Page 1

Horizontal Vent Terminal Location

Outside Walls

INSTALLATION INSTRUCTIONS

C

V

F

V

B

D E

V

Fixed

Closed

Operable

L

H

V

B

Fixed

Closed

V

K

X

I

MM

V

Vent Terminal

X

Air Supply Inlet

Area Where Terminal is Not Permitted

Interior Wall

A

X

V

G

V

B

Operable

V

A J

B

V

Venting

37

Page 2

INSTALLATION INSTRUCTIONS

Venting for Direct-Vent Water Heater (cont.)

The following chart details the minimal dimensional information needed to determine the proper location of

the vent terminal for direct vent and outdoor tankless water heaters. See corresponding letter reference in

the illustration at left.

Venting

Location

A = Clearance above grade, veranda, porch,

deck, or balcony.

B = Clearance to window or door that may be

opened.

U.S. Installation

Requirements

12 in. (30 cm) above anticipated snow

level.

• 6 in. (15 cm) for water heaters less

than or equal to 10,000 Btuh (3 kW).

1

• 9 in. (23 cm) for water heaters greater

than 10,000 Btuh (3 kW) and less

than or equal to 50,000 Btuh (15 kW).

• 12 in. (30 cm) for water heaters

greater than 50,000 Btuh (15 kW).

C = Clearance to permanently closed window.

D = Vertical clearance to ventilated soffit lo-

cated above the terminal within a horizontal

distance of 2 ft. (61 cm) from the centerline

of the terminal.

E = Clearance to unventilated soffit.

F = Clearance to outside corner.

G = Clearance to corner.

H = Clearance to each side of centerline ex-

tended above meter/regulator assembly.

I = Clearance to service regulator vent outlet.

J = Clearance to nonmechanical air supply inlet

to the combustion air inlet to any building or

other appliance.

• 6 in. (15 cm) for water heaters less

than or equal to 10,000 Btuh (3 kW).

• 9 in. (23 cm) for water heaters greater

than 10,000 Btuh (3 kW) and less

than or equal to 50,000 Btuh (15 kW).

• 12 in. (30 cm) for water heaters

greater than 50,000 Btuh (15 kW).

K = Clearance to mechanical air supply inlet. 3 ft. (91 cm) above if within 10 ft. (3 m)

L = Clearance above paved sidewalk or paved

driveway located on public property.

M = Clearance under veranda, porch, deck, or

balcony.

1 In accordance with current ANSI Z223.1/NFPA 54 National Fuel Gas Code.

2 In accordance with current CSA B149.1 Installation Codes.

For clearances not specified in ANSI 223.1/NFPA 54 or CSA B149.1, one of the following shall be indicated:

a) A minimum clearance value determined by testing in accordance with section 2.20, or

b) A reference to the following footnote: “Clearance in accordance with local installation codes and the requirements of the

gas supplier.”

†

A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single-family dwellings and

serves both dwellings.

horizontally.

Not Allowed Not Allowed

Canadian Installation

Requirements

12 in. (30 cm) above anticipated snow

level.

2

• 6 in. (15 cm) for water heaters less

than or equal to 10,000 Btuh (3 kW).

• 12 in. (30 cm) for water heaters

greater than 10,000 Btuh (3 kW) and

less than or equal to 100,000 Btuh

(30 kW).

• 36 in. (91 cm) for water heaters

greater than 100,000 Btuh (30 kW).

3 ft. (91 cm) within a height of 15 ft.

(4,57 m) above the meter/regulator

assembly.

3 ft. (91 cm)

• 6 in. (15 cm) for water heaters less

than or equal to 10,000 Btuh (3 kW).

• 12 in. (30 cm) for water heaters

greater than 10,000 Btuh (3 kW) and

less than or equal to 100,000 Btuh

(30 kW).

• 36 in. (91 cm) for water heaters

greater than 100,000 Btuh (30 kW).

6 ft. (1,83 m)

7 ft. (2,13 m)

†

38

Page 3

Horizontal Vent Considerations

Rising moisture will collect under eaves.

Inside

Corner

Caulk

Caulk

Caulk

Caulk

If soft vent is too close,

block off and install new

vent at another location.

6' (1.8 m) Caulk zone or

to edge of window etc.,

starting within 6' (1.8 m)

4'

(1.2 m)

Rising moisture will collect under eaves.

Inside

Corner

Caulk

Caulk

Caulk

If soft vent is too close,

block off and install new

vent at another location.

6' (1.8 m) Caulk zone

or to edge of window

etc., starting within

6' (1.8 m)

4'

(1.2 m)

12"

(300 mm)

WARNING: Moisture in the flue gas

will condense as it leaves the vent terminal. In cold

weather this condensate can freeze on the exterior

wall, under the eaves, and on surrounding objects.

Some discoloration to the exterior of the building

is to be expected. However, improper location

or installation can result in severe damage to the

structure or exterior finish of the building.

– Do not install vent terminals under any patio or

deck.

– Do not locate vent terminal on the side of a

building with prevailing winter winds. This will

help prevent water lines from freezing and

moisture from freezing on walls and under

eaves.

– Do not locate vent terminal too close to

shrubbery, since flue gases may damage them.

– All painted surfaces should be primed to

lessen the chance of physical damage. Painted

surfaces will require maintenance.

– Guard against accidental contact with people

and pets.

INDOOR TANKLESS WATER

HEATERS

WARNING: For multiple-unit

installation, a minimum distance between vent

terminations must be maintained to prevent

recirculation of vent gases. Maintain a centerto-center distance between each pair of vent

terminations of 24 in. (61 cm) for a two-unit

installation; 24 in. (61 cm) and 36 in. (91.4 cm) for

an installation of three units; and 24 in. (61 cm),

36 in. (91.4 cm), and 24 in. (61 cm) for an

installation of four units.

INSTALLATION INSTRUCTIONS

Venting

– Do not terminate vent directly on brick or

masonry surfaces. Use rust-resistant, sheetmetal backing plate of 1 sq. ft. (30 sq. cm)

behind the vent.

– Caulk all cracks, seams, and joints within

6 ft. (1.8 m) of the vent terminal.

– Caulk around wall faceplate for weather-tight

seal.

– Do not extend exposed vent pipe of indoor

water heaters outside of the building.

– This water heater requires its own separate

venting system. Do not connect the exhaust

vent to an existing vent pipe or chimney.

OUTDOOR TANKLESS WATER

HEATERS

– Install outdoor water heater such that air inlet

and flue outlet are above anticipated snow level.

39

Page 4

INSTALLATION INSTRUCTIONS

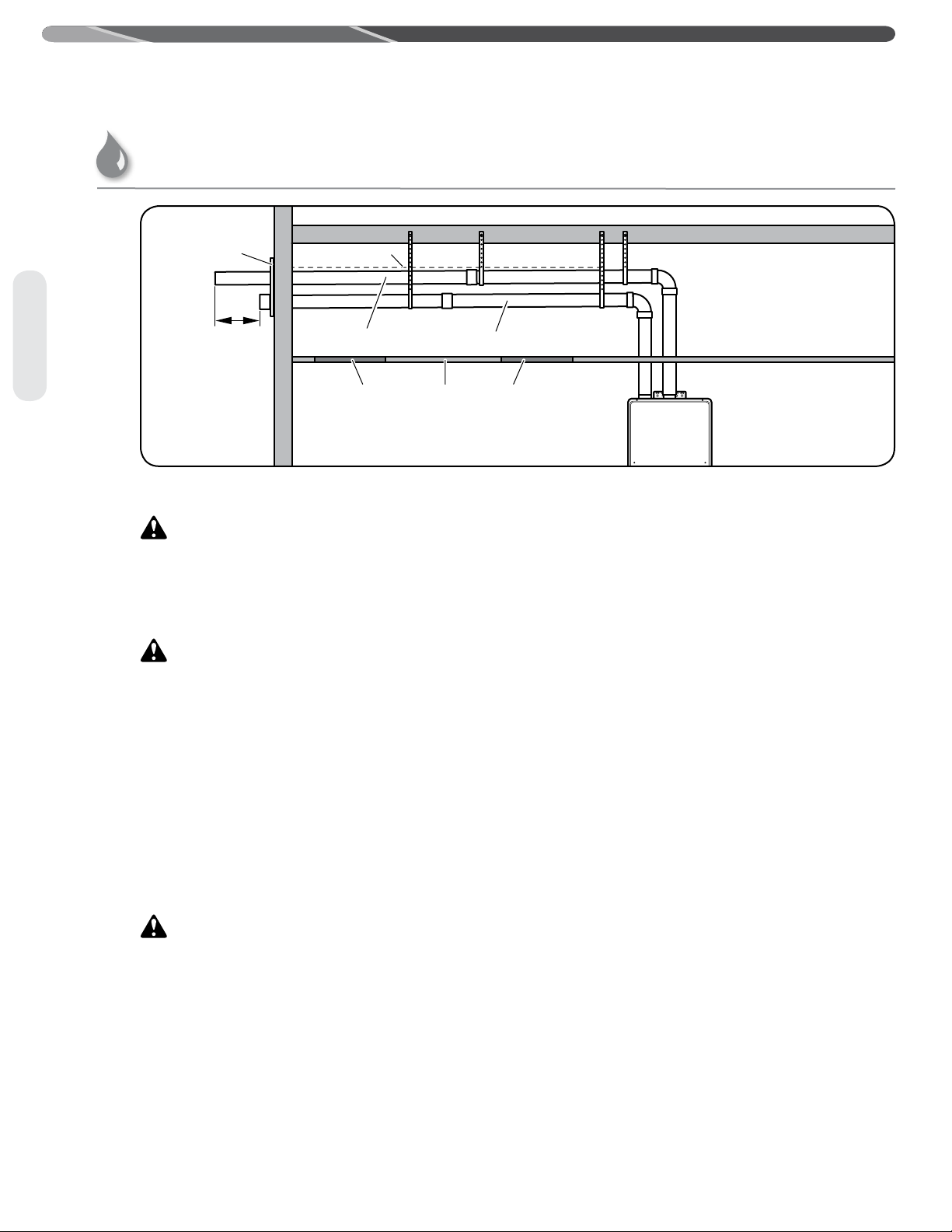

Exhaust Vent Pipe

Air Intake Pipe

Wall Plate

Inspection

Access Panel

(Optional)

Inspection

Access Panel

(Optional)

Ceiling

Downward Slope

12"

(300 mm)

Venting for Direct-Vent Water Heater (cont.)

Venting

40

Horizontal Vent Installation

injury – Solvent cements and primers are highly

flammable. Provide adequate ventilation and do

not assemble near heat source or open flame. Do

not smoke. Avoid skin or eye contact. Observe all

cautions and warnings on material containers.

heater manufacturer-approved Schedule 40 PVC

(foam core is not permitted at any time), Schedule

80 PVC, CPVC, ABS polypropylene, or UL

1738-listed Category III Stainless Steel. No other

vent material is permitted.

Joining Pipes and Fittings

All pipe, fittings, solvent cement, primers, and

procedures, for the U.S., must conform to American

National Standards Institute and American Society

for Testing and Materials (ANSI/ASTM) standards.

For Canada, all pipe, fittings, solvent cement,

primers, and procedures must conform to ULCS636 and vent manufacture specifications.

• Do NOT use solvent cement that has become

curdled, lumpy, or thickened.

• Do NOT thin solvent cement. Observe shelf

precautions printed on the containers.

• For applications below 32°F, use only lower

temperature-type solvent cement.

• Appropriate solvent and cleaner must be used

for the type of vent pipe used (PVC, CPVC, or

ABS).

WARNING: Danger of fire or bodily

CAUTION: Use tankless water

CAUTIONS:

Cleaner-Primer and Medium-Body

Solvent Cement

All joints in vent piping must be properly sealed,

and we recommend using the following material:

PVC materials should use ASTM D-2564-grade

cement.

CPVC materials should use ASTM F-493-grade

cement.

ABS materials should use ASTM D-2235-grade

cement (ABS is not allowed in Canada).

Cementing Joints

1. Cut pipe end square; remove jagged edges and

burrs. Chamfer end of pipe; then clean fitting

socket and pipe joint area of all dirt, grease, or

moisture.

2. After checking pipe and socket for proper fit,

wipe socket and pipe with cleaner-primer. Apply

a liberal coat of primer to inside surface of

socket and outside of pipe.

3. Apply a thin coat of cement evenly in the

socket. Quickly apply a heavy coat of cement to

the pipe and insert pipe into fitting with a slight

twisting motion until it bottoms out.

4. Hold the pipe fitting for 30 seconds to prevent

the tapered socket from pushing the pipe out of

the fitting.

5. Wipe all excess cement from the joint with a

rag. Allow 15 minutes before handling. Cure

time will vary according to fit, temperature, and

humidity.

NOTICES:

• Cement must be fluid; if not, recoat.

• Stir the solvent frequently while using. Use a

natural bristle brush or the dauber supplied with

the can. The proper brush size is one inch.

Page 5

Horizontal Vent Installation (cont.)

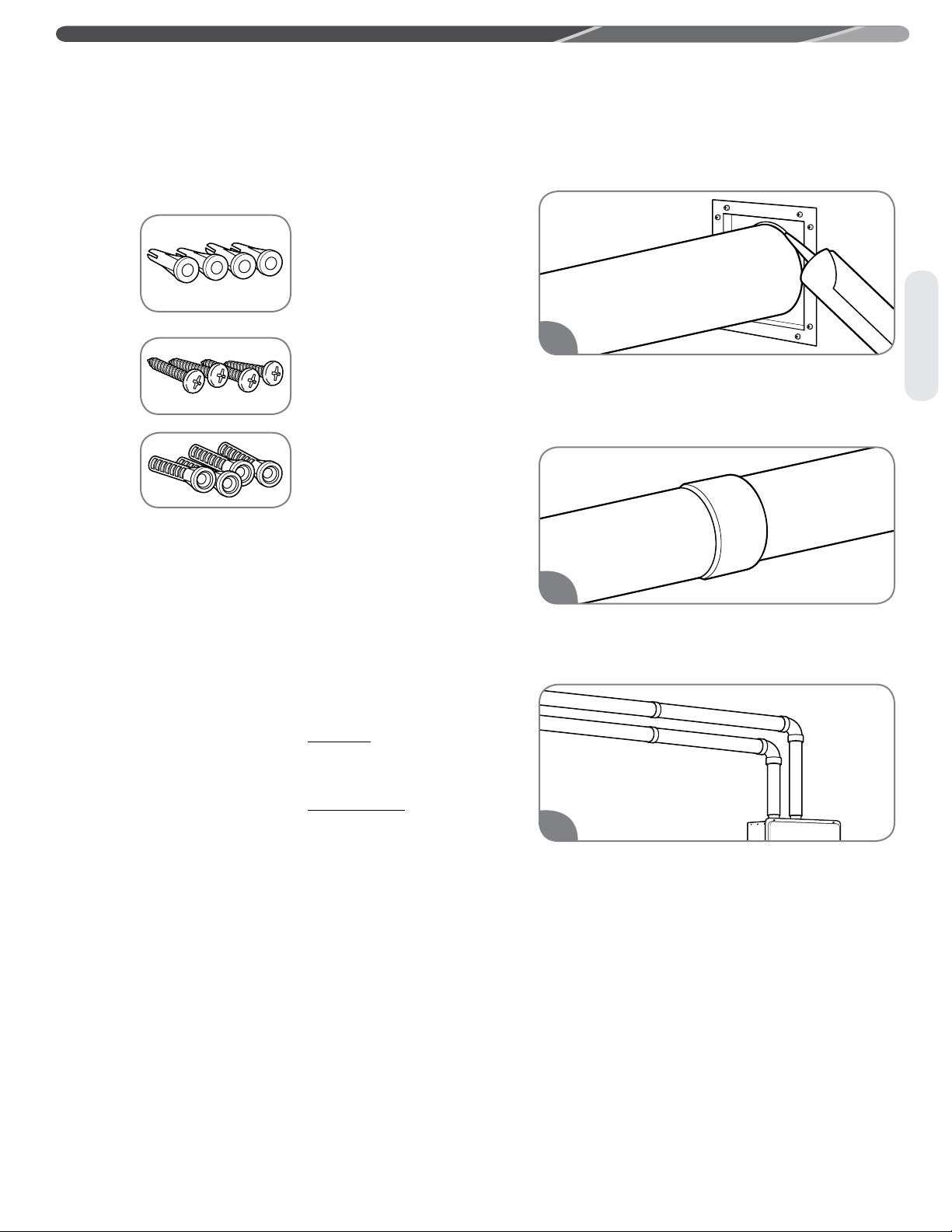

Fasteners will vary depending on the wall type.

For particle board or

composite sheathing, use

4 hollow wall anchors. The

anchors should be at least

1/8 in. (0.3 cm) in diameter

and the appropriate length

for the sheathing thickness.

For plywood or solid

wood sheathing or

members, use 4 #10 x

1 1/4-in. wood screws.

For masonry walls, use

suitable masonry anchors

long enough to pass

through the wall.

NOTICES:

• The distance between the back edge of the

exhaust vent terminal and the exterior wall must

be 12 inches (30.5 cm) more for the exhaust vent

terminal than the air intake terminal.

• To prevent possibility of condensate freeze-up,

do not install vent kits one above the other.

Once the vent terminal location has been

determined, make holes through the exterior wall

to accommodate the vent pipes. Vent pipes must

exit exterior wall horizontally only.

The standard horizontal air intake termination is

a 2-inch or 3-inch pipe which terminates at the

exterior wall and uses a coupling to prevent the

pipe from being pushed back into the structure.

The standard horizontal exhaust outlet termination

is a 2-inch or 3-inch pipe which terminates 12

inches from the air intake termination. Insert a

small length of vent pipe through the wall and

connect the coupling. Connect vent cap or terminal

to the vent pipe on the exterior of the building.

1. Use the vent plate as a template to locate air

intake holes and four mounting holes. Observe

minimum clearances. Vent terminals must be a

minimum of 5.5 inches (14 cm) and a maximum

of 24 inches (61 cm) apart horizontally.

2. Cut two 2 1/2" (6.4 cm) diameter holes (for a

2" [5.1-cm] diameter pipe) or 3 1/2" (8.9 cm)

diameter holes (for a 3" [7.6-cm] diameter pipe)

for the exhaust vent and air intake openings.

Reinstall the decorative sheathing around the

faceplate. The decorative sheathing may be

painted to match the exterior decor.

INSTALLATION INSTRUCTIONS

1

Apply silicone sealant or silicone/latex caulk to

seal the vent pipe to the vent cap to permit field

disassembly for annual inspection and cleaning.

Completely seal where it passes through the wall

plate and where it is attached to the structure.

2

Attach the female end of the next vent pipe

section to the male end of the 2-in./3-in.

(5.1-cm/7.6-cm) vent pipe. See “Cementing

Joints” on page 40.

3

Complete the rest of the vent pipe installation to

the water heater’s flue outlet and air intake.

Venting

41

Page 6

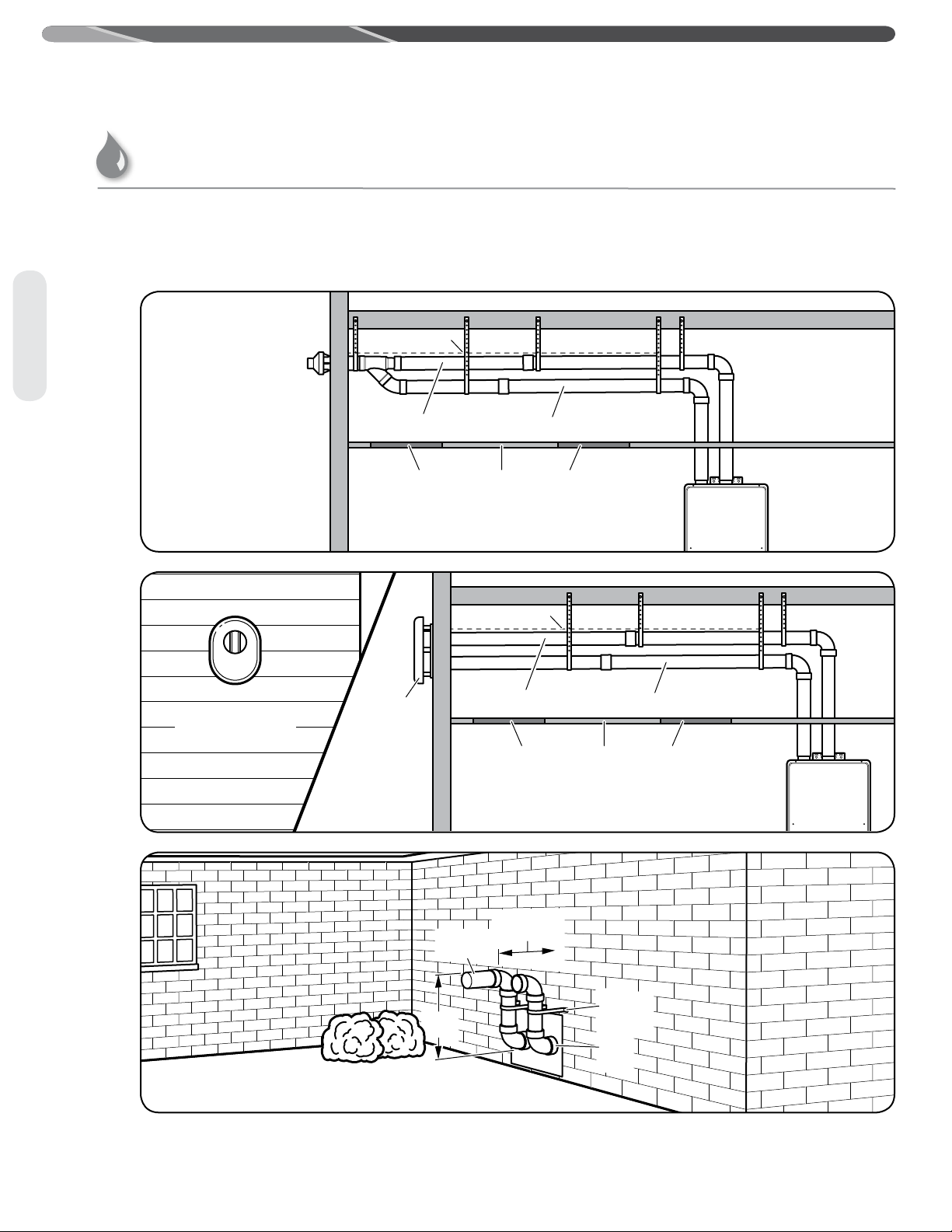

INSTALLATION INSTRUCTIONS

Exhaust Vent Pipe

Air Intake Pipe

Inspection

Access Panel

(Optional)

Inspection

Access Panel

(Optional)

Ceiling

Downward Slope

Exhaust Vent Pipe

Air Intake Pipe

Wall Plate

Inspection

Access Panel

(Optional)

Inspection

Access Panel

(Optional)

Ceiling

Downward Slope

Air

Inlet

Exhaust

Outlet

Pipe

Support

Strap

24"

Max.

12"

From Wall

For information about termination kits, refer to "If You Need Service" on page 26, "Call for

Assistance" for the telephone number to speak to Customer Service Representative.

Venting for Direct-Vent Water Heater (cont.)

Alternative Horizontal Vent Installations

Alternative horizontal vent termination kits are commercially available. Please refer to the instruction sheet

packaged with the kit for complete installation instructions.

Venting

Concentric vent

termination kit

42

Flat horizontal

termination kit

Page 7

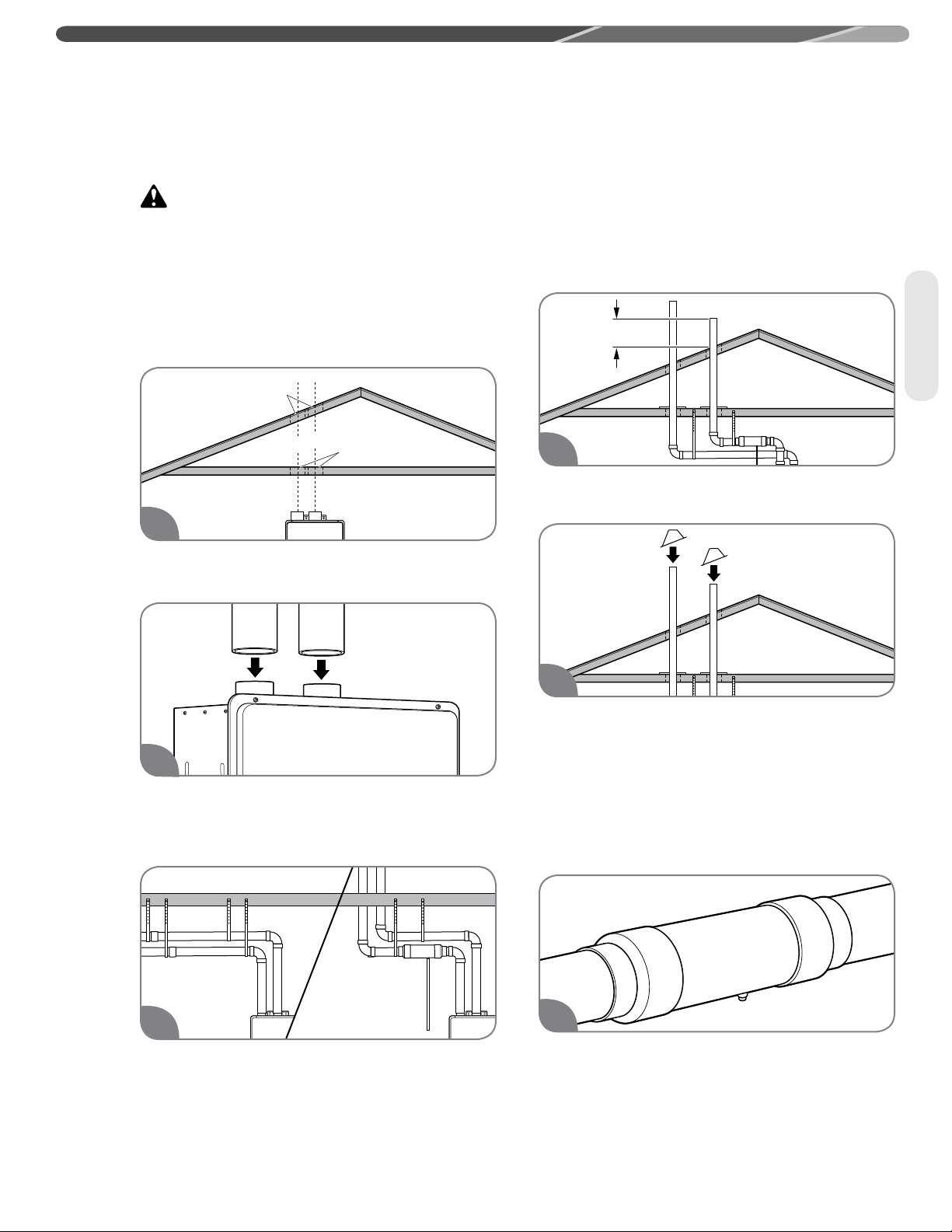

INSTALLATION INSTRUCTIONS

Hole

Through Roof

C

L

Hole

Through Ceiling

C

L

A, B, C, D

Vertical Vent Installation

WARNING: Improper vent

installation can result in death, personal injury,

product damage, and/or poor performance.

NOTICES:

• Only Rheem-approved termination and parts

should be used during installation.

• Maintain the recommended air space clearance

to combustible materials and building insulation.

1

Cut a hole through the roof and interior ceiling to

accommodate the vent pipes.

NOTICE: Free-standing vent pipe that

penetrates a roof/ceiling requires another means of

support from a second location.

Determine the vent terminal height and install

the vent pipe accordingly. Refer to “Vertical Vent

Terminal Location” on page 44 for clearance

requirements.

Venting

4

Install adequate flashing where the vent pipe

passes through the roof.

2

Complete the vent pipe installation to the water

heater’s vent connector fittings. Use cleanerprimer and PVC cement where the vent pipes

join the water heater.

3

Support vertical and horizontal runs as

described on page 35. Vertical supports are

required every 4 ft. (1.2 m) along a vertical pipe

route, after every transition to vertical, and after

every offset elbow.

5

Air Intake Condensate Trap

For vertical terminations or where the air intake

pipe slops down towards the water heater, it is

recommended to install a drain tee assembly. This

is to prevent any condensate or liquid water from

entering the intake of the water heater. Connect

the trap drain line to a suitable drain. Do not

connect it directly to the condensate drain line

from the water heater.

1

One trap method: Glue a 3” by 4” adapter

coupling to each end of a 4” PVC pipe length.

Drill a ½” hole in the side of the larger diameter

pipe. Tap and thread for a ½” barbed fitting,

install fitting. Install the collector with the fitting

facing down. Connect a drain hose to the fitting

and clamp, run hose to a suitable drain.

43

Page 8

A, B, C, D

12" Min.

(300 mm)

Vent Pipe

Through Roof

Optional

INSTALLATION INSTRUCTIONS

Venting for Direct-Vent Water Heater (cont.)

Vertical Vent Terminal Location

Venting

The following chart with diagrams details the minimum dimensional information needed to determine the

proper location of the vertical vent terminal for direct-vent indoor tankless water heaters:

U.S. Installation

Location

A = Minimum clearance above the roof level. 12 in. (30.5 cm) above roof level. 18 in. (45.7 cm) above roof level.

B = Minimum clearance above anticipated snow

level.

C = Maximum clearance above roof level (without

additional support for vent pipe).

D = Maximum clearance above anticipated snow

level (requires additional vent support).

E = Required vent clearance from any gable,

dormer, or other roof structure with building

interior access (i.e., vent, window).

F = Required vent clearance from any forced air

inlet, including dryer and furnace air inlets.

G = Minimum/maximum horizontal distance

between vent terminals

1 In accordance with current ANSI Z223.1/NFPA 54 National Fuel Gas Code.

2 In accordance with current CSA B149.1 Installation Codes.

The vertical intake air termination requires a

Requirements

12 in. (30.5 cm) above anticipated

snow level.

24 in. (61 cm) above roof level. 24 in. (61 cm) above roof level.

24 in. (61 cm) above anticipated snow

level.

4 ft. (1.2 m) 4 ft. (1.2 m)

10 ft. (3 m) 6 ft. (1.8 m)

5.5 in. (14 cm)/24 in. (61 cm) 5.5 in. (14 cm)/24 in. (61 cm)

1

Canadian Installation

Requirements

12 in. (30.5 cm) above anticipated

snow level.

24 in. (61 cm) above anticipated

snow level.

2

return bend or two short or long sweep radius 90°

elbows to keep the inlet downward and prevent

entry of rain. Refer to figure above for the proper

location of the air intake with respect to the

exhaust outlet termination. The vertical exhaust

outlet termination is a 2-inch or 3-inch pipe which

terminates at least 12 inches above the air intake

termination. The air intake and exhaust outlet

terminations must be at least 12 inches above the

roof line or anticipated snow levels.

44

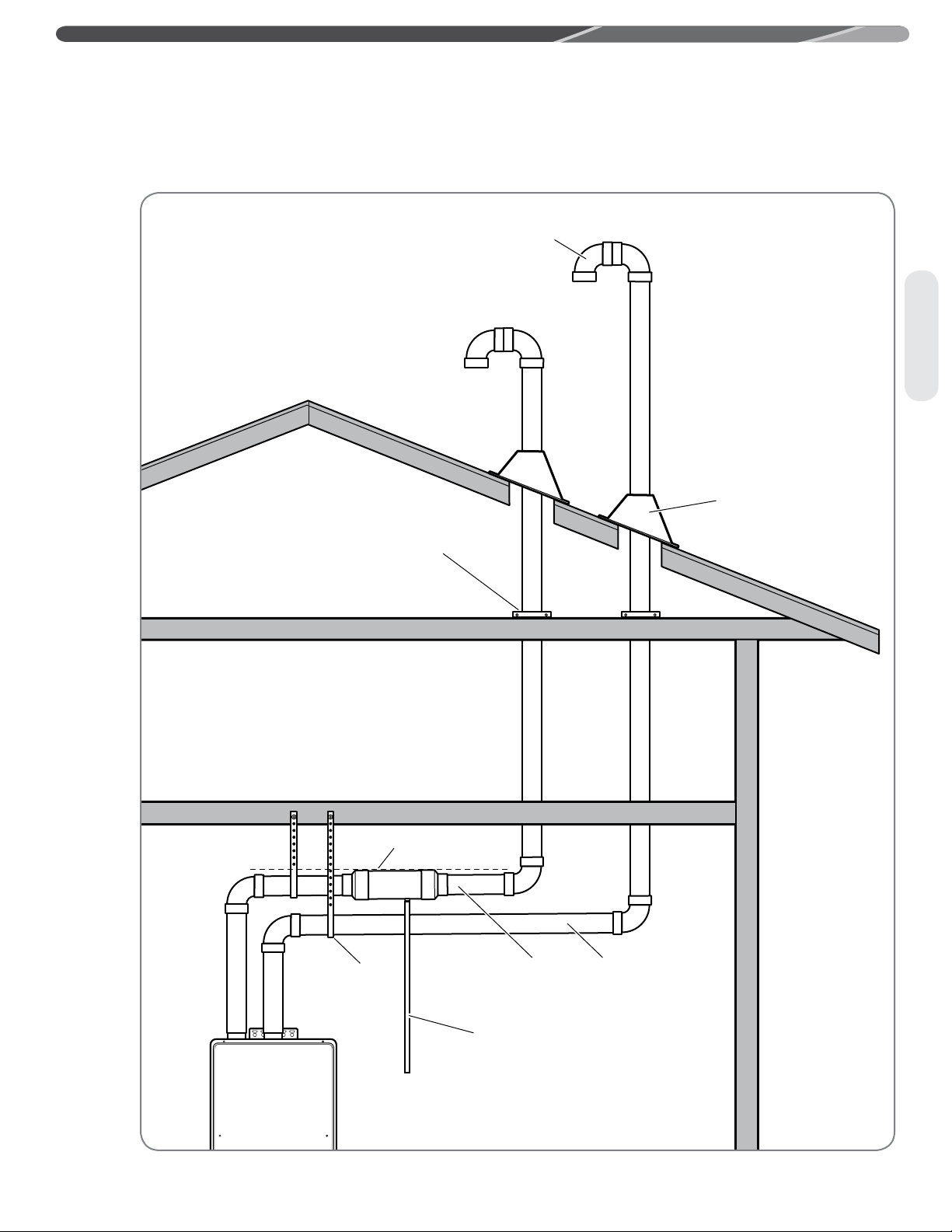

Page 9

Adjustable Roof Flashing

Support Clamp

Upward Slope

Support Hanger

Air Intake

Pipe

Exhaust Vent

Pipe

Condensate

Drain

Optional

Standard Vertical Vent Termination

INSTALLATION INSTRUCTIONS

Venting

45

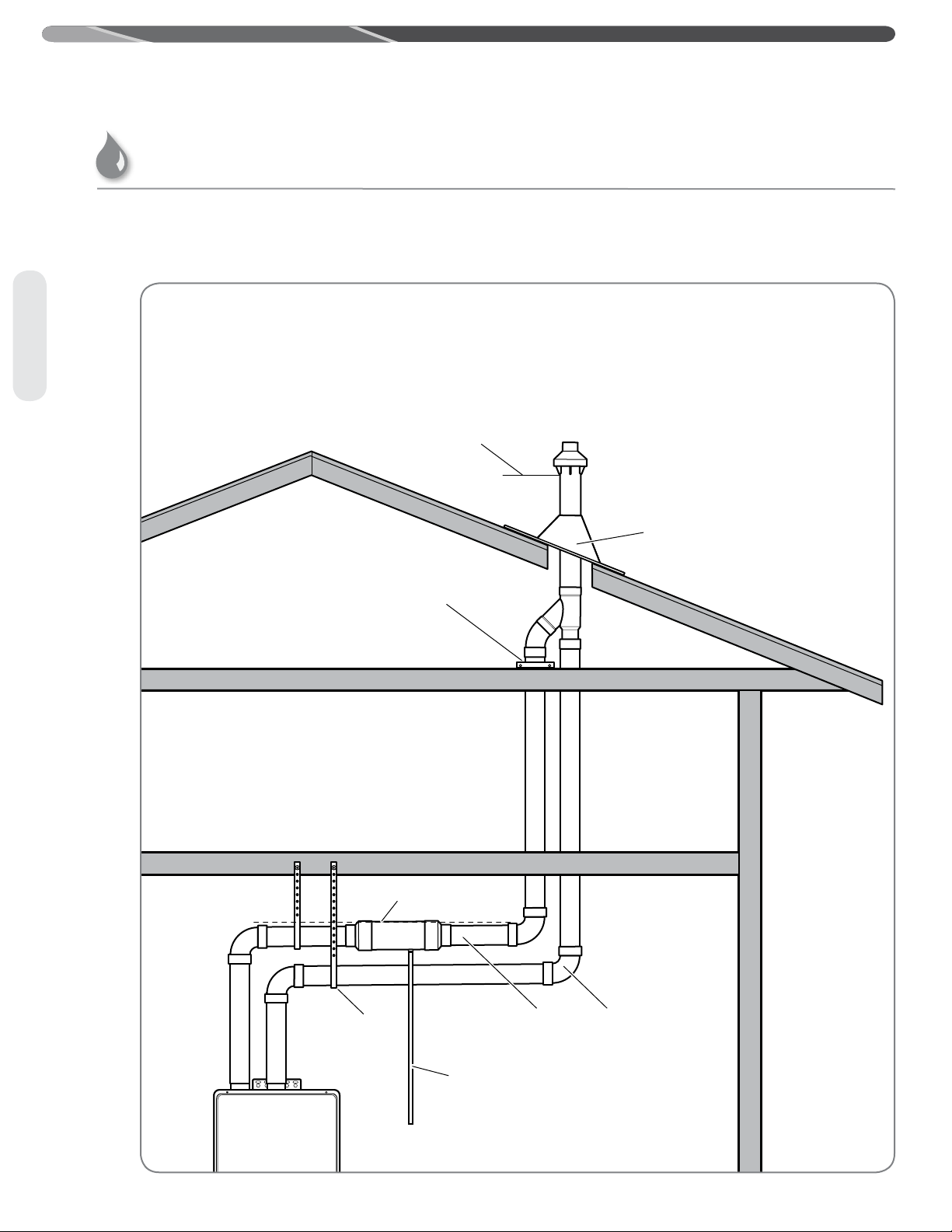

Page 10

Support Hanger

Adjustable Roof Flashing

Support Clamp

Upward Slope

Air Intake

Pipe

Exhaust Vent

Pipe

Minimum Clearance Above

Anticipated Snow Level

Condensate

Drain

INSTALLATION INSTRUCTIONS

Venting for Direct-Vent Water Heater (cont.)

Alternative Vertical Vent Termination

Alternative vertical vent termination kits are commercially available. Please refer to the instruction sheet

packaged with the kit for complete installation instructions.

Venting

46

Page 11

Water Supply

INSTALLATION INSTRUCTIONS

CAUTION: This water heater

MUST ONLY be used with the following water

supply conditions to prevent product damage and

operation failure.

• Clean, potable water free of corrosive chemicals,

sand, dirt, or other contaminates.

• Inlet water temperatures above 32°F (0°C), but

not exceeding 120°F (49°C).

• DO NOT reverse the HOT and COLD water

connections.

• DO NOT connect this water heater to water lines

previously used for space heating. All water

piping and components shall be suitable for

potable water.

• With recommended water quality (see chart).

Chart for Recommended Water Quality Levels

pH

6.5–8.5 Up to 500 mg/L Up to 15 mg/L

TDS (Total

Dissolved Solids)

Free Carbon

Dioxide (CO

)

2

Total

Hardness

Up to

200 mg/L

Aluminum Chlorides Copper Iron Manganese Zinc

0.2 mg/L

Up to

Thermal Expansion

A thermal expansion tank will be required if the

water heater is installed in a recirculation system.

This prevents damage to the heater, related piping,

and the relief valve.

NOTICE: Replacing the relief valve will

not correct the problem!

The expansion tank is designed with a built-in air

cushion that compresses as the system pressure

increases. This relieves the over-pressure condition

and eliminates the repeat operation of the relief

valve.

For other approved methods of thermal expansion,

contact an installing contractor, water supplier, or

plumbing inspector.

Up to

200 mg/L

Up to

1.0 mg/L

Up to

0.3 mg/L

Up to

0.05 mg/L

Up to

1.0 mg/L

Plumbing

Water Supply Connections

CAUTION: IMPORTANT—Do

not apply heat to the HOT or COLD water

connections. If sweat connections are used, sweat

tubing to the adapter before fitting the adapter

to the water connections on the water heater.

Any heat applied to the water supply fittings will

permanently damage the internal components of

the water heater.

NOTICE: In cold environments, ice can

accumulate in the water heater’s connectors. Plug

in the water heater power cord for approximately

10 minutes before making these connections. This

will melt any ice buildup.

Plumbing should be carried out by a qualified

plumbing contractor in accordance with local

codes.

Only use approved plumbing materials.

The minimum diameter of all water pipes should

be 3/4 in. (1.9 cm).

To conserve energy and to prevent freezing,

insulate both COLD and HOT water supply lines.

Do not insulate the drain line or pressure-relief

valve.

47

Page 12

INSTALLATION INSTRUCTIONS

Water Supply

Water Supply Connections (cont.)

Plumbing

To ensure proper operation of the water heater,

follow these water pressure guidelines.

• Operation of the water heater requires a

minimum water pressure of 14 psi (97 kPa) and a

minimum water flow rate of 0.4 gpm (1.5 lpm).

• Water pressure of 40 psi (276 kPa) is required to

achieve maximum flow rate.

• To maintain proper performance, there must be

sufficient water supply pressure.

Required Water Pressure =

Min. Operating Water Pressure

(14 psi [97 kPa])

+ Pipe Pressure Loss

+ Faucet Pressure Loss

+ Safety Margin

(more than 5 psi [34 kPa]).

Water Supply Installation

NOTICES:

• Use only Teflon tape on all COLD and HOT water

connections.

• If the water flow resistance of a showerhead is

too high, the burner in the water heater will fail to

ignite. Keep all showerheads clean from debris

that could cause additional pressure drop.

• If using mixing valves on the outlet, choose

one that prevents COLD water pressure from

overcoming HOT water pressure.

• If multiple water heaters are installed in a

manifold system, the water piping MUST be in

“parallel” and the water pressure at each water

heater should be 40 psi (276 kPa).

• To supply HOT water to upper floors, additional

water pressure will be required (0.44 psi [3 kPa]

per foot of height). Calculate the distance

between the water inlet of the water heater

(ground level) to the HOT water faucet farthest

away from the water heater (upper floor level).

• Well water systems should be set to ensure a

minimum system pressure of 40 psi (276 kPa).

The pressure should remain constant and stable

during the operation of the water heater.

• Gravity water pressure is not recommended.

When the water is supplied from a water supply

tank, the height of the tank, the diameter of the

supply pipes, and their relation to water pressure

need to be taken into consideration.

2

Before attaching the water line to the water

heater, open the shut-off valve. Run the water

until it has purged all contaminants (sand,

debris, air, caulking, etc.).

48

1

Install a COLD water shut-off valve near the

inlet line on the water heater. This valve will be

used for servicing and draining purposes.

NOTICE: It is not recommended to

use pipes with smaller diameters than the water

supply connection of the water heater.

3

Install a service valve on the end of the COLD

water supply line and connect it to the water

inlet on the water heater.

Page 13

Pressure

Relief Valve

Pressure

Relief Valve

Cold Water

Service Valve

Cold Water

Service Valve

Water

Inlet

Water

Inlet

Water

Outlet

Water

Outlet

Hot Water

Service Valve

Hot Water

Service Valve

Drain

Drain

Water Supply Installation (cont.)

4

Open the shut-off valve in the COLD water Inlet

line to check the water flow through the water

heater.

INSTALLATION INSTRUCTIONS

NOTICES:

• Be sure to connect the COLD water inlet and the

HOT water outlet as shown on the water heater.

If reversed, the water heater will not function.

• The flow rate of HOT water may vary when more

than two faucets (appliances, fixtures, etc.) are

being used simultaneously.

• The pipes MUST be completely drainable. If the

HOT water faucets are located at a point higher

than the water heater, place a drain valve at the

lowest point.

Plumbing

5

Close the shut-off valve and remove, clean, and

replace the water filter.

It is recommended to use unions and flexible

copper connections at the COLD and HOT

water lines. They allow the water heater to be

disconnected easily for servicing.

Use the following guidelines when connecting

the HOT WATER OUTLET:

• Connections between the water heater and

point(s) of use should be as short as possible.

• Local codes shall govern the piping used for

water connections.

• To conserve energy and to prevent freezing,

insulate both COLD and HOT water supply lines.

Do not insulate drain line or pressure-relief valve.

Water Piping Arrangement With Service Valve Kit

Service valve kits are available on all tankless

water heater systems. All kits include two full-port

isolation valves to be used in the COLD and HOT

water lines. When installed, these valves allow

one person full diagnostic testing and ease of

flushing the system. Contact your distributor or

place of purchase for availability and installation

information.

49

Page 14

INSTALLATION INSTRUCTIONS

Relief

Valve

Union

Union

Cold Water Supply

Shut-Off Valve

Cold Water

Supply Inlet

Hot Water

Supply Outlet

Relief Valve

Discharge Line

Water Supply (cont.)

Plumbing

Relief Valve

A new pressure-relief valve, complying with the

Standard for Relief Valves and Automatic Gas

Shut-Off Devices for Hot Water Supply Systems,

ANSI Z21.22/CSA 4.4, must be installed at the

HOT water outlet connection of the water heater

during installation. Local codes shall govern the

installation of any relief valves or place of purchase

for availability and installation information.

NOTICES:

• The following drawing illustrates a pressure-only

relief valve. If local codes require a combination

temperature and pressure-relief valve, you may

need to install an extension piece to ensure that

the valve probe is not directly in the flow path of

the water.

•

If local codes require that a temperature and

pressure-relief valve be installed, the manufacturer

recommends a type 40XL Watts temperature and

pressure-relief valve or equivalent model be used.

• Manual operation of relief valves should be

performed at least once a year.

• If the relief valve on the system discharges

periodically, a problem exists. Turn off the water

heater, unplug the unit, and call for service.

For safe operation of the water heater, be sure

that:

• The pressure rating of the relief valve must not

exceed 150 psi (1,034 kPa) or the maximum

working pressure of the water heater. (See the

rating plate on the water heater.)

• The BTUH rating of the relief valve must equal or

exceed the BTUH input of the water heater. (See

the rating plate on the water heater.)

• No valve of any type should be installed between

the relief valve and the water heater.

• Discharge from the relief valve should be piped

to a suitable drain. Piping used should be of a

type approved for the distribution of hot water.

• HOT and COLD water lines should be insulated

up to the water heater. See page 51.

• The discharge line must be NO SMALLER than

the outlet of the relief valve. The drain line must

pitch downward to allow for complete drainage

of the line and the valve.

• The end of the discharge line should not be

threaded or concealed and should be protected

from freezing. No valve of any type, restriction,

or reducer coupling should be installed in the

discharge line.

50

One end of the relief valve discharge line connects

to the HOT water outlet pipe as shown above.

The other end of the pipe should be routed to a

suitable drain to eliminate potential water damage.

Page 15

Hot and Cold Pipe Insulation Installation

Cold Water

Service Valve

Hot Water

Service Valve

Pressure

Relief Valve

Pressure

Relief Valve

Water

Outlet

Water

Outlet

Water

Inlet

Water

Inlet

Drain

Drain

Condensate Drain

INSTALLATION INSTRUCTIONS

WARNINGS:

• When pipe insulation is not rated for the

appropriate weather conditions, install electric

heat tracing or equivalent to prevent freezing of

the pipes.

• Do not insulate or block drain valve on the hot

outlet fitting.

• If pipes are allowed to freeze, the water heater

and the pipes may malfunction or leak due to

freezing water.

NOTICE: The hot and cold water supply

pipes should be insulated to provide additional

freeze protection.

Condensate

Condensate Drainage

Be sure the condensate runs freely to a drain and

does not accumulate inside the water heater. In

cold climates, precautions may need to be taken to

ensure that the condensate drain does not freeze.

• All condensation must drain and dispose of per

local code.

• If the condensate drain gets blocked, an error

code will display on the remote control. If this

occurs, the condensate drain must be cleared.

• Use only PVC or CPVC pipe or flexible tube for

the condensate drain line.

For increased energy efficiency, use pipe insulation

as shown in the diagram. Insulate the pipes all

the way to the top. DO NOT cover any drain or

pressure-relief valve(s).

Plumbing

• The drain pipe (along its entire length) must be at

least the same diameter as the drain line.

• The drain line should be as short as possible and

have a downward slope toward the end.

• The end of the drain pipe should be open to the

atmosphere. The end should not be under water

or other substances.

• Do not connect the drain pipe directly to the

drain sewer.

• Do not connect the drain pipe with an airconditioning evaporator coil drain.

51

Page 16

INSTALLATION INSTRUCTIONS

Union

Manual Gas

Supply Line

Shut-Off Valve

Cap

Sediment Trap

Manual Gas

Shut-Off Valve

Gas Supply

Gas Supply

Gas Supply Connections

WARNING: Do not attempt to

convert this water heater for use with a different

type of gas other than the type shown on the

rating plate. Doing so could result in death,

personal injury, explosion or fire, product damage,

and/or poor operating conditions or performance.

NOTICES:

• Gas piping shall be in accordance with local

utility company requirements and/or in the

absence of local codes, use the latest edition of

National Fuel Gas Code (NFGC), ANSI Z223.1.

In Canada, use the latest edition of CSA B149.1,

National Gas and Propane installation code.

• Apply a thin coat of pipe compound to all

threaded male ends. Compound must be of the

type resistant to the action of LP gas.

• To ensure proper water heater operation, the gas

pipe and gas meter must be sized correctly.

• If flexible connectors are used, the minimum

inside diameter must be 3/4" or greater and the

rated capacity of the connector must be equal

to or greater than the BTU capacity of the water

heater. See manufacturer information for the

gas connector. Lengths over 36 inches are not

recommended.

• Do not use excessive force (over 31.5 ft. lbs.

[42,7 Nm]) when tightening the pipe sections.

Excessive force can damage the water heater,

especially when Teflon pipe compound is used.

52

Page 17

INSTALLATION INSTRUCTIONS

Gas Piping

Pipe-Sizing Procedure – Example

The gas supply must be capable of handling the

entire gas load at the location. Gas line sizing

is based on gas type, the pressure drop in the

system, the gas pressure supplied, and gas line

type. For gas pipe sizing in the United States,

refer to the National Fuel Gas Code, NFPA 54. For

Canadian gas pipe sizing, refer to the Natural Gas

and Propane Installation Code CAN/CSA B149.1.

The information below is provided as an example.

The appropriate table from the applicable code

must be used.

1. Determine the cubic feet per hour of gas

required by dividing the gas input (on the rating

plate) by the heating value of the gas (available

from the local gas company). The gas input

needs to include all gas products at the location

and the maximum BTU usage at full load when

all gas products are in use.

Gas Input of

Cubic Feet Water Heater (BTU/HR)

Per Hour (CFH) = Heating Value of Gas (BTU/FT

2. Use the table for your gas type to find the pipe

size required for your cubic feet per hour of gas

and your pipe length.

Example: The heating value of propane gas for

3

your location is 2500 BTU/FT

. The gas input

of the tankless water heater is 199,900 BTU/

HR. Additional appliances at the location require

75,000 BTU/HR. Therefore, the cubic feet per

hour = (199,900 + 75,000)/2500 = 109 FT3/HR.

If the pipe length is 100 ft., then the 3/4-inch

pipe size capable of supplying 197 FT3/HR of

propane gas will be adequate.

Gas Supply

3

)

Pipe-Sizing Table – Natural Gas

Schedule 40 Metallic Pipe

Inlet Pressure: Less than 2 psi (55 inches W.C.)

Length

10

20

30

40

50

60

70

80

90

100

125

150

175

200

Refer to current National Fuel Gas Code, NFPA 54.

Pressure Drop: 0.3 inches W.C.

Specific Gravity: 0.60

(Capacity in cubic feet per hour)

Pipe Size (inches)

3/4 1 1 1/4 1 1/2

273 514 1060 1580

188 353 726 1090

151 284 583 873

129 243 499 747

114 215 442 662

104 195 400 600

95 179 368 552

89 167 343 514

83 157 322 482

79 148 304 455

70 131 269 403

63 119 244 366

58 109 224 336

54 102 209 313

Pipe-Sizing Table – Propane Gas

Schedule 40 Metallic Pipe

Inlet Pressure: 11.0 inches W.C.

Pressure Drop: 0.5 inches W.C.

Specific Gravity: 1.50

(Capacity in cubic feet per hour)

Length

10

20

30

40

50

60

80

100

125

150

175

200

1/2 3/4 1 1 1/4

291 608 1150 2350

200 418 787 1620

160 336 632 1300

137 287 541 1110

122 255 480 985

110 231 434 892

101 212 400 821

94 197 372 763

89 185 349 716

84 175 330 677

74 155 292 600

67 140 265 543

Pipe Size (inches)

53

Page 18

INSTALLATION INSTRUCTIONS

Gas Supply (cont.)

Gas Supply Installation

4

Gas Supply

1

Install the manual gas appliance shut-off valve

to the gas connection at the water heater. The

shut-off is supplied with the water heater.

2

Install a ground joint union or ANSI design-

certified semi-rigid or flexible gas appliance

connector to the open end of the manual gas

appliance shut-off valve. The (NFGC) ANSI

Z223.1 and CSA B149.1 codes mandate the

use of manual gas shut-off valves.

Using the proper-size piping, fittings, and

components, build the gas supply line to the

water heater.

NOTICE: The gas supply line should

be a minimum of 3/4-in. (1.9-cm) black steel

pipe or other approved gas piping material.

5

Install a sediment trap at the lowest portion of

the gas line.

The inlet gas pressure to the water heater must

NOT exceed 10.5 in. w.c. (2.6 kPa) for natural

gas and 14 in. w.c. (3.5 kPa) for LP gas. For

purposes of input adjustment, the minimum inlet

gas pressure (with main burner on) is shown on

the water heater rating plate. If high or low gas

pressures are present, contact your gas supplier

for correction.

54

3

Install a manual gas supply line shut-off valve

to the end of the gas supply line.

NOTICE: Lever-type gas shut-offs

should all be T-handle type.

Page 19

Leak Testing

WARNING: Never use an open

flame to test for gas leaks, because death,

personal injury, and/or property damage can result.

The water heater and its gas connections MUST

be leak-tested at normal operating pressures

before the unit is placed in operation. These tests

should also include all factory connections.

INSTALLATION INSTRUCTIONS

Turn on the gas shut-off valve(s) to the water

heater.

Use a soapy water solution to test for leaks at all

the connections and fittings. If bubbles are seen,

it indicates a gas leak that must be corrected.

Contact a qualified service technician.

Pressure Testing the Gas Supply

System

CAUTION: Install a gas pressure

regulator in the gas supply line. This regulator

should not exceed the maximum supply pressure.

DO NOT use an industrial-type gas regulator.

Gas Supply

The water heater and its manual gas shut-off valve

must be disconnected from the gas supply piping

system whenever the pressure testing will exceed

1/2 psi (14 in. w.c. [3.5 kPa]).

The water heater must be isolated from the gas

piping system whenever the pressure testing

will be less than and/or up to 1/2 psi (14 in. w.c.

[3.5 kPa]). Closing the manual gas shut-off valve

will isolate the water heater from the gas piping

system.

55

Page 20

INSTALLATION INSTRUCTIONS

Gas Supply (cont.)

Gas Supply

Electrical

56

High-Altitude Installation

The water heater is certified for installations up

to 3,280 ft. (1,000 m) above sea level. The input

rating of this water heater is based on sea level

operation. At higher elevations, the actual input

rate may be lower than the value listed on the

rating label.

Electrical Wiring

DANGER: Shock Hazard – Before

servicing the water heater, turn off the electrical

power to the water heater at the main disconnect

or circuit breaker. Failure to do so will result in

death or serious personal injury.

WARNING: Field wiring connections

and electrical grounding must comply with local

codes or, in the absence of local codes, with the

latest edition of the National Electrical Code, ANSI/

NFPA 70, in the U.S., or Canadian Electrical Code,

CSA C22.1, Part 1, in Canada.

CAUTION:

disconnecting. Wiring errors can cause personal

injury, product damage, and/or dangerous operating

conditions. Verify correct operation after servicing.

Label all wires prior to

NOTICES:

• Do not connect power until venting installation is

complete (see Venting Installation pages 34–46).

• Wait ninety (90) seconds after power is

connected for the first time to initiate operation

of the water heater.

Power Cord

• The electric power supply requirement for this

water heater is 120 VAC/60 Hz, 2 amps.

• A dedicated circuit is recommended for the water

heater. Do not connect to a GFCI or AFCI circuit.

Multiple units may be connected to a single

circuit up to the circuit rating.

• Do not use 3-prong to 2-prong adapters. Do not

use power strips or multiple outlet adapters.

NOTICES:

• For installations above 3,280 ft. (1,000 m)

elevation, contact a qualified service technician

to make the proper altitude adjustments. See

pages 67 and 68 for additional information.

• Do not install this water heater at elevations

above 3,280 ft. (1,000 m) without the proper

adjustments. Please contact your installer, local

gas supplier, place of purchase, or the Rheem

Customer Service phone number listed on

page 26 in the “Call for Assistance” section.

• All direct-vent gas models come with a threeprong power cord. Only use this power cord and

a matching grounded electrical outlet.

• All outdoor gas models do not come with a

power cord. Only hard-wire to an appropriate

power outlet with a ground terminal.

• Keep any excess length of the power supply

cord on the outside of the water heater.

• If local codes require hard-wiring, see

instructions for “Hard-Wiring the Electrical

Connections” below.

Hard-Wiring the Electrical Connections

• Wiring should be performed by a qualified

electrician in accordance with local codes.

• The water heater requires a properly grounded

120 VAC/60 Hz dedicated power supply. Multiple

water heaters may be connected to a single

circuit up to that circuit’s rating.

•

DO NOT connect grounding wire to water pipes,

gas pipes, telephone cables, lighting conductor

circuits, or to any other grounding circuits that

require a GFCI or AFCI (arc fault circuit interrupter).

• An ON/OFF switch must be provided and

installed for the incoming 120 VAC power supply.

• Wire the water heater exactly as shown in the

wiring diagram. This wiring diagram can also be

found inside the water heater cover panel.

• The green screw is provided in the enclosure for

a grounding connection.

• Connect the live wire to the black wire and

neutral wire to the white neutral wire.

Page 21

Wiring Diagram

W: WHITE, BLANC

BK: BLACK, NOIR

BR: BROWN, BRUN

BL: BLUE, BLEU

FOR INDOOR, DIRECT-VENT

GY: GRAY, GRIS

CODE DE COULEUR

COLOR CODE

R: RED, ROUGE

AMBIENT AIR

THERMISTOR

THERMISTOR

VERT/JAUNE

Y: YELLOW, JAUNE

G/Y: GREEN/ YELLOW,

O: ORANGE, ORANGE

G: GREEN, VERT

R4

FLAME ROD 1

ÉLECTRODE DE

DÉTECTION

DE FLAMME 1

MODEL ONLY

POUR MODÈLE INTÉRIEUR À

ÉVENT DIRECT SEULEMENT

HEAT EXCHANGER

THERMISTOR

D’ADMISSION D'EAU

WATER INLET

THERMISTOR

D’AIR AMBIANT

R3

BK

FLAME ROD 2

ÉLECTRODE DE

DÉTECTION

DE FLAMME 2

R2

BK

GAS TYPE

INSTALLATION INSTRUCTIONS

THERMISTOR

DE SORTIE D’EAU CHAUDE

HOT WATER OUTLET

THERMISTOR

THERMISTOR

D’ECHANGEUR DE CHALEUR

THERMISTOR

P.G.F.R VALVE

WATER VOLUME CONTROL MOTORWATER BY-PASS CONTROL MOTOR

MOTEUR DE CONTRÔLE DU VOLUME D’EAU

PSV

−

+

ÉLECTROVALVE DE DÉRIVATION D’EAU

CIRCUIT BOARD

PLAQUE DE CIRCUIT

R1

BK

IMPRIMÉ DE TYPE Â GAZ

MOTOR

MOTEUR

LIMITER

LIMITEUR

MOTOR

MOTEUR

LIMITER

LIMITEUR

GG BL BL

BK R Y O WBR

R Y O WBR

BK

CONTROL 2

BATH REMOTE

TÉLÉCOMMANDE 2

« BATH »

BATH REMOTE

CONTROL 1

TÉLÉCOMMANDE 1

« BATH »

MAIN REMOTE

CONTROL

TÉLÉCOMMANDE

« MAIN »

(USC2-117)

31-98419 2

(USC1-117)

(UMC-117)

8

8

NEUTRALIZER WATER

ON

MARCHE

LEVEL ELECTRODE

ÉLECTRODE DE NIVEAU

CONTACTEUR DIP 1

DIP SWITCH 1

ON

OFF

ARRÊT

4

3

2

1

R

R

D’EAU DE NEUTRALISANT

5

FAN MOTOR

DIP SWITCH 2

CONTACTEUR DIP 2

MARCHE

OFF

ARRÊT

4

3

2

1

YWR BK BL

FM

MOTEUR DU

VENTILATEUR

FOR DIRECT-VENT MODEL ONLY

BL

BOUTON DE RÉGLAGE

BOUTON MAX.

BOUTON MIN.

CIRCUIT BOARD

T

W

M

LED

PLAQUE DE CIRCUIT

SW3SW2SW1

MAX BUTTON ADJUSTER BUTTON

MIN BUTTON

1

2

P

G

123456

W BL R O Y

GND

BK

SV4

SV3

`

POUR MODELE À ÉVENT DIRECT SEULEMENT

SOLENOID VALVE 4

ÉLECTROVALVE 4

SOLENOID VALVE 3

ÉLECTROVALVE 3

SV2

SOLENOID VALVE 2

ÉLECTROVALVE 2

BK

A

4 3 2 1

F

G/Y

SV1

SOLENOID VALVE 1

2

345

USUALLY

DISCONNECTED

NORMALEMENT

K

R

5678

BK

W BK

BK

BK

SV0

ÉLECTROVALVE 1

ÉLECTROVALVE DANS

SOLENOID VALVE 0

1

DÉCONNECTÉ

G

W

BL

B

R

R

BK

BK

( )

123

4

567

YW

1

23

GY

4

BL

W

RÉSISTANCE

RESISTOR

ADMISSION DE GAZ

IG

BK

ELECTRODE

GY

GY

ALLUMEUR

IGNITER

ELECTRODE

Y

R

G

BL

BK

45678

R

Y

G

BK

8C9

BL

456

7

1

2

U

R

H

3

1

WW

2

4

W

W

ANTI-FROST HEATER

CHAUFFAGE ANTI-GIVRE

W

BL

O

W

BR

1

2

3

O

W

BR

1

2

3

3

2

1

BL

1

2

3

V

WATER FLOW SENSOR

CAPTEUR DE DÉBIT D’EAU

S

W

BR

W

BK

R

Electrical

IJ

W

W

W

W

BK

W

BK

W

BK

G/Y or G

AC

120V

FUSIBLE (3A)

FUSE (3A)

OVER HEAT LIMITER

GND

FOR INDOOR, DIRECT-VENT

LIMITEUR DE SURCHAUFFE

`

MODEL ONLY

POUR MODELE INTERIÉUR À

ÉVENT DIRECT SEULEMENT

57

Page 22

INSTALLATION INSTRUCTIONS

Electrical Wiring (cont.)

Remote Control Selection and

Location

WARNING: Field wiring connections

and electrical grounding must comply with local

codes or, in the absence of local codes, with the

latest edition of the National Electrical Code, ANSI/

NFPA 70, in the U.S., or Canadian Electrical Code,

CSA C22.1, Part 1, in Canada.

NOTICES:

•

The provided remote control will allow maximum

temperature settings of 120°F (49°C). Temperatures

up to 140°F (60°C) for residential applications and

up to 185°F (85°C) for commercial applications*

can be achieved with the MAIN (UMC-117) remote

control. Only qualified service personnel should

perform this adjustment.

• An optional cable (EZ Link

CableTM) can be purchased

separately to manifold two

water heaters together.

• Do not attempt to disassemble

a remote control. All controls are

sealed and calibrated for accurate

water heater control and operation.

Review the following considerations before

determining the location of the remote

control(s):

• Do not install any remote control

outdoors or where it can come in

contact with water.

Avoid installing the remote control in

•

the following areas and/or conditions:

– area exposed to heat.

– area exposed to steam.

– area exposed to oil.

– area exposed to direct sunlight.

– areas near stored or used

flammable products.

• Place remote control out of children’s reach.

• The remote control should be installed in a

convenient location (e.g., kitchen, laundry room,

utility room, or directly next to the water heater).

• The maximum distance between the water

heater and the remote control installation

location is limited to 195 ft. (59 m) of wire.

Electrical

58

One remote control is provided with the water

heater. Additional remote controls may be

purchased separately. The available remote

controls are listed in the following chart. Up to

three remote controls can be used with the water

heater. No other manufacturer’s controls are

suitable for use with this water heater.

Remote Control

Model Number

UMC-117 MAIN

USC1-117

USC2-117 BATH 2

MIC-6 or MIC-185**

Manifold System

*A commercial conversion kit can be purchased to achieve temperatures up to 185°F (85°C).

**When a manifold system is installed, the main remote control connected to the manifold controller

(MIC-6 or MIC-185) has priority over the remote controls connected to the water heater.

Remote Control

Description

BATH 1

Manifold System Optional (Sold Separately)

Temperature

Set Point Range Availability

100°F–120°F (38°C–49°C) Factory Default

85°F (29°C)

125°F–140°F (52°C–60°C)

85°F (29°C)

125°F–185°F (52°C–85°C)

100°F–120°F (38°C–49°C) Optional (Sold Separately)

85°F (29°C) Qualified Technician Adjustment

100°F–120°F (38°C–49°C) Optional (Sold Separately)

85°F (29°C) Qualified Technician Adjustment

Adjustment for Residential Products

Adjustment for Commercial Products*

Qualified Technician

Qualified Technician

Page 23

Remote Control Installation

WARNING: Field wiring connections

and electrical grounding must comply with local

codes or, in the absence of local codes, with the

latest edition of the National Electrical Code, ANSI/

NFPA 70, in the U.S., or Canadian Electrical Code,

CSA C22.1, Part 1, in Canada.

INSTALLATION INSTRUCTIONS

4

NOTICES:

• Remote control cable can be any Type–T 18

AWG wire similar to a thermostat wire and need

not be polarity-sensitive.

• It is not recommended to have wiring exposed.

• Do not apply sealant to remote control cable.

• Do not use network cable, telephone wire, or

any twisted-pair cable.

Connecting the MAIN (UMC-117) Remote

Control to a Wall:

1

Drill a 1- to 1 1/2-in. (2.5/3.8-cm) hole at the

proposed control location. Install the remote

control cable between the location of the

remote control and the water heater.

Install the base plate to the wall using suitable

screws and wall anchors.

NOTICE: The tabs on the base plate

should always point out.

5

Connect the remote control to the remote

control cable.

Electrical

6

Position the remote control on the base plate.

2

Remove the remote control from the base plate.

3

Feed the remote control cable through the large

center hole in the base plate.

NOTICE: The tabs on the base plate

should line up with the slots on the back of the

control panel.

Secure the control panel to the base plate with

one screw into the bottom tab.

NOTICE: Do not attempt to connect the

remote control or control wire to the water heater

while the water heater has power applied to it.

Damage to the water heater will occur. Do not

cut or strip the wiring while it is connected to the

water heater or while the water heater has power

applied to it.

59

Page 24

INSTALLATION INSTRUCTIONS

Remote Control

Connection Cover

Remote Control

Connection Cover

Electrical Wiring (cont.)

Connecting the Remote Control to the Water

Heater:

1

Ensure that the power to the water heater has

been disconnected.

4

Firmly tighten the terminal screws by hand.

Secure the remote control extension cable on

5

Electrical

2

Loosen the one screw located on the remote

control connection cover. The connection cover

is made of white plastic.

NOTICE: DO NOT REMOVE FRONT

PANEL. Remote control wires are connected on

the bottom of the unit.

There are no accessible remote control

terminals inside the water heater.

3

Connect the remote control extension cables

from the remote control to the remote control

connection terminals.

the hook located on the side of the remote

control connection base.

Reinstall the remote control connection cover

6

and secure with the one screw.

NOTICE: Do not connect power until

venting installation is complete.

Switch on the power supply to the water heater.

60

NOTICE: The remote control wire

connection terminals are not polarity-sensitive.

7

Check for proper operation of the remote

control and the water heater.

Page 25

Insulation Blankets

INSTALLATION INSTRUCTIONS

In general, insulation blankets for external use

on gas water heaters are not necessary. The

purpose of an insulation blanket is to reduce the

standby heat loss from the water heater’s storage

tank. Since these water heaters do not store water,

they eliminate the need for the insulation blanket.

WARNINGS:

• If local codes require the application of external

insulation blanket kits, carefully follow the

manufacturer’s installation instructions included

with the kit. Only use blanket kits that are

approved for use with your water heater.

• NEVER cover the air inlet, flue outlet, or

operating and warning labels attached to the

water heater. Operating and warning labels

should not be relocated to the exterior of an

insulation blanket. Covering these components

will cause dangerous operating conditions that

can lead to death, personal injury, property

damage, and/or product damage.

The manufacturer’s warranty does not cover any

damage or defect caused by insulation, insulation

attachment, or use of any type of energy-saving

or other unapproved devices (unless authorized

by the manufacturer). The use of unauthorized

energy-saving devices can result in death,

personal injury, and/or property damage. The

manufacturer disclaims any responsibility for

such loss or injury resulting from the use of such

unauthorized devices.

Installation Precautions

• Follow all installation instructions covered in this

manual.

• Check the inlet gas pressure to make sure it is

within the range specified on the rating plate.

• Make sure there is adequate air for combustion

and ventilation as described on pages 37–38 or

page 44 in this manual.

• Maintain proper clearances to combustibles and

noncombustibles as specified on the rating plate.

• Make sure the venting system complies with

local codes, National Fuel Gas Codes (ANSI

Z223.1/NFPA 54) or CSA B149.1, and the

guidelines found on pages 34 through 46 in this

manual.

Electrical

• Contact the local gas company to make sure the

gas meter and gas piping are adequately sized.

• Use only Teflon tape on all male water line

connections and fittings.

• Do not block or restrict any air intake openings.

• Do not remove the front cover unless absolutely

necessary. This should only be done by a

qualified service technician.

• Do not install this product where standing water

may occur.

• Do not use pipe dope on water line connections

and fittings.

61

Page 26

INSTALLATION INSTRUCTIONS

Installation Checklist

A. Water Heater Location

Indoor water heaters must be installed

indoors.

Outdoor water heaters must be installed

outdoors.

Close to area of ventilation termination

(indoor models).

Protected from freezing temperatures.

Proper clearance from combustible material

observed.

Sufficient fresh air supply for proper operation

of water heater.

Air supply free of corrosive elements and

flammable vapors.

Provisions made to protect area from water

damage.

Sufficient room to service heater.

C. Water Supply/Relief Valve

Water supply has sufficient pressure.

Air has been purged from the water heater

and the piping.

Water connections tight and free from leaks.

Water filter is clean and in place.

All piping has been assembled as described

on pages 48 and 49.

Water pipes are insulated and protected from

freezing, if necessary.

Pressure-relief valve properly installed with

discharge line running to open drain.

Discharge line protected from freezing, if

necessary.

D. Gas Supply

Gas type matches listing on rating plate.

Checklist

Combustible materials, such as clothing,

cleaning materials, and rags, clear of the

heater and vent piping.

Water heater is properly attached to the wall.

B. Vent (Indoor Models)

Vent pipe material is PVC and is

manufacturer-approved.

Horizontal air intake and exhaust pipes have

a 1/4" per foot DOWNWARD slope toward the

vent terminal.

Vertical venting is installed as described on

pages 43 and 44.

Connection(s) securely fastened together with

cement and airtight.

All vent runs are properly installed.

Vent terminal is properly installed.

Maximum vent length is observed.

Gas supply pressure is sufficient for the water

heater.

Gas line equipped with shut-off valve, union

and sediment trap as described on page 54.

Approved pipe-joint compound has been

used on all gas pipe connections.

All connections and fittings have been

checked for leaks with a soapy water

solution.

Gas company inspected installation (if

required).

E. Electrical Wiring

Supply cord and/or wiring meets all local

codes, National Electrical Code, ANSI/NFPA

70, in the U.S., or Canadian Electrical Code,

CSA C22.1, Part 1, in Canada.

Voltage matches listing on rating plate.

Water heater is properly grounded.

62

F. Condensate

Condensate drain is properly installed.

Page 27

Lighting the Water Heater

INSTALLATION INSTRUCTIONS

WARNING: Before operating

this water heater, be sure to read and follow

the instructions on the following label, all labels

on the water heater, and the “Important Safety

Information” section in this manual. Failure to

do so can result in unsafe operating conditions

that can result in death, personal injury, property

damage, and/or product damage.

NOTICE: If you have any problems

reading or following the instructions in this manual,

STOP and call a qualified service technician or

contractor.

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING : If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

OPERATING INSTRUCTIONS

1.STOP! Read the safety information above on this label.

2.Turn off all electric power to the appliance.

3.Do not attempt to light the burner by hand.

4.Turn the Gas Shutoff Valve located on the outside of the unit

clockwise to the "OFF" position.

5.Wait five (5) minutes to clear out any gas. If you then smell gas, STOP! Follow "B" in

the safety information above on this label. If you don't smell gas, go to the next step.

6.Turn the Gas Shutoff Valve located on the outside of the unit counterclockwise to

the "ON" position.

7.Turn on all electric power to the appliance.

8.If the appliance will not operate, follow the instructions "To Turn Off Gas To Appliance"

and call your service technician or gas supplier.

GAS SHUTOFF

VALVE

OPEN CLOSE

TO TURN OFF GAS TO APPLIANCE

1.Turn off all electric power to the appliance if service is to be performed.

2.Turn the Gas Shutoff Valve located on the outside of the unit clockwise to the "OFF" position.

Start/Adjust

63

Page 28

INSTALLATION INSTRUCTIONS

Lighting the Water Heater

Operating Instructions

Read, understand, and follow the safety

information listed on the operating label

on page 63 and in the “Important Safety

Information” section in this manual.

4

Turn on all electric power to the water heater.

The water heater burner will automatically light

when there is a demand for hot water.

1

Disconnect all electric power to the water heater.

2

Turn the gas shut-off valve clockwise to the OFF

position. This valve is located on the outside of

the water heater. Wait 5 minutes to clear any

gas. If you don’t smell gas, proceed to Step 3.

NOTICE: If you smell gas, STOP and

follow the safety instructions listed under B on

the operating label or on the front cover of this

manual.

WARNING: Do not attempt to light

the burner by hand. Lighting the burner by hand

is an unsafe operating condition that can result in

death, personal injury, property damage, and/or

product damage.

If the water heater burner will not light, turn off

the water heater as described below and call

your service technician or gas supplier.

Shutting Off the Water Heater

1

Disconnect all electric power to the water heater.

Start/Adjust

64

3

Turn the gas shut-off valve counterclockwise to

the ON position.

2

Turn the gas shut-off valve clockwise to the

OFF position.

Page 29

INSTALLATION INSTRUCTIONS

The contents on pages 65 through 68 should only be performed by qualified

service personnel.

Setting the Water Temperature

WARNING: Improper adjustment,

alteration, service, or maintenance can result in

death, personal injury, property damage, and/or

product damage.

Maximum Temperature Adjustment by

the Main Remote Control (UMC–117)

DANGER: Water temperatures above

125°F (52°C) will result in death and/or severe

burns from scalding.

WARNING: Refer to chart below

and the scald potential warnings on page 4 on this

manual before making an adjustment. Changing

this setting is done at your own risk.

Time/Temperature

Relationship in Scalds

Water Time to Produce

Temperature a Serious Burn

Priority

Indicator

In-Use

Indicator

(Lit during

operation)

Temperature

Adjustment

LED Display

(Displays

water

temperature

and error

codes)

To change the temperature settings up to

140°F (60°C):

Buttons

ON/OFF

Button and

Indicator

1

T

urn on the remote control.

120°F (49°C) More than 5 minutes

125°F (52°C) 1 1/2 to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 1 1/2 seconds

155°F (68°C) About 1 second

Table courtesy of Shriners Burn Institute

Residential water heater temperatures can be

adjusted up to 140°F (60°C). Do not perform the

following adjustment if a setting of up to 140°F

(60°C) is not required.

2

Turn off the gas and water to the water heater

by closing the shut-off valves.

Start/Adjust

3

Press the UP adjustment button repeatedly until

120°F (49°C) shows in the LED display. Hold the

UP button until the “120” on the display starts

to blink.

NOTICE: LED display only shows °F.

65

Page 30

INSTALLATION INSTRUCTIONS

Setting the Water Temperature (cont.)

4

While “120” is blinking, press the UP and

DOWN adjustment buttons at the same time.

“120” will stop blinking.

5

Press the UP or DOWN adjustment button to

set the desired temperature.

6

Turn on the gas and water to the water heater

by opening the shut-off valves.

To limit maximum water temperature setting

to 120°F (49°C):

3

Press the DOWN adjustment button repeatedly

until 100°F (38°C) or 85°F (29°C) shows in the

LED display. Hold the DOWN button until the

number on the display starts to blink.

4

While the number is blinking, press the UP and

DOWN adjustment buttons at the same time.

The number will stop blinking.

5

Press the UP or DOWN adjustment button to

set the desired temperature.

Start/Adjust

66

1

Turn on the remote control.

2

Turn off the gas and water to the water heater

by closing the shut-off valves.

6

Turn on the gas and water to the water heater

by opening the shut-off valves.

Page 31

Minimum Temperature Adjustment by

the Main Remote Control (UMC–117,

USC1–117, and USC2–117)

INSTALLATION INSTRUCTIONS

Residential water heater temperatures can be

adjusted down to 85°F (29°C), when required.

To change the temperature settings down to

85°F (29°C):

1

Turn on the remote control.

2

Turn off the gas and water to the water heater

by closing the shut-off valves.

3

Press the DOWN adjustment button repeatedly

until 100°F (38°C) shows in the LED display.

NOTICE: LED display only shows °F.

4

Press the DOWN adjustment button 3 times

within 5 seconds. The display will show “85.”

5

Turn on the gas and water to the water heater

by opening the shut-off valves.

NOTICE: The maximum flow rate at 85°F

(29°C) is 1.3 gpm (5.0 L/m).

High-Altitude DIP Switch Adjustments

When the water heater is installed above 3,280 ft.

(1,000 m), the settings on the DIP switch located

on the printed circuit board (PCB) need to be

changed. If these settings are not changed, the

water heater may not function properly.

NOTICE: If the water heater is installed

under 3,280 ft. (1,000 m) altitude, no action is

required.

Verify the altitude that the water heater is installed.

1

Start/Adjust

Turn off the gas and water to the water heater

by closing the shut-off valves. The OFF position

is DOWN.

67

Page 32

INSTALLATION INSTRUCTIONS

High-Altitude DIP Switch Adjustments (cont.)

2

Remove the front cover panel on the water

heater.

Dip switch

adjustment

3,280 feet

(1,000 m)

thru

6,560 feet

5

(2,000 m)

If altitude is above 3,280 ft. (1,000 m) and

below 6,560 ft. (2,000 m), change the third

switch on “DIP 2” to the ON position (UP).

Dip switch

adjustment

6,560 feet

(2,000 m)

thru

9,840 feet

5

If altitude is above 6,560 ft. (2,000 m) and

below 9,840 ft. (3,000 m), change the fourth

switch to the ON position (UP).

(3,000 m)

Start/Adjust

Dip Switches

Printed Circuit

3

Find DIP Switch 2 located in the top-right

Board (PCB)

portion of the PCB. The switch labeled “DIP 2”

is the bottom switch.

As set

from factory

4

The factory settings for this switch should all be

in the OFF position (DOWN).

NOTICE: Do not alter any other DIP

switch settings. The manifold pressure will be

reduced accordingly.

6

Replace the front cover panel.

7

68

Turn on the gas and water to the water heater

by opening the shut-off valves.

Page 33

Parts Ordering

PARTS REPLACEMENT

WARNING: For your safety, do not

attempt to disassemble, repair, or replace any

portion of this unit. Refer all repairs, service, and/

or adjustments to qualified service personnel.

Address all parts orders to the distributor or store

where the water heater was purchased. All parts

orders should include:

Direct-Vent Gas Components

1. The model and serial number of the water

heater from the rating plate.

2. Specify the gas type (natural or LP) as marked

on the rating plate.

3. Parts description (as shown below) and number

of parts desired.

Ref # Description

1 Control Board

2 Gas Valve

3 Burner Assembly

4 Blower Motor

5 Burner Manifold

6 Gas Inlet Connector

7 Water Control Body

8 Water Inlet Connector 3/4"

9 Drain Relief Valve

10 Hot Outlet Connector

11 Remote Control Terminal Block

12 Neutralization kit

13 Air Intake Connector

14 Flue Connector

15 Front Cover

Parts

69

Page 34

PARTS REPLACEMENT

Parts Ordering (cont.)

Outdoor Gas Components

Parts

Ref # Description

1 Control Board

2 Gas Valve

3 Burner Assembly

4 Blower Motor

5 Burner Manifold

6 Gas Inlet Connector

7 Water Control Body

8 Water Inlet Connector 3/4"

9 Drain Relief Valve

10 Hot Outlet Connector

11 Remote Control Terminal Block

12 Neutralization kit

13 Front Cover

70

Page 35

NOTES

71

Page 36

NOTES

72

Loading...

Loading...