Panasonic 103 inch plasma Training Manual

103

Panasonic Service and Technology Company

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Technical Guide

103” Plasma Display Monitor

National Training

103

Panasonic Service and Technology Company

Prepared by

Jean Magloire

Panasonic Service and Technology Company

National Training

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Copyright © 2005 by Panasonic Services Company

All rights reserved. Unauthorized copying and distribution is a violation of law.

Warning

This service information is designed for experienced repair technicians only and is not designed for use by the

general public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers

in attempting to service a product. Products powered by electricity should be serviced or repaired only by

experienced professional technicians. Any attempt to service or repair the product or products dealt with in this

service information by anyone else could result in serious injury or death.

103

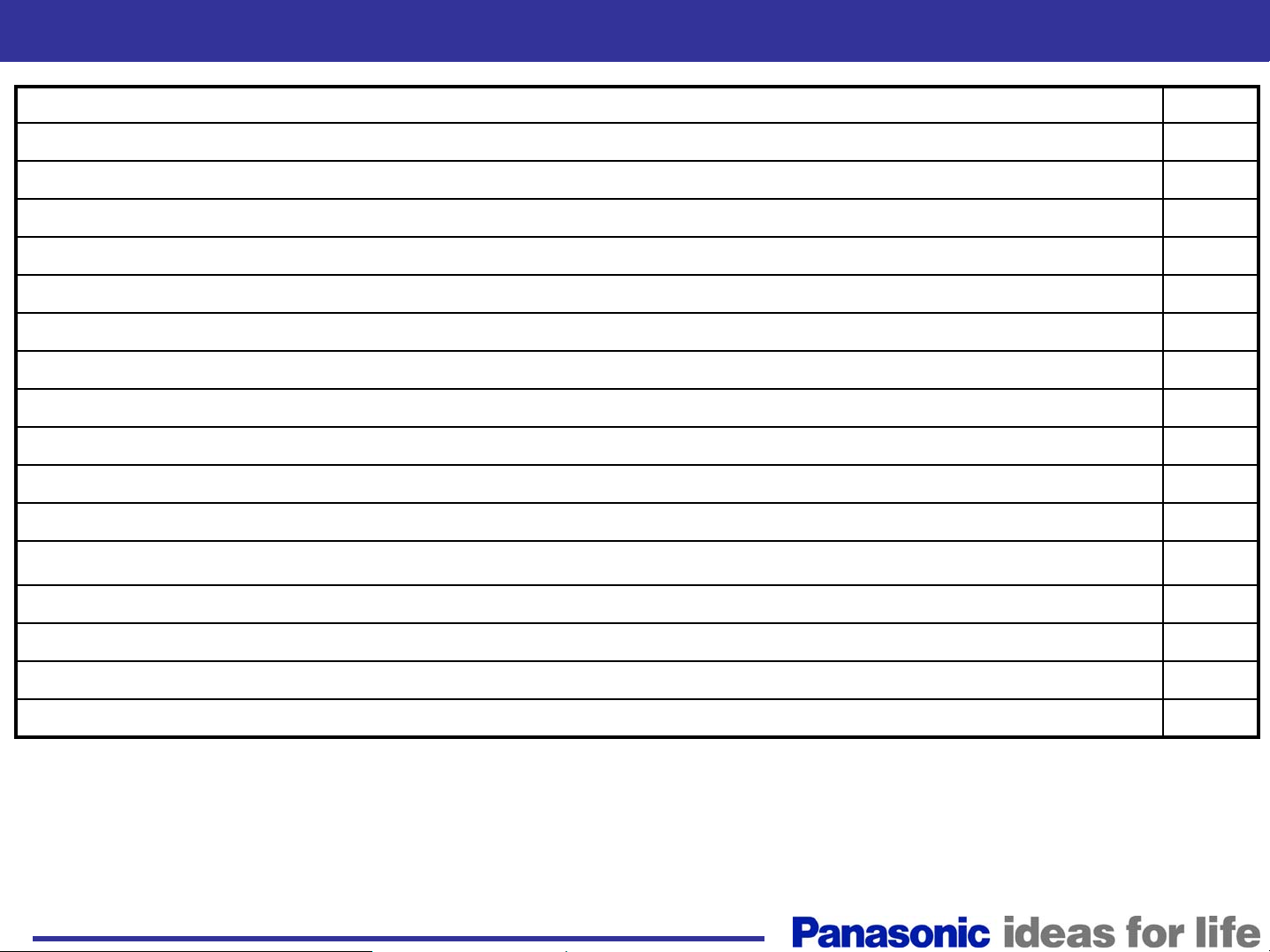

Table of Contents

Subject Page # Subject Page #

Specifications 5 Simplified Block Diagram 36

Installation and Construction 7 Picture signal flow 38

Preparation of Installation using Pedestal Stand 8 Panel Drive (Basic Circuit) 40

Electrical Work 9 Panel Drive 42

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Drawing of Installation with Pedestal Stand 10

Pictures of Installation with Pedestal Stand 11

Pictures of Plasma unit and Eye bolts 12

Pictures of Eyebolt Cap unit and Power Inlet 13

Pictures of Stand Hook and Location for Eyebolt 14

Rear Panel and Vertical Installation 15

Wall Mount Installation 16

Pedestal Stand (TY-ST103PF9) 18

Preparation 19

Wall Hanging Bracket (Horizontal) Building Frame Size 20

103 Plasma Service Support 21

103 Servicing Requirements 22

103” PDP easy facts 25 P Board Circuit (Main Voltages) 77

Chassis structure 29 P Board Circuit (VSUS) 79

Back Covers 30

Troubleshooting for signal symptom

Relationship of board and display area

Picture Trouble

Picture trouble all area

Picture Trouble (Vertical line)

Power Supply Circuit Explanation

Power supply circuit (VDA and Low Voltages)

Power supply circuit (VSUS)

Line Filter

Power supply Circuit Block Diagram

PC Board Block Diagram

P Board Circuit (Standby Operation)

Voltage Distribution

47

48

50

57

59

61

62

64

65

66

69

71

81

Chassis Layout 32

Boards and Description 33

Signal Circuit Explanation 35

Protection Circuit

Panel SOS Circuit _ Power LED Blinks Table

Panel SOS Circuit _ Power LED Blinks 1~8 times

3

83

84

85

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Table of Contents (Continued)

Subject Page #

DS board SOS Circuit _ Power LED blinks 10 times

FAN SOS _ Power LED blinks 11 times

DN board SOS Power LED blinks 13 times

Alignment Procedure

Driver Setup

Driver Setup Voltages

Initialization Pulse Adjustment

Quick adjustment after P.C.B. Replacement

Adjustment Volume Location

Adjustment Test Point Location

How to Enter the Self-check Screen

How to Enter the CAT (Serviceman) Mode

How to Enter the IIC Mode 98

How to Access the pattern generator 99

86

87

88

89

90

91

92

93

94

95

96

97

How to Enter the CD Mode

How to enter the MS Mode

100

101

4

Specifications

Power Source 240 V AC, 50 / 60Hz

Power Consumption 1,500 W

103

103

Specifications

Professional Models

Professional Models

103FHD_USA 11OCT06

Plasma Display panel

Screen size 89.5” (2,269 mm) (W) × 50.5” (1,277 mm)

Mass (weight)

Resolution 1,920 horizontal x 1,080 vertical (1080P)

Contrast ratio 4000:1

Gradation

Drive method: AC type 103-inch, 16:9

aspect ratio

(H) × 103” (2,604 mm) (diagonal)

Approx. 500.0 lbs unpacked, 1000lbs

Crated

280 lbs for Pedestal mount,

55 lbs for wall mount

16-bit processing to produce 4,096 steps of

gradation

Signal Type

Slots Three interchangeable slots

1080/60p/50p, 1080/50i, 720/60p/50p,

480/60i/p, and 575/50i/p video signals

5

103

103

Intentionally left blank

Professional Models

Professional Models

103FHD_USA 11OCT06

6

Installation and Construction

Pedestal Stand

Pedestal Stand

Installation & Construction

Installation & Construction

- preparation

- electrical work

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

- installation procedure

- pedestal stand assembly

7

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Preparation of Installation using Pedestal Stand

Pedestal Stand (TY-ST103PF9)

1) The power source is to be 240V – 1550W

2) Floor strength is to be more than 500kg/m2(102.408lb/ft2). To avoid damaging the floor, prepare an

underlay board, more than 15mm (0.6”) thick and larger than the size of the bottom stand to disperse

load.

3) To prevent personal injury or damage on goods, the following measures must be taken.

* (1) Secure the Plasma by anchoring

* (2) Secure the Plasma to the wall by wires or chains. (against toppling)

* (3) (1)+(2) both

Keep the earthquake-resistance strength and right construction procedure.

4) Prepare two fixing points at the wall or building structure to prevent toppling.

(M10 anchor bolt, more than 45mm (2”) depth)

5) Prepare four fixing points for anchor bolts.

(M12 anchor bolt, more than 60mm (2.4”) depth)

6) Keep more than 300mm (11.8”) of open space from the top and both sides of the unit. Keep

more than 200mm (8”) from the rear cover of the Plasma for heat release.

7) For safety, more than 4 persons are recommended to do the work.

8) Prepare blankets or any soft fabric to prevent damaging the Plasma or the wall/floor

during this installation work.

9) The Plasma Monitor weighs 220kg (500lbs) and the Pedestal Stand 122kg (280lbs).

To perform the installation, a hanging appliance or machine (such as Chain-block) is

recommended.

10) Be careful not to tighten the bolts/screws too much or too little.

11) Perform the installation on a flat surface and follow the instruction of the manual.

8

103

103

Professional Models

Professional Models

Electrical Work

1) The power source for this plasma monitor is 240V-1550W.

Confirm that the source voltage is of the right level and capacity before installation.

(Electrical Work requires a licensed electrician)

2) The prepackaged power cable is 3m length.

3) Confirm the location of the power cord.

Do not allow the cable to be pinched between walls, forcedly bent, or

twisted. The wires within the cable should not be exposed or short-circuited to avoid

possible electrification and the start of a fire.

4) Separate the signal cables from the power cord.

103FHD_USA 11OCT06

AC cord (included as an accessory)

Plug: Volex VS205A (NEMA 6-15P)

9

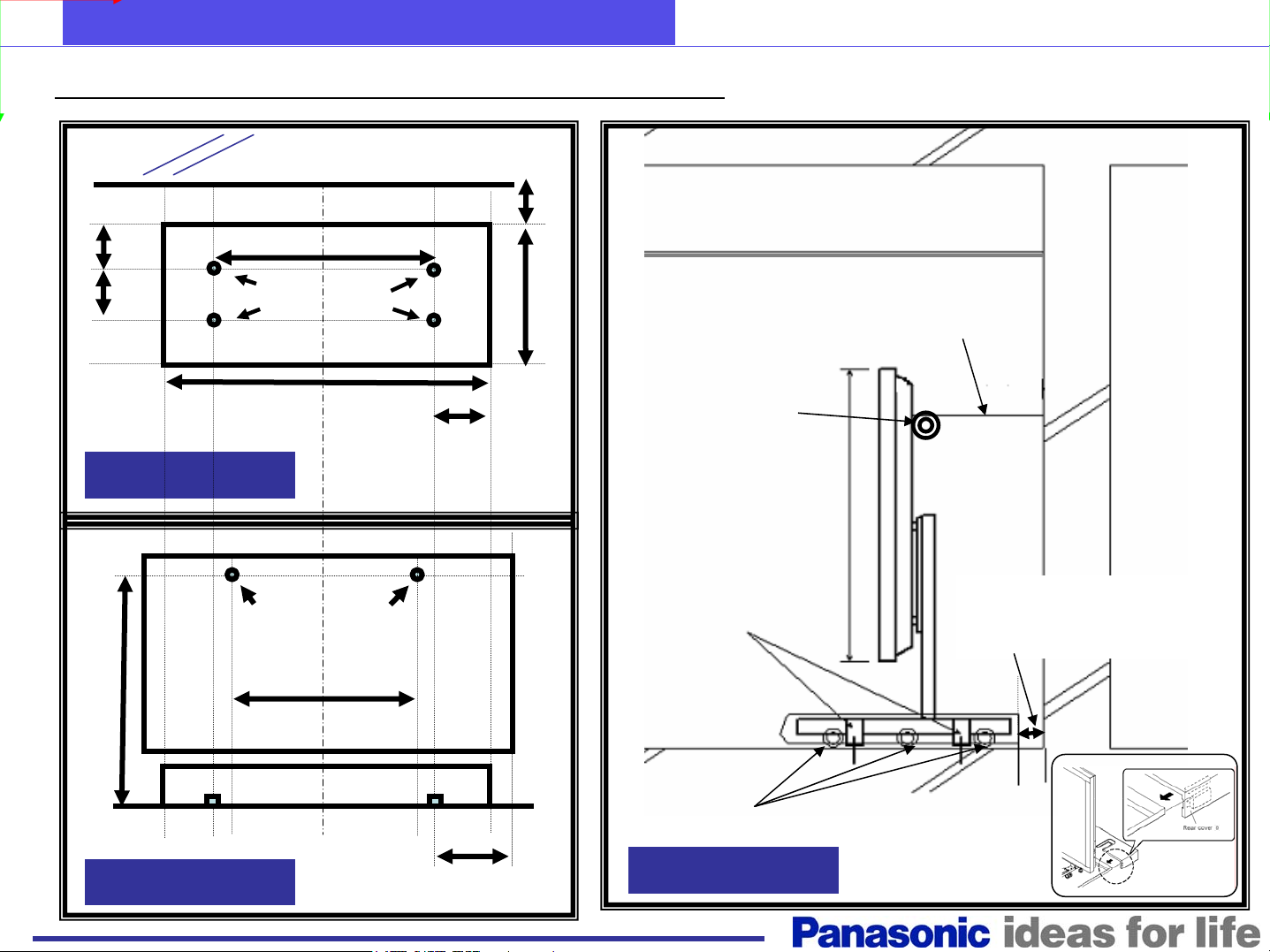

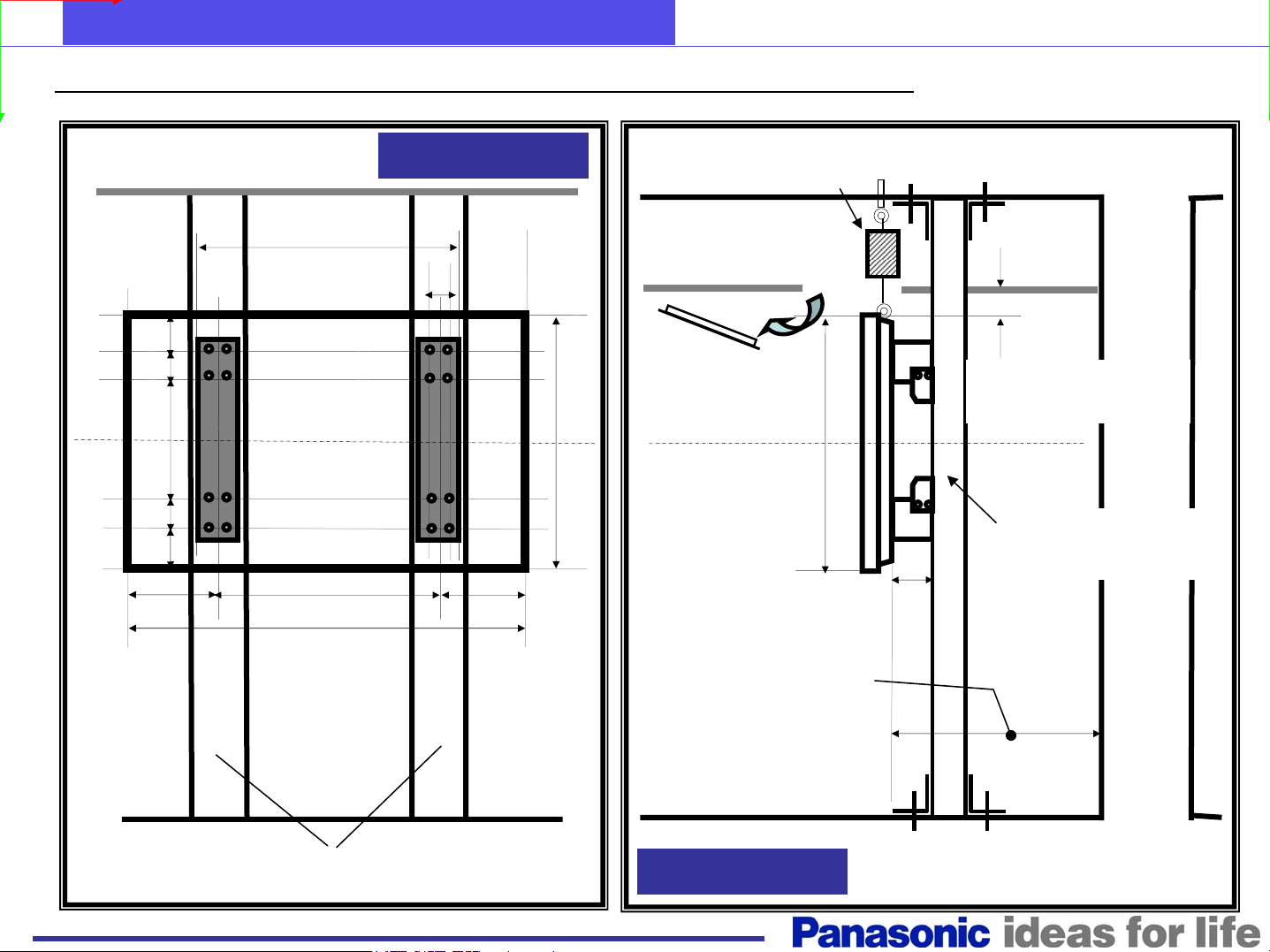

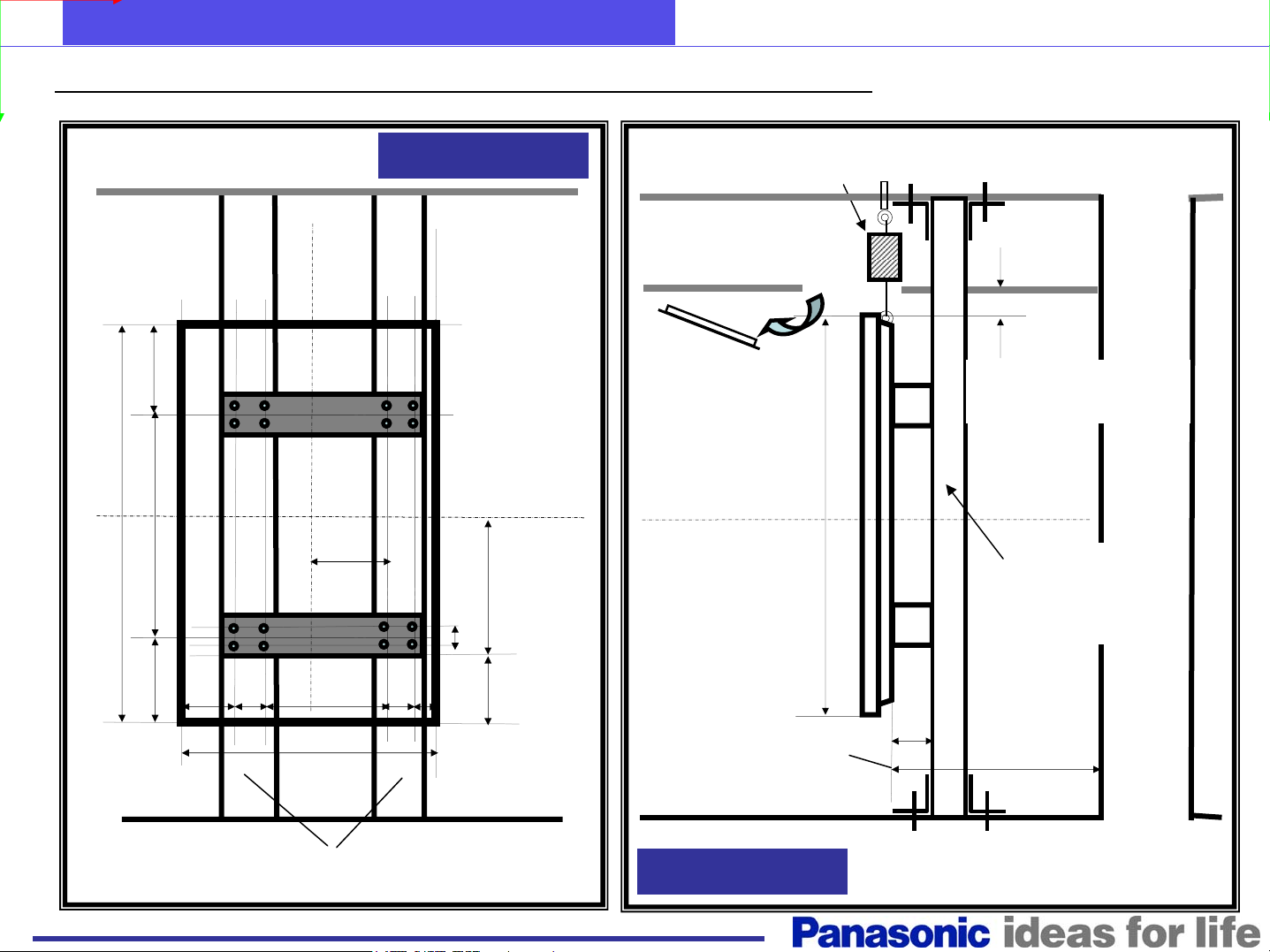

Drawing of Installation with Pedestal Stand

Wall

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

226

405

Aerial View

1,626.8

1,659.4

Anchor Bolts

2,270

Prevent toppling

1,512

305.3

120

870.2

Ceiling

Eyebolts

Anchor Bolts

Wire/chain to

prevent toppling

Wall

Keep 120mm space,

so the rear stand

cover can slide.

Front View

377.3

Floor

Wheels

Side View

10

103

103

Pictures of Installation with Pedestal Stand (1)

Professional Models

Professional Models

Lifting devices must have

enough strength to handle the

load.

103FHD_USA 11OCT06

Installing 103 plasma on the wallhanging bracket using a chain-block with

stand.

11

103

103

Pictures of Installation with Pedestal Stand (2)

Professional Models

Professional Models

103FHD_USA 11OCT06

Switches (Power etc.)

Eyebolt (top)

Ir receiver & LED indicator

12

Pictures of Plasma unit and Eye bolts)

Slot (Interchangeable terminal)

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

13

103

103

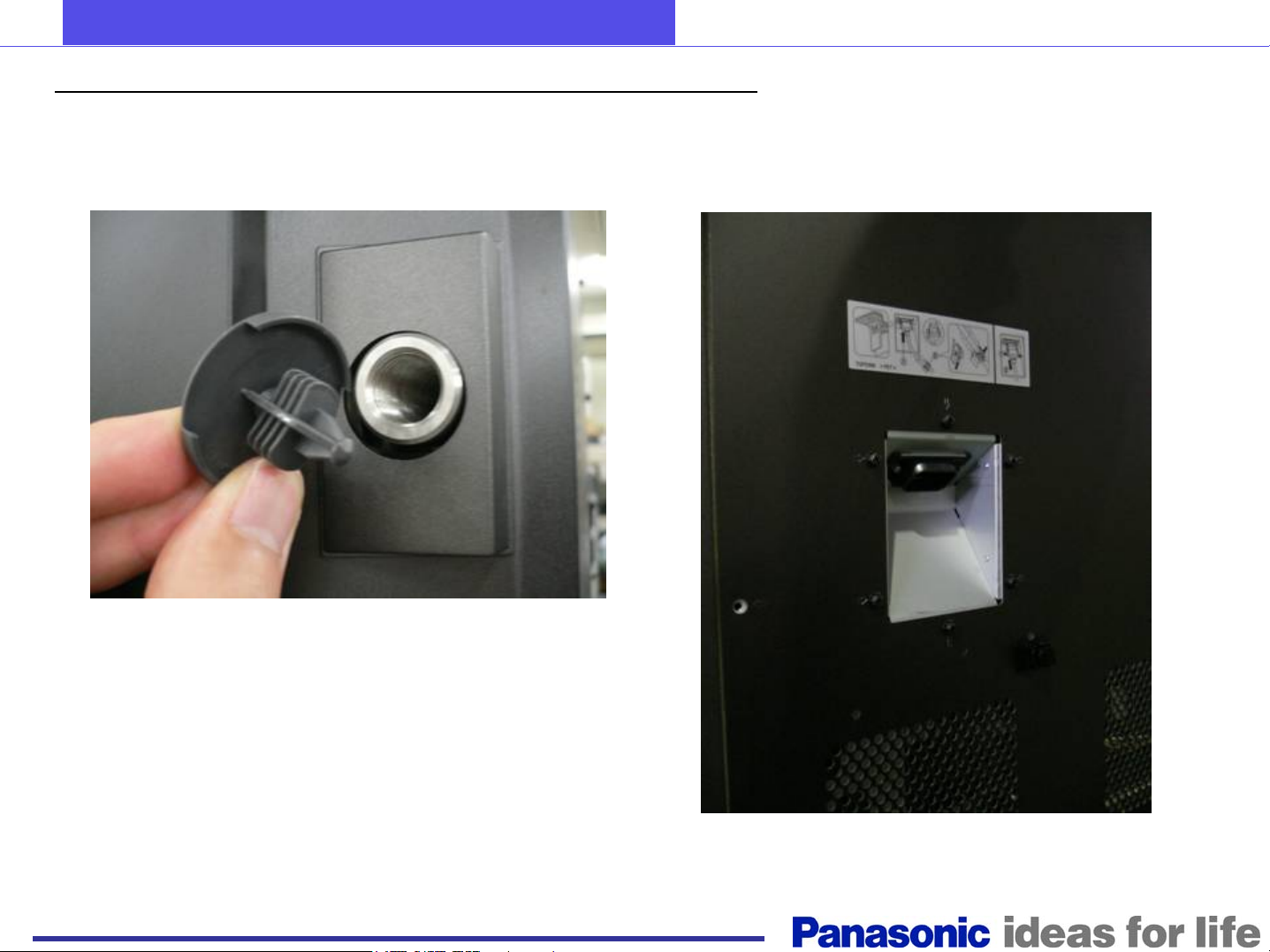

Pictures of Eyebolt Cap unit and Power Inlet)

Professional Models

Professional Models

103FHD_USA 11OCT06

Eyebolt cap (side)

Power inlet

14

103

103

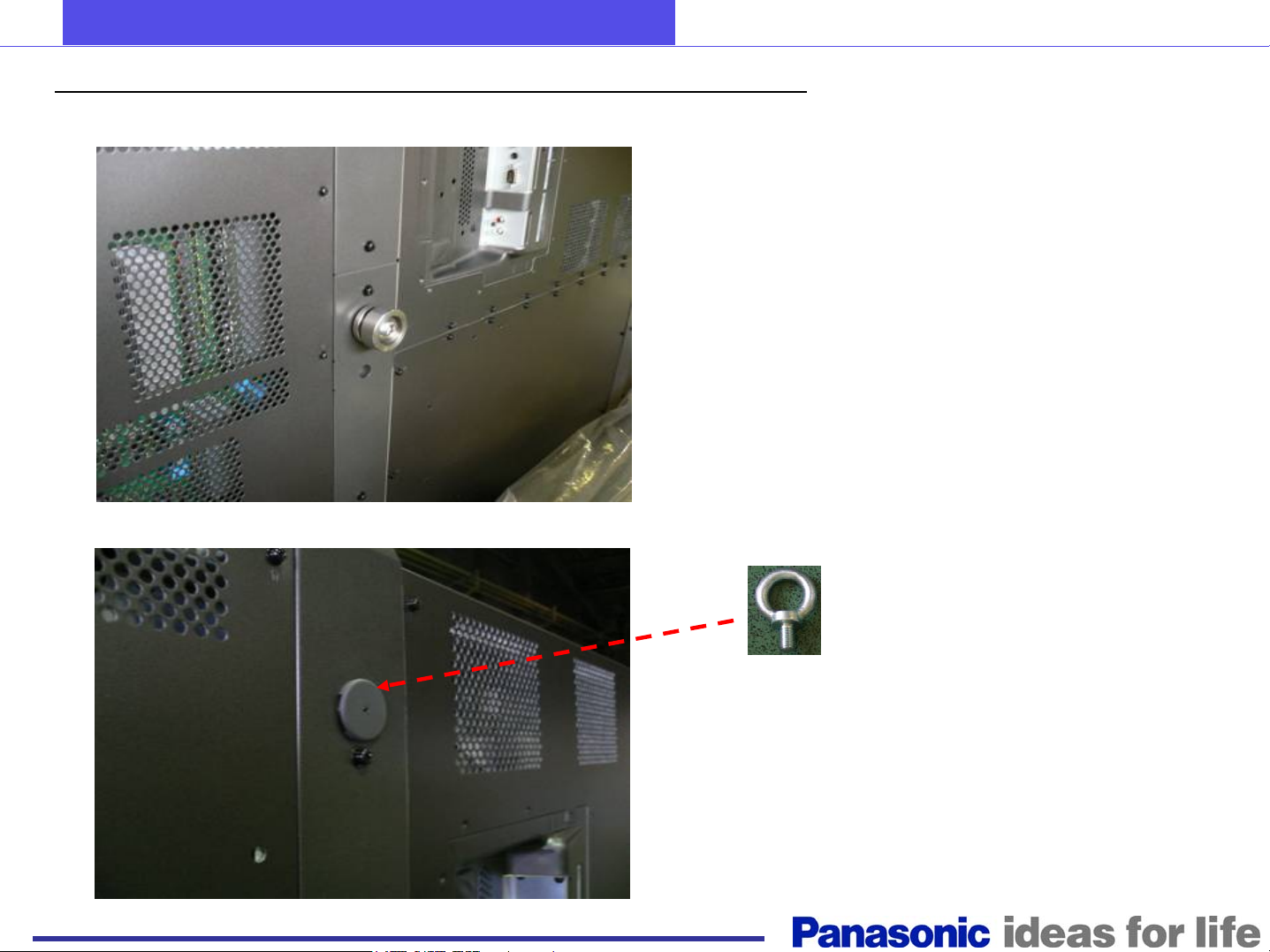

Pictures of Stand Hook and Location for Eyebolt

Stand-hook

Stand-hook position for Pedestal

(default)

Professional Models

Professional Models

103FHD_USA 11OCT06

Eyebolt can be fixed here

Stand-hook position for wall-hanging / anti-toppling

(default : sealed by eyebolt cap)

15

Rear Panel and Vertical Installation

Rear panel

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

This side will be the upper side when the unit is Installed vertically

(with exhaust fan)

16

Wall Mount Installation

Wall Mount Installation

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

17

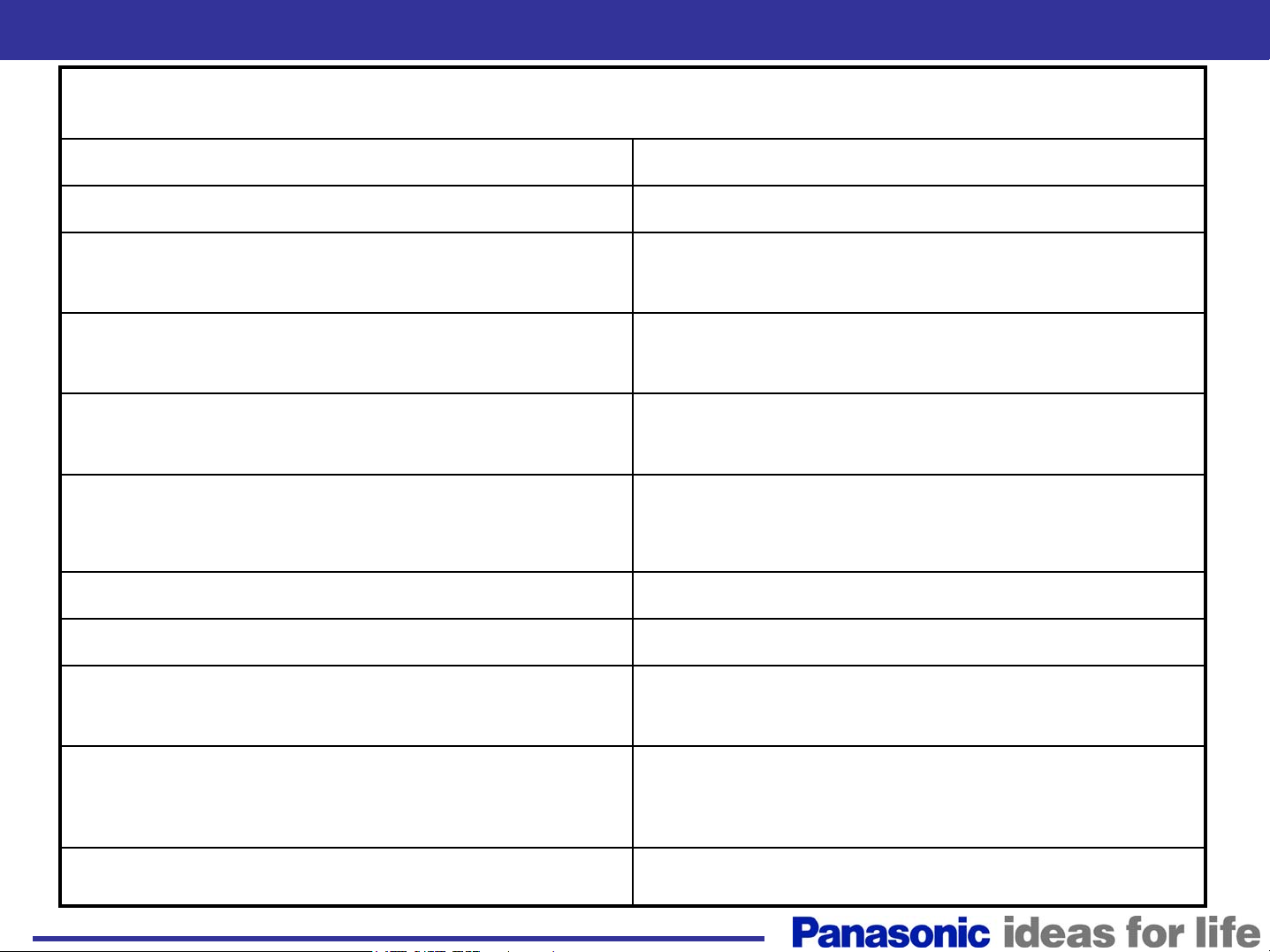

Pedestal Stand (TY-ST103PF9)

103

103

Professional Models

Professional Models

Horizontal Installation

103FHD_USA 11OCT06

18

Vertical Installation

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Preparation

1) Power requirement is 240V-1550W. (refer : “Electrical Work”)

2) Keep more than 300mm of empty space from the top and both sides of the unit. Keep

more than 200mm from the rear cover of the Plasma to maintain the ambient

temperature at 40 degree C or less. Moreover, it is recommended to keep more than

700mm maintenance space at the backside.

3) Do not install the Plasma monitor in an environment that may cause troubles and

problems to its performance.

- near the sprinkler and any sensor

- where it could receive vibration and shock

- near a high voltage cable and power source

- near a source that provides magnetic field, heat, moisture, oily smoke, etc.

- where it can receive the air (exhaust) of a fan or a heater (to prevent dust accumulation)

4) Use appropriate construction methods to select the materials for the construction of the

installation structure.

5) For wall fixing, use M12 x 80mm bolt (or equivalent, commercially available) which is

appropriate to the construction materials (reinforcing steel, concrete and etc.)

7) Tolerance ;

- Wall surface i rregularity : 1.5mm

- Pitch tolerance > horizontal installation: +/-1.0mm left/right, +/- 2.0mm top/bottom

> vertical installation : +/-2.0mm left/right, +/- 1.0mm top/bottom

19

103

103

Professional Models

Professional Models

Wall Hanging Bracket (Horizontal) Building Frame Size

103FHD_USA 11OCT06

Ceiling

113.1

200

733

200

175.1

451.1

1706

1512

2414.2

Front View

120

451.1

1421.2

Winch or chain block

only when maintenance is offered

Wall

Ceiling

Access Hole

Keep 300mm space

for ventilation

1421

Iron structure

(H-frame etc.)

200

Maintenance space

more than 700mm

Iron structure (H-frame etc.)

Floor

Floor

Side View

20

103

103

Professional Models

Professional Models

Wall Hanging Bracket (Vertical) Building Frame Size

103FHD_USA 11OCT06

451.1

1,521

2,414.2

224

Front View

849

120

Winch or chain block

only when maintenance is offered

Ceiling

Access Hole

2414

Wall

Keep 300mm space

for ventilation

Iron structure

(H-frame

etc.)

451.1

225.1

200

733

1421.2

200

63.1

Iron structure (H-frame etc.)

357.1

Floor

200

Maintenance space

more than 700mm

Floor

Side View

21

103

103

Professional Models

Professional Models

103 Servicing Requirements

• ON- Site Service

• Panasonic Broadcast Field Engineers

• Migrate to additional servicing facilities

• Free Access to back of plasma

103FHD_USA 11OCT06

– 24-36 inches access

– Includes power up access

22

103

103

Professional Models

Professional Models

Servicing Requirements (1)

103FHD_USA 11OCT06

23

103

103

Professional Models

Professional Models

Servicing Requirements (2)

F

A

103FHD_USA 11OCT06

F

A

N

S

N

S

Vents along perimeter

24

103” PDP easy facts (1 of 3)

Specifications:

Weight : 500 lbs unpacked

1,000 lbs crated

280 lbs for Pedestal mount, 55 lbs for wall mount

Size: 95” x 56”

Power: 220V AC +/- 10% single phase, 9 ft long power cord

1,550 W

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Vertical Installation: Panasonic logo on the left side

Choice of pedestal or wall mount

Ventilation: factory recommends clearance:

- 12” top and both sides

- 8” back

For wall mount installations: the supporting structure should

support 5 x total weight = 5x 555 lbs = 2,575 lbs

25

103” PDP easy facts (2 of 3)

Delivery and Installation:

Panasonic will ship the PDP using NVC Logistics company

We recommend that NVC will provide the following services:

-site survey for delivery purposes

-Delivery, uncrate, dispose of crating materials

-Transport the PDP to mounting location

-Test PDP for functionality

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

-Install PDP on pedestal (not on wall mount)

Wall mount or custom installations:

We recommend that the System Integrator, that reinforces the

structure, be responsible for mounting the wall mounts and

installation of the PDP.

26

103” PDP easy facts (3 of 3)

Delivery and Installation Pricing:

-DSM/Rep to fill in attached questionnaire detailing level of Service

requested, and email to Steve Beck, copy Theodore Radu

-Steve Beck will then provide a quote for delivery/Installation

-From Customer’s prospective: it is a Panasonic charge labeled as Freight

-Panasonic and NVC do not take any responsibility for reinforcing the

structure (wall or floor)

103

103

Professional Models

Professional Models

103FHD_USA 11OCT06

Recommended action for wall/custom installations:

-The System Integrator is responsible for reinforcing the structure,

mounting the equipment and billing the customer

-The customer will select the Integrator

-If no preferences please email Blue Water Technologies:

Linda Cronowirth at LCronowirth@visual-productions.com

27

, copy T.Radu

103

103

Intentionally left blank

Professional Models

Professional Models

103FHD_USA 11OCT06

28

103

103

Professional Models

Professional Models

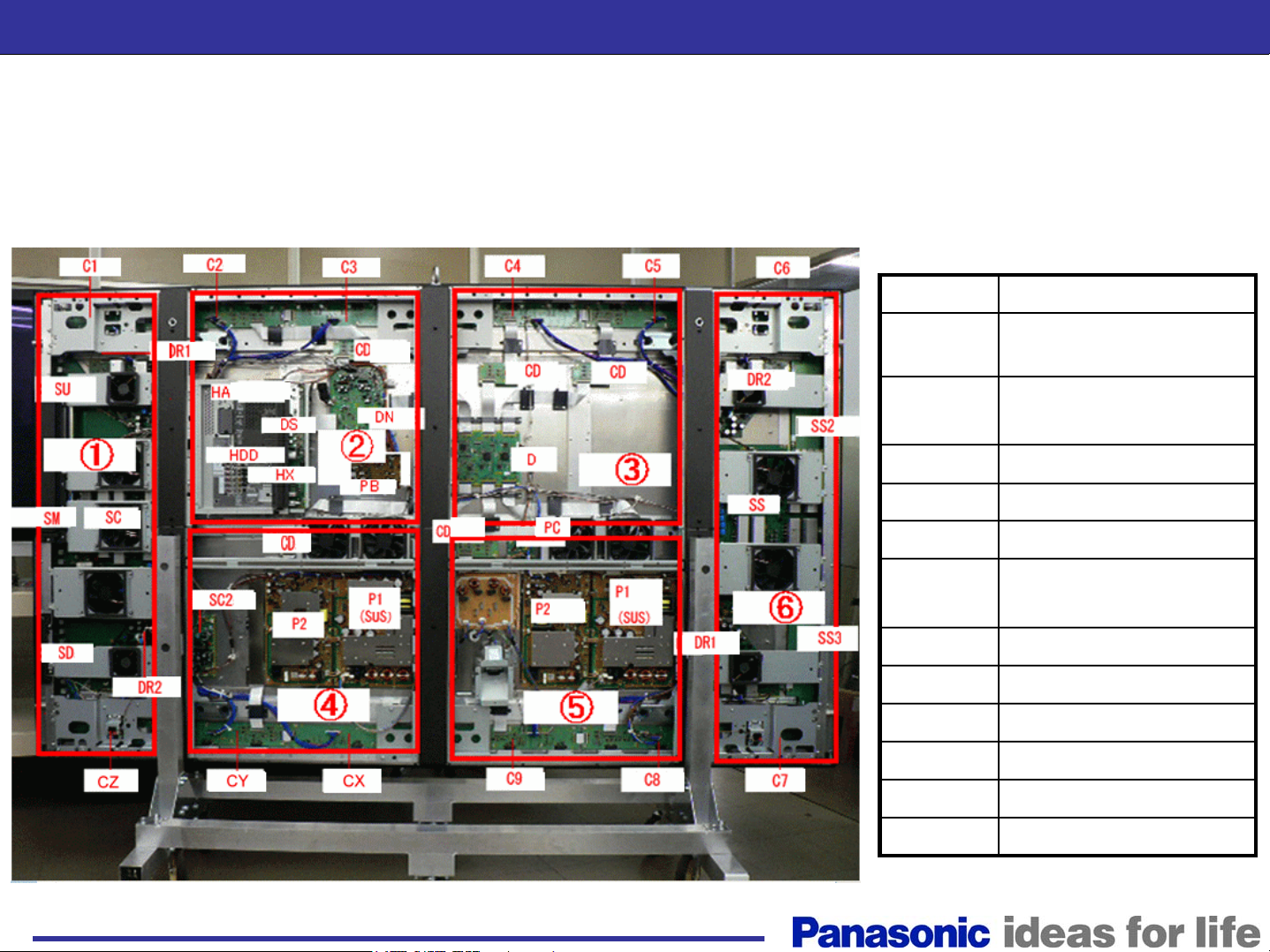

Chassis structure

103FHD_USA 11OCT06

29

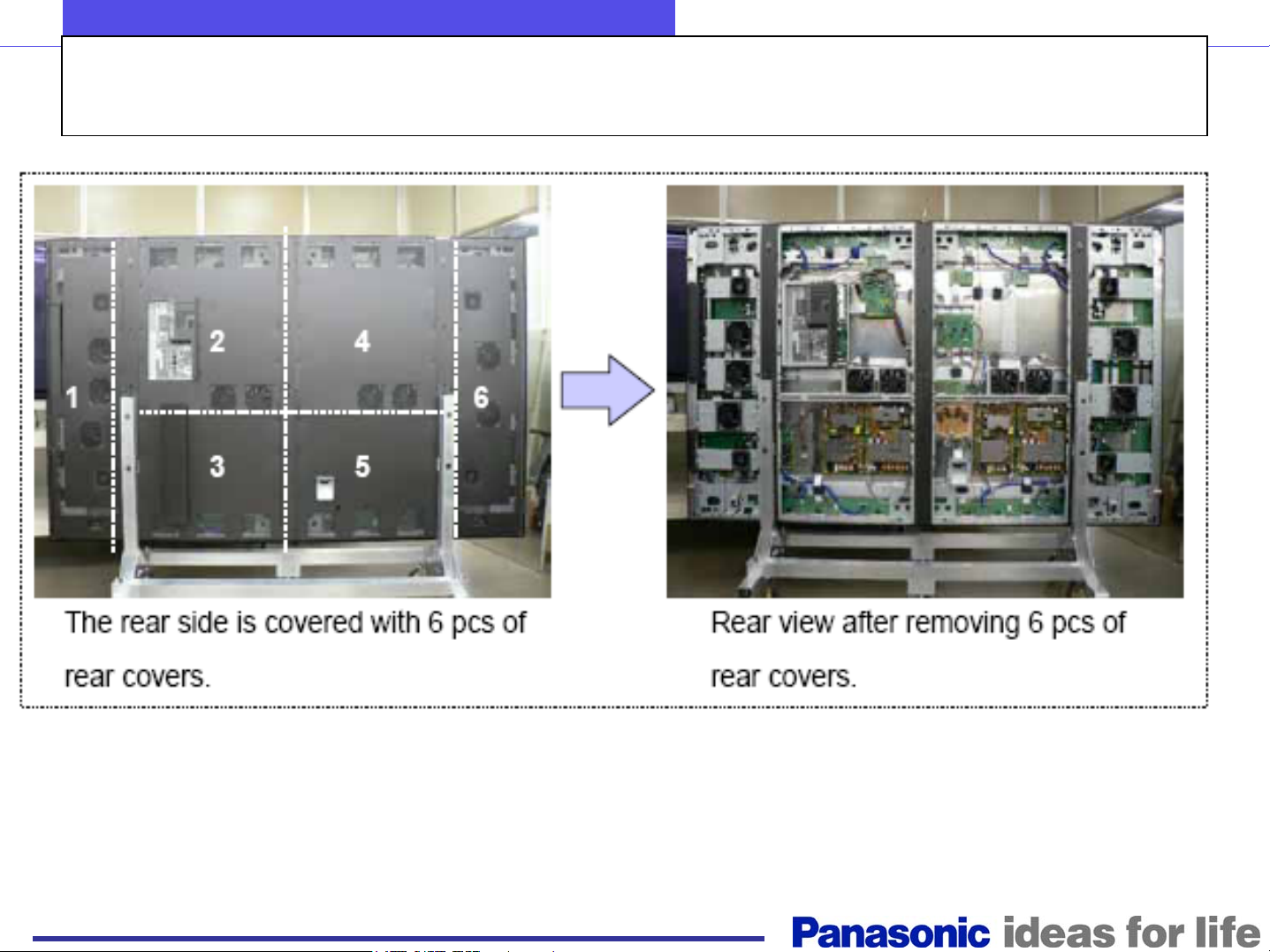

Back Covers

103

103

Professional Models

Professional Models

The unit contains 6 back covers that provide access to

different areas of the board assembly.

Zone Board

103FHD_USA 11OCT06

①

② PB, DS, HX, HA, DN

③ D, CD×2, C4

④ P, CX

⑤ P, F, C9

⑥ SS, SS2, SS3, DR1/2

②+④ FAN, CD

③+⑤ FAN, CD, PC

①+② C2

③+⑥ C5

①+④ CY, SC2

⑤+⑥ C8

SC, DR1/2, SU, SM, SD

C1, CZ, FAN

HDD, CD, C3

C6, C7, FAN

30

Loading...

Loading...