Palstar products are designed by

Hams for Hams carrying on the

Palstar tradition for high-quality

products designed and

manufactured in Ohio, USA.

AT2K 2000 Watt

Antenna Tuner

l 2000 W PEP SSB, 1500 W single tone

l 160 m to 10m

l Variable capacitor with vernier drive

l Dual movement cross needle meter

l 5” x 14.5” x 13.5”

9676 N. Looney Rd,

Piqua, OH 45356 USA

(937) 773-6255

(800) 773-7931

(937) 773-8003 (Fax)

www.palstar.com

PALSTAR

AT2K 2000 Watt Antenna Tuner

Technical Manual

Designed and Manufactured in the USA

Copyright 2014 Palstar, Inc.

PALSTAR

l METERING: Dual movement cross-needle power

and frequency compensated coupler

l INPUT & ANTENNA TUNING: Variable capacitor 413pF 4.5 Kv

6:1 Vernier Drive

l INDUCTANCE: 25 μH roller inductor; 12 ga. wire wound

on steatite ceramic core, silver plated

bar and wheel

l ANTENNA SELECTOR SWITCH: 6 position:

Coax 1 - tuned and tuner bypass

Coax 2 - tuned and tuner bypass

Switch wafers are 3 kV rated

l POWER RANGE SWITCH: 2 position 300 W / 3000 W

l REAR PANEL CONNECTORS:

SO-239: RF Input, Coax 1 & 2, Bypass

COAX: Balanced line (optional balun)

END FED WIRE: High Voltage Nylon66™

terminal post & ground post

12 VDC INPUT: 14mm connector, 2.1mm ID,

5.5mm OD, center positive, 200 ma

l FREQUENCY COVERAGE: 1.8 - 54 MHZ

l POWER MAXIMUM: 2000 W PEP SSB, 1500 W single tone

l IMPEDANCE RANGE: 20 to 1500 Ω, 160m to 10m

(assuming resisitive load)

Reduce power for lower Z-range

l BALANCED OUPUT: 4:1 current type balun (optional external)

l DIMINSIONS: 5” H x 14.5“ W x 13.5” D

l WEIGHT: 13 LBS, 6 Kg

l CHASSIS & COVER: 11 ga., .090 gold Iridite Treated Aluminium

AT2K SPECIFICATIONS

Page 2 PALSTAR

Building on success, Palstar upgraded the best-selling AT1500CV

throughout to create the American-made Palstar AT2K Antenna Tuner.

The AT2K optimizes the performance of your antenna and transmitter

by providing adjustable impedance matching using a T-type circuit

conguration.

The AT2K also measures the power (upgraded to include a PEAK/PEAK

HOLD function) and Voltage Standing Wave Ratio (VSWR or SWR),

which allows you to tune the SWR to the lowest possible for the

selected transmission frequency.

The AT2K also features a precision steatite ceramic core roller inductor

with a plated roller wheel and roller shaft. The smaller size permits

operation on 6 meters.

A high voltage ceramic wafer switch allows selection between coax

feedlines or wire-fed antennas. DIRECT switch positions bypass the

impedance matching circuit but allow for the SWR, FORWARD, and

REFLECTED and PEAK power meter FUNCTIONS.

Tuning is achieved with the front panel mounted controls. The 6:1 ratio

Vernier dials allow for tuning with precision and accuracy, while the

Inductor crank handle facilitates coarse adjustments. The range of the

meter (300W/3000W) is selcted by a push button switch located on the

front panel.

AT2K GENERAL DESCRIPTION

UNPACKING

Carefully remove the AT2K from the shipping carton and

inspect it for signs of damage. If any damage is apparent,

notify the transportation carrier or dealer immediately.

KEEP THE PACKING CARTON for moving, storing, or

reshipping the tuner to us for repair if required.

LOCATION

Select a location for the AT2K that allows the connectors

to be free from any possible contact with people, pets,

or objects during operation and with unrestricted air

ow for cooling.

INSTALLATION PROCEDURE

Connect a coax cable from your transmitter to the RF

INPUT connector on the rear panel. Keep the cable as

short as possible. If you use a linear amplier, connect

your transmitter to the linear amplier input and the

linear amplier output to the AT2K.

DO NOT USE MORE THAN 1500 WATTS (single tone)

through the tuner.

INSTALLATION

Page 3

+

-

To 12-13.8v

Power Supply

2.1 mm

FEMALE plug

Grey

TRACE ID

Protection

Reverse diode

Red Heat Shrink

cover

AT2K DC POWER CORD

PALSTAR

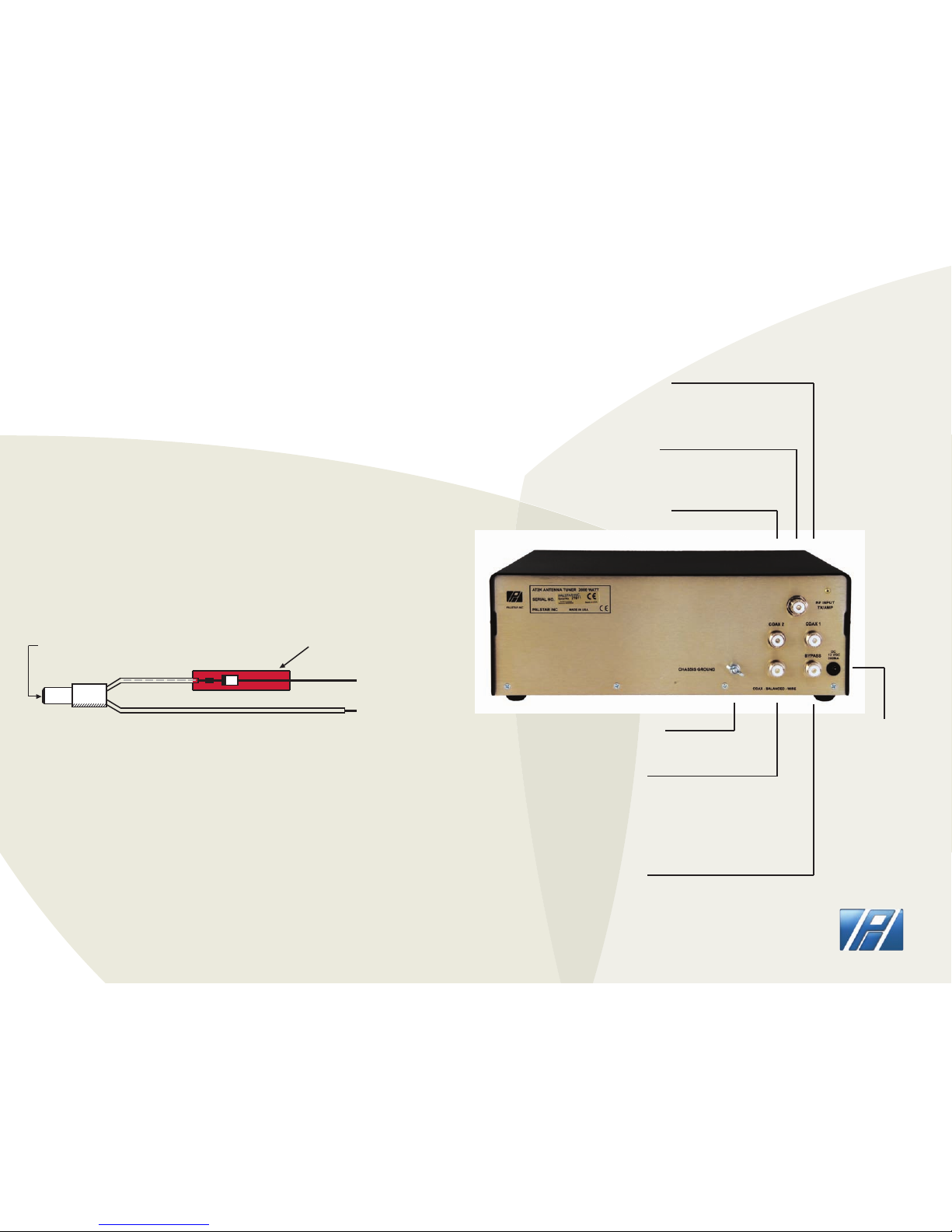

REAR PANEL

GROUND post/wing nut

ground connector

COAX-BAL-WIRE

Use this connector

to connect an optional

external 1:1 or 4:1 balun

for balanced or wire feed

antennas

BYPASS coaxial

connector for output

to dummy load or third

coax output. Bypasses

tuner, but meter circuits

are on if AC adapter is

connected to rear panel

12 VDC INPUT

(2.1 mm plug,

center pin +)

12 VDC adapter

200 mA to power

the meter lamp

COAX 2 coaxial connector

for output to Antenna 2

RF INPUT

coaxial connector

for input from transmitter

or amplier

COAX 1 coaxial connector

for output to Antenna 1

Page 4

FRONT PANEL DESCRIPTION

1. POWER/SWR METER Dual needle meter displays FORWARD and

REFLECTED power in watts. SWR is measured where the two needles

intersect on the red scale. SWR is printed on meter face.

2. PEAK HOLD Select to read Peak Hold on the SWR meter. Peak switch [3]

must be in PEAK position.

3. PEAK Selects between PEAK and AVERAGE power metering display.

4. RANGE Two-position switch selects the range of FORWARD and

REFLECTED power displayed on the power meter. When the RANGE

button is OUT, the FORWARD meter scale reads 300 watts full scale and

the REFLECTED meter scale reads 60 watts full scale. When the RANGE

button is IN, the FORWARD meter scale reads 3000 watts full scale and

the REFLECTED meter scale reads 600 watts full scale.

5. ON Select to turn on the backlight in the meter and enable metering,

and 160 meter functions. The jack on the back panel must be supplied

with 12 VDC for these functions to work.

6. DIRECT-TUNED MODE SWITCH Six-position rotary switch selects an

output connector as follows:

1 2 3 4 5

6 7 8 9

PALSTAR

a. DIRECT BYPASS selects BYPASS COAX CONNECTOR bypassing the

impedance matching circuit, but providing SWR, FORWARD, and

REFLECTED power meter readings.

b. DIRECT COAX 1 selects COAX 1 CONNECTOR bypassing the tuner

matching circuit, but providing SWR, FORWARD, and REFLECTED meter

readings.

c. DIRECT COAX 2 selects COAX 2 CONNECTOR bypassing the tuner

matching circuit, but providing SWR, FORWARD, and REFLECTED meter

readings.

d. TUNED COAX 1 selects COAX 1 CONNECTOR through the impedance

matching T circuit.

e. TUNED COAX 2 selects COAX 2 CONNECTOR through the impedance

matching T circuit.

7. INPUT Continuosly adjustable input capacitor.

8. OUTPUT Continuously adjustable output capacitor.

9. INDUCTOR 25 H continuously variable ceramic roller inductor driven

by a crank handle. Coupled to the crank handle is a gear-driven

precision mechanical counter. The end stop readings

on the turns counter are ZERO and 279. Zero is max imum inductance and 279 is minimum inductance.

μ

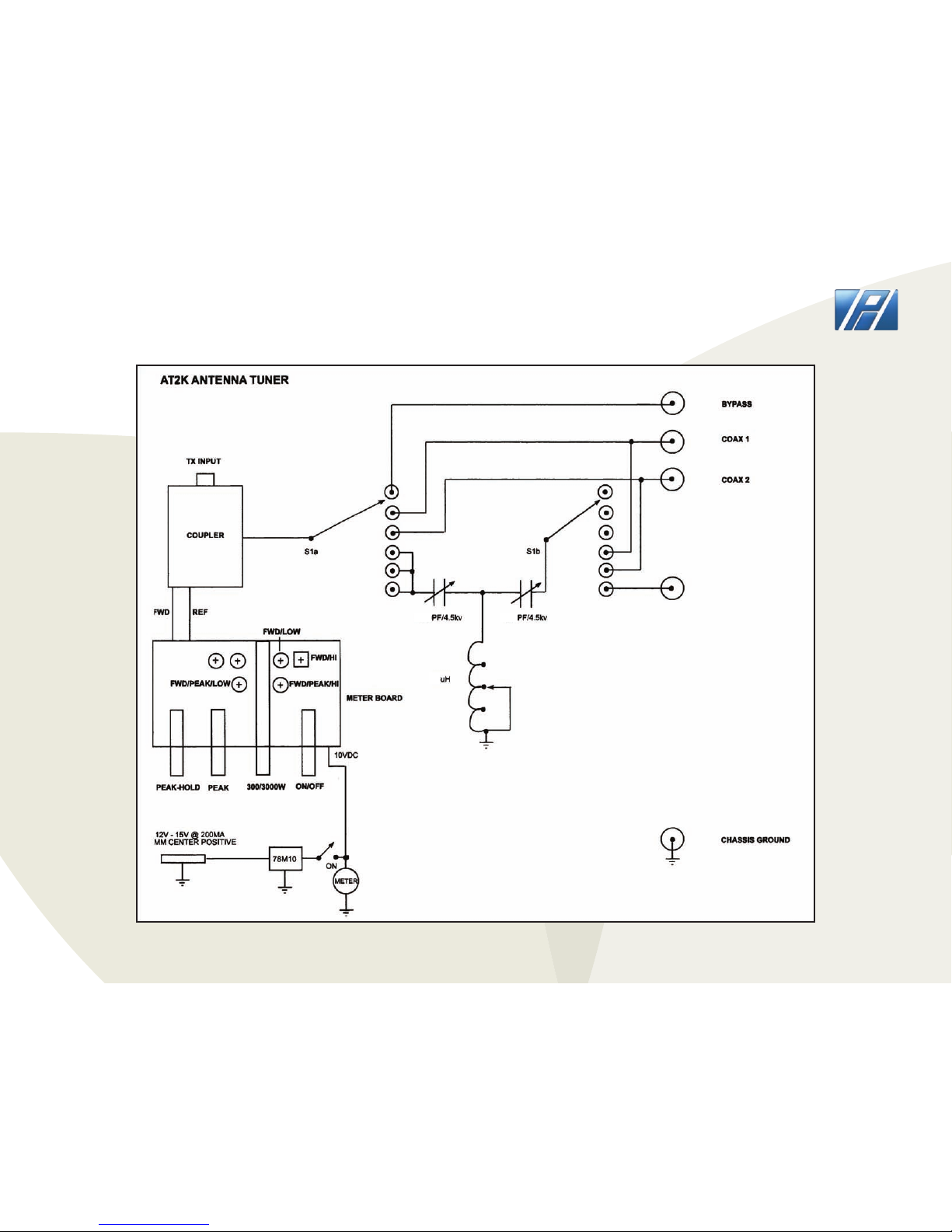

AT2K SCHEMATIC

COPYRIGHT PALSTAR 2011-2014©

PALSTAR

413 413

25

Page 5

Page 6

METER BOARD ADJUSTMENTS

Reverse

Low

Reverse

High

Forward

Low

Forward

High

Peak

Hold

Peak Peak

Low

Power

Range

Peak

High

On/O

PALSTAR

INSIDE VIEW

ROLLER

INDUCTOR

VARIABLE

CAPACITORS

COUPLER

METERING

ASSEMBLY

PEAK/HOLD

PCB

Page 7

OPERATING YOUR AT2K

BEFORE OPERATING

1. To avoid possible damage to the AT2K set INPUT, OUTPUT,

INDUCTOR, and POWER RANGE switches as outlined in the

chart below before applying transmitter power.

2. Begin tuning with your transmitter/amp feeding the tuner

set at a low output power setting (50-100 Watts max).

TUNING

1. Select the band and frequency of desired operation.

2. Set TUNE and INDUCTOR controls to the suggested setting

before applying transmitter power (see chart). Actual settings

will vary from antenna to antenna.

3. Set your transmitter/amplier to a low power output. If your

transmitter has a TUNE position, select that position.

4. If you use a linear amplier, set it to STANDBY. Do not use

the linear amplier until the AT2K is tuned.

WARNING: DO NOT OPERATE THE

AT2K WITH THE COVER OFF.

BAND INPUT OUTPUT INDUCTOR

SUGGESTED AC TUAL SUGGESTED ACTUAL SUGGESTED ACTUAL

160 M

80 M

40 M

20 M

17 M

15 M

12 M

10 M

6 M

50

55

45

50

50

24

24

26

40

65

45

56

60

60

35

35

40

30

32

183

239

264

267

268

271

274

265

PALSTAR

DO NOT EXCEED 1000 WATTS AVERAGE (SINGLE TONE)

5. Set RANGE switch to 300 W (button out).

6. Set the DIRECT/TUNED mode switch to the TUNED

position matching your antenna connection. To tune your

antenna, the switch selection must be set to: COAX 1 TUNED,

COAX 2 TUNED, or BALANCED LINE.Selecting COAX 1 DIRECT,

COAX 2 DIRECT, or BYPASS bypasses the tuning circuitry and

tuning is not possible.

7. Rotate the INPUT, ANTENNA, and INDUCTOR controls for

maximum noise or signal as heard on your receiver. Refer to

preset tuning chart on page 9.

8. Key your transmitter and adjust the power level for a

reading of 50-100 watts on the FORWARD scale. Adjust the

INPUT, OUPUT, and INDUCTOR controls for a minimum

REFLECTED reading while maintaining a FORWARD reading

of 50-100 watts using your transmitter power control.

9. Read the SWR on the red scale at the point where the two

needles intersect. Repeat TUNING the input and antenna

controls until the lowest SWR reading is obtained. The SWR

should be 2:1 or lower.

10. When you have tuned your antenna to the best SWR,

record the settings of the INPUT, ANTENNA, and INDUCTANCE

controls on the chart above for future reference. When you

retune, use these settings as your starting point.

This procedure takes patience the rst time. The input

and antenna controls vary the capacitors and provide

ne adjustments, while the roller inductor crank

provides coarse adjustment.

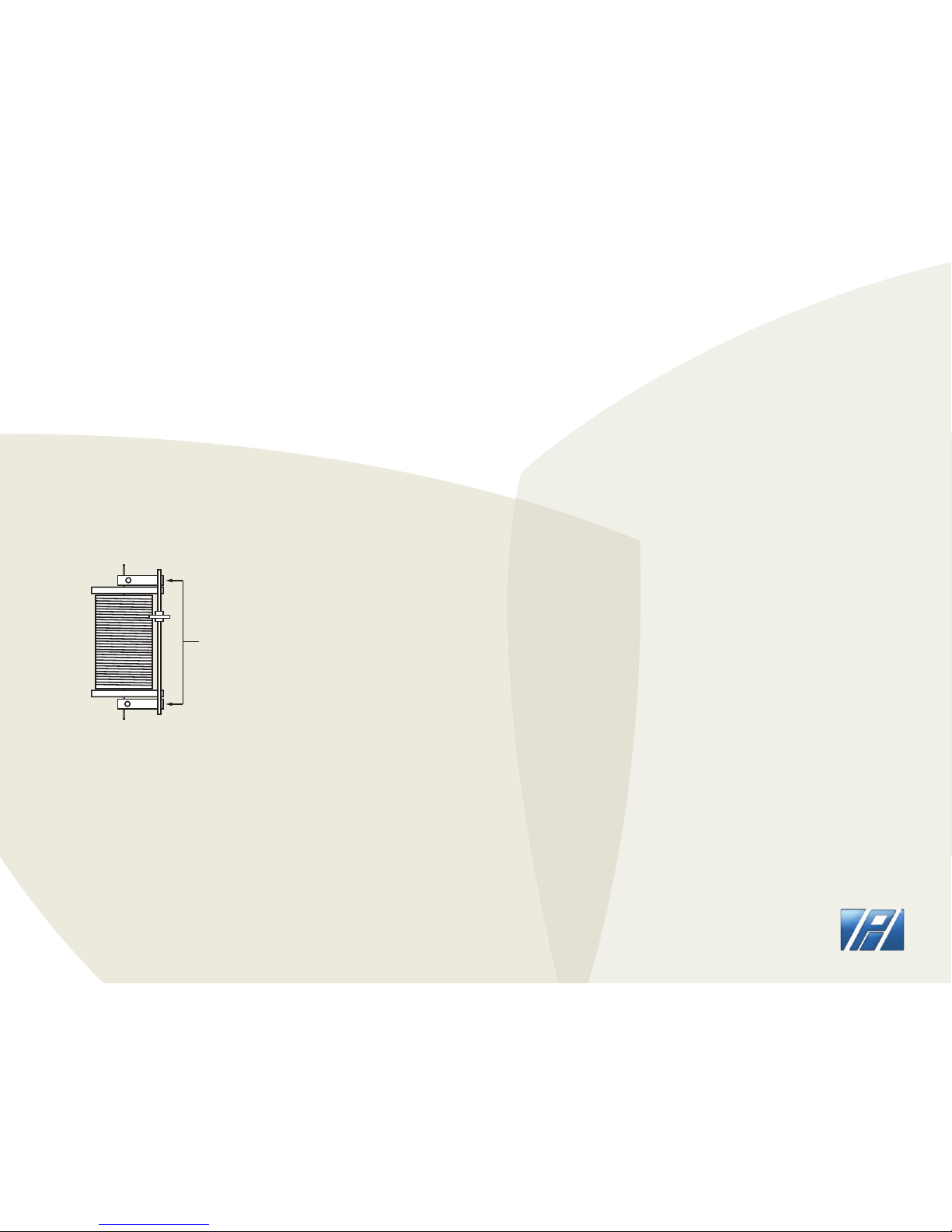

RESTORING THE INDUCTOR WHEEL

Page 8 PALSTAR

To RESTORE wheel pressure on

the inductor push down on the

at springs soldered to the

wheel shaft located on each

end of the shaft.

When approaching the end stops of the roller inductor

(readings of Zero or 279) SLOW DOWN. Slamming the

roller wheel into the mechanical end stops on either

end of the roller inductor will decrease the pressure of

the wheel against the wire wound on the ceramic form.

NOTES:

1. A SWR of 1:1 is best, but an SWR as high as 2:1 may be

acceptable. Check your transmitter/amplier manual for

details.

2. If you cannot get an acceptable SWR, lengthen or

shorten your antenna and/or feedlines and retune.

3. If you get low SWR readings at more than one setting,

use the setting that gives:

- highest FORWARD power reading

- lowest REFLECTED power reading

- uses the largest capacitance (highest number) on the

INPUT and ANTENNA controls.

4. Any time a new or dierent antenna is connected, it is

necessary to repeat the turning procedure for each

antenna.

5. Once every 4-6 months clean the roller coil with Deoxit

D5 contact cleaner and a clean cotton cloth. Do not

remove the conducting grease on the rod that guides the

roller wheel. Do not transfer any of the conducting grease

from the rod to the roller coil body, as this will

contaminate the windings.

Loading...

Loading...