Page 1

SUNLITE® Technical Guide

Multiwall Polycarbonate Sheet

Page 2

Content

Introduction 1

Product Range 1

Standard dimensions 1

Colors 2

Typical physical properties 2

Flammability 2

Chemical resistance, compatible sealants and adhesives 3

Arching radius 3

Wind and snow load calculation 4

Spacing and load calculations 4

Positioning of clamping profiles and fastener location 13

Preparation for glazing 14

Preparations prior to installation 15

Glazing profiles and fastening screws 15

Handling and storage 16

Cutting 16

Drilling 17

Sealing and bonding 17

Accessories 17

General recommendations for working with SUNLITE® sheets 18

1

2

Page 3

SUNLITE® Technical Guide

Introduction

This manual provides basic guidelines for selecting, handling and installing SUNLITE sheets. Due to their hollow core, preliminary

preparation and additional care are required before the actual installation. Please note these guidelines before starting and follow

them carefully.

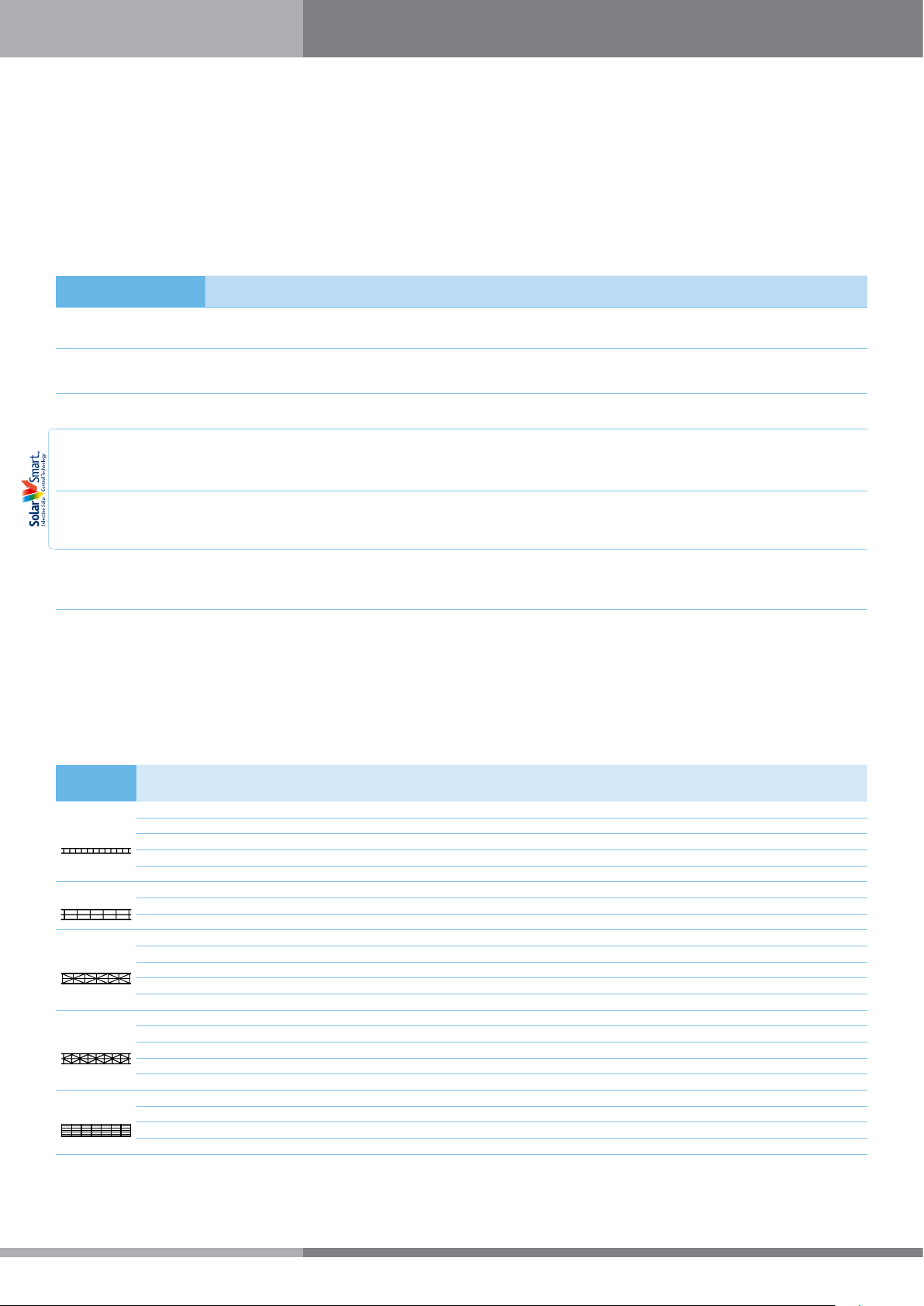

Product Range

Product Description Application

SUNLITE®

SUNLITE® UV2

Flat multiwall polycarbonate sheet with UV protective layer

on one side.

Flat multiwall polycarbonate sheet with UV protective layer

on both sides.

Suitable for both exterior and indoor applications.

Recommended for applications that involve UV

exposure on both sides (e.g. exterior light boxes)

SUNLITE® FR Sheet with higher fire resistance rating. Recommended for applications in populated areas.

Flat multiwall polycarbonate sheet with integrated metallic

SUNLITE® Solar Control

reflective heat-blocking layer. The sheet that transmits less

Available with 25 or 30% light transmission.

Infrared radiation and reduces heat buildup.

SUNLITE® CL

SUNLITE® Smart

Flat multiwall polycarbonate sheet with advanced

SolarSmart™ tint that combines infrared heat blocking with a

clear view due to its high clarity.

Can be tailored to achieve different light and heat

transmissions.

Recommended for commercial greenhouses and

SUNLITE® Plus Flat multiwall polycarbonate sheet with anti-condensation.

closed structures with an open water reservoir, such

as swimming pools.

Notes:

1. Some features of the products above can be combined. Please contact your Palram distributor for more information.

2. All the above products are supplied with a protective masking on both sides, which clearly marks the UV protected side. Protective masking on one side only is

available upon request. The masking should be removed immediately after installation.

3. For transportation, handling and storage instructions and recommendations, please refer to Handling and Storage Guidelines for Palram Sheets.

4. SUNLITE sheets are backed by a 10 years limited warranty, available upon request.

Standard Dimensions

Structure

Twin Wall

Triple Wall

X-Lite

V-Structure

7 Walls

*Other structures, dimensions and weights are available upon request. Please contact your Palram distributor for more details.

Thickness

(mm)

4 0.8 3.8

4.5 1.0 3.7

6 1.3 3.5

8 1.5 3.3

10 1.7 2.9

8 1.7 3.0

10 2.0 2.7

16 2.5 2.3

16 2.5 2.1

25 3.0 1.7

32 3.2 1.6

35 3.5 1.5

40 4.1 1.4

20 2.8 1.85

25 3.4 1.6

32 3.6 1.5

35 3.8 1.45

40 4.0 1.35

10 1.9 2.3

16 2.55 1.75

20 2.9 1.55

25 3.4 1.39

Area Weight

(Kg/m²)

U-Value

(W/m²•°K)

700 980 1050 1200 1220* 1250 1600 1800 1830 2085 2090 2095 2100

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔

Width (mm) (*USA Only)

✔ ✔ ✔

✔ ✔ ✔

✔ ✔

✔ ✔

✔

✔

✔

✔

1

Page 4

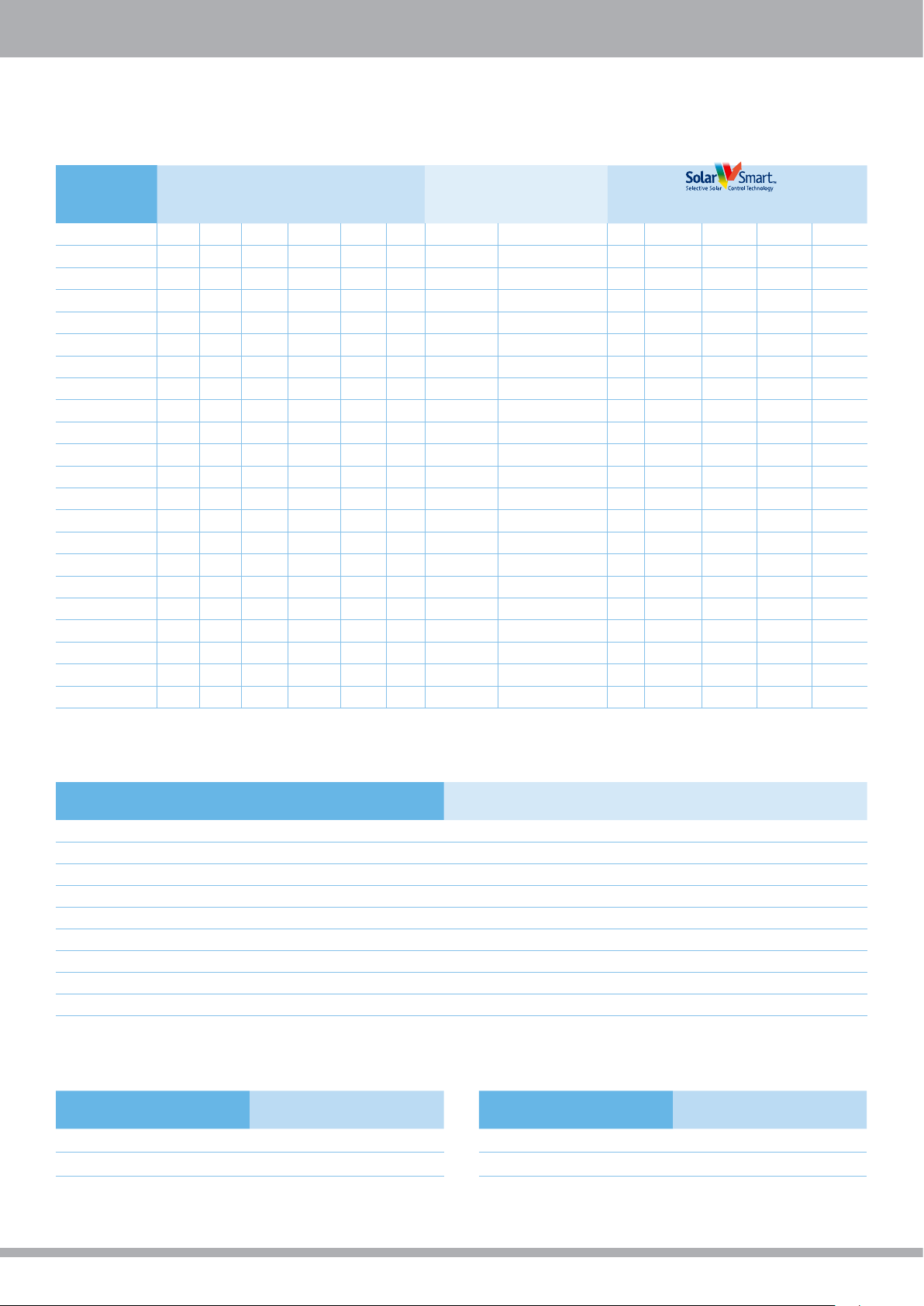

Colors*

Standard Colors Multi-Layered

Structure

Twin wall 4mm 82% 35% 30% 35% 30% 30%

Twin wall 4.5mm 82% 35% 30% 35% 30% 30%

Twin wall 6mm 80% 35% 20% 35% 30% 30%

Twin wall 8mm 80% 35% 35% 35% 30% 25% 45%/34% 60%/55%

Twin wall 10mm 79% 35% 30% 35% 30% 25% 60%/55%

Triple wall 8mm 76% 35% 48% 35% 30% 25%

Triple wall 10mm 76% 35% 48% 35% 30% 25%

Triple wall 16mm 76% 35% 48% 35% 30%

X-Lite 16mm 60% 25% 38% 35% 30%/25%

V-Structure 20mm 63% 25% 20% 10%

V-Structure 25mm 62% 30%

V-Structure 32mm 61% 20% 20%

V-Structure 35mm 60%

V-Structure 40mm 58%

X-Lite 25mm 60% 25% 15% 10% 5% 20% 20%/16% 42%/35%

X-Lite 32mm 58% 20% 15% 10% 5% 20% 20%/16% 42%/35%

X-Lite 35mm 57% 20% 15% 10% 5% 20% 20%/16% 42%/35%

X-Lite 40mm 57% 20% 15%

7 Walls 10mm 64% 45% 29%

7 Walls 16mm 64% 45% 29%

7 Walls 20mm 62% 45% 29%

7 Walls 25mm 60% 40% 22%

*Light transmission values adhere to ASTM D-1003. **Blue, Green and Solar Control are made to order only.

Clear Bronze

White

Opal

White

Diffuser

Green** Blue** Bronze/Opal

Solar Guard

(Solar Control/Opal)

Solar

Ice

Solar

Control**

CL SLT

LT = Light Transmission

ST = Solar Transmission

Smart

Green

Typical Physical Properties

Property Method* Conditions Units Value

Density D-792 g/cm³ 1.2

Heat deflection temperature (HDT) D-648 Load: 1.82 MP °C 135

Service Temperature - Short term °C -50 to +120

Service Temperature - Long term °C -50 to +100

Coefficient of linear thermal expansion D-696 mm/mm °C 6.5x10

Tensile strength at yield D-638 10 mm/min MPa 62

Elongation at break D-638 10 mm/min % >90

Impact falling dart ISO 6603/1 J 40-400

Practical thermal expansion/contraction mm/m 3

* ASTM except where noted otherwise.

Flammability

Method Classification* Method Classification*

BS 476/7 Class 1

EN 13501 B, s1, d0 ASTM E-84 Class A

* Depends on sheet type. For more information please contact your Palram distributor.

ASTM D-635 CC-1 (SUNLITE® FR)

2

Page 5

SUNLITE® Technical Guide

Chemical Resistance & Compatible Sealants

SUNLITE has good resistance to many chemicals. Some chemicals may harm the SUNLITE sheets. Detailed information about these

materials can be found at the Chemical Resistance of Palram Polycarbonate Products brochure. Please contact your Palram dealer

when in doubt about any material or chemical.

When choosing adhesives or sealants to be used during installation of SUNLITE sheets, please refer to Recommended Adhesives and

Sealants for Polycarbonate Products from the Palram websites.

For use of any adhesive or sealant not listed in the above brochure, consult with your Palram dealer to get his approval. Failure

to do so will void any and all warranties.

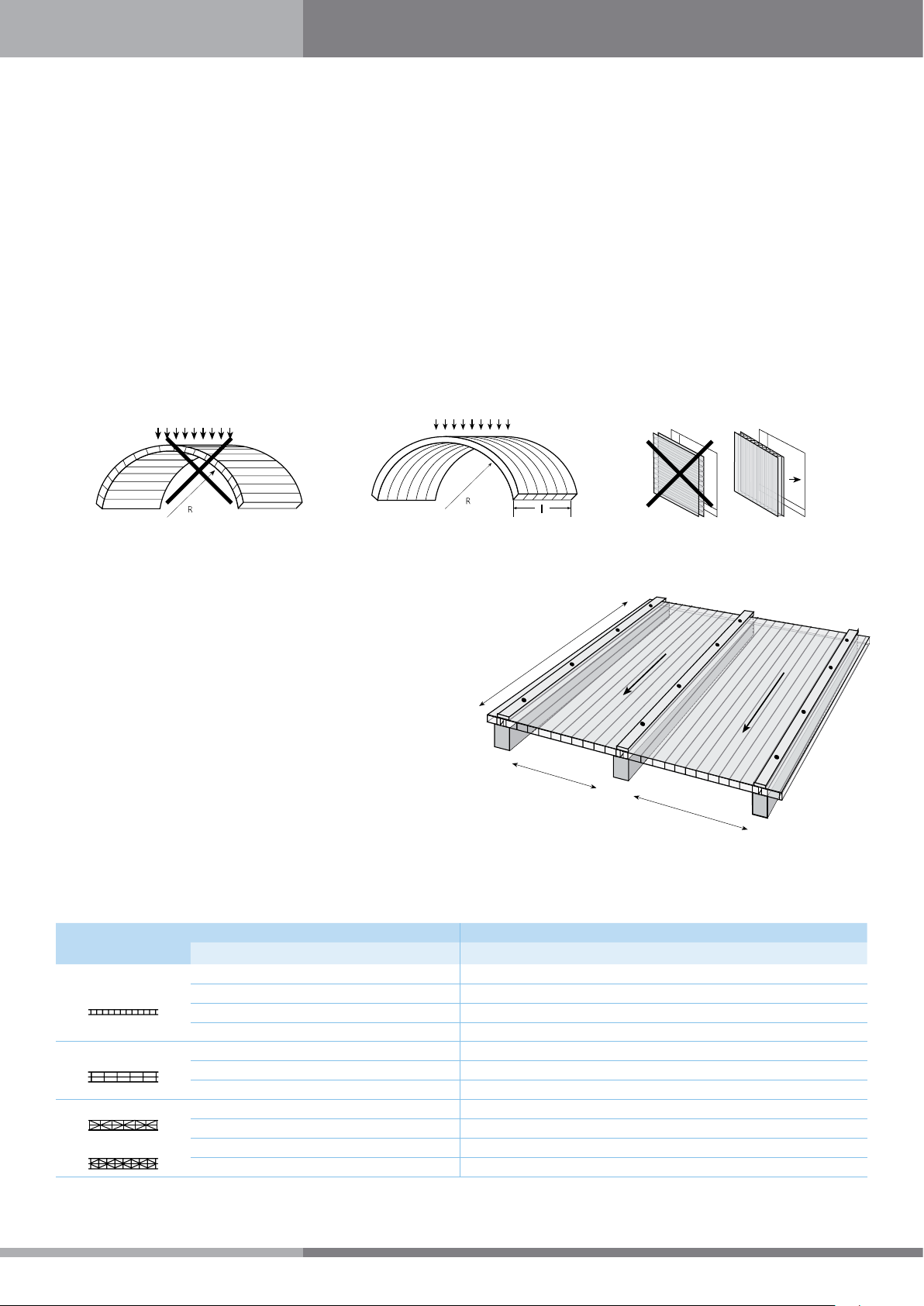

Positioning the Sheets

1. SUNLITE sheets should be installed with the rib channels sloping downwards (Figs. 1a, 1c, 2). That orientation will reduce accumulation

of dirt inside the sheet and ease gravity drainage of any condensation moisture.

Figure 1a Figure 1b Figure 1c

2. Sheets should be installed with the adjoining edges connected by a glazing profile suited to the glazing system.

3. For sheets installed in the flat, horizontal position, (roofs, overhead skylights),

a minimum slope of 5 percent is imperative, with 10 percent and above

preferable. Steeper slopes offer better rainwater drainage and self-

Length

cleaning, and reduce the risk of water and dirt infiltration through

the connectors and fastening screws. Steeper slopes also help to

diminish the visual effect of sheet deflection caused by loading.

Slope > 5%

4. Length dimension is defined as parallel to the ribs, while width

will always be perpendicular to the ribs.

Width

Arching Radius

SUNLITE sheets may be cold bent or curved up to their minimum

permitted radius, using polycarbonate’s natural tolerance for cold

Figure 2

Flat, two-sided clamped glazing

Width

forming with no need for thermal processing. Curving SUNLITE

sheet beyond this minimum permitted radius induces undue stresses and strains in the glazing sheet, causing premature failure and

will void the warranty.

Structure

Twin Wall

Triple Wall

X-Lite

V-Structure

mm Inch mm Feet Inch

Thickness Minimal Cold Bending Radius

4 5/32 700 2.30 28

6 1/4 1,050 3.40 41

8 5/16 1,400 4.60 55

10 3/8 1,750 5.70 69

8 5/16 1,760 5.80 69

10 3/8 2,200 7.20 87

16 5/8 2,800 9.20 110

16 5/8 3,000 9.80 118

25 1 5,000 16.40 197

32 1 1/4 6,400 21.00 252

35 1 3/8 7,000 23.00 276

3

3

Page 6

Wind and Snow Load Calculation

Local building codes and standards in most countries provide details for required design loads, which should be consulted before

installation. The information below is provided for general reference.

Conversion of Wind Velocity Values into Wind (or Static) Pressure

Wind Strength Level

Property Units

Moderate Strong Storm Hurricane

Wind velocity

Static pressure

Km/h 20 40 - 60 80 - 100 120 - 140(+)

m/sec 6 11 - 17 22 - 28 33 - 40

Kg/m² 2 8 - 17 30 - 50 70 - 100(+)

psf 0.4 2 - 4 6 - 10 14 - 20(+)

Snow Load: Snow load from accumulated snow cannot be disregarded. Both structure and glazing should be suitable for this extra

weight. When choosing greenhouse roofing material for snow-bound areas, a single wall corrugated polycarbonate roofing (e.g.

SUNTUF or SUNSKY) may become preferable. Please consult with your Palram distributor.

Indicative snow load Per 1.0 cm (0.4 inch) of height or thickness

Fresh, fine, fluffy snow From 0.8 to 1.9 kg/m² (0.16-0.39 psf)

Wet, watery, compacted snow From 2.0 to 8.0 kg/m² (0.41-1.64 psf)

Spacing and Load Calculations for Different Methods of Installation

1. Four Sides Clamp or Frame

This method utilizes comparatively small, separate glazing elements, cut from larger sheets. SUNLITE is put inside a four-sided frame

or supporting structures, and clamped on all sides. Clamping is done by plastic, wood or metal clamping profiles, with or without

rubber sealing strips, and fastened by nails, screws or bolts to the supporting frame. The frame itself can be made of wood or metal,

according to the design.

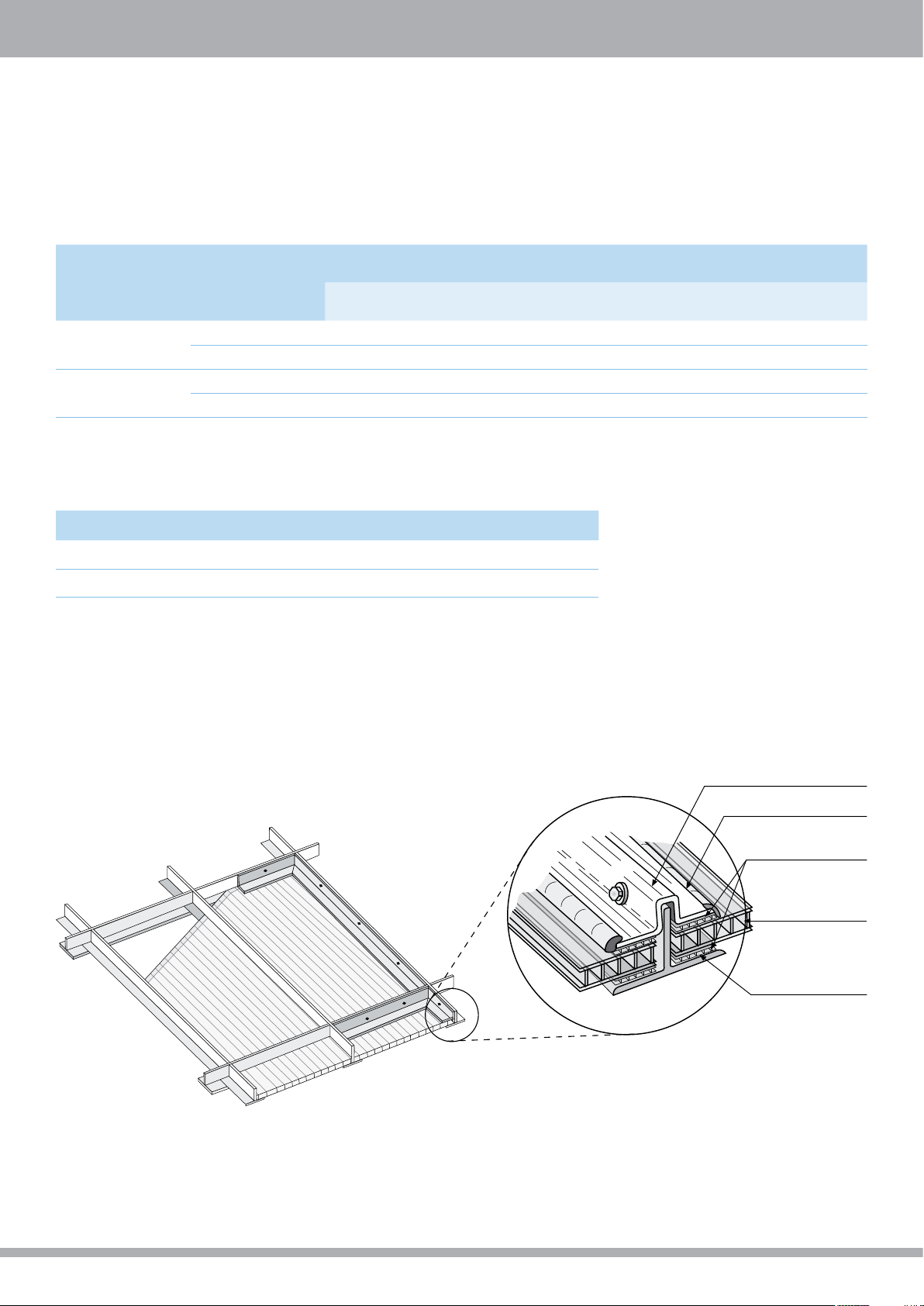

Clamping profile

Silicone sealant

Rubber packing strips

on both sides

SUNLITE glazing

Supporting frame

Figure 3a

Typical four sided clamp installation:

“wet” method, steel frame.

Figure 3a

Typical four sided clamp installation:

“wet” method, steel frame.

The table on top the next page presents the recommended center-to-center spans, for each type of SUNLITE sheet at various wind

or snow loads.

4

4

Page 7

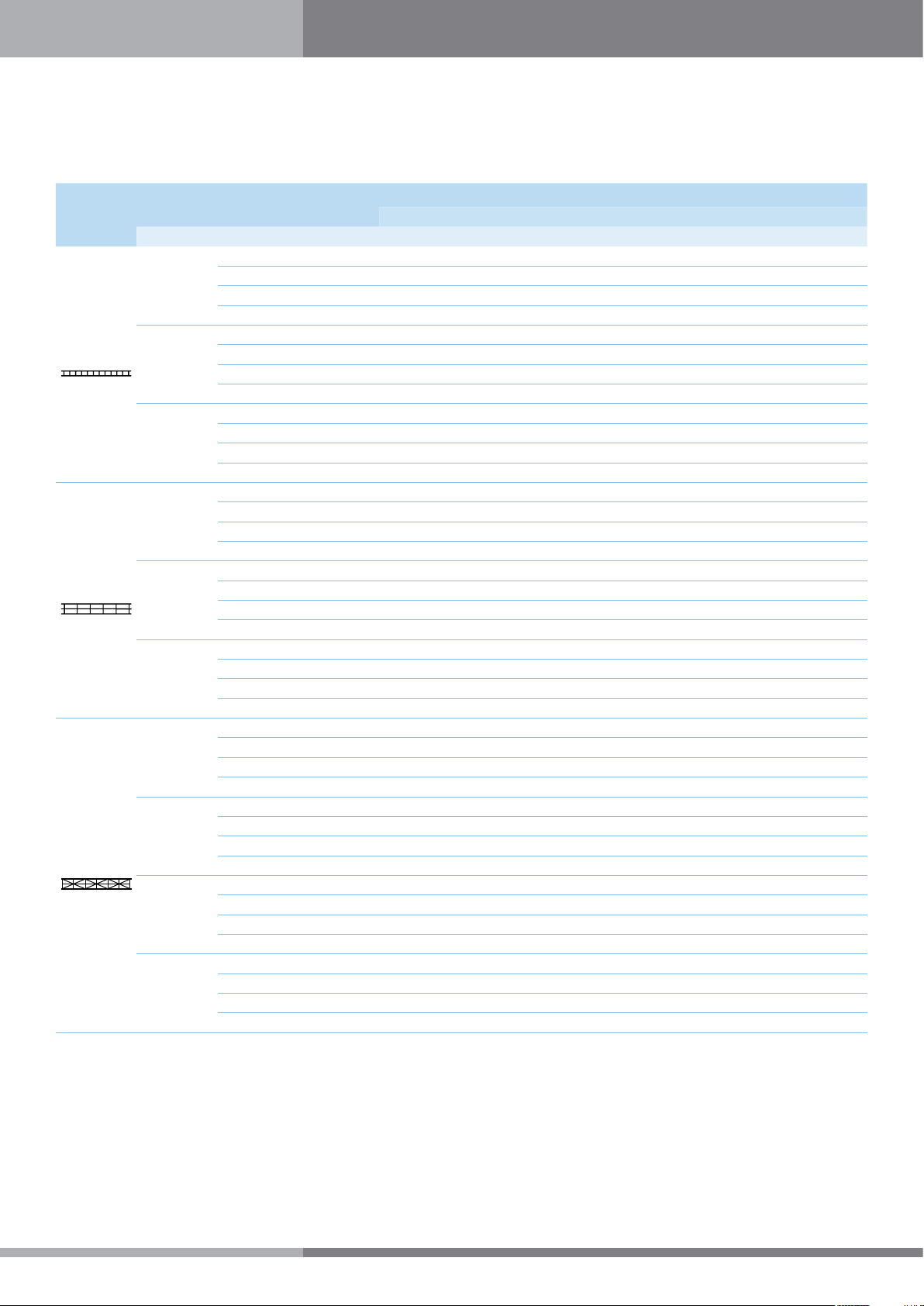

Maximum Recommended Distances Between Centers- Shorter Spans (width)

Under different ratios and loads for four sides clamped / framed flat glazing.

SUNLITE® Technical Guide

Structure

Twin Wall

Triple Wall

X-Lite

Thickness

mm Kg/m² psf mm Inch mm Inch mm Inch

6

8

10

8

10

16

16

25

32

35

Wind/snow

uniform loads

50 10 900 36 700 28 500 20

80 16 700 28 500 20 350 14

100 20 500 20 400 16 - 120 25 400 16 300 12 - -

50 10 1150 45 900 36 600 24

80 16 1000 40 800 28 480 19

100 20 900 36 650 22 450 18

120 25 750 30 600 20 - -

50 10 1250 50 1000 40 750 30

80 16 1200 47 900 30 550 22

100 20 110 43 800 24 500 20

120 25 950 37 700 21 450 18

50 10 1200 47 950 38 650 26

80 16 1050 42 750 29 510 20

100 20 950 37 650 22 470 18

120 25 900 38 650 22 480 19

50 10 1275 51 1050 41 800 32

80 16 1225 49 900 32 600 24

100 20 1125 44 750 26 550 22

120 25 900 38 650 22 480 19

50 10 1500 59 1200 47 1100 43

80 16 1300 52 1100 43 1000 41

100 20 1200 47 1050 41 900 36

120 25 1100 43 950 37 850 33

50 10 1550 61 1250 49 1150 45

80 16 1350 53 1150 45 1050 41

100 20 1240 49 1080 42 950 37

120 25 1130 44 980 38 900 35

50 10 2100 83 1700 67 1400 55

80 16 1950 76 1600 63 1650 53

100 20 1800 70 1500 59 1300 51

120 25 1650 65 1400 55 1250 49

50 10 2100 83 1850 73 1500 59

80 16 2100 83 1700 67 1400 55

100 20 2000 78 1600 63 1350 53

120 25 1850 73 1500 59 1300 51

50 10 2100 83 1875 74 1525 60

80 16 2100 83 1725 68 1425 56

100 20 2025 79 1652 64 1375 54

120 25 1875 74 1525 60 1325 52

Distance between centers (shorter span) according to ratio a:b

Ratio 1:1 Ratio 1.5:1 Ratio > 1.5:1

Notes:

1. SUNLITE 4mm twin-wall is not recommended for constructive applications and is therefor excluded.

2. Data in table according to load tests on typical multi-wall sheets and additional extrapolations.

3. Recommended spans are calculated on the basis of 1/20 maximum deflection (5%) of sheet’s width (In this case crosswise, perpendicular to the rib channels).

4. A SUNLITE glazing sheet may withstand even higher loads without buckling, however, excessive lateral shortening, created by higher deflection, may cause the

edges to slip out of their supports (pop-out).

5

5

Page 8

2. Two-Sided Clamped Glazing

This is a simpler glazing system to install, requiring no mid-sheet

fastening, using long glazing sheets, and held in place by two

glazing profiles on both longitudinal edges. It is not as strong, and

permitted width is limited (the width direction of a multi-wall sheet

is more vulnerable to loads, span-wise, especially the thinner, square

ribbed 6 , 8 and 10 mm sheets).

Side clamp

(Glazing profile)

SUNLITE glazing

Figure 4

Flat, two-sided clamped glazing

Supporting rafter

Maximum Width of SUNLITE Sheets in Two Sides Clamped Flat Glazing

Twin Wall Triple Wall X-Lite

Uniform Load 6 8 10 8 10 16 16 25 32 35

Kg/m² psf mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch

50 10 450 18 540 21 680 27 575 19 700 25 990 39 1100 44 1250 50 1200 48 1200 48

80 16 320 13 430 17 500 20 450 15 525 18 900 36 1050 41 1100 43 1000 38 950 38

100 20 - - 400 16 450 18 400 14 475 17 800 32 1000 35 1050 41 950 37 875 35

120 25 - - - - 400 16 - - 425 14 700 28 975 38 1000 40 900 36 800 32

Note: The notes attached to the previous table, Maximum Recommended Distances, also apply here.

3. Two-Sided Clamped Arched Glazing

1. SUNLITE sheets can be curved into arches within the permitted radius

(see “Arching Radius” on page 3) without damaging their mechanical

Clamping/glazing profile

performance. Moreover, internal stresses induced by curving give the

sheets extra strength and rigidity in both directions, like pre-stressed

concrete elements.

SUNLITE glazing

2. Rigidity and support spans increase as the curve radius is reduced (down

to the minimal permitted radius). Shallow curving should be considered

to be similar to flat panels, while a deep curve significantly adds to the

bridging ability.

Figure 5

The table in the next page shows the growing rigidity from the curving of SUNLITE, at various uniform loads.

Supporting

arch

6

6

Page 9

Maximum Recommended Spans between Arched Supports

According to radius of curve and load for two sides clamped glazing.

SUNLITE® Technical Guide

Structure

Twin Wall

Triple Wall

X-Lite

Thickness

mm mm Inch mm Inch mm Inch mm Inch mm Inch

6

8

10

8

10

16

16

25

32

35

Sheet curvature

radius

50 Kg/m² 10 psf 80 Kg/m² 16 psf 100 Kg/m² 20 psf 120 Kg/m² 24.6 psf

1050 41 2000 79 1730 68 1420 56 1020 40

1500 59 1470 58 1090 43 890 35 660 26

1800 71 1140 45 860 34 690 27 580 23

2200 88 810 32 690 27 - - - 2800 110 500 20 350 14 - - - 4000 158 500 20 350 14 - - - 6000 236 500 20 350 14 - - - 1400 55 1650 65 1450 57 1320 52 1170 46

1800 71 1420 56 1270 50 1070 42 890 35

2200 88 1090 43 890 35 710 28 600 24

2800 110 840 33 620 19 450 18 - 4000 158 600 24 500 19 - - - 6000 236 570 23 480 19 - - - 1750 69 1630 68 1420 56 1170 46 1020 40

2200 88 1320 52 960 38 810 32 660 26

2800 110 890 35 650 26 600 24 550 22

4000 158 750 29 550 22 500 20 450 18

6000 236 700 27 520 21 500 20 420 18

1760 70 1320 52 1170 46 980 39 750 30

2200 87 1025 41 780 31 580 23 520 21

2800 110 750 30 570 23 400 16 - 4000 158 500 20 450 18 - - - 6000 236 480 19 400 16 - - - 2200 88 1220 48 880 35 720 29 580 23

2800 110 780 31 580 23 500 20 450 18

4000 158 620 25 500 20 450 18 400 16

6000 236 550 22 450 18 400 16 - 2800 118 1850 73 1650 65 1450 57 1200 48

4000 158 1450 57 1220 48 940 37 850 34

6000 236 1050 42 1000 40 850 34 800 32

3000 120 1750 69 1600 63 1500 59 1400 55

5000 200 1350 53 1200 47 1100 43 1000 39

5000 197 1650 64 1450 57 1400 55 1350 53

6000 236 1550 61 1350 53 1300 51 1250 49

6400 252 1650 64 1550 61 1350 53 1300 51

8000 315 1550 61 1450 57 1250 49 1200 47

7000 276 1650 65 1550 61 1350 53 1300 51

8200 322 1550 61 1450 57 1250 49 1200 47

according to wind/Snow loads below

Recommended (center-to-center) Distance between Supporting arches

Notes:

1. A hyphen sign in the table (-) means that the sheet cannot be used at the relevant range.

2. Generally a span of less than 600 mm (24 in.) is impractical for this installation configuration.

3. The lowest radius that appears in the upper row of every sheet group in the table is the minimum permitted cold bending radius for that specific sheet type.

7

7

Page 10

4. “Roofing & Cladding” Installation Method

This is a simpler, more practical method, resembling the one used for single-wall, corrugated plastic (or metal) sheets. It employs

longer strips, with wider dimension. Length is as long as possible without excess deformation by thermal expansion. SUNLITE sheets

are laid on top of the purlins, with rib channels directed down the slope, perpendicular to the

purlins. Span between purlins is determined by the load and deflection characteristics

of the specific SUNLITE sheet.

1. The sheets are connected to each other by long connecting elements.

2. The wide variety of these connection methods falls into two main

categories: “wet” or “dry” installation systems. The connecting elements

(made of aluminum, sheet metal or plastic- rigid PVC or polycarbonate) are

designed as connectors, not as load supporting members. They connect the

sheets to each other, achieving one unified watertight exterior shell. Additional

strength and rigidity achieved through them is an added bonus.

Basic inverted “H” polycarbonate connecting profile

An old and simple form enabling a lengthwise (side by side) connection between twin/multi-wall sheets. It

is sometime offered with a specific size profile for each sheet thickness, or in versatile, more flexible design enabling the use of one

profile with 2 consecutive thicknesses (4-6 & 8-10 “H” profiles). This connecting method is practically inappropriate for the thicker

SUNLITE panels.

1. “Dry” method: The edges on both sides are inserted into the profile, holding

the sheets by “dry” mechanical friction, with the sheets on both sides fastened

to the structure, along the purlins, by fixing screws, about 500-600 mm (20-24

inches) apart.

2. “Wet” method: both the profile channels are half-filled with silicone, which

acts, after installation and curing, both as sealer and adhesive. It may offer better weatherproofing at shallower slopes, than the “dry”

system, but is very difficult to install properly and cleanly (Figure 7).

Figure 6

Figure 7

Basic, inverted H polycarbonate connecting profile

Notes:

1. The connector itself is not fixed to the purlins.

2. Both systems are basic and disclose several shortcomings: difficult and bothersome installation, plain looks, weak and imperfect

connection and sealing. Installation may prove to be lengthy and messy for inexperienced hands. They are, however, considered the

cheapest.

Two-part polycarbonate connecting profile, which is made of the following:

1. A lower base profile, usually the more rigid of the two, on which the edges of the adjoining sheets are placed. Usually the base

profile is fastened to the purlins by screws through the middle, with both edges free, letting the sheets slide easily due to the thermal

expansion and contraction process.

2. The upper part, usually more flexible than the base, clips on the base profile by hand pressure, holding both sides of the adjoining

sheets in place by mechanical pressure.

This type is easier to install, more reliable in holding the sheets and sealing the connection. It is used, mostly, in “dry” installation, but

could be assisted by silicone on the upper and lower profile. “Wet” installation like this is difficult to keep clean during installation and

with long sheets may lose its effectiveness due to excessive expansion.

Figure 8a Figure 8b Figure 8c

Figure 8

Drawing of typical two-part polycarbonate connecting profiles currently used

8

8

Page 11

SUNLITE® Technical Guide

Combination of metal and plastic two-part connecting profile

Offers added strength and rigidity. The lower part of the profile is made of metal- (mostly aluminum ), and the upper part is made of

plastic (rigid PVC or polycarbonate), clipped on top of the metal profile, pressing on the edges of the two adjoining sheets.

Figure 9

Description of Typical Two-Part Plastic and Metal Connecting Profiles Currently Used

Wood connecting profiles

Developed from wooden window frames, support the installed SUNLITE sheets. They are usually used together with the “wet” system,

with rubber packing strips and silicone sealant. Lengths are generally limited by the nature of wood. If long, laminated wooden rafters

are used, they usually come with one or more of the other connecting solutions below.

Aluminum

Wood

Silicone sealant

Rubber Strip

Wood

“Dry” system “Wet” system

Figure 10

Description of Typical Two-Part Wood Connecting Profiles Currently used in the Market

Metal connecting profiles

Comprise the largest group of connecting profiles. They come in wide variety of designs, are made from aluminum or steel, in “dry” or

“wet” systems, and in plain or sophisticated detailing and finish. Some profiles are equipped with built-in drains, EPDM rubber weather

strips, concealed fixing screws, and high-end finish, for more luxurious structures.

Figure 11a Figure 11b

Figure 10

Typical two-part metal system connecting profiles currently used.

9

Silicone sealant

Steel

support

Figure 11c Figure 11d

Steel clamping bar

Epdm sealing/padding

strips on both sides.

9

Page 12

Mid-Sheet Fasteners

(Not recommended for DIY Applications)

1. A wider sheet has to be fastened to the supporting structure

by additional fastening along its width, as the connectors

on both longitudinal sides are not enough to hold the sheet

down, against the uplift force it has to withstand.

2. Fastening is usually done by screws, inserted along the

supporting internal purlins, spaced about 500mm (20in.) apart.

Figure 12

Schematic isometric view

of partial installation with

mid-sheet fasteners

3. Along the edge purlin, the fastening screws should be inserted about 300 mm (12 in.) apart.

4. A hole must be pre-drilled into each screw location. The diameter of that hole should be 2 mm larger than that of the screw, to

allow for thermal expansion movements. In case of dark colored sheets predrill even larger holes, and use wider fastener washers.

5. An electric screwdriver with an adjustable clutch should be used to tighten the screws. Avoid excess overtightening, which might

induce undue internal stresses, causing premature failure and buckling of the sheet. Pay attention to insert the screws perpendicular

to the material face, as inclined insertion could damage the sheet and/or result in leaks.

Figure 13

Typical installation screws

and obligatory washers

Figure 13a

Incorrect - Overtightening

Figure 13a

Self-tapping screw

6. Use of self-tapping or self-drilling screws is recommended. In case of wooden structures, suitable wood-screws should be used.

All the screws should be corrosion resistant, with at least heavy-duty hot-dipped galvanized finish, or stainless steel (if used in an

extremely corrosive environment). The screws should be 6.35mm (1/4in.) diameter, with length according to sheet thickness, type of

washer and type of supporting structure.

7. Each screw should be fitted with a conical corrosion resistant steel washer, with specifications as the screws above or of aluminum,

at least 1mm (0.04 in.) thick, 25mm (1 in.) diameter, with a Specially Shaped integral rubber gasket, EPDM (see Palram special washer/

gasket fig. 13g). The screw should be tightened carefully, with no distortion of the washer and rubber gasket, or the flat face of the

sheet Palram will supply the suitable fasteners and washers with the SUNLITE sheets unless required otherwise.

Figure 13b

Self-drilling screw

Figure 13b

Wood screw

25mm special washer/gasket

Figure 13b

Correct

Figure 13g

Figure 13c

Incorrect - Non-perpendicular

drilling and insertion

10

10

Page 13

SUNLITE® Technical Guide

8. Screw buttons: Improved performance can be obtained by replacing the

washers with special plastic screw buttons, fitted with a suitable rubber gasket,

with or without a closing cap. They fit the thickness of each type of sheet (6, 8,

10, 16 mm, and possibly 25 mm), differing by sleeve length. Their advantage:

the sleeve prevents excessive tightening and local squashing around the

screw, and is softer on the sheet, reducing risk of tear or shear around the

screw’s stem. They also offer a seal between the fastener hole and the open

channels of the sheet, preventing possible infiltration of water and dirt into

the internal space of the sheet. Screw buttons can suit the 6.35mm (1/4 in.)

screws mentioned above, although it is recommended to use slightly longer

screws to accommodate the button thickness.

Palram recommends perforating SUNLITE for fastening as little as possible, and

prefers the use of clamped edge installation. Palram recommends that the

use of fastening screws in a glazing system, even with plastic buttons, should

be limited to economical, price conscious projects only. Two or four-sided

clamped glazing is a preferred choice.

Optional cover

Design spans between Supporting Purlins

According to Designated Loads for the Roofing and Cladding Method

Max. Recommended Spans between Support Purlins - Flat / Slightly Curved Roofing/Glazing

Figure 14

>30 mm

>2 mm more than

diameter of button stem

Rubber gasket

Plastic button

Fastening screw

Thickness

Distance (center-to-center) between supporting purlins - according to wind/Snow loads below

Structure

mm mm Inch mm Inch mm Inch mm Inch

6 900 36 800 32 650 26 500 20

Twin Wall

Triple Wall

X-Lite

Notes:

1. Span calculation is based on general professional know-how, previous experience & specialized expertise with this type of products.

2. Spans depicted are drawn from loading tests and extrapolations based on L/20 deflection (5%) at the specific span and load using continuous multi-span

supports. The values refer to mid-spans. Edge-spans (lower & upper ends) should be approx. 20% smaller.

3. SUNLITE panels can withstand higher loads and/or wider spans without failure. However the involved deflections will exceed L/10 (10%) of the span, which is

unacceptable in most cases.

Curving SUNLITE sheets gives them higher strength and rigidity, as in the case of two-sides clamping described in the next page.

8 1150 46 1000 40 850 34 650 26

10 1250 50 1150 46 1050 42 900 36

8 1120 44 970 38 820 32 620 25

10 1220 48 1125 45 1020 41 870 35

16 1600 64 1450 58 1250 50 1130 45

16 1650 65 1500 59 1300 51 1180 46

25 1850 74 1700 68 1550 62 1425 56

32 2050 82 1900 76 1750 69 1600 63

35 2075 82 1925 76 1775 70 1625 64

50 Kg/m² 10 psf 80 Kg/m² 16 psf 100 Kg/m² 20 psf 120 Kg/m² 25 psf

11

11

Page 14

Maximum Recommended Distances between Support Purlins

For Curved Roofing/Cladding, According to Curvature Radius and Load.

Structure Thickness Sheet curvature radius

mm mm Inch mm Inch mm Inch mm Inch mm Inch

1050 41 2000 79 1730 68 1420 56 1020 40

1500 60 1570 62 1570 62 1200 48 1200 48

1800 72 1420 56 1420 56 1150 46 1150 46

Twin Wall

Triple Wall

X-Lite

6

8

10

8

10

16

16

25

32

35

2200 86 1380 55 1380 55 1150 46 1150 46

2800 110 1260 50 1260 50 1100 44 1100 444

4000 158 1150 46 900 36 850 34 780 31

6000 236 900 36 800 32 650 26 500 20

1400 55 1570 62 1570 62 1570 62 1570 62

1800 72 1880 74 1420 56 1420 56 1420 56

2200 86 1730 68 1380 55 1380 55 1380 55

2800 110 1470 58 1470 58 1250 50 1100 43

4000 158 1250 50 1150 46 1050 40 900 32

6000 236 1150 46 1000 40 850 34 650 26

1750 69 1885 74 1885 74 1885 74 1885 74

2200 88 1725 68 1725 68 1725 68 1725 68

2800 110 1470 58 1470 58 1250 50 1100 43

4000 158 1250 50 1150 46 1050 40 900 32

6000 236 1150 46 1000 40 850 34 650 26

1760 70 1420 55 1420 55 1380 53 1380 56

2200 86 1380 53 1380 53 1380 53 1250 49

2800 110 1380 53 1380 53 1250 49 1070 42

4000 158 1150 46 1050 42 1050 42 750 30

6000 236 1100 44 960 38 825 33 625 25

1800 72 1885 74 1885 74 1885 74 1885 74

2200 86 1725 68 1725 68 1725 68 1725 68

2800 110 1750 69 1750 69 1750 69 1465 58

4600 158 1570 62 1570 62 1260 50 1260 50

6000 236 1260 50 1180 47 1075 42 900 36

2800 110 2100 83 2050 81 2000 79 1950 77

4000 158 1750 69 1700 67 1650 65 1600 63

6000 236 1600 63 1400 56 1250 50 1150 46

3000 118 2125 84 2075 81 2025 79 1975 77

4000 158 1800 71 1750 69 1700 67 1650 65

6000 236 1600 63 1400 56 1250 50 1150 46

5000 197 1300 90 2050 80 1770 70 1500 59

6000 237 2100 69 1850 73 1570 62 1300 51

6400 252 2200 86 2050 80 1770 67 1500 59

8000 315 2100 82 1950 76 1670 65 1400 55

7000 276 2200 86 2050 80 1770 67 1500 59

8200 323 2100 82 1950 76 1670 65 1400 55

Recommended (center-to-center) Distance between Supporting arches according

to wind/Snow loads below

50 Kg/m² 10 psf 80 Kg/m² 16 psf 100 Kg/m² 20 psf 120 Kg/m² 24.6 psf

Notes:

1. SUNLITE 4mm twin-wall is not recommended for constructive applications and is therefor excluded.

2. The specified spans are based on L/20 deflection (5%) at the specific span and load, using continuous multi-span supports. The values refer to mid-spans.

Edge-spans (lower & upper ends) should be approx. 15-20% smaller.

3. Spans depicted in all but the largest radii (6.00-8.00 m) derive from division of a full 180º barrel vault of the specific radius into equal size sectors. For instance - an

arch with 1.10m radius is divided into 2 equal parts of 1.73 m length. An arch of 1.50 m radius is divided into 3 parts each 1.57 m long, and so on)

4. Curved SUNLITE is more rigid and allows for a much wider span than in flat installation, especially in smaller radii. Rigidity and strength are reduced as the radius is

increased (for same type of panel). A lightly curved panel behaves almost the same as a flat one.

12

12

Page 15

SUNLITE® Technical Guide

Figure 15

Schematic description of standard

curved roofing in a vault.

Connecting profiles fastened to purlins

General Notes for Structural Design

1. The recommended support spacing, as specified in the load/span tables, should not supersede the requirements of local structural

and construction codes. The final values are to be dictated by actual conditions on site and engineering design.

2. The end spans, i.e. the distance between the edge support (or purlin) and the first internal purlin should be up to 80 percent of the

commonly recommended span for this load and type of sheet, or the value dictated by the design engineer.

SUNLITE glazing

Supporting arched structure

Supporting purlins

Positioning of Clamping Profiles and Fastener Location

1. Using the four-sided clamped glazing system, the support bars should be underneath (or inside), and the glazing clamps on top (or

outside). SUNLITE must be installed with the clamping profiles covering all four edges of the sheet. (These are load-bearing elements,

which connect the glazing to the supporting structure, transferring loads from the glazing to it.)

2. Using the two-sided clamped glazing system, the support bars (and glazing clamps) should be installed covering the two longitudinal

edges of the sheet, parallel to the rib channels. (Again, these are load-bearing elements, connecting the glazing to the supporting

structure, transferring loads from the glazing to it.)

3. Using the roofing/cladding method, glazing connectors (of any version) should be installed on both long sides of each sheet (parallel

to the rib channels). Their main duty is connecting adjoining sheets. They may assist transferring loads to the structure, but here the

fastening screws transfer most of the load to the supporting structure (the purlins). The screws, with their metal washer and rubber

gaskets, should be inserted along the length of the supporting purlins, about 500-600 mm (20-24 in.) apart and 300-400 mm (12-16

in.) at the edge purlin. When using metal glazing connectors, they are positively fastened to the purlins.

When using polycarbonate connecting-profiles, some types are fastened and others do not. In that case, the fastening screws will be

placed on both sides of the connector, about 200-250 mm (8-10 in.) on each side.

13

13

Page 16

Preparation for Glazing

Determination of Rabbet Depth and Thermal Expansion Allowance

These parameters depend on the SUNLITE sheet dimension, and relate to the four sides of the sheet (four-sides clamping system), or

to the two edges parallel to the rib channels (two-sides clamping system).

1. Allowance for expansion - SUNLITE roughly expands 3mm for every meter (/ in. per 3 / ft.) of length (or width) for a service

temperature range of about 50°C (90°F), the practical working range in most cases. For a sheet of 1m (or 40 in.) wide, 1.5m (60 in.) long,

a net allowance of 3 mm (width) and 5mm (length) should suffice in theory. We recommend doubling this allowance for practical

reasons. Allowance should be divided between both sides of the sheet. When the ends of panels are protected by a recessed ‘U’

channel, allow suitable internal space for thermal expansion.

2. Edge Engagement: (the overlap of the glazing over its frame).

3. Rabbet Depth: (expansion allowance + edge engagement). Palram recommends a rabbet depth of at least 20 mm

(0.8 in.) for widths up to 1.0 m (40 in.) and a depth of 25-30 mm (1.0 - 1.2 in.) for wider spans.

Wooden frame

a

b

Wooden clamping

profile

Silicone sealant

SUNLITE sheets

Rubber sealing

strip

Legend

a = Expansion allowance

b = Edge Engagement depth

c = Rabbet depth: a+b

Fastening screw

Figure 16b

“Wet” Glazing

Figure 16c

Schematic Sketch of Rabbet depth and Expansion Allowance (”Wet” and “Dry” methods)

a. Sheet width

b. Sheet length

c. Sash (frame) width

d. Sash length

e. Edge Engagement depth (overlap)

f. Thermal expansion allowance

g. Rabbet Depth e + f

a

Figure 16b

“Dry” Glazing

Top aluminum

b

glazing profile

Rubber sealing

profile/gasket

SUNLITE sheets

Sealing gasket

Bottom aluminum

glazing profile

Fixing screws

Supporting

steel beam

14

14

Page 17

SUNLITE® Technical Guide

Preparations Prior to Installation

1. Ensure smaller thermal expansions by installing sheets - especially colored sheets - at ambient temperatures of 10-25 °C (50-77 °F).

It is generally recommended to avoid installing sheets at colder or hotter temperatures.

2. Peel off the protective film at both open ends of the sheet (the width sides) to about 80-100 mm (3.5-4 in.) from the edges of the

sheet, to enable taping of the aluminum sealing tape. If a factory installed temporary seal is taped over the open ends, it should be

removed prior to the installation of the aluminum tape. Tape the sealing tape straight along the open-end side, so it will cling well

and evenly to both sides of the sheet, making sure that all the open ends of the rib channels are properly sealed.

3. Peel off the masking along the edges of length sides at both sides of the sheet, for about 80-100 mm (3.5-4 in.) from the edges,

preparing the sheet for the insertion into the connecting profiles or the glazing frame.

4. Remove the underside masking just prior to the actual installation on the roof. Premature removal of protective film may result in

damage to the sheet during handling.

5. Remove the upside, exterior protective film as soon as the installation of the whole glazed area is completed, or very short time

afterwards. Failing to do so would expose the protective film to direct sunlight that may fuse it to the sheet’s face. This will result in

difficulty to remove the protective film due to deterioration of the film, and ultimately void the warranty.

Impermeable

tape

Figure 17a

Partial or Complete

Removal of Protective Film

Prior and after Installation

6. Ensure the use of the proper type of sealing tape according to the application used, verifying that the prepared sheets are mounted

correctly.

Please note: In case of curved installation, where both open ends are situated at the bottom - apply the ventilated tape on both ends.

Take care to protect the sealing tapes at both ends from mechanical damage by covering the edges with aluminium U-profiles, or

cover them with polycarbonate U-shaped profiles (Fig-17c).

Installation of Sealing Tape

Figure 17b

on Open Ends of Sheet

Figure 17c

Installation of Impermeable Tape at Top of the Sheet and

Installation of Ventilated Tape at the Bottom of the Sheet

Ventilated

filter tape

U-protective

end cap

Glazing Profiles & Fastening Screws

Type of glazing/clamping profile used in the installation of SUNLITE sheets, differs according to the glazing system chosen:

1. Framing profiles are similar in concept and detail to those used in fixed glass windows, curtain walls and skylights, made of wood,

steel or aluminum, but wider, allowing for the larger Edge Engagement depth required for SUNLITE. The frames are prepared in advance,

and glazing is done after they are all in place, along with completion of the other finishing jobs. (See Figures 3a, 3b).

2. Two and four-sided clamped glazing employ practically the same profiles used for framing, as used in curtain walls and skylights.

Almost all are prepared prior to the glazing work, and just the clamps, the rubber packing profiles (and silicone sealant in ”wet” glazing)

are installed along with or after the glazing is in place.

3. The roofing and cladding glazing installation method installs SUNLITE over the supporting skeleton, rafters and purlins. The glazing

profiles, which are usually flatter by design, consist of top and bottom parts, made of polycarbonate, rigid PVC or a combination (a

bottom aluminum profile and top profile made of polycarbonate, or rigid PVC). SUNLITE sheets and their connecting profiles (also

acting as glazing profiles) are installed together, advancing step by step. Most profiles are flexible enough to be easily shaped into

curves by hand, when installed over curved structures, enabling inexpensive implementation of curved glazing.

15

15

Page 18

Handling and Storage

1. SUNLITE sheets should be transported and stored horizontally, on a flat, sturdy pallet

whose dimensions are equal to or larger than the sheets themselves. The sheets must be

secured and fastened to the pallet during transportation and handling on site. It is possible

to stack the sheets with the longer sheets at the bottom and the shorter on top, leaving no

unsupported overhang.

2. While moving a pallet with a forklift, always use forks as long as the sheets’ width. Shorter

forks on a wider pallet may cause damage to the sheets.

Figure 18

3. SUNLITE sheets leave the factory in packages, wrapped in white, watertight polyethylene.

The wrapping should be taken off as close to the actual time of installation as possible. Storage of the sheets should be in a covered,

dry, ventilated place, away from direct sunlight and rain.

4. Avoid leaving the sheet pallet in the rain, even if still wrapped, for extended periods, as water may condense inside the hollow

core. Extended exposure to direct sunlight may cause heat buildup, softening the protective film, fusing it to the sheet face, making

removal difficult or impossible.

5. Avoid leaving the sheets stored unwrapped, with their ends open, for more than a few days, as dust may collect inside the hollows.

6. Important! Never cover the pallet with, or place on the pallet, materials that collect heat or are good heat conductors

(e.g. dark objects, metal profiles or pipes, steel sheets etc.) They may collect and deliver excess heat, and damage the sheets.

7. When necessary to store the pallet in the open, cover it with a white opaque polyethylene sheet, cardboard, or any other insulating

material, taking care to cover the pallet completely.

Cutting

1. A. SUNLITE sheets can be cut with standard wood or metal workshop equipment. Saw blades designed especially for plastic yield best

results. A circular saw (fixed or portable, with small teeth suited for hardwood), rotating at high speed, band saw or a jigsaw (best for

short, complex cuts) can all be used, taking care to advance the blade slowly. A hand and hacksaw may also be used for local cutting.

2. Always support the sheet in the vicinity of the cut and clean (with compressed air and/or by a vacuum cleaner) the dust and debris

generated by the cutting. Running clean compressed air through the hollow channels, blowing away sawdust and shavings inside

is a good practice.

3. Sheets of low and intermediate thickness, with modest dimensions, can be cut (taking the appropriate precautions) with a short,

thin, sharp blade. A special cutting-wire hand tool may also be used, to make lengthwise cuts.

Figure 19

16

16

Page 19

SUNLITE® Technical Guide

Drilling

1. Drilling can be carried out with drill bits intended for metal. When pre-drilling for a fastening screw, the hole’s diameter should be 2

mm larger than that of the screw used. As when cutting, always support the sheet in the vicinity of the place being drilled, and clean

away the sawdust and shavings, both on and inside the sheet.

2. Special attention must be given to drill all the required holes perpendicular to the face of the sheet.

3. Though drilling the sheet for fastening is a common way of installation, it is recommended to be used mostly in plain, economyoriented projects, and used sparingly elsewhere.

Figure 20

Sealing and Bonding

1. Silicone Sealants: Palram strongly recommends ‘Dow Corning 3793’ - white, or ‘Otto Chemie Novasil S-64’ - white or translucent.

2. Sealant and Weather Strips: Applied in “wet” or “dry” systems.

The “Wet” system can use IDL 311 L Butyl rubber double-sided sticky tape by Sellotape, or simple neoprene or EPDM rubber strips,

combined with the silicone sealant above.

The “Dry” system uses neoprene or EPDM rubber packing strips (in simpler framing system), or profiled neoprene or EPDM rubber strips

inserted into grooves in the metal connecting/framing profiles. Mechanical pressure of the clamping profile on the rubber gasket

achieves the sealing, like in glass systems.

3. Sealing the Sheets is done by aluminum impermeable, or ventilated filter sticky tapes, as described in the paragraph “Pre-preparation

of the sheet” above. Such specialty tapes can be obtained from the leading tape manufacturers, or through Palram dealers (See figures

17b, 17c).

For alternative materials, please refer to our Recommended Adhesives and Sealants for Palram Polycarbonate Products brochure

available at the Palram website, or consult with your Palram distributor.

Accessories

Palram invests ceaseless efforts to create a complementary of accessories for the SUNLITE range of products, easing use, avoiding

runaround trying to find suitable solutions for proper installation. SUNLITE can now offer suitable corrosion resistants fasteners,

special washer/gasket combos and compatible sealing & bonding silicones. Immediately in line, or shortly, are basic polycarbonate

“H” connectors and “U” end-caps, along with impermeable and ventilated aluminum sealing tape for end closure. Various specialized

aluminum glazing profile, EPDM rubber sealing strips and gaskets will follow in the near future.

Please consult your local SUNLITE distributor for details.

Different aluminum or steel glazing profiles, structural elements, sealing materials and other components required for the completion of

varied projects appear, in concept, in the sketches in this manual. Such products & materials are usually available through professional

suppliers of metals and glazing accessories. Other designated elements like gutters, closures, ridge caps, trimming, flashing etc. are to

be specially fabricated according to specific design.

17

17

Page 20

General Recommendations for Working with SUNLITE® Sheets

Cleaning

1. Keeping SUNLITE clean will yield the best long-term results. Self-cleaning by rain is usually sufficient.

Local small areas may be washed using diluted mild household detergents. Make sure the detergent

contains no abrasives or solvents. Pre-wash with warm water, then wash the stained area with a soft

sponge or brush, preferably with hot water, until the stain disappears. Rinse with water and dry with a

soft cloth.

2. Heavy oil or tar stains can be removed with an isopropyl alcohol watery solution. Rub the area gently

with a soft rag. Follow with the treatment depicted above, rinsing with a lot of water.

3. Avoid dry cleaning, as the sand and dust particles clinging to the exterior of the glazing may scratch the surface.

4. Large areas may be professionally washed by high-pressure water jet, possibly adding a mild compatible detergent, and/or a steam

jet.

5. Avoid the repeated sliding of sheets over each other, even when still

protected by the masking film. This action generates electrostatic charge in

the sheet, attracting dirt and dust and hindering cleaning.

Figure 22

Safety Measures During Installation and Maintenance

1. When installing SUNLITE or doing maintenance work, always consider the sheet to be unfit

to support a person’s weight. Always use stepping ladders or crawling boards, supported by

the roof structural elements, when working on a glazed roof of any kind.

2. Never step on SUNLITE sheet between the purlins or in the middle of a framed glazing! In

emergency, step only on the lines of purlins or of structural framing.

Figure 21

Figure 22

3. Never leave the glazing sheets unattended on the roof or at the glazing area, until all

the required fastening clamps or screws are secured properly. Throughout the installation

process, always ensure that the sheets ready for installation are temporarily secured against

sudden wind gusts.

Warning!

Do not step directly on the sheets

between the purlins!

18

18

Page 21

SUNLITE® Technical Guide

19

2

Page 22

All marketing materials and any content therewith provided by Palram® are provided solely for the purpose of supporting and enhancing the marketing of Palram® products.

These materials are protected by Palram’s intellectual property rights and may not be used for any other purpose or in connection with the sale of products of any other manufacturer.

These materials may not be transferred to or used by any third party without prior permission of Palram.

PALRAM H.Q.

Tel: +972 4 8459900

Fax: +972 4 8444012

palram@palram.com

www.palram.com

In as much as Palram Industries has no control over the use to which others may put the material, it does not guarantee that the same

results as those described herein will be obtained. Each user of the material should make his own tests to determine the material’s

suitability for his own particular use. Statements concerning possible or suggested uses of the materials described herein are not to

be construed as constituting a license under any Palram Industries patent covering such use or as recommendations for use of such

materials in the infringement of any patent. Palram Industries or its distributors cannot be held responsible for any losses incurred

through incorrect installation of the material. In accordance with our company policy of continual product development you are

advised to check with your local Palram Industries supplier to ensure that you have obtained the most up to date information.

©1998 Palram Industries Ltd | PALSUN is a registered trademark of Palram Industries Ltd

PALRAM EUROPE LTD.

Tel: +44 1302 380777

Fax: +44 1302 380778

sales.europe@palram.com

www.palram.com

PALRAM AMERICAS

Tel: 610 2859918

Fax: 610 2859928

palramamericas@palram.com

www.palramamericas.com

02.2015

Loading...

Loading...