Page 1

®

SUNTUF

Corrugated Polycarbonate Sheet with Anti-Condensation

Plus

Greenhouse Installation Guide

61326 - 03.2014

Page 2

Page 3

Greenhouse Installation Guide

Content

Introduction 2

Main Benefits 2

Profile Dimensions 2

Distance Between Purlins 3

Handling and Storage 3

Cutting 3

Drilling 4

Chemical Resistance - Compatible Adhesives & Sealants 4

Sealing 4

Use of Shading Compounds 5

Positioning the Sheets 5

Overlap 5

Arching Radius 6

Roof and Wall Fastener Location 6

Screws, Washers and Gaskets 6

Sheet to Sheet Stitching Fasteners 7

Additional Accessories 7

Standard Accessories for SUNTUF® Plus 8

1

Page 4

Greenhouse Installation Guide

Introduction

SUNTUF Plus has special benefits that allow it to give plants the best nurturing conditions. SUNTUF Plus sets the standard for efficient

greenhouse roofing with more than 25 million square meters currently installed, offering guaranteed elimination of condensation dripping

and optimal PAR light transmission needed for plant growth.

SUNTUF Plus with the unique condensation control allows up to 30% light transmission increase at peak condensation periods,

as seen in the table below. The sheet also reduces disease resulting from condensation dripping. SUNTUF Plus is offered with

anti-condensation treatment on both sides for retractable greenhouse roofs.

Main Benefits

Up to 90% light transmission

Eliminates condensation drip

Retains its performance for many years

Virtually unbreakable

Blocks out UV and far IR radiation

Available with 20% and 100% light diffusion

Allows energy savings of up to 50%

Flexible and easy to install

Optional UV protection on both sides

Wide service temperature range

Available in 1260 mm and 1870 mm widths

In cold climates: Reduces snow buildup in comparison with twin-wall

a10 year limited warranty

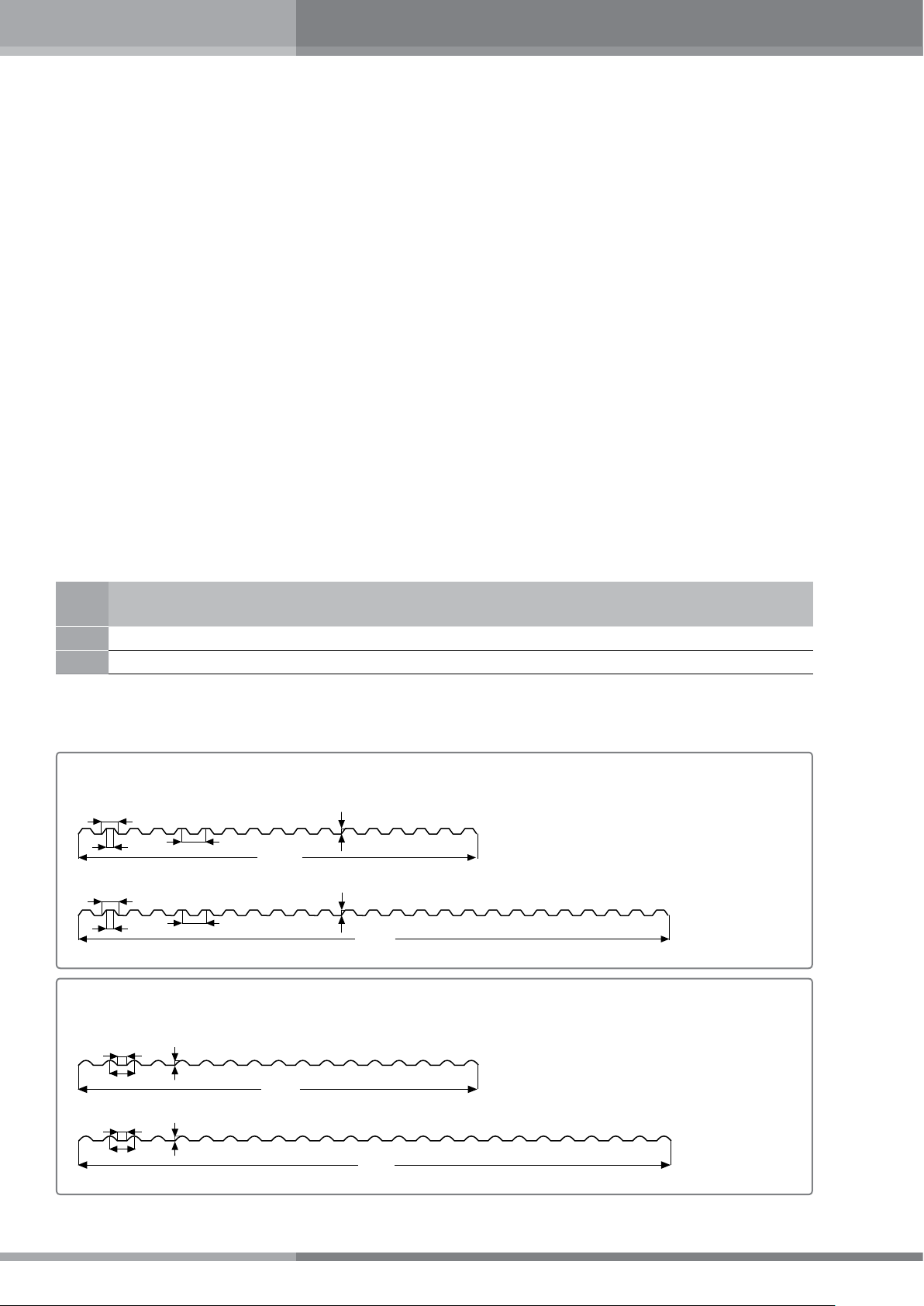

Profile Dimensions

Width

(mm)

1260 1210 76 17 1* 3.5

1870 1820 76 25 1* 2.5

* Two corrugations length overlap is recommended for slopes below 15%, or in case of extreme weather conditions (excessive

rain and/or wind.)

Greca 76/18 Profile

Effective Width

(mm)

26

26

76

76

Corrugations Pitch Distance

(mm)

1651

1260

1651

1870

Number of Corrugations Wave Overlap Percent Overlap

Omega 76/15 Profile

30

76

30

76

2

15

15

1260

1870

Page 5

Distance Between Purlins

Greenhouse Installation Guide

Profile Sheet Thickness

(mm)

Greca/Trapeze 76/18 0.8 1.20

Omega 76/15 0.8 1.15

1. The dimensions depicted above do not supersede the requirements of local construction codes. The distances depicted

above were calculated based on the structural properties with the following factors being taken into consideration: sheet

deflection, potential wind load, potential snow load, hail and application load according to usual construction practice.

2. When designing a new roof, it is strongly recommended that the slope be above 10% (5.7°). (Consult your local Palram

representative when recovering an existing greenhouse whose slope is shallower than this value).

3. The recommended maximum panel length is 7.0 m. The recommended maximum distance between the edge and first

purlin is 900 mm or the value dictated by the design engineer. (See drawing on page 4, Figure 8b).

Wall purlins distance can be increased by 10% of roof recommendation.

Theoretical Weight

(Kg/m)

Load

(Kg/m)

90 1200

150 1000

Distance Between

Roof Purlins

(mm)

Distance Between

Wall Purlins

(mm)

1200120 1100

Calculate the number of sheets as follows:

1. Divide the length of the roof (the length of the gutter) by the effective width of the sheet.

2. Calculate the required length of the sheet (to be no greater than 7.0m) according to purlin to purlin distance, plus the

required extension beyond first and last purlin and overlap distance, if exists.

Handling and Storage

1. Palram corrugated sheets must be transported and stored horizontally on a flat, sturdy pallet whose dimensions are equal to

or larger than the sheets themselves. The sheets should be secured and fastened to the pallet. It is possible to store sheets

of smaller dimensions on top of larger sheets of the same type. (Never store sheets of larger dimensions on top of smaller

sheets!) SUNTUF Plus must be stored in a cool and shaded location.

2. Important: Never cover the pallet with, or place on the pallet, materials

that are good conductors of heat (e.g. Metal, pipes, clear or dark objects).

3. In cases where it is necessary to store the pallet outdoors, cover it with a

white opaque polyethylene sheet, card board, or any other material that

does not absorb or conduct heat. The total pallet must be covered.

Cutting

It is possible to cut SUNTUF Plus corrugated sheets using a circular saw with small teeth, rotating at a high speed, taking care

to advance the saw slowly. It is also possible to use a portable electric saw (Jig Saw) or sheet metal shears. In any case, it is

important to support the sheet in the vicinity of the cut and clean away the dust and debris generated by cutting.

3

Page 6

Greenhouse Installation Guide

Drilling

1. Drilling should be carried out with a drill bit intended for metal. The hole

diameter must be 4 mm larger than the diameter of the screw to be used.

It is important to support the sheet in the vicinity where the sheet is being

drilled. The dust generated by drilling must be cleared away before the

insertion of the screw.

2. Special attention should be given to drill all the required holes perpendicular

to the face of the material.

90°

Chemical Resistance - Compatible Sealants and Adhesives

1. SUNTUF Plus sheets are resistant to a variety of chemicals and exhibit limited resistance to a second group of chemicals.

A third group of chemicals will attack and cause damage to the sheet. The degree of damage will depend on the severity

of attack and time of exposure.

2. Choose only sealants and adhesives which are compatible with SUNTUF Plus (see paragraph G).

3. Beware of installing the sheets on wet paint, or other incompatible materials, which may damage the polycarbonate

sheets.

4. Use of sealants or adhesives not included in the recommended list must receive the Manufacturer’s explicit

approval. This can be obtained through your distributor. Use of materials not on the list, or which have not received

the Manufacturer’s explicit approval, may harm the sheet and will void all warranties and any responsibility of the

manufacturer for the performance of SUNTUF Plus.

5. Your local distributor can provide additional information and forward materials for evaluation of their comparability with

SUNTUF Plus.

Sealing

1. Compatible silicone sealants recommended for use with

Palram polycarbonate sheets:

Manufacturer Sealant

Soudal MS Clear

Bison Polymax

For information on alternatives, please consult your Palram

distributor.

2. Shaped foamed Polyethylene closure strip should be

used to prevent the entry of water, wind, insects or other

small animals between installed sheets. A seal between

the sheet and the edge purlin of the roof can be created

using a sealing strip in the form of the profile. It is held in

place by the same screw used to fasten the sheet to the

purlin. The sealing strip should be manufactured from

cross-linked polyethylene foam (XPE).

Silicone Sealant

Shaped foamed

polyethylene top and

bottom sealing strips.

Butyl rubber strip

4

Page 7

Greenhouse Installation Guide

90°

Lay Sheets against Wind Direction

Direction of Wind and Rain

100 mm

M

Length Overlap

120-200 mm

Lay Sheets against Wind Direction

Direction of Wind and Rain

120-200 mm

3. Butyl rubber sealing strip should be used where the pitch is less than 15%

or in case where penetration of wind or fumes must be prevented. The

strip should be placed between the sheets at the width end lap, along

and exteriorly to the screw line.

Warning: Do not use materials which are not recommended by Palram.

Specifically, polyurethane foam should not be used as insulating foam with

SUNTUF Plus. Contact with this material will render the sheets fragile. When

in doubt, consult your Palram distributor.

Butyl rubber strip

Use of Shading Compounds

1. It is possible to apply shading compounds on SUNTUF Plus sheets.

2. Use only recognized commercial brands, confirmed to be compatible with polycarbonate. Do not apply dubious mixtures

that may contain incompatible components, which will attack and damage the sheets.

3. In case of doubt, consult your SUNTUF Plus distributor, who can advise you on the proper use of shading compounds.

4. You can ask for recommendations on compatible formulations that were tested and confirmed for use by Palram Industries.

Note that all the recommended formulations are water-soluble and will eventually be washed away by rains.

5. Shading compounds should be easily removed using a strong water jet in conjunction with vigorous brushing with a soft

bristle brush, or wiping with soft cotton rags.

Positioning the Sheets

1. Only one side of a SUNTUF Plus sheet is UV protected*. This side must always

face out toward the sun. The UV protected side is indicated by a sticker or

polyethylene strip along the length of the sheet. The sticker or polyethylene

strip must be removed immediately after the sheet is installed.

2. The sheets should be laid down on the roof or set upon the wall against

the primary direction of wind and rain.

3. Do not step on the panels between purlins.

4. Stepping ladders and other devices required for safe work should be used.

5. Never leave panels unattended until all the required screws have been

tightened.

6. Due to the sheets’ low weight, SUNTUF Plus can be rolled for the purpose

of lifting them to the roof. The sheets must be rolled perpendicular to the

length of the corrugations, with the upper UV protected side facing outwards

and the lower side with the anti-condensation treatment facing inward.

* Except for SUNTUF Plus UV2 which is manufactured with co-extruded UV protection on both

sided when a special order has been placed.

Overlap

1. Width overlap (sheet edge):

Minimum overlap: 120 mm

Minimum distance of 60 mm of

each sheet’s edge from center line

of supporting purlins (line of screws).

Maximum overlap: 200 mm

2. Length overlap: One corrugation**

3. Roof Edge: Sheets at the roof’s edge

should extend beyond over the edge

support by not more than 100 mm.

Width Overlap

inimum Slope 10%

Direction of Wind and Rain

Lay Sheets against Wind Direction

Edge Purlin to

Purlin Distance

Internal Purlin to

Purlin Distance

** Two corrugations length overlap is recommended for slopes below 15%, or in case of extreme

weather conditions (excessive rain and/or wind.)

5

Page 8

Greenhouse Installation Guide

Lay Sheets against Wind Direction

Direction of Wind and Rain

Minimum Slope 10%

Width Overlap

120-200 mm

19 mm washer

19 mm washer

Greca Profile

Omega Profile

25 mm washer

Lay Sheets against Wind Direction

Direction of Wind and Rain

19 mm washer

19 mm washer

Greca Profile

Direction of Wind and Rain

Gr-76 1870

Gr-76 1870

Gr-76 1870

Arching Radius

When covering curved structures, it is possible to set the sheets on an arched framework

so that they will arch within the range of elasticity of the sheets without inducing stress.

The minimum radius of the arch created is 3.00 m for Omega and 4.00 m for Greca.

Roof and Wall Fastener Location

1. A fastening screw should be inserted into at least every third corrugation valley at each internal purlin.

2. Along the edge purlin, the screws are to be inserted into alternate corrugation valleys.

3. Along the length overlap, the screws are to be inserted into the overlapping corrugation crest on top of each purlin.

4. A hole must be pre-drilled into each screw location. The diameter of the hole must be 4 mm larger than that of the screw.

5. The screws should be tightened with an electric screwdriver with an adjustable clutch, taking care not to over-tighten.

Excessive tightening may harm the sheet and cause premature failure.

6. Sheet-to-sheet stitching fasteners are recommended along the length of overlapping corrugations between the purlins,

at least 2 units at every span (See “Sheet-to-sheet stitching fasteners”, Page 7).

Positions for fastening roof or wall screws at internal purlin.

Positions for fastening roof or wall screws at edge purlin.

19 mm washer

25 mm washer

Omega Profile

Screws, Washers and Gaskets

1. General Recommendations: For optimal long-term maintenance

free service, Palram strongly recommends the use of heavyduty corrosion resistant screws, and special metal washers with

profiled 4 mm (at least) thick EPDM rubber gaskets*, 19 mm

(crest) or 25 mm (valley) diameter (in Greca profile both crest

and valley with 19 mm), to fasten the sheets to the supporting

structure and seal the fastener’s hole (Figure 1).

2. Use of self-tapping screws with pre-drilled holes or self-drilling

screws is recommended. For wooden purlins, a special woodscrew should be used (Figure 2).

3. The screw placed into corrugation crest should be 6.3 x 38 mm

(/ x 1 / in.) or a #12 or 14 gage screw. Screws placed in a

corrugation valley should be 6.3 x 25 mm (1/4 x 1 in.). Each

screw should be fitted with a conical corrosion resistant metal

washer at least 1 mm (0.04 in.) thick and a special EPDM gasket.

The screw should be tightened moderately without deforming

the washer and rubber gasket or distorting the corrugation.

4. Special attention should be given to the insertion of the screws

perpendicular to the material face. Oblique insertion could

damage the sheet and/or result in leaks (Figure 2).

* Palram offers to supply, upon demand, the recommended fastener combinations

mentioned above, along with the SUNTUF Plus sheets.

19 mm washer

Greca Profile

19 mm washer

25mm washer/gasket19mm washer/gasket

Figure 1

Self-tapping screw Self-drilling screw Wood screw

Figure 2

INCORRECT -

Non-perpendicular drilling

and insertion.

CORRECT INCORRECT -

Excess over tightening

Figure 3

6

Page 9

Sheet-to-Sheet Stitching Fasteners

Trave di sostegno Supporto a Omega

SUNTUF® Plus

Side-lap profiles Stitching Fasteners

Greenhouse Installation Guide

Top and bottom pre-drilled metal side-lap profiles are

recommended for improved tightening of lapping sheets,

between purlins, with /" x 1” self-tapping screws every 400

mm and /" x 2” self-drilling screws above each purlin.

Additional Accessories

1. Omega Purlins: Palram recommends building

the greenhouse utilizing special Omega

shaped purlins to prevent condensation

drips from the purlins. Care must be taken

to collect the condensation water at the

edge of the purlins.

Fastening Metal Profile: it is possible

to install a special sheet metal angle

profile for tightening the roof sheets

along the purlins. The profile will be

30 x 40mm, 2mm thick.

Fastening distance – no more than 1200 mm.

Stitching Fasteners: It is possible to use /" x /” selftapping screws every 400 mm at the side-lap crest top for

stitching the lapping sheets.

Sheet-to-sheet fastening screw between overlapping

corrugations (detail), for Greca profile.

Sheet-to-sheet fastening screw between overlapping

corrugations (detail), for Omega profile.

SUNTUF® Plus

Special care must be taken to fasten the angel

profile on top of the Side-lap/mid crests,

without over tightening, to avoid distorting

the corrugations.

2. Corner / Side Ridge Closure: Two adjoining galvanized

sheet-metal covering profiles (flashings) are used for

closing the cladding sheets where the roof meets the

gable wall, or a vertical closure between two walls corner.

a) the internal 100x100x1.5 mm profile is used to attach

both edges of the cladding sheets to the structure.

b) the external 150x150x0.6 mm flashing profile will fasten

to the internal profile through the cladding sheets and

will close the gap between them, at the corner.

copertura angolare

metallica superiore

150 X 150 X 0.6mm

copertura angolare

metallica inferiore

100 X 100 X 1.5 mm

7

Page 10

Standard SUNTUF® Plus Accessories

SUNTUF® Plus SUNTUF® Plus

Sigillatura corrugata

SUNTUF® Plus SUNTUF® Plus

SUNTUF® Plus

Profilo Omega

Trave di sostegno Supporto a Omega

SUNTUF® Plus

All items below can be purchased from Palram Industries and its distributors.

Universal Ridge Cap - Greca Profile

(Omega Profile Universal Ridge Cap is also available)

Dimensions: 1270 x 150 x 150 mm

1270 x 270 x 270 mm

Number of Corrugations: 17

Net Length: 1210 mm

Greenhouse Installation Guide

SUNTUF® Plus SUNTUF® Plus

Flat Ridge Cap 150°

Dimensions:

2500 x 210 x 210 mm

Net Length: 2400 mm

Corrugated Sealing Strip

SUNTUF® Plus

Flat Side Ridge - 90°

Dimensions:

2500 x 160 x 160 mm

Net Length: 2400 mm

SUNTUF® Plus

Universal Ridge Cap

8

Page 11

All marketing materials and any content therewith provided by palram® are provided solely for the purpose of supporting and enhancing the marketing of Palram® products.

These materials are protected by Palram’s intellectual property rights and may not be used for any other purpose or in connection with the sale of products of any other manufacturer.

These materials may not be transferred to or used by any third party without prior permission of Palram.

PALRAM H.Q.

Tel: +972.4.8459.900

Fax: +972.4.8444.980

palram@palram.com

www.palram.com

In as much as Palram Industries has no control over the use to which others may put the material, it does not guarantee that the same

results as those described herein will be obtained. Each user of the material should make his own tests to determine the material’s

suitability for his own particular use. Statements concerning possible or suggested uses of the materials described herein are not to

be construed as constituting a license under any Palram Industries patent covering such use or as recommendations for use of such

materials in the infringement of any patent. Palram Industries or its distributors cannot be held responsible for any losses incurred through

incorrect installation of the material. In accordance with our company policy of continual product development you are advised to

check with your local Palram Industries supplier to ensure that you have obtained the most up to date information.

©1997 Palram Industries Ltd. | SUNTUF is a registered trademark of Palram Industries Ltd.

PALRAM EUROPE LTD.

Tel: +44.1302.380776

Fax: +44.1302.380788

sales.europe@palram.com

www.palram.com

PALRAM AMERICAS

Tel: 610.285.9918

Fax: 610.285.9928

palramamericas@palram.com

www.palramamericas.com

Loading...

Loading...