Panasoic SC HM810, HM910 Service Manual

RQZM0167

Service Manual

MODEL

SC-HM910

SC-HM810

Control

remoto

UNIT

SA-HM910 Stereo

SB-HM910 Front Speaker

SB-PS810 Surround Speaker

SA-HM810 Stereo

SB-HM810 Front Speaker

SB-PS810 SB-PS810

SB-HM910 SB-HM910

SA-HM910

Control

remoto

Stereo system

SC-HM910

SC-HM810

SB-HM810 SB-HM810

SA-HM810

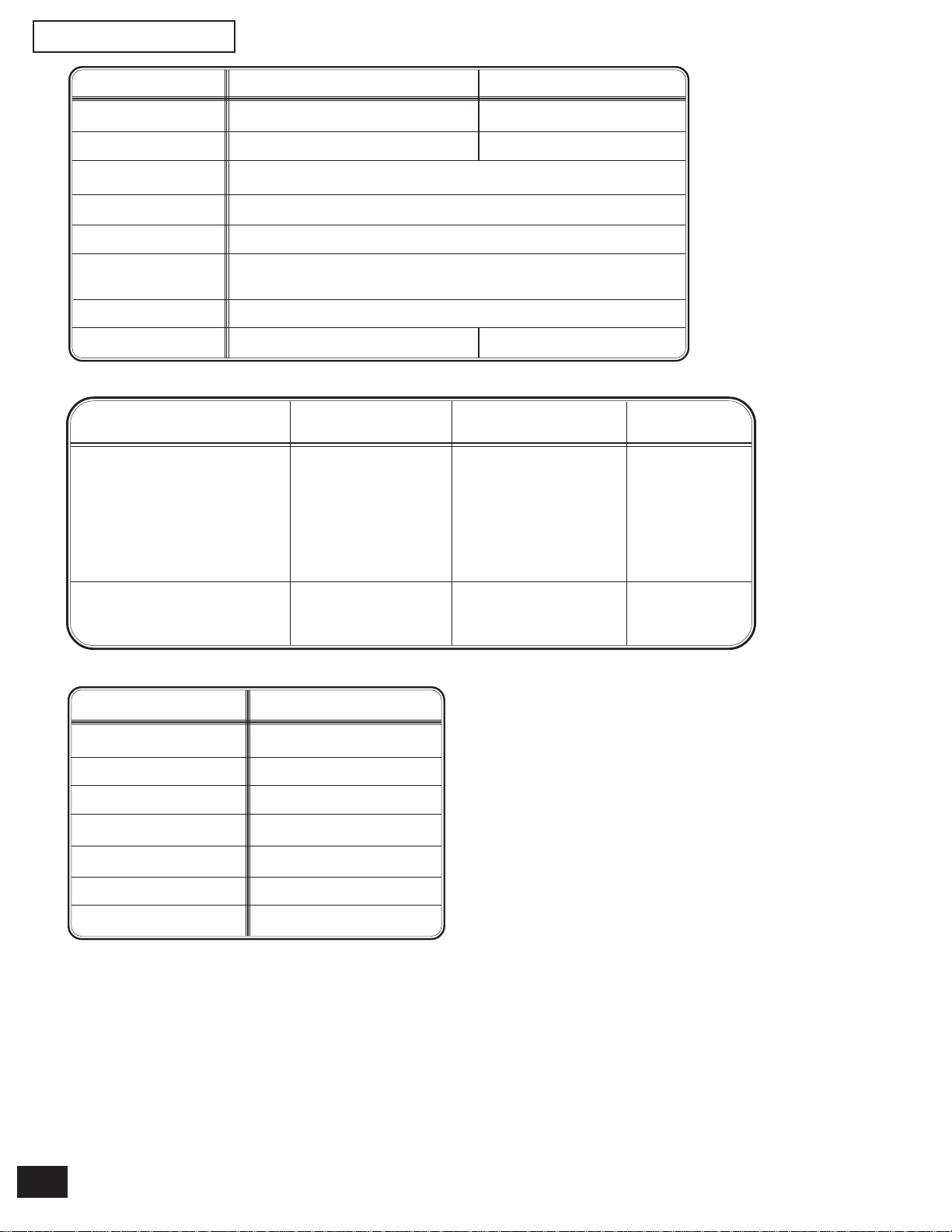

ESPECIFICATIONS

POTENCIA DE SALIDA (AMPLIFICADOR)

Front (Low) 114 W RMS per channel (6 Ω), 80 Hz , 10% DAT

SA-HM810

Surround 32 W RMS per channel (8 Ω), 1 kHz , 10% DAT

Front (Low) 130 W RMS per channel (6 Ω), 80 Hz , 10% DAT

SA-HM910

Surround 50 W RMS per channel (8 Ω), 1 kHz , 10% DAT

Subwoofer 100 W RMS (8 Ω), 80 Hz , 10 % DAT

Notes:

1. All the information are subject to change without notice.

2. Weigth and dimensions are approximate.

(High) 54 W RMS per channel (6 Ω), 1 kHz , 10% DAT

(High) 70 W RMS per channel (6 Ω), 1 kHz , 10% DAT

SC-HM910/SC-HM810

AMPLIFIER SA-HM810 SA-HM910

Power output: 4700 W PMPO 7500 W PMPO

Power consumption: 190 W 280 W

Supply: 127 V ca ±10% 60 Hz

Input sensitivity: 250 mV

Frecuency range AM: 520 - 1710 kHz (10 kHz steps )

Frecuency range FM: 87,5 - 108,0 MHz (0,1 MHz steps )

Dimensions (b x h x l ): 360 mm x 425 mm x 340 mm

Weight: 9,7 kg aprox. 9,8 Kg aprox.

87,9 - 107,9 MHz (0,2 MHz steps )

SPEAKERS INPUT DIMENSIONS WEIGHT

IMPEDANCE (b x h x l)

SB-HM910

FRONT 355 mm x 560 mm x 340 mm 9,2 Kg aprox.

Super Tweeter 3 cm - - - - - - - - Tweeter 6 cm - - - - - - - - Woofer 17 cm - - - - - - - - -

Super Woofer 30 cm - - - - - - - - (High) 6 Ω - - - - - (Low) 6 Ω - - - - - -

SB-PS810

SURROUND

Full Range 10 cm 8 Ω 205 mm x 145 mm x 160 mm 1,3 Kg aprox.

SPEAKER SB-HM810

Input impedance: 6 Ω

Super Tweeter: 3 cm

Tweeter: 6 cm

Woofer: 17 cm

Super Woofer: 25 cm

Dimensions (b x h x l ): 355 mm x 560 mm x 340 mm

Weight: 8,9 kg aprox.

2

SC-HM910/SC-HM810

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general

public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service

a product. Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to service or repair the porduct or products dealt with in this service information by anyone else could result

in serious injury or death.

CONTENTS

Page

1 Safety Precaution........................................................................................................................................................4

2 Before Repair and Adjustment .................................................................................................................................... 4

3 Protection Circuitry......................................................................................................................................................5

4 Accessories.................................................................................................................................................................5

5 Front panel controls ....................................................................................................................................................6

6 Handling Precautions For Traverse Deck ...................................................................................................................8

7 Operation Checks and Main Component Replacement Procedures ..........................................................................9

8 Precaution of Laser Diode ........................................................................................................................................ 31

10 Self-Diagnostic Function ...........................................................................................................................................33

11 Cd Test Mode Function.............................................................................................................................................35

12 Measurements and Adjustments .............................................................................................................................. 36

13 Schematic Diagram...................................................................................................................................................38

14 Printed Circuit Board................................................................................................................................................. 54

15 Block Diagram...........................................................................................................................................................66

16 Wiring Connection Diagram ......................................................................................................................................74

17 Illustration of IC, Transistors and Diodes ..................................................................................................................75

18 Terminal Function of IC.............................................................................................................................................76

19 Troubleshooting Guide..............................................................................................................................................79

20 Parts Location and Replacement Parts List.............................................................................................................. 80

3

SC-HM910/SC-HM810

1 Safety Precaution

1. Before Servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacture’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4- After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to prevent the

customer from being exposed to a shock hazard.

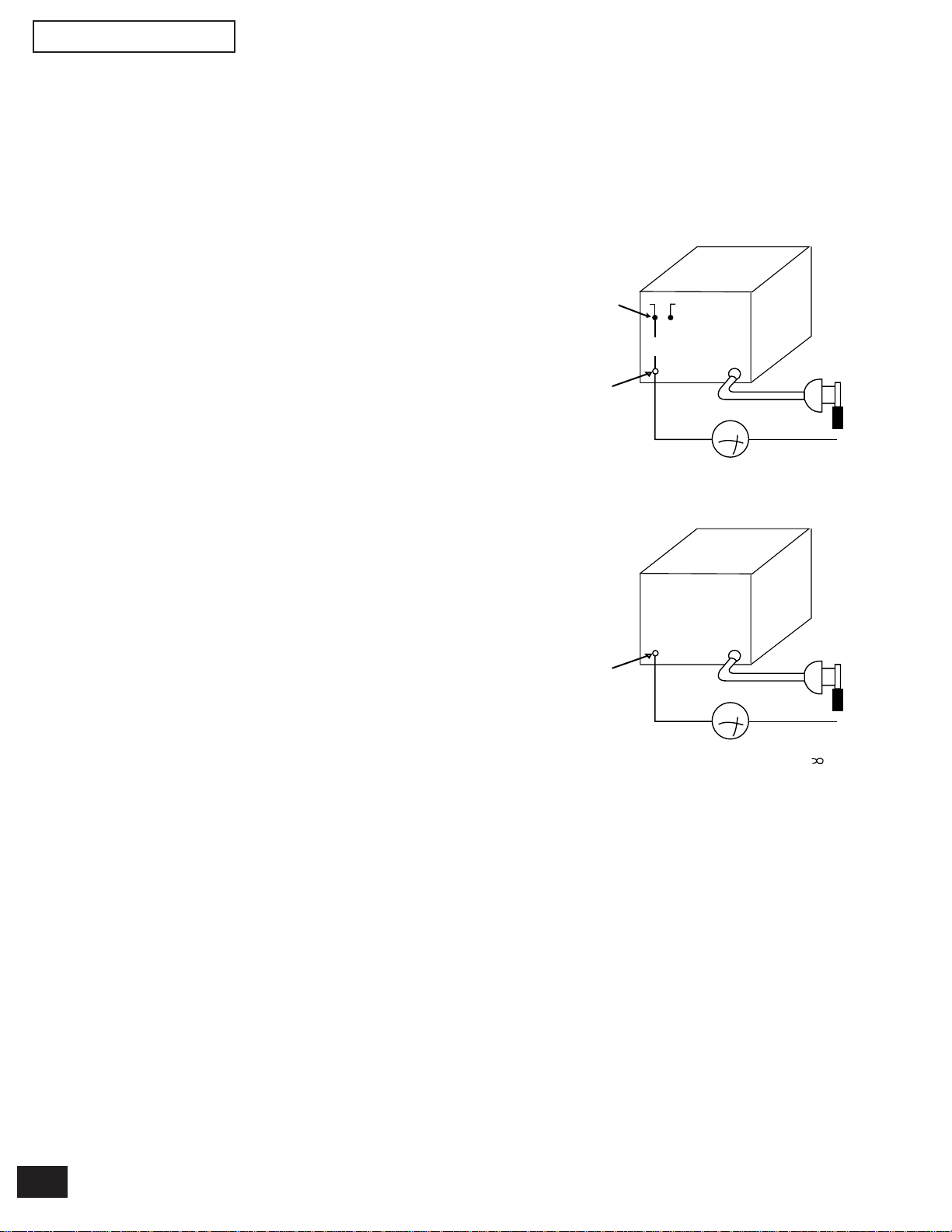

1.1 Insulation Resistance Test

1. Unplug the power cord and short the two prongs of the plug with a

jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with ohmmeter between the jumper

AC plug and each exposed metal cabinet part, such as screwheads,

antenna, control shafts, handle brackets, etc.

Equipment with antenna terminals should read between 2.7MΩ

and 3.9MΩ to all exposed parts* (Fig.1).

Equipment without antenna terminals should read approximately

infinity to all exposed parts. (Fig.2).

*Note: Some exposed parts may be isolated from the chassis by

design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard. The equipment should be repaired and

rechecked before it is returned to the customer.

Antenna

terminal

Exposed

metal part

Ohmmeter

Resistance = 2.7 MΩ - 3.9 M Ω

Fig. 1

Exposed

metal part

Ohmmeter

Resistance = Approx

Fig. 2

2 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors POWER PCB SC-HM910 C556, C557, C558, C559, C561, POWER PCB

SC-HM810 C531, C532, C533, C534 and TRANSFORMER PCB SC-HM910 C705, TRANSFORMER PCB SC-HM810 C402 through

a 10 Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this way destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 127V, 60Hz in NO SIGNAL mode should be ~800mA.

4

SC-HM910/SC-HM810

3 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed.

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

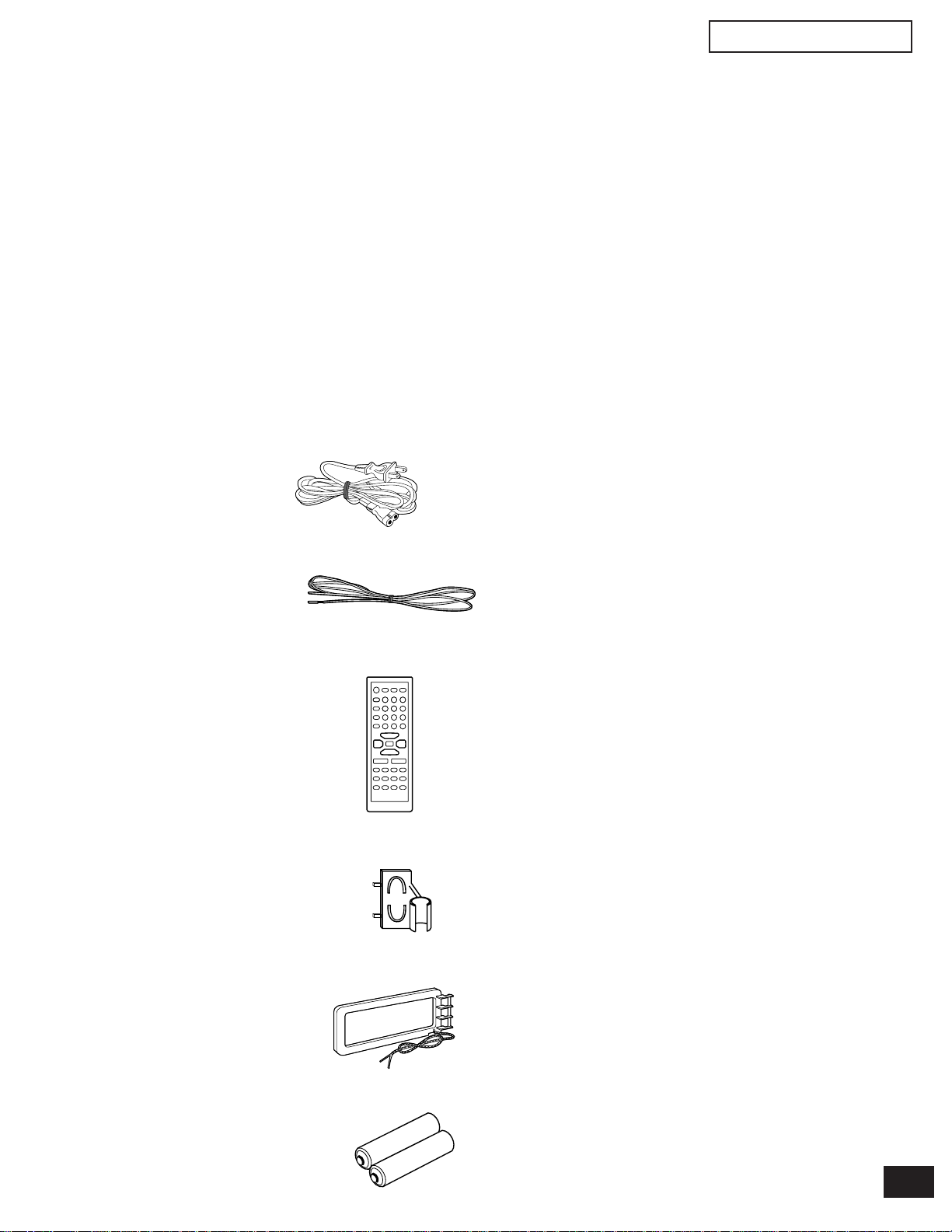

4 Accessories

Cable de alimentación (SJA168-1A) .................................. 1 pza.

Antena FM (N1EAYY000004) ............................................. 1 pza.

Control Remoto (N2QAHB000037) ..................................... 1 pza.

Soporte de la Antena AM (RMN0244)................................. 1 pza.

Antena AM (RSAM0002) ..................................................... 1 pza.

Baterías para el control remoto (UM-3PA) ........................ 2 pzas.

5

SC-HM910/SC-HM810

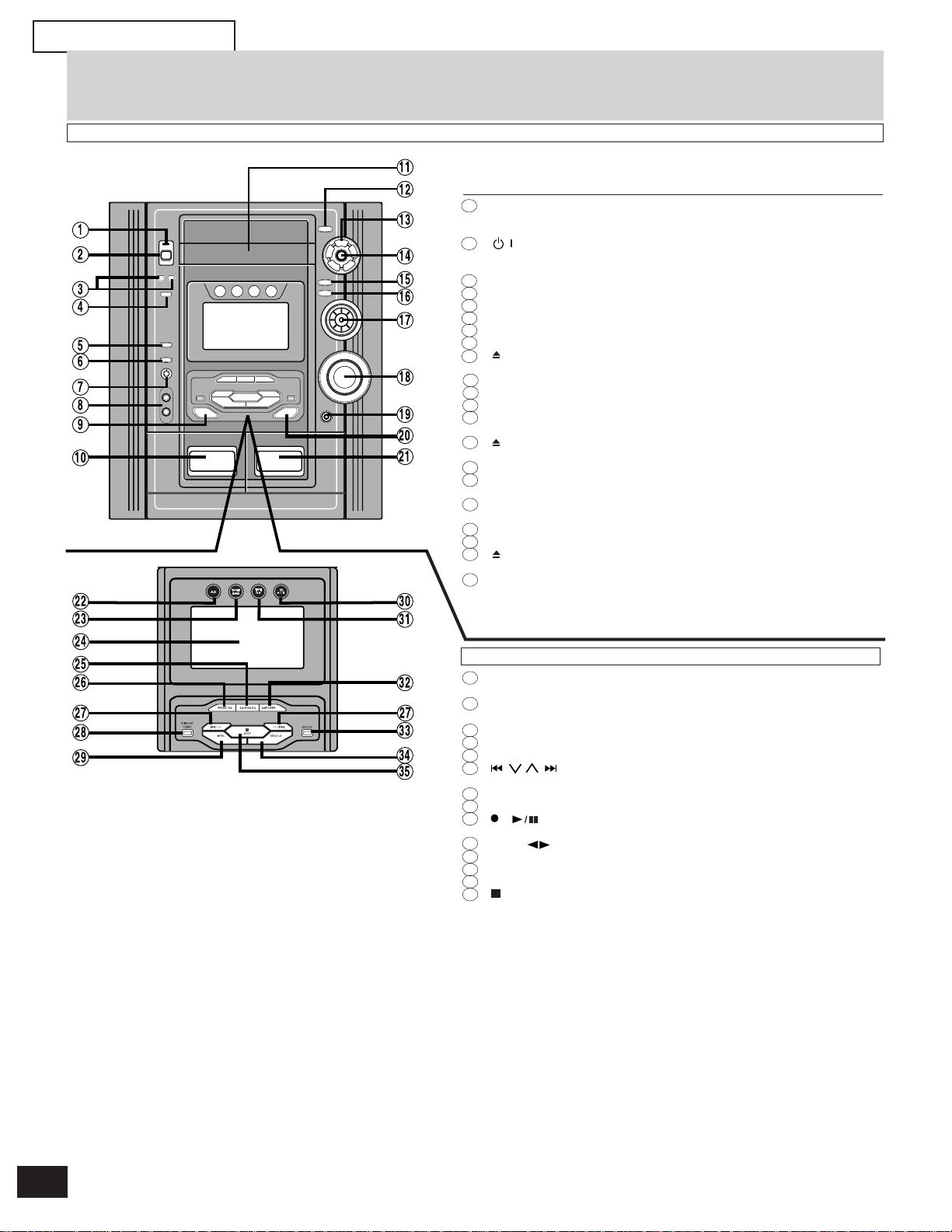

5 Front panel controls

Unidad principal

No. Nombre Pág.

1 (AC IN) Indicador de alimentación (Este indicador se

2 ( / , POWER ) Botón de encendido y modo de espera

3 (RHYTHM 1 , 2) Botones para activar los ritmos de

4(SENSOR) Sensor de señal para el control remoto

5 (APPLAUSES) Botón para activar el efecto de aplausos

6 (EXPLOSION) Botón para activar el efecto de explosión

7 (MIC VOL) Control de volumen del micrófono

8 (MIC 1 , 2) Entradas para micrófono

9 ( DECK 1, OPEN) Botón para abrir el compartimento de

10 (DECK 1) Compartimento para la reproducción de cinta

11 Charola para discos compactos

12 (MARKER) Botón para marcar las melodías

13 (1 - 5 ) Botones indicadores y de acceso directo para

14 ( ) Botón para abrir / cerrar la charola de discos

15 (ENTER) Botón para introducción

16 (TITLE SEARCH) Botón que permite seleccionar por título las

17 Perilla Selector de melodías y álbumes MP3/WMA

18 (VOLUME DOWN, UP) Control de volumen

19 (PHONES) Salida de audífonos

20 ( DECK 2, OPEN) Botón para abrir el compartimento de repro-

21 (DECK 2) Compartimento para la reproducción y graba-

encenderá cuando el Sistema Estéreo esté

conectado).

(En modo de espera, el Sistema Estéreo consume

una pequeña cantidad de corriente eléctrica).

ambientación

reproducción de cinta

la reproducción de discos compactos

compactos

melodías y álbumes

ducción y grabación de cinta

ción de cinta

Consola central

22 (AUX) Botón para reproducción de la unidad auxiliar

23 (TUNER, BAND) Botón para seleccionar la banda de emisoras

24 Visualizador

25 (S. SOUND EQ)

26

(PRESET EQ)

27 ( / , / )

28 (-DISPLAY/–DEMO) Botón selector del modo de visualización

29 ( REC) Botón para grabación

30 (CD, ) Botón para reproducción y pausa de discos

31 (TAPE, ) Botón para reproducción y dirección de cintas

32 (S.WOOFER) Botón para el refuerzo de graves

33 (DELETE) Botón para borrar

34 (DECK 1/2) Botón selector de cintas

35 ( , STOP) Botón para alto total y borrar melodías

........................................................................

de radio

Botón para realzar la calidad del sonido

Botón selector del ecualizador prefijado

Botón para adelantar/atrasar los discos compactos/

cintas, seleccionar emisoras, ajustar la hora

compactos

programadas

6

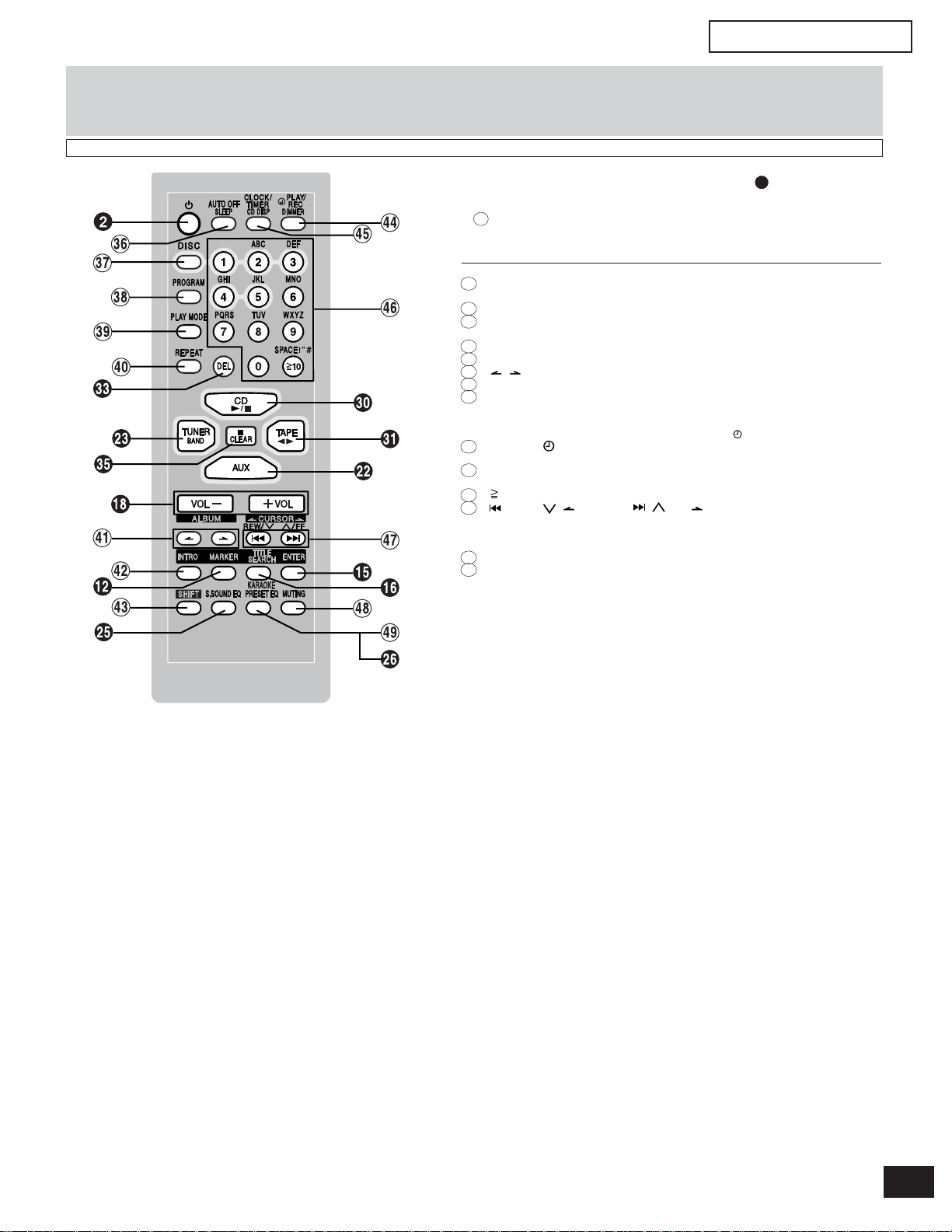

5 Front panel controls

Control remoto

SC-HM910/SC-HM810

Los números que se encuentran en círculo negro como el 2 , son funciones que

se pueden operar tanto en el Sistema Estéreo como en el control remoto y se

encuentran referenciados en la página 6. Los botones que están en blanco como

el 36 , son funciones que se realizan sólo por medio del control remoto.

No. Nombre Pág.

36 (SLEEP, -AUTO OFF) Botón para el temporizador programado y

37 (DISC) Botón selector de discos compactos

38 (PROGRAM) Botón para programar melodías de discos

39 (PLAY MODE) Botón selector del modo de reproducción

40 (REPEAT) Botón para repetir melodías

41 ( , , ALBUM) Botones para cambiar de álbum

42 (INTRO) Botón de introducción

43 (SHIFT) Botón para usar las funciones etiquetadas en

44 (DIMMER, PLAY/REC) Botón para opacar la iluminación y activar el

45 (CD DISP, CLOCK / TIMER)

46 ( 10, 1-9, 0, A-Z, SPACE!”#)Botones numéricos y caracteres

47 ( , REW/ , CURSOR, , /FF, CURSOR)

48 (MUTING) Botón para silenciar el volumen

49 (KARAOKE) Botón para activar los efectos de karaoke

apagado automático

compactos y preajustar emisoras

naranja; al presionar

uno de los siguientes botones:

[CLOCK/TIMER], [ PLAY/REC], [KARAOKE].

temporizador de reproducción y grabación

Botón para seleccionar el modo de visualización

y ajustar el reloj y el temporizador

de CD/rebobinado de cinta, sintonización/

selección de emisoras

la hora

[SHIFT] presione también

[AUTO OFF],

Botones de búsqueda

preajustadas y ajuste de

7

SC-HM910/SC-HM810

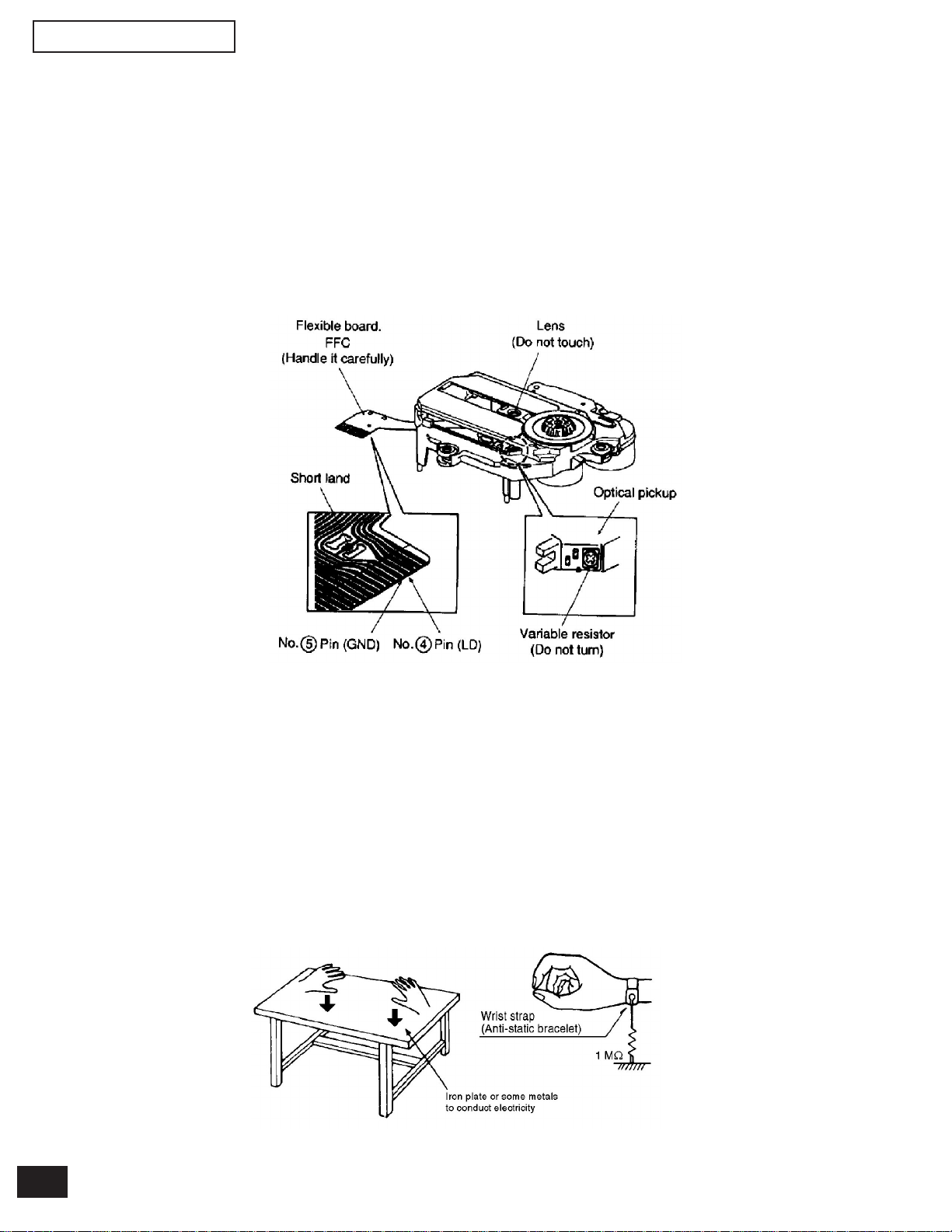

6 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static electricity of clothes

or human body.

So. be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. The short land between the No. 4 (LD) and No. 5 (GND) pins on the flexible board (FFC) is shorted with a solder build-up to

prevent damage to the laser diode. To connect to the PC board be sure to open by removing the solder build-up and finish the

work quickly.

3. Take care not to apply excessive stress to the flexible board (FFC).

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

Grounding for electrostatic breakdown prevention

1. Human body groundling

Use the anti-satatic wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) isplaced, and ground the

sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the traverse

deck (optical pickup).

Caution when Replacing the Traverse Deck:

The traverse deck has a short point shorted with solder to protect the lazer diode against electrostatics breakdown. Be sure to remove

the solder from the short point before making connections.

8

SC-HM910/SC-HM810

7 Operation Checks and Main Component Replacement Procedures

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the

main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

Gear for servicing (jig) information

1. This unit has a gear which is used for checking items (open/close of disc tray, up/down operation of traverse unit by

manually) when servicing.

2. For preparation of gear (for servicing), Perform the procedures as follows.

3. In case of re-servicing the same set, the “gear for servicing” may has been taken off because it has been used.

The “gear for servicing” must be stored.

1. Remove the gear provided with mechanism cover 2. Insert the hexagonal screwdriver (2 mm) into

theas shown below. the gear, and then project the tip of screwdriver

for 1~2mm in length.

9

SC-HM910/SC-HM810

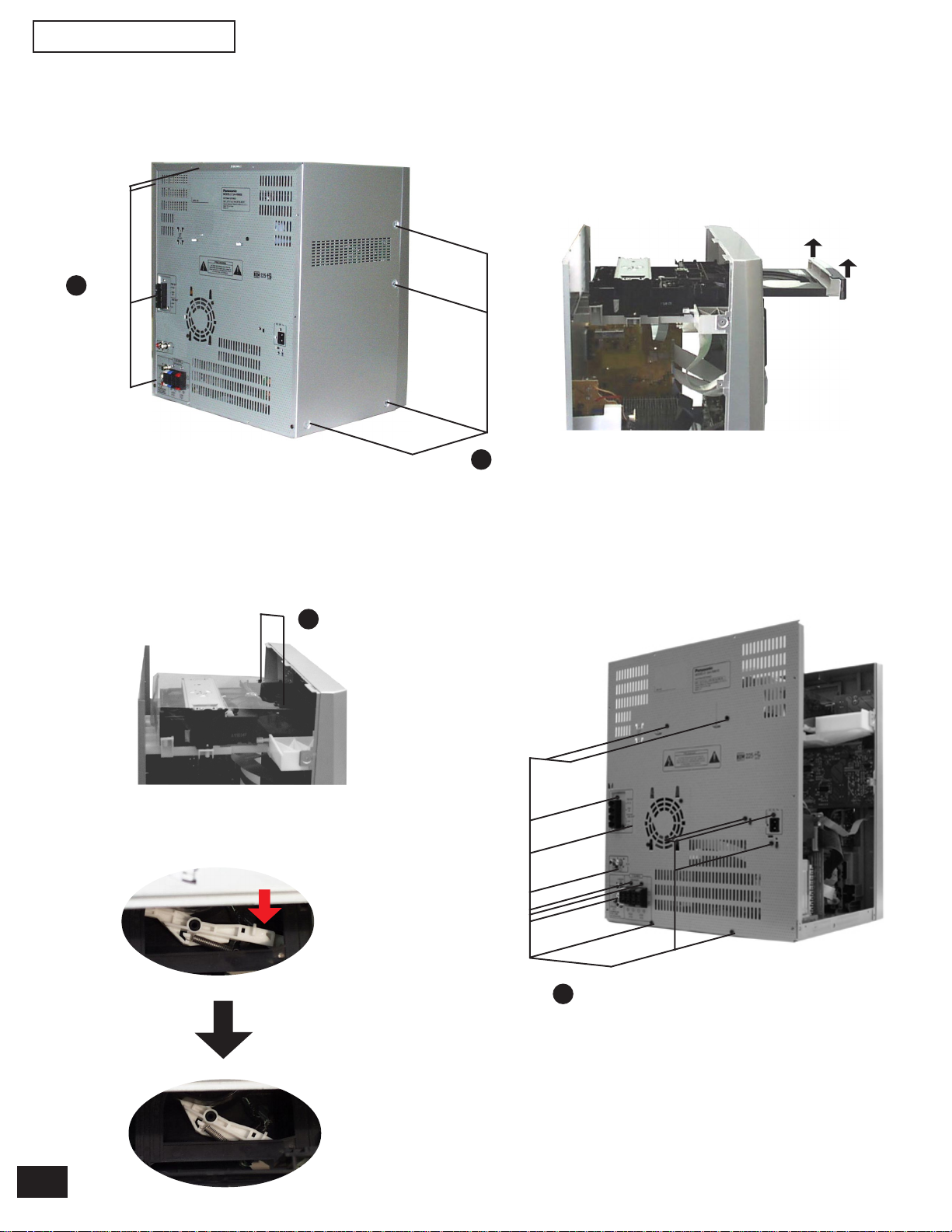

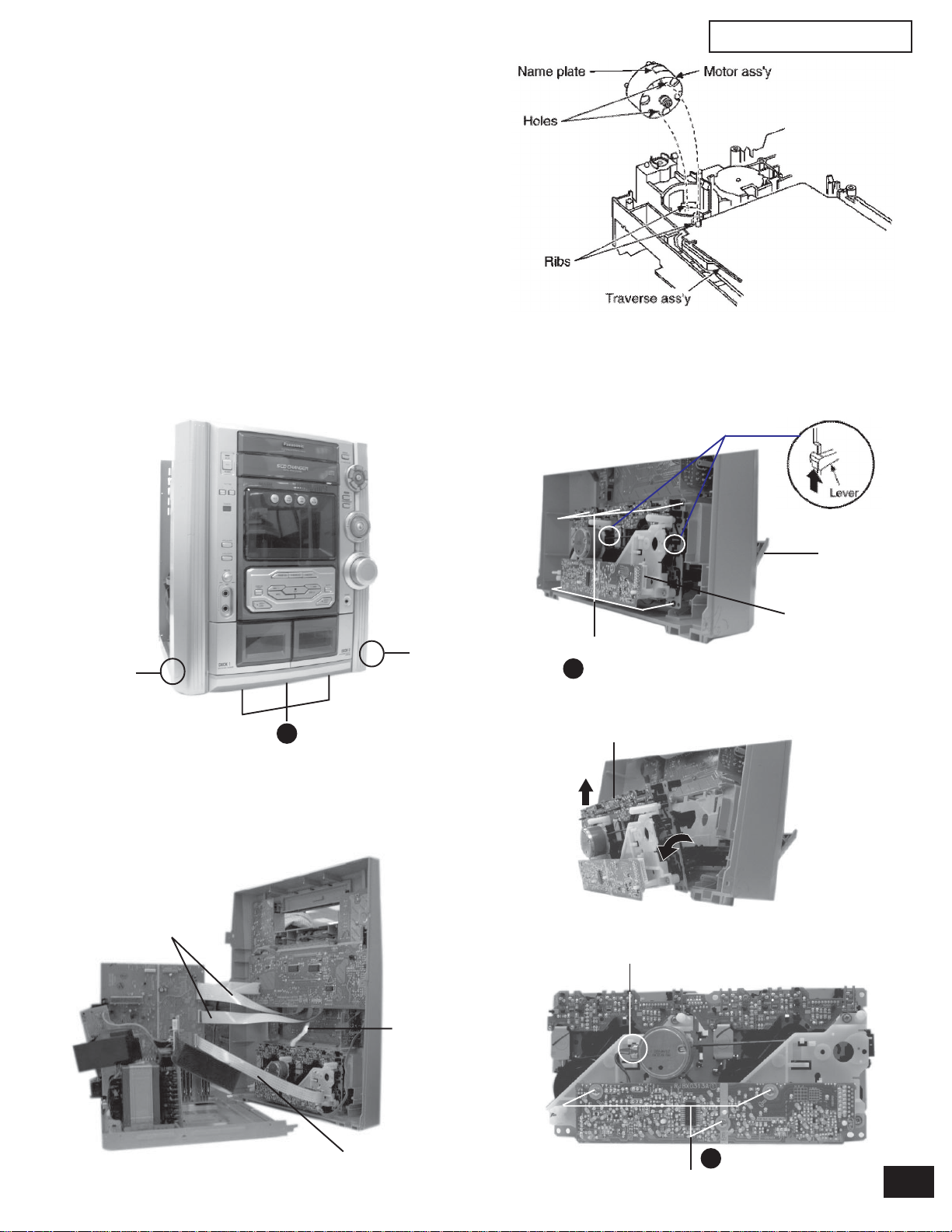

7.1 Disassembly and assembly main unit

Step 1 Remove 4 screws each side and 8 screws at rear panel.

Step 2 Lift up both sides of cabinet ass’y, push the cabinet

ass’y toward the rear and remove the cabinet ass’y.

b x 8

Step 5 Pull out the CD tray as shown and remove the CD

lid. Push back the CD tray after the CD lid has

been removed.

CD lid

a x 4

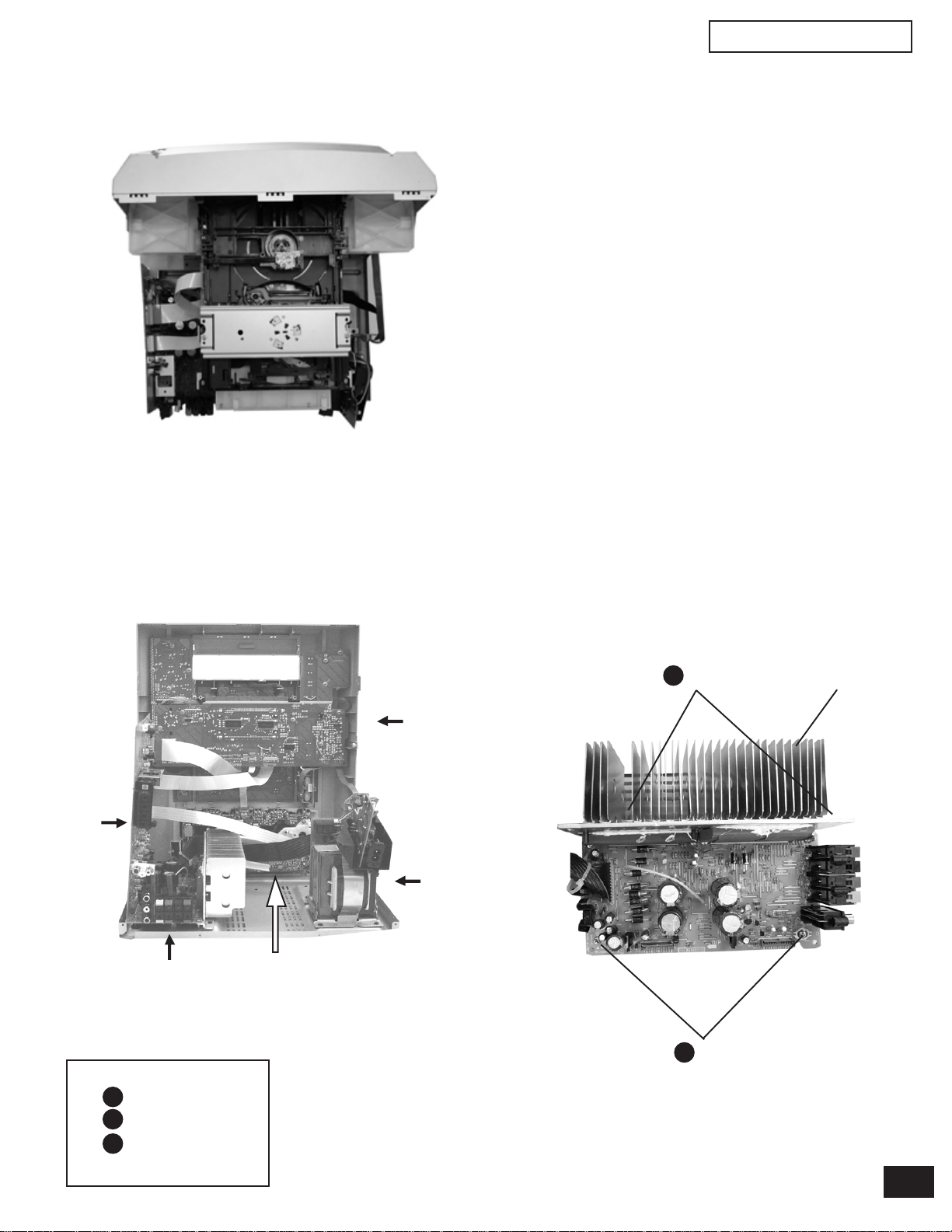

7.2 Disassembly for the CD changer ass’y

(The CD changer unit can be removed after the CD Lid is removed)

• Follow the (Step 1) (Step 2) of item 7.1.

Step 3 Remove 2 screws and remove the dust cover.

Step 6 Remove the screws.

b x 2

Step 4 To open the CD tray, release the lever as show.

10

b x 13

Step 7 Remove the wire CN309 and CN310 (main P.C.B.),

release the 2 catches and remove the CD changer

base together with the CD changer.

SC-HM910/SC-HM810

Catch

CN310

CN309

Catch

7.3 Checking for Main, Panel, Deck and Power P.C.B.

Step 8 Remove 4 screw.

b x 2

Heat Sink

Main

Power

: RHD30002-H

a

: XTBS3+8JFZ1-A

b

c

: XTB3+20J-A

Panel

Transformer

Deck

c x 2

11

SC-HM910/SC-HM810

7.4 Main Component Replacement Procedures

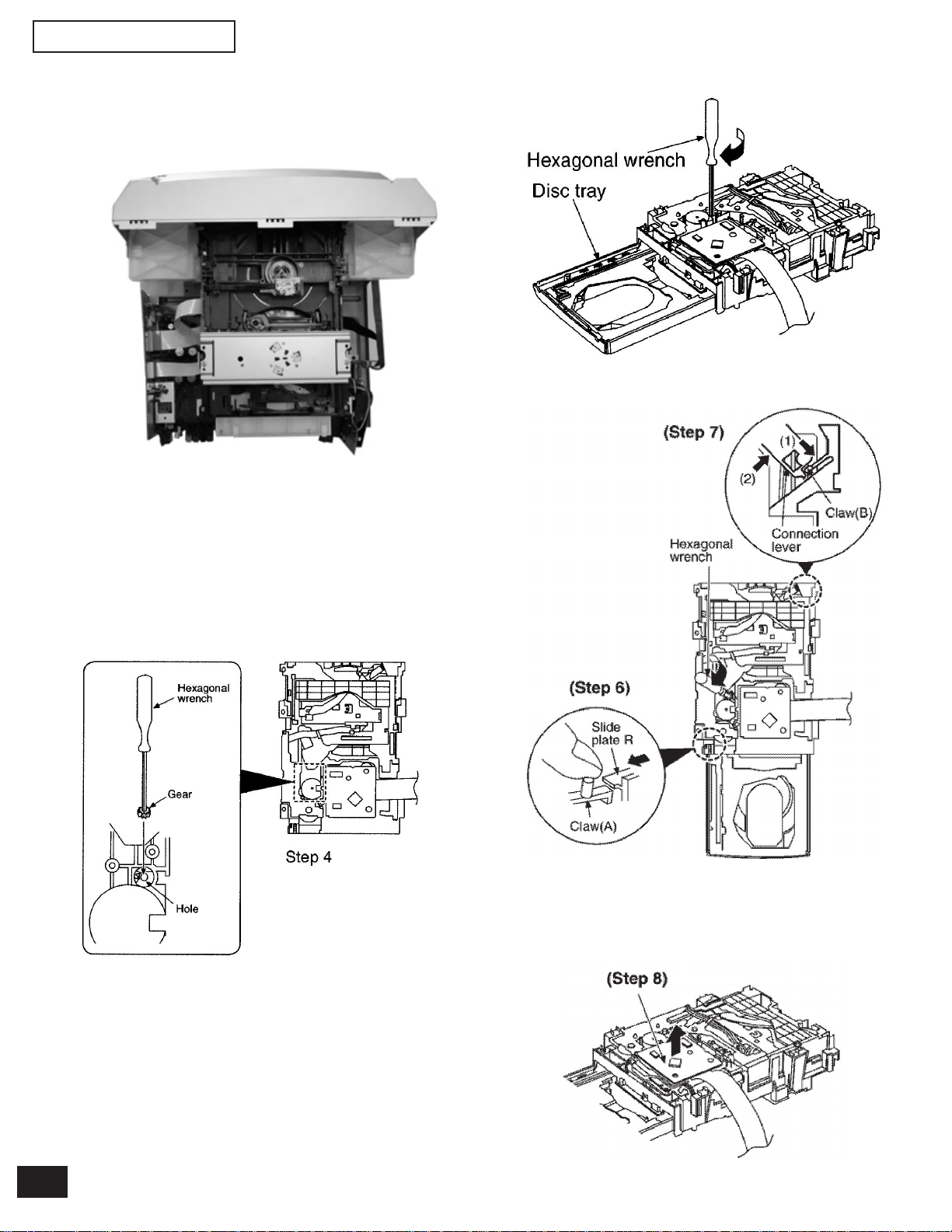

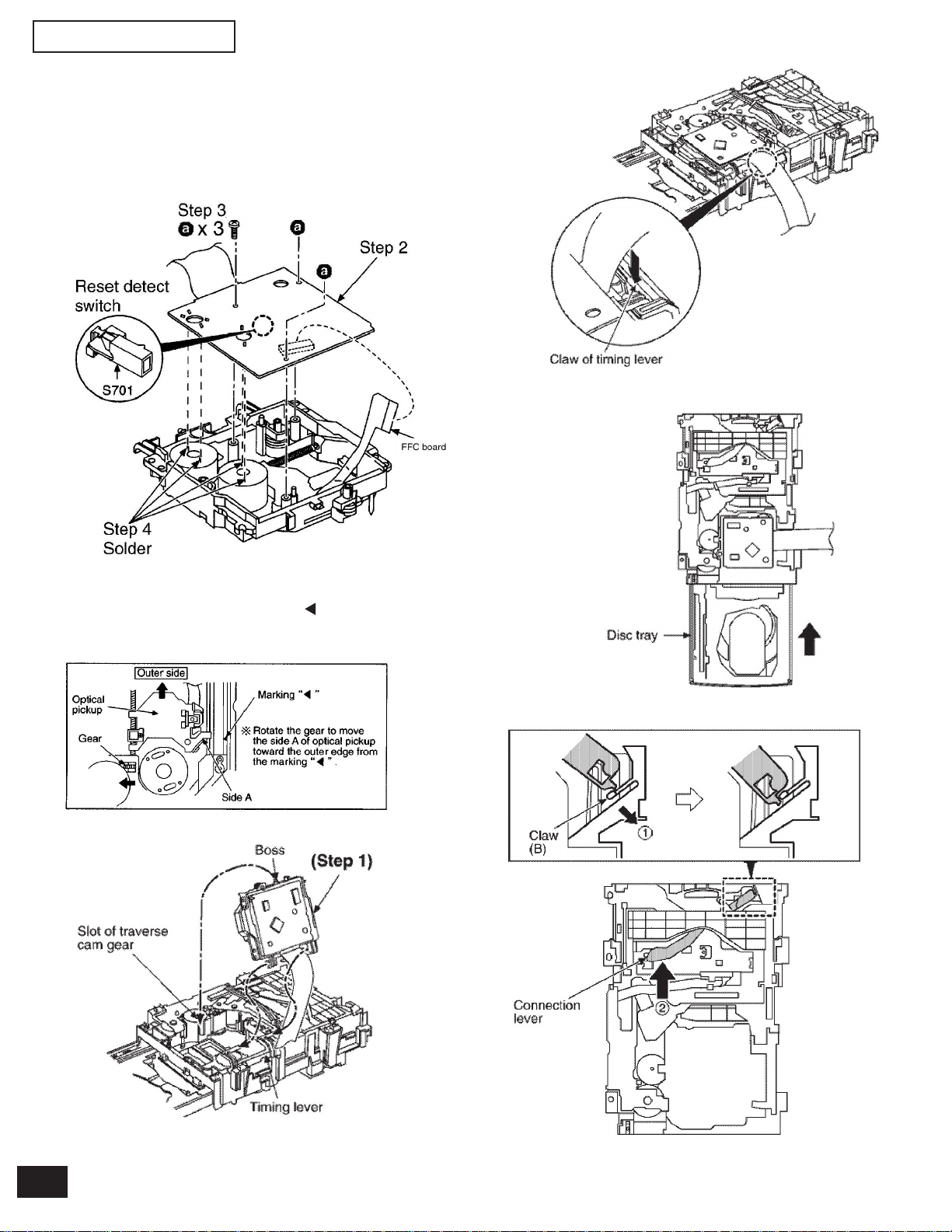

7.4.1. Replacement of the Traverse Deck

Step 1 Follow the (step 1 ) - (step 2) of item 7.1.

Catch

CN310

CN309

Step 2 Remove the wire CN309 and CN310 (main

P.C.B.), release the 2 catches.

Step 3 Remove the CD changer unit.

(Back side)

Catch

Step 5 Rotate the hexagonal wrench in the direction of arrow

(clockwise), and then open the disc tray fully.

Step 4 Insert the gear with hexagonal wrench into the hole.

12

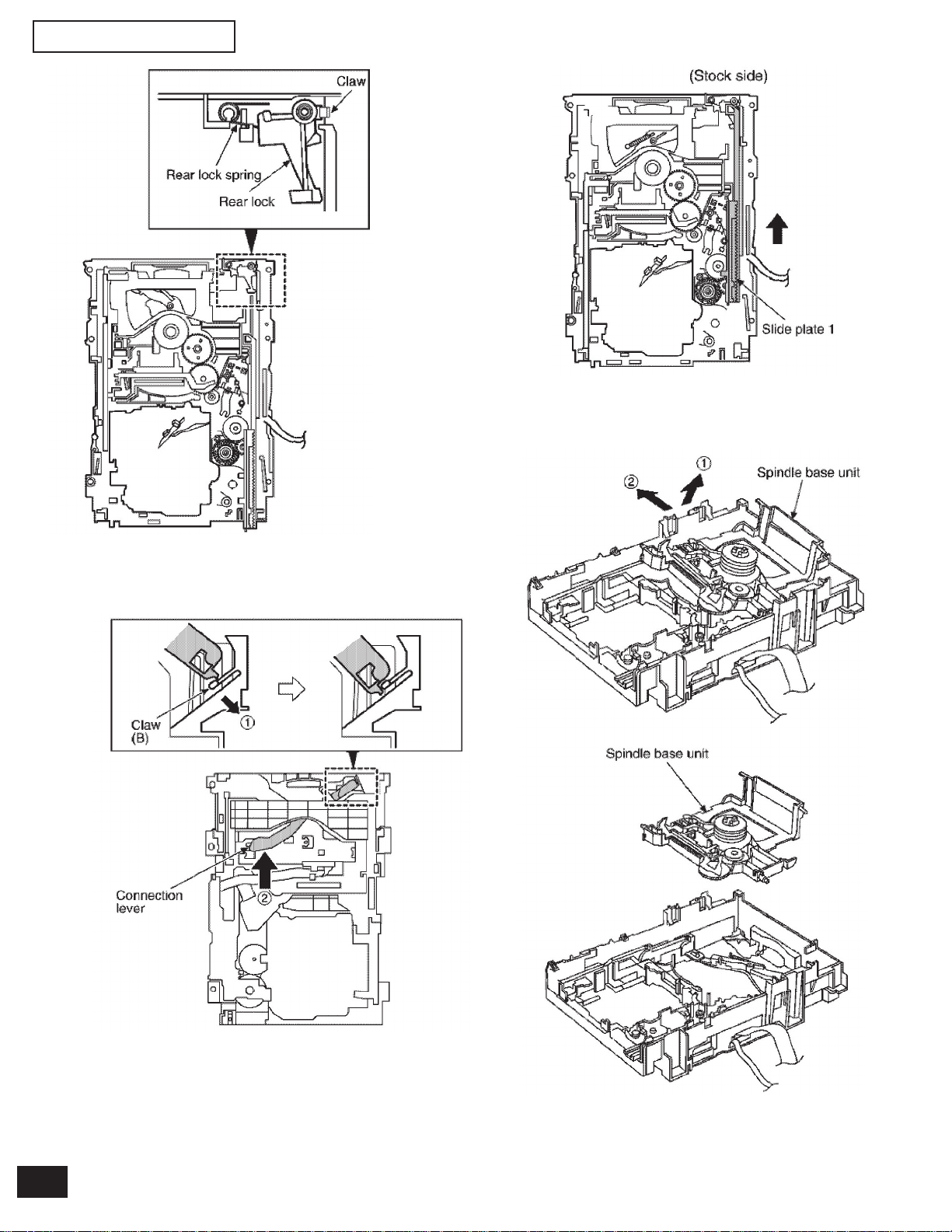

Step 6 With pressing the claw (A), rotate the hexagonal

wrench clockwise. (The slide plate R moves for a little

amount.)

Step 7 Pressing the claw (B) in the direction of arrow (1), the

connection lever moves in the direction of arrow (2).

Step 8 Lift up the traverse deck ass’y.

(Step 12)

SC-HM910/SC-HM810

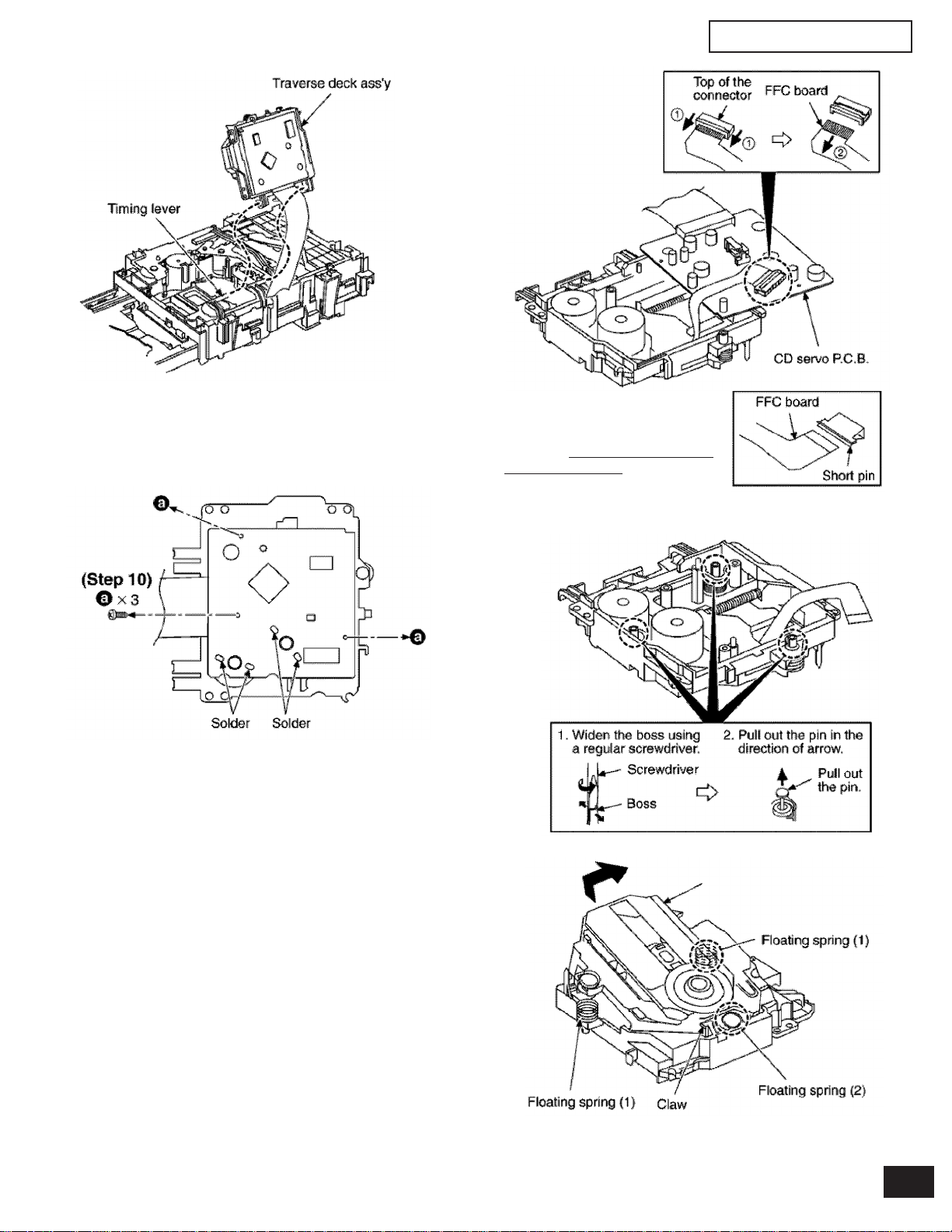

Step 9 Remove the traverse deck ass’y from the timing lever.

Caution:

When removing or inserting the traverse deck avoid touching the

OPU lens and pressing onto the turntable.

Step 10 Remove 3 screws.

Step 11 Unsolder the motor terminals (4 points).

Caution:

Insert a short pin into the traverse

unit FFC board.

(Refer to “

for Traverse Deck”.)

Step 12 Remove the FFC board from the connector, and then

Handling Precautions

remove the CD Servo P.C.B.

Step 13 Remove the pin.

Step 14 Release the claw, and then remove the traverse deck

ass’y

13

SC-HM910/SC-HM810

Note:

Be careful no to lose the 3 floating spring because those will

also be removed on removal of the traverse deck ass’y.

• Installation of the CD Servo P.C.B. after replacement

Step 1 Connect the FFC board.

Step 2 Install the CD servo P.C.B. in the traverse deck ass’y.

Step 3 Remove 3 screws.

Step 4 Solder.

Step 3 Force the claw of timing lever.

• Note for installation of the CD servo P.C.B.

Before installing the CD servo P.C.B., move the optical pickup

toward the outer edge from the mark “ “.

(Otherwise, the rest detect switch (S701) mounted on the CD

servo P.C.B. may be damaged.)

• Installation for traverse deck ass’y

Step 4 Force the disc tray fully.

Step 1 Install the traverse deck ass’y to the timing lever.

Step 2 Align the boss of traverse deck ass’y with the slot of

traverse cam gear.

14

Step 5 With pressing the claw (B) in the direction of arrow (1),

force the connection lever in the direction of arrow (2).

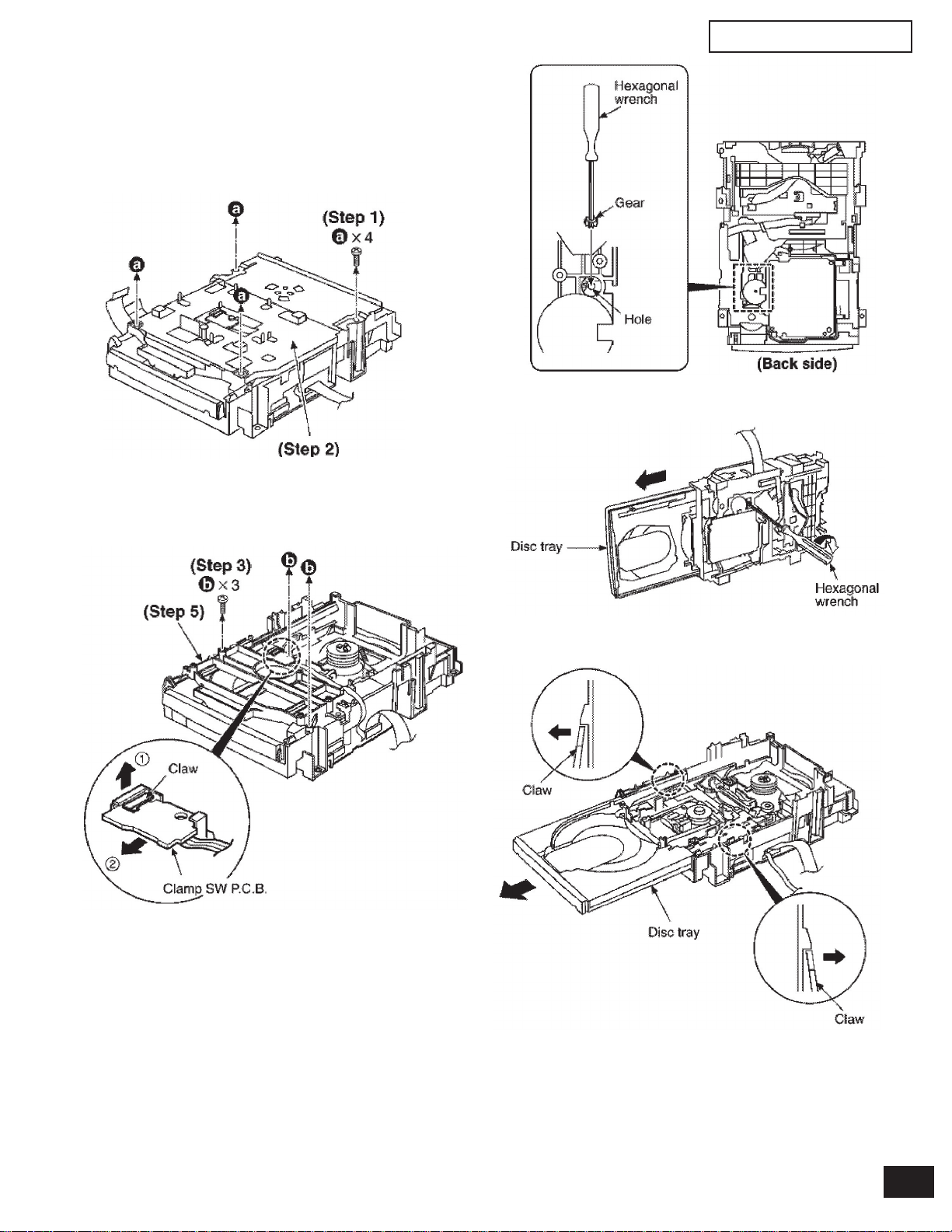

7.5 Replacement for the disc tray

• Follow the (Step 1) - (Step 2) of item 7.1

• Follow the Disassembly for the CD changer of item 7.2.

• Follow the (Step 1) - (Step 8) of item 7.4.

Step 1 Remove 4 screws.

SC-HM910/SC-HM810

Step 6 Insert the gear with hexagonal wrench into the hole.

Step 2 Remove the upper plate.

Step 3 Remove 3 screws.

Step 7 Rotate the hexagonal wrench in the direction of arrow,

and then open the disc tray fully.

Step 4 With lifting the claw in the direction of (1), draw the clamp

SW P.C.B. in the direction of arrow (2).

Step 5 Remove the mechanism cover.

Step 8 Release the both claws, and then draw the disc tray.

15

SC-HM910/SC-HM810

Step 9 With forcing the left guide bar manually because the

left guide bar interfers with claw, draw the disc tray.

(Installation of the disc tray after replacement).

Step 1 Slide the drive rack fully in the direction of arrow:

Note:

Force the right guide bar of tray base manually not to move

upwards.

Step 4 Holding the disc tray manually, push the disc tray in

the direction of the arrow.

Step 2 Holding the drive rack not to move, install the disc tray.

Step 3 Align the drive rack with the drive gear.

16

SC-HM910/SC-HM810

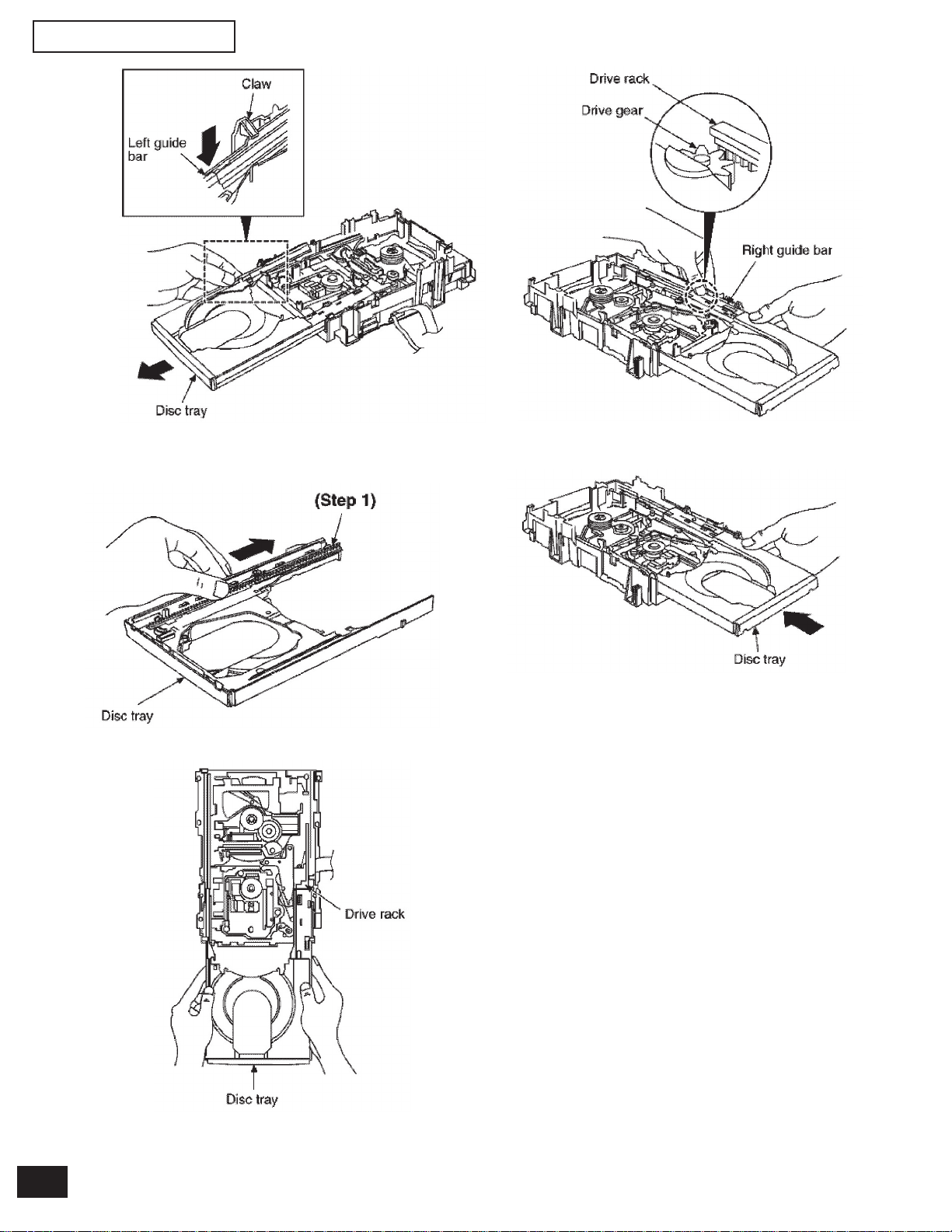

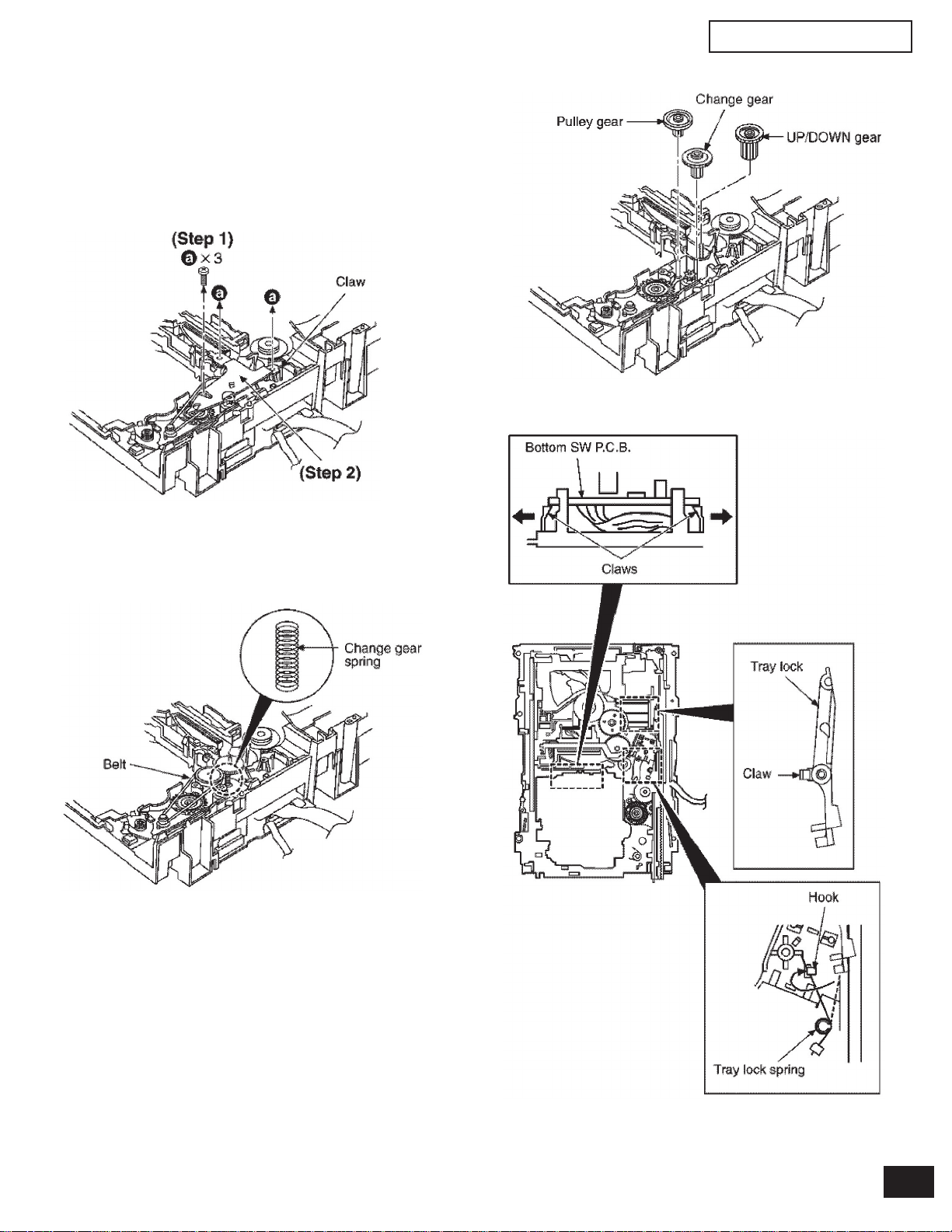

7.6 Disassembly and reassembly for mechanism base drive unit

• Follow the (Step 1) - (Step 2) of item 7.1

• Follow the Disassembly for the CD changer of item 7.2.

• Follow the (Step 1) - (Step 14) of item 7.4.

• Follow the (Step 1) - (Step 9) of item 7.5

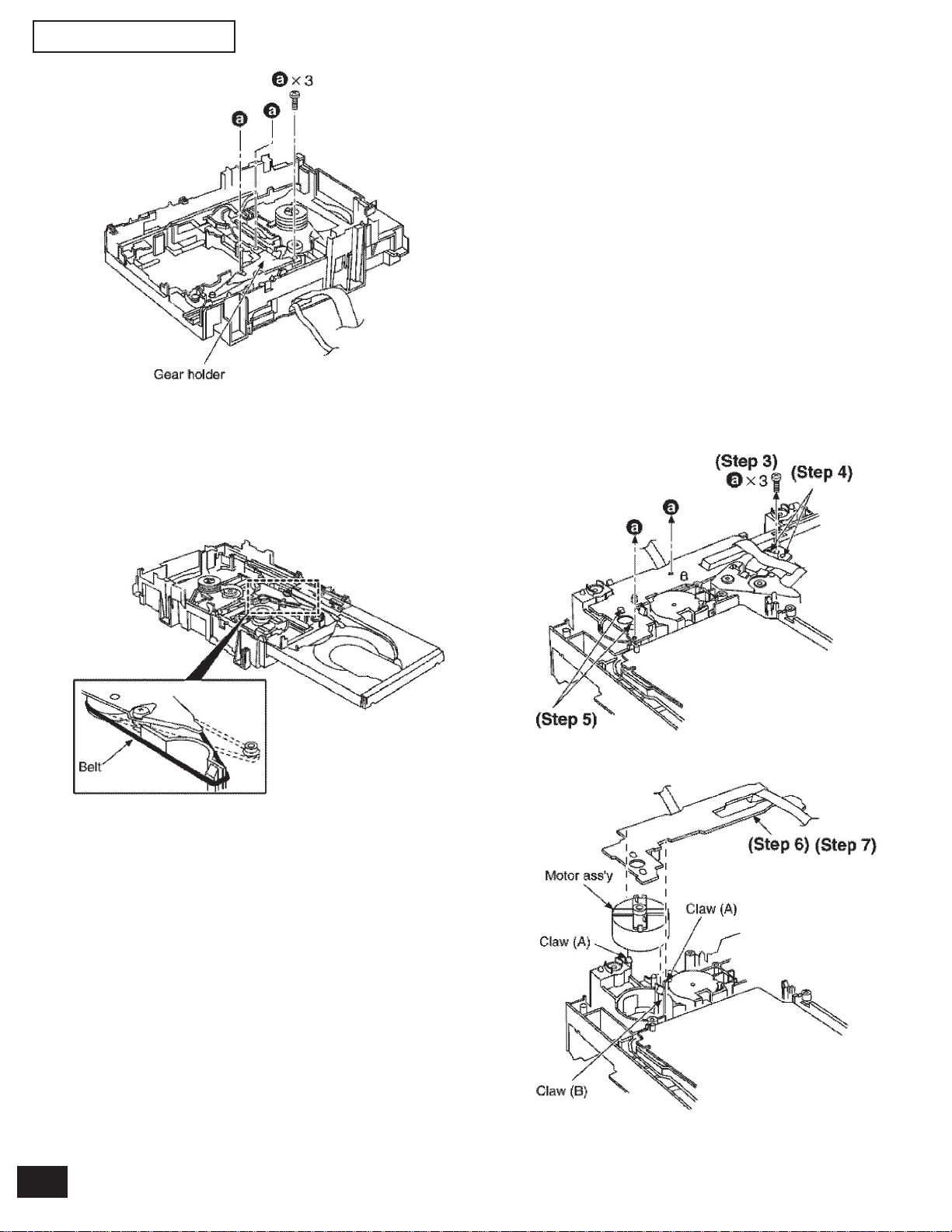

Step 1 Remove 3 screws.

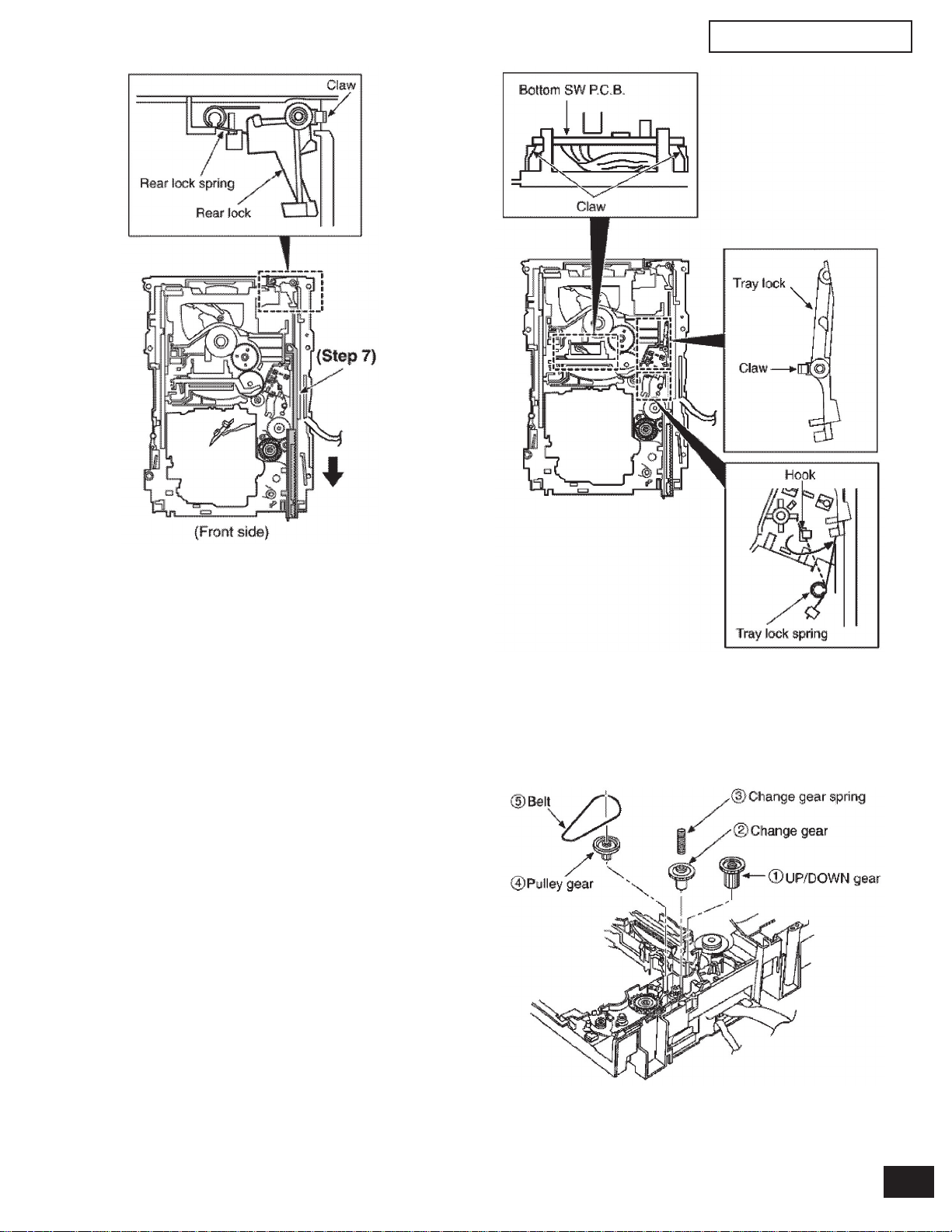

Step 5 Release the 2 claws, and then remove the bottom

SW P.C.B.

Step 2 Release the claw, and then remove the gear

holder.

Step 3 Remove the belt and change gear spring.

Note:

Take care not to lose the change gear spring.

Step 4 Remove the pulley gear, change gear and

UP/DOWN gear.

Step 6 Install the tray lock spring to hook temporary.

Step 7 Release the claw, and then remove the tray lock.

Step 8 Release the claw, and then remove the rear lock.

17

SC-HM910/SC-HM810

Step 11 Lift up the left end of spindle base unit in the direction

of arrow (1), and then remove the unit in the direction

of arrow (2).

Step 9 Pressing the claw (B) in the direction of arrow (1), force

the connection lever in the direction of arrow (2).

Step 10 Move the slide plate 1 to the end of stock side.

18

Step 12 Remove slide plate 1 and slide plate 2.

Step 13 Remove the traverse relay gear, traverse cam gear and

drive gear.

SC-HM910/SC-HM810

Step 3 Rotate the disc lever in the direction of arrow (1), draw

the disc lever.

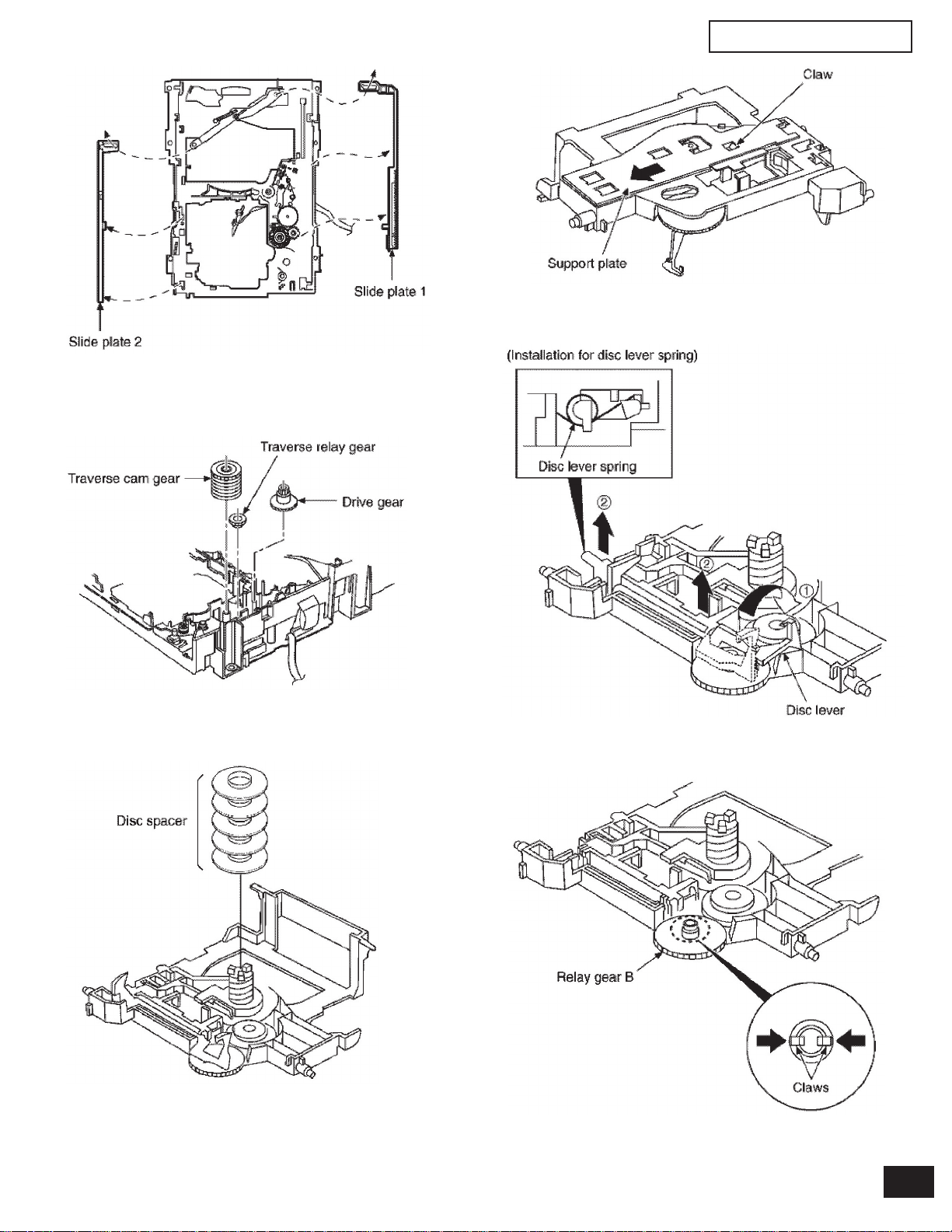

(Dissassembly/reassembly for the spindle base unit)

Step 1 Draw the 5 disc spacers.

Step 2 Pushing the claw, slide the support plate in the direc-

tion of arrow, and then remove it.

Note:

Take care not to lose the disc lever spring.

Step 4 Release the 2 claws, and then draw the relay gear B.

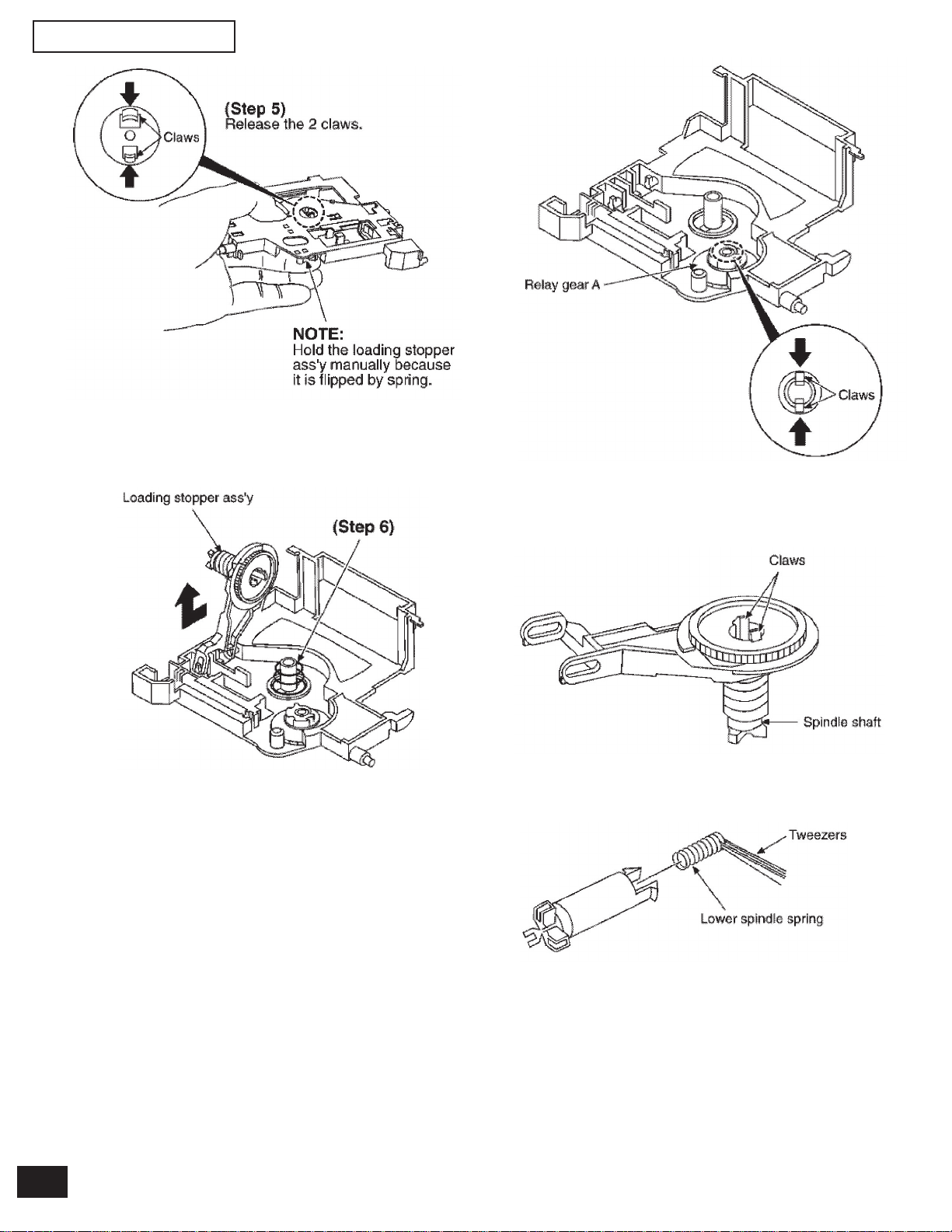

Step 5 Release the 2 claws as shown below.

19

SC-HM910/SC-HM810

Note:

Hold the loading stopper ass’y manually because it is flipped by

spring.

Step 8 Release the 2 claws, and then remove the relay gear

A.

Step 9 Release the 2 claws, and then remove the spindle shaft.

Step 6 Remove the cushion spring.

Step 5 Remove the loading stopper ass’y in the direction of

arrow.

20

Step 10 Remove the lower spindle spring with tweezers.

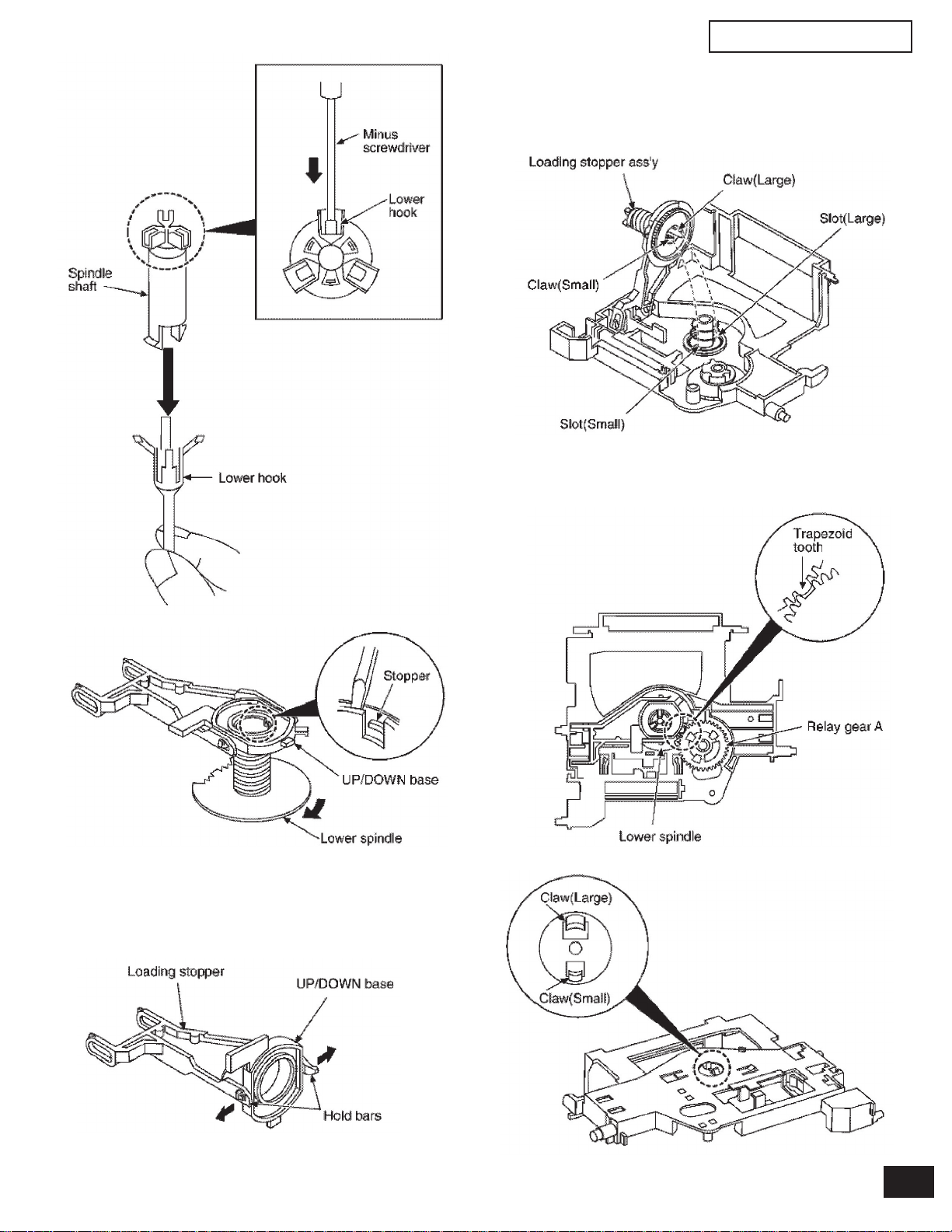

Step 11 Force the lower hook with thin tip of minus screwdriver.

SC-HM910/SC-HM810

(Installation for loading stopper ass’y)

Step 1 Align the claw of loading stopper ass’y with the slot of

spindle base. (Caution should be exercised when alignment of claw due to the size of claws.)

Step 2 Lower the loading stopper ass’y, and then align the

lower spindle with the trapezoid tooth of relay gear A.

Step 12 Squeeze the shaft of lower hook, and then draw it.

Step 13 Rotate the lower spindle in the direction of arrow until

the lower spindle interferes with stopper.

Step 14 Insert the thin tip of minus screwdriver between the

lower spindle and UP/DOWN base, and then slacken

the lower spindle to release the stopper. Then, rotate

the lower spindle and remove it.

Step 3 Force the loading stopper ass’y, latch the claw firmly.

Step 15 Rotate the UP/DOWN base at a 90 angle. Then, spread

the hold bars of loading stopper and remove the UP/

DOWN base.

(Reassembly for mechanism base drive unit)

21

SC-HM910/SC-HM810

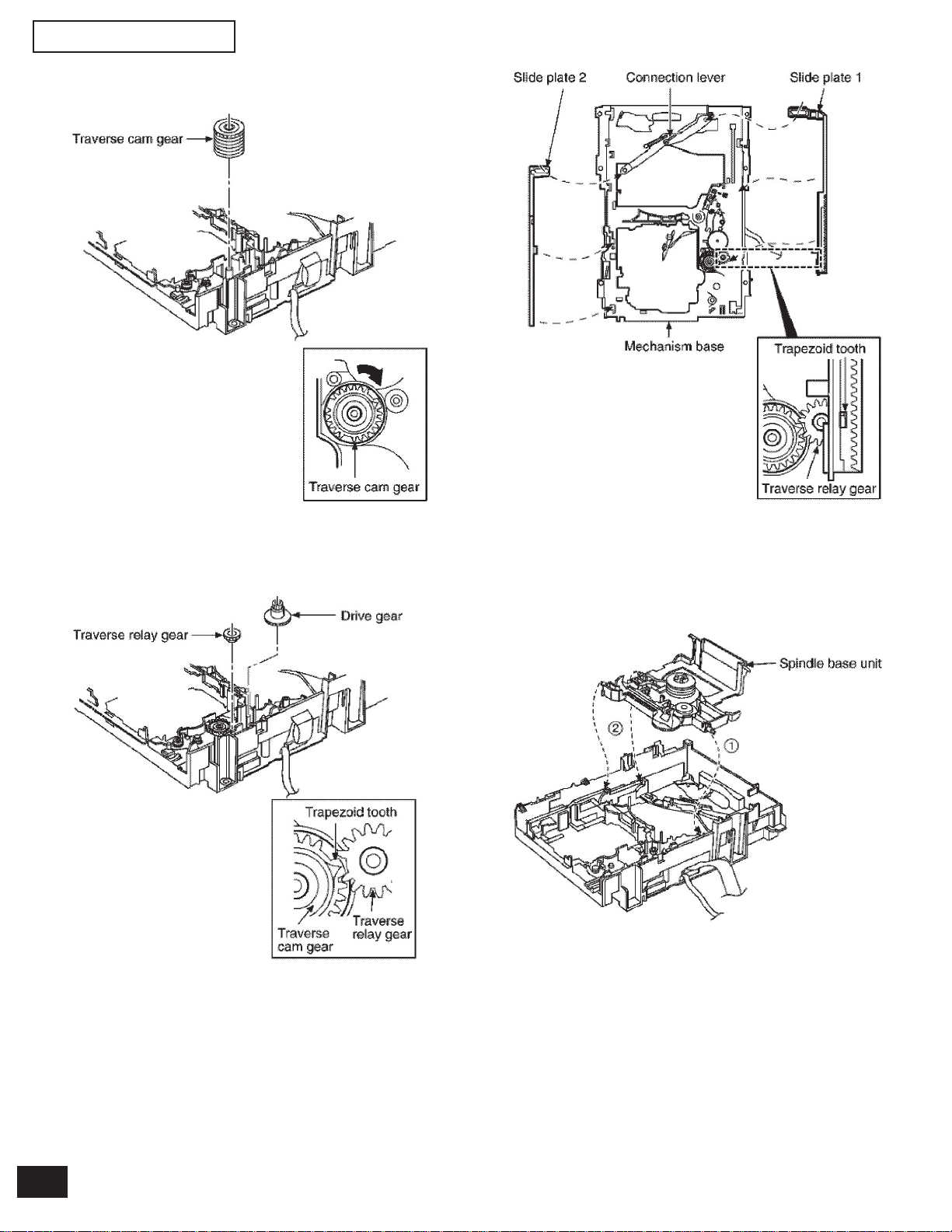

Step 1 Install the traverse cam gear.

Step 2 Rotate the traverse cam gear to the direction of arrow.

Step 3 Install the drive gear and traverse relay gear.

Step 4 Install the slide plate 2 to the mechanism base, and

then match to the connection lever.

Step 5 Install the slide plate 1 to the mechanism base, and

then match to the connection level and align the trapezoid tooth of traverse relay gear with the slide plate

1.

Step 6 Install the spindle base unit. (First, slide plate 1.)

*When installing the traverse relay gear, align the trapezoid tooth

of gear with tooth of traverse cam gear.

22

SC-HM910/SC-HM810

Step 7 Move the slide plate 1 to forward fully.

Step 8 Install the rear lock. (The claw should be latched.)

Step 9 Install the bottom SW P.C.B. (The claw should be

latched.)

Step 10 Install the tray lock. (The claw should be latched.)

Step 11 Remove the tray lock spring from hook, and then latch

to the tray lock.

Step 12 Install the UP/DOWN gear, change gear, change gear

spring, pulley gear and belt in the order of (1) - (5).

Step 13 Install the gear holder, and then tighten the screw (a).

23

SC-HM910/SC-HM810

7.7. Replacement for the motor ass’y

• Follow the (Step 1) - (Step 2) of item 7.1.

• Follow the Disassembly for the CD Changer of item 7.2.

• Follow the (Step 1) - (Step 8) of item 7.4.

• Follow the (Step 1) - (Step 7) of item 7.5.

Step 14 Install the tray base, traverse ass’y mechanism cover

and upper plate.

(operation check after servicing).

Check the proper operation of following items with gear and

hexagonal screwdriver.

1. Open/close of tray base.

2. Moving the tray base to the stock side.

3. UP/DOWN operation of spindle base unit.

4. UP/DOWN operation of traverse ass’y.

Step 1 Install the belt temporarily.

Note:

Take care not apply the grease to the belt.

Step 2 Upset the CD loading unit.

Step 3 Remove 3 screws.

24

Step 4 Unsolder the plunger terminals (2 points).

Step 5 Unsolder the motor terminals (2 points).

Step 6 Release the 2 claws (A), and then remove the Motor

P.C.B.

Step 7 Release the claw (B), and then remove the motor ass’y.

(Notice for motor ass’y installation)

1. Locate the name plate of motor to the traverse ass’y.

2. Align the hole of motor with the ribs.

7.8. Replacement for the pinch roller ass’y and head block

• Follow the (Step 1) - (Step 2) of item 7.1.

• Follow the Disassembly for the CD Changer of item 7.2.

• Follow the (Step 1) - (Step 14) of item 7.4.

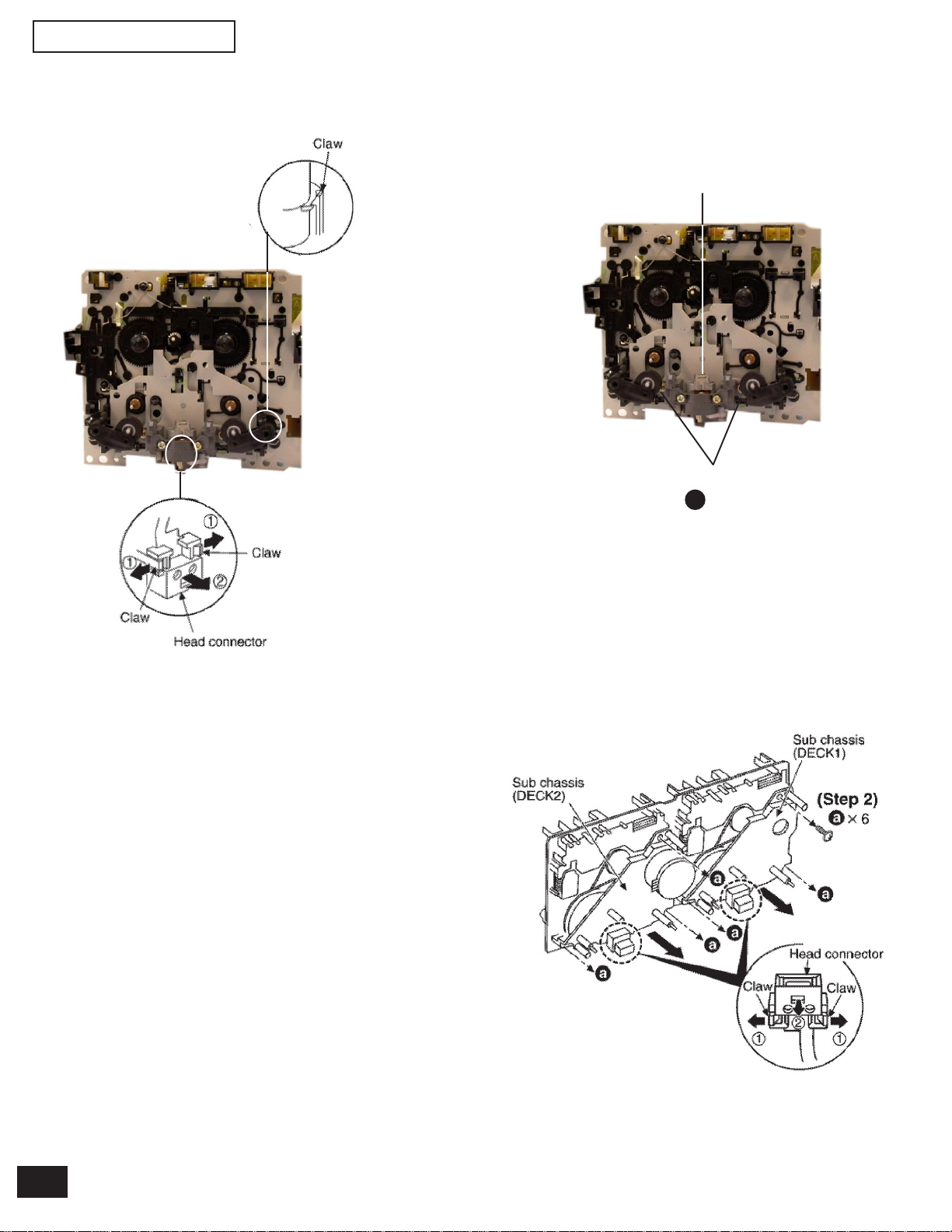

Step 1 Remove the connector.??

Step 4 Pull out the FFC.

Step 5 Remove the flat cable from the connector.

Step 6 Push the lever upward, and then open the cassette lid

ass’y (For DECK1 and DECK2).

SC-HM910/SC-HM810

Claw

Claw

a x 3

(step 2)

Step 2 Remove 3 screws.

Step 3 Remove the 2 claws, and then draw the front panel

ass’y.

(Step 4)

Cassette

lid

ass’y

(Step 7)

(Step 8)

a x 5

Step 7 Remove the flat cable from the connector (CN1001).

Step 8 Remove the 5 screw.

Cassette mechanism

(2)

(1)

Step 9 Tilt the cassette mechanism in the direction of arrow

(1), and then remove it in the direction of arrow (2).

(Step 10)

(Step 7)

(Step 5)

Step 10 Unsolder the motor

terminals.

a x 3

(step 11)

25

SC-HM910/SC-HM810

Step 11 Remove 4 screws.

Step 12 Remove mechanism Deck P.C.B.

* The mechanism as shown below is for DECK 1. For the one of

DECK 2, perform the same procedures.

Pinch roller ass’y (R)

(RXL0125)

Step 13 Release the 2 claws, and then remove the pinch roller

(R), (F).

Step 14 Release ther 2 claws, and then remove the head con-

nector.

(Head Blook

DECK1: RED0063-1

DECK2: RED0074-1)

(Step 15)

a x 2

Step 15 Remove 2 screws.

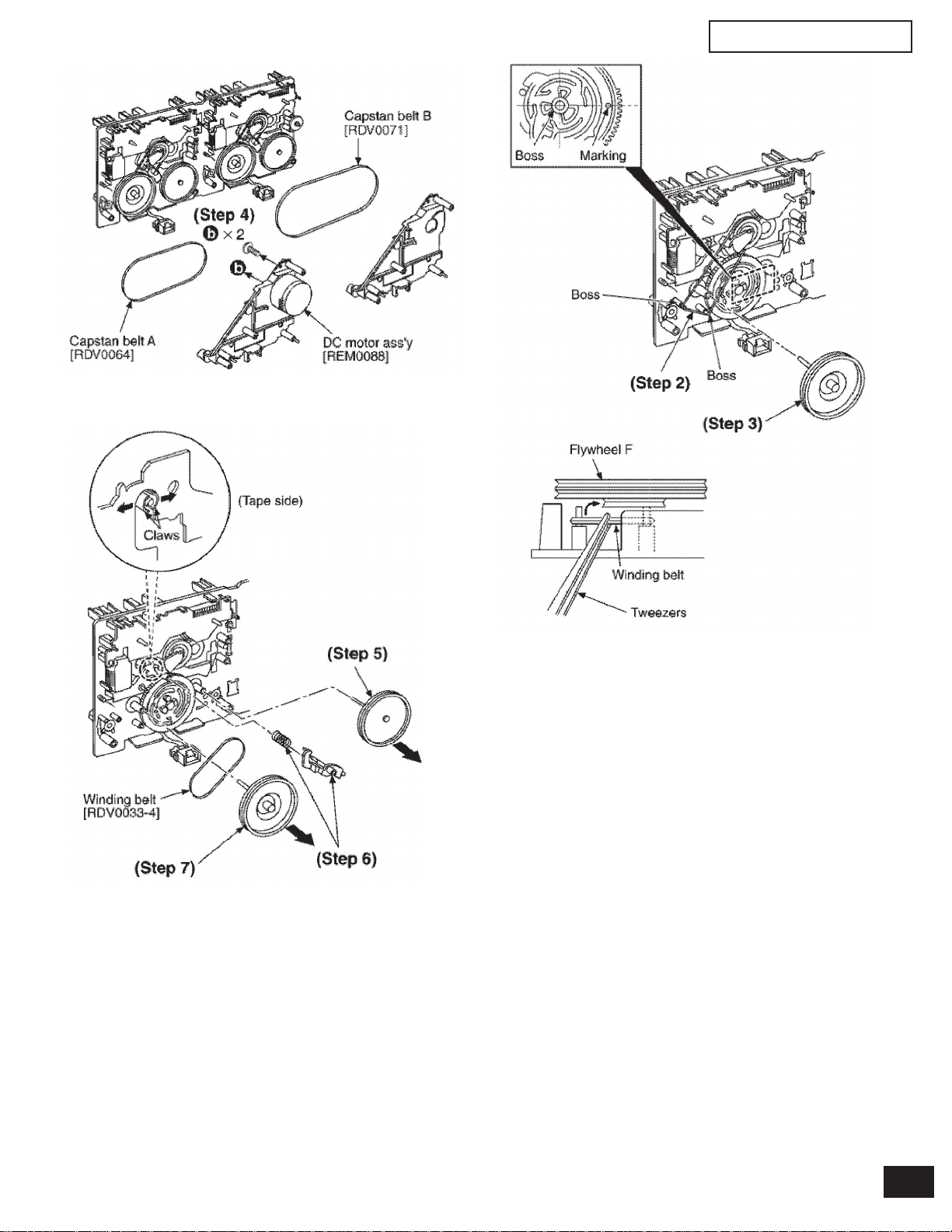

7.9. Replacement for the CD motor ass’y. capstan belt A, capstan belt B

and winding belt

• Follow the (Step 1) - (Step 2) of item 7.1

• Follow the Disassembly for the CD Changer of item 7.2.

• Follow the (Step 1) - (Step 14) of item 7.4.

• Follow the (Step 1) - (Step 11) of item 7.9

Step 1 Release the 2 claws, and then remove the head con-

nector.

Step 2 Remove 6 screw.

Step 3 Remove the sub chassis

26

Step 4 Remove 2 screws.

SC-HM910/SC-HM810

Step 5 Remove the flywheel R.

Step 6 Release the claw of tape side, and then remove the

winding lever and spring.

Step 7 Remove the flywheel F.

(Installation of the belt)

Step 1 The boss and marking should be positioned horizon-

tally.

Step 2 Put the winding belt on the pulley temporarily.

Step 3 Install the flywheel F.

Step 4 Put the winding belt on the flywheel F.

Step 5 Install the winding lever and spring while pressing the

winding arm in the direction of arrow.

Step 6 Install the flywheel R.

27

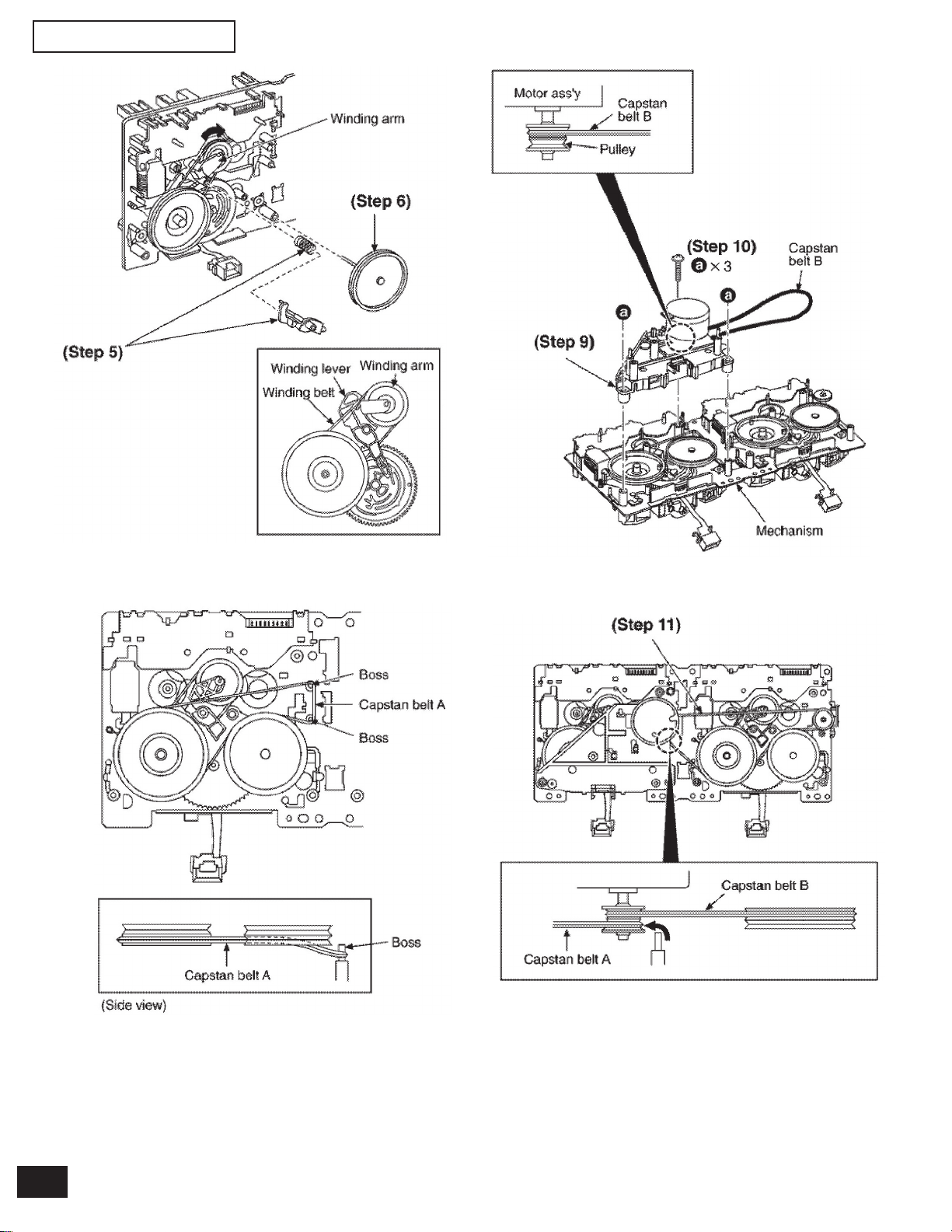

SC-HM910/SC-HM810

NOTE:

The winding lever should be positioned as shown below.

Step 7 Put the capstan belt A temporarily as shown below.

Step 10 Remove 3 screws.

Step 11 Put the capstan belt B as shown below.

Step 8 Put the capstan belt B on the motor ass’y pulley.

Step 9 Installl the sub chassis to the mechanism, and then

lighten screws.

28

Step 12 Put the capstan belt A on the motor ass’y pulley.

SC-HM910/SC-HM810

7.10.Replacement for the CD motor ass’y. capstan belt A, capstan

belt B and winding belt

• Follow the (Step 1) - (Step 2) of item 7.1

• Follow the Disassembly for the CD Changer of item 7.2.

• Follow the (Step 1) - (Step 14) of item 7.4.

• Follow the (Step 1) - (Step 11) of item 7.9

Step 1 Remove 2 screws.

Step 2 Unsolder the plunger terminals (2 points).

Step 3 Release the 3 claws, and then remove the mechanism

P.C.B.

a x 1

(step 1)

Claw ClawClaw

a

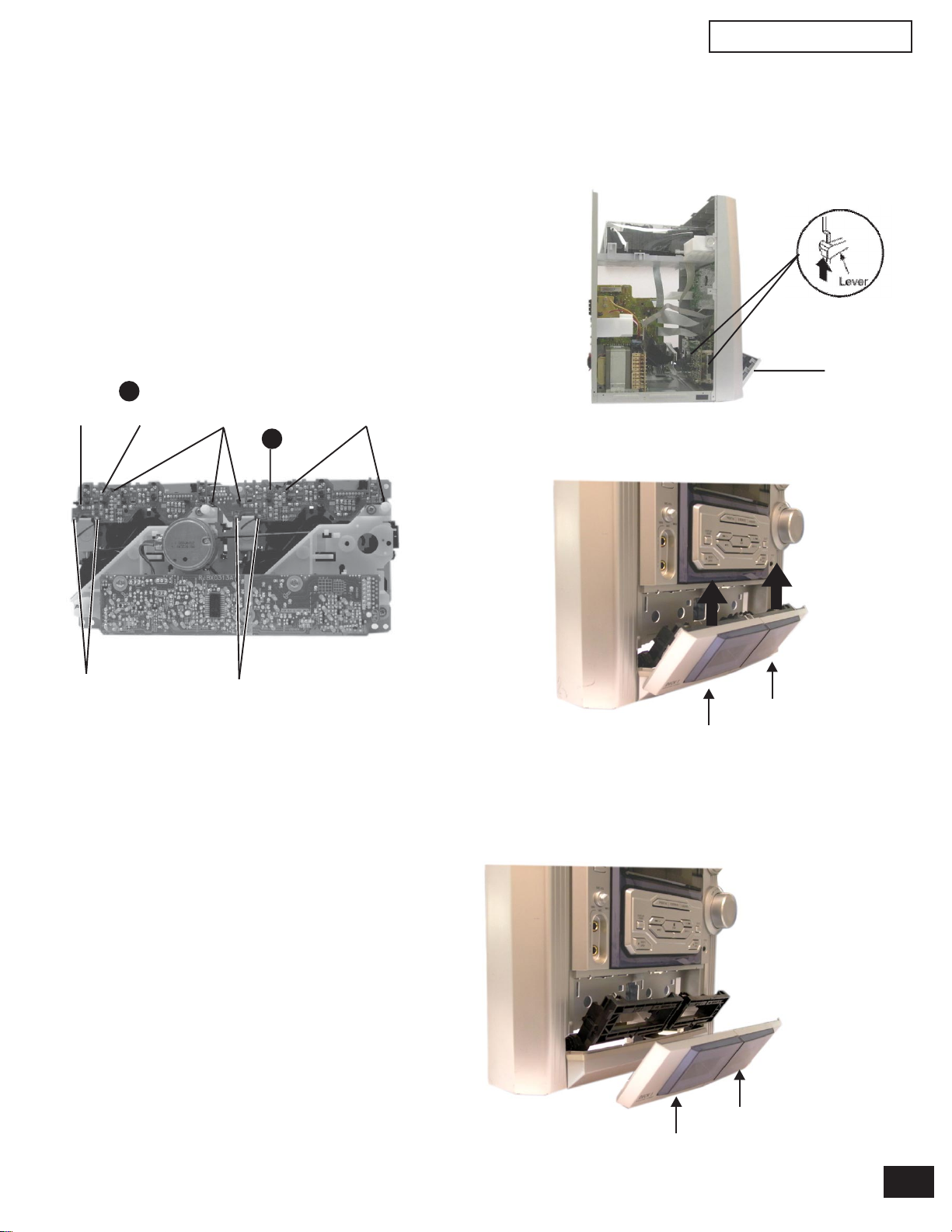

7.11.Replacement for the cassette

lid ass’y

• Follow the (Step 1) - (Step 7) of item 7.1

Step 1 Force the lever upward, open the cassette lid ass’y (For

DECK 1 and DECK2).

Cassette

lid

ass’y

Step 2 Lift up the cassette lid ass’y in the direction of arrow.

(For DECK1 and DECK2).

(Step 2)(Step 2)

Cassette lid ass’y

Cassette

lid ass’y

(DECK1)

Step 3 Remove the cassette lid ass’y. (For DECK1 and

DECK2).

Cassette lid ass’y

(DECK1)

(DECK2)

Cassette lid ass’y

(DECK2)

29

SC-HM910/SC-HM810

7.12.Measure for tape trouble

• Follow the (Step 1) - (Step 2) of item 7.1

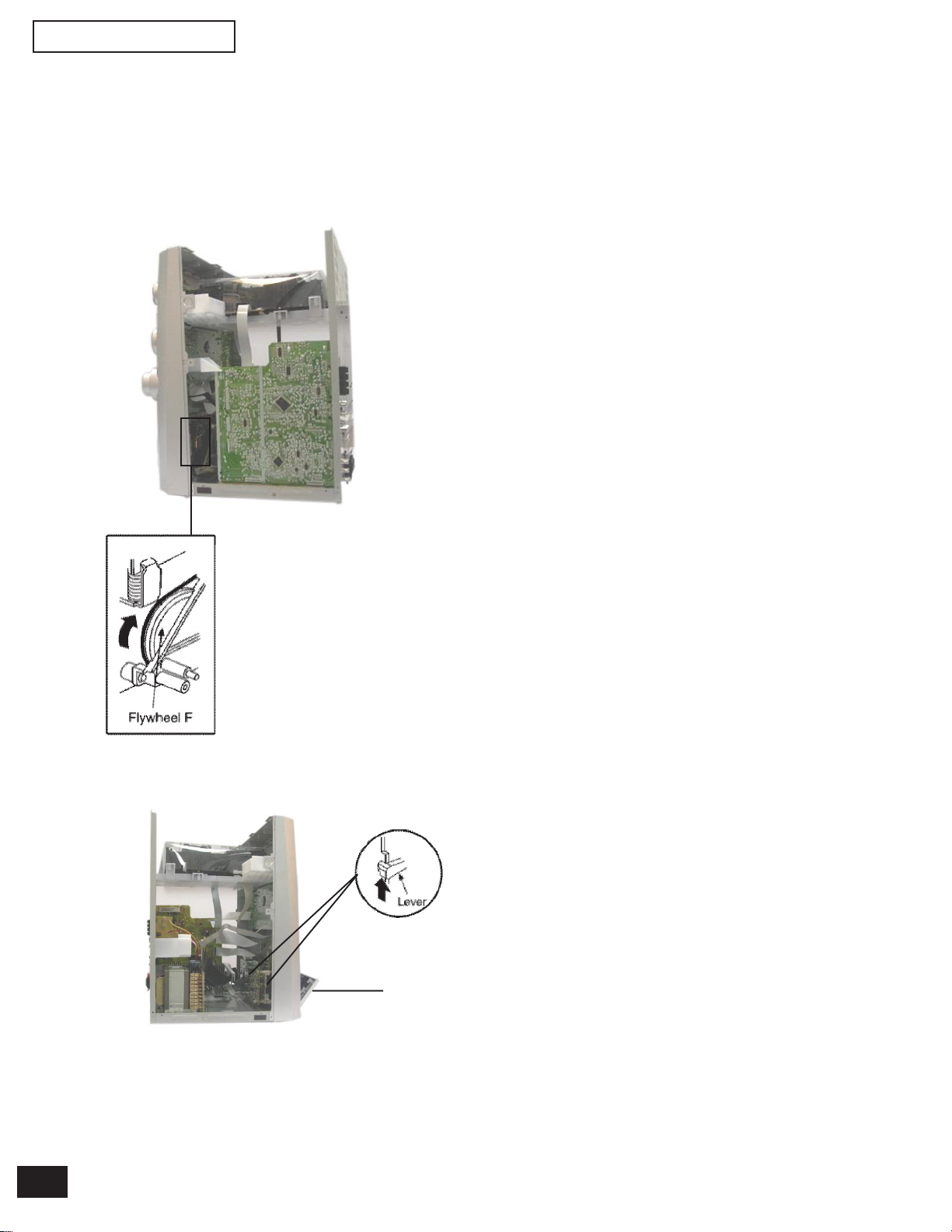

Step 1 If a cassette tape cannot be removed from the deck

since the tape is caught by the capstan or pich roller

during playback or recording, rotate the flywheel F in

the direction of the arrow to remove the tape.

Step 2 Force the lever upward and open the cassette lid ass’y.

Take the cassette tape off.

Cassette

30

lid

ass’y

Loading...

Loading...