Paloma PH-28RIFSN, PH-28CIFSN (Indoor) (NAT. Gas) PH-28RIFSP, PH-28CIFSP, PH-28ROFN, PH-28COFN Engineering Handbook

...

R

Tankless Gas Water Heaters

PH-28RIFSN; PH-28CIFSN (Indoor) (NAT. Gas)

PH-28RIFSP; PH-28CIFSP (Indoor) (L.P. Gas)

PH-28ROFN; PH-28COFN (Outdoor) (NAT. Gas)

PH-28ROFP; PH-28COFP (Outdoor) (L.P. Gas)

PH-28RDVSN; PH-28CDVSN (Direct Vent) (NAT. Gas)

PH-28RDVSP; PH-28CDVSP (Direct Vent) (L.P. Gas)

(R: Residentail Model; C: Commercial Model)

Indoor Water Heater

Outdoor Water Heater

Direct Vent Water Heater

I

S

G

E

N

D

C

E

D

R

E

I

T

F

I

®

CERTIFIED

Engineering Handbook

R

WARNING: If the information in these instructions is not followed

exactly, a fire or explosion may result causing property damage,

personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance. To do so may result in an explosion or fire.

- WHAT TO DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use any phone in your building.

* Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

* If you cannot reach your gas supplier, call the fire department.

* Do not return to your home until authorized by the gas supplier or fire department.

- Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

WARNING: Improper installation, adjustment, alternation, service or maintenance

can cause property damage, personal injury, or death. For assistance or additional

information, consult with a qualifi ed distributor.

WARNING: The content on this manual is intended for use by qualifi ed service

personnel ONLY.

Table of Contents

Page

Specifi cations ................................................................. 3

External Dimensions ...................................................... 4 ~ 5

Schematic Construction ................................................. 6 ~ 8

Operational Principle ..................................................... 9 ~ 12

Capacity ......................................................................... 13 ~ 14

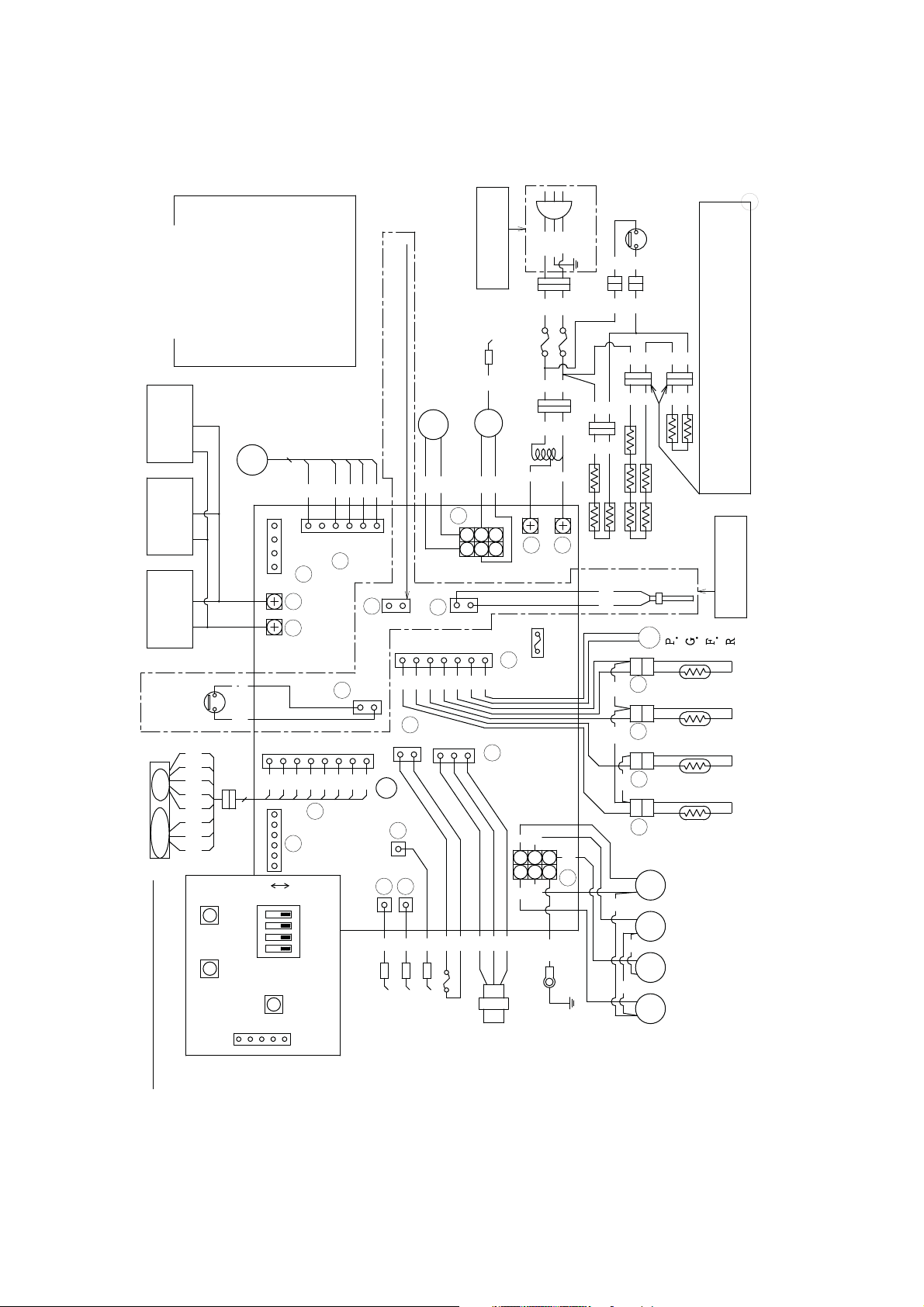

Wiring Diagram ............................................................. 15

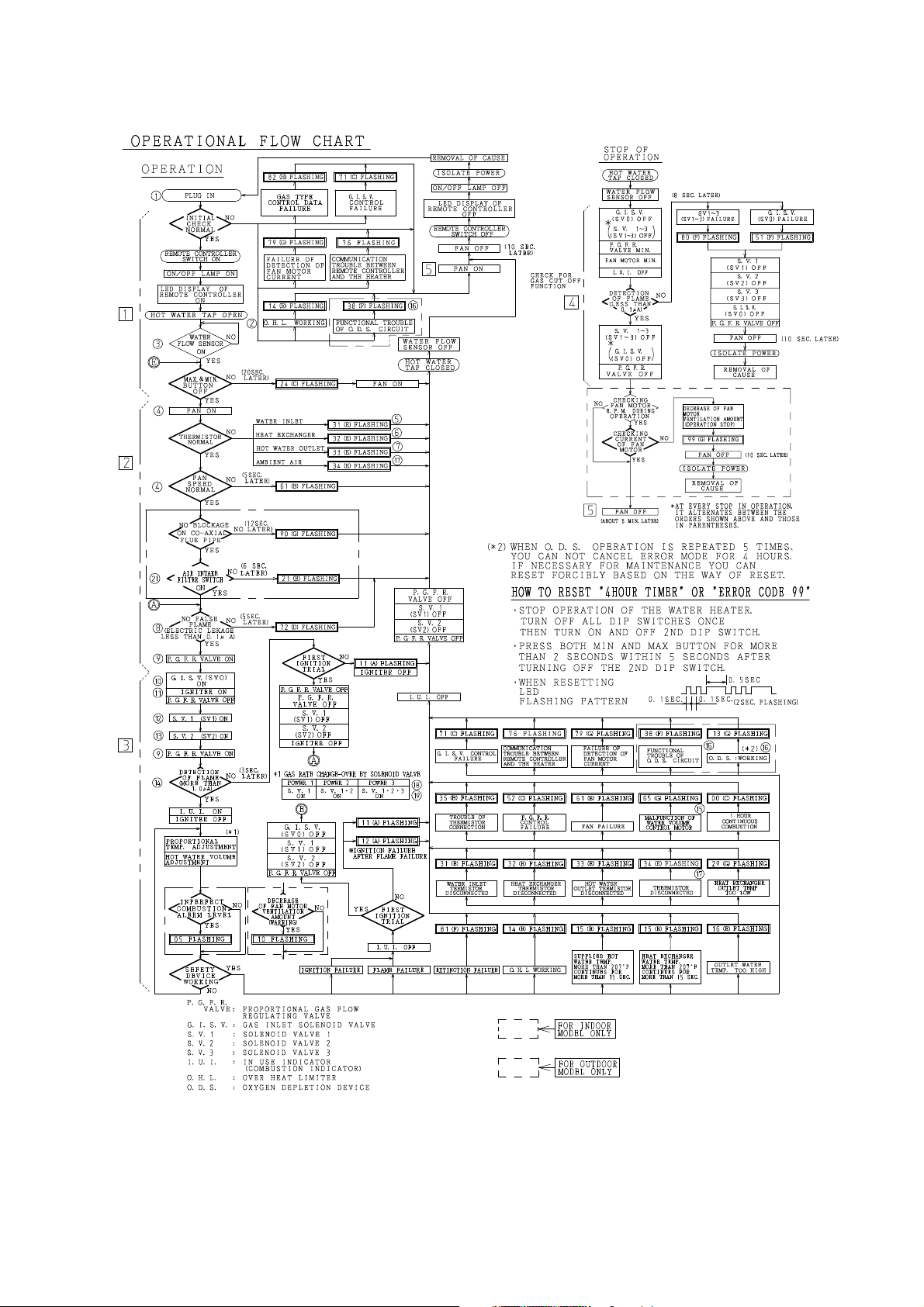

Operational Flow Chart & Maintenance Information.... 16

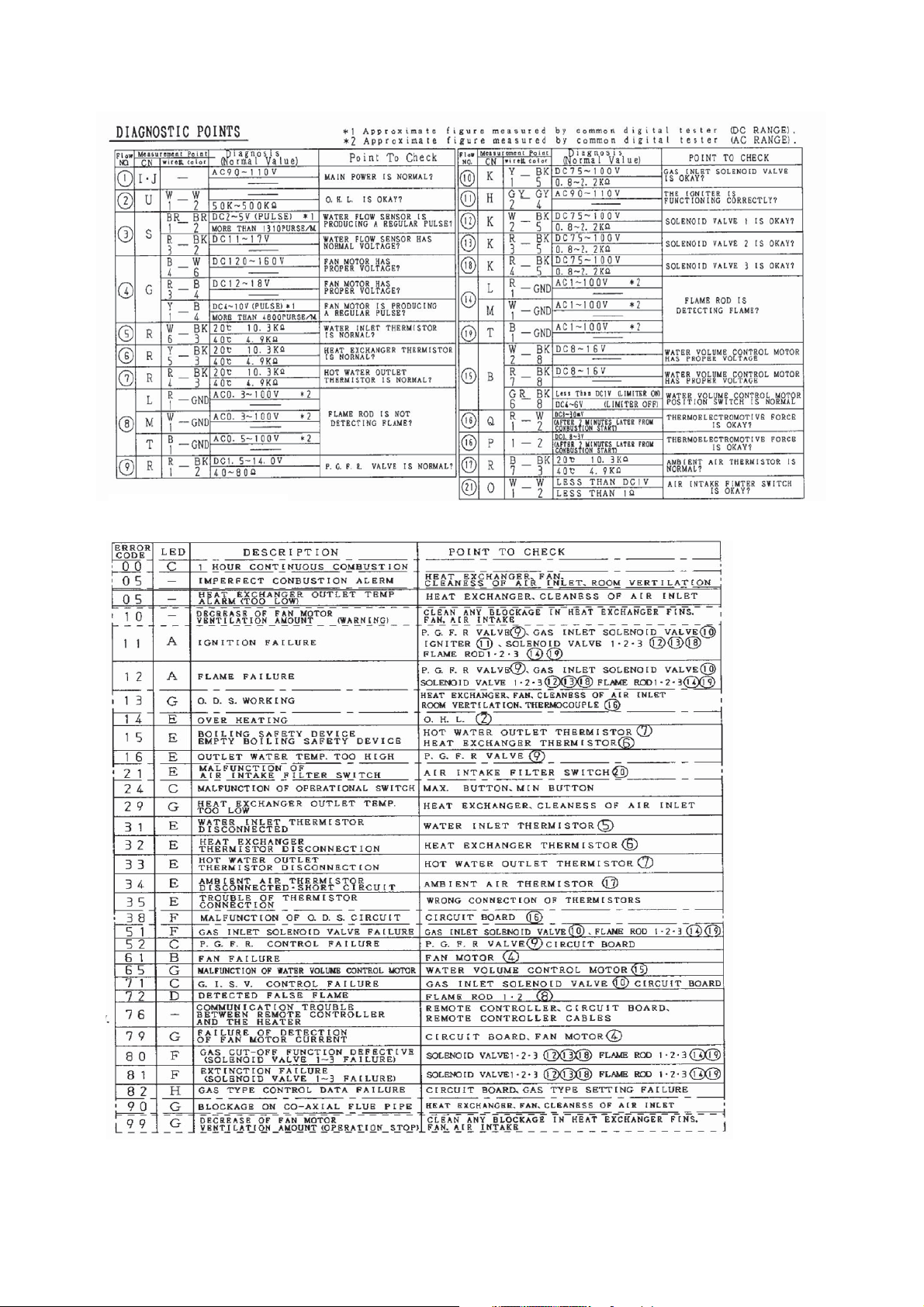

Diagnostic Points ........................................................... 17 ~ 22

Hints for Diagnosis ........................................................ 23 ~ 34

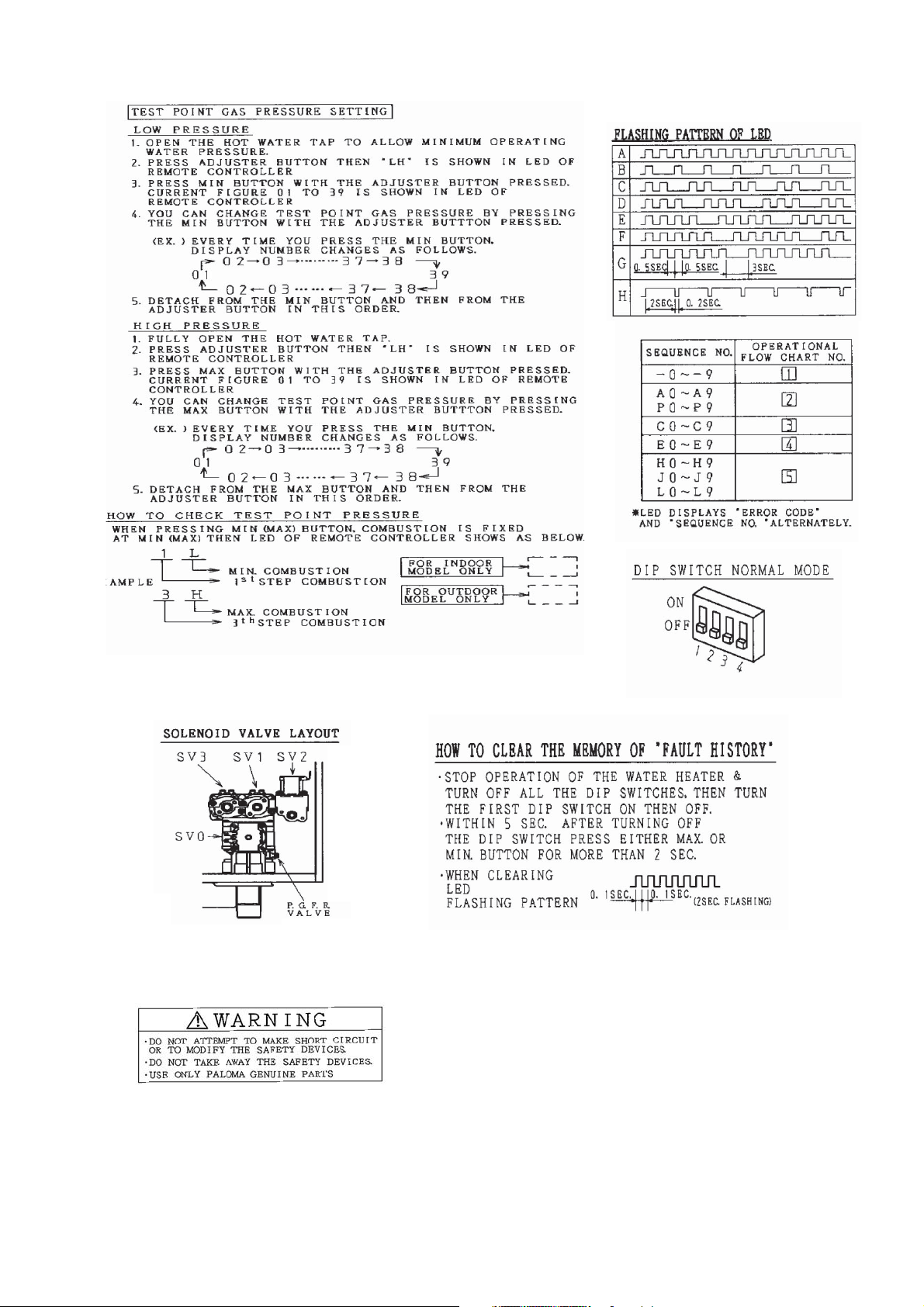

Adjustment ..................................................................... 35 ~ 47

How to Disassemble Each Parts ..................................... 48 ~ 52

Schematic Disassembly and Parts List .......................... 53 ~ 67

- 2 -

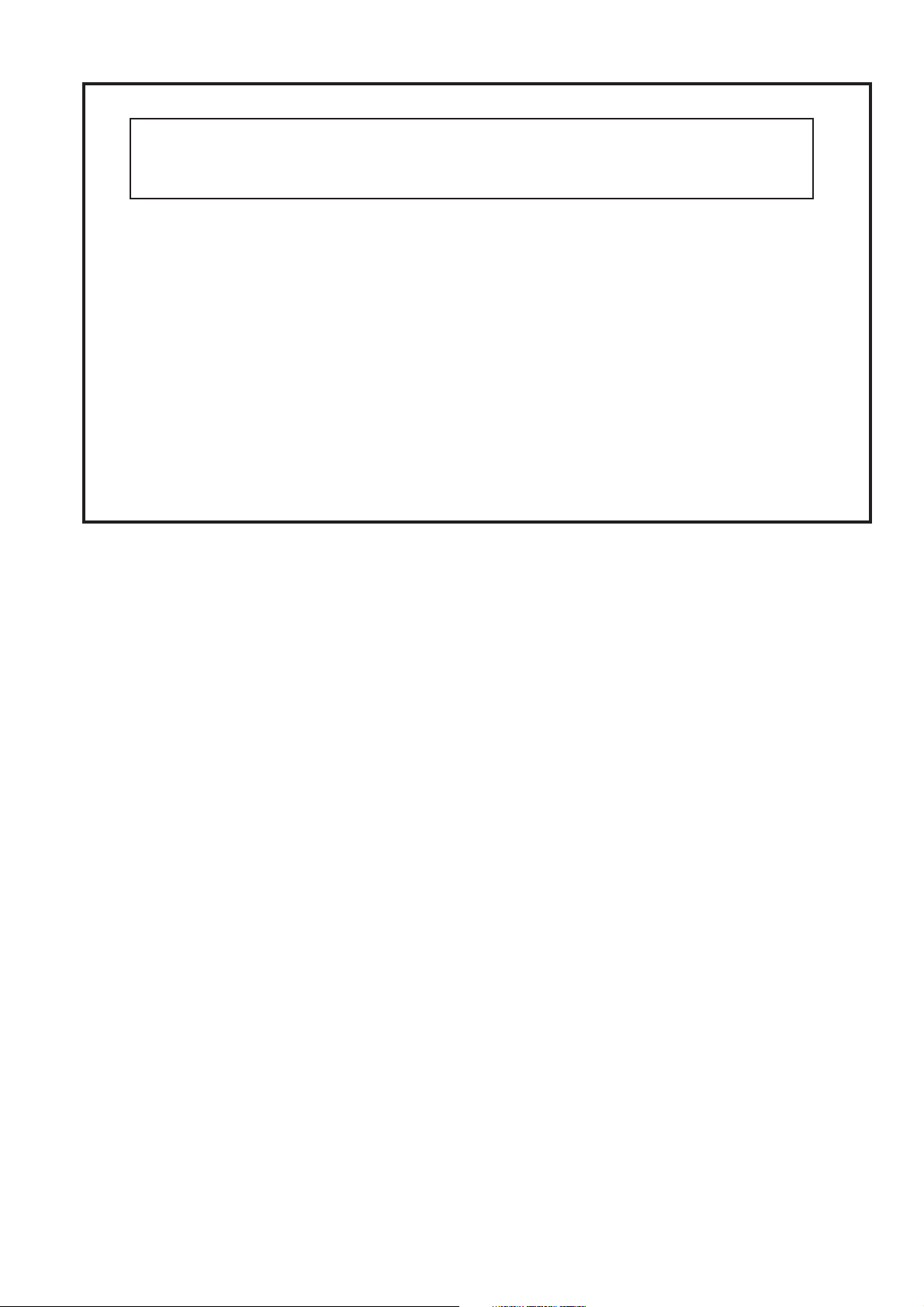

SPECIFICATIONS (Approx.)

Model PH-28RIFSN (NAT)

PH-28RIFSP (L.P.)

PH-28CIFSN (NAT)

PH-28CIFSP (L.P.)

Purpose Domestic Hot Water Supply & Circulating

Rated Gas Input

(Btu/Hr.)

Dimensions (in.) 14 7/8 (W) x 25 3/8 (H) x 11 1/8 (D)

Net Weight (lbs.) 65

Installation Indoor W all Mounting Type

Working Water Pressure 14 psi ~ 150 psi

Minimum Water Flow 0.66 GPM

Maximum Flow Rate 7.4 GPM at 45ºF Temperature Rise

Gas Connection 3/4” NPT Female (w/supplied Gas Shutoff Valve)

Water Connection 3/4” NPT Male

Vent Size 4” Special Venting

Max. Vent Length 37.5 Feet Three 90º Elbow N/A (Outdoor Installation) 37.5 Feet Three 90º Elbow

Effi ciency Rating 84%

Energy Factor 0.82

Inlet Gas Pressure

before water heater

Hot Water Supply Factory Setting 100ºF

Electrical Portion Electrical Rating 120VAC/60Hz, Less than 2 Amps

Safety Devices Oxygen Depletion Safety Sensing Burner (Indoor & Direct Vent)

Freeze Protection Minus 30ºF (Without Wind-Chill Factor)

Optional Accessory First Bath Remote Control (USC1-117); Second Bath Remote Control (USC2-117)

19,000 (Min.)

199,900 (Max.)(Modulating)

Can be vented either hori-

zontally or vertically

(Category III)

Natural Gas: Min. 4.0” w.c. Max. 10.5” w.c.

L.P. Gas: Min. 8.0” w.c. Max. 14.0” w.c. (Do not exceed maximum pressure.)

Adjusting Range R:100ºF ~ 120ºF (140ºF); C: 100°F ~ 180°F

Max. Setting Up to 140ºF(R) or 180°F(C)(w/ Main Remote Control &

Power Supply Cord 3 Pin Power Supply Cord 10 Feet (Indoor & Direct Vent)

Over Heat Limiter Film Type for Entire Heat Exchanger

Flame Failure Safety Flame Rod Type

DUOnex ™ for 2-Unit Manifolding

MIC-180 for Multi-Unit System Controller (2 to 6 units); MICS-180 for Expansion Board

(Up to 20 units); MIC Communication Cables (16, 32 & 65 feet)

High Altitude Adjustment Chips for use at altitudes above 3,280 feet, and up to 9.840 feet

PH-28ROFN (NAT)

PH-28ROFP (L.P.)

PH-28COFN (NAT)

PH-28COFP (L.P.)

19,000 (Min.)

199,900 (Max.)(Modulating)

Outdoor W all Mounting

Type

N/A (Outdoor Installation) 4” Special Venting

Dip Switch Adj.)

PH-28RDVSN (NAT)

PH-28RDVSP (L.P.)

PH-28CDVSN (NAT)

PH-28CDVSP (L.P.)

19,000 (Min.)

199,900 (Max.)(Modulating)

Direct Vent Indoor Wall

Mounting T ype

Can be vented either horizontally or vertically

(Category III)

Hot Water Flow Rate and Temperature Rise

Temp. Rise (ºF) 45 50 60 70 80 90 100

Water Flow (GPM) 7.4 6.7 5.6 4.8 4.2 3.7 3.4

Note: Special Venting: The adapter, vent pipe, elbow, vent terminal, etc. Should be UL 1738 Certifi ed Category III Stainless

Steel Venting Material (e.g. AL29-4C). “B” vent is not permitted.

Since we are constantly improving our products, all specifi cations are subject to change without notice.

- 3 -

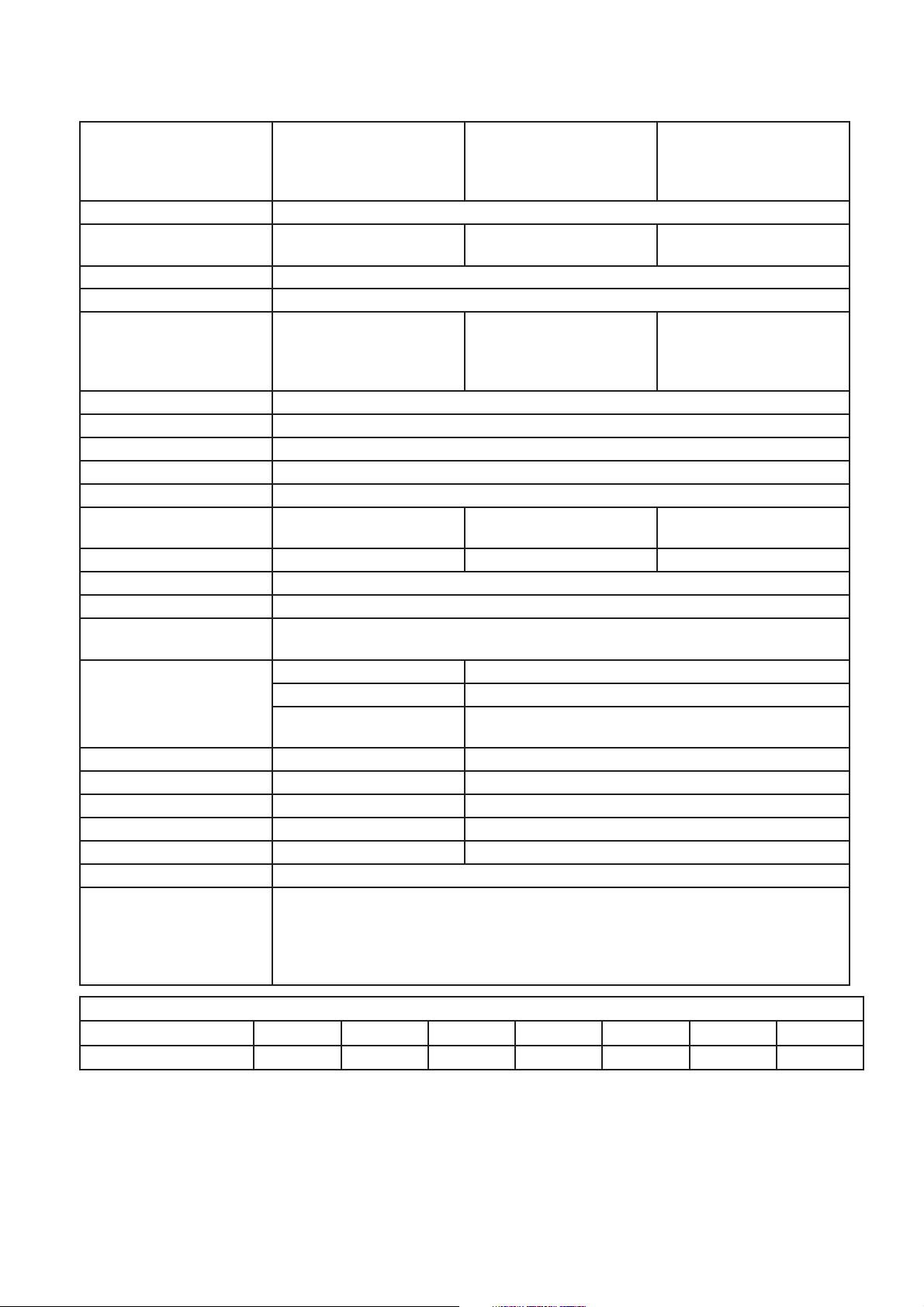

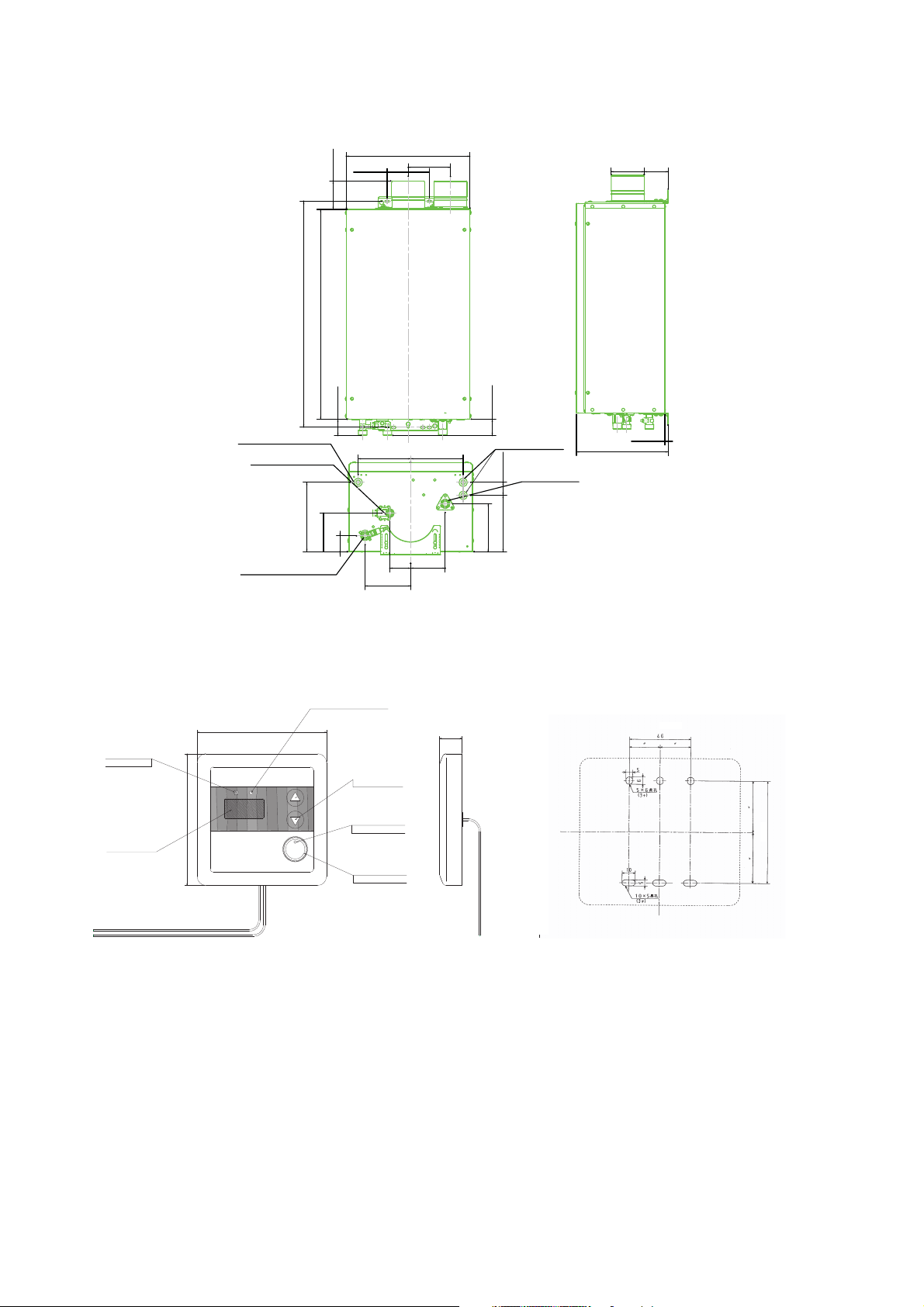

EXTERNAL DIMENSIONS

(PH-28RIFS & PH-28CIFS Indoor Model)

3.45”(87mm)

25.39” (645mm)

27.36” (695mm)

1.89” (48mm)

POWER SUPPLY CORD HOLE

COLD WATER INLET

3/4"NPT(M)

8.39” (213mm)

4.69” (119mm)

1.93” (49mm)

HOT WATER OUTLET

3/4"NPT(M)

14.96” (380mm)

5.12” (130mm)

6.34” (161mm)

2.52”

(64mm)

5.51”

(140mm)

6.34” (161mm)

4.17” (106mm)

1.97” (50mm)

WIRING HOLE

1.57”6.81” (173mm)

5.79” (147mm)

GAS INLET

(40mm)

3/4"NPT(M)

(W/Supplied Gas Shutoff Valve)

Ø4” (101.6mm)

0.39” (10mm)

11.10” (282mm)

(PH-28ROF & PH-28COF Outdoor Model)

14.96” (380mm)

5.12” (130mm)

- 4 -

0.73”

26.46” (672mm)

27.36” (695mm)

0.33”

POWER SUPPLY CORD HOLE

COLD WATER INLFT

3/4"NPT(M)

HOT WATER OUTLET

3/4"NPT(M)

(18.5mm)

3.19”

25.39” 645mm)

(8mm)

8.39” (213mm)

(81mm)

2.13” (54mm)

1.89”

(48mm)

4.69” (119mm)

1.93” (49mm)

1.97”

6.30” (160mm)

2.52”

5.51”

(64mm)

(140mm)

3.54” (90mm)

8.17”(207mm)

8.82”(224mm)

14.29” (363mm)

(50mm)

6.10” (155mm)

4.17”

(106mm)

0.59” (15mm)

0.59” (15mm)

1.97”

5.79” (147mm)

3/4"NPT(M)

(W/Supplied Gas Shutoff Valve)

1.73” (44mm)

(50mm)

WIRING HOLE

1.57”

(40mm)

6.81” 173mm)

GAS INLET

0.43”

(11mm)

9.02’ (229mm)

9.02” (229mm)

11.10” (282mm)

0.39”

(10mm)

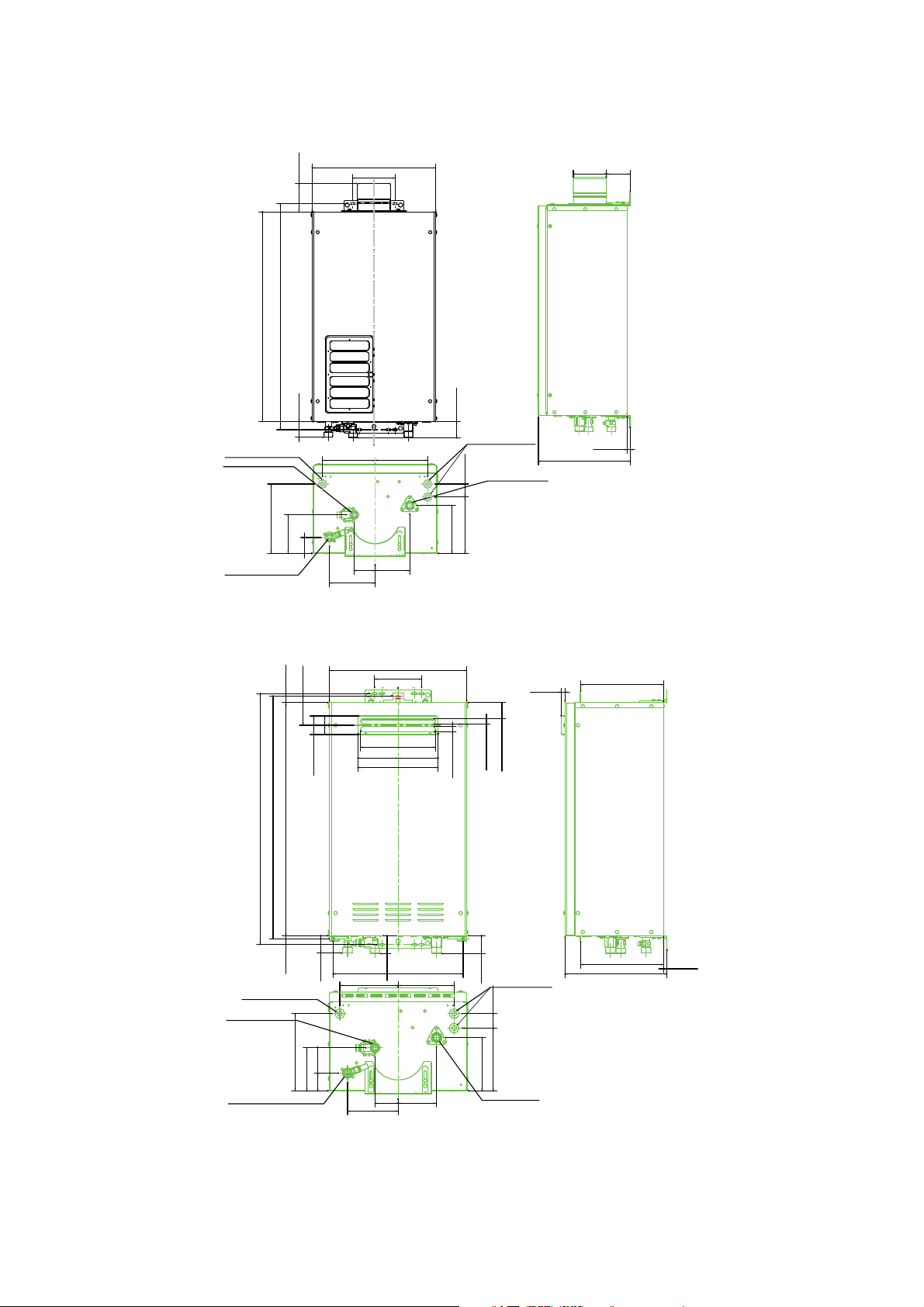

EXTERNAL DIMENSIONS

(PH-28RDVS & PH-28CDVS Direct Vent Model)

25.39” (645mm)

27.36” (695mm)

3.45

14.96” (380mm)

5.12”

(130mm)

5.12” (130mm)

Ø4” (101.6mm)

POWER SUPPLY CORD HOLE

COLD WATER INLFT

3/4"NPT(M)

HOT WATER OUTLET

(Remote Control)

4 3/4” (120mm)

COMBUSTION

INDICATOR

PRIORITY

F

4 3/4” (120mm)

LED DISPLAY

°

8.39” (213mm)

3/4"NPT(M)

POWER

ON/OFF

1.89” (48mm)

6.34” (161mm)

4.69” (119mm)

1.93” (49mm)

PRIORITY INDICATOR

TEMPERATURE

ADJUSTMENT

BUTTON

POWER ON/OFF

INDICATOR

POWER ON/OFF

BUTTON

2.52”

(64mm)

5.51”

(140mm)

6.34” (161mm)

4.17”

(106mm)

7/8” (21mm)

1.97” (50mm)

WIRING HOLE

1.576.81” (173mm)

GAS INLWR

3/4"NPT(M)

(W/Supplied Gas Shutoff Valve)

5.79” (147mm)

0.39” (10mm)

11.10” (282mm)

1 7/8” 46mm)

3 1/4” (83.5mm)

- 5 -

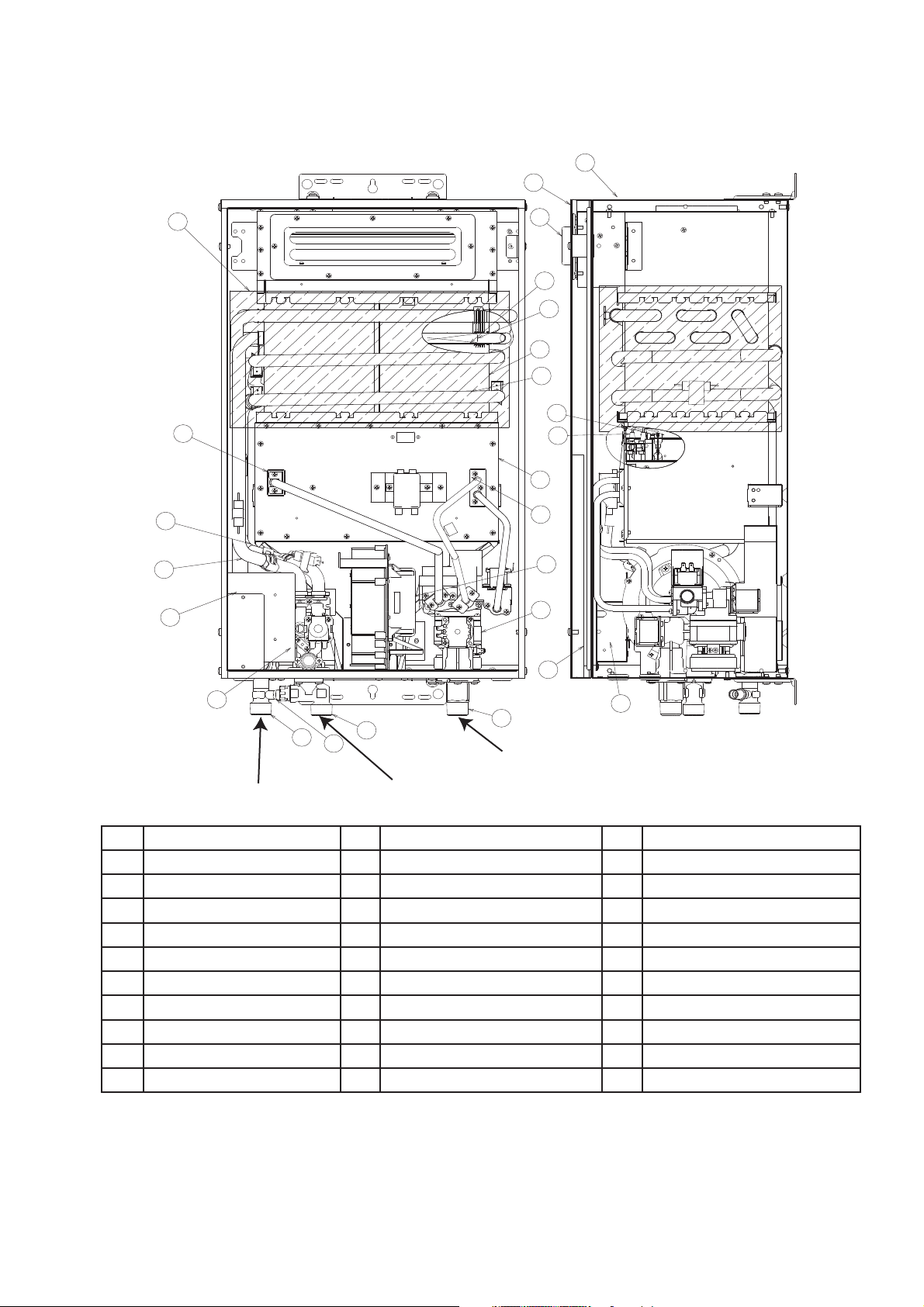

SCHEMATIC CONSTRUCTION

(PH-28RIFS & PH-28CIFS Indoor Model)

4

2

1

26

6

8

5

7

10

14

12

13

11

19

17

18

24

22

Hot Water Outlet

Connection 3/4” NPT (M)

21

23

Water Inlet Connection

3/4” NPT (M)

20

9

15

3

16

25

Gas Connection 3/4” NPT (F)

(W/Supplied Gas Shutoff Valve)

No. Name of Parts No. Name of Parts No. Name of Parts

1 Front Cover 11 Sensing Burner Assembly 21 Water Inlet Connection

2 Back Cover 12 Orifi ce Stand L Assembly 22 Hot Water Outlet Connection

3 Air Filter Assembly 13 Orifi ce Stand R Assembly 23 Drain Valve

4 Exhaust Flue Top 14 Electrode 24 Water Control Body Assy.

5 Heat Exchanger 15 Fan Assembly 25 PC Board

6 Heat Transfer Coil 16 Gas Control V alve Assembly 26 Film Type OHL

7 Water Supply Coil 17 Water Supply Pipe

8 Turbulence Plate 18 Hot Water Supply Pipe

9 Inner Case 19 Bypass Pipe

10 Main Burner 20 Gas Connection

- 6 -

SCHEMATIC CONSTRUCTION

(PH-28ROF & PH-28COF Outdoor Model)

2

1

25

4

6

8

5

7

10

11

13

9

18

16

17

12

14

15

3

23

21

20

22

19

Gas Connection 3/4” NPT (F)

24

(W/Supplied Gas Shutoff Valve)

Hot Water Outlet

Connection 3/4” NPT (M)

Water Inlet Connection

3/4” NPT (M)

No. Name of Parts No. Name of Parts No. Name of Parts

1 Front Cover 11 Orifi ce Stand L Assembly 21 Hot Water Outlet Connection

2 Back Cover 12 Orifi ce Stand R Assembly 22 Drain Valve

3 Rain Cover 13 Electrode 23 Water Control Body Assy.

4 Flue Outlet 14 Fan Assembly 24 PC Board

5 Heat Exchanger 15 Gas Control Valve Assembly 25 Film Type OHL

6 Heat Transfer Coil 16 Water Supply Pipe

7 Water Supply Coil 17 Hot Water Supply Pipe

8 Turbulence Plate 18 Bypass Pipe

9 Inner Case 19 Gas Connection

10 Main Burner 20 Water Inlet Connection

- 7 -

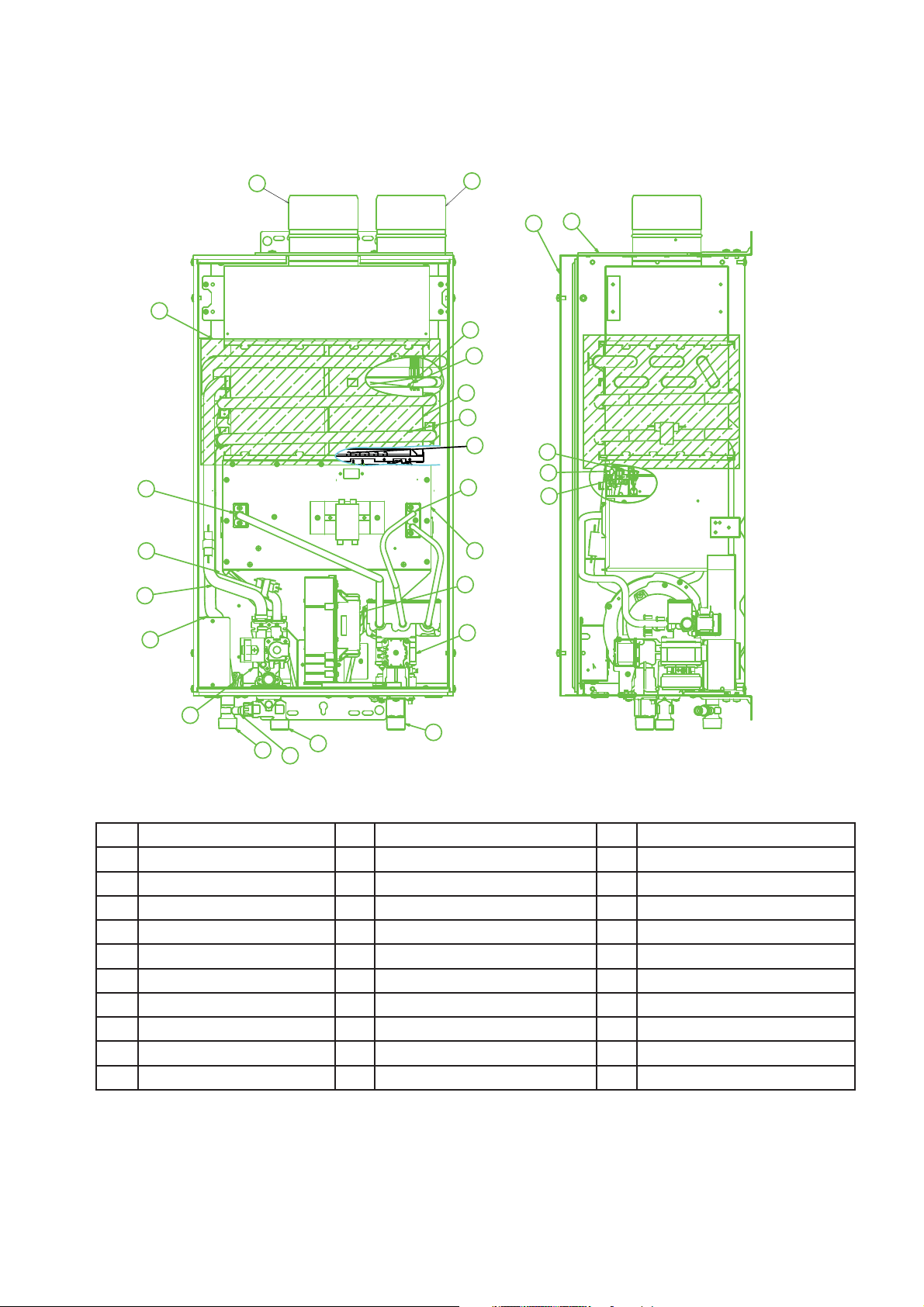

SCHEMATIC CONSTRUCTION

(PH-28RDVS & PH-28CDVS Direct Vent Model)

11

18

16

24

14

12

3

2

1

6

8

5

7

26

9

10

13

25

4

17

23

21

22

20

15

19

No. Name of Parts No. Name of Parts No. Name of Parts

1 Front Cover 11 Orifi ce Stand L Assembly 21 Hot Water Outlet Connection

2 Back Cover 12 Orifi ce Stand R Assembly 22 Drain Valve

3 Air Intake 13 Flame Rod 23 Water Control Body Assy.

4 Exhaust Flue Top 14 Fan Assembly 24 Film Type OHL

5 Heat Exchanger 15 Gas Control Valve Assembly 25 Sensing Burner Assembly

6 Heat Transfer Coil 16 Water Supply Pipe 26 Burner Rod

7 Water Supply Coil 17 Hot Water Supply Pipe

8 Turbulence Plate 18 Bypass Pipe

9 Inner Case 19 Gas Connection

10 Main Burner 20 Water Inlet Connection

- 8 -

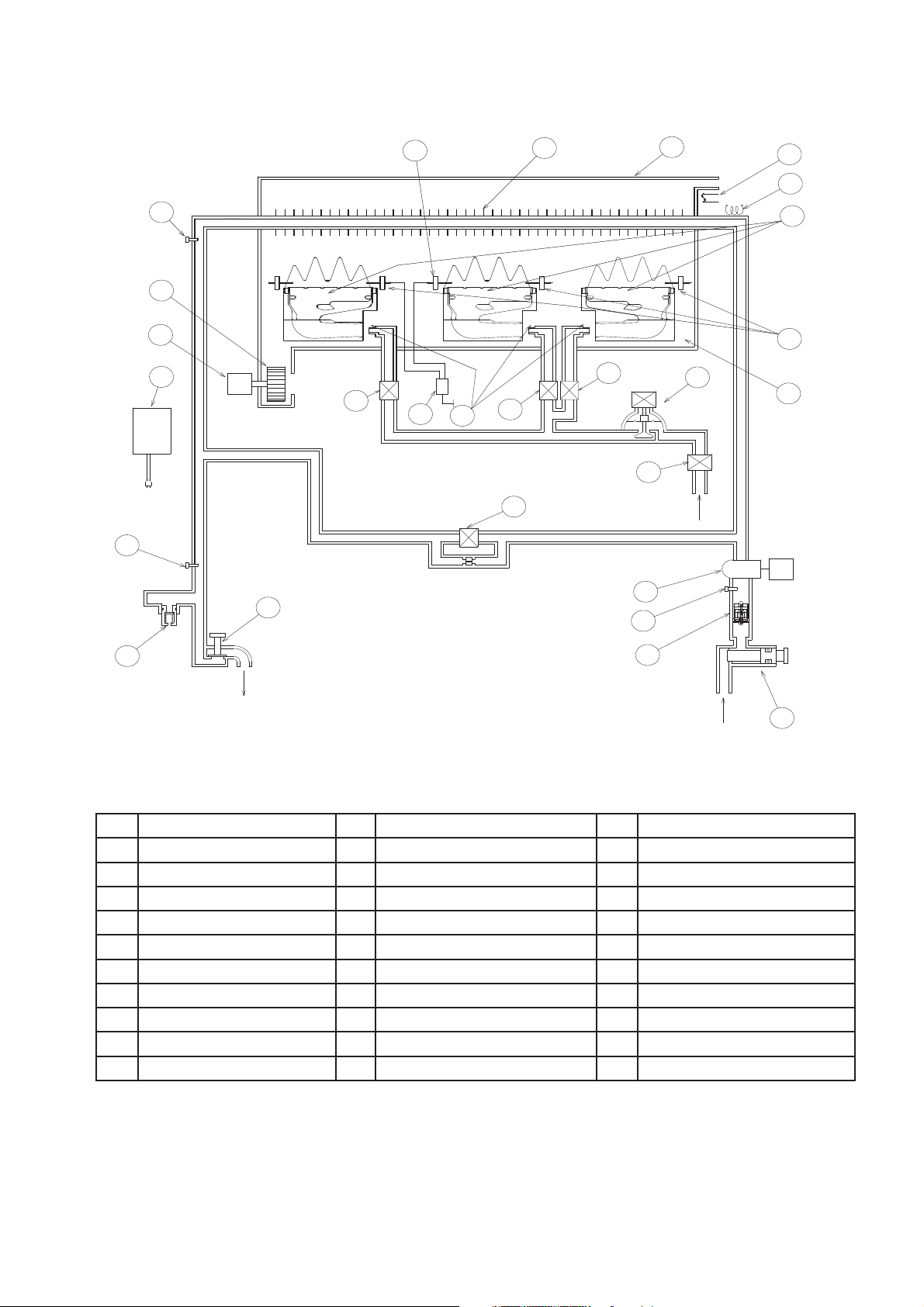

OPERATIONAL PRINCIPLE

9

Gas

21

13

20

23

15

18

22

17

5

24

25

27

M

12

16

14

19

11

10

2

Inlet

6

M

7

1

4

26

Hot Water

Outlet

3

8

Water

Inlet

No. Name of Parts No. Name of Parts No. Name of Parts

1 Hot Water T ap 11 Solenoid Valve 2 21 Exhaust Outlet

2 Bypass Solenoid Valve 12 Solenoid Valve 3 22 Combustion Chamber

3 Water Flow Sensor 13

Proportional Gas Control Valve

23 Freeze Protection Heater

4 Water Inlet Thermistor 14 Orifi ce 24 Fan

Heat Exchanger Thermistor

5

Hot W ater Outlet Thermistor

6

15 Main Burner 25 Fan Motor

16 Igniter 26 Drain V alve

7 Water Flow Servo 17 Electrode 27 PC Board

8 Water Filter 18 Flame Rod

9 Gas Inlet Solenoid Valve 19 Heat Exchanger

10 Solenoid Valve 1 20 Film Type OHL

- 9 -

OPERATIONAL PRINCIPLE

WHEN SUPPLYING HOT WATER

1) By opening the Hot Water Top (1), the water fl ows through the Water Flow Sensor (3) to the Heat

Heat Exchanger (19).

2) The frequency signal is given from the Water Flow Sensor (3) and when the PC Board (27) senses the signal

that reached a certain frequency, the Fan (24) starts to turn round.

3) After the Fan (24) turned round and pre-purged, the Gas Inlet Solenoid Valve (9), Solenoid Valve 1 (10) and

Solenoid Valve 2 (11) open at the same time. Then, the Proportional Gas Control Valve (13) becomes an

ignition motion and allows the gas to fl ow to the Main Burner (15) (and Sensing Burner for PH-28RIFS,

PH-28CIFS, PH-28RDVS and PH-28CDVS only).

4) At the same time, the Igniter (16) continuously makes sparks and ignites the Main Burner (15).

After ignited, when the Flame Rod (18) senses the fl ame and make sure the combustion, the Proportional

Gas Control Valve (13) fi nishes the ignition motion.

5) After fi nished the ignition motion, the proportional gas control is started. When there is a temperature

difference between the hot water temperature that is sensed by the Hot Water Outlet Thermistor (6) and the

set temperaturer on the Remote Control, the PC Board (27) judges it and open or close the Solenoid

Valve 1 (10), Solenoid Valve 2 (11) and Solenoid Valve 3 (12), and also the Proportional Gas Control Valve

(13) continuously adjusts the gas volume in order to maintain the outlet temperature from the Heat

Exchanger (19).

The Water Flow Servo (7) also adjusts the proper amount of water fl ow to supply a stable hot water

temperature at all times.

6) According to the adjustment of the gas volume by the Proportional Gas Control Valve (13), a signal from the

PC Board (27) is also sent to the Fan Motor (25) in order to maintain the relation between the gas volume

and air volume at all times.

7) (For PH-28RIFS, PH-28CIFS, PH-28RDVS and PH-28CDVS only) When the air intake or venting is

blocked, or the oxygen of the air intake is not suffi cient, the output of the Thermocouple that is located at the

Sensing Burner would be changed. The PC Board (27) senses this change and controls the Fan (24),

Proportional Gas Control Valve (13), etc. in order to prevent the imperfect combustion. Further, if such

condition is proceeded, it shuts off the Gas Inlet Solenoid Valve (9), Solenoid Valve 1 (10),

Solenoid Valve 2 (11), Solenoid Valve 3 (12) and Proportional Gas Control Valve (13) in order to stop the

operation.

8) When the Hot Water Tap (1) is closed, the frequency signal from the Water Flow Sensor (3) is stopped and

the Gas Inlet Solenoid Valve (9), Solenoid Valve 1 (10), Solenois Valve 2 (11), Solenoid Valve 3 (12) and

Proportional Gas Control Valve (13) turn off and becomes a post-purge motion.

9) When the time of the post-purge is up, the Fan (24) stops.

- 10 -

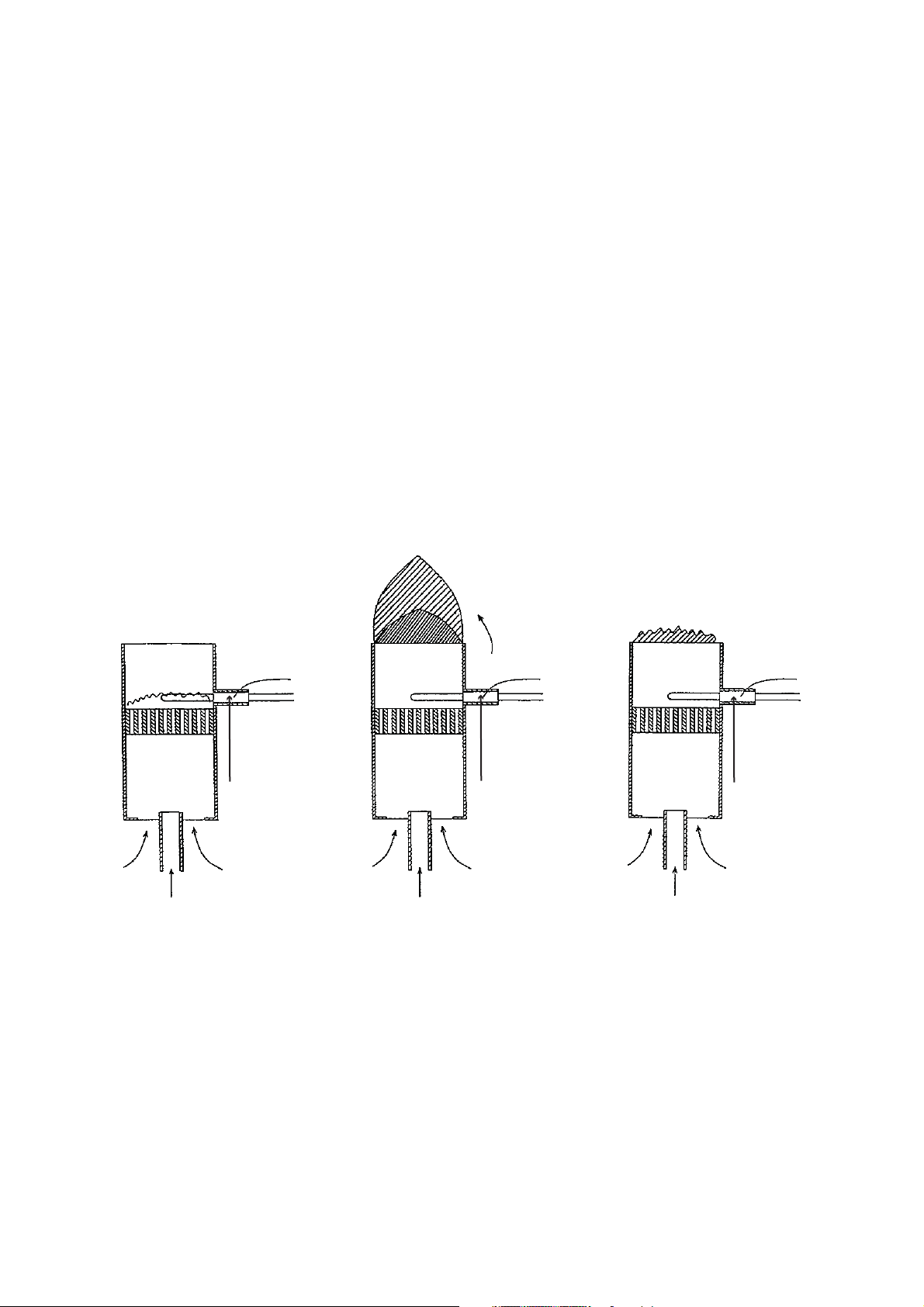

Oxygen Depletion Safety Device (O.D.S.D.)

[Sensing Burner]

(Indoor Model & Direct Model Only)

The sensing burner is a all primary air type ceramic burner that consists of an outer jacket surrounding the flame

opening and a thermocouple to detect flame temperature. In case oxygen level decreases due to blocked or

clogged air intake or flue venting, or by contaminated air, location of the flame will change as well as its

temperature by the thermocouple. The sensing burner is located in the part of the main burner and designed to

monitor the flame condition at all times. Therefore, it shut off gas before the imperfect combustion occurs in the

main burner.

NORMAL

========

BLOCKING LACK OF OXYGEN

========================

The flame lifts away

from the thermocouple.

(Blocked or clogged vent, fan etc.)

Secondary Air

The flame lifts away

from the thermocouple.

(Contaminated air in room, etc.)

ThermocoupleThermocouple Thermocouple

Gas

Primary Air Primary Air

(Decrease)

Gas

Primary Air

(Lack of Oxygen)

Gas

- 11 -

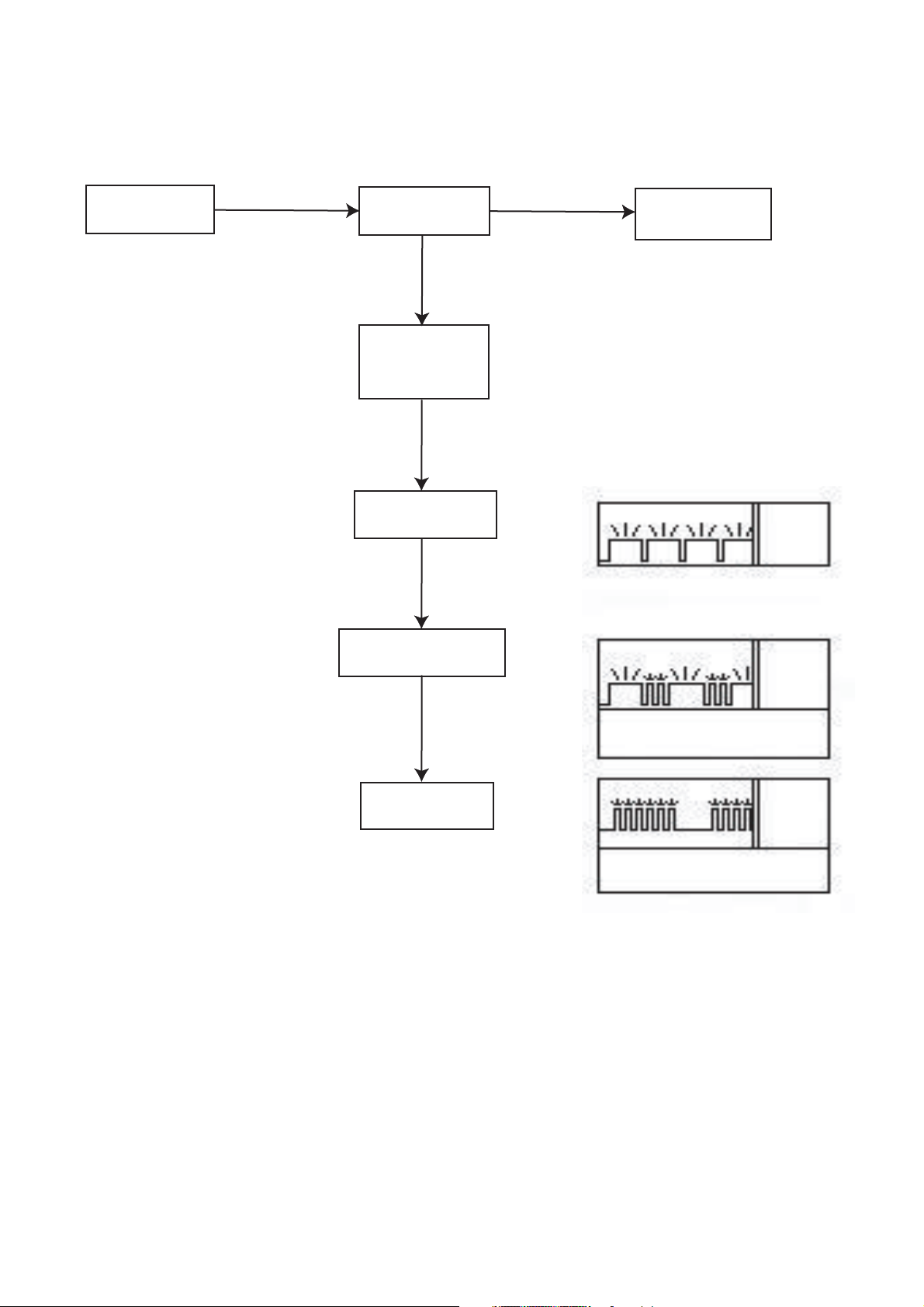

If Imperfect Combustion Happens.....

(Indoor Model &

Direct Model Only)

Ignition

Sensor Stand-By

Lead Time

Cold: 2 Min.

Hot: 30 Sec. - 1 Min.

Decrease of Thermo

Electric Current

Decrease of Thermo

Electric Current

Secondary Warning

(Alarm + Light)

Normal Air

Flow Rate

Decrease of Thermo

Electric Current

Input Down

(Increase Air

Flow Rate)

Primary Warning

(Light)

Water Flow

Servo OFF

Automatic Control To Resolve

Imperfect Combustion

(Display on Remote Control)

Both Red and Green

flashing at the same time

Both Red and Green

flashing at the same time

Extinction

Post- Purging

Monitor Code

No Error

Code

Monitor Code

05

Decrease of Thermo

Electric Current

Shut Down

(After- Purging)

NOTE: Shutdown by impeefect combustion can be reset by pressing power switch (ON/OFF Button).

However, if it occurs 5 times within 4 hours, the water heater will not recover for the next 4 hours.

Every 60 seconds, you hear

noticing alarm (Beep sound).

Only Red lamp flashing

6 times

Monitor Code

13

- 12 -

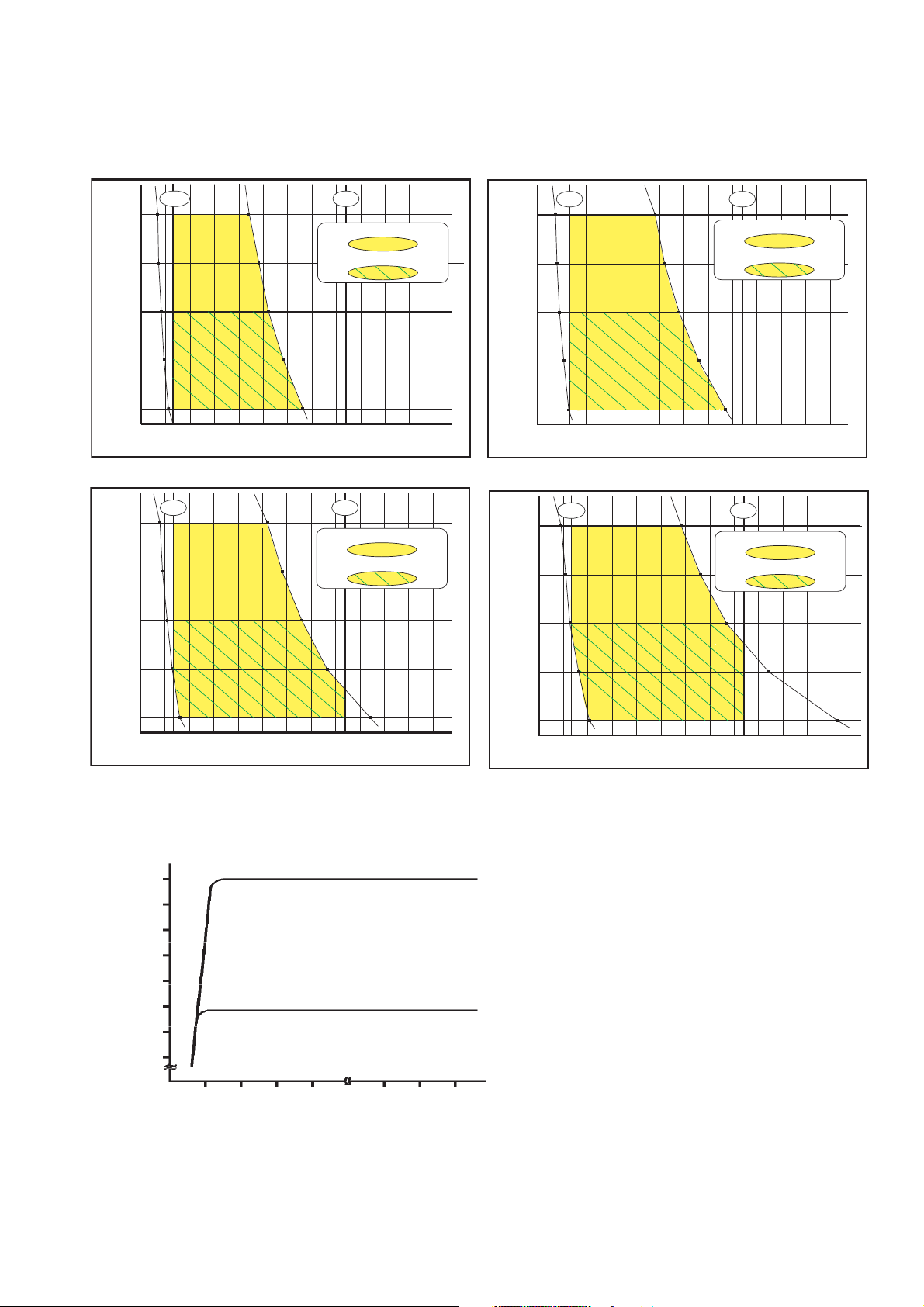

Capacity

Hot Water Capacity Curve: Residential Models

Inlet Water Temperature : 40°F

0.66

GPM

140

130

120

Outlet Temperature (°F)

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

Inlet Water Temperature : 60°F

0.66

GPM

140

130

When maximum temperature is set at 140°F

When maximum temperature is set at 120°F

Water Flow Rate (GPM)

When maximum temperature is set at 140°F

When maximum temperature is set at 120°F

GPM

GPM

Inlet Water Temperature : 50°F

7.4

Outlet Temperature (°F)

0.66

GPM

140

130

120

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

Water Flow Rate (GPM)

7.4

GPM

When maximum temperature is set at 140°F

When maximum temperature is set at 120°F

Inlet Water Temperature : 70°F

7.4

0.66

GPM

140

130

7.4

GPM

When maximum temperature is set at 140°F

When maximum temperature is set at 120°F

120

Outlet Temperature (°F)

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

Water Flow Rate (GPM)

Water Pressure & Water Flow Rate:

7.4

6.9

6.4

5.8

5.3

4.8

Water Flow Rate (GPM)

4.3

Inlet Water Temperature: 70

(At The Outlet Hot Water Temperature : 110 )

Inlet Water Temperature: 40

°F

°F

(7.4)

(4.8)

120

Outlet Temperature (°F)

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11. 0

Water Flow Rate (GPM)

°F

14 30 45 60 105 120

135

Water Pressure (psi)

- 13 -

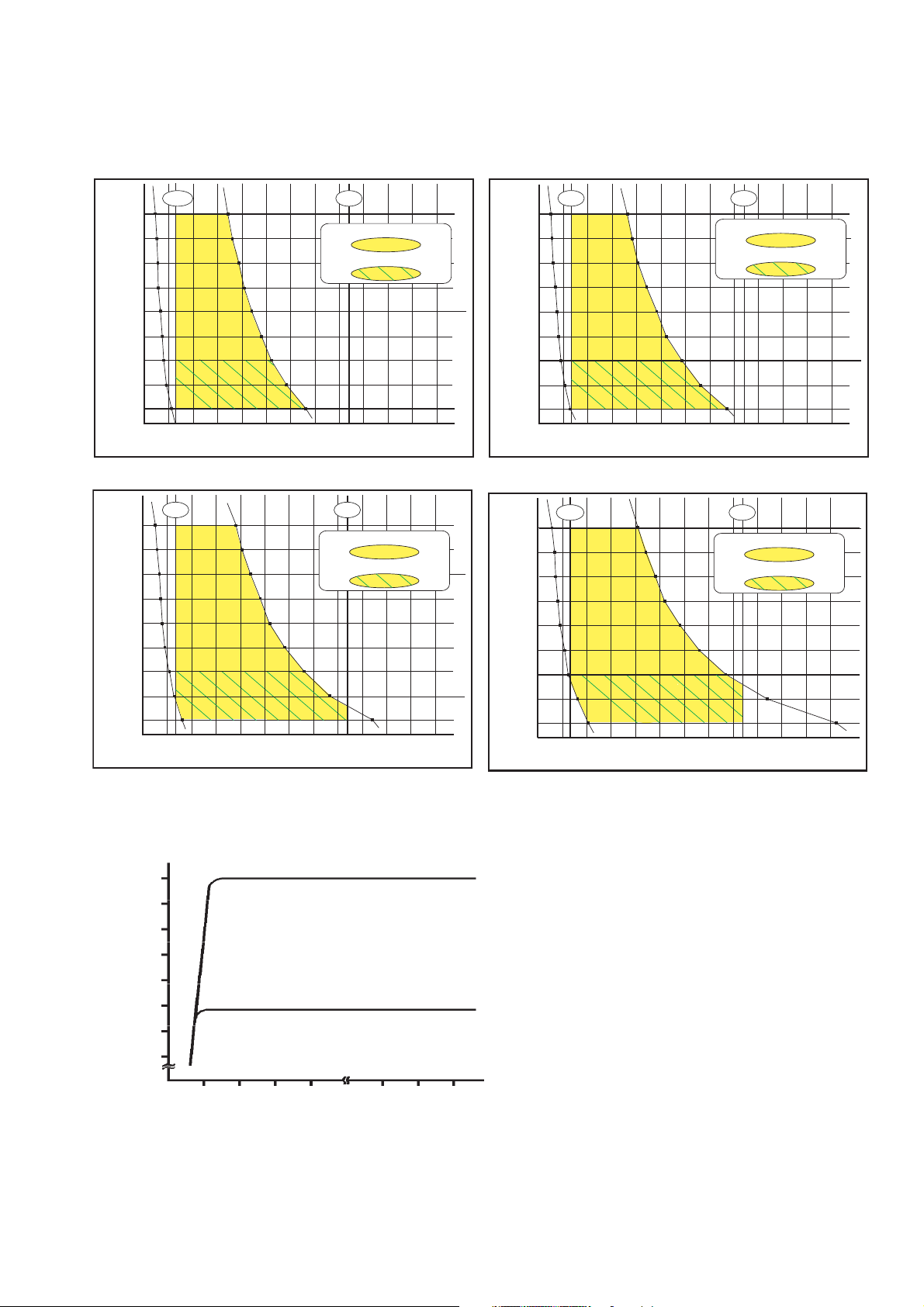

Capacity

Hot Water Capacity Curve: Commercial Models

Inlet Water Temperature : 40°F

0.66

GPM

180

170

160

150

140

130

Outlet Temperature (°F)

120

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

Inlet Water Temperature : 60°F

0.66

GPM

180

170

160

150

140

130

Outlet Temperature (°F)

120

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

When maximum temperature is set at 180°F

When maximum temperature is set at 120°F

Water Flow Rate (GPM)

When maximum temperature is set at 180°F

When maximum temperature is set at 120°F

Water Flow Rate (GPM)

GPM

GPM

Inlet Water Temperature : 50°F

7.4

Outlet Temperature (°F)

0.66

GPM

180

170

160

150

140

130

120

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

Water Flow Rate (GPM)

7.4

GPM

When maximum temperature is set at 180°F

When maximum temperature is set at 120°F

Inlet Water Temperature : 70°F

7.4

Outlet Temperature (°F)

0.66

GPM

180

170

160

150

140

130

120

110

100

0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11. 0

Water Flow Rate (GPM)

7.4

GPM

When maximum temperature is set at 180°F

When maximum temperature is set at 120°F

Water Pressure & Water Flow Rate:

7.4

6.9

6.4

5.8

5.3

4.8

Water Flow Rate (GPM)

4.3

- 14 -

Inlet Water Temperature: 70

(At The Outlet Hot Water Temperature : 110 )

Inlet Water Temperature: 40

14 30 45 60 105 120

°F

°F

(7.4)

(4.8)

135

°F

Water Pressure (psi)

Wiring Diagram

A wiring diagram is also located on the inside of the front cover panel.

Slightly different by model and serial number.

AC

120V

W

BK

G/Y

GND

BK

BK

(RED)

W W

BK

(BLUE)

W

H

M

T

E

R

W

R

BK BK

BK

COLOUR CODE

W:WHITE

R:RED

CONTROL2

REMOTE

BATH

(USC2-117)

CONTROL1

REMOTE

BATH

(USC1-117)

REMOTE

MAIN

CONTROL

(UMC-117)

AIR

INTAKE

FILTER

SWITCH

BR

W

MOTOR

R GR Y B O

B

LIMITER

WATER VOLUME

CONTROL MOTOR

SW2

SW1

B:BLUE

BR:BROWN

BK:BLACK

GY:GRAY

GR:GREEN

FAN

MOTOR

5

FM

1

2

3

4

D E

W

W

8

6

7

R

GR

BK

8

A

ON

OFF

MAX

BUTTON

MIN

BUTTON

SW3

ADJUSTER

Y:YELLOW

O:ORANGE

G/Y:GREEN/YELLOW

W B R O Y

1

2

3

4

5

6

G

F

P

O

2

1

1

2

3

4

5

Y B O

W

BR

B

4

3

2

1

DIP SWITCH

BUTTON

LED

FOR INDOOR

MODEL ONLY

W

BK

BK

IG

FUSE(3A)

W

BK

W

BK

ELECTRODE

WATER BY-PASS

SOLENOID VALVE

WV

IGNITER

CONNECTOR FOR CHECKING

THERMOELECTROMOTIVE FORCE

GR

GR

GY

R

AC

100V

R

GY

TRANSFORMER

H

5

6

4

I

3

2

1

J

Q

1

4

5

6

W Y R

2

2

3

BK

BK

1

R

R

FUSE

(5A)

2

1

7

B

U

2

T

L

M

W W R

1

B

1 3 2

W

S

1

4

B Y

R

BK

BR

BOARD

CIRCUIT

W

R

2

5

6 3

K

BK

G/Y

GND

BK

FROST

PROTECTION

THERMOSTAT

BK

W

W W

W

BK

(RED)

W

W

W

THE CONNECTORS OF DUAL AND MULTIPLE

ANTI-FROST

HEATER

C O U

O

+

-

R1

R2

R3 R4

BK

BK

BK

L

P

E

V E

L

V A

PSV

E R

I S

T

H

M

O T W

H

L E

T

U

O

H E R M

T

X C H A N

E

E A

T

H

E R

I S

T

H

M

L E T

I

N

E R

T

A

W

E R M

T

H

I

A

R

M B

E N

I

A

L V E

V A

O L

N O

S

E

A S

SV0

G

V A

O L E N O I D

SV1

S

L V E 2

V A

O L E N O I D

S

L V E 3

V A

O L E N O I D

SV3 SV2

S

ARE INTERAPPLICABLE TO THE BODY

CONNECTORS EACH OTHER.(RED)

FOR INDOOR

MODEL ONLY

O R

T

E R

T

A

T

S T

R

I

O

R

E

G

T

R

O

S

R

I

T

O

T

0

I

D

I

L

T

E

N

L

1

V E

WIRING DIAGRAM

WATER

OVER HEAT

FLAME ROD1

FLAME ROD2

LIMITER

FLAME ROD3

FLOW

SENSOR

- 15 -

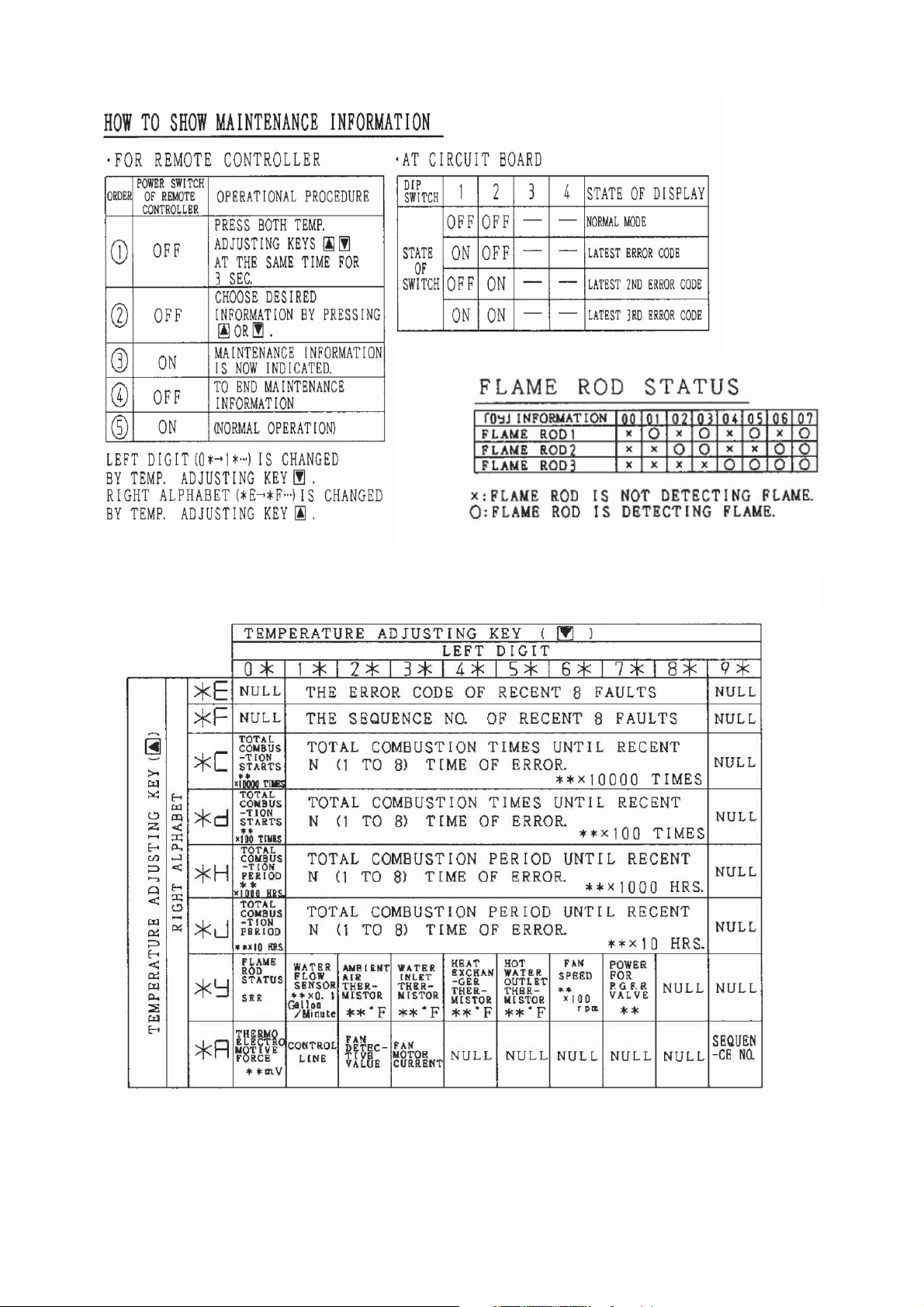

Operational Flow Chart & Maintenance Information

- 16 -

Diagnostic Points

k

The voltage showed is the value of operating condition when the water heater operates according to the flow chart.

The resistance showed is the value of load side when turned off the electric power and disconnected the connector.

5

- 17 -

- 18 -

MAINTENANCE INFORMATION SHOWN IN LED DISPLAY OF REMOTE CONTROL

ABOVE

- 19 -

Error Codes

Code Fault Remedy

05 Imperfect Combustion Alarm Clean air inlet fi lter.

Clean combustion air fan.

Clean heat exchanger fi ns.

Check for adequate combustion air ventilation openings and clean if necessary.

Check vent system for partial blockage and correct as necessary.

10 Decrease of Fan Motor Ventilation

Amount

Air Supply or Exhaust Blockage

(Warning)

11 Ignition Failure

No Ignition

12 Flame Failure Ensure you have gas to the appliance.

13 Oxygen Depletion Sensor (O.D.S.)

Working (Poor or Improper Combustion)

14 Over Heating Ensure high fi re and low fi re manifold pressure is correct.

Check all vent components for proper connections.

Check that nothing is blocking the fl ue inlet or exhaust.

Ensure condensation trap/drain was installed correctly.

Ensure heat exchanger fi ns, fan, and air intake are not blocked.

Ensure you have gas to the appliance and valves are turned ON.

Ensure gas type and pressure is correct.

Bleed all air from gas lines.

Ensure gas line, meter, and regulator are sized properly.

Ensure appliance is properly grounded.

Check gas solenoid valves for open or short circuits.

Ensure igniter is operational.

Check igniter wiring harness for damage.

Ensure maximum vertical vent length does not exceed allowable limits.

Ensure total maximum vent length does not exceed allowable limits.

Ensure gas type and pressure is correct.

Bleed all air from gas lines.

Ensure fl ame rod wire is connected.

Check fl ame rod for carbon build-up.

Ensure gas line, meter, and regulator are sized properly.

Ensure appliance is properly grounded.

Check gas solenoid valves for open or short circuits.

Check power supply for proper voltage and voltage drops.

Disconnect remote control; if it runs.

Disconnect and re-connect all wiring harnesses on unit and PC board.

Ensure proper venting material was installed.

Ensure maximum vertical vent length does not exceed allowable limits.

Ensure total maximum vent length does not exceed allowable limits.

Ensure there is plenty of fresh air to the unit.

Unit needs 1 square inch (6.5 cm2) for each 1,000 BTU of input.

Check for a foreign materials in combustion chamber and/or O.D.S. Device.

Check gas type of unit and ensure it matches gas type being used.

Check heat exchanger for cracks and/or separations.

Check for restrictions in airfl ow around unit and vent terminal.

Check for a foreign materials in combustion chamber and/or exhaust piping.

Check for clogged heat exchanger (scale buildup).

- 20 -

Code Fault Remedy

15 Boiling Safety Device Check for closed water heater inlet valve or restriction in cold water inlet

pipe (must be fully open).

Check for clogged heat exchanger (scale buildup).

On commercial water heater, lower set point temperature below 180F at

high altitude.

16 Outlet Water Temperature Too High

Over T emperature Warning

21 Malfunction of Air Intake

Filter Switch

24 Malfunction of Operational Switch Disconnect remote control and retry.

29 Heat Exchanger Outlet Temp.

Too Low

31 Water Inlet Thermistor Fault Check thermistor wiring for damage.

32 Heat Exchanger Thermistor Fault Check thermistor wiring for damage.

33 Hot Water Outlet Thermistor Fault Check thermistor wiring for damage.

34 Ambient Air Thermistor Fault Check thermistor wiring for damage; Ohm out thermistor.

35 Improper Thermistor Connection Check that all thermistors are connected to proper connections on PCB.

38 Malfunction of O.D.S. Circuit The sensor itself is not responding to a self check from the PCB. Check

51 Gas Inlet Solenoid Valve Fault Check gas inlet solenoid valve wiring harness for loose or damage termi-

52 Proportional Gas Control Valve

Fault

61 Fan Failure Ensure fan motor will turn freely. (Motor will operate with a small amount

Check for clogged heat exchanger (scale buildup).

Check for restrictions in airfl ow around unit and vent terminal.

Check for a foreign materials in combustion chamber and/or exhaust piping.

Make sure air fi lter door is properly seated.

Make sure front panel is properly installed.

Verify unit is electrically grounded.

Press max button on PCB to reset; Press min button on PCB to reset.

Clean air inlet screen.

Clean heat exchanger fi ns.

Ohm out thermistor.

Check and clean scale from thermistor.

Ohm out thermistor.

Check and clean scale from thermistor.

Ohm out thermistor.

Check and clean scale from thermistor.

Check and clean ambient air thermistor.

Ensure fan blade is tight on motor shaft and it is in good condition.

Check for restrictions in airfl ow around unit and vent terminal.

wiring harness. Check for proper voltage.

nals.

Ohm out solenoid valve.

Check proportional gas control valve wiring harness for loose or damage

terminals.

Ohm out proportional gas control valve.

of restriction.)

Check wiring harness to motor for damaged and/or loose connections.

Check venting length not to exceed max lengths and bends.

- 21 -

Loading...

Loading...