PAN MULTILAYER CERAMIC CAPACITOR Specification

Document No.: M01-00-E-03

PRODUCT: MULTILAYER CERAMIC CAPACITOR

TYPE : CHIP CAPACITOR

APPROVED BY CUSTOMER

PAN OVERSEAS ELECTRONIC CO., LTD.

TAIWAN HEAD OFFICE:

TEL: 02-25213252~5, 02-25634133

FAX: 02-25373069

TAIWAN FACTORY:

TEL: 06-6982143, 06-6982331

FAX: 06-6983400,(QA:06-6993898)

PAN OVERSEAS

PAN OVERSEAS (GUANG ZHOU):

TEL: 86-20-82237476

FAX: 86-20-82237475

PAN OVERSEAS (KUN SHAN):

TEL: 86-512-57707888

FAX: 86-512-57711076

QUALITY ASSURANCE DEPARTMENT

APPROVED

▓

TAIWAN

CHECKED

□

GUANG ZHOU□KUN SHAN

PREPARED

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

Code

voltage

Code

voltage

Code

voltage

Code

voltage

Code

voltage

6.3V

200V

630V

3000V

10V

250V

1000V

4000V

16V

100V

500V

2000V

5000V

Length (L)

Width (W)

Thickness (T)

MB(Min)

G(Min)

6.3~ 50V

6.3~250V

6.3~500V

10.16±0.5

15.24±0.5

1. SCOPE

This specification is applicable to Pan Overseas multilayer ceramic capacitors.

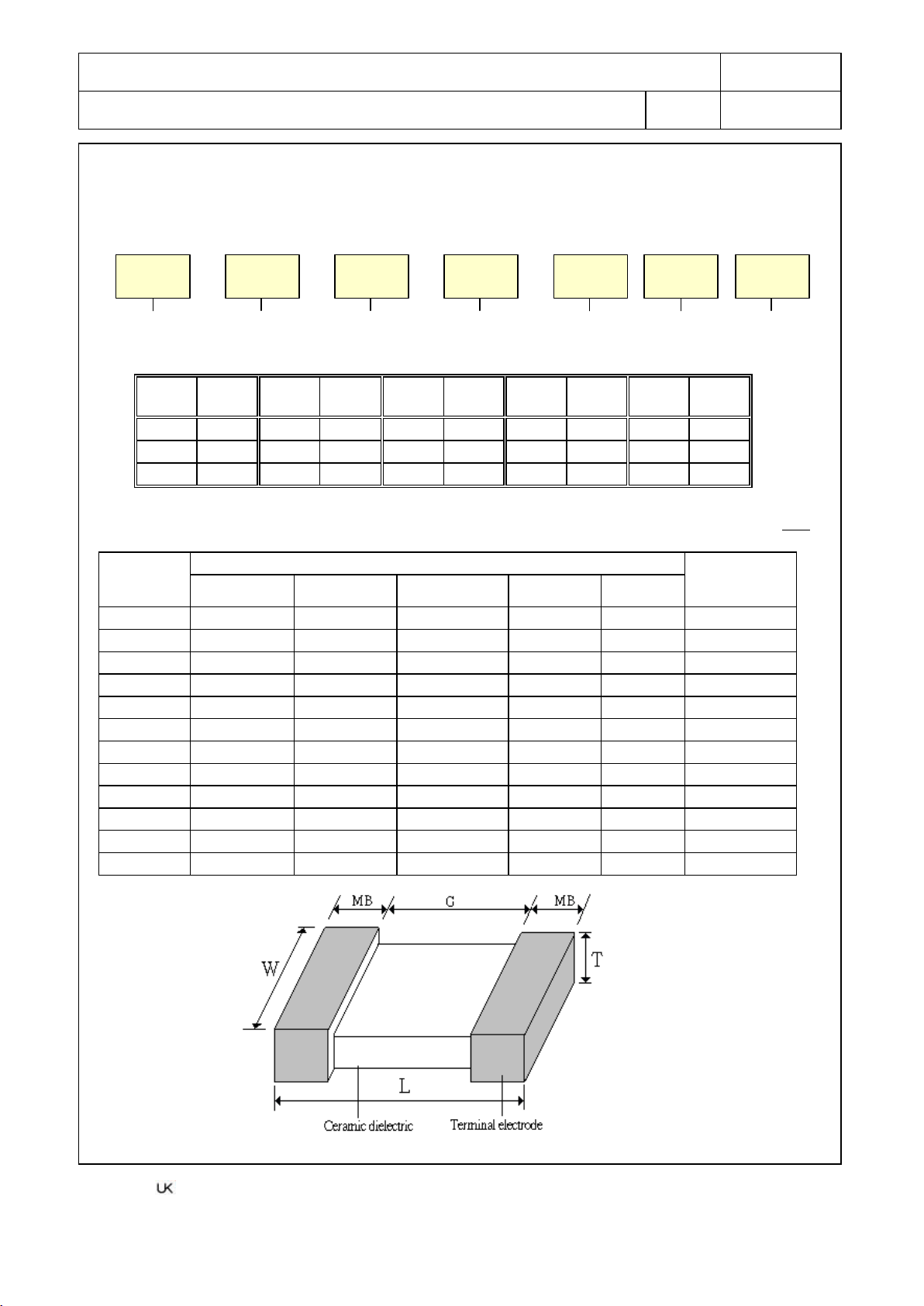

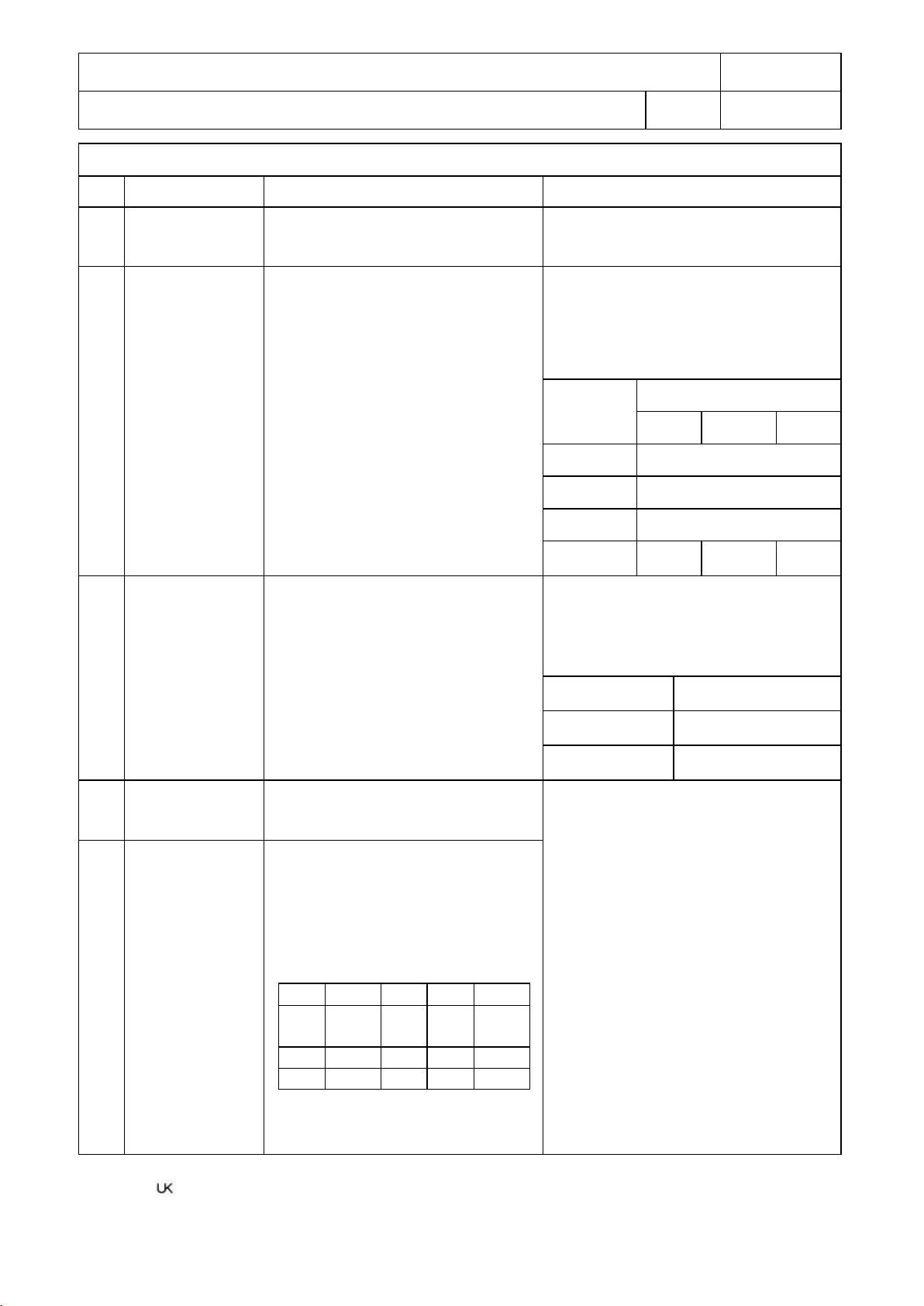

2.CODE CONSTRUCTION

U 0805 C

:

102

J N T

À Á Â Ã Ä Å Æ

À Rated Voltage:

K

N

B

Rated

T 25V G

U 50V H

A

Rated

C

Rated

D

M

M2

Rated

M3

M4

M5

Á Part Dimension:

Dimension

Page: 1

Rated

Unit: mm

0402 1.0±0.05 0.5±0.05 0.5±0.05 0.10 0.30

0603 1.6±0.1 0.8±0.1 0.8±0.1 0.20 0.40

0805 2.0±0.2 1.25±0.1 1.40 max. 0.25 0.70

1206 3.2±0.2 1.60±0.2 1.52 max. 0.25 1.40 6.3~1KV

1210 3.2±0.3 2.5±0.3 1.8 max. 0.25 1.40 6.3~1KV

1808 4.5±0.35 2.0±0.3 2.0 max. 0.25 2.15 6.3~5KV

1812 4.5±0.35 3.2±0.3 1.8 max. 0.25 2.15 16~5KV

2220 5.7±0.4 5.0±0.4 1.8 max. 0.25 3.30 16~5KV

2225 5.7±0.4 6.3±0.4 1.8 max. 0.25 3.30 16~5KV

3640 9.2±0.5

2.0 max. 0.50 2.70 16~5KV

5550 14.0±0.5 12.7±0.5 2.5 max. 0.50 10.5 16~5KV

8060 20.3±0.5

2.5 max. 0.50 16.8 16~5KV

PAN OVERSEAS

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

M Tolerance

Z Tolerance

and RH 45 to 75%.

If any doubt and argument has been encounter in judgement, the final test shall be done at 25±2

+80% / -20%

Code

Capacitance(pF)

Code

Capacitance(pF)

102

1R5

222

472

103

+125

+125

+85

+85

-82%

+85

-56%

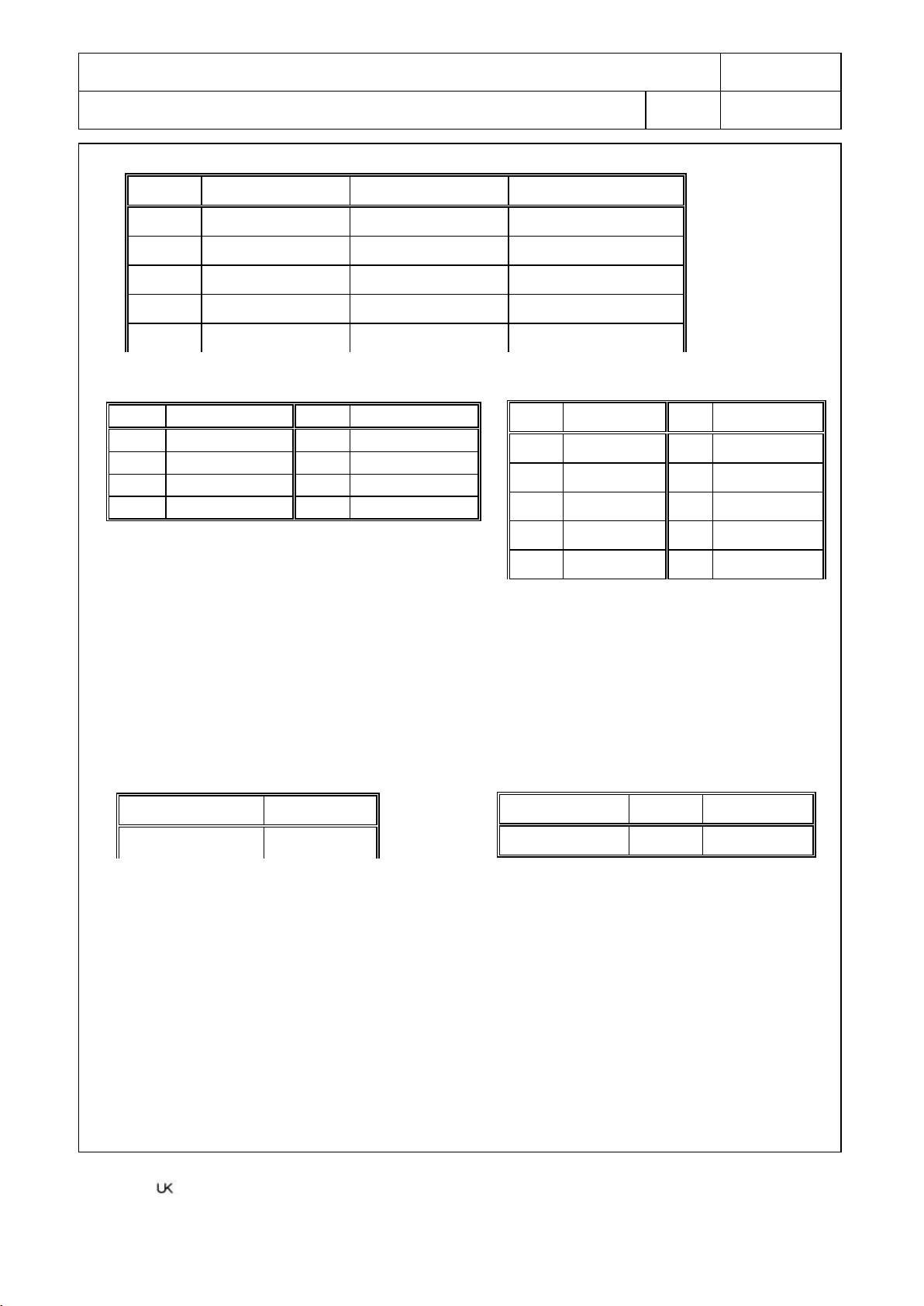

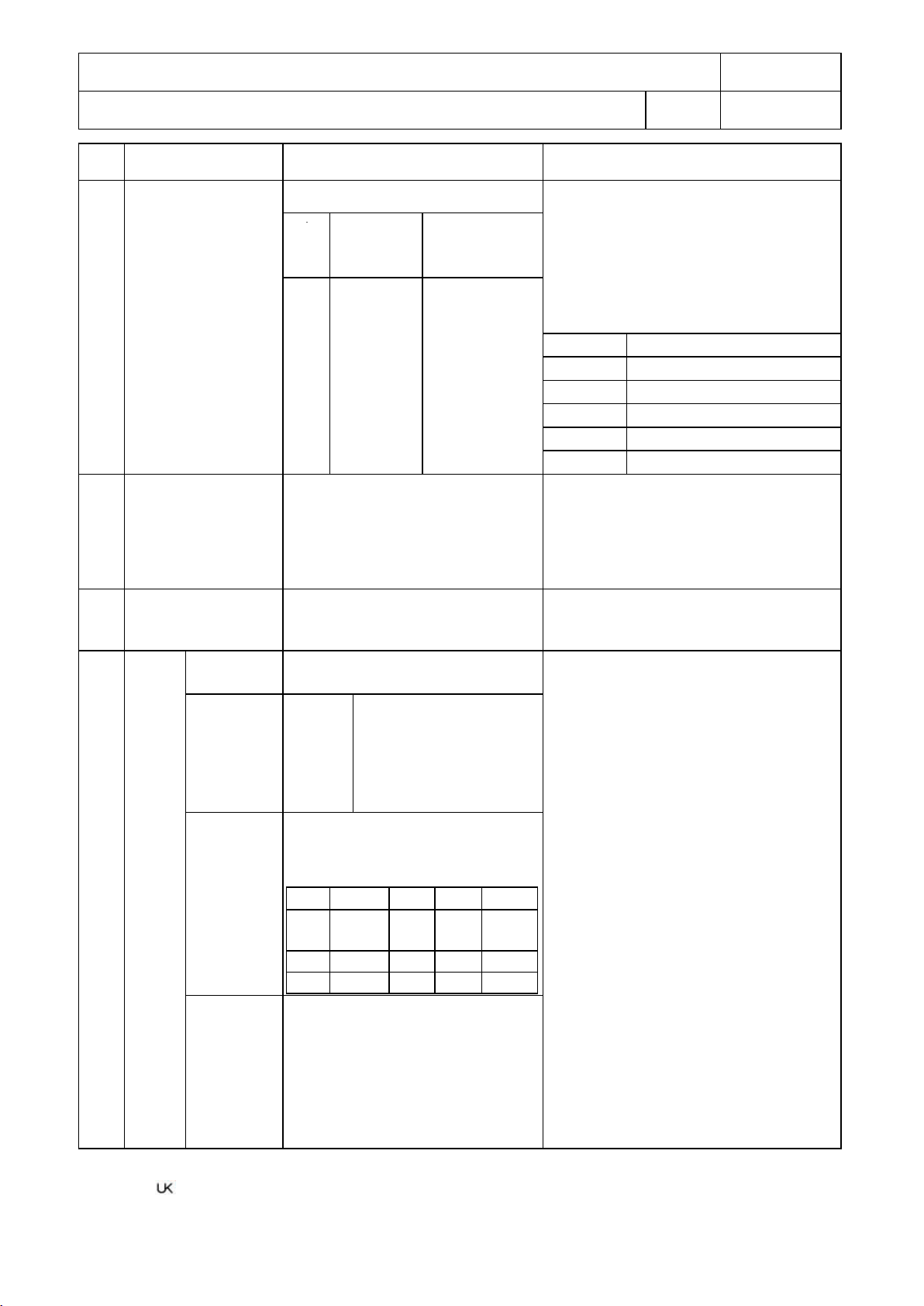

Temperature Characteristics Code:

Code Temp. Coefficient Operation Temp. Capacitance Change

C NP0 (Class I)

R X7R (Class II)

X X5R (Class II)

F Y5V (Class II)

E Z5U (Class II)

à Capacitance Code:

010 1 *

1.5

100 10 *

101 100 *

-55℃ ~

-55℃ ~

-55℃ ~

-30℃ ~

+10℃ ~

1000 *

2200 *

4700 *

10000 *

℃ 0 ± 30 ppm/℃

℃

℃

± 15%

± 15%

℃ +22% ~

℃ +22% ~

Ä Tolerance Code:

Code Tolerance Code Tolerance

B ± 0.1pF J ±5%

C ±0.25pF K ±10%

D ±0.50pF M ±20%

F ± 1% Z

G ± 2%

Page: 2

PS: 1. * -- Two significant digits followed by no. of zeros

2. Temperature coefficient (T.C.) vs. Proper tolerance applied:

NPO: For all tolerance

X7R、X5R: K、

Y5V、Z5U: M、

Å Termination Code:

Code N

Termination Type Nickel

3. STANDARD TEST CONDITIONS

:

Æ Packaging Code:

Code B T

Packaging Type Bulk Tape & Reel

Tests shall, unless otherwise specified, be carried out at 15 to 35℃

℃,RH45 to 55% and 860~1060mbar. (Based on JIS standard)

4. DISPOSITION

If question to the measuring result in judgement, take the capacitor under a specified temperature

for 30 minutes at least before measurement.

PAN OVERSEAS

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

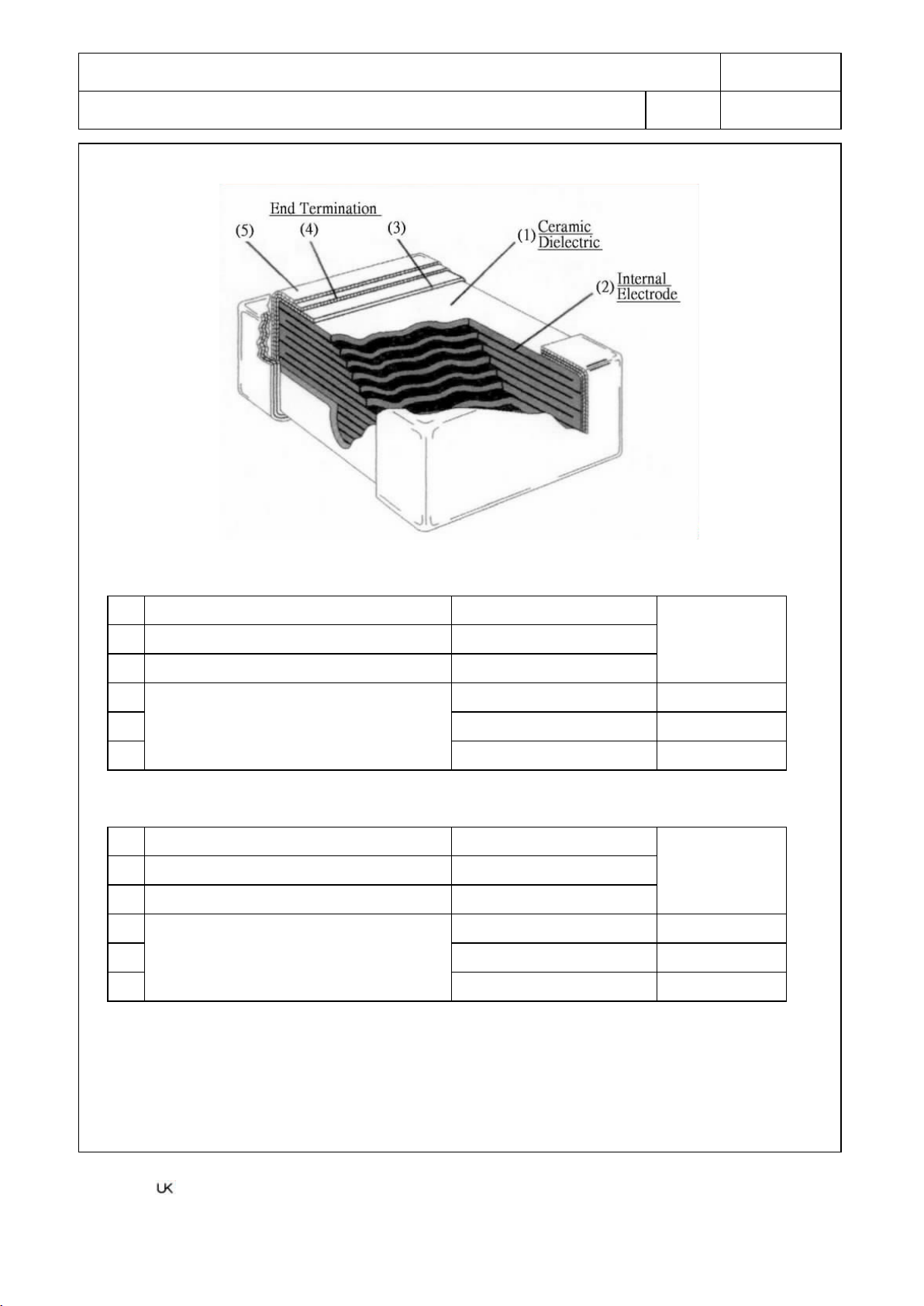

Cu layer

5. STRUCTURE:

Page: 3

Ag / Pd SERIES:

NO Specifications Material

1 Ceramic dielectric Ceramic

2 Internal Electrode Ag-Pd

Termination

Plating

thickness

3 Ag layer 40μm min

4 Ni layer 1.5-3.5μm min

5

End Terminal

Sn-Pb layer or Sn layer 3-8μm min

BME SERIES:

NO Specifications Material

1 Ceramic dielectric Ceramic

2 Internal Electrode Ni

3

4 Ni layer 1.5-3.5μm min

5

End Termination

Sn-Pb layer or Sn layer 3-8μm min

Termination

Plating

thickness

40μm min

6. STORING CONDITION AND TERM

Recommends the storing of products within 6 months at temperature 15~35℃ and humidity

70%RH max. If the product stored over 6 months, please reconfirm its solderability before use.

PAN OVERSEAS

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

Visual inspection & Dimension

Apply DC tested voltage for 60

< 30pF :

。

Page: 4

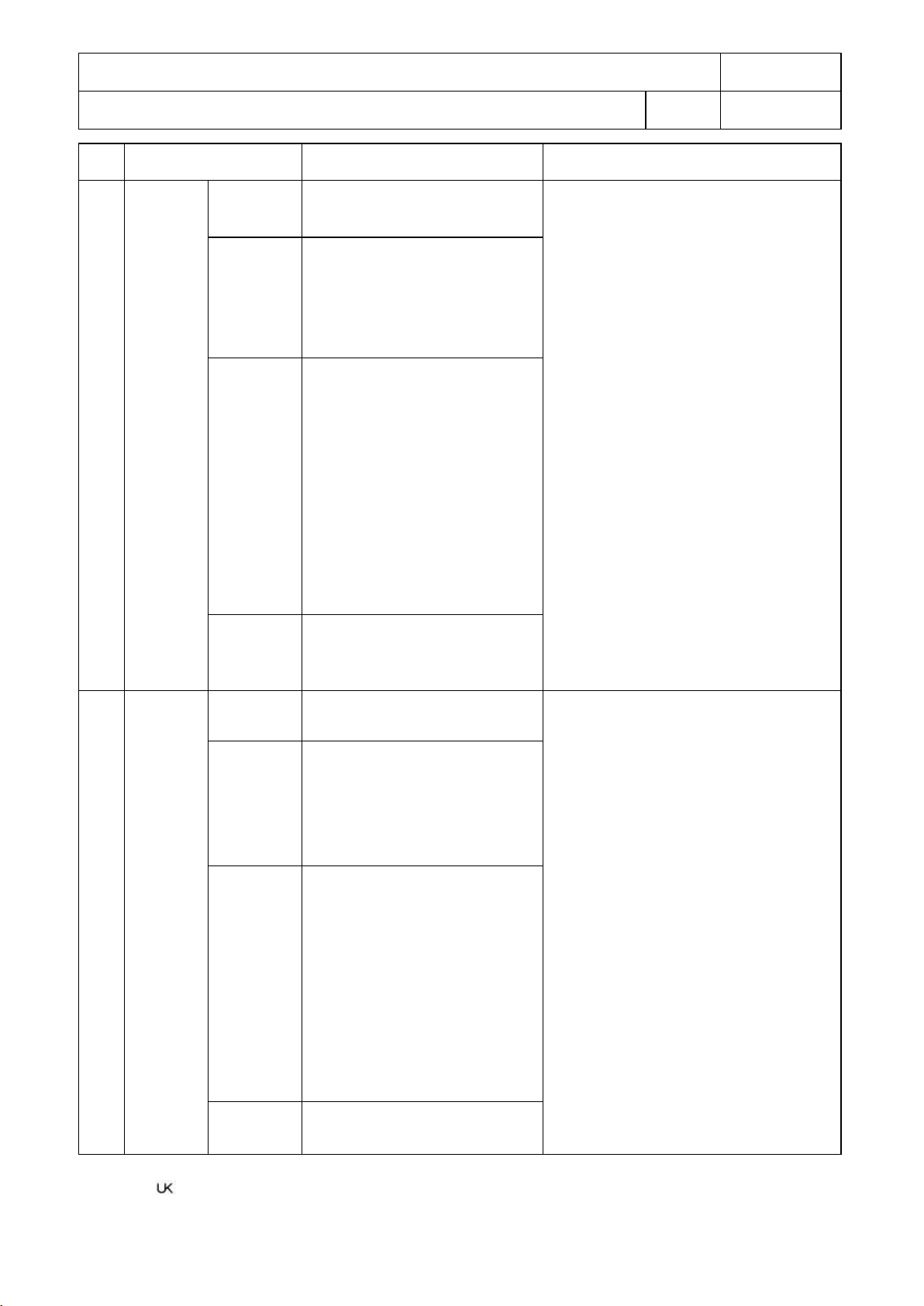

7. PERFORMANCE:

NO. Item Performance Test or Inspection method

(1) External

Appearance

Voltage Proof Withstand test voltage without

(2)

No defects which may affect

performance.

Insulation breakdown or other

damage.

measurement

DC Tested voltage shall be applied for

1~5sec. Charge/discharge current

shall not exceed 50 mA .

(PS: Ra – Rated Voltage )

Rated

voltage

DC Tested voltage

NPO X7R/X5R Y5V

≦200V 2.5Ra

250V 2.0Ra

500V/630V 1.5Ra

Insulation

(3)

Resistance

(4) Capacitance

(Cap.)

(5) Dissipation

Factor (D. F.)

NPO:

100,000MΩ Min. or

R‧C ≧ 1,000 Ω.F

(Whichever is smaller)

X7R, X5R, Y5V, Z5U:

10,000MΩ Min or

R‧C ≧ 1,000Ω.F

(Whichever is smaller)

Within the specified tolerance that

refers on page 2

NPO:

≧30pF: Q ≧ 1000

Q≧400+20C

PS: C: Nominal Capacitance (pF)

X7R、X5R、Y5V& Z5U:(Max. value)

T.C.≧50V 25V 16V

X7R/

X5R

Z5U 4.0% --- --- ---

Y5V 5.0% 7.5% 9.0% 12.5%

2.5% 3.0% 3.5% 5.0%

≦

10V

≧1K

V 1.5Ra 1.25Ra -----

±5

minute.

(PS: Ra – Rated Voltage)

Rated voltage

DC Tested voltage

<1KV 1.0 Ra

≧1KV 1KV

Measuring frequency:

Z5U、Y5V、X7R、X5R:1KHz±50Hz

NPO:>1000pF:1KHz±50Hz。

≦1000pF:1MHz±100KHz

Measuring voltage:

Z5U:0.5 Vrms

NPO、X7R、X5R、Y5V:1.0±0.2 Vrms

PAN OVERSEAS

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

The temperature coefficient is

determined using the capacitance

measured in step 3 as a reference.

Test the specimen from step 1

through step 5, the capacitance shall

be within the specified tolerance for

the capacitance coefficient and

Temperature(℃)

NPO

X7R

X5R

Y5V

Z5U

-55~+125

-55~+125

0±30(ppm/℃)

+22%~ -56%

Completely soak both terminal electrodes in

a. For Tin-Lead Sn/Pb) Termination product:

b. For Lead-free (Pure Sn) Termination

Completely soak both terminal

electrodes in solder at 270±5℃ for

appearance

C<30pF:Q≧400+20*C

(Max. value)

for

Leave the capacitors in ambient

condition for

hours before

Page: 5

NO. Item Performance Test or Inspection method

(6) Temperature

Characteristic of

Temperatures Coefficient

Operating Capacitance

T.C.

Capacitance

Temperature Change(ΔC)

℃

℃

-55~+85℃

-30~+85℃

± 15%

± 15%

+22%~-

82%

+10~+85℃

capacitance change as left table.

Step

1 Base Temp.(25℃)±2℃

2 Min. Operation Temp.±2℃

3 Base Temp.(25℃)±2℃

4 Max. Operation Temp.±2℃

5 Base Temp.(25℃)±2℃

(7) Solderability

New solder to over 95% of

termination

solder at specified temperature for 3±0.5 sec.:

235±5℃

(8) Leaching

(9) Solder-

ing to

Heat

External

Cap. change

(ΔC/C)

D.F.

I.R.

New solder to over 95% of

termination

No mechanical damage.

NPO

X7R/X5R

Z5U

Y5V

±2.5% or ± 0.25 pF max.

( Whichever is larger)

±7.5%

±20%

±20%

NPO: C≧30pF:Q≧1000

PS: C: Nominal Capacitance (pF)

X7R、X5R、Y5V& Z5U:

T.C.≧50V 25V 16V

X7R/

X5R

Z5U 4.0% --- --- ---

Y5V 5.0% 7.5% 9.0% 12.5%

NPO:

X7R、X5R、Y5V、Z5U:

2.5% 3.0% 3.5% 5.0%

100,000MΩ Min. or

R‧C ≧ 1,000 Ω.F

(Whichever is smaller)

10,000MΩ Min or

R‧C ≧ 1,000Ω.F

(Whichever is smaller)

≦

10V

product: 245±5℃

40±1 sec.

Completely immerse both

terminations in solder at 270±5℃

10±3 sec.

24±2

measurement.

*Preconditioning:(only for Class 2):

Perform a heat treatment at 150 +0-

10℃ for one hour and then let sit for

24 ± 2 hours at room temperature.

Perform the initial measurement.

PAN OVERSEAS

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

PS: C: Nominal Capacitance

X7R/ X5R: Less than 2 times

Y5V & Z5U: Less than 1.5

min. or 25

A. Humidity load: (Not apply for the

product with rated voltage

Apply the rated voltage at

temperature 40±2℃ and humidity

90 to 95%RH for 1000+48/-0

Leave the capacitors in ambient

condition for the following time

* Charge / discharge current shall. not

* Preconditioning:(only for Class 2):

Apply the

(Whichever is larger

PS: C: Nominal Capacitance

X7R/ X5R: Less than 2 times

Y5V & Z5U: Less than 1.5

Page: 6

NO. Item Performance Test or Inspection method

(10)

Humidity

(Steady

state)

&

Humidity

load

External

appearance

Cap. change

(ΔC/C)

D.F.

No mechanical damage.

NPO: ± 5% or ±0.5 pFmax.

(Whichever is larger)

X7R/

X5R:±

12.5

﹪

Y5V: ±30%

Z5U: ±30%

NPO:

C≧30pF: Q ≧350

10pF≦C<30pF:

250V):

hours.

before measurement.

Class 1:1~2 hours.

Class 2:24±2hours.

Q≧100+2.5*C

C<10pF: 200+10*C

(pF)

exceed 50 mA.

rated DC voltage for 1hour

at 40±2℃. Remove and let sit for

of initial value

48±4 hours at room temperature.

Perform initial measurement.

≧

(11) Load Life

I.R.

External

appearance

Cap. change

(ΔC/C)

D.F.

I.R.

times of initial value

500MΩ

(Whichever is smaller)

Ω*F

No mechanical damage.

NPO: ±3% or ±0.3pFmax.

X7R/

X5R:±

12.5

﹪

Y5V: ±30%

Z5U: ±30%

NPO:

C≧30pF: Q≧350

30pF>C≧10pF:

Q≧275+2.5*C

C<10pF:Q≧200+10*C

(pF)

of initial value

times of initial value

1000MΩ min. or 50Ω*F

(Whichever is smaller)

B. Humidity (Steady state):

The test procedure is same as that

in Humidity load but only without

rated voltage applied.

Apply 2×rated voltage at maximum

operating temperature ±2℃ for 1000

+48/-0 hours.

)

Leave the capacitors in ambient

condition for the following time

before measurement.

Class I: 1~2 hours

Class II: 24±2 hours

* Charge / discharge current shall. not

exceed 50 mA.

* Preconditioning:(only for Class 2):

Apply 200% of the rated DC voltage

for 1 hour at the maximum operating

temperature ± 3℃. Remove and let sit

for 24±2 hours at room temperature.

Perform initial measurement.

PAN OVERSEAS

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

(Whichever is larger

PS: C: Nominal Capacitance

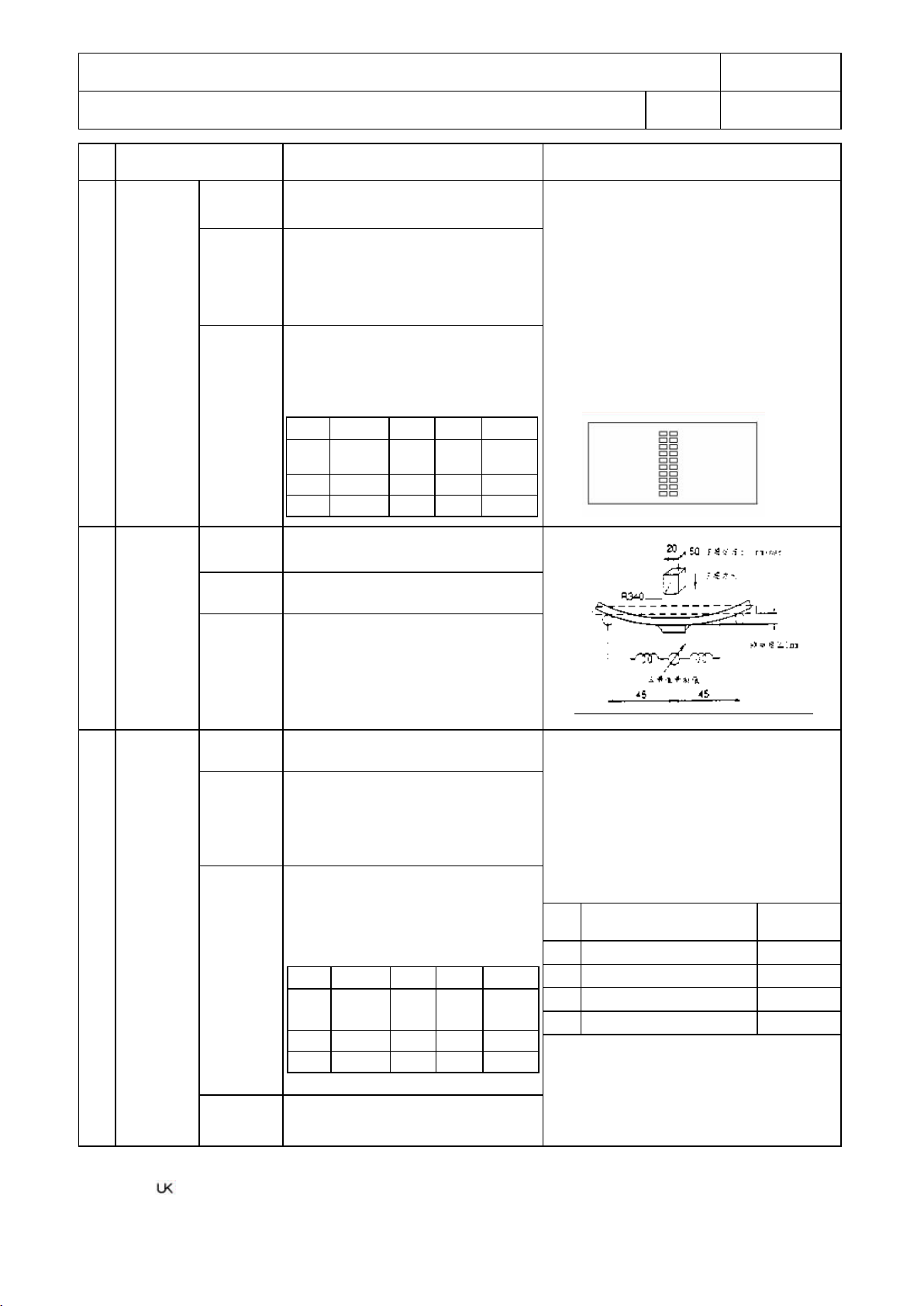

Solder the capacitors to the test jig as shown

in figure below with IR-Reflow method. The

capacitor shall be subjected to a simple

harmonic motion with the entire frequency

range, from 10 to 55 Hz and return to 10

Amplitude(total excursion):1.5mm

Amplitude tolerance:

This motion shall be applied for a period of 2

hours in each of 3 mutually perpendicular

appearance

appearance

The capacitor shall be subject 5 cycles

according to four heat treatments

Then Leave the capacitors in ambient

condition for the following time

Step

Duration

(min.)

1

2

3

4

min. or 500

*Preconditioning:(only for Class 2):

Perform a heat treatment at 150

+0-10

X5R

Page: 7

NO. Item Performance Test or Inspection method

(12)Vibration

(13)Deflectio

External

appearance

Cap.

change

(ΔC/C)

D.F. or Q

External

Without distinct damage

NPO: ±2.5% or ±0.25pF max.

)

X7R

/ X5R:±

Y5V、Z5U: ±

NPO: C≧30pF:Q≧1000

C<30pF:Q≧400+20*C

X7R、X5R、Y5V& Z5U:(Max. value)

T.C.≧50V 25V 16V

X7R/

Z5U 4.0% --- --- ---

Y5V 5.0% 7.5% 9.0% 12.5%

2.5% 3.0% 3.5% 5.0%

7.5

20%

﹪

(pF)

≦

No cracking or marking defects

(Not apply for 0402 product)

Hz ,shall be transverse in 1 min.

directions (a total of 6 hours)

10V

±15%

shall occur

n

Bending

Flexure ≧ 1mm

strength

Cap.

change

(ΔC/C)

NPO: ±5% or±0.5pFmax.

( Whichever is larger)

X7R

/ X5R

: ±12.5﹪

Y5V: ±30﹪

(14

Temperatur

)

e cycle

PAN OVERSEAS

External

Cap.

change

(ΔC/C)

D.F.

I.R.

No mechanical damage.

NPO: ±2.5% or ±0.25pFmax.

( Whichever is larger)

X7R

/ X5R:±

7.5

﹪

Y5V: ±20﹪

NPO:

C≧30pF:Q≧1000

C<30pF:Q≧400+20*C

X7R、X5R Y5V&Z5U: (Max. value)

T.C.≧50V 25V 16V

X7R/

X5R

Z5U 4.0% --- --- ---

Y5V 5.0% 7.5% 9.0% 12.5%

2.5% 3.0% 3.5% 5.0%

10000MΩ

(Whichever is smaller)

≦

Ω*F

10V

(Not apply for 0402 product)

listed in the following table.

before measurement.

Class II: 2 ~ 24 hours

Temperature (℃)

Min. Operation Temp.±3 30±3

Room Temp. (25℃) 2 ~ 5

Max. Operation Temp.±3 30±3

Room Temp. (25℃) 2 ~ 5

℃ for one hour and then let sit

for 24±2 hours at room temperature.

Perform the initial measurement.

PAN OVERSEAS ELECTRONIC CO., LTD

M01-00-E-03

SPECIFICATION OF MULTILAYER CERAMIC CHIP CAPACITOR

Ver: 3

Page: 8

PAN OVERSEAS

Loading...

Loading...