Palstar HF-AUTO RF NETWORK, HF-AUTO Technical Manual

Palstar products are designed by

Hams for Hams carrying on the

Palstar tradition for high-quality

products designed and

manufactured in Ohio, USA.

HF-AUTO Automatic

Antenna Tuner

l 2 watts to 1800 watts PEP

l 160 m to 6m

l Tuning time 10 secs or less

l Large 4 line display

l 12.5” x 6.5” x 16.5”

9676 N. Looney Rd,

Piqua, OH 45356 USA

(937) 773-6255

(800) 773-7931

(937) 773-8003 (Fax)

www.palstar.com

HF-AUTO RF NETWORK

Technical Manual

Designed and Manufactured in the USA

Copyright 2014 Palstar, Inc.

PALSTAR

PALSTAR

l NETWORK CONFIGURATION: High-Pass network, shunt variable

16 μ H inductor, series xed 10 μ H inductor

l DIFFERENTIAL CAPACITOR: 470 pF - 10 pF - 470 pF;

Voltage rating 5.5 kV

l L AND C: Stepper motor-controlled

l FREQUENCY RANGE: 1.8 MHZ to 54 MHZ

l MATCHING RANGE: 8:1

l POWER RANGE: 1800 watts PEP/CW 1.8-29.9 MHZ;

800 watts PEP 50-54 MHZ

l TUNING LEVEL: Minimum level 2 watts,

single tone carrier up to 200 watts

l TUNING ACESS TIME: Typically <10 secs 80m to 6m;

3-5 secs 80m to 160m

l DUTY CYCLE: 100% SSB AND CW

l DIGITAL DISPLAY: RF Power, SWR, Frequency, Antenna

selection, Position of L and C;

Modes: Auto, Manual, Bypass, Setup

l OUTPUT: 3 Output connectors S0-239

l CHASSIS & COVER: 11 ga. .090 gold Iridite Treated Aluminium,

Powder-coated top cover and front panel

l DC POWER: 12 - 13.8 VDC at 4 Amps Peak, 3 Pin

Amphenol Type connector cord supplied

l DIMINSIONS: 12.5” W x 6.75“ H x 14” D

l WEIGHT: 20 LBS, 9 Kg

HF-AUTO SPECIFICATIONS

Page 14

Page 1

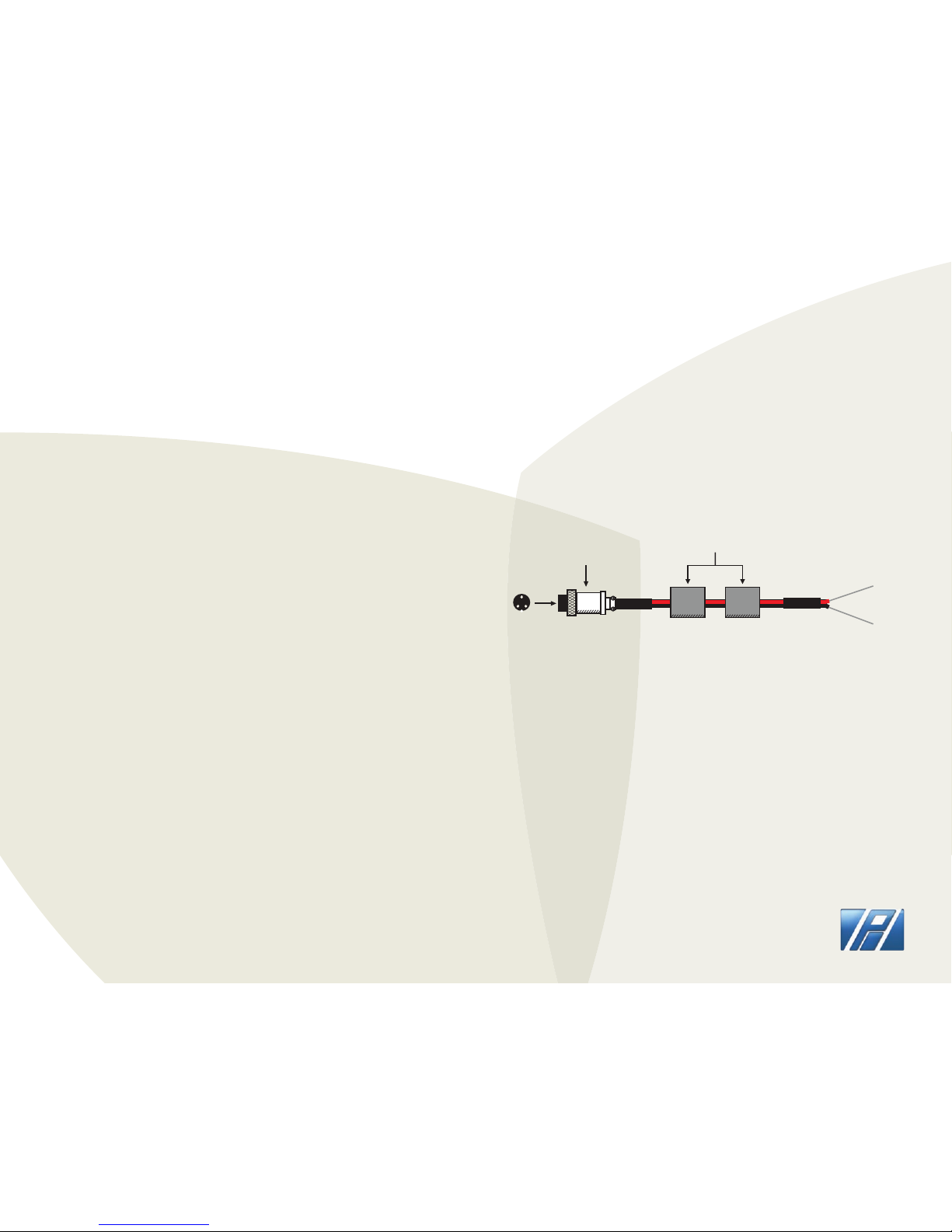

HF-AUTO POWER CABLE

PALSTAR

+

-

To 12-13.8v

Power Supply

3 PIN AMPHENOL

type plug

FERRITE BEADS

HF-AUTO DC POWER CORD

+

-

NC

IF THERE IS MAINTENANCE REQUIRED IT WILL MOST

LIKELY BE RELATED TO MECHANICAL ISSUES:

l ROLLER SHAFT: the wheel rides should be lubricated

with our factory-made conductive grease.

This grease is available from Palstar at NO CHARGE.

l DIOXIT-D5 spray is always very useful for cleaning the

wire on the roller coil. Do not use the spray directly. Put

a small amount on a cotton cloth and hand wipe the

roller once a year while turning the roller crank.

l All set screws are the CAP POINT type and take care to

carefully tighten these screws with a 5/16” allen key

wrench, which is available from any hardware outlet.

REPAIR OR REPLACEMENT MODULES

l All PC Boards are removeable with standard American

tools in case of failure.

l The rear panel (relay PCB) has custom S0-239

connectors that can be loosened witha 3/4“ socket and

4 x 6-32 keps nuts. Remove these nuts and two

connections from the variable and the entire relay PC

Board is removable without a soldering iron.

l Both the front and rear panels can be lowered by

removing the 3 countersink screws from the bottom edge

of each panel.

MAINTENANCE REQUIREMENTS

The HF-AUTO is a matching system that is a complete stand-alone RF

Tuneable Auto T Network tuner.

It is completely independent of data from an external source to

determine frequency of tracking from Band to Band. As a result of this

feature, the HF-AUTO will function with any transmitting device

without interconnecting data cable attachments.

The HF-AUTO uses an RF Coupler that provides voltage and current

information from 1.8 MHZ to 54 MHZ.

This informtion is then processed by a pair of processing devices that

provide accurate phase oriented forward and reected values that are

used in two TI processors to calculate SWR.

This allows for detection of frequency and SWR at very low levels,

typically 2 watts, and is scaled to read these levels up to 1800 watts.

The processors establish the threshold for tuning and uses this

information to see if a tuning sequence is required.

A preset voltage for all the frequencies are used to determine the

positions of the variable dierential capacitor and the roller inductor

by a precise mechanical sprocket and kevlar belt system.

This determines with great accuracy and repeatability the exact

location of L&C needed to execute a tune sequence. This system

samples DC voltage and compares this to the intended frequency band

and sees that if the SWR is more than the preset tuning set by the user

then the steppers for L & C will adjust to that voltage which will

represent the mimimum SWR.

This will be better than 1.2:1, typically 1.05.

Page 2

Page 13

THEORY OF OPERATION

PALSTAR

Loading...

Loading...