Page 1

www.palram.com

PALIGHT®

Flat Foamed PVC Sheet

CREATING

SOLUTIONS

Fabrication Guide

Page 2

PALIGHT®

1

Contents

Subject Page Subject Page

Introduction to PALIGHT 1 Adhesive Bonding of PALIGHT 4

Features and Benefits 1 Heat Bending 5

Cutting 1 Thermoforming 5

Drilling 1 Heating Cycle 5

Milling 1 Processing Temperatures 5

Routing 1 Painting 6

Thermal Expansion / Contraction 2 Graphic Applications 7

Screwing and Nailing 2 Direct Digital Printing 8

Installation 2 Laminating 8

Exterior Signs 3 Chemical Resistance 11

Tips on Sign Installations with Posts 3 PSDS Information (Replaces MSDS) 15

Significant Items to be Considered 3 Recommended Uses and Restrictions 15

Screwed Joints 3 Further Information 15

Riveted Joints 3 Physical Properties Table 15

Frame Fastening of Flat PALIGHT Sheets 3

Hanging Signs 3

Some Foam PVC products manufactured by others may contain lead.

PALIGHT is manufactured without lead or any other heavy metal.

Page 3

Fabrication Guide

Introduction to PALIGHT®

PALIGHT foamed PVC sheet is versatile, flexible, lightweight, and durable and is ideal for use digital or screen printing, fabrication,

and construction.

PALIGHT Premium Foam PVC exhibits the whitest color available and has been successfully tested and approved by digital flatbed

printer manufacturers worldwide. Printers and display buidlers will benefit from its consistent, smooth, and bright surface for

producing high quality displays.

PALIGHT is easily handled, cut and fabricated using conventional tools and equipment, and can be printed, painted or laminated.

Features and Benefits

Ease of Fabrication

Light Weight

Chemical Resistant

Superior Insulating Characteristics

Moisture Resistant

Great Flammability Ratings

Heavy Metal Free

Cutting

Circular Saws

PALIGHT material up to 3 mm thick can be cut with a knife or blade.

For PALIGHT sheets 3 mm and thicker, carbide-tipped, triple chip, ground type circular saws can be used.

The following settings are recommended:

Rake angle: 0 to 15

Clearance angle: 10 to 20

Cutting speed: 4,000 to 8,000 feet per minute

Feed: 70 to 90 feet per minute

Tooth pitch: 0.080” to 0.040”

Band Saws

High speed steel blades normally recommended for wood or plastic can be used for PALIGHT material utilizing the following

guidelines.

6 to 8 teeth per inch

Cutting speed: 3,000 to 5,000 feet per minute

Feed: up to 40 feet per minute

Saber Saws

Rough cut type blades ground for plastics can be used on PALIGHT sheets. Smooth metal-cutting blades are not

recommended.

Drilling

PALIGHT can be drilled with carbide-tipped bits using twist drills recommended for metals.

The following settings are recommended:

Point angle: between 90 to 110

Spiral angle: 30

Relief angle: 10

Cutting speed: 150 to 1,300 feet per minute

Feed rate: 0.01 to 0.02 inches per revolution

The minimum distance from the edge should be 2 times the hole diameter. In an effort to reduce heat build up during drilling of

thicker PALIGHT sheets, it may be necessary to periodically remove the drill bit from the PALIGHT material.

2

Page 4

PALIGHT®

Milling

PALIGHT can be milled by using standard milling machines of various types utilizing the following guidelines:

Relief angle: 5 to 10

Rake angle: -10 to 0

Cutting speed: 3,000 to 3,500 feet per minute

Cutting feed: 0.12 inches per revolution

Routing

PALIGHT material can be easily routed using multi-fluted carbide tools on standard woodworking

routers. Standard tools and machines can be utilized with no need to alter equipment. Adjust feed and

speed rates as needed to achieve the best edge finish on the PALIGHT parts.

Thermal Expansion / Contraction

As with most plastics, PALIGHT foamed PVC will expand and contract with an increase or reduction in temperature. This material

property is known as linear thermal expansion and contraction.

Since PALIGHT can be used in a wide variety of indoor and outdoor applications, linear thermal expansion and contraction may need

to be considered during the fabrication and installation of the material. It is important to take in to account the temperature at which

the PALIGHT material was fabricated as well as the temperature of the installation.

PALIGHT should not be used in applications or climatic conditions that exceed 140° F (ambient or surface temperature), at which

temperature the PALIGHT will soften and permanently deform. Dark colors are generally not recommended for outdoor use, as they

absorb heat and can easily exceed the maximum allowable temperature of 140° F.

PALIGHT Linear Expansion / Contraction

Quick Reference

Total Temp.

Change (∆)

20°F

40°F 0.071 0.089 0 .142 0. 178 4 mm 20 -28 in.

60°F 0 .107 0.13 3 0. 213 0.266 5 mm 31 - 43 in.

80°F 0 .142 0.17 8 0.284 0.355 6 mm 47 - 70 in.

100 °F 0. 178 0.222 0. 355 0.444

120 °F 0 .213 0.266 0.426 0.533

140 °F 0.249 0 . 311 0.497 0.622

Expansion / Contraction of Material at

Standard Lengths / Widths (in inches)

48 in. 60 in. 96 in. 120 in. 2 mm 6 - 8 in.

0.036 0.044 0.071 0.089 3 mm 12 -16 in.

Sheet Thickness Distance Between Fastening Points

Distances Between Fastening Points

for Screw and Rivet Joints

Screwing and Nailing

Any type of screw or nail can be used to fasten PALIGHT material. Power nailers and screw driving equipment are suggested. Inserting

the screw or nail in an elongated slot or an oversized hole is recommended so that the material can expand or contract if fluctuations

in temperature occur. For best results, use oversized washers or grommets in combination with screws.

Installation

PALIGHT is manufactured as an extruded foam PVC product with a directional grain running the entire length of the sheet. This

manufacturing process gives PALIGHT greater flexural strength in the direction of the extrusion. The grain of the PALIGHT should

always be installed perpendicular to the fastening point.

3

Page 5

Fabrication Guide

25mm

Exterior Signs

PALIGHT, when used correctly and with basic mechanical fixing methods is suitable for exterior use. Using PALIGHT can provide an

excellent weatherproof sign substrate ready for screen printing, painting, or vinyl graphics.

Tips on Sign Installations with Posts

The following tips have been compiled to be used as a general guide for fixing PALIGHT for a minimum amount of breakage.

Unusual designs falling outside the examples given may require certain modifications when considering PALIGHT.

Significant Items to be Considered

1. Bolt holes should always be larger than the bolt shaft to allow for thermal expansion and contraction, thus eliminating the possible

stress at bolt fixing points. The use of washers spread the compressive load when bolts/nuts are tightened. Be sure not to over

tighten as this will weaken the connection.

2. Split timber posts are the best to use because the PALIGHT is supported evenly on both sides. If steel or aluminum poles are

used, nylon bolts and washers give the best results. Be certain not

to skimp on fasteners for these types of installation. They should be

evenly spaced and away from the top and bottom edges.

Screwed Joints

For the attachment of PALIGHT, basically all known through bolts are

acceptable. For outdoor mounting, it is recommended that the bolt

shank be passed through the PALIGHT in prepared holes or suitably

dimensioned slots that leave adequate clearance between the bolt

shank and the PALIGHT.

The screws should only be tightened firmly enough to allow the

sheet to expand and contract in all directions without warping or

buckling. Tapping screws or screws with form fitted passage of the shank through the sheet should be avoided, but are allowed for

interior uses with predictably low temperature variations.

The diameter of the hole or length of the slot should not be less than 2.5 times the shank diameter of the fastener. Disc washers

should be used to cover the holes or to bridge the slots and they should be large enough to ensure adequate load distribution.

Precise centering of the screws in holes and slots is essential to permit free movement of the sheet in all directions.

Frame Fastening of Flat PALIGHT Sheets

PALIGHT can be fastened utilizing various different framing materials such as, but not limited to, wood, aluminum, steel and vinyl.

Besides the inherent rigidity of PALIGHT sheets, which is dependent on thickness, all possible exterior stresses, e.g., wind pressure,

etc., must be taken into consideration in frame fastening. For appropriate mechanical and elastic property values the data sheet

should be consulted. Dimensional changes due to thermal expansion (or contraction) must be taken into consideration by leaving

sufficient clearance between the sheet edge and the frame.

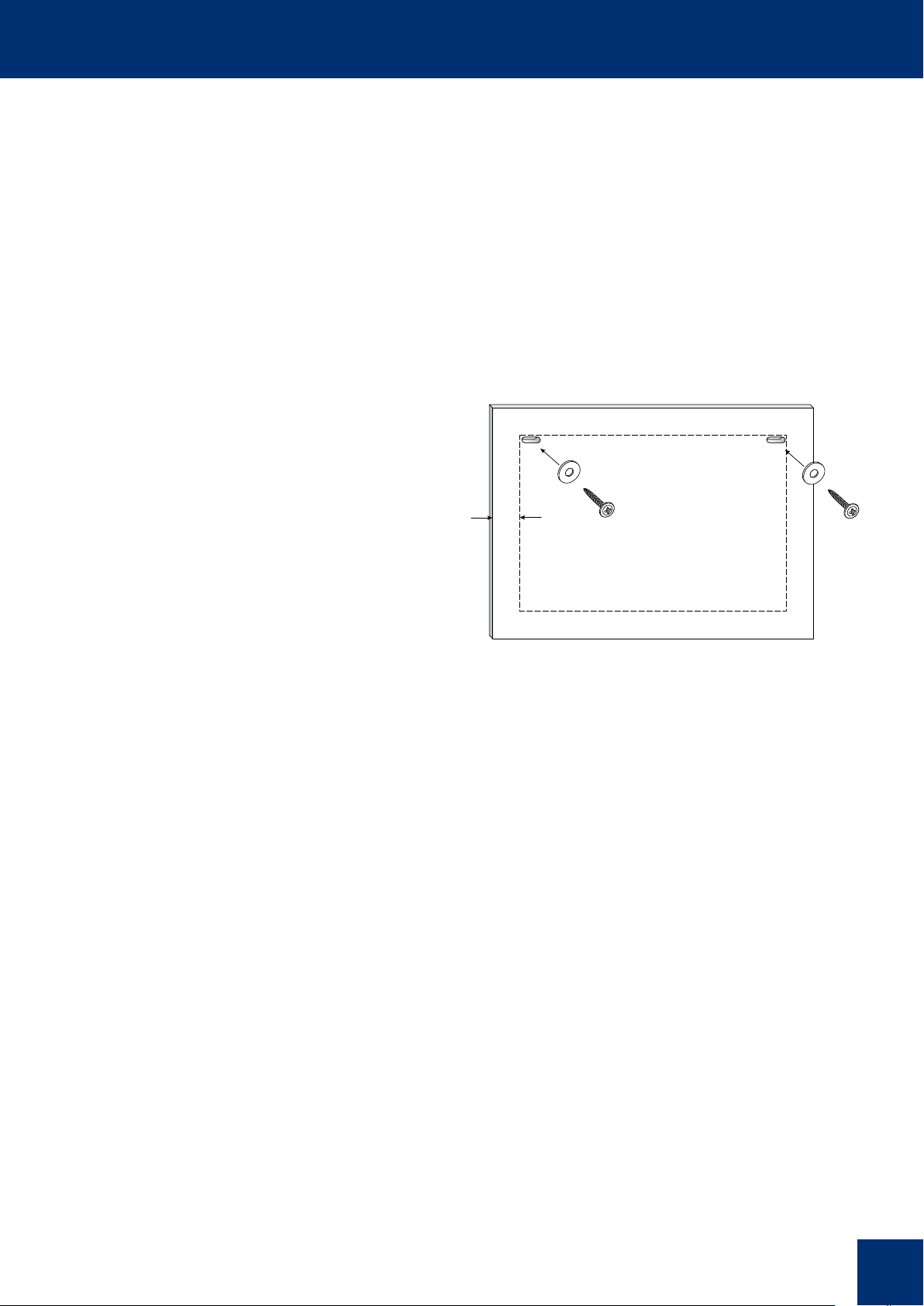

Hanging Signs

PALIGHT may be successfully used as interior hanging signs. As PALIGHT is an extruded sheet product, thin gauges or large hanging

signs may require additional support. The addition of an aluminum or thick walled plastic “C” channel across the top, bottom, or

around the perimeter may be needed to alleviate any tendencies to warp. When the additions of supporting channels are not

an option, the method illustrated below may also be used to help prevent bowing. Holes should be located 2-1/2 times material

thickness from edge.

4

Page 6

PALIGHT®

Adhesive Bonding of PALIGHT

General Information

PALIGHT material can readily be bonded to itself or other materials. Commercially available adhesives that are suitable for bonding

rigid PVC materials can be used for this purpose.

There are several considerations when choosing an adhesive:

1. The material to be bonded with PALIGHT

2. Strength required—structural vs. non-structural

3. Temperature range expected

4. Expansion/contraction

5. Ease of application methods, curing times

6. Cost effectiveness

7. Environmental and safety considerations—flammability, fumes, odors, etc.

Surface Preparation

In order to attain the optimum bond, the PALIGHT material surfaces to be bonded must be cleaned and degreased using a white

cloth soaked in isopropyl alchohol.

Selection of Adhesives

The selection of the proper adhesive for a project depends on the materials to be joined, as well as the end use and other considerations

mentioned previously. The following suggestions serve as general guidelines:

A. Bonding PALIGHT Material to PALIGHT Material

1. For edge bonding and joining parts made of PALIGHT material, use a PVC solvent such as (THF, MEK, cyclohexanone solvent

systems).

2. For bonding large areas: If using PVC solvent such as pipe cement, spread with notched trowel and work rapidly.

B. Bonding PALIGHT Material to Non-Porous Solid Material (such as PVC, other plastics or metal):

1. Contact adhesive with solvent:

a. Neoprene, nitrile, polyurethane or other synthetic rubber types.

b. Adhesive must be applied to both faces. Parallel beads of adhesive are often preferred because it allows evaporation of

solvent providing faster cure.

c. Use a slow setting adhesive, when bonding large areas. This allows for more time to properly install the panels prior to the

adhesive curing.

d. For bonding PALIGHT material to flexible PVC sheets, only plasticizer-resistant types of adhesives should be used.

C. Bonding PALIGHT Material to Porous Materials (such as paper, textiles, fabrics or wood).

1. Contact adhesive with solvent: Same systems as for non-porous materials.

2. Construction mastic, structural silicone adhesives.

Considerations such as expected temperature ranges (expansion/contraction), substrate and size of PALIGHT material panels should

be taken into consideration when deciding on a method of attachment.

Heat Bending

PALIGHT sheet material can be bent by using Calrods, radiant heaters, strip heaters or air-circulated ovens. Heat guns can also be used

on small areas. To ensure best results, a rheostat should be used to control heating of the PALIGHT so that the surface temperature

does not exceed 340 F. Heating PALIGHT material over 340 F can cause the surface to become rough and possibly discolor.

When using a metal contact strip heater, cover the heater strip with Teflon spray to prevent marking the PALIGHT. Different sizes of

rectangular heating bars can be used to produce bends of different radii. The larger the heated area of the PALIGHT, the larger the

radius that can be created. PALIGHT should be heated from both sides when the sheet is thicker than 4 mm. PALIGHT requires heating

at the rate of approximately 30 to 40 seconds per millimeter of thickness prior to bending.

To form tighter bends with smaller radii, use a small heated area on the upper surface (inside the bend) of the PALIGHT sheet and a

larger heated area on the bottom surface (on the outside of the bend) of the sheet. A minimum radius of twice the sheet thickness is

necessary to avoid breakage. When bending PALIGHT into an angle, typically the extension of the PALIGHT on either side of the angle

should be at least 20 times the thickness of the PALIGHT material.

For example, 6 mm (1/4”) PALIGHT would require the extension on each side to be 120 mm (4-3/4”) in order to avoid warping of the

material. For sides less than 20 times the material’s thickness, the entire sheet must be heated. Once the PALIGHT is bent, place it in a

fixture, such as a jig or clamp, to cool. Fans and/or compressed air will speed the cooling process.

5

Page 7

Fabrication Guide

Painting

The painting of PALIGHT is easily accomplished with paints known to have compatibility with rigid PVC.

Selection of a paint system for each use should be guided by the following:

1. Cost effectiveness

2. Ease of application.

3. Safety and Environmental — odor, solvent systems, toxicity, etc.

4. Convenience and speed — one part vs. two part, one coat vs. multiple coats.

5. Solvent and/or chemical resistance.

6. Outdoor weatherability & reflectance value.

(When painting PALIGHT with darker colors, for use in exterior applications, it is imperative that the paint has a light reflectance value of

55 or higher in order to avoid excessive heat absorbtion, which will result in distortion of the PALIGHT.)

I. Types of paints known compatible with PALIGHT sheet

A. Vinyls

B. Acrylic Lacquers

C. Two part polyurethanes

With PALIGHT, water-based latex systems and oil-based enamels generally do not have the good adherence properties of solvent based

systems. Although, the use of primers can improve the adherence of non-solvent based systems, the adherence is usually minimal.

II. Surface Preparation

A. The surface to be painted must remain dry, clean, and grease free.

B. Any surface scratches on PALIGHT will have a tendency to telegraph through the paint. In order to remove small scratches or

dents, rapidly fan a heat gun over the affected area. Care must be taken not to leave the hot air in one place for too long, as the

surface can be disformed.

C. It is highly recommended that the surface be cleaned with a rag moistened with isopropyl alcohol prior to painting.

III. Adhesion Test

A. The paint system chosen should always be tested for adequate adhesion. To test for adhesion, conduct the Cross Hatch Test after

the paint has dried for at least 24 hours.

1. Make eleven parallel cuts 1/16” apart with a razor blade knife. Make eleven similar cuts at 90 degrees to cross the first set.

2. Across the scored area apply a strip of strong tape, such as #610 Scotch tape. Press firmly.

3. Immediately remove the tape by pulling it back upon itself at 180 degrees in one rapid motion.

4. There shall be no removal of the paint squares to obtain a good adhesion rating.

IV. Application

A. Paints can usually be applied with a brush or roller, although conventional air spray equipment will provide a more consistent

appearance.

B. Consult paint manufacturer’s literature for recommended application technique and thinning requirements.

V. Drying

PALIGHT is a thermoplastic material. It should not be dried at temperatures in excess of 150° F. For drying and cure times, consult

paint manufacturer’s literature.

CAUTION: Due to the wide variety of paint products on the market, and the fact that some paints have been known to embrittle or

bow PALIGHT, testing is recommended for the initial use of any coating system before commercialization.

6

Page 8

PALIGHT®

Graphic Applications

PALIGHT performs superbly in a wide range of graphic applications including those involving paints, screen printing, digital flatbed

printing and vinyl films. PALIGHT can be used to create weather-resistant signs, displays or Point of Purchase (POP) materials. The

smooth PALIGHT surface is ideal for all types of graphics, and it requires little surface preparation or surface treatment.

General Considerations

To ensure best results for any graphic application using PALIGHT, consider the following factors that may affect the finish installation:

Environmental and safety concerns

Weathering

Chemical resistance

Ease of application

Cost-effectiveness

Hardness

Scratch resistance

Priming or multi-coat paint applications

TIP: Because of the wide range of products available, select paints carefully for each application. Initial testing of the selected

paint system is recommended before a production run.

Cleaning / Pretreating

Before screen printing or painting PALIGHT, the surface area should be cleaned with isopropyl alcohol and a clean white cloth.

Depending on the specific application, certain pre-treatments may also be required, as described in the following sections.

Screen Printing

With PALIGHT, the process of Screen Printing is easily accomplished. The surface of PALIGHT has a closed cell matte finish that makes

mistakes easily wipe off with the appropriate thinner.The use of Vinyl and Vinyl/acrylic, solvent based inks are very compatible with

PALIGHT.

The use of Water Based Screen Printing Inks has also had some success with PALIGHT material. Ink manufacturer directions must be

followed for good adhesion. Surface preparation of PALIGHT for screen printing is similar to those of painting.

A. The surface to be screen printed area must remain dry, clean, and grease free.

B. Any surface scratches on the PALIGHT will have a tendency to shadow through the ink.

In order to remove small scratches or dents, rapidly fan a heat gun over the affected area. Care must be taken not to leave the hot air

in one place for too long, as the surface can become deformed. It is highly recommended that the surface be cleaned with a white

cloth moistened with isopropyl alcohol prior to printing.

All screen printing inks should be tested in a manner which duplicates your printing process before initiating production. It is strongly

recommended to consult the appropriate ink manufacturer regarding any required ink additives such as catalyst for proper adhesion

and exterior usage. Screen Printing ink should air dry, rather than be heat dried. Temperatures in excess of 150° F may cause warping

or bowing of PALIGHT material.

Most UV Screen Printing Inks that are compatible with rigid PVC will work on PALIGHT. The most important factor to be considered

when using UV systems is the curing oven. Low wattage bulbs should be used to keep the temperature below 150° F. The use of UV

curing systems, which have variable speed conveyors, are considered the best type to use with PALIGHT.

Direct Digital Printing

Wide format and flatbed printers use various ink and ink curing technologies to allow high quality printing at relatively high speeds.

High quality digital printing depends on various factors:

Printer capabilities •

Ink technology and quality •

Type of printing substrate and quality•

Machine operator•

PALIGHT’S bright whiteness enables printers to print directly on it and achieve accurate, consistent color values and brightness.

The PALIGHT is Suitable for use with UV curing and solvent-based digital inks, and for IR drying when water-based inks are used.

PALIGHT retains superb whiteness, even after intense UV curing.

7

Page 9

Fabrication Guide

Protective Film Masking

The protective polyethylene film mask helps prevent surface abrasion and stains. However, removing the protective film may cause

an increase of static electric charge, which can affect ink coverage. Therefore, after peeling the film away from the sheet, the static

electricity that has built up in the sheet should be discharged using an ionized gun or a suitable device provided by the printer

manufacture.

Cleaning PALIGHT and Preparing for Printing

The surface should be clean before printing. Carefully inspect each panel to ensure there is no: dust, fingerprints, residue or other

problematic substances that may affect ink coverage or adhesion. If needed, the PALIGHT should be cleaned with a damp rag, or

with isopropyl alcohol.

Ink

PALIGHT is suitable for all types of inks: Aqueous, Solvent-Based, and UV-curable. In fact, PALIGHT has been tested and approved by

major printer OEM’s around the world, including AGFA, Gandinnovations, HP, Mutoh, Océ, and more. Consult the printer manual or

contact the printer manufacturer for recommendations and compatibility information.

Drying the ink

The two main drying technologies are:

IR (Infrared) – Long exposure to high temperature in the drying tunnel may cause distortions in the sheet.

UV (Ultraviolet) – UV levels must be adjusted according the printing speed and substrate. UV overexposure can cause discoloration

of both the ink and substrate.

Print Head Adjustment

The distance between the print head and the substrate can have a significant affect on print quality. Manufacturer specifications,

combined with and operator experience, should determine print head distance from the substrate.

The suggested starting distance should not be more than 2 mm from the print head to the substrate.

Laminating

PALIGHT is an ideal material for applications that require lamination. This section provides preparation information processes as well

as detailed instructions for the various types of lamination that can used with PALIGHT. Because prints are one of the most frequently

laminated materials, the sections that follow will generally refer the lamination of a print, although many other materials can be used.

Please Note! Since PALIGHT material may warp when heated above 150°F or when heated from one side only, it cannot be used in

any lamination process requiring heat.

Adhesion

For best results, the PALIGHT material should be cleaned with isopropyl alcohol prior to adhesion and allowed to dry thoroughly.

When laminating with pressure-sensitive adhesives, a force of 25–40 psi is required. Proper spacers are also critical. Because force must

be applied equally across the material, the top roll must move evenly from left to right while maintaining even contact between top

and bottom laminating rolls. To achieve even contact, “zero the nip,” then use spacer shims to preset the nip opening for a particular

laminate. Use sufficient pressure to completely eliminate any air bubbles between the PALIGHT material, the adhesive and the print

or other material.

The lamination will achieve maximum bonding in three hours. If the lamination has been performed properly, the finished mount

can be flexed without the print becoming loose in the center. To prevent moisture from becoming trapped between layers of porous

material (such as paper) and creating blisters, the level of moisture in both the material to be laminated and the atmosphere should

be reduced before pressing. Some materials may require pre-drying. PALIGHT is nonporous and does not need pre-drying.

Preventing Surface flaws

Surface blemishes, such as wrinkles, can be caused by misalignment of the adhesive roll or too much pressure or rollers that are not

parallel. Trapped dirt or lumps of hardened adhesive common with glossy prints may create small bumps in the finished product.

In order to prevent these problems, equipment used for PALIGHT lamination must be kept clean. Use a fresh roll or sheet of transfer

adhesive if bumps are caused by hardened adhesive. Dirt problems can be minimized by using an ionizing static eliminator. Using

prints or other materials made with a paper 0.007” or thicker can help prevent strike through.

For best results, wipe down the back of the print and the face of the PALIGHT mount with a clean, dry cloth before it passes through

the roll nip. Whether the finished product is to be used indoors or outdoors, a clear, high gloss overlay will help protect against fading

as well as enhance the color.

Laminating Techniques

Four techniques are recommended for laminating materials to PALIGHT, as described in the following sections. Depending upon the

type of applications and the equipment available, one or more of these processes may be appropriate for a particular application.

None of these processes involves the use of heat. Because PALIGHT may warp at temperatures above 140 F or when heated from one

side only, it cannot be dry mounted or hot mounted.

8

Page 10

PALIGHT®

The four recommended lamination techniques for PALIGHT are:

Cold laminating with a press using adhesive-backed paper

Cold laminating using a vacuum press

Hand laminating using transfer adhesive

Hand laminating using spray adhesive

Cold Laminating with a Press using Adhesive-backed Paper

This process is most frequently used by commercial photo labs. Either of two types of liner films, a single release liner film or a double

release liner film, can be used for this process. The basic process for laminating with a press using adhesive-backed paper is described

in the following section.

1. Set the roller pressure properly for the thickness of the pre-coated mounting substrate.

2. Place the mounting substrate on a flat surface and expose approximately one inch of the adhesive by peeling back the release

paper. Fold back the release paper, making an even crease across the paper.

3. Carefully position the print on top of the substrate, using the folded release paper to prevent contact with the exposed adhesive.

Once positioned correctly, carefully apply the print to the exposed adhesive, pressing from the center toward the edges to ensure

a smooth tack.

4. Place the direction switch in the forward position and the speed control on medium.

5. Insert the materials to be processed into the laminator opening. Feed the substrate between the rollers until the pressure roller

rests on the tacked portion of the material.

6. Hold the un-tacked portion of the print up and against the pressure roller. Feed the substrate through the rollers while peeling

the release paper off the mounting substrate with one hand. To prevent wrinkles, the print must be held against the

roller with the opposite hand while the substrate feeds through the press.

7. Remove the mounted print from the rear of the laminator and trim it to the required size.

Coating using Single Release Liner Films

1. Set the pressure properly for the thickness of the substrate(s) to be processed.

2. Load the supply roll of pressure-sensitive adhesive.

3. Pull approximately 12 inches of adhesive film forward off the roll. Rest the film, adhesive side up, on top of the pressure roller.

4. Create a leader board by cutting a piece of substrate slightly larger than the width of the adhesive film and approximately four to

six inches long. Lay the leader board across the adhesive film and smoothly adhere the bottom of the leader to the adhesive.

5. Place the direction switch in the forward position and the speed control on medium.

6. Pull the leader down and push it between the rollers. Feed the leader between the rollers approximately three to four inches. Be

sure that the adhesive stays firmly adhered to the leader.

7. Once this process has been completed (referred to as “stringing the web”) and the adhesive is feeding without wrinkles, the

laminator is ready for production.

8. To coat, feed a substrate behind the leader board and between the roller while depressing the foot switch. Feed until the substrate

exits the rollers and automatically stops feeding. At this time, another substrate may be fed between the rollers for coating. This

process is suitable for films with a paper release liner and leaves a 3/8” to 1/2” gap between the coated substrates to facilitate the

trimming process.

9. After exiting the laminator, the coated substrates should be split apart and trimmed.

Coating using Double Release Liner Films

Coating with double release liner film, requires the use of a take-up mechanism to automatically remove and rewind one of the

release liners during the coating procedure.

1. Set the pressure properly for the thickness of the substrates to be processed.

2. Load the supply roll of pressure-sensitive adhesive.

3. Adhere double-stick tape or a pressure-sensitive adhesive film, to the surface of the take-up shaft.

4. Pull approximately 18 inches of adhesive film forward off the roll and adhere one release liner side smoothly to the take-up shaft,

taking care to ensure that the film is square with the supply roll and no diagonal wrinkles are apparent.

5. Separate the adhesive film from the release liner secured to the take-up shaft and pull the adhesive film and remaining release

liner down so that it rests adhesive side up on top of the pressure roller.

6. Lay a leader board the same thickness as the substrates to be used across the exposed adhesive.

9

Page 11

Fabrication Guide

Cold Laminating with a Vacuum Press

This method is suggested for small and medium-sized photo shops for mounting prints utilizing a spray adhesive.

1. Spray the adhesive on the back of the piece to be mounted, keeping the spray six to eight inches from the surface. If using a

double coat of adhesive, the second coat should be applied in a direction perpendicular to the first coat. For bonding most art

materials, the adhesive is typically applied only to one surface, usually the back of the print.

2. Allow the spray to dry two to four minutes before mounting so that the adhesive becomes tacky. If blisters occur from trapped

solvent, allow the adhesive to dry slightly longer than four minutes.

3. Position the print on the PALIGHT material and place inside the vacuum frame.

4. Apply vacuum for 10 minutes.

Hand Laminating using Transfer Adhesive

For small shops or display makers without access to presses, this method can be used for the lamination of flat, relatively small items

utilizing a transfer adhesive.

1. Using a sheet of transfer adhesive having both sides covered by release paper, peel away and fold back the release paper 1/2” inch

from one edge.

2. Place the edge of the print to be laminated on the exposed adhesive.

3. Remove the rest of the release paper while lifting the print slightly to avoid contact with the adhesive, then use a roller or a

squeegee to smooth the print evenly onto the adhesive.

4. With the print facing down and the remaining release paper facing up, smooth out any excess air from between the print and the

adhesive with a squeegee.

5. To laminate the print to the PALIGHT material, peel away and fold back the release paper 1/2” inch from one edge.

6. Placing the print evenly on the PALIGHT material, tack the exposed adhesive to the PALIGHT.

7. Gradually remove the liner while pressing closely with a hand roller or a squeegee to eliminate any air bubbles until the entire

print has been laminated.

Hand Laminating using Spray Adhesive

For small shops or display makers without access to equipment, this method is recommended for the lamination of flat, relatively

small items utilizing a spray adhesive.

1. Spray the adhesive on the back of the piece to be mounted, keeping the spray six to eight inches from the surface. If using a

double coat of adhesive, the second coat should be applied in a direction perpendicular to the first coat. For bonding most art

materials, the adhesive is typically applied only to one surface, preferably the back of the print.

2. Allow the spray to dry between two to four minutes before mounting so that the adhesive becomes tacky.

3. Place the adhesive side of the print or other item on the PALIGHT surface, pressing smoothly from the center of the piece to the

edges in order to eliminate any wrinkles and trapped air immediately.

4. Place a clean sheet of PALIGHT over the laminated piece to weigh it down. Although the bond should be at maximum strength

after fifteen minutes, allow 24 hours before exposing the piece to any sudden temperature or humidity changes.

Delaminating

A print mount can be delaminated within five minutes if a pressure sensitive adhesive, has been used. Although the print is usually

destroyed, the PALIGHT material can be reused. If five minutes have already passed, a hot air gun or a hair dryer can be used to heat

the material in order to peel off the lamination. Isopropyl alcohol or mineral spirits can be used to remove the remaining adhesive.

Chemical Resistance

The mechanism of chemical attack on thermoplastics in general, and PALRAM PVC sheets in particular, differs significantly from the

mechanism of corrosion of metals. Corrosion of metals results in a gradual loss of surface material as a result of electrolytic action by

the relevant chemicals. Chemical attack on PALRAM PVC sheet, where it occurs, consists generally of absorption of the chemical by the

PVC sheet and its subsequent swelling. The chemical resistance behavior of PALRAM PVC sheets is therefore simple to determine. The

chemical resistance is expressed in terms of weight change (usually an increase) and volume change.

The table that appears in the following pages lists the resistance of PALRAM PVC sheets to a number of commonly encountered

chemicals and other corrosive media at room temperature. (Information on chemical resistance at higher temperatures will be

supplied upon request.) Where the chemical resistance varies with concentration, the results of tests at different concentrations is

presented. The information listed is based on long-term laboratory tests and actual service installations.

For chemicals and corrosive media not listed in the list, please contact your PALRAM representative. He will place you in contact with

the PALRAM Technical Support Department.

It is important to note that PALRAM PVC sheets are generally not recommended for use with acetone, ketones, ethers, and aromatic

and chlorinated hydrocarbons.

The information on chemical resistance is based on our research and experience. It serves as a basis for recommendation.

PALRAM does not guarantee chemical resistance, unless specific tests are carried and separate documentation is supplied.

10

Page 12

PALIGHT®

The table on the following pages uses the following key:

R Resistant LR Limited Resistance (gradual attack over time may occur)

N Not Resistant (rapid attack or attack over short time period will occur)

IMPORTANT NOTE: To download the most up-to-date version of the following Chemical Resistance list, please visit the following

URL: http://www.palram.com/Media/Doc/Chemical_Resistance_PVC.pdf

Chemical Concentration %* Resistance Chemical Concentration %* Resistance

Acetaldehyrde 100 N Bromobenzene N

Acetic Acid 80 R Butadiene N

Acetic Acid 100 LR Butane N

Acetic Anhydride N Butyl Acetate N

Acetone N Butyl Alcohol R

Acrylonitrile N Butyl Stearate R

Acetylene R Butyric Acid N

Ajax R Calcium Chloride Saturated R

Allyl Alcohol LR Calcium Hydroxide R

Aluminum Chloride Saturated R Calcium Hypochlorite R

Aluminum Fluoride R Calcium Nitrate R

Aluminum Hydroxide R Calcium Sulfate R

Aluminum Sulfate Saturated R Camphor R

Ammonia (Gas) R Carbon Dioxide Gas (Moist) R

Ammonia (Liquid) N Carbon Disulfide N

Ammonium Acetate R Carbon Monoxide R

Ammonium Bifluoride R Carbon Tetrachloride N

Ammonium Bisulfate R Castor Oil R

Ammonium Chloride R Caustic Potash (Potassium Hydroxide) 50 R

Ammonium Fluroide 25 LR Caustic Soda (Sodium Hydroxide) 50 R

Ammonium Hydroxide 28 R Chlorine Dioxide 15 R

Ammonium Nitrate R Chlorine Gas (Dry) N

Ammonium Sulfate Saturated R Chlorine Gas (Wet) N

Ammonium Sulfide Saturated R Chlorine Water 2 R

Amyl Acetate N Chloroacetic Acid R

Amyl Alcohol Pure LR Chlorobenzene N

Aniline N Chloroform N

Antimony Trichloride R Chrome Alum Saturated R

Aqua Regia (3 parts HCl:1 part HNO3) N Chromic Acid 10 R

Arsenic Acid 80 R Citric Acid Saturated R

Barium Chloride R Copper Fluoride R

Barium Hydroxide R Copper Nitrate R

Barium Sulfate R Copper Sulfate R

Barium Sulfide R Corn Syrup R

Beer R Cottonseed Oil R

Beet (Sugar Liquor) R Cresol N

Benzaldehyde LR Cresylic Acid 50 R

Benzene N Cupric Chloride Saturated R

Benzoic Acid R Cuprous Chloride Saturated R

Benzyl Alcohol R Cyclohexane N

Bleach 12% Chlorine R Cyclohexanol N

Boric Acid R Cyclohexanone N

Brake Fluid LR Dextrose R

Brine R Detergent (most) R

Bromic Acid R Diesel Fuel R

Bromine (Liquid) N Diethyl Ether (Ethyl Ether) R

Bromine (Water) LR Dimethyl Amine N

Bromine (Vapor) 25 R Dioctyl Phthalate N

11

Page 13

Fabrication Guide

The table on the following pages uses the following key:

R Resistant LR Limited Resistance (gradual attack over time may occur)

N Not Resistant (rapid attack or attack over short time period will occur)

IMPORTANT NOTE: To download the most up-to-date version of the following Chemical Resistance list, please visit the following

URL: http://www.palram.com/Media/Doc/Chemical_Resistance_PVC.pdf

Chemical Concentration %* Resistance Chemical Concentration %* Resistance

Acetaldehyrde 100 N Bromobenzene N

Acetic Acid 80 R Butadiene N

Acetic Acid 100 LR Butane N

Acetic Anhydride N Butyl Acetate N

Acetone N Butyl Alcohol R

Acrylonitrile N Butyl Stearate R

Acetylene R Butyric Acid N

Ajax R Calcium Chloride Saturated R

Allyl Alcohol LR Calcium Hydroxide R

Aluminum Chloride Saturated R Calcium Hypochlorite R

Aluminum Fluoride R Calcium Nitrate R

Aluminum Hydroxide R Calcium Sulfate R

Aluminum Sulfate Saturated R Camphor R

Ammonia (Gas) R Carbon Dioxide Gas (Moist) R

Ammonia (Liquid) N Carbon Disulfide N

Ammonium Acetate R Carbon Monoxide R

Ammonium Bifluoride R Carbon Tetrachloride N

Ammonium Bisulfate R Castor Oil R

Ammonium Chloride R Caustic Potash (Potassium Hydroxide) 50 R

Ammonium Fluroide 25 LR Caustic Soda (Sodium Hydroxide) 50 R

Ammonium Hydroxide 28 R Chlorine Dioxide 15 R

Ammonium Nitrate R Chlorine Gas (Dry) N

Ammonium Sulfate Saturated R Chlorine Gas (Wet) N

Ammonium Sulfide Saturated R Chlorine Water 2 R

Amyl Acetate N Chloroacetic Acid R

Amyl Alcohol Pure LR Chlorobenzene N

Aniline N Chloroform N

Antimony Trichloride R Chrome Alum Saturated R

Aqua Regia (3 parts HCl:1 part HNO3) N Chromic Acid 10 R

Arsenic Acid 80 R Citric Acid Saturated R

Barium Chloride R Copper Fluoride R

Barium Hydroxide R Copper Nitrate R

Barium Sulfate R Copper Sulfate R

Barium Sulfide R Corn Syrup R

Beer R Cottonseed Oil R

Beet (Sugar Liquor) R Cresol N

Benzaldehyde LR Cresylic Acid 50 R

Benzene N Cupric Chloride Saturated R

Benzoic Acid R Cuprous Chloride Saturated R

Benzyl Alcohol R Cyclohexane N

Bleach 12% Chlorine R Cyclohexanol N

Boric Acid R Cyclohexanone N

Brake Fluid LR Dextrose R

Brine R Detergent (most) R

Bromic Acid R Diesel Fuel R

Bromine (Liquid) N Diethyl Ether (Ethyl Ether) R

Bromine (Water) LR Dimethyl Amine N

Bromine (Vapor) 25 R Dioctyl Phthalate N

12

Page 14

PALIGHT®

The table on the following pages uses the following key:

R Resistant LR Limited Resistance (gradual attack over time may occur)

N Not Resistant (rapid attack or attack over short time period will occur)

IMPORTANT NOTE: To download the most up-to-date version of the following Chemical Resistance list, please visit the following

URL: http://www.palram.com/Media/Doc/Chemical_Resistance_PVC.pdf

Chemical Concentration %* Resistance Chemical Concentration %* Resistance

Phosphorous (Yellow) R Sodium Ferricyanide R

Phosphorous Pentoxide R Sodium Ferrocyanide R

Phosphorous Trichloride N Sodium Fluoride R

Photographic Chemicals R Sodium Hydroxide 50% R

Picric Acid N Sodium Hypochlorite 16% Chlorine R

Plating Solutions R Sodium Nitrate R

Potassium Bichromate R Sodium Nitrite R

Potassium Bromate R Sodium Perchlorate R

Potassium Bromide Saturated R Sodium Peroxide R

Potassium Chloride R Sodium Sulfate R

Potassium Chlorate R Sodium Sulfide R

Potassium Chromate R Sodium Sulfite R

Potassium Cyanide R Sodium Thiosulfate R

Potassium Dichromate R Stannic Chloride R

Potassium Ferricyanide R Stannous Chloride R

Potassium Fluoride R Stearic Acid R

Potassium Hydroxide 50 R Succinic Acid R

Potassium Nitrate R Sugar Saturated R

Potassium Perborate R Sulfur Dioxide (Dry Gas) R

Potassium Perchlorate R Sulfuric Acid R (LR)

Potassium Permanganate 10 R Sulfurous Acid <80 (>80) R

Potassium Persulfate R Tannic Acid R

Potassium Sulfate R Tanning Liquors R

Propane R Tartaric Acid R

Propyl Alcohol (1Propanol) 100 R Tetraethyl Lead R

Propylene Dichloride N Tetrahydrofuran N

Propylene Oxide N Tetrasodium Pyrophosphate R

Pyridene N Thionyl Chloride N

Pyrogallic Acid R Titanium Tetrachloride R

Salad Oil R Toluene N

Salicylic Acid R Trichloroacetic Acid R

Selenic Acid R Trichloroethylene N

Silicic Acid R Triethanolamine R

Silver Cyanide R Triethylamine N

Silver Nitrate R Trimethylamine LR

Silver Sulfate R Trisodium Phosphate R

Sodium Acetate R Tuepentine LR

Sodium Benzoate R Urea R

Sodium Bicarbonate R Vasilene N

Sodium Bichromate R Vegetable Oils R

Sodium Bisulfate R Vinegar R

Sodium Bisulfite R Vinyl Acetate N

Sodium Carbonate R Water (Demineralized or Sea) R

Sodium Chlorate R Wine or Whiskey R

Sodium Chloride R Xylene N

Sodium Chlorite N Zinc Chloride R

Sodium Cyanide R Zinc Nitrate R

Sodium Dichromate R Zinc Sulfate R

13

Page 15

Fabrication Guide

Recommended Uses and Restrictions

Please consult the relevant product and/or application information for this product within this guide, or in other related sales

literature.

Further Information

Additional information on this product may be obtained by calling your PALRAM Sales or Customer Service Contact.

PALIGHT Physical Property Table:

0.12 in. (3mm) Sheet 0.39 in. (10mm) Sheet

Property* Conditions* ASTM Method Units* Value* Value*

Physical

Water absorption 23°C D-570 % 0.5 0.8

Density g/c m 0.65-0.7 0.55-0.6

Mechanical

Tensile strength at yield 10mm/min D-638 MPa 16 11

Elongation at break 10mm/min D-638 % 30 20

Flexural strength at yield 10mm/min D -790 MPa 28 22

Flexural modulus 10mm/min D-79 0 MPa 900 900

Impact strength notch charpy 23°C D -256 J/m 29 17

Thermal

Service temperature °F (°C) -10 to 55°C -10 to 55°C

Heat deflection temperature D-648 °F (°C) 63 63

VICAT softening temperature Load: 264psi D-15 25 °F (°C) 75 75

Coefficient of linear thermal expansion Load: 11Kg D-696 cm /cm°C 6.7 6.7

Thermal conductivity C-17 7 W/mk 0.07 0.07

* PALIGHT GPS and PALIGHT Marine may have slightly different physical properties. Please consult the web site for specific product specifications.

PSDS Sheet

Download a detailed copy of the PSDS (use in place of MSDS Sheet) for PALIGHT at the following URL (Adobe Acrobat

required):

http://www.palram.com/Media/Doc/PALRAM_PSDS_Foamed_PVC.pdf

14

Page 16

Inasmuch as PALRAM Industries has no control over the use

to which others may put the material, it does not guarantee

that the same results as those described herein will be

obtained. Each user of the material should make his own tests

to determine the material's suitability for his own particular

use. Statements concerning possible or suggested uses

of the materials described herein are not to be construed

as constituting a license under any PALRAM Industries

patent covering such use or as recommendations for use of

such materials in the infringement of any patent. PALRAM

Industries or its distributors cannot be held responsible

for any losses incurred through incorrect installation of

the material. In accordance with our company policy of

continual product development you are advised to check

with your local PALRAM Industries supplier to ensure that

.you have obtained the most up to date information

For more information please visit www.palram.com

70977 - 06.10

PALRAM Europe Ltd.

Tel (44) 1302 380776

Fax (44) 1302 380788

E-mail sales.europe@palram.com

Web www.palram.com

PALRAM Israel Ltd.

Tel

(972) 4 8459 900

Fax (972) 4 8459 980

E-mail palram@palram.com

Web www.palram.co.il

PALRAM Industries Ltd.

PALRAM Americas Inc.

Tel 610 285 9918

Fax 610 285 9928

E-mail palramamericas@palram.com

Web www.palramamericas.com

©1997 PALRAM Industries Ltd.

PALIGHT is a registered trademarks of PALRAM Industries Ltd.

Loading...

Loading...