Page 1

SUNTUF® Technical Guide

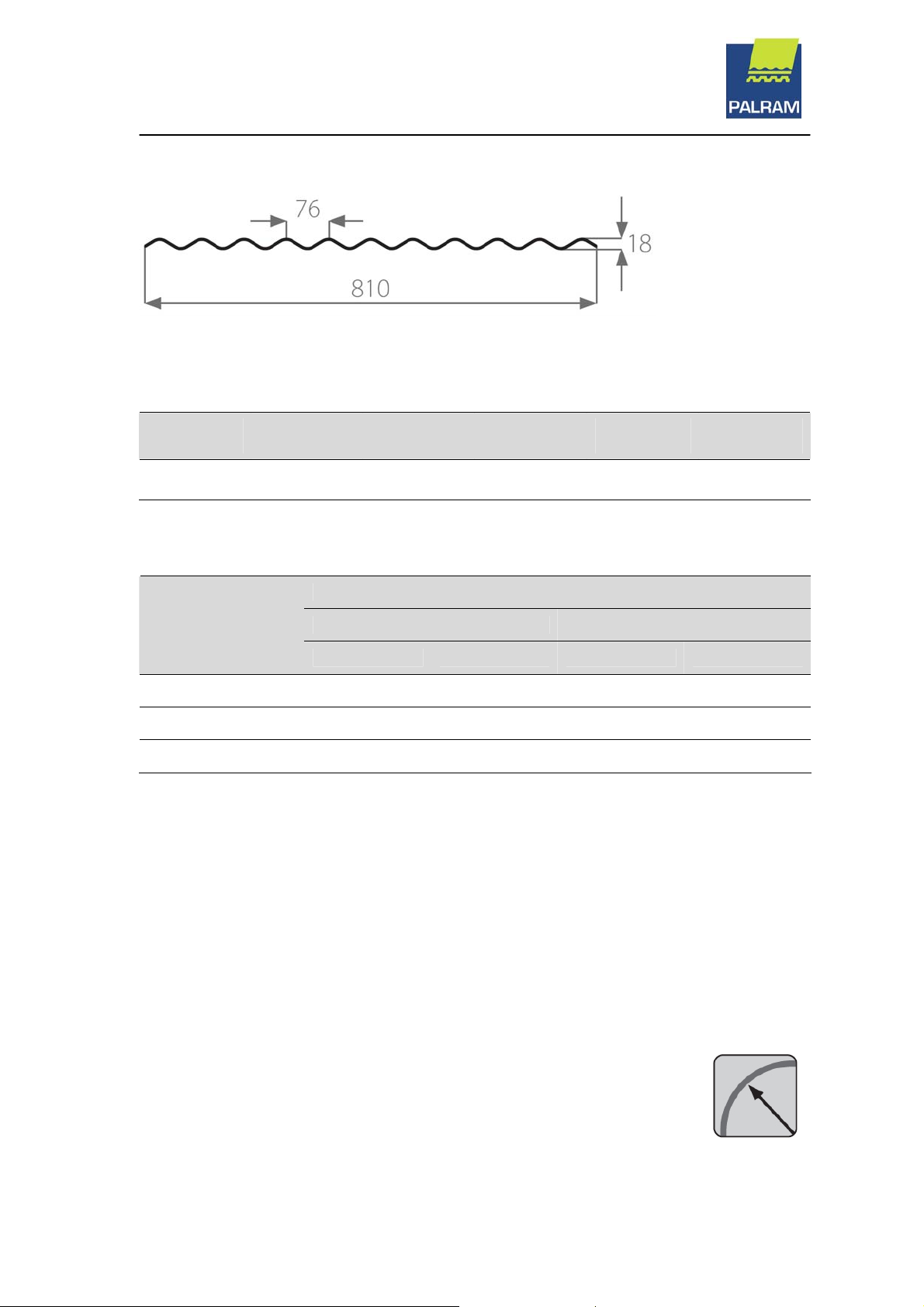

Profile: Iron 76/18 (Sinus)

Profile Drawing

Profile is also available in other widths: 660, 860, 1140 and 1260.

Profile Dimensions

Profile

(mm)

76 / 18 0.8 – 1.5 1.5 - 11.8 900 830 7.8

Thickness

(mm)

Length

(m)

Overall width

(mm)

Cover Width

(mm)

Side-Lap

( % )

Load / Span Data

Maximum Roof Span (mm)

Load

(kg/m²)

Mid Field End Field Mid Field End Field

50

80

110

The specified dimensions do not supersede the requirements of local construction codes.

The maximum purlin spans are based on continuous beam calculation model and practical testing.

The criterion for allowed deflections is L/20.

In vertical walls the spans can be increased by 10%.

The mentioned load refers to both wind and snow loads.

Minimum recommended slope – 10%.

Maximum recommended panel length - 7.0 m.

Curved Roof

850

700

600

0.8 mm 1.0 mm

640

525

450

900

850

750

675

640

560

Minimum curving radius 4.0 m.

26/02/2009

1

Page 2

SUNTUF® Technical Guide

Profile: Iron 76/18 (Sinus)

Positioning

Make sure the UV protected side faces out.

Side-lap of SUNTUF panels must be installed against the primary direction of rain.

The SUNTUF panels must be located and installed without any stresses.

Do not pull, stretch or force the sheets when the profiles are not perfectly matched.

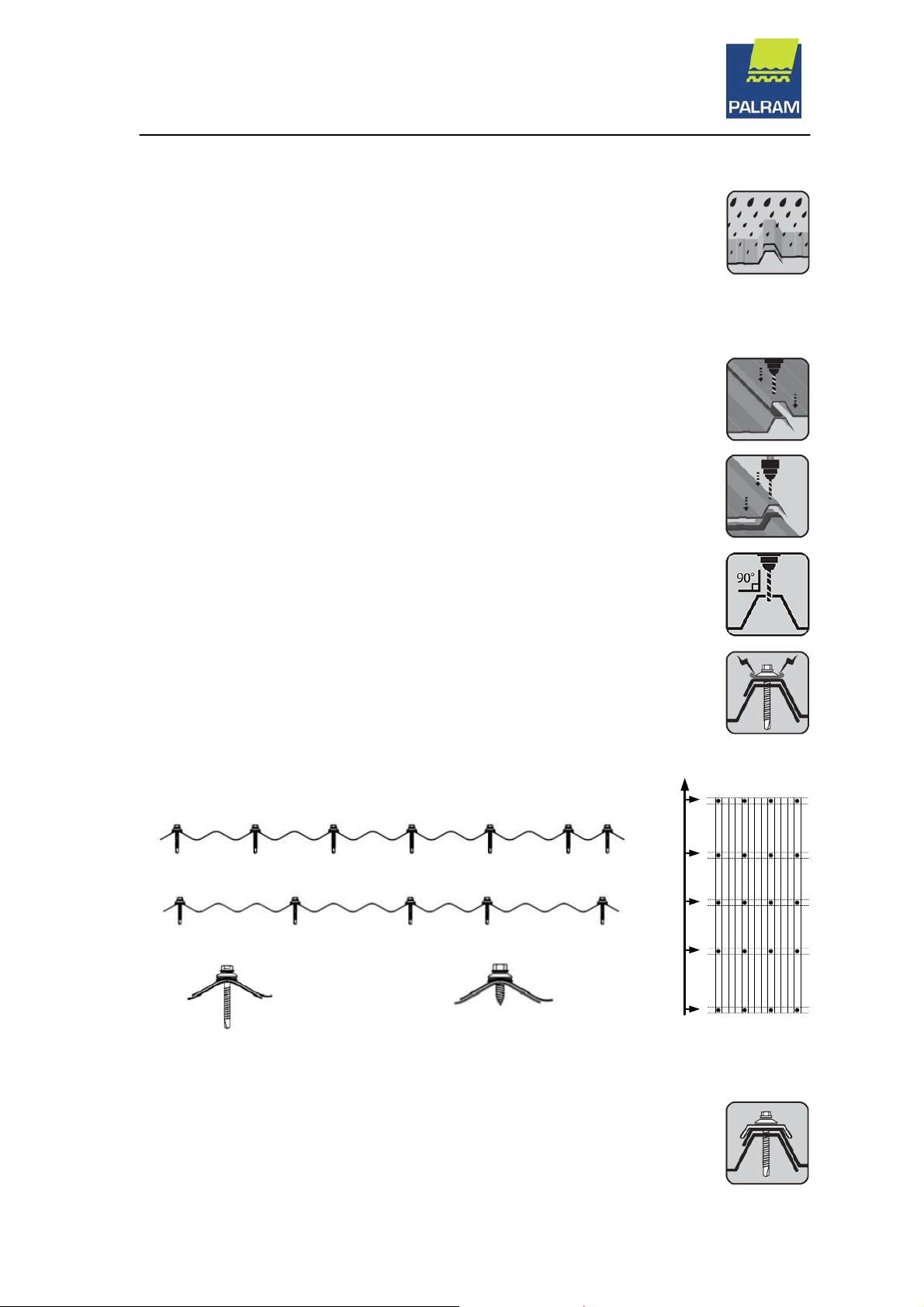

Fastening

Apply sealing tape over the SUNTUF panel side-lap corrugation crests, where covered

by the next panel.

Apply sealing tape along the bottom and top End-lap (if there is), along screws

centerline or two tapes on both sides of screw centerline.

Pre-drill 10mm holes at crests where screws are positioned.

Start fastening the screws from the first side-lap (left) through the pre-drilled holes (3).

Start fastening the screws on the lower edge purlin (End-lap), through every other

corrugation crest (1).

Fasten screws at the internal purlins, through every third corrugation crest, starting at

the same side (2).

Fasten screws at the upper edge purlin, through every other corrugation crest, starting

at the same side (1).

Do not over-tighten!

• Fasten the stitching screws at every 300 mm (4).

Fastening Location

1)

2)

3) 4)

Screws and Washers Specification

Crest fixing: Self-drilling 5.5mm (¼") x 40mm (1½") screw + matched metal crest rider

(Storm washers) with EPDM gasket or 19mm diameter- galvanized / aluminum /

stainless metal washer attached to EPDM rubber gasket of 55 to 65 shore hardness.

Side Stitching: 5.5mm x 19mm (3/4”) self-tapping screw with 19 mm washer/gasket.

26/02/2009

2

Page 3

SUNTUF® Technical Guide

Profile: Iron 76/18 (Sinus)

Important Notes

Use only PALRAM approved accessories, including EPDM rubber

washers, silicones, sealing tape, closure fixtures etc.

For clear SUNTUF onto wooden purlins, apply white acrylic paint, or

aluminum tape, in order to prevent over-heating of the purlins.

Cutting / Sawing tools

Table or Portable circular saw with small teeth.

Jigsaw.

When Sawing use high blade speed and slow feed rate.

Support the sheet in the vicinity of the cut and clean dust and

splinters away.

Fastening Tips

Use adjustable electric screwdriver.

The screw must be installed perpendicular to the SUNTUF sheet.

Important: Do not over-tighten.

Safety

Do not step directly on the panel.

Use stepping boards.

Work according to local safety regulations.

Handling and Storage

Store in a shaded place, protect from direct sunlight and rain.

Avoid covering the sheets with heat absorbing materials.

Avoid contact or environment of chemicals.

Protect the sheets from any physical damage.

Inasmuch as PALRAM Industries has no control over the use to which others may put the material, it does not guarantee that the same results as

those described herein will be obtained. Each user of the material should make his own tests to determine the material’s suitability for his own

particular use. Statements concerning possible or suggested uses of the materials described herein are not to be construed as constituting a license

under any PALRAM Industries patent covering such use or as recommendations for use of such materials in the infringement of any patent. PALRAM

Industries or its distributors cannot be held responsible for any losses incurred through incorrect installation of the material. In accordance with our

company policy of continual product development you are advised to check with your local PALRAM Industries supplier to ensure that you have

obtained the most up to date information.

26/02/2009

3

Loading...

Loading...