Page 1

PALSUN®

Flat Solid Polycarbonate Sheets

PALGARD™

Flat Solid Polycarbonate Abrasion Resistant Sheets

Architectural, Safety & Security

Glazing Guide

for Designers, Engineers & Professional Consultants

Page 2

PALSUN® PALGARD™

Glazing Guide

Contents:

Part A. Technical Data & Principal Indications for Use

Page

1. Introduction, abbreviated Definitions & Typical Glazing Applications: …………………….……3

2. PALSUN Family:…………………………………………………….…………………………………..4

3. Standard Dimensions, Weight & Colors:……………………………………………………….……5

4. General Characterizations & Physical Properties:………………………………………….….…...6

5. PALGARD Enhanced Attributes……………………………………………………………………….7

6. Optical Characterization & Properties:…………………………………………………….………..8

7. PALSUN Thermal-Insulation Properties:…………………………………………………..……….10

8. PALSUN Acoustic Properties:……………………………………………………………..…………10

9. Durability under Environmental & Climatic Conditions:…………………………………………11

10. PALSUN Flammability:……………………………………………………………………………….12

11. PALSUN Chemical Resistance:………………………………………………………………………13

12. Sealants, Sealing & Glazing Accessories, Bonding Agents & Adhesives:……………………….13

13. Choosing the Appropriate PALSUN Type for the Intended Application:………………………..14

Part B. Installation Instructions, Directives & Recommendations:

1. Flat PALSUN & PALGARD Glazing Installation on Supporting Frames

according to Supporting Method & Span. Load tables………………………………………………...15

2. Installation of Curved PALSUN Glazing on Supporting arches

according to Arch Radius & Supports Span. Load tables……………………………………………..20

3. General Indications for Curved PALSUN Installation:……………………………………………..23

4. Directives, Instructions & recommendations for Flat & Curved PALSUN Glazing:……………..26

5. Principles of Planning & Engineering Design with PALSUN® Glazing:…………………………..24

2

Page 3

PALSUN® PALGARD™

Glazing Guide

PART A. DATA & PRINCIPAL INDICATIONS FOR USE

1. Introduction, abbreviated Definitions & Typical Glazing Applications

:

PALSUN®: Flat solid polycarbonate sheet, in transparent & translucent configuration, for use as safety &

security glazing, in flat or curved configurations. PALSUN family Includes many types as could be

observed further on.

PALGARD™: Flat solid polycarbonate sheet, mostly in transparent configuration, with additional

abrasion resistant silica coat on one or two sides, for enhanced resistance to scratches, vandalism and

graffiti, chemical attack & haze. A member of the PALSUN family.

Contrary to regular PALSUN, PALGARD sheets should always be installed in the flat position, never to be

curved, as it might crack the silica coat(s).

Polycarbonate: A thermoplastic material offering extraordinary strength & impact resistance along

with very high flexibility, glass-like transparency & light-transmission, relatively high working

temperature range & excellent workability & fabrication qualities.

Can be fabricated & formed in practically any available industrial process, such as extrusion,

thermoforming, injection-molding, casting etc.

Polycarbonate glazing/cladding (of any type) blocks completely the whole range of harmful solar UV

radiation, while transmitting the whole range of visible light and near IR radiation.

Therefore, People and hardware covered by polycarbonate elements have the best protection against

deterioration & disintegration from UV radiation

This guide refers to flat solid polycarbonate sheets produced by an industrial co-extrusion process.

Possible Applications:

• Windows in buildings of all types,

• Glazed curtain walls and light-transmitting roof-cover.

• Natural lighting apertures (Skylights, Sidelights) in roofs and walls.

• Transparent indoors partitions.

• Transparent acoustical barriers on side of roads & highways and noisy public places (schoolyards,

playing grounds, stadiums & sport arenas, automotive sports etc.)

• Transparent stationary and mobile shields of all types.

• Windows for transportation vehicles (trains, buses &, cars, aircraft, ships & boats etc.).

PALSUN & PALGARD may come in a variety of thickness, shades & colors & light-transmission rates.

PALSUN may also come in a number of surface finishes.

Important Note

:

PALGARD is a part of PALSUN family and identical in most details and properties.

Whenever and wherever PALSUN is mentioned in this manual PALGARD is included, and vice

versa, unless specifically stated otherwise.

3

Page 4

PALSUN® PALGARD™

Glazing Guide

2. PALSUN Family

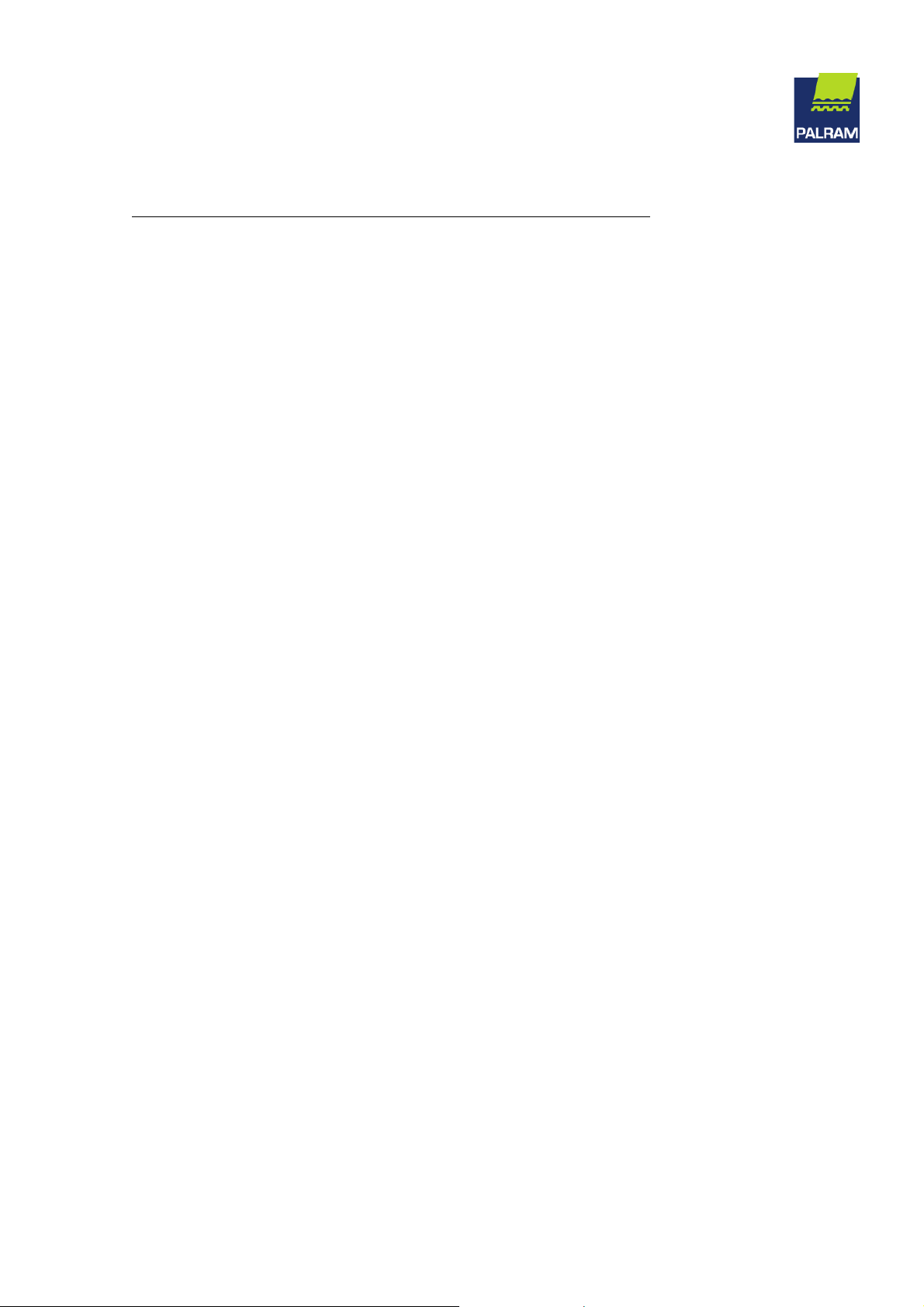

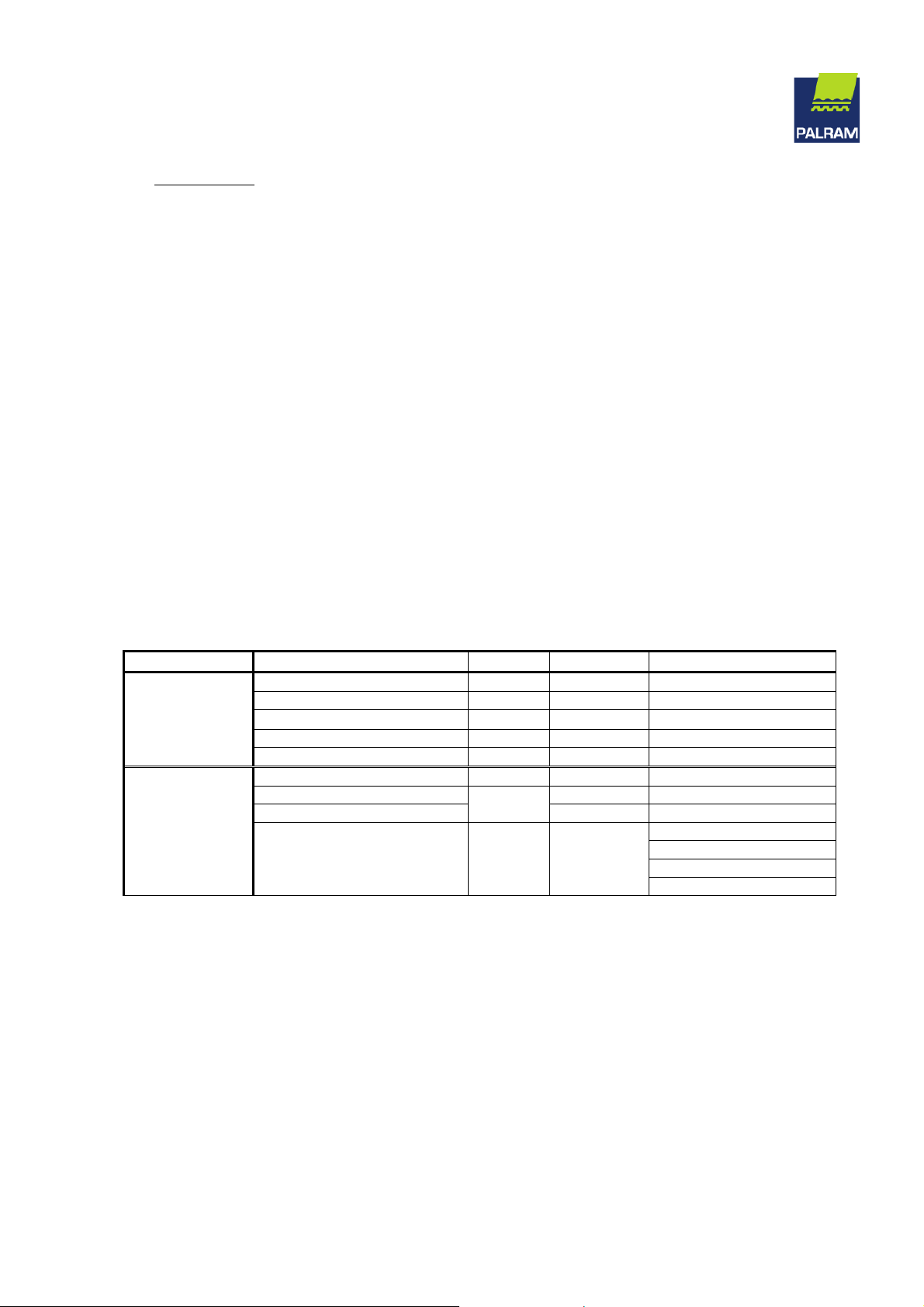

Table 1. PALSUN Family – Description & Indications for Use

Ser.

Type & Name of

No.

Product

A B C d

1

PALTOUGH

2

PALSUN

3

PALSUN plus

PALSUN

4

Embossed

5

PALSUN Matte

Finish

6

PALSUN FR

PALSUN

7

Solar-Control

8

PALSUN Mirror

9

PALGARD Clear

PALGARD

10

Translucent

Notes:

1. all PALSUN & PALGARD sheets appearing in the table are produced with polyethylene protective masking on

both sides of the sheet (or on one side on special order). The UV protected side (and the silica coated side on

PALGARD) is clearly marked on the appropriate protective film. The masking would be peeled-off only during

actual installation or immediately after its conclusion.

2. For instructions on transportation, handling & storage see relevant sections further on in this manual.

3. PALSUN & PALGARD sheets carry 10 years limited guaranty, as appears in PALRAM Guaranty Certificate, provided on

demand.

4. PALSUN & PALGARD sheets can be supplied as transparent, translucent or opaque configurations, in a few standard

sizes, colors & tints, thickness & light-transmission. Non-standards properties upon special demand, subject to minimal

order & agreed surcharge. For more details contact local PALRAM dealer.

:

Description

UV stabilized sheet, smooth on both

sides

Sheet smooth on both sides, with

integral co-extruded UV protective layer

on its external side.

Sheet smooth on both sides, with

integral co-extruded UV protective

layers on both sides.

Sheet embossed on one side, with

integral co-extruded UV protective layer

on the external smooth side, unless

otherwise required

Sheet smooth on one side, with antiglare matte finish for better light

diffusion, on the other

An high fire resistance sheet,

conforming to US Fire Standard UL 94

V-0

A tinted, metallic hued, semi-reflective

sheet with integral solar-radiation

control enabling regulated transmission

of visible light with reflectance of most

solar longer wave heat radiation

Sheet smooth on both sides, with

integral co-extruded UV protective layer

on its external side & mirror metallic

coated film on the other .

A colorless transparent sheet, smooth

on both sides, with integral co-extruded

UV protective layer on the external side

(or both) & abrasion resistant silica coat

on one side (generally external) or both.

Same as PALGARD Clear but in specialorder translucent version.

Comments & Indications

for Use

For indoor applications only. Available also

in other configurations as appears in

paragraph 4, 5 & 6 in the table.

Applied on exterior wall windows, curtainwalls, skylights & sidelights or internal

artificial lighting elements

To be applied in open outdoors glazing,

with possible UV exposure on both sides

(sound barrier for instance) & external

artificial lighting elements

Possible UV protective layers on both sides.

3 possible embossing shapes: “hill & valley”,

“Prismatic”, “Hair-Cell”

With integral co-extruded UV protective

layer on the external side or on both.

With integral co-extruded UV protective

layer on the external side or on both.

Available in all possible combinations

appearing in this table.

With integral co-extruded UV protective

layer on the external side or on both.

Available in aluminum shade (gray) & Solar

Ice (pearly -white). Other hues & colors on

special demand subject to minimal quantity

order.

For indoor & outdoor applications. Internal

mirror finish film will always be installed

against a rigid, sealed backup or other

sealed, impermeable protective element.

Other tints (bronze, gray etc.) at 5%

surcharge & 5.0 t min. order. To be used

same as flat PALSUN glazing (and variants)

with enhanced cleaning options & improved

scratch resistance

To be installed in the flat position only.

Non-standard. Available At special order, min. 5 t.

per order /color + agreed surcharge

4

Page 5

PALSUN® PALGARD™

Glazing Guide

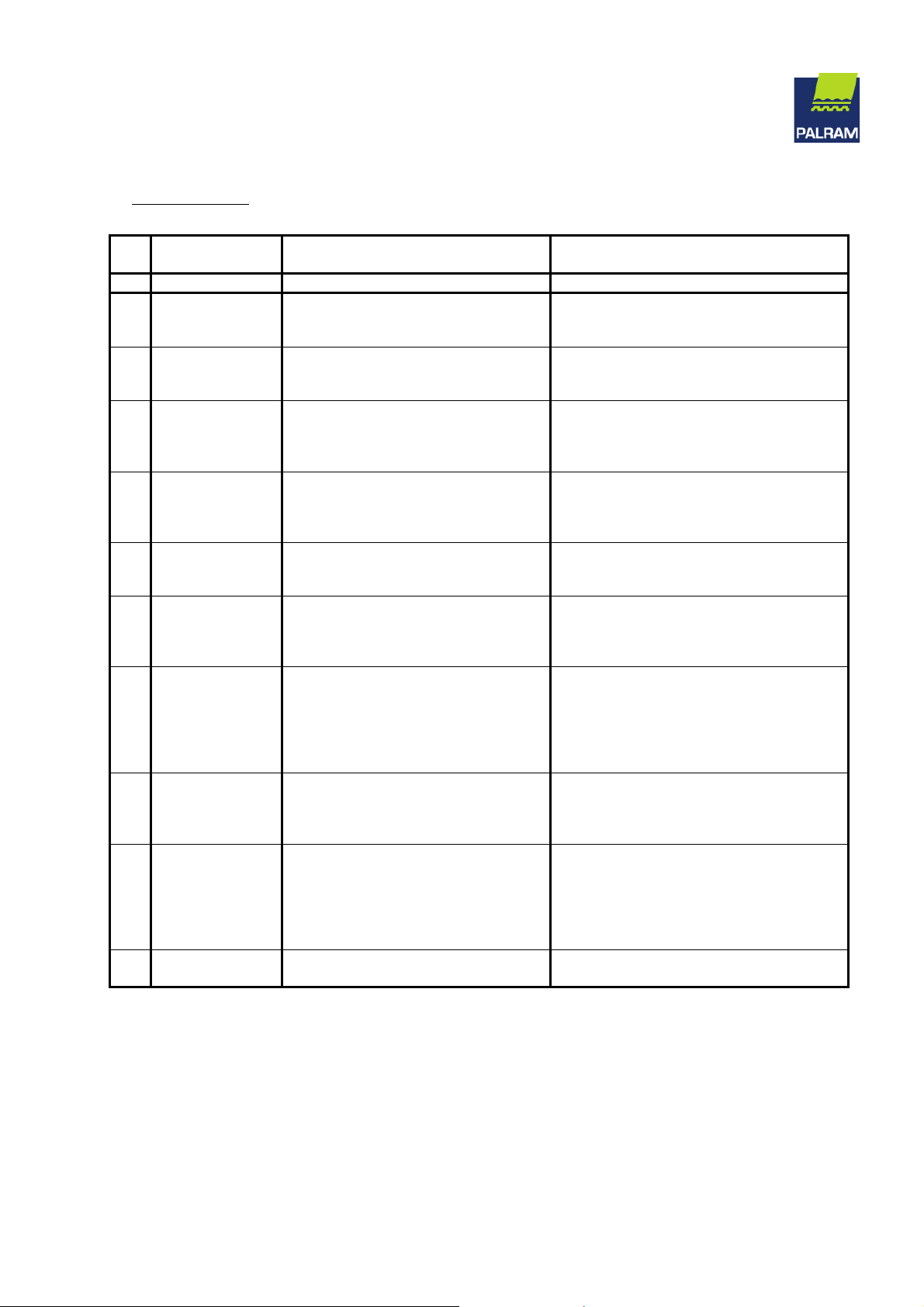

3. Standard Dimensions, Weight & Colors:

Table 2. PALSUN Standard Dimensions, Weight, Colors & Tints:

Thickness Standard Dimensions (mm x mm)

mm 1250 x 2050 1220 x 2440 2050 x 3050

1.0 NA

1.5 NA

2.0

3.0

4.0

5.0

6.0

8.0

10.0

12.0

Table 3. Standard PALGARD Sheets/Panels:

Thickness

Standard

Dimensions

mm mm x mm gr/m2 Transparent Translucent

3.0 3,600

Theoretical

Weight

Theoretical

Weight

2

gr/m

1,200

1,800

2,400

3,600

4,800

6,000

7,200

9,600

12,000

14,400

Standard Colors & Tints

Standard Colors & Hues

Transparent Translucent

Colorless

Bronze

Solar-Gray

Solar-Control

Solar-Ice

Matte

(Diffuser)

Opal-White

4.0 4,800

5.0 6,000

6.0 7,200

8.0 9,600

10.0 12,000

12.0

Notes:

1. PALSUN Non-Standard Choices

production standard are available to special order, subject to minimal agreed quantity.

2. Certain PALSUN types are produced in limited choice of thickness, size, finish or color/tint. Please consult your

local PALRAM distributor about availability prior to order.

3. When a certain color or tint is required it is advisable to ask the distributor or salesperson for a typical agreed

color sample which would be the only binding proof for the true color ordered.

4. Final shade of a sheet’s color would be determined by the thickness & light-transmission percentage

requested. A thicker sheet would need lighter shade for a fixed percentage.

5. Standard PALGARD sheets

2000x3000

14,400

are produced only in 2.00 x 3.00m dimensions, in 3-12mm thickness & colorless hue.

colorless

Other standard colors

(bronze or similar) 5% surcharge,

min.5 t. per order /color

: Other colors & shades, in-between thickness, width & length other than

Non-standard.

At special order,

min. 5 t. per order /color

+ agreed surcharge

5

Page 6

PALSUN® PALGARD™

Glazing Guide

4. Polycarbonate General Characteristics & Physical Properties:

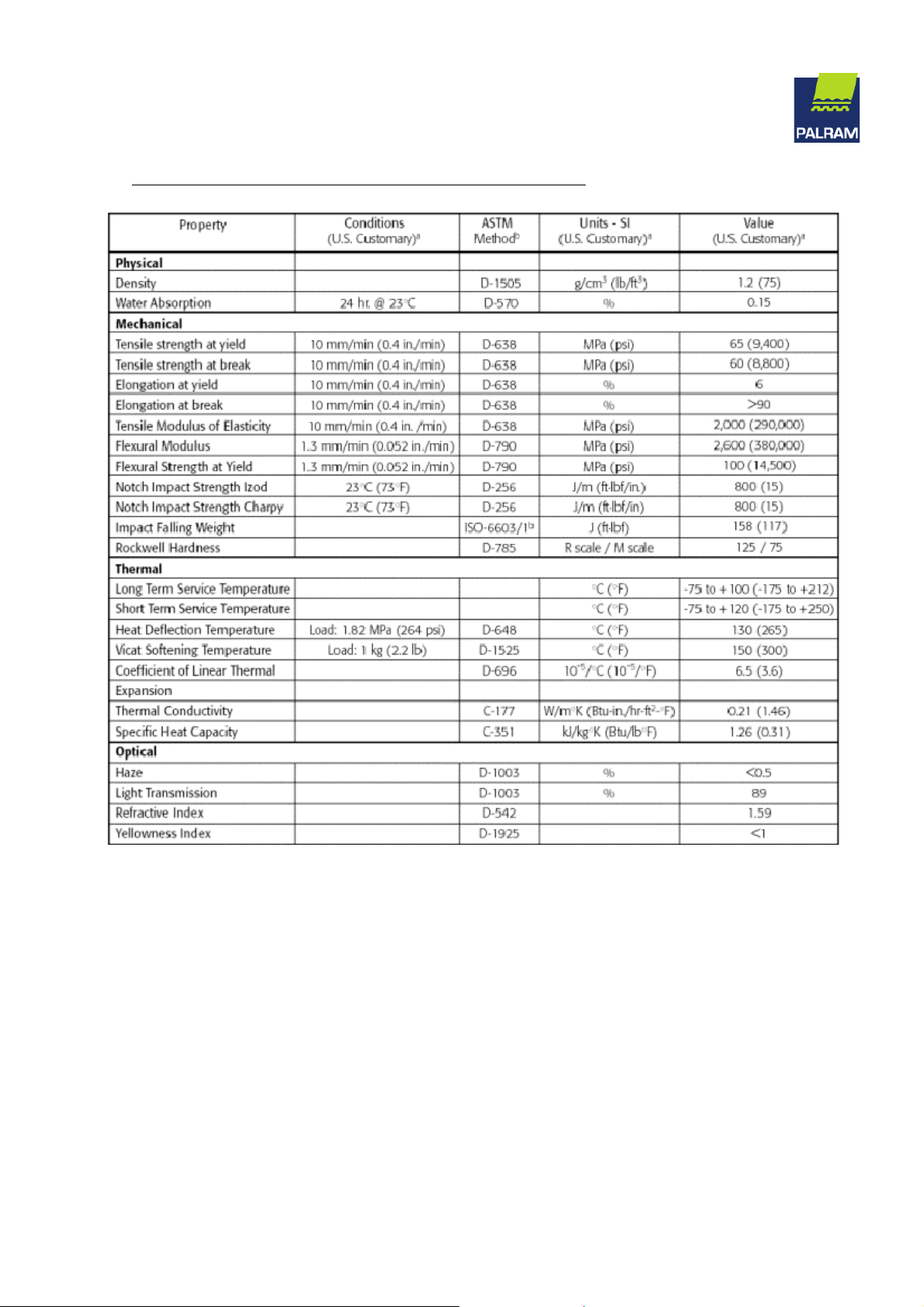

Table 4: Typical Properties of PALSUN, PALTOUGH & PALGARD Sheet (3 mm = 0.12 in.)

Notes:

1. Conditions, units and values in the table, in U.S. Customary units, are presented within brackets.

2. Results depicted in this table were obtained by following indicated ASTM method, except where another method is

indicated by a (b) symbol.

3. All 3 sheet types are basically polycarbonate, with identical properties, save additional thin UV protective layer(s) or the

ultra-thin silica (abrasion resistant) coat(s) and their contribution to the specific sheet behavior.

4. Test results depicted correlate (when applicable) to a 3.0mm (1/8 in.) thick sheet.

6

Page 7

PALSUN® PALGARD™

Glazing Guide

5. PALGARD Enhanced Attributes (Compared with regular PALSUN):

a. Visible Light Transmission: Improved by PALGARD silica coat by approximately 1.5% (to 91%)

b. Yellowing Index: Improved by PALGARD silica coat to < 0.75.

c. Chemical Resistance: PALGARD coated side presents better resistance than the non-coated side, or

parallel PALSUN or PALTOUGH. It could be subjected, for limited periods, to harsher chemicals or more

effective cleaning agents during removal of persistent grime or occasional graffiti.

d. Cleaning Persistent Grime & Graffiti Removal: PALGARD coated side can withstand spray-paints,

motor oils, alcohol based markers & other relatively aggressive chemicals along with brisk use of alcohol,

kerosene and even gasoline as cleaning agents.

PALSUN or PALTOUGH are more vulnerable to these materials and might be harmed by contact with

them.. Damage scope depends on duration of exposure & type of chemical.

Resistance duration to each cleaning agent differs, so use it gradually, from the most gentle to the

harshest. Wash-off immediately as cleaning is completed, with lots of clean water and mild detergent.

e. Weather Resistance: PALGARD coated side(s) offers even better weathering durability, confirmed by

thousands of hours of accelerated exposure and years of field tests in harsh climate conditions.

f. Abrasion Resistance: PALGARD meets ASTM D-1044 & ANSI Z26.1 TEST #17 Taber Abrasion Test with

good results, displaying good resistance to friction & chaffing with people in crowds.

PALGARD can endure intentional abuse to a measure, however once gouged by sharp objects (knives,

screwdrivers etc), a deeply scratched surface could not be restored.

7

Page 8

PALSUN® PALGARD™

Glazing Guide

6. PALSUN® & PALGARD™ Optical Characterization & Properties:

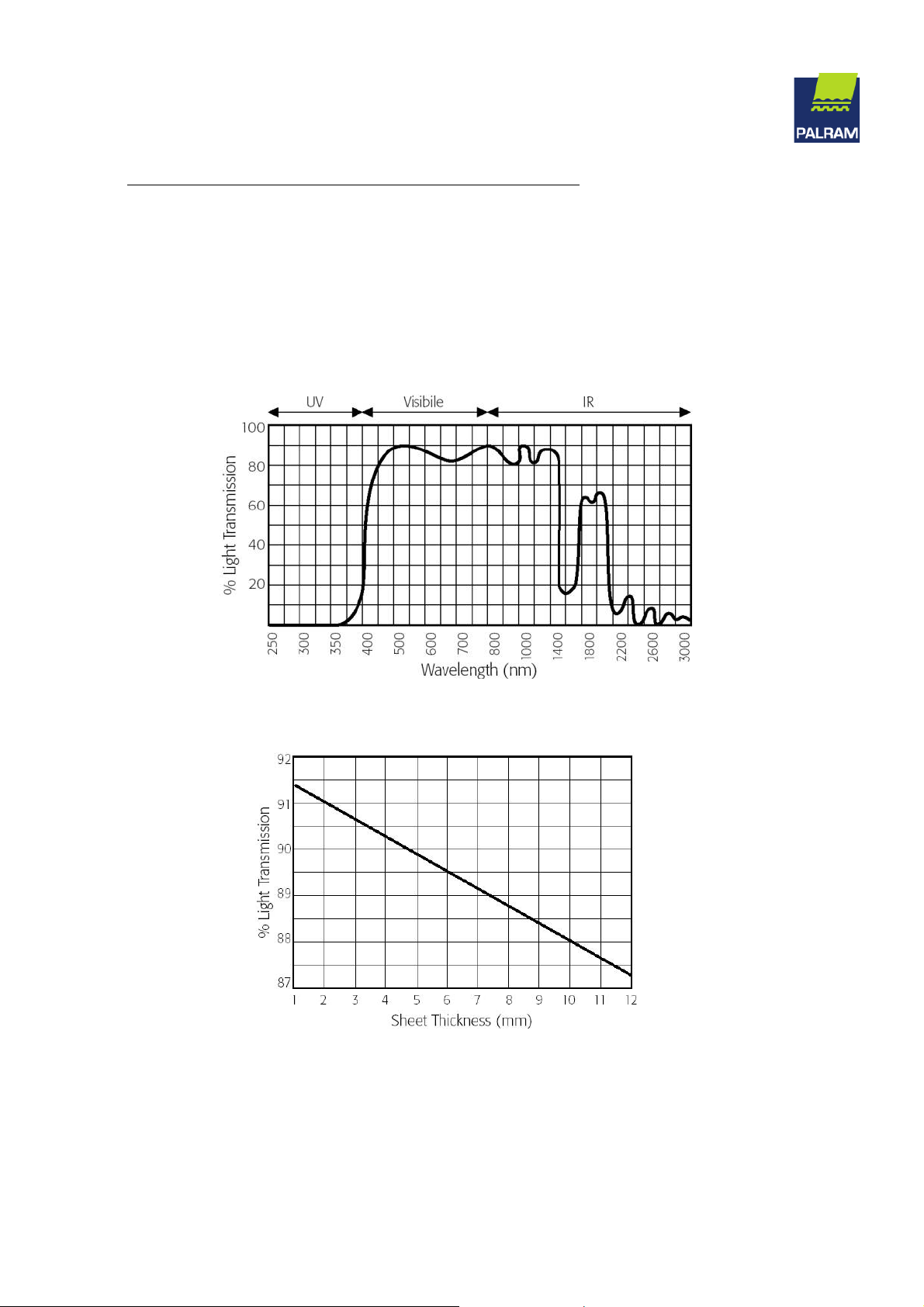

a. Blocking UV Radiation: All the siblings of the solid polycarbonate sheets family block practically all

the destructive & harmful UV radiation range (250 to 400 nm), and a considerable part of the longwave far IR (Infra-Red) heat radiation range (see graph 1).

b. Visible-Light Transmission: In this 400 to 800 nm wavelengths range a typical clear, colorless PALSUN

(or the two others) will transmit about 87 to 91 percent of the incident visible light radiation.

c. Light-Transmission as a Function of Sheet Thickness: Percentage of light transmission drops slightly

& linearly with each gradual increase in thickness (see graph 2).

Graph 1. % Light Transmission of PALSUN &

PALGARD Sheet (3 mm) Versus Wavelength

Graph 2. PALSUN & PALGARD Sheet % Light

Transmission Versus Sheet Thickness

8

Page 9

PALSUN® PALGARD™

Glazing Guide

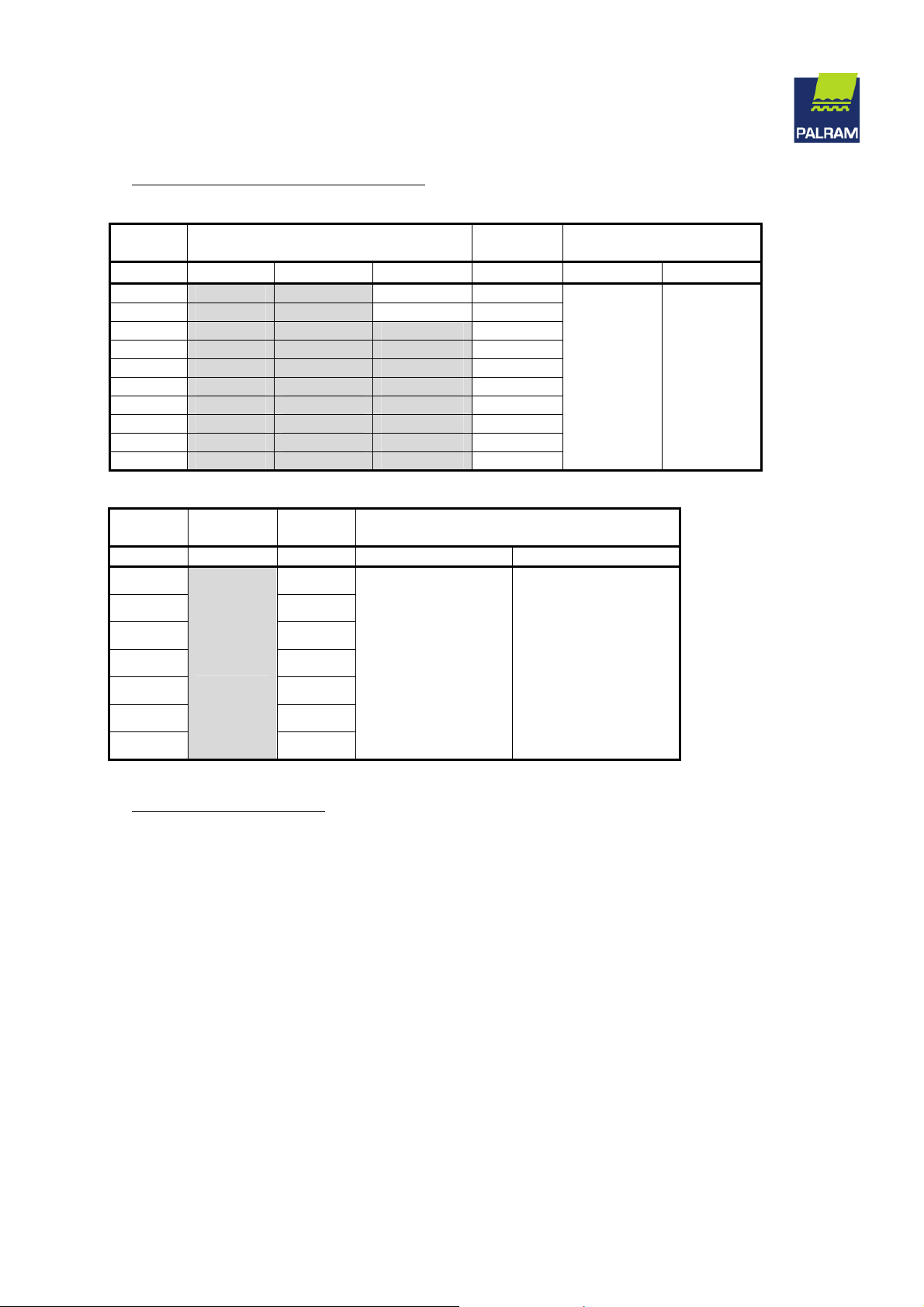

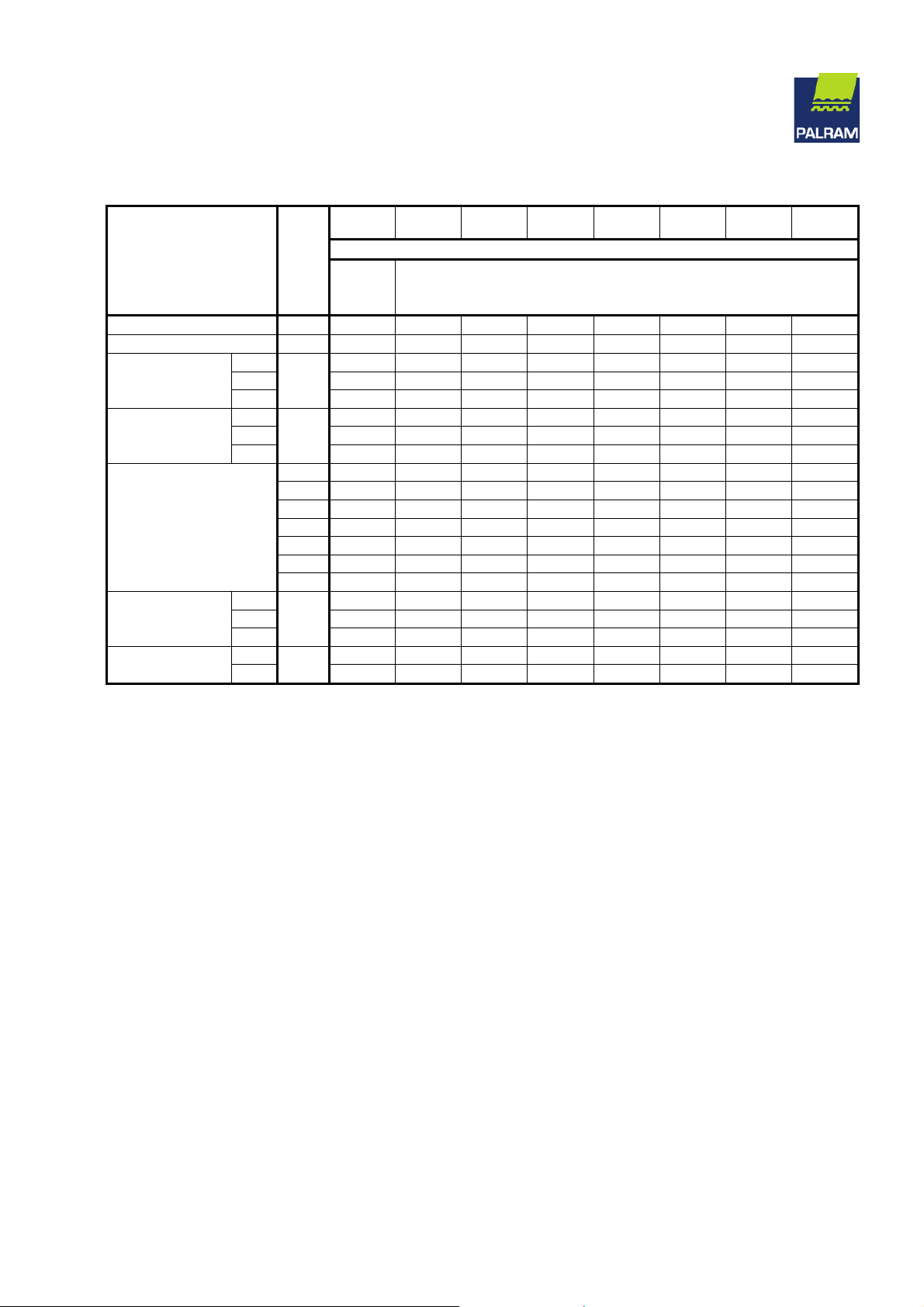

Table 4. PALSUN & PALGARD Optical & Thermal Properties - Solar Radiation Transmission

Thickness

LT % LR % ST % SR % SA %

PALSUN Type

(Standard PALGARD

Comes only in Clear)

Clear

Clear Embossed

50% 50 7 54 7 39 26 74 0.75

Bronze

Solar Gray

Opal-White

Solar Control

(Aluminum Gray)

Solar Ice

(Pearly White)

Notes:

1. Values in this table are based mostly on known data about the various sheets in it and partly on theoretical

calculations & interpolations. Performance of other sheets absent from table would be assessed by

approximated extrapolations.

2. See enhanced definitions below for acronyms on top of table.

35% 35 6 42 6 52 32 68 0.64

20%

50% 50 7 54 7 39 37 63 0.75

35% 35 6 42 6 52 32 68 0.64

20%

20% 20 30 18 33 49 58 42 0.36

35% 35 28 35 28 37 47 53 0.54

50%

35% 35 56 33 49 18 58 42 0.34

50%

(mm)

ASTM

D1003

88 10 84 10 4 12 88 1.00

3.0

85-87 10-12 81-83 10-12 3-7 14 86 1.00

3.0

All

20 6 28 6 66 39 61 0.52

All

20 6 27 6 67 38 62 0.54

1.0 35 55 40 47 13 53 47 0.54

1.5 45 50 48 41 11 46 54 0.52

2.0 39 54 42 45 13 52 48 0.41

3.0 28 58 36 48 14 57 43 0.35

4.0 19 59 24 61 15 69 31 0.31

5.0 14 60 21 72 17 71 29 0.26

6.0 11 61 13 77 21 77 23 0.23

All

50 24 48 24 28 48 52 0.64

All

50 45 46 38 16 46 54 0.51

Obligatory Standard / Testing Method

ASTM

E424-71

% STt %

SR

t

SC

Definitions

Visible Light Radiation: The range of the light spectrum wavelength from 400 to 700 nm.

% Light Transmission (%LT): Percentage of incident visible light passing through a light transmitting object

.

% Light Reflection (%LR): Percentage of incident visible light striking an object, reflecting back as is.

% Light Absorption (%LA): Percentage of incident visible light striking an object and absorbed by it.

%LT + %LR + %LA = 100%

Solar Radiation: The solar spectrum ranging from 300 to 2400 nm. Includes UV, visible, NIR &

FIR radiation.

% Solar Transmission (%ST): Percentage of complete range of incident solar radiation passing directly

through a light transmitting object.

% Solar Reflection (%SR) Percentage of incident solar radiation striking an object, reflecting back as is.

% Solar Absorption (%SA): Percentage of incident solar radiation that strikes an object and is absorbed by

it.

%ST + %SR + %SA = 100%

Total Solar Transmission (%ST

Total Solar Reflection (%SRt): Percentage of incident solar radiation reflected by an object, including solar

%STt + %SRt = 100%

Shading Coefficient (SC): The ratio of total solar radiation transmitted by a given material to that

): Percentage of incident solar radiation transmitted by an object, including the

t

direct solar transmission plus a part of the solar absorption reradiated inward.

reflectance plus a part of the solar absorption, reradiated outward.

transmitted by a regular clear glass, with 87% LT.

It can be approximately calculated by: SC = 1.15 x ( %ST + 0.27.%SA ) / 100

%ST + 0.27 x %SA = %STt

SC = 1.15 x STt/100

9

Page 10

PALSUN® PALGARD™

Glazing Guide

7. PALSUN® Thermal-Insulation Properties:

PALSUN is not an insulating material, but still offers lower thermal conductivity and better insulation than

comparable glass. When considering thermal efficiency and energy lose in winter (heating) or summer

(air-conditioning) PALSUN may contribute substantially in lowering total heating & cooling cost & energy

cutback for single glazing systems.

Table 5. PALSUN Vs. Glass Heat Insulation Comparison:

lazing thickness PALSUN Glass

mm in. K Value

3.0

5.0

6.0

9.5

12.0

Notes:

1. Where PALSUN is mentioned it holds for PALGARD too. Its properties are identical to PALSUN.

2. PALSUN K-value shows significant drop (better insulation) as thickness grows. Compared to glass 12mm

PALSUN glazing offers better insulation by more than 20% than its glass counterpart.

3.In between values to be calculated by interpolation.

8. PALSUN® Acoustic Properties

1

/8

13

/64

¼

3

/8

½

5.49 5.87

5.21 5.80

5.09 5.77

4.69 5.68

4.35 5.58

:

Though less than half the weight of an equivalent glass pane, PALSUN glazing offers quite close sound

insulation properties along with much higher impact strength.

These combined properties make PALSUN glazing an excellent candidate for see-through sound barriers:

lightweight, easy to maintain or replace if necessary, highly transparent and vandal-proof.

PALGARD, with identical inherent basic properties and more, portrays even better advantages for

choosing it for the job(see page 7).

Following table portrays the acoustic performance of PALSUN glazing compared to glass:

Table 6. PALSUN Vs. Glass Sound Insulation Comparison:

lazing

hickness

mm in. dB dB

4

5

6

8

10

12

Notes:

1. Sound insulation/noise reduction values refer to single layered solid glazing pane of the depicted thickness for both

materials.

2. The somewhat higher acoustic reduction value of comparable glass results from its higher specific weight/density

(more than twice than that of polycarbonate).

5

/32 24 30

13

¼

5

/16 28 32

25

½

PALSUN Glazing

Sound Reduction

/64 25 30

26 31

/64 30 33

31 34

Glass Pane Sound

Reduction

10

Page 11

PALSUN® PALGARD™

doors use)

Glazing Guide

9. Durability under Environmental & Climatic Conditions:

The UV segment of the Solar radiation is destructive and harmful to most plastics & polymers.

The extent of crazing, deterioration of external surface & final disintegration depends on type of polymer

and duration of exposure.

Further damage and accelerated deterioration might be caused by environmental aspects such as ice,

water & humidity, extreme temperature changes, strong winds with dust and sand particles, air &

chemical pollution etc. Amount of damage depend on location, height (above sea level and relative to

near surroundings) climate conditions, air pollution level & nature etc.

A typical & easily recognizable sign of deterioration is substantial yellowing followed by significant

transparency loss, surface roughness & shallow crazing. Such deterioration also indicated a serious drop

in strength and impact resistance.

PALSUN and PALGARD of all types are UV shielded by an integral co-extruded UV protective layer, on one

(external) or both sides (for outdoors applications), providing long-term safeguard against UV

deterioration. Both sheets are inherently resistant to extreme weather condition s most environmental

circumstances. PALGARD has a few more enhanced attributes as mentioned in page 7.

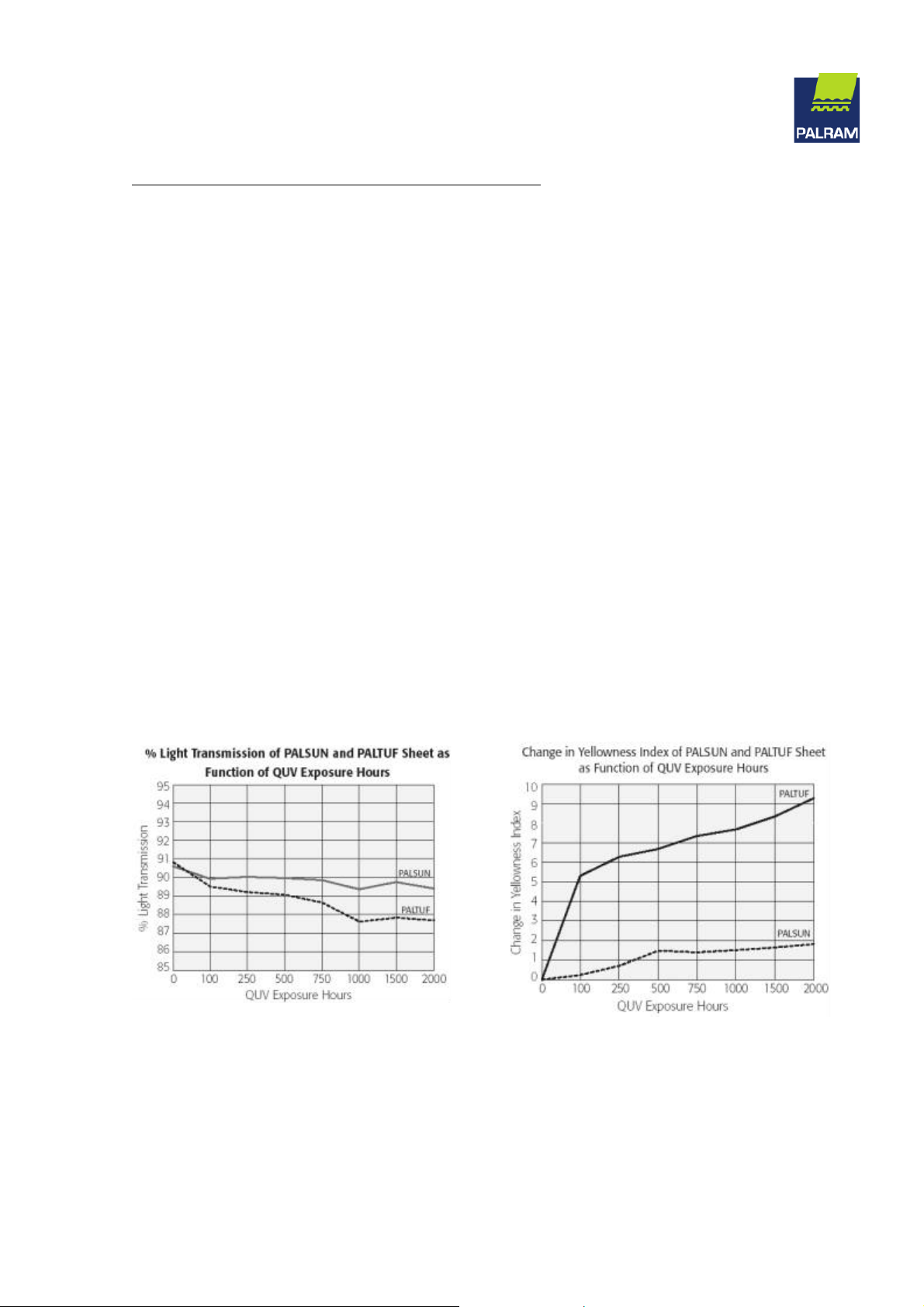

QUV Laboratory tests (accelerated UV exposure) made according to ASTM E-58 (88) US Standards show

that after 2,000 h of accelerated exposure, equal to 20 years of normal exposure to intensive solar

radiation at hot & sunny climates, there was an almost negligible reduction in light transmission and

minimal decrease in physical properties.

All the above assure product longevity and years of service. PALSUN and PALGARD will keep their look,

strength & optical quality for many years of service, under extreme conditions and intensive exposure to

direct sunlight with the minimal reduction of physical properties.

Following graphs show influence of said QUV tests on unprotected polycarbonate sheet Vs PALSUN.

Graph 3. Change in % Light Transmission

as a Result of QUV Exposure Hours

(PALTUF

in

-flat solid polycarbonate sheet for

Graph 4. Change in Yellowness Index

as a Result of QUV Exposure Hours

11

Page 12

PALSUN® PALGARD™

Glazing Guide

10. Flammability:

General Comment: As a thermoplastic, regular PALSUN eventually melts and burns under the intense

heat of a blazing fire. However, PALSUN does not propagate flame. It solidifies and self-extinguishes as

soon as the direct flame is taken away.

Regular PALGARD behavior is the same, though when silica coated on both sides the coats help to retard

the glazing from catching fire for a few more minutes, as silica is inert to fire.

PALSUN® FR: Flame retardant additives make the sheets virtually non-combustible. When the flame

licks the glazing it only gets scorched and eventually melts, solidifying quickly when the direct heat

source is removed.

Drippings do not ignite other combustible materials, as they actually do not burn.

Smoke and heat extraction: In an actual full-scale combustion, when PALSUN overhead glazing (as in

skylights) is exposed to intense heat it will soften at 150° -160°C and eventually produce apertures in the

glazing, enabling heat and smoke to escape, thus reducing temperatures inside the structure and

extracting the asphyxiating smoke. It helps cooling the interior and facilitates firemen duty in

extinguishing the fire.

Flammability Classifications: PALSUN & PALSUN FR, same as parallel PALGARD, are classified as appears

in the following table, based on tests executed by certified independent testing laboratories.

Table 8: PALSUN® Fire Classifications listed according to the relevant codes or standards

PALSUN® Type Standard Country Description Classification

DIN 4102 Germany - B-1

Regular PALSUN

PALGARD

PALSUN FR

PALGARD FR

Note: *Classification depends on

BS 476/7 UK Clear Class 1Y

NSP 92501, 4

CSE RF 2/75/A CSE RF 3/77 Italy - Class 1

UL-94 USA - V-0, V-1, V-2*

NSP 92501, 4 France Clear M-1

UL-94 Clear/Opaque V-0

ASTM D-2863-87

AU 1530.3-1982

France

USA

Australia All

Clear M-1, M-2 (depend on thkns)

Clear/Opaque LO.I. = 30

Ignitability Index = 9

Spread of Flame Index = 8

Heat Evolved Index = 10

Smoke Developed Index = 8

12

Page 13

PALSUN® PALGARD™

Glazing Guide

11. PALSUN® Chemical Resistance:

a. PALSUN glazing of all types are compatible with many common materials and chemicals, show limited

resistance to others, and are utterly incompatible with a third group, with which contact may be

harmful and even devastating.

Damage extent depends on type of material or chemical the glazing may be exposed to, and on the

nature and duration of said exposure.

b. PALGARD uncoated side reacts to the three chemical groups same as regular PALSUN, while the silica

coated face portrays higher resistance to materials & chemicals enabling better cleaning and graffiti

removal options. (See page 7)

c. A wider & more detailed table depicting PALSUN resistance to a wide range of chemicals appear in

Appendix 1, page XX.

12. Sealants, Sealing & Glazing Accessories, Bonding Agents & Adhesives

Adhesives, sealants and Glazing Accessories are products & materials often required during installation of

PALSUN glazing.

Guidelines for their use, appearing below, must be followed:

1. Use only sealants, adhesives and rubber glazing strips, gaskets & sealing profiles compatible with

PALSUN and approved by PALARM or its distributors.

EPDM rubber sealing strips and gaskets are the preferred choice, (though the use of neoprene is

permitted) due to a longer life expectancy and durability.

2. Use of sealants, adhesives and other sealing products not included in PALRAM approved list must

receive the Manufacturer's explicit consent, to be obtained through your local distributor.

3. Use of soft PVC gaskets and/or sealing strips is absolutely forbidden. It is detrimental and may cause

severe glazing deterioration and failure.

3. Use of materials that are not on the list, and/or which have not received the Manufacturer’s explicit

approval, may harm the glazing and void all warranties and any responsibility of the Manufacturer for

the performance of PALSUN.

Your local distributor can provide additional information, and forward materials for testing and

evaluation of their compatibility with the PALSUN sheets.

The recommended list of sealants, bonding materials and adhesives could be obtained from your local

PALRAM distributor on request.

:

13

Page 14

PALSUN® PALGARD™

Glazing Guide

13. Selection of the Appropriate PALSUN® Type for the Intended Application:

Most PALSUN family sheets are manufactured in thickness of 1.0 to 12 mm.

a. PALTUF: Sheets are intended exclusively for indoor use (transparent partitions, interior design

applications, industrial safety shields, and thermo-formed parts for indoors use).

May also be used in outdoors pavilions (exhibitions), or similar temporary structures.

Use of PALTUF sheets outdoors, for permanent applications, even in areas with mild UV radiation

(Northern Europe, USA, Canada and the like) is not recommended!

b. Thin PALSUN sheets: Frequently used in temporary structures, (exhibitions, pavilions etc.).

These are often used in conservatories or other horticultural / agricultural structures, where better fit &

finish are expected, along with economy and comparative low cost .

Thin PALSUN sheets are repeatedly used in thermo-forming applications, where forms generated render

them rigid and suitable for special requirements, in signs and other advertising elements.

c. PALSUN sheets for Permanent Glazing Applications:

The recommended installation method is inside a suitable supporting frame, made of metal (steel or

aluminum), wood or rigid PVC profiles. Glazing thickness is determined according to sash width of said

frame, the wind/snow loads dictated by environmental conditions and building codes existing at the

actual location of said structure.

Recommended Installation method is installing the glazing in fully “floating” position, clamped on its

four, three or two edges, without screws or bolts through the glazing as fasteners. Other possible options

could be observed further on.

d. Regular PALSUN Glazing: To be installed in windows, curtain-walls, upper-end skylights & sidelights

in flat, sloped, horizontal, vertical or curved positions, good-quality shades & canopies, covered walkways,

railway & bus stations and more.

e. PALSUN Plus Glazing: In outdoors applications where the glazing would be subjected to direct

sunlight exposure from both sides (Sound barriers, Safety walls in sports arenas and the like).

f. PALSUN FR: where higher level of fire resistance is required.

g. PALGARD (regular, Plus & FR): Similar to PALSUN but where higher abrasion resistance & heavy-duty

cleaning and graffiti removal are required. A restriction: Only for flat installation!!!

h. Colors, Shades & Light Transmission: Selected according to architectural & practical needs

in standard or specially prepared variations.

14

Page 15

PALSUN® PALGARD™

Glazing Guide

PART B.

INSTALLATION INSTRUCTIONS, DIRECTIVES & RECOMMENDATIONS

CLARIFICATION: Wherever PALSUN is mentioned - PALGARD is included, unless noted otherwise.

1. Flat PALSUN® & PALGARD™ Glazing Installation on Supporting Frames.

Supporting Methods & Appropriate Load Tables:

a. PALSUN glazing should be installed, similarly to glass, in or on a supporting framework, on which the

glazing would be supported on all its edges (4 sides clamped), on 3 sides or on two long edges (2 sides

clamped), with or without a glazing groove, and clamped to that frame with glazing bars or profiles.

b. PALSUN glazing could be installed, similarly to glass, in the “wet” or “dry” methods:

Basic installation procedures follow. Other variations of said methods are also used.

1) “WET” METHOD: A compatible polymeric putty is applied along the window sash, on all its perimeter

as a base for laying the PALSUN glazing, exactly like it is done in “wet” glass installation.. Then the glazing

is laid in place, leaving enough thermal expansion gaps around it. Glazing bars are then covered with

same putty and installed on the perimeter, fastened to the window frame, clamping the glazing. Finally,

compatible elastomeric sealing compound, (like silicone) is applied all around, inside and out, to assure

window’s impermeability.

Alternate version of that method uses “dry” rubber strips or spacers instead of putty, both in the sash and

on the glazing bar, as base layers, with final silicone application around glazing edges.

“Wet” method is used in wood or metal frames, in regular windows or on heavy-duty framing such as

sound barriers. The method is now less popular, and the “dry” method gets to be preferred.

Figure 2. Typical Limited Size PALSUN “Wet”

Glazing with Rubber Strip Spacers, Glazing Clamp

& Peripheral Silicone Sealing Inside and Out.

Illustration Depicts Sheet Steel Framing. (Right)

Size is limited due to limited sash depth.

Figure 3. Typical Extended Size PALSUN “Wet” Glazing,

with Rubber, or XPE Strip Spacers both sides, Glazing

Clamp & external Peripheral Silicone Sealing. Illustration

Depicts Heavy-Duty Steel Frame, Suitable for Large Public

Structures (stadiums, sports arenas, Sound Barriers). (Right)

Extended Glazing Size due to wide Engagement Dept & High

Frame Rigidity .

Figure 1. Typical Limited Size PALSUN

“Wet” Glazing with Putty, Glazing Clamp &

Peripheral Silicone Sealing Inside and Out.

Illustration Depicts Wood Frami ng. (Left)

Size is limited due to limited sash depth.

15

Page 16

PALSUN® PALGARD™

g

p

g

Glazing Guide

2) “DRY” METHOD: Uses only “mechanical” means, such as

various profiles & bars, of wood, PVC but mainly metal ones, including

simple flat, bent, RHS profiles in regular steel or aluminum, or

Figure 4. Typical Glazing

with Simple RHS Steel

Profiles & Designated

EPDM rubber Glazing Strips

specifically designated regular & stainless steel or aluminum profiles, with

specially made sealing strips & gaskets.

The method does not rely on chemical bonding or sealing of adhesive

pastes and compounds of any kind. Connections, fastening and sealing are

done by various types of fasteners or specially designed mechanical profiles with

details enabling connections of elements by special tongue &

groove design, material springiness and flexibility etc.

Impermeability & sealing are arrived at by careful design &

appropriate materials used, both of the rigid frame profiles

and resilient rubber gaskets of many types.

Professional design circles believe “Dry” method is “cleaner” &

more elegant in appearance, operates better (when designed

well), more durable and longer lasting than its “wet”

counterpart.

Figure 5. Typical Glazing with Combined

Wood & Aluminum Profiles and

nated EPDM rubber Glazing Strips

Desi

It also enables certain large-scale design options impossible or awkward

to execute in “wet” systems.

Basic idea of a “dry” glazing system, either vertical or sloped (“horizontal”)

is laying the glazing pane on a springy EPDM rubber or similar compatible

glazing strip attached to the supporting frame along the

window sash, usually on four sides, and clamp it with

appropriate glazing bars or profiles, also equipped with suitable

sealing strips, so those clamps tighten the glazing fully on all its

Figure 6. Typical Glazing with Heavy

Duty Steel & Aluminum Profiles &

Designated EPDM rubber Glazing

perimeter, with the external gaskets squeezed tight to the glazing,

sealing it against water & dirt infiltrating.

The system should be designed so that should some water succeed

to penetrate this first defense line they should accumulate and drain

downward through internal channels in the frame (second defense

line), and should not reach the internal glazing gaskets (last defense).

This is especially important in skylights & sloped roofing, where

rainwater stands more chance of accumulating & infiltrating.

Figure 7. Existing Curtain Wall Aluminum

& Glass System Optional for PALSUN

Glazin

of Limited Dimensions

Similar glazing systems exist for glass skylights & curtain-walls, all around

the world, and a few could also be used for limited thickness & spacing

solid polycarbonate glazing. The main requirement of any optional profile

series selected is deep enough window sash which enables at least15 to

20mm edge engagement depth plus 2-3mm gap for thermal expansion

each side.

Figure 8. Existing Aluminum & Glass Sloping

Skylight system O

of Limited Dimensions

tional for PALSUN Glazing

16

Page 17

PALSUN® PALGARD™

Glazing Guide

c. Flat Glazing Requirements according to Size, Support System & Wind/Snow Loads:

1) General Glazing Comments

:

a) Shape & Dimensions Ratio

A glazing pane can come in many shapes but most common is four-sided, generally rectangular. Ratio

between rectangle’s dimensions a (width) and b (length) is crucial in determining the load bearing ability

of a glazing pane (or any flat, load bearing element).

Best case is when a = b (a square) all four glazing supported sides carry the loads equally.

Glazing rigidity & strength are optimal in both directions.

A round glazing is actually even better as it got no distant corners.

As a:b ratio grows smaller, (say 1:1.5) the effect of the further supports on the glazing bearing ability is

reduced, until at a:b = 1:2 the shorter sides have only negligible influence on the glazing load capacity.

From that ratio down a glazing should be considered as supported only on its two long sides and local

supports at the ends reckoned only as added safety bonus.

b) Four, Three & Two Sides Clamped Glazing:

In reality a glazing isn’t just supported, but clamped tightly along its edges (harnessed). Clamping adds

significantly to glazing’s load capacity. A glazing harnessed on all four sides has the largest load capacity.

Each decrease in clamped sides number reduces load capacity of said glazing.

Designs requiring only three or two sides clamping would need to increase glazing thickness or reduce

allowed span.

:

c) General Load Tables Comments:

(1) Following PALSUN tables are based on a commonly accepted maximal glazing deflection, at the middle

of each span under a depicted load, of 1/20 or 5% of said span. This rate, accepted for plastic glazing,, does

not indicate imminent failure or break of glazing sheet.

(2) Plastics high flexibility and impact properties produce higher deflections than usual rates for glass &

other conventional building materials, however such deflection rate will cause no damage to the glazing

and it will return to its original position when loads are removed.

(3) Plastics high flexibility needs larger rabbet and engagement depth prepared for PALSUN glazing,

assuring positive seat, preventing glazing extraction due to shortening by undue deflection.

(4) Only tables 9 & 10 (flat glazing) suits both PALSUN & PALGARD. Table 11 (curved glazing) suites

PALSUN only as PALGARD should not be curved.

(5) Plastics higher thermal expansion rate requires larger allowance gap for the PALSUN glazing to assure

free thermal expansion, preventing distortion & possible buckling.

(6) Other glazing details (clamping, sealing etc.) are similar to those familiar from glass, with plastics

specific fitting points, as mentioned elsewhere in this guide.

(7) Data in tables is based on professional expertise, accumulated knowledge & experience, actual tests

made on typical glazing panels, similarity to other products’ behavior, interpolations & educated

estimates.

(8) PALSUN tables begin with 4mm (5/32”) thickness as lowest thickness recommended for permanent

quality glazing. 1 to 3mm sheets are suitable for signs, advertising, vacuum-forming, agricultural

structures, exhibitions pavilions etc.

(9) A PALSUN sheet may withstand even larger loads without buckling, but undue shortening by higher

deflection may cause a pullout when the glazing edges slip out of their Supporting frame.

(10) Additional internal supports, perpendicular to main rafters or supporting arches, can add more snowload capacity when required, while uplift wind-load remains the same. Such configuration suites heavy

snow-bound areas while uplift wind forces are moderate.

This option should be calculated separately, according to pertinent conditions.

17

Page 18

PALSUN® PALGARD™

Glazing Guide

Table 9. Wind/Snow Load Chart. Flat, 4 Sides Clamped, Single Panel, Single Span.

Max Recommended Span, on Center, amid Width Supports (Shorter glazing dimension),

under Progressive (light to heavy) Wind/Snow Loads, at Various Glazing Ratios:

Thickness

(Gauge)

mm in. kg/m2 psf mm in. mm in. mm in.

4

5

6

8

10

12

Wind/Snow

Uniform Loads

5

/32

13

/32

¼

5

/16

13

/16

½

50 10

80 15

120 25

150 30

200 40

50 10

80 15

120 25

150 30

200 40

250 50

50 10

100 20

150 30

200 40

250 50

300 60

50 10

80 15

120 25

150 30

200 40

250 50

300 60

50 10

100 20

150 30

200 40

250 50

300 60

50 10

100 20

150 30

200 40

250 50

300 60

Max. Support Span (Glazing Width) according to Ratio

a:b

Ratio 1:1 to 1:1.2 Ratio 1:1.2 to 1:1.5 Ratio 1:1.5 to 1:1.8

1200 48 1150 46 1050 42

1150 46 1050 42 1000 40

1080 43 1020 41 920 37

1020 41 980 39 880 35

980 39 880 35 800 32

1350 54 1280 51 1200 48

1280 51 1180 47 1100 44

1180 47 1100 44 1020 41

1120 45 1020 41 950 38

1020 41 950 38 880 35

950 38 880 35 800 32

1650 66 1580 63 1520 61

1480 59 1420 57 1350 54

1320 53 1250 50 1180 47

1200 48 1120 45 1020 41

1080 43 980 39 880 35

920 37 850 34 750 30

2050 81 1920 77 1780 71

1820 73 1750 70 1620 65

1750 70 1620 65 1480 59

1620 65 1480 59 1320 53

1480 59 1350 54 1180 47

1350 54 1200 40 1050 42

1220 41 1080 43 920 37

2050 81 2050 81 1950 78

2050 81 1920 77 1780 71

1900 76 1750 70 1650 66

1750 70 1580 63 1480 59

1580 63 1400 56 1320 53

1400 56 1220 41 1080 43

2050 81 2050 2050 81

2050 81 2050 81 2050 76

2050 81 1920 75 1880 69

1880 75 1720 69 1550 52

1720 69 1580 63 1400 56

1550 62 1420 57 1220 49

Notes:

1. For a glazing ratio smaller than 1:1.8 see “Table 10. Flat, 2 Sides Clamped PALSUN Load Chart”.

2. Glazing table begins with 4mm (5/32”)thickness as the lowest thickness recommended for permanent quality glazing.

Thinner sheets fit signs, advertising, vacuum-forming, agricultural structures, temporary pavilions etc.

18

Page 19

PALSUN® PALGARD™

Glazing Guide

Table 10. Wind/Snow Load Chart: Flat, 2 Sides Clamped, Single Panel, Single Span.

Max Recommended Span, on Center, between Width Supports, under Progressive Wind/Snow Loads:

Max. Support Distance (Glazing Width) (mm / in.)

Uniform Load

4 5 6 8 10 12

kg/m2 psf mm in. mm in. mm in. mm in. mm in. mm in.

50 10

80 16

100 20

120 25

150 30

200 40

250 50

300 60

780 31 980 39 1280 51 1800 71 1950 78 2050 81

680 27 820 33 1150 46 1680 66 1850 73 2050 81

620 25 700 28 1080 43 1550 61 1780 70 2020 80

580 23 620 25 980 39 1400 55 1700 67 1950 77

420 17 580 23 850 34 1180 47 1600 63 1780 70

NA NA 420 17 650 26 1050 42 1480 59 1550 61

NA NA NA NA 450 18 950 38 1280 51 1350 53

NA NA NA NA NA NA 820 33 1080 43 1220 48

Note:

Preceding General Glazing Comments & Table 9. notes above pertain also for this table.

PALSUN Type (mm)

Figure 9. Typical

ORT Technical College, Natanya, Israel.

Cold-Bent, Angled Frameless Ridge, 6mm Clear PALSUN.

PALGARD may be Used, but Bending at the Ridge will Damage Silica Coat along Bent Line.

Flat PALSUN Glazing, Skylight Canopy over Main Entrance.

19

Page 20

PALSUN® PALGARD™

Glazing Guide

2. Curved PALSUN® Installation on Supporting arches Supporting Methods & Appropriate Load

Tables.

Table 11. PALSUN® Wind/Snow Load Chart: Curved, 2 Sides Clamped(Metric version):

Sheet

Thickness

mm mm

4

5

6

8

10

12

Curvature

Radius

700

900

1100

1300

1500

1800

2000

2200

2800

4000

6000

900

1100

1300

1500

1800

2000

2200

2800

4000

6000

1100

1300

1500

1800

2000

2200

2800

4000

6000

1500

1800

2000

2200

2500

2800

4000

6000

1800

2200

2800

4000

6000

2200

2800

4000

6000

See notes page 23

Max. Recommended on Center Distance between Supporting Arches

according to Wind/Snow Loads Below (mm)

Uniform Wind/Snow Loads (kg/m2)

50 80 100 120 150 200 250 300

2050 2050 2050 2050 2050 1900 1750 1600

2050 2050 1850 1650 1500 1350 1200 1000

2050 1900 1750 1600 1450 1250 1050 900

1950 1800 1650 1480 1320 1180 1000 820

1800 1650 1500 1380 1200 1050 900 750

1650 1580 1420 1320 1120 950 820 700

1580 1480 1350 1250 1050 880 750 650

1500 1400 1300 1180 980 800 680 600

1350 1250 1180 1100 900 720 600 NA

1200 1050 950 850 780 650 450 NA

850 780 720 650 600 450 NA NA

2050 2050 2050 2050 2050 2050 1900 1750

2050 2050 2050 2050 2050 1900 1750 1600

2050 2050 2050 2050 1950 1750 1600 1450

2050 2050 2050 1950 1850 1700 1550 1400

2050 2050 1950 1850 1750 1550 1350 1150

2050 1950 1850 1750 1550 1350 1150 1050

1950 1850 1750 1650 1500 1300 1100 1000

1600 1500 1400 1300 1200 1050 900 750

1400 1300 1200 1100 1000 850 750 600

1200 1050 950 850 750 600 450 NA

2050 2050 2050 2050 2050 2000 1900 1750

2050 2050 2050 2050 2050 1900 1750 1600

2050 2050 2050 2050 1900 1750 1600 1450

2050 2050 2050 1950 1800 1650 1500 1350

2050 2050 1950 1850 1700 1550 1400 1250

2050 1950 1850 1750 1650 1500 1350 1200

1700 1600 1500 1400 1300 1150 1000 850

1600 1500 1400 1300 1150 1000 850 720

1480 1380 1300 1200 1080 920 780 620

2050 2050 2050 2050 2050 1900 1750 1600

2050 2050 2050 2050 1950 1800 1650 1500

2050 2050 2050 2000 1900 1750 1600 1450

2050 2050 2050 1950 1850 1700 1550 1400

2050 2050 1920 1850 1720 1580 1420 1280

2050 1950 1820 1720 1600 1450 1300 1150

1950 1820 1720 1620 1500 1350 1200 1000

1820 1680 1520 1380 1250 1100 950 780

2050 2050 2050 2050 2050 1950 1800 1650

2050 2050 2050 2050 2000 1850 1700 1550

2050 2050 2050 1950 1800 1750 1600 1450

2050 2050 2000 1900 1780 1620 1480 1320

2050 1920 1820 1720 1550 1400 1250 1100

2050 2050 2050 2050 2050 2050 1950 1800

2050 2050 2050 2050 2050 1950 1800 1650

2050 2050 2050 2050 1950 1800 1650 1480

2050 2050 2050 1950 1720 1580 1420 1280

20

Page 21

PALSUN® PALGARD™

Glazing Guide

Table 11a. PALSUN® Wind/Snow Load Chart: Curved, 2 Sides Clamped, (US Customary Version):

Sheet

Thickness

Curvature

Radius

in. mm in. ft

28 2 1/3

36 3

44 3 2/

52 4 1/3

4

59 5

71 6

5

/32

79 6 2/

87 7 1/

110 9 2/

158 13 1/

236 20

36 3

44 3 2/

52 4 1/3

59 5

13

/64

5

71 6

79 6 2/

87 7 1/

110 9 2/

158 13 1/

236 20

44 3 2/

52 4 1/3

59 5

6

71 6

79 6 2/

1

/4

87 7 1/

110 9 2/

158 13 1/

236 20

59 5

71 6

79 6 2/

8

87 7 1/

98 8 2/

5

/16

110 9 2/

158 13 1/

236 20

71 6

13

/32

10

87 7 1/

110 9 2/

158 13 1/

236 20

87 7 1/

12

110 9 2/

158 13 1/

1

/2

236 20

See notes next page

Max. Recommended on Center Distance between Supporting Arches

according to Wind/Snow Loads Below (in.)

Uniform Wind/Snow Loads (psf)

10 15 20 25 30 40 50 60

81 81 81 81 81 75 69 63

81 81 73 65 59 53 48 40

81 75 69 63 57 50 42 36

3

77 71 65 58 52 47 40 36

71 65 59 54 48 42 36 36

65 62 56 52 45 38 33 28

62 58 53 50 42 35 30 26

3

59 55 51 47 39 32 27 24

3

53 50 47 44 36 29 24 NA

3

48 42 38 34 31 26 18 NA

6

34 31 29 26 24 18 NA NA

81 81 81 81 81 81 75 69

81 81 81 81 81 75 69 63

3

81 81 81 81 77 69 63 57

81 81 81 77 73 67 61 55

81 81 77 73 69 61 53 46

81 77 73 69 61 53 46 42

3

77 73 69 65 59 51 44 40

3

63 59 55 51 48 42 36 30

3

55 51 48 44 40 34 30 20

6

48 42 38 34 30 20 450 NA

81 81 81 81 81 79 75 69

3

81 81 81 81 81 75 69 63

81 81 81 81 75 69 63 57

81 81 81 77 71 65 59 53

81 81 77 73 67 61 55 50

3

81 77 73 69 65 59 53 48

3

67 63 59 55 51 46 40 34

3

63 59 55 51 46 40 34 29

6

58 54 51 48 43 37 31 21

81 81 81 81 81 75 69 63

81 81 81 81 77 71 65 59

81 81 81 79 75 69 63 57

3

81 81 81 77 73 67 61 55

3

81 81 76 73 68 62 56 50

3

81 77 72 68 63 57 51 46

3

77 72 68 64 59 53 48 40

6

72 66 60 54 50 44 38 31

81 81 81 81 81 77 71 65

81 81 81 81 79 73 67 61

3

81 81 81 77 71 69 63 57

3

81 81 79 75 70 64 58 52

6

81 76 72 68 61 55 50 44

81 81 81 81 81 81 77 71

3

81 81 81 81 81 77 71 65

3

81 81 81 81 77 71 65 58

6

81 81 81 77 68 62 56 51

21

Page 22

PALSUN® PALGARD™

Glazing Guide

Notes for Tables 11 & 11a:

1. PALSUN glazing sheets should be installed with their curved edges sustained on the supporting arches, with

15 to 25mm (

2. Thin sheets (up to 6mm or ¼”) could be bent as relatively short glazing panels, 2.00 to 3.00m at 1000-1220mm

width (6’7” to10’ length, at 40” to 48” width). Thick sheets of 8mm (5/16”) and up could be cold curved only as

special order long panels (4.00 to 7.00m or 13’2” to 23’ long) particularly when installed in full 2050mm (6’9”)

width or close.

3. Supporting arches & clamps should withstand total maximum permitted loads without difficulty.

4. Spans less than 500mm (20”) are generally impractical for such installation method.

5. Lowest radius value depicted is minimal permitted radius for that specific PALSUN sheet.

6. Depicted spans are suitable for most common stationary structures, under pressure or uplift loads . Special

structures, like mobile pool covers, may use wider spans, subject to preceding approval.

5

/8”-1”) edge engagement, depends on span, plus 2-3mm (3/32”- 1/8”) thermal expansion gap.

Figure 10. Typical Curved PALSUN Glazing, Skylight Canopy over Main

Entrance to Office Building & Shopping Arcade.

Cold-Curved, 6mm Clear PALSUN.

PALGARD Should not be Used as Curving would Damage the Silica

Coat.

22

Page 23

PALSUN® PALGARD™

Glazing Guide

3. General Indications for Curved PALSUN Installation:

a. Clamping: Curved PALSUN glazing should be installed almost identically to flat installation, similarly to

glass, in or on an arched supporting framework, on which the glazing would be supported, adapted &

clamped on two or four of its edges, with or without a glazing groove. The clamps (glazing bars or

profiles) should also be curved by simple hand pressure (in simple, shallow curves) or by designated rollforming in deep curves and/or complex profiles.

b. “Wet” or “Dry”?: PALSUN curved glazing could be installed similarly to flat glass or PALSUN, in “wet”

or “dry” methods. Basic installation procedures and details are shown on the flat PALSUN installation

previously depicted. Variations of said methods are also used.

c. Stronger when Curved!: PALSUN, like any sheet shaped material, gets stronger & more rigid when it is

curved. Strength and rigidity increase as the PALSUN sheet curve (“radius”) nears the minimal permitted

bending radius (deepest allowed curve), as can be observed in the curved glazing load table.

d. Minimal Curving Radius: Essentially, PALSUN minimal permitted curving radius is calculated as 175

times the sheet thickness. This rate was arrived at after a careful testing, which showed that at this

minimal radius the sheet isn’t damaged and still retains its typical properties. A sheet could be bent to an

even smaller radius, but undue internal stresses created by excess curving would lead to crazing, fracture

& eventual failure.

e. “Cold” Vs. Thermal Curving”: All the above refers to “cold” curving, i.e. forming the sheet at average

ambient temperature by forcing it to a curved shape relying on polycarbonate’s natural flexural

properties.

PALSUN glazing could be curved to an even smaller radius by a thermo-forming process without any illeffects of excess stresses. A costly procedure limited by size & availability of required thermoforming

equipment.

f. Spring Back: Cold curved PALSUN is springy, pushing back trying to retain its original shape. The

thicker and shorter the sheet the more difficult it is to bend it and keep that shape. This must be taken

into consideration both at the design and at execution stages. Proper structural framework and glazing

bars should be selected to withstand the loads.

Figure 11. Schematic

Sketch of PALSUN

Glazed Dome Skylight

Figure 12. Diagonal Look

through Curved PALSUN

Vaulted Walkway

23

Page 24

PALSUN® PALGARD™

Glazing Guide

4. Directives, Instructions & recommendations for Flat & Curved PALSUN® Glazing:

a. Rabbet Depth:

Depth prepared for glazing

engagement (e) plus half of the

expansion gap (

depth prepared in the frame for

glazing installation.

Rabbet depth grows as glazing

width grows.

Table 12 below depicts edge

engagement (e) dimensions

respectively to glazing width.

PALSUN edge engagement is larger

than glass because of its higher

flexibility & deflection, which might

generate glazing fallout through

shortening due to excess deflection.

b. Thermal Expansion Gap:

Next Table 13 exhibits

recommended gap for thermal

expansion according to glazing pane

length. Half that gap is to be

provided all around the glazing but

it really is nil at the bottom and full

at the top. Gap required is also wider

due to polycarbonate higher thermal

expansion coefficient.

Table 12. PALSUN Glazing Rabbet Depth Width according to Width & Thickness of PALSUN Glazing

(a) PALSUN Glazing width (t) Glazing Thickness (e+

mm in. mm in. mm in.

Up to 700 Up to 28 3

701 - 900 28 – 35 4

901 – 1100 35 – 43 5

1101 – 1300 43 – 51 6

1301 – 1500 51 – 59 8

1501 – 1700 59 – 67 10

1701 - 2000 67 - 79 12

Table 13. Thermal Expansion Gap for PALSUN Glazing according to Length

PALSUN Glazing

Length (b)

Expansion Gap (f)

Note: As a rule of thumb, an inclusive gap of 1mm is required for every 300-400mm of sheet length. Half this gap should

be left at both width sides, while a whole gap provided at top length side and nil at the bottom.

1

/2f). It is the whole

Correct Term’s Name

Rabbet (not Rebate)

Engagement

Figure 13. Schematic Details

of PALSUN Glazing inside A

Supporting Frame

k. e + ½ f = Rabbet Depth

1

/2 f) Rabbet Depth

1

/8

5

/32

13

/64

15 - 20

39

/64 – 13/16

¼

5

/16

13

/32

20 - 30

13

/16 – 1¼

½

mm 300-700 701-1000 1001-1300 1301-1700 1701-2000 2001-2500 2501-3000

ft. 1-2.35 2.35-3.35 3.35-4.35 4.35-5.70 5.7-6.70 6.70-8.20 8.20-10

mm 2 3 4 5 6 7 8

in.

5

/64

1

/8

5

/32

13

/64

¼

9

/32

5

/16

24

Page 25

PALSUN® PALGARD™

g

(

)

Glazing Guide

c. PALSUN® Installation in a Partial Frame:

PALSUN could be installed clamped on three sides and frameless

on the fourth (generally top), and even clamped on two sides only.

This situation requires a thicker, more rigid glazing pane than that

installed in a full frame. Rate of thickness increase is to be

determined along 2 parameters: glazing size (particularly width)

and maximal anticipated wind-loads. Such a method is usually

used in vertical installations, many times in sound barriers.

d. Fastening PALSUN® with Bolts, Screws or Rivets:

A possible option, even if not truly recommended.

Installed in or on a supporting frame with bolts/screws through

pre-drilled oversize holes in the PALSUN sheet.

1) Holes would be 2mm larger in diameter than bolt or screw

used, to enable thermal expansion.

2) Each bolt/screw would be equipped with a

metal (stainless/aluminum) washer, with a compatible

shaped soft EPDM gasket under the bolt head, on top side of

the glazing, to distribute the bolt’s pressure and pad the

fastener’s surrounding. (fig.15)

3) Tightening should be controlled & carefully executed, avoiding

excess local pressure on the glazing and distortion of the

gasket. Under no circumstances would an impact wrench be

used for the job.

4) A minimal distance of 2.5 times bolt/screw diameter, from glazing

edge to nearest hole edge, would be maintained, never less than

12mm.

5) Bolt fastening with pressure distribution clamping

bars, with compatible EPDM strip should be

preferred over fastening with separate oversize

washers. (Fig.16)

6) Fastening with bolts/screws would be selected,

mostly, in projects where sheer strength of

fastening has an obvious preference over

appearance, or when full length clamping profiles

may interfere with proper rainwater drainage

(shallow angled overhead skylights or roof glazing.

Fig. 17).

Ø30-40mm rigid

Figure 14. Typical

Partial Frame, 3

Sides Clamped

Glazin

Figure 15. Basic Screw Fastening with

Separate washers. Under the Glazing a

Thin EPDM Strip Padding

Figure 16. Typical Heavy-Duty Pressure

Distributing Bar Clamped Glazing, with

Bolts Fastening, in a Sound Barrier

in a Sound

Figure 17. High-End, Heavy-Duty Aluminum

Sub-Frame with Separate Bolts & Washers

Fastened Glazing in a Variable Slope, Very

Shallow in Parts, New Olympic Stadium Roof,

Athens 2004

Left

25

Page 26

PALSUN® PALGARD™

b

b

b

Glazing Guide

e. Indications for Design & Execution of PALSUN Glazing Supporting Frames:

1) PALSUN safety Glazing as Glass Replacement in Existing Window Frames

PALSUN glazing could be installed in conventional residential housing wood, steel or aluminum doors &

windows, or subdivided ones used in schools and educational facilities, replacing fragile and unsafe glass

panes. Old-fashioned fenestration it is usually glazed by the “wet” method, with sealing paste &

compatible putty, while recent types are almost certain to be of the “dry” type. Limited rabbet depth

suffices for the relatively small sized conventional windows.

a

Figure 18a,b,c. PALSUN “Wet” Glazing in Conventional

Wooden Windows, New or Refurbishe d.

:

c

a

a

c

Figure 19a,b. PALSUN “Wet” Glazing in Conventional

Steel Windows, in Light & Heavy Duty Versions, New

or Refurbished.

Figure 20a,b,c. “Dry” Glazing in Conventional

Aluminum Systems, New or Refurbished:

a. Hinged Window

b. Fixed Window

c. Designated Blast/Gas Security Window

26

Page 27

PALSUN® PALGARD™

C

k

k

p

G

H

Glazing Guide

2) PALSUN Safety Glazing in See-Through Sound Barriers:

Supporting frames in such barriers, erected along noisy main roads & highways, around and inside sports

arenas & stadiums, or near similar boisterous facilities, are mostly heavy duty structures, designed to

withstand possible brushing with road vehicles or unruly crowds. Such framework is

mostly made of heavy weather protected steel elements, with suitable detailing as mentioned above.

A

Figure 21A. Top, Bottom & Side

Cross Section Detail (A), RHS

-Support & Clamp + Spacer

Bac

Legend:

W (Net Glazing Width) < 2050mm

(Base Wall Height) By Design

h

1

(Net Glazing Length) < 6000mm

h

2

1) Concrete Base Wall

2) Vertical Structural Post

3) Noise Source Side

4) Noise Reduction Side

5) Top Level Support & Clamp

6) Bottom Level Support & Clamp

7) PALSUN Acoustic Glazing

8) PALRAM EPDM Dry Glazing Strip

9) Fastening Bolt & Nut (or SDS Screw)

10A) EPDM (or suitable other) Spacer

10F) Bottom Bent Steel Structural Sill.

11A) Plastic Stopper for Fastener Hole.

11F) EPDM Bottom Glazing Spacer

12B) Indicated Socket Entry for Fastening.

12F) Steel Insert in Concrete Base Wall.

B

Figure 21B. Vertical Mid-Post

Cross Section Detail (B), RHS

-Support & Clamp

Bac

Figure 21C. Vertical Mid-Post Cross

Section Detail (B), RHS Back-Support

& Fabricated Clam

D

Figure 21D. Vertical Fabricated Mid

-Post Cross Section Detail (B), with

Bolted-On Back-Clamps.

E

F

I

Figure 21G. Vertical INP/HEB

Mid-Post, Cross Section Detail (B),

with Bolted-On Clamp.

Figure 21H,I. Typical Façade Segment &

Vertical Cross Section of a See-Through

PALSUN Glazed Acoustic Barrier

27

Figure 21E,F. Top, Bottom (& Side)

Cross Section Detail (A), Fabricated

Supports & Bolted-On Back Clamps

Page 28

PALSUN® PALGARD™

b

b

b

Glazing Guide

3) PALSUN Glazing in curtain walls, skylights & sidelights:

Supporting Framework Options:

a) Wood: Heavy Duty Rectangular section beams, girders,

joists & rafters of all sizes & wood types, with appropriate

EPDM glazing strips and durable, weather resistant finish.

Typical glazing bar and support beam section width

about 60 mm.

Section height as required by design.

b) Plain steel or aluminum: Heavy-duty standard

elements such as RHS or L, H & U professional profiles of

varied shapes, size & thickness.

Typical glazing bar and support beam section width

about 60 mm. Section height as required by design.

Equipped with appropriate EPDM glazing strips and

durable, weather resistant finish.

a

Figure 22a,b. Heavy-Duty Wood Frame

& PALSUN Glazing.

a. Side-Support with Side Spacer.

b. Mid-Support with Glazing both sides

a

c) Hybrid Systems: Joint efforts by mixed frame components as steel or wood support structure &

assigned aluminum glazing profile. Internal support structure gets 60mm wide EPDM glazing strip

bonded to its front and the external clamping bars get designated small shaped EPDM sealing strips

Figure 23a,b. Heavy-Duty Metal Frame

& PALSUN Glazing.

a. Side-Support with Side Spacer.

b. Mid-Support with Glazing both sides

Aluminum

a

Wood

Figure 24a,b. Hybrid System Frame

Components & PALSUN Glazing.

a. Wood Support & Aluminum Clamp.

b. Steel Support & Aluminum Clamp.

28

Page 29

PALSUN® PALGARD™

b

Glazing Guide

d) Existing Glass Oriented Curtain-Wall Profile Systems in PALSUN Glazing:

Existing high-end glass oriented designated systems for public or office buildings, for

up to 1200mm, due to limited (up to 20mm) rabbet depth. Suitable profile series, mostly in aluminum but

some in stainless steel, are available from many suppliers all over the world. Only systems of 55mm

profile width and more, with at least 20mm rabbet depth, should be considered.

Depicted below are two typical aluminum curtain wall systems, from two separate sources, with identical

width and similar details. There are differences though in rabbet depth as the German system (a) gets

better thermal insulation (thermal bridge), as it is intended for a much colder climate.

a

Figure 25a,b. Existing Curtain Wall/Skylight

Aluminum Systems & PALSUN Glazing.

a. A Typical System of German Origin.

b. A Typical System of Israeli Origin.

Existing heavier duty systems, upgraded versions of the formerly mentioned series, are wider by design

(about 70mm), but their rabbet depth is enlarged only by 3-4mm, so the wider profiles can sustain wider

PALSUN glazing but less than might be anticipated by the larger profiles.

e) Existing Multi-Wall Oriented Systems:

Multi-wall oriented aluminum profile systems prepared

for improved quality flat polycarbonate multi-wall sheets,

may suit PALSUN glazing too. However these systems offer

relatively light gauge profiles. They could be used only in

light to medium duty requirements, as they need

additional supportive sub-structure under or behind to

withstand higher loads.

These systems should not be selected for use in

2

installations with loads higher than 150kg/m

or where

glazing thicker than 6mm is required. The profiles would

warp under the heavy loads or by the forceful pressure of

the heavy glazing edges.

In most cases these systems suit both vertical or sloped (leveled)

installations, as a part of the existing profiles is prepared with

internal drainage channels and even condensation water collecting

Figure 26. Existing Flat Multi-Wall Aluminum

Profile Glazing System with Steel Supporting

Sub-Structure

gutters.

PALSUN glazing of

Steel Supporting

Sub-Structure

29

Page 30

PALSUN® PALGARD™

A

Glazing Guide

e) Specialized Systems for Polycarbonate Glazing:

Particularly designated profile systems for use with solid

polycarbonate glazing are produced by (or for) contractors

specializing in polycarbonate glazed structures. These series offer

deeper rabbet depth and are produced in heavy gauge suitable

for the thickest PALSUN sheet and relatively heavy loads, intended

for specially shaped, high-end public & office buildings. Such

profiles are not freely available for purchase, and could be

acquired only as parts of complete projects. Such profiles are

usually more elaborate and may offer additional properties as

external condensed vapor drainage systems for skylights as well as

internal channeling solutions for rainwater infiltration.

Profile illustrated on Fig. 27 can be used either as vertical post or as

overhead skylight support girder, as it has internal channeling for

infiltrated rainwater.

Profiles fitted with external condensation water drainage systems are more suitable & efficient for

overhead skylights, as they provide extra protection from cold drippings from above.

Any of these options would require specific

accessories like designated EPDM glazing profiles of

specific shapes to fit the intended purposes and

profile, along with the more common compatible

silicone sealant, self-adhesive sealing & spacing strips

etc. required for these types of structures.

Figure 27. Typical Heavy-Duty Aluminum

Profile of a Specialized Glazing System,

Generally meant for Vertical Installation.

Figure 28. Heavy-Duty Aluminum Profile for

Specialized Glazing Systems, Equipped

with External Condensation Channeling.

Figure 29. Heavy-Duty PALSUN Glazing & Specialized

luminum System with External Condensation Channeling

on a Vaulted Skylight over a Shopping Mall.

30

Page 31

PALSUN® PALGARD™

b

b

Glazing Guide

5. Principles of Planning & Engineering Design with PALSUN® Glazing:

a. Color, Tint, Light & Heat Transmission:

Almost any color & tint, in any rate of light transmission and thickness (up to 12mm) could be obtained ,

subject to minimal quantity order. In relatively small quantities only standard colors &

light-transmission rates could be supplied, subject to production runs availability & date.

b. Standard & Custom Sheet Dimensions:

Normal PALSUN sheets could be obtained in 3 standard dimension (in mm): 1250 x 2050,

1220 x 2440, 2050 x 3050. in relatively small projects these are the basic sizes the glazing panes should

be derived from, preferably with minimal or no waste.

In large scale PALSUN projects it is possible to order sheets of at any required dimensions, up to

2050mm width. Any length up to 12.00m could be obtained. However due to polycarbonate higher

thermal expansion rate we recommend the use of sheets no longer than 6.50 to 7.00m.

c. Forming PALSUN Glazing:

Important Note: This specific paragraph refers only to PALSUN. Currently available PALGARD sheets

should not be bent or curved, as these acts may break or damage the abrasion resistant silica coat!

1) Cold Forming:

a) Unlike glass, PALSUN glazing could be formed to a desired shape quite easily, by “Cold Curving”,

relying on PALSUN glazing’s natural flexibility, subject to minimal bending radius suitable to the specific

sheet thickness, or by “Linear Cold Bending”, using a mechanical “Brake Press” bending machine, similar

to the one used to bend flat sheet-metal.

a

Figure 31 a,b. Cold Bent PALSUN Glazing

a. Linear Cold Bending Process (Top)

b. Linear Cold Bent Glazing in a Skylight

(Bottom)

a

Figure 30 a,b. Cold Curved PALSUN Glazing

a. Cold Curving Process (Top)

b. Cold Curved Glazing in Skylights (Bottom)

31

Page 32

PALSUN® PALGARD™

Glazing Guide

b) Linear cold bending could be used for forming a frameless ridge in a two-way sloped skylight,

or similar project getting clean one piece glazing running both ways. (Fig. 9, Fig.31a,b.)

c) It should be noted that linear cold bending requires knowledge & expertise in processing plastics, while

cold curving is relatively simple and easier to perform with less experienced workers.

d) Detailed “Cold Curving” & “Linear Cold Bending” processing information is available at PALSUN

Fabrication chapter.

2) Thermoforming:

a) PALSUN sheets can be quite easily fabricated by thermal processing. There is a special PALSUN type

designated specifically for thermal processing, equipped with special heat resistant masking films, able

to withstand the temperatures required for polycarbonate processing. This sheet requires no special

preliminary treatment and can be fabricated with its protective masks on, which protects

the prepared sheet from damage during further handling & installation.

b) A regular PALSUN sheet requires, in most cases, peeling-off the masking on both sides prior to a drying

process in a special oven to get rid of the moisture content in the sheet. A thermoforming process

without pre-drying would lead to bubbles and internal irregularities in the sheet created by

the evaporation of the water content under the over 100

o

C temperatures required by the process.

c) The simplest fabrication, requiring no pre-drying, is

“Linear Thermal Bending”. In this process the sheet is

heated from one or both sides (depending on sheet

thickness) by linear electric heating elements, until the

bending area reaches the proper temperature (110-

o

C)and softens. Then the sheet is bent along the

120

desired line to the required angle and left to cool down.

It is preferable to perform such bending in a special

bending device, enabling a clean and accurate bending

in direction, measurement and bending angle. (Fig. 32

right)

do not place the sheet too close to the heating

elements, for fear of scorching and meltdown.

It is possible to perform a few sequential linear bends

on the same sheet to achieve special angles & shapes.

Figure 32. Hot Line Bending Device

for PALSUN Straight-line Bending.

d) Another thermoforming method enables bending a flat PALSUN sheet into an arched form smaller in

radius than possibly allowed by “cold curving”.

The sheet is “baked” inside a suitable oven to the required temperature until it softens, then taken out

and placed, quickly, over a prepared mold where it “drapes” down on the round mold, with possible

assistance of careful hand pressure pushing both ends towards the mold, and held there for a few

seconds until it cools a little and retains its desired shape.

A variation of that method uses an oven large enough to contain both the necessary PALSUN sheet and

the suitable heat resistant round mold with wheels. The sheet is placed on top of said mold and pushed

into the oven, where it ”bakes” and eventually drapes down due to its own weight. After a fixed period,

arrived at by experience, it is taken out, given last finishing touches by hand and left to cool down.

32

Page 33

PALSUN® PALGARD™

Glazing Guide

e) Other PALSUN thermoforming procedure use various

methods, sometimes integrated with each other, based

on heating and forming in molds under mechanical

pressure, compressed air or suction (vacuum-forming).

They enable creating 3 dimensional glazing panels,

much tougher and rigid than their basic thickness may

suggest. It enables preparation of skylighting domes,

canopies, roof or wall glazing panels of thinner material

at lower cost

d. Basic Guidelines for Correct Design & Application of PALSUN Glazing:

1) General Comments:

a) PALSUN at all variations is an excellent glazing material for different applications of glazing and lighttransmitting cladding. Careful design and implementation according to Manufacturer directives,

recommendations and installation instructions would lead to many years of satisfying service.

Disregard of Manufacturer design directives & recommendations and careless or indifferent follow-up of

the installation instructions may lead to faulty function, failings & damages. Breakage and eventual

failure, and a substantial reduction in glazing endurance.

b) PALRAM Tech-Support department will supply the designers with state-of-the art professional

assistance and consultation during all stages of design and preparation of necessary specifications for

tenders, and further direct & instruct said designers, project managers and supervisors how to oversee

the main & sub-contractor’s form and quality of execution.

2) Basics for Design:

Figure 33. Small Household Greenhouse Clad with

Thin-Walled Vacuum-Formed PALSUN panels

a) PALSUN Thickness: Sheet thickness would be determined according to glazing design, supporting

frame, glazing spans and local engineering codes for wind/snow loads, and/or from special man-made

reasons (crowd swarming, vandalism or violence), as appears elsewhere in this guide.

b) Prevention of Mechanical damage: Regular PALSUN is softer than glass, even if much more impact

resistant. PALSUN surface might be damaged from hits, mechanical strikes, abrasive and polishing

substances, cleaning tools & accessories, even those which do not chemically attack the polycarbonate

glazing.

We Recommend:

• PALGARD: Whenever such conditions are anticipated, and the design allows it, use PALGARD sheet

for better mechanical surface resistance.

• Obstacles for Vandals: When possible, prepare in the design a barrier or obstacle creating a gap

wide enough to prevent or interfere with a direct damaging contact between a probable assailant

and the glazing.

• Maintenance & Cleaning: Prepare in advance clear and easily recognizable signs with proper

instructions for the recommended Maintenance & Cleaning.

33

Page 34

PALSUN® PALGARD™

Glazing Guide

c) Control of Light & Heat Transmission: Colorless transparent PALSUN (Clear) or

tinted transparent sheets of all variations are handsome and aesthetic, transmit a lot of

light and it is possible to enjoy the scenery and clouds in the sky by day and the moon

and stars by night. lovely.