COMMANDER HF-2500

COMMANDER HF-2500 MAGNUM

Owner’s Manual

PALSTAR, INC.

Command Technologies Division

9676 N. Looney Road

Piqua, Ohio 45356

U.S.A.

Customer Service and Sales Telephone: 800-773-7931

International: 937-773-6255

Fax: 937-773-8003

E-mail: info@palstar.com

Rev. 2.5 28 June 2010

2

Table of Contents

Introduction 3

Specifications 4

Unpacking Instructions 5

Vacuum Tube Installation 5

HV Transformer Installation 6-8

Safety Warnings and Precautions 9

Connections 10

Rear Panel View 11

Front Panel View & Tuning Procedure 12

Theory of Operation & Adjustments 14

Warranty, Service, and Returns 16

RF Deck View 17

HF-2500 HV Power Supply Schematic 18

Access Plate Illustration 19

MAGNUM HV Power Supply Schematic 20

AC Mains & Step-Start Schematic 21

Control Board Schematic 22

Tuned Input & T/R Switch Schematic 23

RF Deck Schematic 24

Amplifier Test Card 25

PHOTO APPENDIX:

Dual Meters Diagram 26

Meter Board 27

Step-Start Board 28

Power Supply 29

Introduction

The Commander HF-2500 and Commander HF-2500 MAGNUM are class AB2 linear power

amplifiers. They have been designed for operation on all amateur frequencies from 1.80 MHz

to 29.7 MHz, excluding the 30 meter band.

Two Eimac 3CPX800A7 pulse rated ceramic-metal triodes configured in a grounded grid

circuit allow for conservative operation at 1500 watts continuous carrier output. A pressurized

forced air cooled chassis, including the high voltage supply insures cool operation with high

duty cycle emission modes.

The output circuit utilizes extra heavy duty components with vernier reduction drives on all

tuning controls. Easily accessed rear panel controls allow for operator adjustment of input

VSWR and ALC.

An automatic time delay circuit, insures proper cathode conditioning before RF drive can be

applied. A protective circuit shuts down the amplifier in the event of excessive grid current. A

resistor located in the high voltage B+ circuit protects the tube in the event of an internal tube

arc. Metering function includes plate voltage, plate current, grid current and relative output.

3

4

Specifications

COMMANDER HF-2500/HF-2500 MAGNUM

HF Linear Power Amplifier

• Band Coverage: 160, 80, 40, 20, 17, 15, 12, and 10 meter amateur radio bands.

• Types of Emissions: SSB, FM, CW, AM, RTTY, SSTV.

• Driving Power Required: 20 to 60 Watts nominal at rated continuous carrier output.

• Maximum Output Power: 1500 Watts Continuous Carrier.

• Duty Cycle: 100 percent in Amateur service at 1500 watts output power

• Input impedance: 50 Ohm unbalanced

• Output Impedance: 50 Ohm unbalanced: SWR 2:1 or less

• Harmonic Suppression: Exceeds all FCC requirements

• Keying: Requires contact closure of sinking +5 VDC at 15 mA.

• Metering: Plate voltage, plate current, grid current, and relative power

• A.L.C.: Negative going, adjustable from rear panel

• Front Panel Controls: Plate metering switch; On/Off switch; Standby/Operate switch;

Tune; Load; Band selector switch.

• Rear Panel Controls: Tuned input adjustment; ALC adjustment; RF input; RF output;

ALC output; Keying; ground connection; AC power inlet.

• Tube Complement: Two Eimac 3CPX800A7 pulse rated ceramic/metal triodes.

• Cabinet Size: 18.25" W x 8.5" H x 20.75" D (46.3cm x 21.6 cm x 52.7 cm)

• Power Requirement: 200/234 VAC, 50/60 Hz, 20 Amperes

5

UNPACKING

Carefully remove the Commander HF2500/HF-2500 MAGNUM Amplifier from its shipping

carton making sure there is no damage evident from shipping. If there is any damage, notify the

delivering shipper immediately, fully describing the damage.

The HV power transformer was shipped separately, as its weight would damage the cabinet

in transit.

Do not destroy the packing material since it may be reusable later, should you require factory service or need to transport the Amplifier for any other reason.

TRANSFORMER INSTALLATION

Remove the top cover from the amplifier chassis. Install the transformer following the illustrated procedure beginning on next page (page 6).

SHIPPING BLOCK

The 3CPX800A7 tubes are shipped installed in the amplifier, held in place by a Styrofoam block. Remove the block before use.

200/234 VAC Operation

The Commander HF2500/HF-2500 MAGNUM come factory wired for 234 VAC operation.

For best operation, you should use a dedicated 234VAC main capable of supplying 20 Amps of

peak AC current.

Commander Amplifiers manufactured for export are wired for 234 VAC or 200 VAC depending on the final destination.

6

HF-2500 Transformer

Installation Procedure

Here is the transformer and its mounting screws

Lift the transformer into amplifier chassis

Position the transformer over the mounting holes in

the chassis and insert the provided 1/4-20 Phillips

head screws through the transformer mounting tabs

and into the threaded inserts in the chassis plate and

tighten.

Plug the connector on the transformer into the mating

one on the wiring harness. It is keyed so that it cannot be plugged in backwards. Make sure that the

connector halves are pressed together until the lock

tabs snap in place.

Plug the second connector on the transformer into the

mating one on the AC Mains PCB. It is keyed so that

it cannot be plugged in backwards. Make sure that

the connector is pressed in until the lock tabs snap in

place. Re-install top cover.

This completes HF-2500

transformer installation.

HF-2500 Magnum

Transformer Installation

7

Procedure

Here is the transformer and its mounting screws

Lift the transformer into amplifier chassis

Position the transformer over the mounting holes

in the chassis and insert the provided 1/4-20

Phillips head screws through the transformer

mounting tabs and into the threaded inserts in the

chassis plate and tighten.

Plug the first connector on the transformer into

the mating one on the chassis wiring harness. It

is keyed so that it cannot be plugged in backwards. Make sure that the connector halves are

pressed together until the lock tabs snap in place.

8

Plug the second connector on the transformer

into the mating one that comes from the AC

control board. It is keyed so that it cannot be

plugged in backwards. Make sure that the

connector halves are pressed together until the

lock tabs snap in place.

Dress the wires and connectors down out of

the way

This completes HF-2500 Magnum

transformer installation.

9

!! WARNING !!

CONTACT WITH VOLTAGES IN THIS AMPLIFIER CAN BE

!!! FATAL!!!

CAUTION:

• DO NOT attempt any type of service or repair on this amplifier without first removing the

AC power and allowing AT LEAST 10 MINUTES FOR THE HIGH VOLTAGE CAPACI-

TORS TO BLEED OFF !

• DO NOT operate this amplifier with the top or bottom covers removed. THE VOLTAGES

INSIDE THE CABINET ARE DEADLY ! EXPOSURE TO UNSHIELDED RF AT

THESE POWER LEVELS IS HAZARDOUS TO YOUR HEALTH !

• Never attempt operation without first connecting your amplifier to an appropriate antenna or

dummy load. The antenna SWR should not exceed 2:1. The dummy load should have an

impedance of 50 Ohms with sufficient power handling capability. DAMAGE TO THE AM-

PLIFIER MAY RESULT IF OPERATED WITHOUT A CONNECTION TO A PROPER

LOAD.

• NEVER OPERATE THIS AMPLIFIER WITHOUT AN EARTH GROUND CON-

NECTED TO THE REAR PANEL GROUND TERMINAL.

• Do not obstruct the ventilation holes located on the top, bottom, and sides of the cabinet.

These holes provide sufficient intake and exhaust of cooling air. SEVERE OVERHEAT-

ING AND SERIOUS DAMAGE WILL RESULT IF SUFFICIENT VENTILATION IS

NOT PROVIDED.

• Never operate any amplifier using an extension cord.

10

Connecting Your Amplifier

• Connect the RF output of your transceiver to the RF Input connector on the rear of the HF-

2500/HF-2500 MAGNUM with 50 Ohm coaxial cable.

• Connect the existing station antenna tuner or a Wattmeter and dummy load to the RF Output

connector on the HF-2500/HF-2500 MAGNUM with RG-8 or better coaxial cable.

• Connect the Keyline jack on the rear of the HF-2500/HF-2500 MAGNUM to the normally

open terminal of the relay jack on your transceiver. The Key jack on the HF-2500/HF-2500

MAGNUM has positive 5 VDC open circuit and requires the sinking of 15 mA of current

when pulled to ground.

• Connect as short a ground lead as possible from a good RF ground to the Ground Post on

the HF-2500/HF-2500 MAGNUM.

• Connect the ALC phono jack to the ALC connection on your transceiver using a shielded

cable. Consult your transceiver manual for proper ALC connection details.

To Antenna

Antenna

Tuner

HF-2500 Amplifier

Ground

ALC TX GND

Ground

Key

ALC

Transceiver

RF Ouput

RF Input

RF Output

Wattmeter

To

Dummy

Load

To Earth

Ground

Rear Panel View

11

AC Mains

Twistlock

Connector

Key Line

(to transceiver)

RF Output

(to Wattmeter

& Antenna

or Antenna

Tuner)

Tuned Input

Adjustments

(One for each

band)

Ground

Post

Y

ALC

(to transceiver)

X

G

RF Input

(from

Transceiver)

WHITE

BLACK

GREEN

Automatic Level

Control Adjust

To 200/234VAC @ 20A

}

To Safety Ground

AC Power Twistlock Connector Wiring

(View looking at rear panel)

12

Band Switch

Tune Control Transmit

Load Control Standby/Operate

Grid Current/

Relative Power

Meter

Switch

Indicator

LED

Plate Current/

Plate Voltage

Meter

Status-Trip

Indicator

LED

Power

On/Off

TUNING PROCEDURE

Set the front panel controls to the following positions:

ON - OFF Switch. OFF

STANDBY - OPERATE STANDBY

BAND SWITCH DESIRED BAND

TUNE CONTROL PRESET TUNE SETTINGS (See test sheet)

LOAD CONTROL PRESET LOAD SETTINGS (See test sheet)

After the controls have been preset and the amplifier is connected to a suitable RF load,

switch the On/Off switch to the On position. The following will occur:

A. The meters will illuminate.

B. The step-start relay will actuate and the HV will begin to ramp up.

C. After 2 seconds the step-start relay will disengage and the HV will now be at its normal

no-load voltage level.

D. The 3 minute filament timer will start. The green “Status-Trip” LED will flash (1Hz

rate) during the 3 minute warm-up interval.

E. After 3 minutes the “Status-Trip” LED stops flashing and the amplifier is ready for use.

Place the Standby/Operate switch in the Operate position. The amplifier will not switch to

the “Operate” state if the Keyline is active when the switch is thrown (this protects the amp in

13

case it is inadvertently keyed when the switch is thrown). Key the exciter with no RF drive applied. The red transmit LED should illuminate, and the meter should indicate approximately

120 mA of plate current. Apply 5 to 10 watts of RF drive, the plate current should rise slightly.

If the plate current rises above 1200 mA, reduce drive. Adjust the TUNE to achieve maximum

output power as indicated on an EXTERNAL WATTMETER.. COMPLETE THESE AD-

JUSTMENTS AS QUICKLY AS POSSIBLE TO AVOID STRESSING THE TUBES.

Adjust the LOAD control to reduce grid current while maintaining output power as indicated on the relative output meter or an external Wattmeter. Next, increase the drive in small

increments and adjust the LOAD control to REDUCE the grid current . Under normal conditions the grid current should not exceed 15-20mA at maximum power output.

Readjust the TUNE control to again peak the power output. If the grid current rises above

100mA. quickly reduce drive by adjusting the LOAD control clockwise to reduce grid current.

Repeat these adjustments as required to achieve the desired output up to 1500 Watts.

[NOTE: Avoid operation at high grid current levels (~60mA or greater). If the grid current

is allowed to reach or exceed 120mA, the controller will immediately un-key the amplifier and

the “Status-Trip” LED will flash rapidly, indicating that a grid current limit (a “Grid-Trip”) has

occurred.

Expect to use the TUNE CONTROL to peak the power output and

and rotate the LOAD control CLOCKWISE to lower the grid current.

In order to reset the Grid-Trip circuitry, the exciter must be un-keyed and the “StandbyOperate” switch must be switched to “Standby” and then back to “Operate.” Once the GridTrip has been reset, the “Status-Trip” LED will stop flashing and remain illuminated.

Do NOT exceed 1200mA plate current.]

Note that when increasing output power the tune scale will always read higher and the load

will read lower. Also, the supplied inspection sheet has all of these settings and they should be

used as a guide for this procedure. If your settings vary widely from these you have something

wrong and should start over.

If your planned operation is on SSB, you should reduce the load control slightly counterclockwise, reducing the TOTAL output slightly about 30 to 50 Watts. This adjustment is necessary to insure that the amplifier is sufficiently loaded to handle the plate current peaks caused

by the complex voice patterns during SSB operation. Nominal plate and grid current read-

ings during SSB operation will be about 30 to 40% of the key down CW readings.

CAUTION: THE TUNE AND LOAD AIR VARIABLE CAPACITORS MAY ARC IF

MAXIMUM DRIVE IS APPLIED BEFORE THE AMPLIFIER IS PROPERLY TUNED. ALWAYS FOLLOW THE DESCRIBED TUNE-UP PROCEDURE TO AVOID CAPACITOR

ARCING. ARCING MAY ALSO OCCUR IF YOU ATTEMPT TO TUNE INTO AN ANTENNA WITH A VSWR GREATER THAN 2:1.

14

Theory Of Operation

The Commander HF-2500/HF-2500 MAGNUM uses a pair of C.P.I. Eimac 3CPX800A7

pulse rated ceramic/metal triodes in a class AB2 grounded grid configuration. Nominal drive

power of 20 to 60 Watts will produce 1500 Watts of clean RF output power.

This amplifier will operate on the following amateur bands: 160, 80, 40, 20, 15, 17, 12 and

10 meters.

Metering Functions

The Commander HF-2500/HF-2500 MAGNUM has two illuminated cross-needle panel meters. The left-hand meter continuously displays 3CPX800A7 grid current and relative output

power. Under typical operating conditions the grid current will be 20-50mA.

Plate voltage and Plate current are continuously displayed on the right-hand meter. The

typical plate current under nominal rated output (1500 Watts) should range from approximately

700mA to 800mA on the HF-2500, and 900mA to 1100mA on the HF-2500 MAGNUM, with an

absolute maximum of 1200mA.

Tuned Input Circuits and Adjustments

The tuned input circuits utilize an π impedance matching circuit with a high Q design.

These circuits employ RF phase compensating capacitors to reduce intermodulation products.

The use of mica trimmer capacitors allows adjustments to match the transceiver to the amplifier. The rear panel provides easy access to these trimmer capacitors. A front panel band switch

selects the appropriate input filter.

Your Commander amplifier has mica trimmer capacitors which are easily accessed thru

holes located on the rear panel. The tuned input circuits are factory tuned and should not be readjusted unless necessary. You can easily make adjustments for any change in your preference

for operating frequency range. Also, slight adjustments may be necessary because of slight variances in impedances between your transceiver and the tuned input circuitry of the amplifier.

1. Install a SWR meter between the transceiver and the amplifier.

2. Make sure the Standby/Operate switch is in the Operate position and the band switch

is set to the same band as the one for which you are making adjustments. Your amplifier should also be properly tuned and loaded (preferably onto a dummy load of sufficient capacity).

3. Apply drive, observe the SWR, and adjust the trimmer capacitor for minimum SWR.

Be careful not to overdrive the amplifier.

4. Repeat this procedure for each band.

Automatic Level Control and Adjustments

An adjustable Automatic Level Control (ALC) circuit limits the peak output power. When

properly set, this circuit insures that the amplifier can not be overdriven. Rear panel access allows for easy manual adjustment. A sample of the RF input derives the ALC voltage.

Your transceiver's internal ALC will maintain linearity. The amplifier's ALC will prevent

overdriving the amplifier. The HF-2500/HF-2500 MAGNUM's ALC circuit was designed for

negative going ALC voltage. Proper adjustment is as follows:

1. Use an insulated tool when making these adjustments.

2. Tune the amplifier for operation on the 20 meter band for full 1500 watts output.

15

3. With your transceiver set for 20 meter SSB operation, set the transceiver's microphone

gain for normal operation as specified in its owners manual.

4. While speaking louder than normal into the microphone, adjust the ALC pot through the

access hole on the rear panel . Adjust for 1500 Watts maximum output as indicated on

an external peak reading Wattmeter.

5. On some newer model transceivers this adjustment can be made in the CW position. On

these models (with your output at 1500 Watts) simply adjust for a slight drop in output.

Output Filter Circuit

The π variable network filter transforms the plate load impedance from approximately 2500

Ohms down to 200 Ohms, Two air variable capacitors and an associated inductor accomplish

this transformation. A heavy duty band switch selects the proper inductance from high Q inductors with appropriate taps for the desired band of operation.

A design Q of 14 allows for good harmonic attenuation on all bands. A special reactancetuned ferrite core 4 to 1 transmission line transformer steps down the 200 Ohm output of the π

circuit to the 50 Ohm nominal antenna impedance. This also provides further harmonic attenuation of the output in the same manner as an L coil in a π-L network.

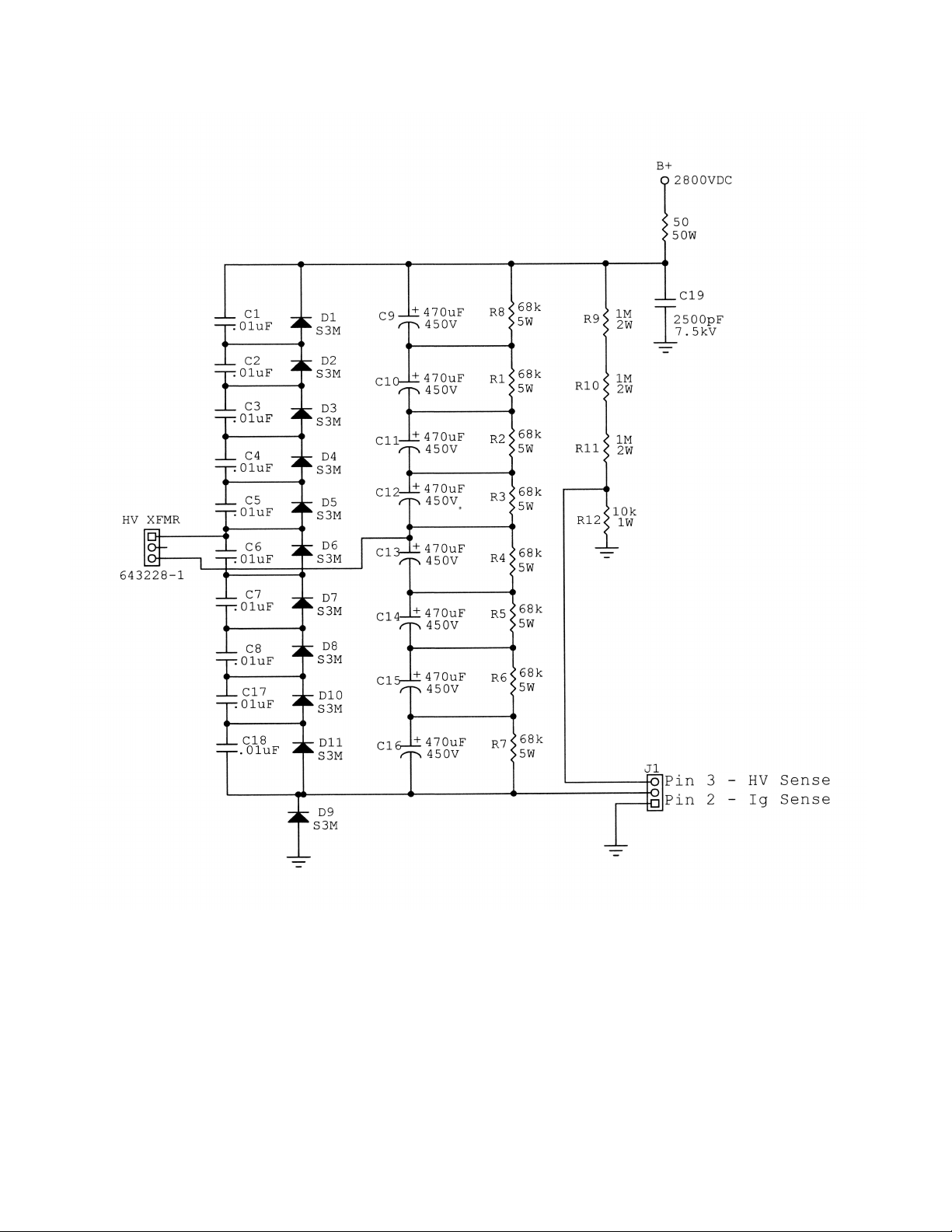

High Voltage Supply

The high voltage supply operates from 200/234 VAC, 20 Ampere line. The primary of the

high voltage transformer is switched on and off with relays and incorporates a step-start circuit

to limit in-rush current while the high voltage filter capacitors charge. The front panel On/Off

switch applies AC mains power to the controller circuitry which then controls AC power to the

filament and HV transformers. In the HF-2500 approximately 900 VAC is applied to a full

wave voltage doubler circuit. In the HF-2500 MAGNUM, 2400 VAC is applied to a full wave

bridge. Metering of the tube anode and grid current is accomplished by shunt resistors located

in the negative return of the 3CPX800-A7 cathode. Plate voltage metering is accomplished by a

resistor divider network in the B+ line of the high voltage circuit.

16

Limited Warranty

Palstar Inc. warrants the Commander HF-2500 and HF-2500 MAGNUM to be free from defects in material and workmanship under normal use and service to the original buyer for a

period of one (1) year from the date of delivery to that buyer (the “Warranty Period”). Palstar Inc.’s obligation under this warranty is limited to repair or replacement of the product at it’s

option at the Palstar factory in Piqua, OH.

This warranty is effective only when the product is returned to the factory with all transportation charges prepaid and examination of the product discloses the product, in Palstar’s judgment, to have been defective during the Warranty Period.

The Warranty Period shall not extend beyond its original term with respect to interim inwarranty repairs by Palstar. This Warranty Period shall not apply to any product which has been

repaired or altered by anyone other than Palstar without prior written authorization. Warranty

does not extend to any products which have been subject to damage from improper installation,

application or maintenance in accordance with the operating specifications. Palstar neither assumes nor authorizes any person to assume for it any obligation or liability other than herein

stated.

Shipping Your Amplifier Back to the Factory

Due to the necessity of shipping the amplifier with the HV transformer removed, please

contact the factory for instructions before sending an amplifier back to us. There are circumstances in which it may not be necessary to return the HV transformer, thereby saving you shipping charges. When you call, Palstar will inform you if transformer return is necessary. If

transformer return is necessary, remove it from the amplifier cabinet and ship it separately, and

must be in its original packing.

Repair Policy

When sending in a product for service, see the section above. If not using the original packing materials, please “double” box it carefully with suitable padding and ship it insured for your

protection. Please include a note clearly describing the problem, how you wish the item returned and how you wish to pay for the service. Package your unit properly. Palstar, Inc. is not

responsible for merchandise damaged in shipment. Our service rate is $30 per hour (1/2 hr.

minimum).

Return Policy

All returns must receive prior authorization from Palstar. Returned items must be received

in original—AS SHIPPED—condition including the original box, manuals, accessories, and

copy of sales receipt. Returns must be within 14 days of purchase. Returned items are subject to

a 25% restocking fee. Shipping is not refundable.

HF-2500/HF-2500 MAGNUM RF Deck

17

18

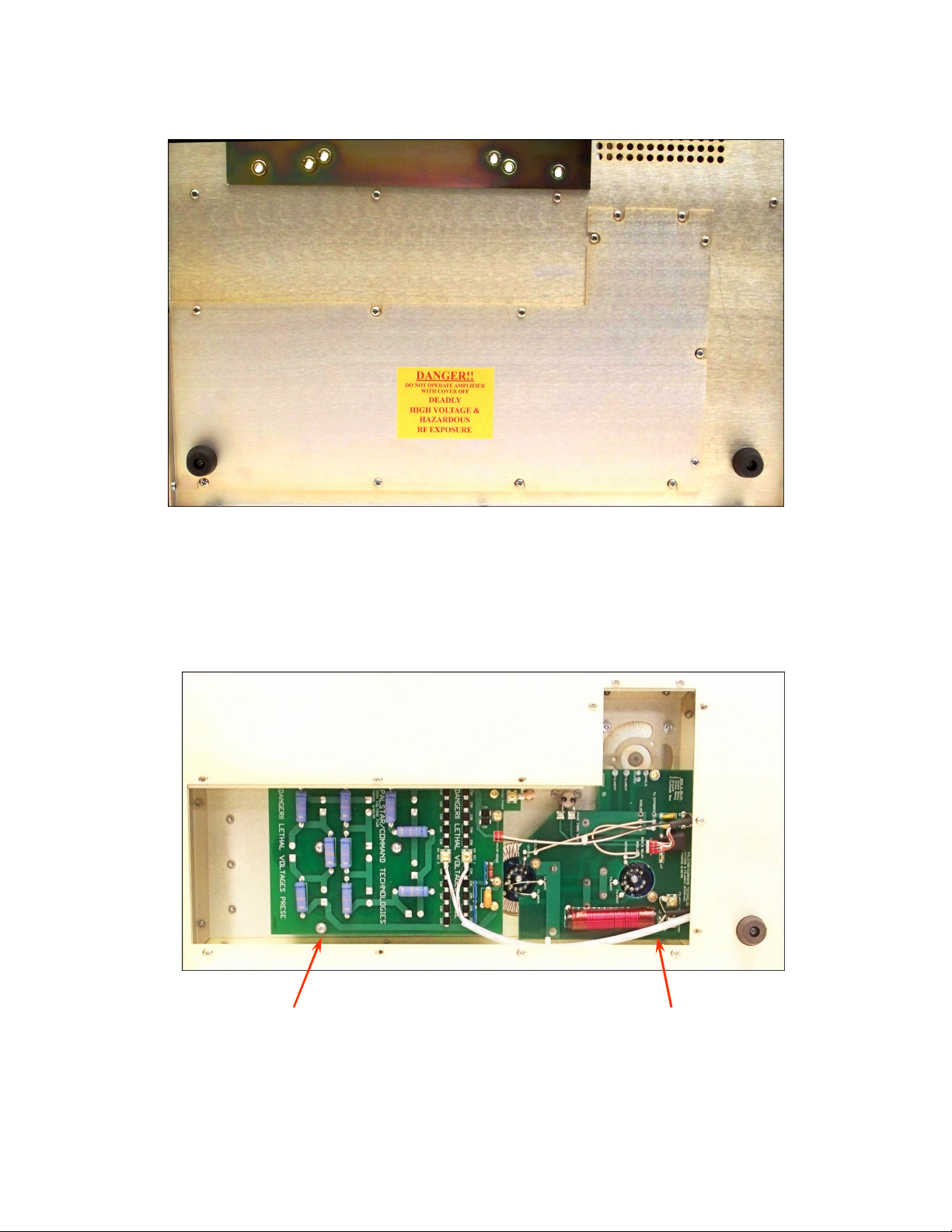

Bottom View showing access plate

Access Plate Removed

HV Power Supply PCB Cathode and Filament Interface PCB

HF-2500 HV Power Supply

19

20

HF-2500 Magnum HV Power Supply

21

~ 13.5VAC

AC Mains and Step-Start Board

22

Control and Metering Board

23

24

RF Deck

Amplifier Test Card

25

26

Dual Meters

Grid Current: Scale

0-60ma Single Tube Top

0-120ma Two Tubes Mid

0-180ma Three Tubes Bottom

Grid Current: Scale

0-600ma Single Tube Top

0-1200ma Two Tubes Mid

0-1800ma Three Tubes Bottom

Meter Board

27

Cathode

Fuse

28

Step-Start Board

AC Main Fuse

(20A) x 2

AC

Interlock

Step/Start Relays x 4

Top

Full Wave Bridge Power Supply

29

Bottom

30

Palstar Incorporated

9676 N. Looney Rd.,

Piqua, OH 45356 USA

Customer Service and Sales Telephone:

1-800-773-7931

Fax:

1-937-773-8003

Email:

info@palstar.com

Loading...

Loading...