Page 1

AHR5

11/2002

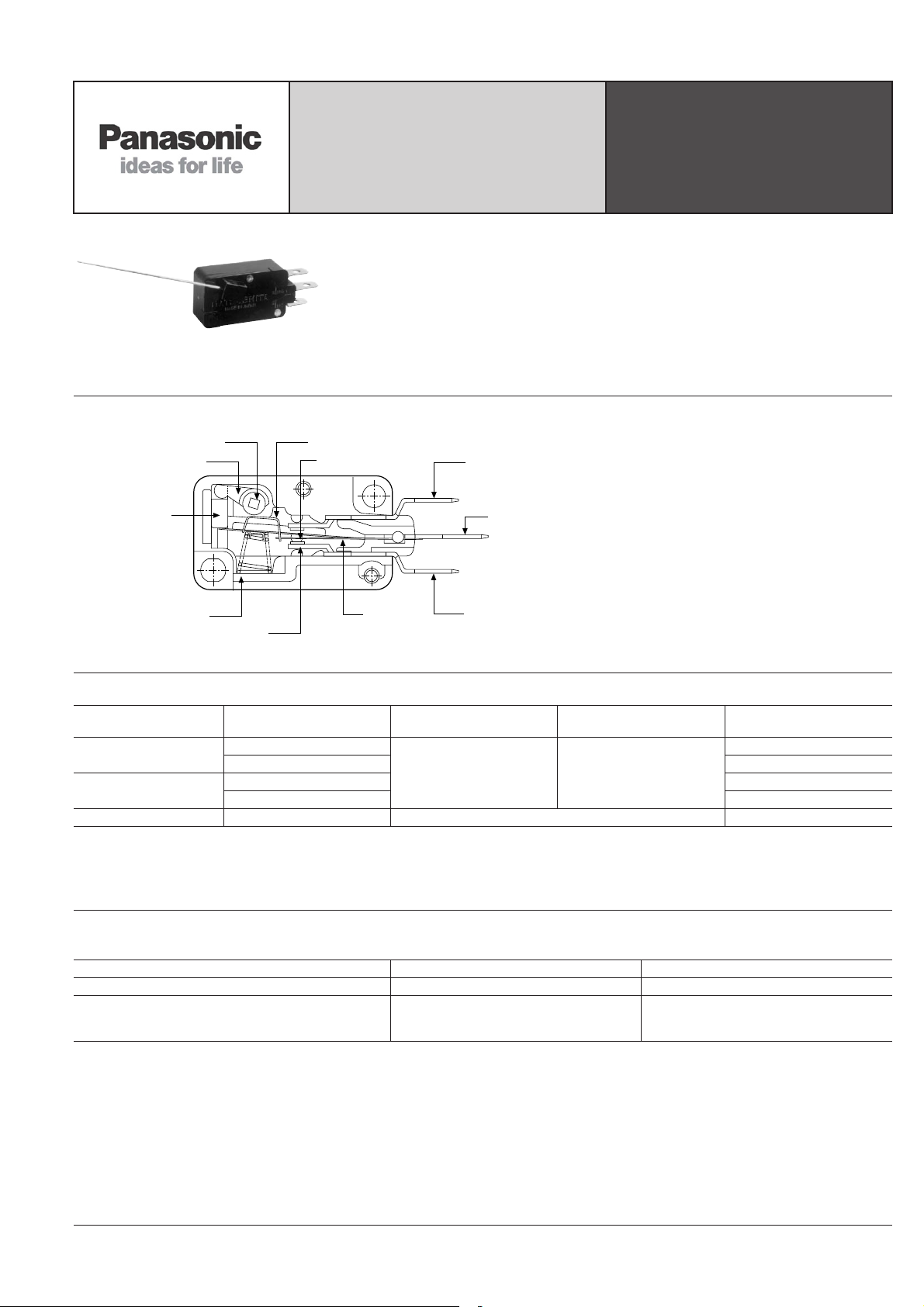

The AHR5 switch with actuating

lever and retainer assembled

CONSTRUCTION

Rotating

shaft

Handle

Pin

plunger

HIGH CONTACT PRESSURE

WITH LIGHT OPERATING

ACTION

FEATURES

• High contact pressure with light operating action

• Easy installation of the lever—Tools

or adhesives are unnecessary for attaching the actuating lever

• Low-level circuit type is also available

Actuating spring

Movable contact

Solder and

Q.C. (187)

N.O. terminal

Common

terminal

V-ROTARY

ACTION (AHR5)

SWITCHES

TYPICAL

APPLICATIONS

• Vending machines

Restoration

spring

Stationary

contact

Operating spring

N.C. terminal

PRODUCT TYPES

Type Retainer mounting direction Operating force (max.) Release force (min.)

Standard (Silver alloy)

Low-level circuit type

(Gold clad)

Actuator lever 52.3mm 2.059inch — AHR5801

Remarks: 1. The retainer is provided with the switch body without assembled.

2. Actuating levers are available separately.

(AHR5801, length: 52.3mm 2.059inch)

3. As for International standard, please refer to the “Information”.

Counter-clockwise

Clockwise AHR5411

Counter-clockwise AHR540161

Clockwise AHR541161

0.1N•cm {10.2gf•cm} 0.013N•cm {1.3gf•cm}

SPDT .187 Quick-connect/

solder terminal

AHR5401

SPECIFICATIONS

1. Contact rating (Resistive load)

Type Standard rating Low-level rating

Standard (Silver alloy) 5A 250V AC

Low-level circuit type (Gold clad) 1A 250V AC

6V DC 5mA

12V DC 2mA

24V DC 1mA

75

Page 2

AHR5

11/2002

2. Characteristics

Type Standard type Low-level circuit type

Expected life

(min. operations)

Mechanical (at O.T. rated)

Electrical (at O.T. max.)

Insulation resistance Min. 100MΩ (at 500V DC insulation resistor meter)

Between terminals 600 Vrms for 1 min.

Between terminals and

Dielectric strength

other exposed metal parts

Between terminals and

ground

Contact resistance (initial)

(by voltage drop at 1A 6 to 8V DC)

Max. 50mΩ

Vibration resistance (pin plunger) 10 to 55 Hz at amplitude 0.75mm (Contact opening: max. 1msec.)

Shock resistance (pin plunger)

Allowable operating speed 1 to 100°/sec.

Max. operating cycle rate 240

Ambient temperature –25°C to +65°C –13°F to +149°F (no freezing below 0°C)

Ambient humidity Max. 85% R.H.

Unit weight 7g .25oz

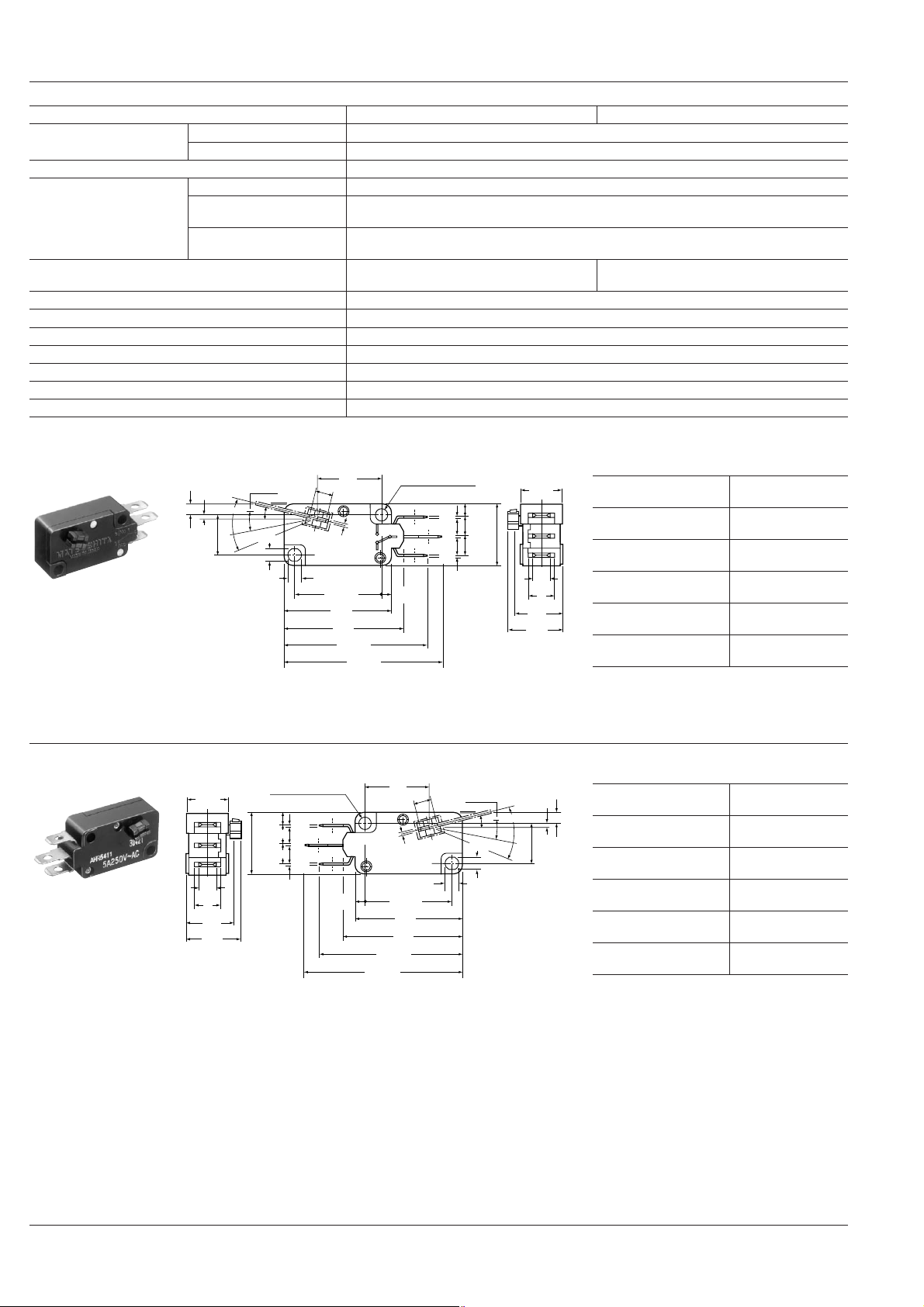

DIMENSIONS

(Counterclockwise)

2.8

.110

10.3

.406

1.0

.039

±0.1

±.004

P.T.

25° max.

M.D.

15° max.

F.P.15°

O.T.13° min

+0.25

3.1

–0.05

+.010

.122

–.002

16.6

.654

4.6

±5°

.181

NO

0.75

.030

2

±0.15

3.4

±.006

.134

±0.1

22.2

±.004

.874

27.8

1.095

31

1.221

±0.8

37

±.032

1.457

±0.8

41

±.032

1.614

+0.25

3.1 DIA. HOLE

–0.05

+.010

.122 DIA. HOLE

–.002

1

3

NC

2.8

.110

.020

.020

.020

±0.8

2.9

±.032

.114

0.5

±0.8

5.2

±.032

.205

0.5

±0.8

5.2

±.032

.205

0.5

15.9

.626

6

10

(at 60 cpm)

4

(at 20 cpm)

5 × 10

2,000 Vrms for 1 min.

2,000 Vrms for 1 min.

(by voltage drop at 0.1A 6 to 8V DC)

2

294m/s

{30G}

10.3

.406

Operating force, Max.

(Initial value)

Release force, Min.

(Initial value)

Pretravel

(Initial value)

Movement differential

(Initial value)

Overtravel

(Initial value)

Free position

.236

11.7

.461

13.7

.539

4.75

.187

6

(Initial value)

Max. 50mΩ

mm inch TORERANCE: ±0.4 ±.016

15°±5° (From the

horizontal axis)

0.1 N·cm

{10.2 g·cm}

0.013 N·cm

{1.3g·cm}

25° max.

15° max.

13° min.

(Clockwise)

10.3

.406

4.75

.187

.236

11.7

.461

13.7

.539

+0.25

3.1 DIA. HOLE

–0.05

+.010

.122 DIA. HOLE

–.002

±0.8

2.9

±.032

.114

0.5

±0.8

.020

5.2

±.032

.205

0.5

±0.8

.020

5.2

±.032

.205

0.5

15.9

.626

6

.020

.110

2.8

41

1.614

37

1.457

±0.8

16.6

.654

22.2

.874

1.221

±.032

4.6

.181

0.75

.030

.134

27.8

1.095

31

±0.8

±.032

10.3

.406

1.0

.039

2.8

.110

Operating force, Max.

(Initial value)

Release force, Min.

±0.1

±.004

(Initial value)

Pretravel

(Initial value)

Movement differential

(Initial value)

Overtravel

(Initial value)

Free position

(Initial value)

0.1 N·cm

{10.2 g·cm}

0.013 N·cm

{1.3g·cm}

25° max.

15° max.

13° min.

15°±5° (From the

horizontal axis)

M.D.

15° max.

±5°

F.P.15°

±0.15

3.4

±.006

±0.1

±.004

O.T.13° min

+0.25

3.1

–0.05

+.010

.122

–.002

P.T. 25° max.

76

Page 3

NOTES

11/2002

1. Method of attaching actuating lever

Insert tha lever in the rotating spindle,

then place the retainer over the spindle to

lock the lever in place as shown in Fig. 1.

Be sure that the retainer has snapped

over the lugs on the rotating spindle, with

the lugs entering fully into the holes in the

retainer.

Retainer

Hole (2 places)

Actuating lever

Rotating spindle

Lug section (2 places)

2. Regarding the actuating lever

As an accessory, the standard lever

(Product No. AHR5801) is available separately.

0.7 DIA. .028 DIA.

Stainless steel

90°

Standard lever

AHR5801

Less than

0.5R

.020R

1.2±0.2

.047±.008

52.3

2.059

At time of mounting,

50 mm from center of rotating spindle

3. Cautions regarding design of actuating lever

The dimensions of the lever at the mounting section are as shown in Fig. 2. These

dimensions should be used in the design

of an alternate actuating lever. The material can be stainless steel wire or piano

wire. The standard lever length is 50 mm

1.969 inch. A lever in excess of this length

would have a weight which could cause

erroneous operation.

d = 0.7±0.015 DIA.

d = .028±.001 DIA.

AHR5

4. Regarding switch mounting

Mount the switch to a smooth surface using M3 screws. Tighten the screw with 3 to

5 kg-cm torque. To prevent loosening of

the mounting screws, it is recommended

that spring washers be used in combination with adhesive material for locking the

screws.

In the mounted condition, the insulating

distance between each terminal and

ground should be checked for assurance

of proper distance.

5. Regarding changes in operating

characteristics

When selecting the V rotary action switch,

allow ±20% to the rated operating and release forces.

(Example)

OF: 10.2 g-cm max. specification

10.2 × (100+20%) = 12.24 g-cm

RF: 1.3 g-cm min. specification

1.3 g-cm × (100–20%) = 1.04 g-cm

6. Adjustment of the operating object

The positioning of the operating object

should be such that when direct force is

not applied to the actuator, the actuator is

in its free position. The operating object

should apply force in the operating direction. The standard value of overtravel to

be used should be set within the range of

70% to 100% of the rated O.T. value. Furthermore, if the operating position limit is

exceeded, the electrical and mechanical

life of the switch will be shortened.

7. Avoid using V Rotary switches in the

following conditions:

• Where the ambient temperature exceeds the range of –25°C to +65°C –13°F

to +149°F.

• Where the relative humidity exceeds

85%.

• Where the permissible operating speed

of 1 to 100°/sec. is exceed.

• Where the operating speed of 240 cpm.

is exceeded.

• Where the lever length of 50mm

1.969inch is exceeded.

77

Loading...

Loading...