Page 1

PALSUN® Technical Guide

Flat Solid Polycarbonate Sheet

Page 2

Content

PALSUN® Product Range 3

Standard Dimensions 3

Colors 4

Physical Properties 5

Impact Strength 6

Optical Characteristics 7

Solar Transmission Properties 8

SolarSmart™ Technology 9

Thermal Characteristics 10

Protection from the Harmful Effects of UV Radiation 11

Acoustic Properties 11

Weather Resistance 12

Flammability 12

General Recommendations for Working With PALSUN® 13

Determination of Required Sheet Dimensions 14

Installation 18

Mechanical Fastening 22

General Fabrication Guidelines 23

Sawing & Cutting 23

Routing 27

Drilling 28

Finishing 29

Cleaning 30

Cold Forming 31

Thermoforming 32

Printing 36

Chemical Resistance 37

Adhesives and Sealants 41

Selection of Appropriate PALSUN® Sheet 41

2

Page 3

PALSUN® Technical Guide

PALSUN® Product Range

Some of the products' features below can be combined. Please contact your Palram dealer for further information.

Product Description Features & Applications

PALTUF®

PALSUN®

PALSUN® UV2

PALSUN® FR

PALSUN® Solar Control

PALSUN® Breeze

PALGARD™

Notes:

1. All the above sheets are supplied with a protective polyethylene (PE) film on both sides (one side upon request), with the UV protected side clearly marked. This film

should be removed immediately after installation.

2. For transportation, handling and storage instructions and recommendations, please refer to Handling and Storage Guidelines for Palram Sheets.

3. PALSUN sheets are backed by a 10 years limited warranty, available upon request.

4. Most PALSUN sheets are available in the transparent, translucent or opaque form, in a variety of colors, either standard or custom ordered.

UV stabilized, general purpose, flat solid

polycarbonate sheet.

Flat solid polycarbonate sheet with UV protective

layer on one side.

Flat solid polycarbonate sheet with UV protective

layer on both sides.

Sheet with higher fire resistance rating

(e.g. UL 94 V-0).

Sheet with integrated heat-blocking layer. This

metallic reflective layer that transmits less Infrared

radiation and reduces heat buildup.

This advanced heat-blocking SolarSmart™ tint

offers a clear view due to its high clarity.

Sheet with abrasion resistant layer on one or both

layers.

Recommended for indoor use only.

Suitable for both exterior and indoor applications.

Optional surface textures:

Embossed (E-102)

Prismatic

Hair-cell

Matte - Anti-glare effect

Recommended for applications that involve UV exposure on

both sides (e.g. exterior light boxes)

Recommended for applications in populated areas.

Available with 20, 35, or 50% light transmission.

Can be tailored to achieve different light and heat

transmissions.

Recommended for applications in high traffic areas, harsh

chemical environments or those requiring anti-vandal

properties.

Standard Dimensions*

Thickness (mm)

1

1.5

2

2.5 - 6

8

9 - 12.7

2 - 18

*Other dimensions and specifications are available upon request, subject to a minimum order.

Width x Length

(mm)

1220 x 2440

1250 x 2440

1220 x 2440

1250 x 2440

2050 x 3050

2450 x 3050

Smooth

Both sides

✔ ✔

✔ ✔ ✔

✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔

✔ ✔

✔

Embossed

Both sides

Surface Finish

Matte

One side

Hair Cell

One side

Prismatic

One side

3

Page 4

Colors

Color Group Description Colors

Clear

Transparent

Translucent

Transmits up to 90% natural daylight, resulting in high

lighting within the structure.

Low haze colors offering high clarity.

Breeze and Smart are SolarSmart™ colors with that

reduce heat buildup while allowing a clear view

through the sheet (see page 9 for more details on

SolarSmart products).

White Opal: Transmits 11-50% visible light with high

light dispersion, produces mild and even lighting

within the structure.

Diffuser: Transmits 50% visible light with high light

dispersion, produces diffused and consistent lighting

within the structure.

LB (Light Box): Diffuser sheet for illuminated signs and

display applications, offering 44-50% light transmission.

Clear

Solar Gray BlueBronze

Smart

Red

Blue*

White

Yellow

Mint

Green

Opal

Solar Control

(Solar Metallic Grey)

Smart

Green*

White

Diffuser

Solar

Olympic

Green

Bluish

Breeze*

LB

(Light Box Diffuser)

Solar Ice

Red

Opaque* Colors that transmit very little to no light.

Dark Green

Cream

Ral 9001

Red Brick

Light Grey

Ral 7035

Black Dark Blue

Dark Grey

Brown

Off-White

* Subject to minimum quantity. Custom colors and light transmissions are also available in this manner.

** Colors shown above are a reproduction of the actual color. To accurately represent the colors, contact your Palram distributor and request a sample color chip.

SolarSmart™ - Energy Efficiency

SolarSmart™ are energy-efficient colors break the traditional ratio

between light transmission and shading coefficient. SolarSmart™

panels block Infrared energy that causes heat buildup, and transmit

“cool light” that reduces air-conditioning and lighting costs.

More energy-saving, natural

visible light is transmitted.

SolarSmart™ Panel

Blocking Infra-Red

reduces heat buildup.

4

Page 5

Physical Properties

The following table displays physical properties of 3mm (0.12 inch) PALSUN and PALTUF sheets.

PALSUN® Technical Guide

Property Method**

Physical

Density D-792 g/cm (lb/ft) 1.2 (75)

Water Absorption D-570 24 hr. @ 23°C % 0.15

Mechanical

Tensile strength at yield D-638 10 mm/min (0.4 in./min) MPa (psi) 62.5 (9,100)

Tensile strength at break D-638 10 mm/min (0.4 in./min) MPa (psi) 65 (9,500)

Elongation at yield D-638 10 mm/min (0.4 in./min) % 6

Elongation at break D-638 10 mm/min (0.4 in./min) % >80

Tensile Modulus of Elasticity D-638 1 mm/min (0.4 in./min) MPa (psi) 2,300 (290,000)

Flexural Modulus D-790 1.3 mm/min (0.052 in./min) MPa (psi) 2,350 (343,000)

Flexural Strength at Yield D-790 1.3 mm/min (0.052 in./min) MPa (psi) 93 (13,600)

Notched Impact Strength Izod D-256 23°C (73°F) J/m (ft·lbf/in.) 800 (15)

Notched Impact Strength Charpy D-256 23°C (73°F) J/m (ft·lbf/in.) 800 (15)

Impact Falling Weight ISO-6603/1b J (ft·lbf ) 158 (117)

Rockwell Hardness D-785 R scale / M scale 125 / 75

Thermal

Long Term Service Temperature °C (°F) -50 to +100 (-175 to +212)

Short Term Service Temperature °C (°F) -50 to +120 (-175 to +250)

Heat Deflection Temperature D-648 Load: 1.82 MPa (264 psi) °C (°F) 135 (275)

Vicat Softening Temperature D-1525 Load: 1 kg (2.2 lb) °C (°F) 150 (300)

Coefficient of Linear Thermal Expansion D-696 mm/m °C (Mil/in. °F) 0.065 (0.036)

Thermal Conductivity C-177 W/m K (Btuin/hrft°F) 0.21 (1.46)

Specific Heat Capacity C-351 kJ/kg°K (Btu/lb°F) 1.26 (0.31)

Optical

Haze D-1003 Clear Sheet % <0.5

Light Transmission D-1003 Clear Sheet % 89

Refractive Index D-542 Clear Sheet 1.586

Yellowness Index D-1925 Clear Sheet <1

Electrical

Dielectric Constant

Dissipation Factor

Dielectric Strength Short Time D-149 500 V/s kV/mm (V/mil) >30 (>770)

Surface Resistivity D-257 Keithley Ohm 10

Volume Resistance D-257 Keithley Ohm-cm 10

D-150 50 Hz 3.0

D-150 1 MHz 2.9

D-150 1 KHz 0.001

D-150 1 MHz 0.01

Conditions

(U.S. Customary)*

Units - SI

(U.S. Customary)*

Value

(U.S. Customary)*

* Conditions, units and values in U.S. Customary units are presented in the table within parentheses.

** ASTM except where noted otherwise.

5

Page 6

Impact Strength

PALSUN sheets are manufactured from polycarbonate, the

most versatile, toughest transparent thermoplastic. PALSUN

has 200 times the impact strength of glass, offering excellent

protection against riots and public disturbances, breaking &

entering or acts of vandalism.

PALSUN can endure attacks by rocks, clubs, hammers and

thrown objects, and still to retain its original shape, maintain

its integrity with minimal indentations to its surface.

The amount of damage depends on the object mass and

energy, and sheet’s thickness. PALSUN sheets will retain these

energy-absorbing properties over a wide temperature range

(50° to + 100° C).

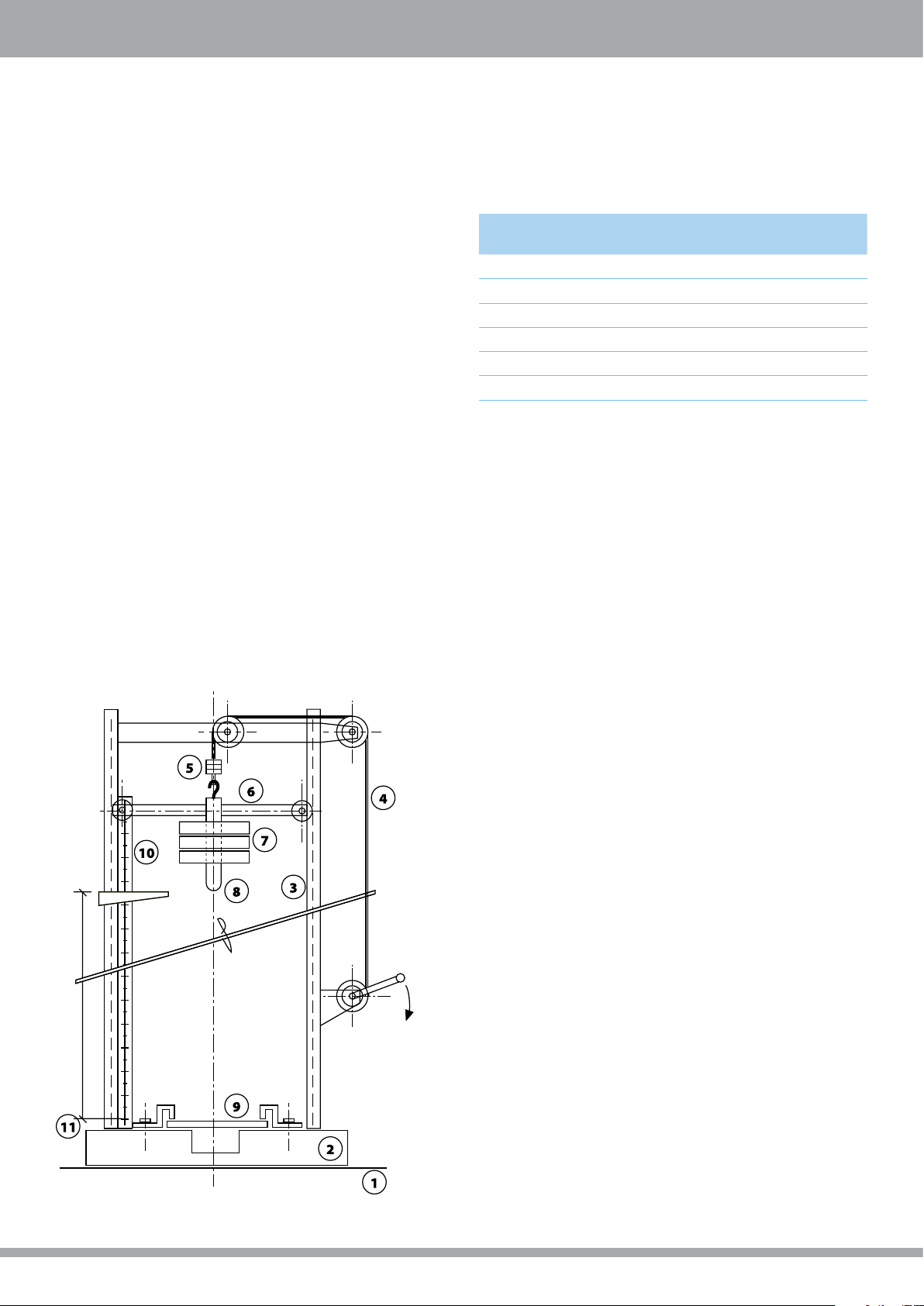

Falling Dart Method

A uniform energy increment is employed during testing. Energy is decreased or increased by uniform increment after testing

each specimen, depending upon the result (failed / not failed) observed for the former tested sample. A 20 mm diameter dart,

weighing 8 kg, with a rounded tip, is raised to a certain height and released to fall on a suitably sized sample.

Principles: Impact strength is determined by the known weight and height. Adjustment is done by altering height while using a

constant mass.

E50: 50% of Impact Failure Energy. The energy that will cause 50% of the tested samples to fail.

N.B.**: No Break. The energy required to break the sample is greater than what the test instrument can deliver.

Typical impact failure energy of PALSUN® sheets*

Thickness

mm

2 110 100% ductile

3 150 100% ductile

4 190 100% ductile

5 290 100% ductile

6 400 100% ductile

8 - 18 N.B.** N.B.**

* According to ISO 6603/1 1985(E): Determination of multi-axial impact behavior

of rigid plastics.

Energy at Failure

E50 (Jouls)

Type of Failure

Falling Dart Impact Testing Device (Schematic Figure)

Legend

1. Leveled floor

2. Stablized base

3. Supporting guidrails

4. Lifting mechanism

5. Disengagement mechanism

6. Guidance bar

7. Changeable weight

8. 20 mm diameter head falling dart

9. Tested specimen

10. Calibration bar

11. Changeable drop height

6

Page 7

Optical Characteristics

PALSUN® Technical Guide

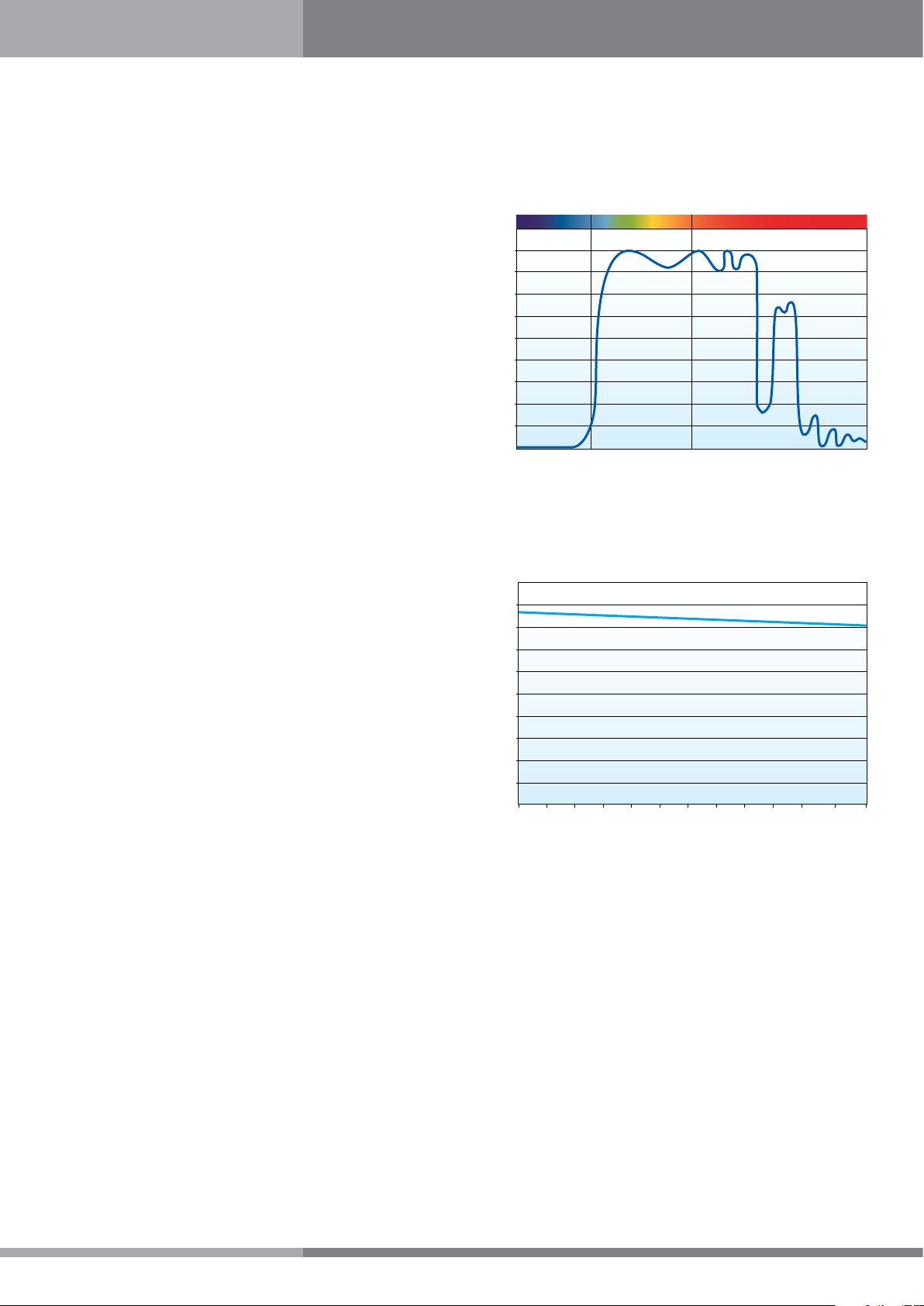

Ultraviolet (UV) Radiation Blocking - PALSUN sheets completely

block out potentially harmful UV radiation and a significant

portion of Infrared (IR) radiation. Over the visible light range, a

typical 3 mm (0.125 inch) thick clear PALSUN sheet transmits

about 89% (average) of incident light, as seen in the attached

graph.

Light Transmission Versus Thickness

Light transmission decreases slightly with increased thickness

(see attached graph).

Figure 2:

Solar Transmittance of Clear 3mm PALSUN®

UV VISIBLE LIGHT INFRA-RED

100

90

80

70

60

50

40

30

% Solar Transmittance

20

10

0

250

300

350

400

500

600

700

800

1000

1400

1800

Wavelength (nm)

Figure 3: Light Transmission Versus Thickness

100

90

80

70

60

50

40

30

% Light Transmission

20

10

0

0 1 2 3 4 5 6 7 8 9 10 11 12

Thickness (mm)

PALSUN® & PALTUF®

2200

2600

3000

7

Page 8

Solar Transmission Properties

Solar energy transmission is an extremely important consideration

with transparent materials. Geographic location and typical thermal/

Figure 4: Solar Radiation Schematic Behavior Through

Light Transmitting Material

optical properties of the specific glazing are the main factors

influencing solar heat gain. Various types of PALSUN - textured,

tinted, opal, diffused, and heat blocking SolarSmart™ sheets - can

be used to deliver the exact quantity and quality of light desired.

Each of these products transmit different amounts of direct light in

varying levels of light diffusion, which may help to spread the light

throughout the structure or enclosure. The sheets also vary in their

selectivity index (SI) values, which determines how efficiently they

keep heat out while letting more “cool light” in (See next page for

more information on SolarSmart™ products). Although colors and

tints reduce the percentage of visible light transmitted through the

sheets, but solar energy is still absorbed by the glazing itself, and in

turn transferred by convection and far IR radiation from the heated

glazing into the building. PALSUN sheets with embossed or matte

surfaces, or diffuser colors, diminish glare and dazzle, preventing

damage by direct irradiance. However solar energy is still transmitted

through and increases the solar heat gain inside the structure.

Color*

Clear 90 <1 0.87 1.00

Bronze

Solar Grey

White Opal 28 100 0.32 0.37

White Diffuser 80 100 0.87 1.00

Solar Ice 20 100 0.37 0.45

Solar Control

Solar Olympic

Smart Green 70 42 0.58 0.67

Smart Blue 70 42 0.57 0.65

Bluish Breeze 70 42 0.55 0.63

*Values in the table above relate to 3mm Sheet. Further information on additional products is available upon request.

Terminology Used in the Table

Solar Radiation: The solar spectrum ranging from 300 nm to 2400 nm. Included are UV, visible and Near-IR radiation.

Visible Light Radiation: The portion of the light spectrum whose wavelength ranges from 400nm to 780nm.

% Light Transmission (ASTM D-1003): Percentage of incident visible light that passes through an object.

% Solar Heat Gain (SHGC): The percent of incident solar radiation transmitted by an object which includes the direct solar transmission plus the part of the solar

absorption reradiated inward.

Shading Coefficient (ASTM E424-71): The ratio of the total solar radiation transmitted by a given material to that transmitted by normal glass, whose light transmission

is 87%. It can be approximately calculated by: %ST + (0.27 x %SA) = %ST

% Light Transmission

ASTM D-1003

20 <1 0.45 0.52

35 <1 0.56 0.64

50 <1 0.65 0.75

20 <1 0.44 0.51

35 <1 0.56 0.64

50 <1 0.65 0.75

20 67 0.33 0.36

35 52 0.45 0.52

50 50 0.54 0.61

20 35 0.41 0.47

35 20 0.52 0.60

50 63 0.63 0.73

%Haze

ASTM D-1003

SC = (1.15 x STt)/100

t

Solar Heat Gain (SHGC)

ASTM E-424-71

Shading Coefficient

ASTM E-424-71

8

Page 9

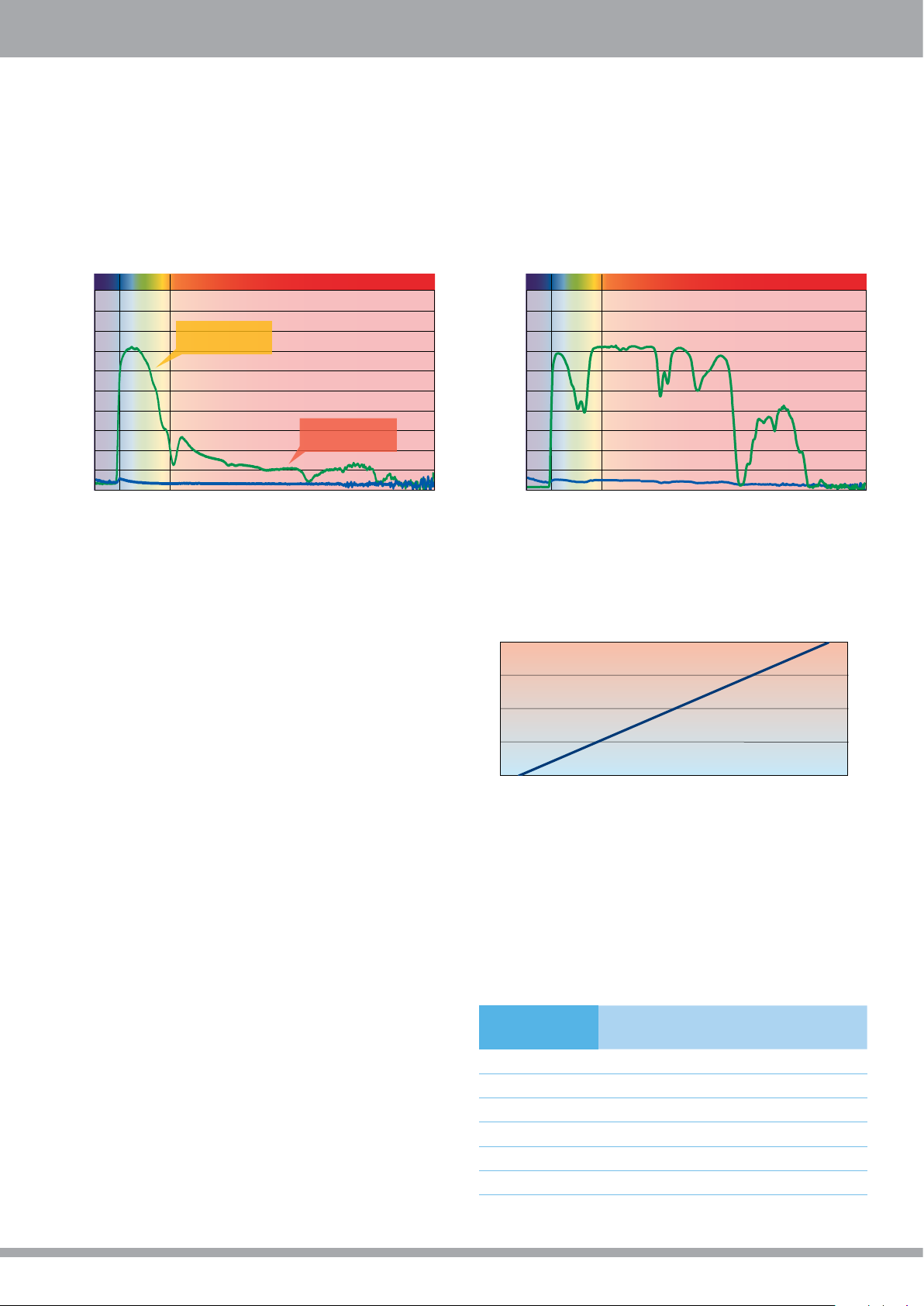

SolarSmart™ Technology - Efficient Daylighting

Enjoy light

without heat.

Promoting Energetic Efficiency and Well Being

SolarSmart technology defies standard transmission of solar energy in transparent sheets and allows more

versatile color and solar transmission specification per project. Unlike regular tints, SolarSmart sheets and

panels admit more natural daylight while reflecting outwards Infrared radiation that creates heat. This

characteristic breaks the traditional link between shading coefficient and light transmission, allowing a

different perspective on the specification of natural light in architectural design.

PALSUN® Technical Guide

Breeze

Smart

Solar Control

SolarSmart tints allow better use of natural lighting without sacrificing the interiors. More natural light results

in a healthier and more productive ambience. Energy saving is also promoted through reduction of both

illumination and air conditioning requirements.

Color Specification

SolarSmart™ tints can be applied to any Palram transparent polycarbonate sheet or panel system, including

PALSUN. The tints can be blended with any color to tailor the desired appearance and solar properties.

Technology Groups

The SolarSmart product range includes 3 technology groups, which have different characteristics and

appearance. For more information please refer to the SolarSmart™ Technology brochure.

Efficiency Comparison

The graph below demonstrates the efficiency of SolarSmart products in comparison with clear and standard

colored sheets. The graph shows how SolarSmart™ tints enable higher light transmission specification while

maintaining or decreasing shading coefficient values.

100%

Breeze

75%

Clear

Smart

Solar Control

Standard

50%

Light Transmission

25%

0%

0.3

Bronze

White Opal

0.4 0.5 0.6 0.7 0.8 0.9 1

Shading Coefficient

Solar Grey

Sky Blue

3mm

Polycarbonate

Sheet

Tested according

to ASTM E-424

9

Page 10

Heat-Blocking with High Clarity by PALSUN® Breeze

PALSUN glazing with Breeze tint transmits plenty of incident daylight (70%), while absorbing/blocking a large portion of the Infrared

radiation, thus significantly reducing heat buildup within the structure. PALSUN Breeze also provides a clear view due to its high

transparency, which is uncommon for heat-blocking products.

PALSUN® 3mm Breeze 70%LT

Solar Performance Graph (250-2,500nm)

UV LIGHT INFRA-RED

100

90

%Solar Trnasmission / Reflection

80

70

60

50

40

30

20

10

0

250

500 750 1000 1250 1500 1750 2000 2250 2500

Transmits plenty

of natural daylight

Transmittance

Reflectance

Transmits very little

Infrared heat

Wavelength (nm)

Thermal Characteristics

Thermal Expansion

The thermal expansion of PALSUN sheets is higher than that of

glass. This important factor must be taken into account when

mounting the sheets. The graph on the right shows the degree

of expansion/contraction as a function of temperature.

PALSUN® 3mmTrans. Blue 68%LT

Solar Performance Graph (250-2,500nm)

UV LIGHT INFRA-RED

100

90

80

70

60

50

40

30

20

10

%Solar Trnasmittance / Reflectance

0

250

500 750 1000 1250 1500 1750 2000 2250 2500

Transmittance

Reflectance

Wavelength (nm)

Expansion/Contraction with Temperature

60

40

20

0

Temperature (°C)

-20

-2 -1 0 1 2

Dimensional Change (mm/m)

Service Temperature

The temperature range over which the characteristics of PALSUN are retained extends from -50°C to +120°C (-60°F to +250°F) for

short periods and from -50°C to +100°C (-60°F to +210°F) for long periods. This range of temperatures make PALSUN sheets suitable

for use in most climates.

Thermal Insulation

On very hot days, the surface temperature of the sheet might reach up to 60°C (140°F). The U-value characterizes the degree of

thermal transmittance offered by a given glazing material, so higher U-values are associated with materials that are poor insulators

and result in a greater loss of heat. The following table compares

the U-values of glass and PALSUN sheets of equivalent thicknesses.

Thicker sheets of a given material will offer greater thermal insulation

and be characterized by a lower U-value and reduced heat loss. For

any given thickness, the U-value of PALSUN sheet is lower than that

of glass. This means that heat loss from the building interior, as well

as penetration of heat or cold into a building, will be less if it were

glazed with PALSUN than for one glazed with glass. This can result in

a significant reduction in energy costs both for heating in winter and

air-conditioning during the summer. Note that use of Solar Control

sheets will insulate just as well, but will also reduce air-conditioning

costs because of Near Infra-Red reflection and reduced heat buildup.

mm in

Thermal Insulation of PALSUN® vs. Glass

Thickness

3 (0.12) 5.47 5.81

5 (0.20) 5.19 5.72

6 (0.24) 5.07 5.68

8 (0.31) 4.48 5.60

10 (0.39) 4.63 5.52

12 (0.47) 4.43 5.45

PALSUN U-Value

(W/m·°K)

Glass U-Value

(W/m·°K)

10

Page 11

PALSUN® Technical Guide

Protection from the Harmful Effects of UV Radiation

Exposure to solar ultraviolet (UV) radiation is widely known as a major health concern by now. The adverse affects were once thought

to be associated with solar UV radiation in the 280-315nm (UV-B) range. However, in recent years it has become apparent that exposure

to UV-A (315-400nm) is also detrimental. In addition to skin cancer, premature aging has been associated with exposure to UV-A.

Both UV-A and UV-B portions of the UV spectrum are blocked out by PALSUN sheets. This screening of harmful UV radiation can be

observed in the figure below.

A comparison of the UV protection offered by PALSUN and that offered by sunscreen is indicated in the graph on the right. Note

that no barrier is as effective as PALSUN sheet. Activity below PALSUN will be more protected than that offered by proper application

of sunscreen, though the latter is sufficient in almost all cases. The key word in the previous sentence is proper. Improperly applied

sunscreen or forgetting to apply skin screen will result in undesirable levels of exposure. In addition, note that protection factors

are computed on the basis of UV-B exposure. There is as yet no way to compute protection to UV-A exposure. It should also be

noted that formulations that only block out UV-B are still being marketed. When playing or swimming below PALSUN, protection is

always complete. When swimming, there is no danger that the protection will be washed away. In the last ten years, it has also been

documented that UV exposure can also cause damage to the eyes, specifically to the cornea. Wearing sunglasses manufactured from

polycarbonate protects the eyes. However, most people remove their glasses when entering the pool. This is a factor for both public

and private pools to consider when contemplating a choice of covering.

Irradiance of UV Radiation Trough Various Protective Barriers

(PF=Protective Factor)

0.7

0.6

0.5

0.4

0.3

0.2

Irradiance (W/m/min)

0.1

0

300 310 320 330 340 350 360 370 380 390 400

Direct Sunlight

(PF-0)

Window Glass

(PF-10)

Wavelength (nm)

Sun Tan Lotion SPF 15

(5g/m PF-37)

PALSUN®

(PF-81)

Acoustic Properties

Though only about half the weight of an equivalent glass panel, PALSUN glazing offers similar sound insulation properties along with

much higher impact strength. These combined properties make PALSUN glazing the preferred material for see-through sound barriers:

lightweight, easy to maintain or replace if necessary, highly transparent and vandal-proof.

The table on the right portrays the acoustic performance of PALSUN glazing versus glass.

Acoustic Insulation of PALSUN® Sheets According to EN 1793

Thickness

mm

12 31

15 33

Sound Reduction

dB

11

Page 12

Weather Resistance

Solar UV radiation attacks many polymeric materials. The rate of deterioration and crazing on the exterior surface will vary for

different polymers. Further erosion is accelerated by water, dirt, air pollution, chemicals etc. The extent of attack depends on

environmental factors such as location, altitude, local weather conditions, air pollution etc. The best initial indication is yellowing,

followed by a significant reduction in light transmission and structural strength.

All PALSUN sheets (excluding those designated PALTUF, which are UV stabilized) are manufactured with a co-extruded, UV

protective layer on one or two sides. This protective layer assures a long lifetime of service. PALSUN sheets retain their toughness

and optical quality under intense UV exposure, with minimal reduction in their properties.

2000 hours of accelerated weathering (UV exposure, QUV - ASTM G154) tests, simulating 20 years of exposure in hot, sunny

climates cause only a minor decrease in light transmission and a slight increase in yellowness Index for PALSUN. The changes

in UV stabilized PALTUF sheet are greater.

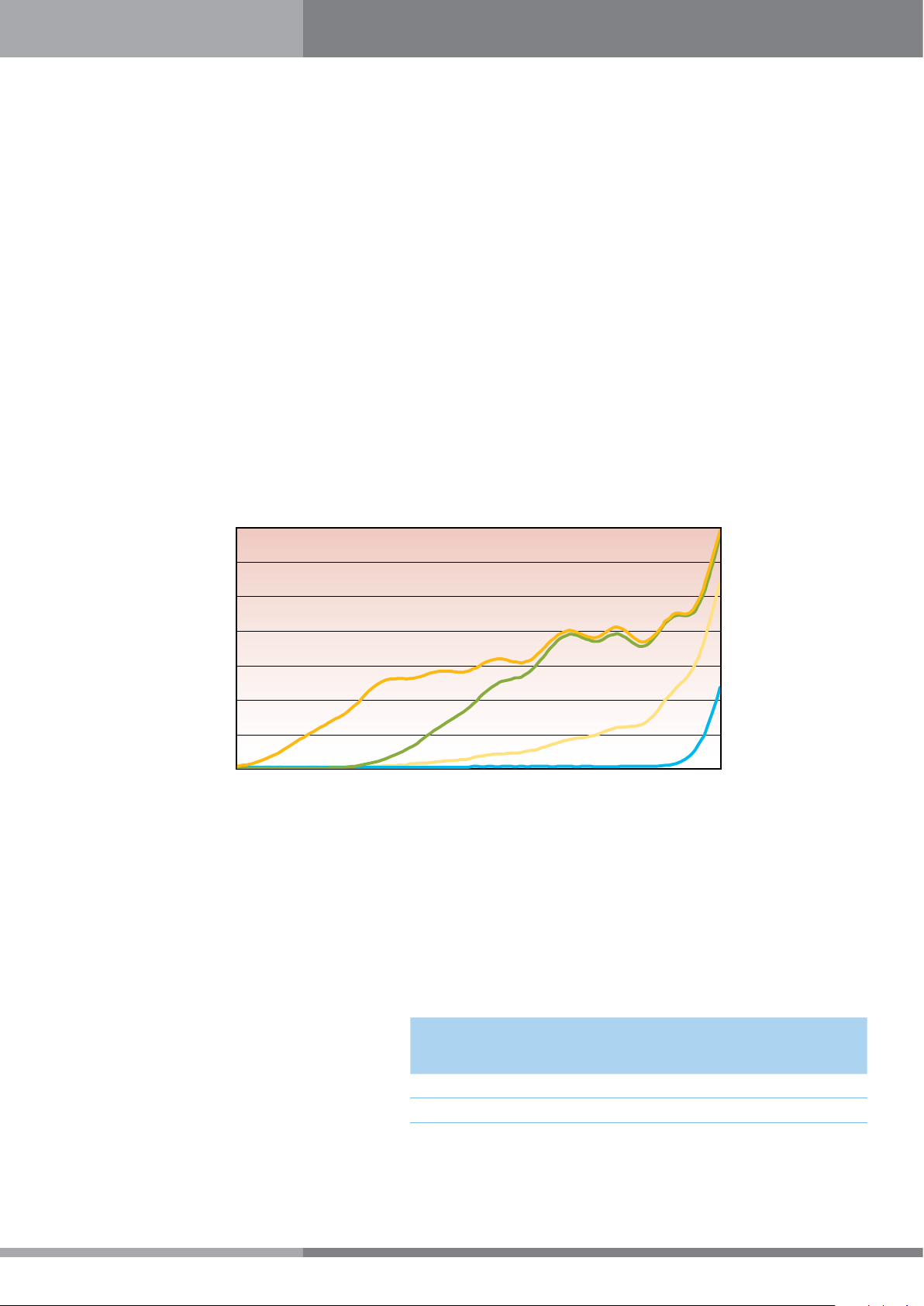

The effect of QUV on 3 mm PALSUN & PALTUF sheets appears in the graphs below.

Figure 6a

% Light Transmission Loss of 3mm Sheets

95

94

93

92

91

90

89

88

%Light Transmission

87

86

85

0 100 250 500 750 1000 1500 2000

Accelerated Weathering (QUV Hours)

PALSUN®

PALTUF®

Flammability

Figure 6b

Yellowness Index Change in 3mm Sheets

10

9

8

7

6

5

4

3

2

Change in Yellowness Index

1

0

0 100 250 500 750 1000 1500 2000

PALSUN®

Accelerated Weathering (QUV Hours)

PALTUF®

General

As a thermoplastic, PALSUN eventually melts and burns under the intense heat of a blazing fire. However, PALSUN does not propagate

flame, and is solidified and self-extinguished as soon as the direct flame is taken away. PALSUN doesn’t produce any toxic fumes or

gases when it burns.

PALSUN® FR

PALSUN FR is a fire retardant flat solid polycarbonate sheet with improved flammability ratings. The flame retardant additives make

the it virtually non-combustible. When flame licks the sheet, it will only get scorched and eventually melt, solidifying quickly when the

direct heat source is removed. Drippings do not ignite other combustible materials, as they do not actually burn.

Smoke and heat extraction

In an actual, full-scale combustion, when PALSUN overhead glazing (as in skylights) is exposed to intense heat it will soften at 150°

-160°C and produce apertures in the glazing, enabling heat and smoke to escape. Reduced temperatures inside the structure help

to extinguish the fire.

12

Page 13

PALSUN® Technical Guide

Flammability Classifications

PALSUN and PALSUN FR are classified as appears in the following table, based on tests executed by certified independent testing

laboratories.

PALSUN® PALSUN® FR

Standard Classification* Standard Classification*

EN 13501 B, s1, d0 UL-94 V-0

NSP 92501, 4 M1(1 mm) ASTM D-2863-87 L.O.I. = 30

NSP 92501, 4 M2 (1.5 to 12mm)

BS 476/7 Class 1y Spread of Flame Index = 8

DIN 4102 B1, B2 Heat Evolved Index =10

CSE RF 2/75/A, CSE RF 3/77 Class 1 Smoke Developed Index = 8

UL-94 V2 (File e221255)

ASTM D-635 CC1

* Depends on thickness. For additional information please contact your PALSUN distributor.

AU 1530.3-1982

Ignitability Index = 9

General Recommendations for Working With PALSUN®

Handling & Storage

1. PALSUN sheets should be transported and stored horizontally, on a flat, sturdy pallet whose dimensions are equal or larger

than the largest of the sheets.

The sheets should be secured to the pallet during transportation and on-site handling. It is possible to stack the sheets with

the longer sheets at the bottom and the shorter on top, leaving no unsupported overhang.

2. When moving a pallet with a forklift, always use forks as long as the sheets’ width. Shorter forks used on a wider pallet may

cause damage to the sheets.

3. PALSUN sheets leave the factory in packages, wrapped in white, watertight polyethylene. The wrapping should be removed

as close to the actual time of installation (or use) as possible.

Storage of the sheets should be in a covered, dry, ventilated place, away from direct sunlight and rain.

4. Avoid extended exposure to direct sunlight, which may cause excessive heat buildup. Long term heating may lead to softening

of the protective polyethylene masking, fusing it to the sheet’s face and making removal difficult or even impossible.

5. Avoid leaving the sheets stored unwrapped. Dirt may accumulate on the sheets and/or their edges, attracted by electrostatic

charges in the sheets, necessitating extra time and labor for cleaning before installation.

6. Whenever necessary to store the pallet in the open, cover it with white opaque polyethylene sheet, cardboard or any other

insulating material, taking care to cover the stack completely.

Figure 7: Storing PALSUN® Sheets

13

Page 14

Determination of Required Sheet Dimensions

The information below is presented to assist in ordering the required dimensions.

Determination of Sheet Size

Due to thermal expansion, PALSUN & PALTUF sheets have to be cut

accurately at predetermined lengths smaller than the dimensions

of the frame. At the end of the frame, clearance must be left for

expansion. The following tables and diagram help calculate the

required sheet dimensions. In addition, there is a table showing

the expansion clearance necessary for various sizes of PALSUN &

PALTUF sheets.

Determination of Thickness

In order to determine the required thickness, the following table

lists the sheet thickness required for a given wind load and width

(at the narrow side of the sheet).

A-A

A

a - width

BB

b - length

A

B-B

PALSUN® Recommended Panel width

Wind/Snow Load Chart for Flat 4 Sides Clamped, Single Panel, Single Span

Length / Width Ratio (b/a)

Thickness

4mm

5mm

6mm

Load

(kg/m)

50 985 875 820 795 785

75 860 765 715 695 685

100 780 695 650 630 620

125 725 645 605 585 575

150 685 605 570 550 540

175 650 575 540 525 515

200 620 550 515 500 490

50 1235 1090 1025 995 980

75 1075 955 895 870 855

100 980 865 815 790 775

125 910 805 755 730 720

150 855 755 710 690 680

175 810 720 675 655 645

200 775 685 645 625 615

50 1450 1300 1225 1200 1175

75 1300 1150 1075 1050 1025

100 1175 1025 975 950 925

125 1090 965 910 885 865

150 1025 910 850 830 815

175 975 865 810 790 775

200 925 825 775 755 740

Ratio 1:1 Ratio 1.25:1 Ratio 1.5:1 Ratio 1.75:1 Ratio 2:1

14

Page 15

PALSUN® Recommended Panel width - 4 sides clamped (Continued)

PALSUN® Technical Guide

Length / Width Ratio (b/a)

Thickness

Load

kg/m

Ratio 1:1 Ratio 1.25:1 Ratio 1.5:1 Ratio 1.75:1 Ratio 2:1

50 1975 1750 1625 1590 1575

75 1725 1525 1425 1390 1375

100 1565 1390 1300 1270 1250

8mm

125 1455 1290 1210 1180 1160

150 1375 1210 1140 1110 1090

175 1300 1150 1080 1050 1035

200 1250 1100 1035 1005 990

50 2050 2050 2050 1990 1960

75 2050 1910 1795 1740 1715

100 1960 1735 1630 1580 1555

10mm

125 1820 1610 1515 1465 1445

150 1710 1515 1425 1380 1360

175 1625 1440 1355 1310 1290

200 1555 1375 1295 1255 1235

50 2050 2050 2050 2050 2050

75 2050 2050 2050 2050 2050

100 2050 2050 1955 1895 1870

12mm

125 2050 1935 1815 1760 1735

150 2050 1820 1710 1655 1630

175 1950 1730 1625 1575 1550

200 1865 1655 1555 1505 1480

50 2050 2050 2050 2050 2050

75 2050 2050 2050 2050 2050

100 2050 2050 2050 2050 2050

14mm

125 2050 2050 2050 2050 2025

150 2050 2050 2000 1930 1900

175 2050 2000 1890 1835 1810

200 2050 1925 1810 1755 1730

50 2050 2050 2050 2050 2050

75 2050 2050 2050 2050 2050

100 2050 2050 2050 2050 2050

15mm

125 2050 2050 2050 2050 2050

150 2050 2050 2050 2050 2025

175 2050 2050 2025 1950 1925

200 2050 2050 1925 1875 1850

50 2050 2050 2050 2050 2050

75 2050 2050 2050 2050 2050

100 2050 2050 2050 2050 2050

18mm

125 2050 2050 2050 2050 2050

150 2050 2050 2050 2050 2050

175 2050 2050 2050 2050 2050

200 2050 2050 2050 2050 2050

* For wind load data in N/m units, multiply value by 10 (e.g. 40 kg/m = 400 N/m).

Notes:

1. For 2 sides clamped installation please refer to the ratio 2:1 column.

2. The table is referring to various ratios of Length (b) and width (a) and valid for both Snow and wind load.

3. The table is referring to 4 sides clamped, flat installed Palsun panels.

4. Bedding depth shall be minimum 20mm.

5. The values are calculated according to deflection criterion of L/20 of the short span.

6. The table is not referring to self-weight deflections which might cause aesthetic issues.

7. The table is not referring to the sheet flexibility when vertically installed.

8. The data in the table refer to the short dimension, a.

15

Page 16

PALSUN® Recommended Panel Width for Curved Installation - Metric

Maximum Recommended on Center Distance between Supporting Arches

Maximum Recommended on Center Distance between Supporting Arches

According to Wind/Snow Loads Below (mm)

Uniform Wind/Snow Loads

Thickness

Sheet Curvature

Radius

50 80 100 120 150 200 250 300

700 2050 2050 2050 2050 2050 1900 1750 1600

900 2050 2050 1850 1650 1500 1350 1200 1000

1100 2050 1900 1750 1600 1450 1250 1050 900

1300 1950 1800 1650 1480 1320 1180 1000 820

1500 1800 1650 1500 1380 1200 1050 900 750

4mm

5mm

6mm

8mm

10mm

12mm

* See notes on next page

1800 1650 1580 1420 1320 1120 950 820 700

2000 1580 1480 1350 1250 1050 880 750 650

2200 1500 1400 1300 1180 980 800 680 600

2800 1350 1250 1180 1100 900 720 600 NA

4000 1200 1050 950 850 780 650 450 NA

6000 850 780 720 650 600 450 NA NA

900 2050 2050 2050 2050 2050 2050 1900 1750

1100 2050 2050 2050 2050 2050 1900 1750 1600

1300 2050 2050 2050 2050 1950 1750 1600 1450

1500 2050 2050 2050 1950 1850 1700 1550 1400

1800 2050 2050 1950 1850 1750 1550 1350 1150

2000 2050 1950 1850 1750 1550 1350 1150 1050

2200 1950 1850 1750 1650 1500 1300 1100 1000

2800 1600 1500 1400 1300 1200 1050 900 750

4000 1400 1300 1200 1100 1000 850 750 600

6000 1200 1050 950 850 750 600 450 NA

1100 2050 2050 2050 2050 2050 2000 1900 1750

1300 2050 2050 2050 2050 2050 1900 1750 1600

1500 2050 2050 2050 2050 1900 1750 1600 1450

1800 2050 2050 2050 1950 1800 1650 1500 1350

2000 2050 2050 1950 1850 1700 1550 1400 1250

2200 2050 1950 1850 1750 1650 1500 1350 1200

2800 1700 1600 1500 1400 1300 1150 1000 850

4000 1600 1500 1400 1300 1150 1000 850 720

6000 1480 1380 1300 1200 1080 920 780 620

1500 2050 2050 2050 2050 2050 1900 1750 1600

1800 2050 2050 2050 2050 1950 1800 1650 1500

2000 2050 2050 2050 2000 1900 1750 1600 1450

2200 2050 2050 2050 1950 1850 1700 1550 1400

2500 2050 2050 1920 1850 1720 1580 1420 1280

2800 2050 1950 1820 1720 1600 1450 1300 1150

4000 1950 1820 1720 1620 1500 1350 1200 1000

6000 1820 1680 1520 1380 1250 1100 950 780

1800 2050 2050 2050 2050 2050 1950 1800 1650

2200 2050 2050 2050 2050 2000 1850 1700 1550

2800 2050 2050 2050 1950 1800 1750 1600 1450

4000 2050 2050 2000 1900 1780 1620

6000 2050 1920 1820 1720 1550 1400 1250 1100

2200 2050 2050 2050 2050 2050 2050 1950 1800

2800 2050 2050 2050 2050 2050 1950 1800 1650

4000 2050 2050 2050 2050 1950 1800 1650 1480

6000 2050 2050 2050 1950 1720 1580 1420 1280

(kg/m)

1480 1320

16

Page 17

PALSUN® Recommended Panel Width for Curved Installation - US Customary

Maximum Recommended on Center Distance between Supporting Arches

PALSUN® Technical Guide

Max. Recommended on Center Distance between Supporting Arches

According to Wind/Snow Loads Below (in.)

Uniform Wind/Snow Loads

(psf)

Thickness

Sheet Curvature

Radius

(mm)

In. mm In. Ft. 10 15 20 25 30 40 50 60

28 2’ – 4” 81 81 81 81 81 75 69 63

36 3’ 81 81 73 65 59 53 48 40

44 3’-8” 81 75 69 63 57 50 42 36

52 4’-4” 77 71 65 58 52 47 40 36

5

/32”

13

/

64

1

/4”

5

/16”

13

/32”

1

/2”

Notes for Tables “PALSUN® Recommended Panel Width for Curved Installation”:

1. PALSUN glazing sheets should be installed with their curved edges sustained on the supporting arches, with 15 to 25mm (5/8” to 1”) edge engagement, depending

on the span, in addition to a thermal expansion gap of 2-3mm (/”- /”).

2.

Thin sheets up to 6mm (¼”) can be bent as relatively short glazing panels, 2m to 3m at 1000 to1220mm width (6’7” to10’ length, at 40” to 48” width). Thick 8mm

sheets (/”) and above can be cold curved only as special long panels 4m to 7m (13’ 2” to 23’), particularly when full width of 2050mm (6’ 9”) or similar is installed.

3. Supporting arches and clamps should withstand total maximum permitted loads without difficulty.

4. Spans under 500mm (20”) are generally impractical for an installation method of this type.

5. The lowest radius value indicated is the minimal permitted radius for that specific PALSUN sheet.

6. Indicated spans are suitable for most common stationary structures, under pressure or uplift loads. Special structures, like mobile pool covers, may use wider spans,

subject to preceding approval.

4mm

5mm

”

6mm

8mm

10mm

12mm

59 4’-11” 71 65 59 54 48 42 36 36

71 5’-11” 65 62 56 52 45 38 33 28

79 6’-7” 62 58 53 50 42 35 30 26

87 7’-3” 59 55 51 47 39 32 27 24

110 9’-2” 53 50 47 44 36 29 24 NA

158 13’-2” 48 42 38 34 31 26 18 NA

236 19’-8” 34 31 29 26 24 18 NA NA

36 3’ 81 81 81 81 81 81 75 69

44 3’-8” 81 81 81 81 81 75 69 63

52 4’-4” 81 81 81 81 77 69 63 57

59 4’-11” 81 81 81 77 73 67 61 55

71 5’-11” 81 81 77 73 69 61 53 46

79 6’-7” 81 77 73 69 61 53 46 42

87 7’-3” 77 73 69 65 59 51 44 40

110 9’-2” 63 59 55 51 48 42 36 30

158 13’-2” 55 51 48 44 40 34 30 20

236 19’-8” 48 42 38 34 30 20 450 NA

44 3’-8” 81 81 81 81 81 79 75 69

52 4’-4” 81 81 81 81 81 75 69 63

59 4’-11” 81 81 81 81 75 69 63 57

71 5’-11” 81 81 81 77 71 65 59 53

79 6’-7” 81 81 77 73 67 61 55 50

87 7’-3” 81 77 73 69 65 59 53 48

110 9’-2” 67 63 59 55 51 46 40 34

158 13’-2” 63 59 55 51 46 40 34 29

236 19’-8” 58 54 51 48 43 37 31 21

59 4’-11” 81 81 81 81 81 75 69 63

71 5’-11” 81 81 81 81 77 71 65 59

79 6’-7” 81 81 81 79 75 69 63 57

87 7’-3” 81 81 81 77 73 67 61 55

98 8’-2” 81 81 76 73 68 62 56 50

110 9’-2” 81 77 72 68

158 13’-2” 77 72 68 64 59 53 48 40

236 19’-8” 72 66 60 54 50 44 38 31

71 5’-11” 81 81 81 81 81 77 71 65

87 7’-3” 81 81 81 81 79 73 67 61

110 9’-2” 81 81 81 77 71 69 63 57

158 13’-2” 81 81 79 75 70 64 58 52

236 19’-8” 81 76 72 68 61 55 50 44

87 7’-3” 81 81 81 81 81 81 77 71

110 9’-2” 81 81 81 81 81 77 71 65

158 13’-2” 81 81 81 81 77 71 65 58

236 19’-8” 81 81 81 77 68 62 56 51

63 57 51 46

17

Page 18

Installation

Choice of the Frame

PALSUN & PALTUF sheets can be mounted in most existing frames made of wood, rigid PVC, aluminum or other metals. It is recommended

to use neoprene or EPDM packing (never use soft PVC) to secure the sheet in its frame, rather than fixing with screws. Butyl rubber

sealing strip or silicone sealant (PALRAM has tested and recommends Dow Corning Q3-7098 or Q3-3793 and Novasil S 64) are also

permissible. For a list of compatible adhesives and sealants see Palram “Recommended Adhesives and Sealants for Polycarbonate Sheets”.

Adjusting The Sheet to Frame Dimensions

(“c” and “d” refer to the indicated dimension in the diagram shown

below).

If sash dimension “c” or “d” is: Trim sheet by:

Sheet Thickness Required for Given Sheet Width* and Rabbet

Depth. (“a” and “e” refer to the indicated dimensions in the diagram

shown below).

300 mm (11.8 in.) 1 mm (0.04 in.)

300 mm (11.8 in.) - 700 mm (27.6 in.) 2 mm (0.08 in.)

700 mm (27.6 in.) - 1000 mm (39.4 in.) 3 mm (0.12 in.)

1000 mm (39.4 in.) - 1300 mm (51.2 in.) 4 mm (0.16 in.)

1300 mm (51.2 in.) - 1700 mm (66.9 in.) 5 mm (0.20 in.)

1700 mm (66.9 in.) - 2000 mm (78.7 in.) 6 mm (0.24 in.)

2000 mm (78.7 in.) - 2300 mm (90.6 in.) 7 mm (0.28 in.)

2300 mm (90.6 in.) - 2700 mm (106 in.) 8 mm (0.31 in.)

2700 mm (106 in.) - 3000 mm (118 in.) 9 mm (0.35 in.)

Example Frame

Legend

a . . . Sheet width

b . . . Sheet length

c . . . Sash width

d . . . Sash length

e . . . Edge engagement

f . . . Thermal expansion allowance

g . . . Rabbet depth = ½f + e

A-A

Width* (a) Thickness Rabbet Depth (e)

700 mm (28 in.) 3 mm (0.12 in.) 15-20 mm (0.6 - 0.8 in.)

900 mm (35 in.) 4 mm (0.16 in.) 15-20 mm (0.6 - 0.8 in.)

1100 mm (43 in.) 5 mm (0.20 in.) 15-20 mm (0.6 - 0.8 in.)

1300 mm (51 in.) 6 mm (0.24 in.) 20-30 mm (0.8 - 1.2 in.)

1500 mm (59 in.) 8 mm (0.31 in.) 20-30 mm (0.8 - 1.2 in.)

1700 mm (67 in.) 10 mm (0.39 in.) 20-30 mm (0.8 - 1.2 in.)

1900 mm (75 in.) 12 mm (0.47 in.) 20-30 mm (0.8 - 1.2 in.)

*Width refers to the smaller dimension.

A

c

f

e

db

BB

½f ½f

a

e

A

B-B

18

Page 19

PALSUN® Glazing

PALSUN® Technical Guide

GA-2004 Glazing Detail

19

Page 20

Glazing System Detail

Designed by Checked by Approved by

Date

Date

Hybrid Glazing System Detail

20

Page 21

Oriented Glazing System Detail

PALSUN® Technical Guide

Wet Glazing Detail

21

Page 22

Glazing System Detail

Mechanical Fastening

PALSUN & PALTUF sheets can be fastened with nuts and bolts, providing that several points be kept in mind:

Never use rivets, as they apply excessive force and could cause cracks in the sheets.

Always drill a slightly over-sized hole by 2-3mm (/” - /”) to compensate for thermal expansion.

Never use soft PVC washers!

Use neoprene and aluminum washers to distribute the load.

When using mechanical fasteners, they should be evenly spaced to avoid stress accumulation at particular points.

With nuts and bolts, tighten moderately and use only rust-free materials.

Wherever possible, a “floating sheet in frame” is preferable, similar to glass, and without mechanical drilled fasteners.

Treatment of Sheets after Installation

The sheet’s polyethylene masking must be removed after it is installed. The masking covers the sheet to protect it during handling,

storage, and installation, but once the sheet is installed - it must be removed within 24 hours.

A non-standard masking that can be left on the sheets for up to one month and then removed immediately is available upon

special request and is subject to a minimum quantity order.

PALSUN & PALTUF sheets may be cleaned by carefully following the instructions on page 30.

22

Page 23

PALSUN® Technical Guide

General Fabrication Guidelines

Tools

PALSUN sheets can be fabricated with standard power or hand tools for wood or metal, as long as they are well sharpened and

have the clearance required for machining rigid plastics. Only speed regulated tools should be used. The highest possible speed

that will not melt the sheet during processing, due to the heat buildup, will achieve the best results.

High-Speed steel tools are adequate in most cases. Carbide-tipped tools are preferred for continuous production lines.

Tools should be set up so just the cutting edges should come into actual contact with the fabricated material, to reduce frictional

heat buildup.

Cooling

Cooling is not required under standard machining conditions.

When high-speed machining is necessary, clean water or compressed air can be used to cool the material and tool, and remove

the machining chips.

Never use cooling oil or emulsions, as they may damage the PALSUN sheet.

In order to avoid induced internal stresses generated by overheating, care must be taken to keep heat buildup to absolute

minimum.

Size Regulation

Due to the high thermal expansion rate of PALSUN, which is considerably greater than that of metals, glass or concrete, precision

measurement checks should always be done at a fixed reference ambient temperature.

Protective Film (Masking)

The PALSUN polyethylene (PE) protective masking may be left on the sheet during most regular fabrication, to prevent damage

to the surface.

Fabrication Markings

When necessary, mark sheets to be fabricated on the protective masking. If, for some reason, it is necessary to mark directly on

the sheet, use wax pencils or felt tipped marking pens.

Marking the exposed surface by scratch marks with sharp objects may initiate fractures and induce failure under load.

Sawing & Cutting

A variety of power saws, either table mounted or portable can be used to saw PALSUN. Shearing or punching are also possible.

Laser or water-jet cutting are less common but also possible techniques.

Table Mounted or Portable Circular Saws

These types of saw are widely used to saw PALSUN. There are two major workshop types and one portable type:

A Moving Table, Fixed Blade Bench Saw: is preferable for long, straight sawing.

Radial Arm Saw: is generally used for “cross-cut” (width) or diagonal sawing.

Portable Circular Saw: usually restricted for use on site for straight cutting, is slower and not as accurate as table saws. This type of

saw may be attached underneath a special bench to function as an on-site, limited operation fixed table saw.

Circular Saw Blades

Should be fine toothed hollow ground, or preferably carbide tipped, triple chipped or alternate bevels (Alt 1 and Alt 2, see

figures 9a & 9b on next page, respectively), with minimal blade body contact with the cut material. Such blades can offer clean,

good quality cuts.

23

Page 24

Generally Accepted Recommendations for Circular Blade Specifications

Property Units Sign Value

Clearance angle α 10 – 20°

Rake angle γ 5 – 15°

Alternate double-bevel angle (Alt. 1) α° 45°

Alternate bevel angle (Alt. 2) β° 10 – 15°

Cutting speed - m/min. (ft/min) 1,000 - 3,000 (3,300 - 10,000)

Rate of feed mm/sec. (inch/sec.) 30 (/)

Thin gauge: 1.5-2.5 mm tooth pitch (/” - /” ) Teeth per mm ( Teeth per inch) t 2.5 - 6 (10 - 12)

Heavy gauge: 3.2 - 12 mm tooth pitch (/” - /” ) Teeth per mm (Teeth per inch) t 6.5 - 8.5 (3 - 4)

Notes:

1. 2 Possible alternatives (Alt 1 & Alt 2, see figures 9a & 9b below) are supplied by different tools manufacturers as alternate beveled teeth for blades intended for cutting

plastics, and both offer satisfactory cuts (line 3 in the table).

2. For sawing thin gauge sheets of less than 2mm thickness, It is recommended to batch together 10 - 15 such sheets, with a thicker (3-4mm) bottom sheet for support.

3. Shearing is the preferable option for cutting a single thin gauge sheet.

Palram Particular Circular Saw Cutting Recommendations

These recommendations are based on technical know-how, particular tests and vast practical experience accumulated during years

of work. These recommendations are to be accepted only as general guidelines.

Figure 8: Typical Circular Saw Blade (segment)

Figure 9a: ALT1 - Alternate Teeth Configuration Figure 9b: ALT2 - Alternate Teeth Configuration

24

Page 25

Saw Blade Specifications for Cutting PALSUN up to 5mm Thickness

Property Units Value

Clearance angle mm (inch) 300 (12)

No. of teeth in blade 96

Thickness mm (inch) 2.2 - 3.2 (/” - /” )

Teeth angles Rake: 45° Clearance: 15°

Alternating: Left - Right

Tooth appearance

Speed rpm 1800 - 2400

Saw Blade Specifications for Cutting PALSUN 6mm Thickness and Above

PALSUN® Technical Guide

Property Units Value

Clearance angle mm (inch) 350 (14)

No. of teeth in blade 108

Thickness mm (inch) 2.2 - 3.2 (/” - /” )

Teeth angles Rake: 10° Clearance: 15°

Alternating: Left - Right

Tooth appearance

Speed rpm 1800 - 2400

Notes:

1. Teeth shapes sketches are not to scale. They should be considered to serve only as an indication.

2. The PALSUN should be placed on a firm flat base and clamped into position during sawing.

3. When sawing PALSUN, it is recommended to leave the protective masking on.

4. If the cut sheet vibrates during sawing, cardboard sheet padding may be placed beneath it to absorb the vibrations.

5. When sawing thin gauge PALSUN it is recommended not to cut single sheets by themselves, but saw a pack of 5-10 sheets at the time, clamped firmly together to

a steady base.

6. Low to moderate feed rate should be used when the sheets approach the blade, or vice versa. A feed rate that is too high can cause gumming, splitting or breaking

of the sheet edges.

Band Saw

Band saws can be used for cutting PALSUN sheets of most thicknesses with

acceptable results. Band saws are workshop tools. In PALSUN fabrication they are

mostly used to cut formed parts or irregular shapes. It is possible to cut flat sheets

in straight lines too, but in limited length and width, due to the tool’s limitations.

Thin gauge sheets are better sawed when stacked to a thickness of 10 -12

mm (0.4 - 0.5 in.)

The preferred band saw blade should have slightly set teeth, with 10 – 20 mm

(0.4” - 0.8” inch) blade widths.

Figure 10: Typical Band Saw Blade Configuration

25

Page 26

Recommended Band Saw blade Properties

Property Sign Units Value

Clearance angle α 10 – 20°

Rake angle γ 5 – 15°

Cutting speed m/min (ft/min) 1,000 - 6,000 (1,950 - 3,300)

Rate of feed mm/sec (inch/sec) 20 (/)

Thin gauge: 1.5-2.5 mm tooth pitch (/” - /” ) t Teeth per mm (Teeth per in.) 1.5 - 2.0 (12 - 18)

Heavy gauge: 3.2 - 12 mm tooth pitch (/” - /” ) t Teeth per mm (Teeth per in.) 2.5 - 3.5 (7 - 10)

Notes:

1. A band saw is suitable for cutting curved lines and 3-dimensional, formed parts.

2. For cutting a few formed objects of the same shape, they must be firmly clamped together.

3. A band saw cutting usually yields rougher finished edge, which must be smoothed by sanding and polishing.

An endless belt sander is a preferred tool for such an operation.

4. Palram recommends using a circular saw for better-finished edges, whenever possible.

Portables: Jigsaw or Saber Saw

Portable saws of these types use short movement, reciprocating blades, instead of one-direction orientation, continuous

movement blades like those of circular or band saws, and are much slower in operation.

Chipping: Various sized chips are broken off on both edges of the sawing line, leaving the cut edges rough and uneven.

Gumming: Chips and splinters from the advancing saw blade overheat during the sawing process, melt and create a mass of

cooled down material in front of the blade and on both sides of the cut. The swarf sticks to the edges, leaving an unsightly, rough

edge finish, which would be difficult to clean.

Jigsaw or saber saw cutting usually results in an inferior finish of the cut edges, worse than the results achieved by a circular

saw. Palram recommends sanding and polishing of the cut edges as standard practice. An endless belt sander is the preferred

tool for such an operation.

Gummed material may also stick to the blade itself and cause seizure.

The same uncontrolled heat that creates gumming may also induce undue internal stresses along the edges of the cut,

necessitating cooling of the sheet.

Recommended Remedies:

Choose the correct tooth size and pitch.

Select a more appropriate saw speed.

Lower the feed rate.

Examine the sharpness of the blade.

Examine the blade alignment.

Cool the blade with compressed air when long cuts are required.

Take frequent pauses during long production runs, to let the saw blade cool down.

Begin sawing with the blade already running at the full recommended speed.

26

Page 27

PALSUN® Technical Guide

Routing

A versatile technique, enabling diversity of edge fabrications and trimming of PALSUN sheets, notably for parts too large or of irregular

shape for a band saw. With sharp two-flute straight cutters, this technique can produce very smooth edges.

The feed rate should be slow, to avoid excessive heat buildup and shattering.

As a safety measure, when routing, always guide the sheet with a suitable jig.

A jet of compressed air can be used to cool the bit and the sheet at the spot of cutting and assist in chip removal.

Static bench routers: Fast, strong and stable, for complex and accurate straight-line fabrications.

Portable routers: Less powerful, for smaller or on site jobs. Also used for trimming and edge fabrications of irregular shapes.

Can perform certain small milling jobs like butt shaping on rectangular or round apertures or tongue and groove butt finish

on thicker sheets.

Applications - Primary Edge Finishing

Quick and accurate trimming or finishing of straight-edged or curved cut PALSUN sheets.

Easily produced straightedge corners or curved butts.

Preparation of varied lap and butt joint fabrications.

Applications - Tooling

Routers: Universal, commercially available equipment.

Routing cutters: new metalworking cutters, kept at utmost sharpness.

Recommended Band Saw blade Properties

Property Units Value

Clearance angle 5 - 10°

Rake angle 0 - 10°

Router speed - w/o load rpm 15,000 - 22,000

Cutting speed m/min. (ft./min.) 100 - 500 (330 - 1640)

Feed rate mm/rev. (inch/rev.) 0.1 - 0.5 (0.004 - 0.07)

Routing and milling tips For clean, smooth routing work ensure cutter’s sharpness and faultless alignment before starting work.

Compressed air jet cooling following the cutting head improves the culter’s speed, cut quality and blows the swarf away. Let

the tool reach its maximum (unloaded) operating speed before commencing work.

Milling & Joining

A portable router, with suitable cutters, can be used for small milling jobs.

A standard woodworking jointer-planer, preferably with carbide or high-speed blades/cutters, can be used for trimming, resulting

in a good quality edge finish.

Avoid excessive stock removal, which may result in shattering or rough edges. A cut of 0.4 mm (0.016 in.) or less per pass is

recommended.

Finishing Recommendations for Well Done Sawing and Cutting

Unintended saw marks, rough or jagged corners, or uneven, drawn edges created by imperfect shearing may result in crazing

and cracking, that can develop further to failure under load.

Palram recommends finishing the edges of cut PALSUN sheets by finishing the edges to a smooth appearance.

This will ensure that no cracks will develop from the irregularities at the edges.

Smoothing techniques are discussed in

“Finishing” Section on page 29.

27

Page 28

Drilling

General Indications

Drill bits: Regular, new high-speed steel twist drills, or new carbide-tipped drills are suitable for drilling holes in PALSUN sheets of

various thicknesses, as long as they are sharpened well. They are used mainly for bores up to 12 mm(1/2 “) diameter.

Figure 14a: Regular Drill Bit Figure 14b: Flat Chisel Edged Drill Blade

Larger holes may be drilled by flat, chisel edged drill blades with a triangular cutting tip, similar to those used in woodworking, kept

always very sharp. Rake angle should be about 5° to avoid side friction. They are used mainly for bores from 12 to 20mm (/ “ to / “).

Commercially available cutting cups or circle cutters of several types can be used for performing large round apertures.

Speed: Decrease the drill’s speed as hole diameter and / or sheet thickness gets larger. Drilling speed may vary due to actual conditions.

Feed rate: May vary due to actual conditions.

Drilling Speed and Feed Rate Change in Accordance with Bore Diameter

Hole Diameter Drill Speed Feed Rate

mm Inch 1 Inch 2 rpm mm/rev inch/rev

3 / 0.12 1500 - 1800 0.03 - 0.07 0.012 - 0.028

6 / 0.24 800 - 1500 0.03 - 0.07 0.012 - 0.028

10 / 0.4 500 - 1000 0.01 - 0.07 0.004 - 0.028

15 / 0.6 350 - 700 0.07 0.028

20 / 0.8 250 - 350 0.07 0.028

Recommended Drill Bit Configurations

Property Sign Units Value

Clearance angle 10 – 20°

Rake angle γ° 0 – 10°

Drill tip angle β° 110 – 150°

Helix angle α° 30°

Cutting velocity m/min. (ft./min.) 15 - 30 (49 - 98)

Notes: For small gauge sheets (1 - 2 mm or 0.04 - 0.08 in.) we recommend using flatter tip drill bits (β = 140 - 150°) for achieving a cleaner bore with less risk of chipping.

28

Page 29

PALSUN® Technical Guide

Drilling tips and recommendations

Location: Locate holes no closer to the edges than 2 – 2.5 times the diameter of the pertinent hole, with a 10mm (0.4 inch)

minimum.

Precision: It is imperative to keep the sheet (or stack of sheets) firmly clamped to a stable workbench (or a similar base) to avoid

fluttering during drilling.

Cooling: Usually cooling is not required with regular drills.

However, in cases of deep drilling, like putting perpendicular holes through the sheet’s edge, or when drilling through a stack of

sheets, cooling both the drill bit and the vicinity of the hole with a jet of compressed air is a good practice.

It is also recommended, when drilling deep holes, to stop frequently, pull the drill out and clear the hole from swarf and debris

with compressed air.

Preventing internal stresses: Producing a clean, smooth bore, keeping heat buildup to the minimum, by the procedure

described above, prevents excessive heat buildup, meltdown and gumming of the drilling dust and debris, and possible seizure

of the bit. It also prevents undue internal stresses at the vicinity of the hole.

Honing and polishing the edge of the hole by mechanical or chemical means contributes to keeping the sheet stress-free,

preventing cracking.

Maintaining the edge: Carbide tipped twist drill bits are preferable for long or continuous production runs. They are more

durable and improve the edge quality.

Finishing

General Comments

Reasons, Means and Targets

The final step in fabrication, finishing improves both the practical and aesthetic properties of PALSUN sheet prior to assembly.

Grinding & Polishing

This is mostly done as a part of edge preparation.

Practical objective: Rough, uneven, untended edges may be starting points for crazing and cracks after the PALSUN sheet is

installed and subjected to day by day exposure to wind loads, UV radiation and thermal expansion & contraction, not to mention

man-made impacts.

Aesthetic objective: Nicely finished, smooth edges are a must for a quality appearance of the finished product, often installed

with exposed edges.

Decorating: A type of finishing intended mostly for aesthetic appearance or for display purposes. Executed by painting, printing,

films or hot stamping.

Grinding / Sanding

General

A primary stage in edge finishing, rough or jagged edges and cutting tool marks created by a saw, shearing machine or a router,

can be removed by grinding.

Grinding / Sanding Recommendations

A belt sander, equipped with a 400-500 grit belt, running at 20 - 30 m/sec (65 - 100 ft./sec), is the preferred option, applying low

contact pressure during operation. Wet sanding and waterproof belts are preferable, as they prevents heat buildup, sanding

dust accumulation, and prolong sanding belt life.

A reciprocating or orbital sander can also be used, but it can be applied only by the dry sanding method.

Manual Sanding can also be used, wet or dry, working with successive grit size abrasive paper (Starting with 100, then 280-grit

silicon-carbide, and finally 400-600 grit sandpaper).

29

Page 30

Cleaning

General Polycarbonate Cleaning Guidelines

Never use abrasive or high alkaline cleaners on PALSUN sheets.

Do not use cleaners on PALSUN sheets for an extended period of time. Rinse immediately with clean, cold water.

Do not apply cleaners in direct sunlight.

Never use sharp objects, wipers (squeegees) or razors on PALSUN sheets.

Do not clean with gasoline.

Always practice safety first and never step directly on PALSUN sheets.

Always test cleaners in a small inconspicuous area prior to cleaning entire panel to prevent adverse results.

When using a pressure washer, do not allow the spray tip to come too close to the panel, as it could have enough pressure to

penetrate or tear the panel.

Avoid dry cleaning, as sand and dust particles clinging to the exterior of the panels may scratch the surface.

General Cleaning Instructions for Products

The Palram polycarbonate products can be easily cleaned utilizing a soft sponge or cloth made from 100% cotton, lukewarm

water and a mild dish washing detergent. All surfaces should then be rinsed with cold water and dried with a soft cotton cloth

to reduce water spotting. In some instances this procedure may be inadequate and require the use of additional cleaning agents.

The agents listed below have all been approved for use at room temperature.

30

Page 31

PALSUN® Technical Guide

Cold Forming

Cold Curving

1.

PALSUN sheets can be cold bent or curved, within their minimal permitted bending radius, without damaging their mechanical

performance. The minimal permitted bending radius for a PALSUN sheet is a factor of their thickness and should be calculated in the

following manner: 200 x sheet thickness (e.g. for a 5mm PALSUN sheet, 5 x 200 = 1000mm minimum cold bending radius). Moreover,

based on our experience and observations, the internal stresses induced by curving give them extra strength and rigidity in both

directions, as in pre-stressed concrete elements.

2. Rigidity and support spans increase progressively as the curve radius is reduced (down to the minimal permitted radius). A shallow

curve should be considered virtually the same as a flat panel, while a deep curve may add significantly to the bridging ability.

Brake Forming

General Notes

1. PALSUN sheets can be cold-bent in a straight line (line bending). Standard metalworking tools, like a brake press, may be used for

bending. The bending process results in permanent plastic deformation. The degree and quality of this change depend on the

thickness of the PALSUN sheet, the final bending angle required, and the actual tools used.

When brake forming of PALSUN is conducted, the internal elastic stresses induced along the bent line reduce the mechanical

2.

properties, UV resistance, and chemical resistance of the sheet along the bending line. Palram recommends using this process for less

demanding applications, and protecting the cold bent areas of the sheet from contact with aggressive chemicals or excessive forces.

3. Annealing can reduce the residual stress level induced by the cold bending process, improving the sheet’s mechanical properties.

The maximum angles that can be obtained using this process depend on the PALSUN sheet thickness, and the extent of the internal

4.

elastic strain. Palram recommends a 24-48 hour delay for sheet to relax after bending. In order to achieve the desired angle, the

sheet has to be bent 20-40 degrees in excess of that angle, depending on the angle and sheet thickness. During the stress relaxation

period immediately after bending, the bent sheet will expand and regain the required shape.

5. Certain types of sheets are not suitable for either cold or thermal forming, such as PALGARD abrasion resistant sheet. This type is

supplied with a tough, scratch-proof finish, which can not be bent and must be installed “as is”.

Practical Recommendations & Work Instructions

1. Preparations of the PALSUN Sheets and Tooling for Bending:

a. Cut the sheet to its required pre-bending size. Palram recommends leaving the protective film on both sides during the cutting,

edge preparation and cold bending operations.

b. Sand and polish the sheet’s edges to a very smooth finish. Rough edges or the tiniest fissure may initiate cracks and fractures at the

vicinity of the bending lines, due to internal stresses induced by the bending process.

Palram recommends conducting preliminary bending tests on small samples of the same (or varied) thickness of the intended sheet,

c.

and try a few different values of excess bending. After arriving at a satisfactory result you can start production.

It is advised to use special tooling, like blades and anvils, designed for plastic sheet bending. Standard metalworking blades and anvils are not

d.

necessarily suitable for bending plastic sheets. For plastics, we recommend using a special bending blade with a straight, rounded business

edge. The edge radius should be about 4-6 mm (0.16 to 0.24 in.). The thicker the sheet, the larger edge radius required. The anvil channel outer

“banks” (corners) should be rounded. Both blade and anvil are to be smooth and polished, with no projections, irregularities or rough edges.

Please note that an anvil channel for plastics bending is different than the one suitable for metalworking. It has a wider, flat bottom

and much steeper “banks”.

2. Cold Bending Fabrication:

a. Bending a sheet with an UV protected side (the printed protective film side) on the exterior of the bend gets best results. Therefore,

unless otherwise requested, lay the sheet to be bent with the printed side face down.

b. For optimal results, perform the brake forming quickly, with an additional 20-40 degrees as explained above, then leave the sheet

to relax for 24-48 days.

31

Page 32

3. Installation

a. Cold bent polycarbonate is more sensitive to mechanical or chemical abuse in the vicinity of the bend. Therefore, Palram

recommends a design that offers better protection for bent areas from any detrimental influence.

b. Avoid putting additional strain on bent parts, like forcing a bent angle in or out to fit into an existing framework.

Thermoforming

Pre-Drying

General Guidelines

Nearly all types of PALSUN sheets are suitable for various thermoforming (TF) procedures. However, due to a native small moisture

content absorbed after manufacture, they demand a thorough pre-drying process prior to most thermoforming techniques.

During this process, the sheet’s temperature will be raised to over 160°C (320°F). Avoiding this preliminary treatment may result in

moisture blisters, marring the appearance of the finished product, and/or reduce its properties.

Higher thicknesses require longer periods in the drying oven.

Typical Pre-Drying Time in Oven for Various Thicknesses*

Sheet Thickness Drying Time at 125°C (260°F)

mm Inch Hours

1 0.04 1.5

2 0.08 4

3 0.12 7

4 0.15 12

5 0.2 18

6 0.24 26

8 0.32 45

Notes: Time for thicker sheets can be calculated through interpolation.

The sheets are put into an oven, with the protective film removed from both sides, and arranged 20-30mm (3/4”-1”) apart, to

enable free air circulation. They can be stacked horizontally (on stays or suspended) or vertically- just so they will not be distorted

or twisted.

The pre-drying process should be performed as close as possible to the actual forming. Fully dried sheets taken out of the oven

and cooled down to room temperature may be workable within 1 to 10 hours (depending on relative humidity and temperature

in the workshop).

Longer delay may necessitate repeated pre-drying session. A recommended practice, if possible, is leaving the pre-dried sheets

in the switched-off oven until the actual thermoforming process. This method saves energy and time on the thermoforming

apparatus.

32

Page 33

PALSUN® Technical Guide

Guidelines to the Heating Process

Good quality thermoformed products can only be achieved through a careful and controlled heating process. All parts of the

treated sheet should reach even, uniform temperature, achieved by a slow, controlled heating rate, avoiding sudden changes in air

circulation and temperature. Such events may result in hot spots and possible distortions. Sheet edges must maintain the same

forming temperature as the whole sheet.

Pre-heating of the clamping frame from 120°C to 130°C is recommended.

Temperature Regulation: Continuous regulation of the sheet’s temperature must be maintained inside the thermoforming device itself.

PALSUN sheet (of any type) tends to cool quite quickly, and may need a regulating system for adding or dispersing of excess heat on the spot.

The sheet’s temperature at the thermoforming zone (or the whole sheet) should be kept between 180°C and 210°C during the forming process.

Forcing the sheet to form at a lower temperature may induce detrimental internal stresses, reducing the sheet’s impact

resistance and increasing its chemical sensitivity. Internal stresses are invisible and can be detected only by polarized light.

Annealing may reduce the stresses, although it is a complicated process and could be inefficient or impossible to perform in most cases.

Protective Polyethylene (PE) masking in Thermoforming: Special masking is available for sheets intended for thermoforming and

should be specified in these cases. This type of masking may be kept on the sheet when practicing most thermoforming methods

and peeled off right before performing the procedure. When using sheets with standard masking, it should be removed prior to the

thermal treatment, otherwise it is likely to fuse into the sheet’s face.

Hot-Line Bending

General Guidelines

1.

Description: A simple bending technique, used for forming local, straight line, one axis bent parts (such as corners, boxes, and

machine guards). This type of bending is usually preferable (if possible) to cold line-bending.

2. The process: A bending device with localized heaters on one or two sides of the sheet to be bent is used. The “sandwiched“ twosided heating method is preferable, since it retains the same temperature on both sides at the time. a one-side heater method

requires turning the sheet over a few times during the heating period, in order to maintain optimal temperature on both sides.

Steps & Indications

One-sided heating method may suffice for sheets up to 3 mm (0.12 in.). Thicker sheets or more demanding cases require using two-

sided heating. Keeping control of the sheet’s temperature limits of 155-167°C (31-332°F) is of the utmost importance.

Forcing the bend at lower temperatures will render the sheet fragile at the bend. This simple bending process enables working with

regular sheets, without pre-drying. Experimenting with small samples before final execution is highly recommended.

Figure 15: Heat bending device

33

Page 34

PE Masking: When preparing for bending of regularly cladded sheets- peel off the masking on both sides of the sheet along the

bend line for about 100 mm (4 in) on each side in TF prepared sheets. It is possible to process the sheet with the masking on, up

to 5 mm (0.2 in) thickness. For sheets of 6 mm thickness or more the PE masking should be removed along the bending line, as

described above. Always test a few samples before proceeding to production.

Heaters: Linear IR (Infrared) or resistance wires strip heating elements are used, preferably with heat reflectors. The width of the

heated zone depends on the number of elements used, the spacing between them depends on their specific thermal output and

the distance from the target sheet.

Bending process: When the sheet has reached the required temperature the heaters are to be switched off. The sheet, held in

pivoted clamps, preferably equipped with a caliper, is then bent to the required angle and secured there until it cools down and sets.

Note: It is recommended to perform the bend a few degrees tighter than the required angle, as the angle may increase as the sheet

cools. The desired angle may be reached after a few trials.

Cooling is to be done in ambient air, taking care to avoid sudden drafts. These can cause distortion of the final product.

The minimal Hot-Line Bending Radius is 3 times the thickness of the bent sheet. Larger radii can be achieved by widening the

heated zone.

Forming - Notes for Consideration

Local hot line bending (or any other localized heating) induces internal stresses in the finished part, reducing the chemical resistance

of the element at the bending line zone. Such treatment is therefore recommended for use in less demanding environments.

Localized heating and cooling expansion/contraction characteristics are unpredictable in many cases. Short elements (up to

1.00m or 3.0’) usually remain flat. Longer elements may distort to a concave shape (the outer edges are longer than the line-

bent side due to uneven contraction).

This phenomenon can be corrected or reduced by simple jigs or frames, which hold the part in the right position during the

cooling period.

It is always advised to fabricate experimental test samples to check feasibility of the bending operation.

PALSUN® Thermoforming Tips

Consistent part-to-part uniformity is better ensured if the sheet blanks prepared for the thermoforming process are cut from the

basic sheet always at the same direction.

Best results in thermoforming are achieved when parts are heated to temperatures just above the HDT (150 °C- 300 °F).

Thermoforming parts below the HDT temperature induces internal stresses.

Secure the cooling area for thermoformed parts against undue drafts. Uneven cooling may result in warping and/or curling of parts.

Assure precise and systematic control over oven temperature and heating time.

PALGARD (abrasion resistant) and PALSUN FR (fire retardant) are not recommended for use in thermoforming. The bending and

stretching involved during the process will permanently damage the sheets.

34

Page 35

Fault and Remedies in Thermoforming Practice

# Recognized Fault Probable Cause Proposed Treatment

PALSUN® Technical Guide

Hot Line

Bending

Drape

Forming

Vacuum

Forming

Blown

Free

1

Bubbles in sheet

2 Working temp. too high Decrease working temp. + + +

3

4 Mold under-heated Increase mold temp. +

5 Late extraction of part Diminish cooling cycle +

Hair fissures, fragile parts

6 Vacum speed too high Reduce vacum rate +

7 Mold corners too sharp Round sharp corners +

8 Basic sheet size too small Increase sheet size +

9

10 Mold lead inadequate Check spacing-min. depth x 2 +

Webbing

11 Vacum speed too high Reduce vacume rate +

12 Basic sheet size too large Clamp/mold spacing <50mm +

13

Blurred or partial detailing

14 Sheet rigid, under-heated Extend heating period or temp. +

15

Product sticks to mold

16 Product release delayed Shorten release period +

17 Draft angle too steep Enlarge draft angle up to 4-6° +

18

Marked zones on product

19 Suction holes misplaced Install new, better placed holes +

20 Sheet overheated Decrease heating period/ temp. + +

21

Exterior flaws / roughness

22 Suction holes misplaced Install new, better placed holes +

23

Inconsistent shape of part

24 Irregular heating/ cooling Prevent drafts, fix faulty heater + + + +

25 Product release delayed Shorten release period +

Moisture content too high Pre-drying + + + +

Part overheated Decrease heating period + +

Erratic heating Prevent hot or cold spots +

Vacum too weak Seal leaks/add vacum holes +

Mold overheated Decrease mold temperature +

Irregular finish of mold Treat mold to consistent finush +

Dirt/ grime on sheet / mold Wipe/Vacum-clean mold/sheet + +

Mold/ brace under-heated Extend pre-heat of mold/brace +

35