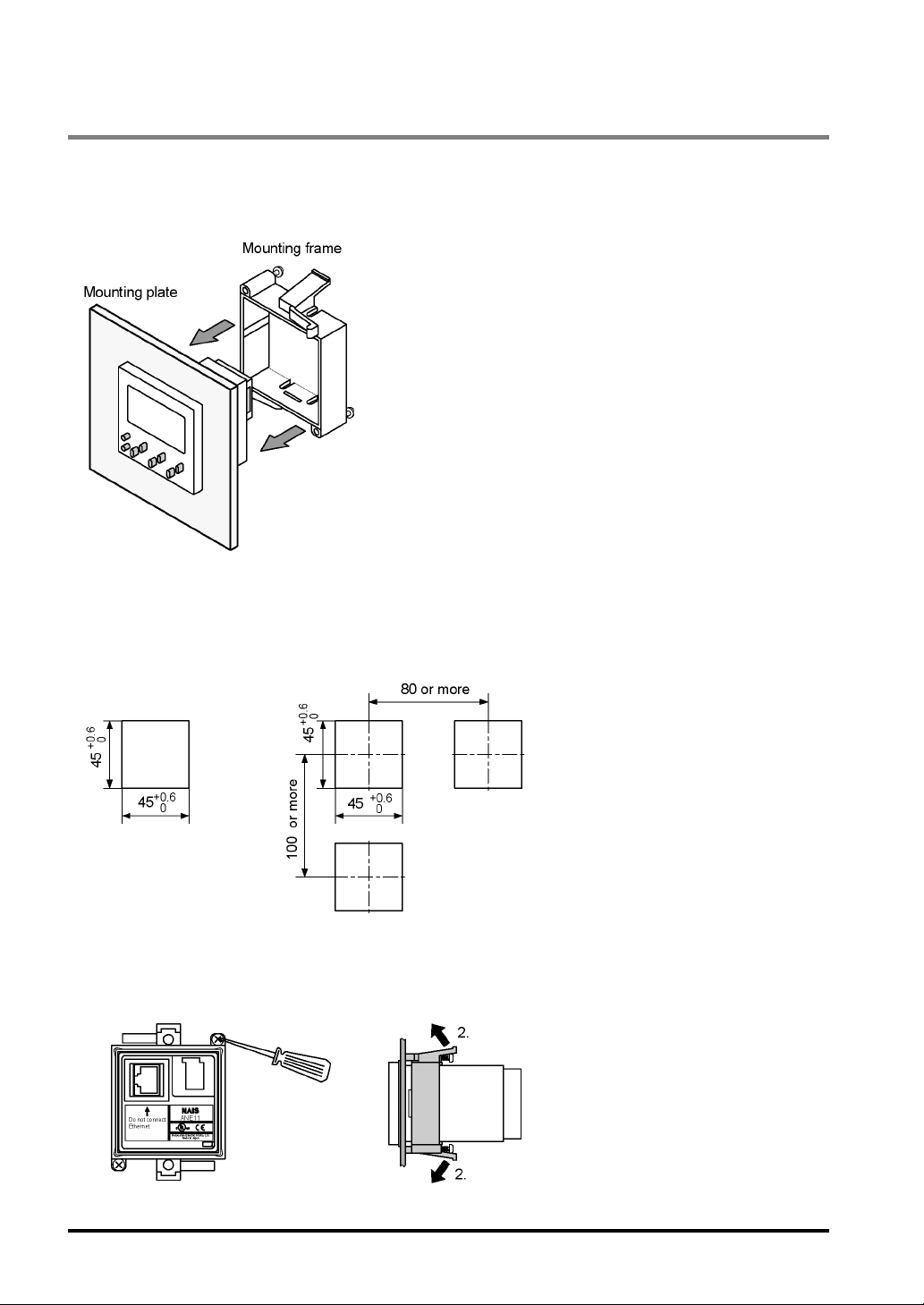

3.3.2 Operation Unit

Installing the operation unit only

Mount the operation unit onto the front side of the mounting plate, insert the mounting frame into the rear

side of the operation unit, then tighten the mounting frame with the screws.

Sizes of the mounting plate

Use 1 to 5mm thick panel.

To install a single unit: To install multiple units:

To remove the operation unit:

1. Loosen screws.

18

2. Remove the mounting frame while

pulling the tabs in the arrow directions.

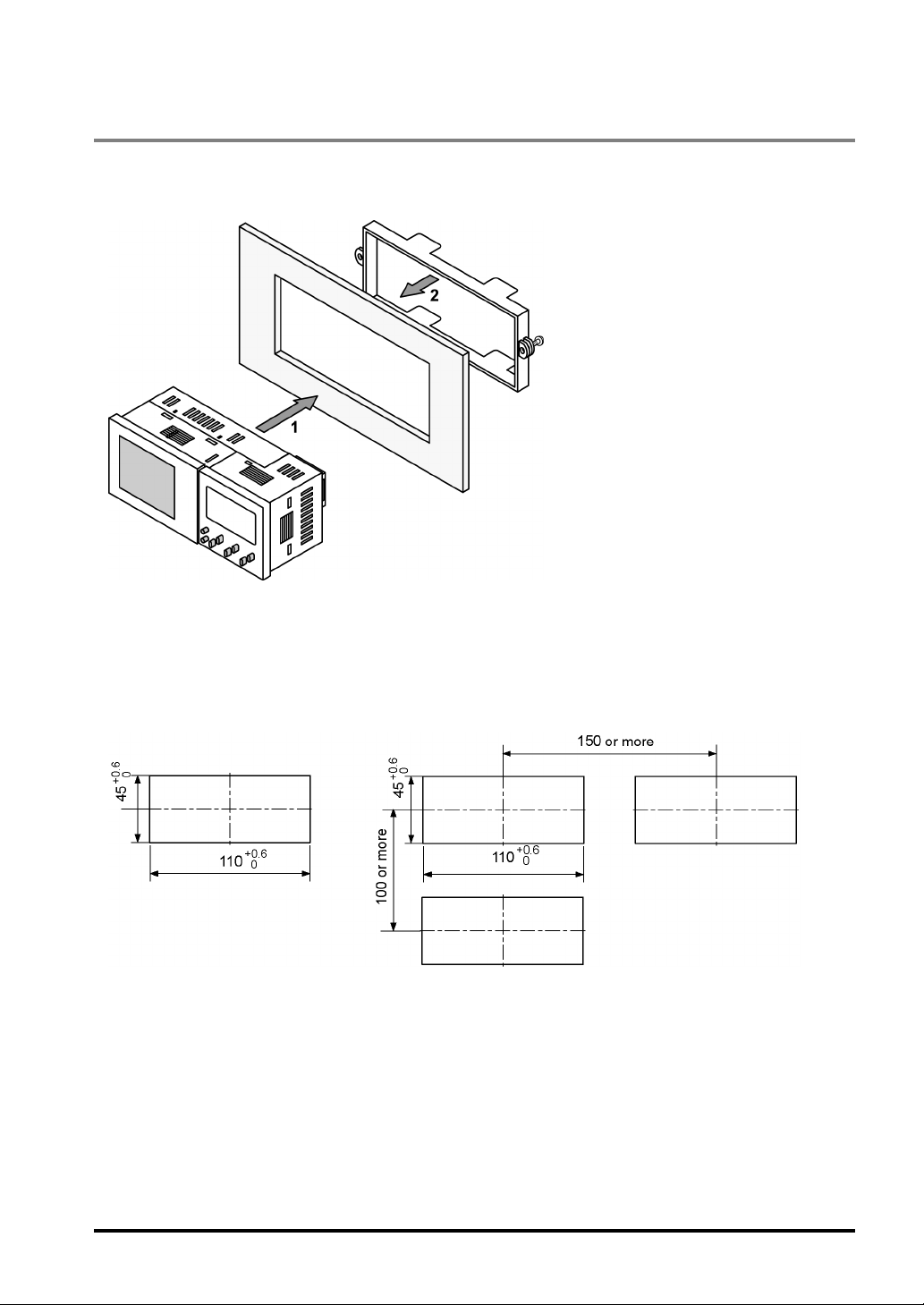

3.3.3 Finder Unit

To mount the finder unit:

Assemble the operation unit first, mount the finder unit onto the front side of the mounting plate, and then

insert the mounting frame into the rear side of the fixing plate.

Sizes of the mounting plate

Use 1-5mm thick panel.

To install a single unit: To install multiple units:

19

3.3.4 Installation Environment

Installation Environment

Avoid installing the LightPixAE20 in the following locations:

Locations with direct sunlight or environmental temperatures exceeding a range of 0ºC to +40ºC.

Locations with a relative humidity exceeding a range of 35%RH to 85%RH (without dew condensation

at 25ºC)

Locations with a lot of fine particles, iron filings, salt, oily smoke or conductive dusts

Locations with a lot of dusts, oily smoke, conductive dusts, or corrosive or flammable gases

Locations where the product can contact oil or chemicals

Locations near organic solvents (such as benzene, paint thinner, and alcohol) or strongly alkaline

materials (such as ammonia and caustic soda)

Locations within 100mm of high-voltage wires (or devices), power-driven lines (or devices), radios,

transmitters and devices generating large switching surge (be sure to keep more than 100mm space

between the LightPixAE20 and these devices)

Noise Countermeasure

Do not bundle the optional cable connecting between the main unit and the operation unit, and input

/output signal cables connecting to the main unit together with motor or power cables. Ensure that they

are at least 100m apart. Keep the signal cables as short as possible.

If the external devices connected to the main unit are connected with directive conduction load (a motor

or relay), equip noise-absorbing elements such as noise killers at the load side.

Lighting equipment for image process generates signal of extremely high level due to high frequency

lighting. If you use external lighting, arrange the wiring of power transmission and signal cables

carefully.

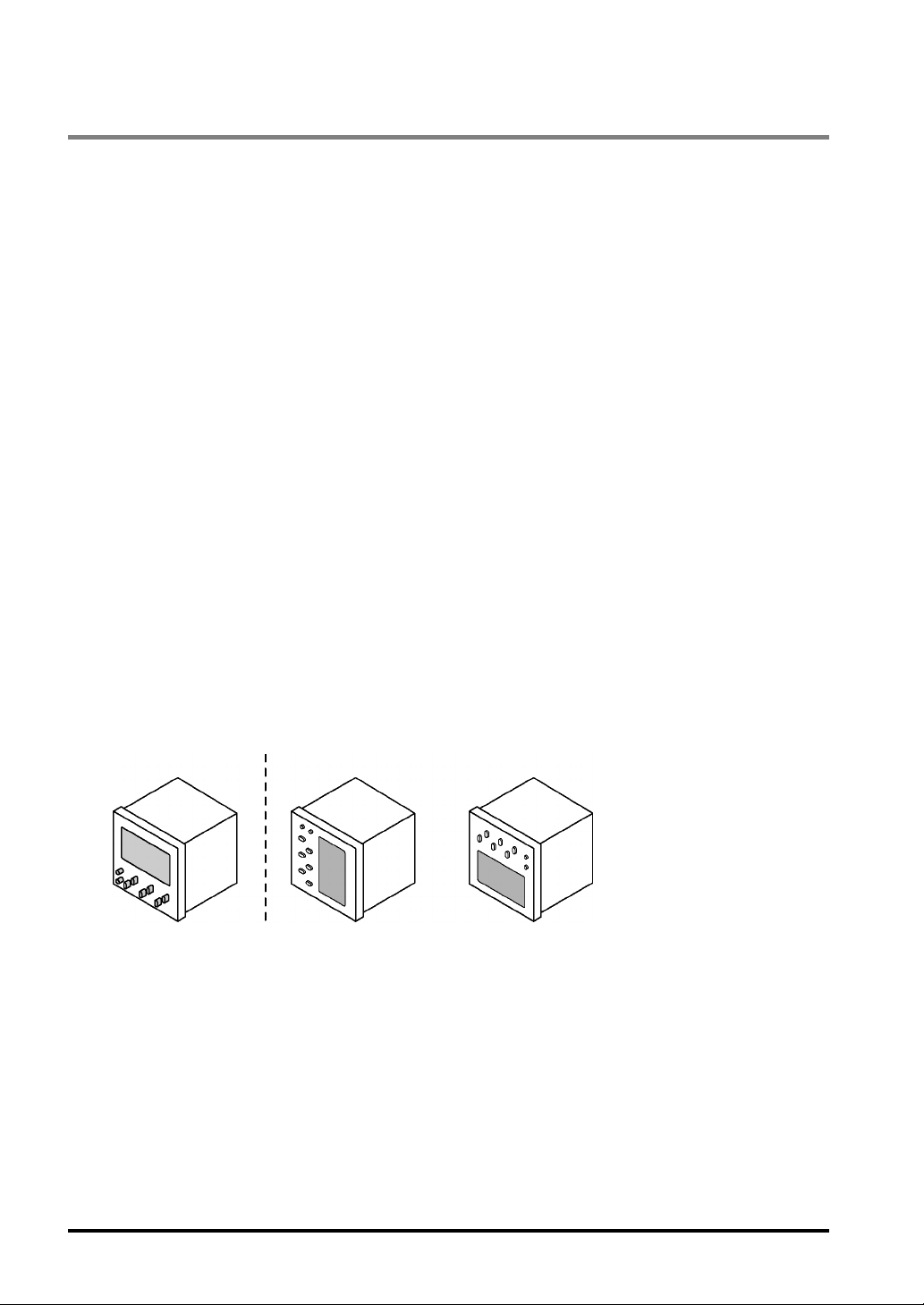

Countermeasure for Heat Radiation

When installing the operation unit (or the operation unit with finder unit), set the device in the following

direction for heat radiation.

Correct Wrong

20

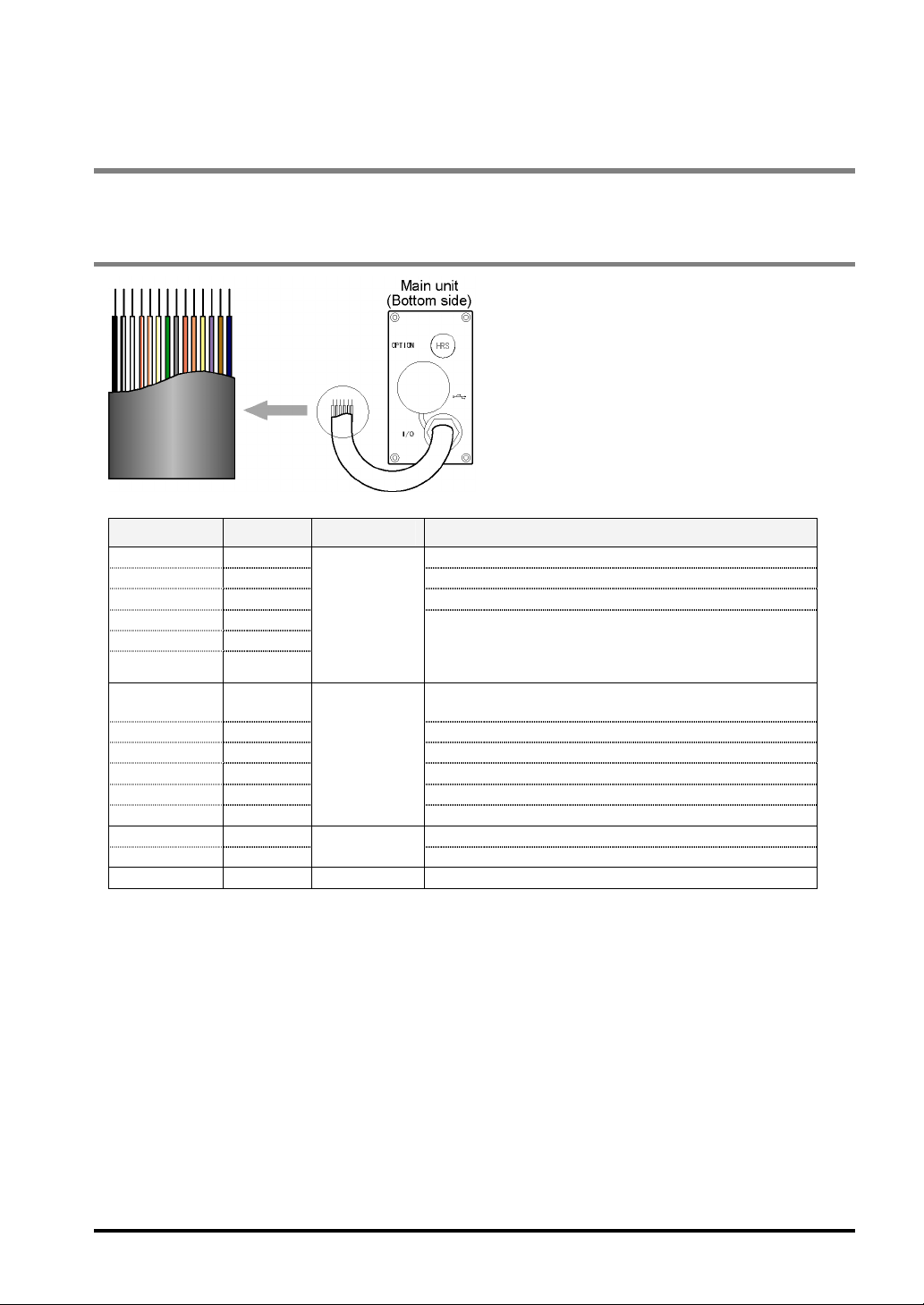

3.4 Input/Output Cables for Connecting Power Supply Unit or External Devices

The cables for connecting to the power supply unit or external devices are attached on the LightPixAE20.

3.4.1 Sequence of Input/Output Signals

Color Signal Input/Output Description

White COM (IN) COM for input

Red TRIGGER Read start signal

Gray TEACH Switching from TEACHING mode to RUN mode

Orange TYPE1

Yellow TYPE2

Purple TYPE3

White/ Black COM

(OUT)

Black READY Ready completion signal

White/Yellow ALARM Alarm signal

White/Brown OUT1 Judgement result output 1

White/Red OUT2 Judgement result output 2

White/Orange OUT3

Brown 24 V 24 V DC +

Blue GND

Frame F.E. - Functional earth

Input

Output

Power supply

Specifies product type number for switching product

types

(Binary input: Specify the number subtracted one from

the product number.)

COM for output

Judgement result output 3

24 V DC -

21

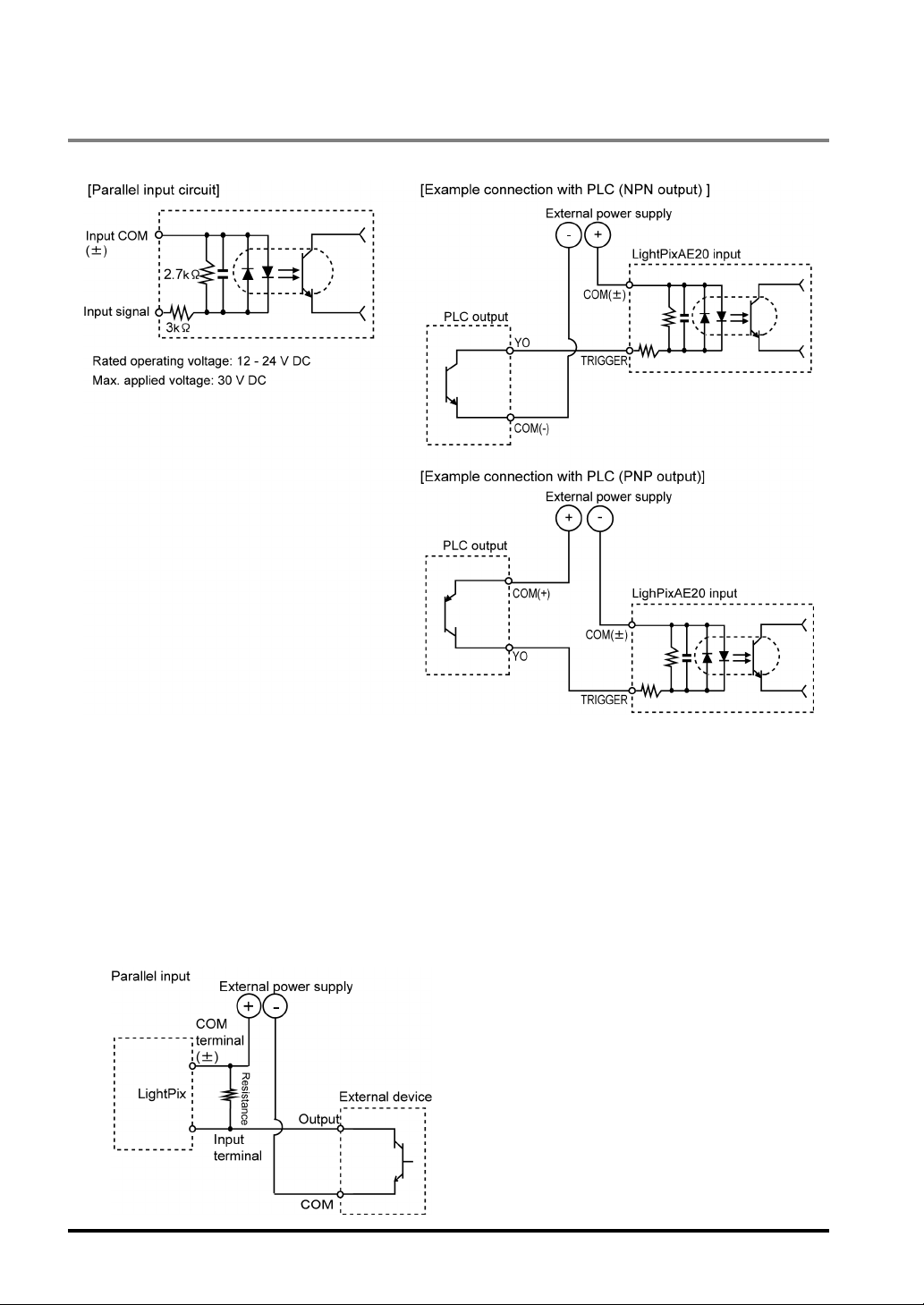

3.4.2 Input Signal

Circuit

Notes on Parallel Input

• To prevent input signal chattering, use a non-contact input (transistor etc.). If chattering occurs, inputs

may be missed or input recognition may be delayed.

• Be careful when using only full-wave rectification (including ripples) power supply for DC input, as it

may cause abnormal operation.

• Current leakage at the input side may not turn input off. In such as case, connect a resistor following

the figure below.

• If Input to the LightPixAE20 is not turned off due to current leakage when 2-line photoelectric sensor (or

proximity sensor) is used, connect a bleeder resistor.

• Even in cases where in-line LEDs such as LED reed switches are connected with an input contact

point, Voltage more than the ON voltage must be applied to the LightPixAE20 input terminal.

22

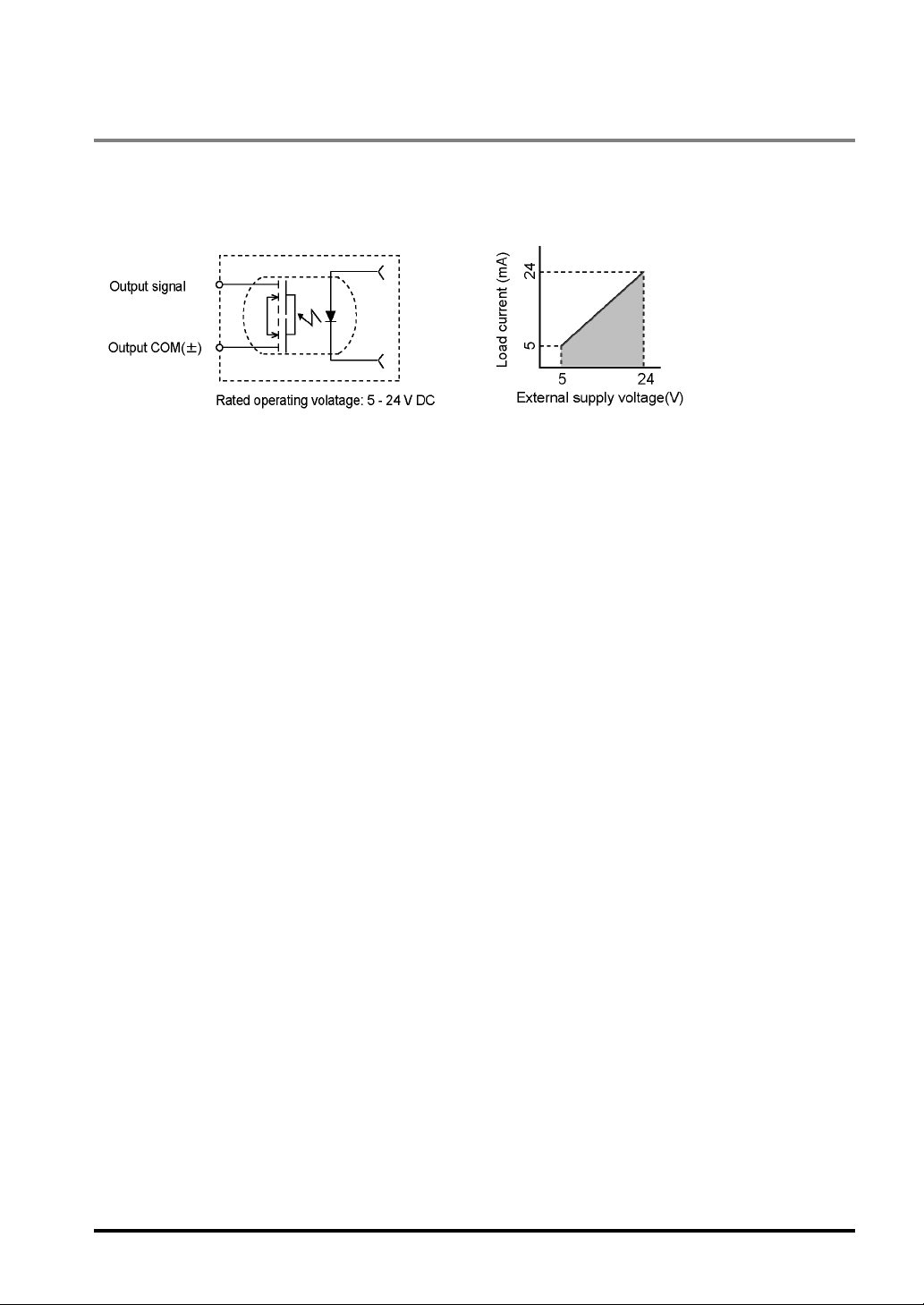

3.4.3 Output Signal

Circuit

Output part: PhotoMos relay

The output load should be within the specified range. See the figure shown below.

Notes on Parallel Output

• Leakage current at the time of output signal OFF is less than 100 µA.

• The LightPixAE20 has a low load capacity so that you can connect the LightPixAE20 to a PLC, etc. Do

not connect directly with a device having a high load capacity such as a valve without passing it through

our Power-Photo relay.

• The output circuit contains no built-in fuse. If it is necessary to prevent from burning out the output

circuit in the event of output load short circuit, mount a fuse externally. However, it may not be able to

protect internal elements in the event of short circuit.

23

Loading...

Loading...