Palmgren 80342A, 80341A User Manual

operating manual & parts list 80341A & 80342A

33″

RADIAL ARM BENCH AND

FLOOR DRILL PRESSES

Read carefully and follow all safety rules and operating instructions before first use of

this product.

30982.29-0111

DESCRIPTION

Palmgren Radial Arm Drill Presses feature a heavy cast iron base,

work table and head. Head moves 12” forward and backward using

a rack and pinion. Head also swivels 360° around column, tilts 90°

right and 45° left. Work table height is also adjustable using rack

and pinion. Table can be tilted 45° both right and left, and rotates

360° on a vertical axis. Work table surface is precision ground

which features slots for secure, accurate mounting of workpiece.

Other features of the Palmgren drill press are an enclosed ball

bearing quill assembly, quick belt change and tension mechanism,

positive quick-adjust feed depth stop and a

1

/2 HP, 1725 RPM motor.

Chuck and chuck arbor are included.

Palmgren drill presses are ideal for use in home shops, mainte-

nance shops and light industrial applications. Spindle speeds are

adjustable for drilling steel, cast iron, aluminum, wood and plastic.

UNPACKING

Check for loose, missing or damaged parts. If any damage or loss

has occurred, claim must be filed with carrier immediately. Check

for completeness. Immediately report missing parts to dealer.

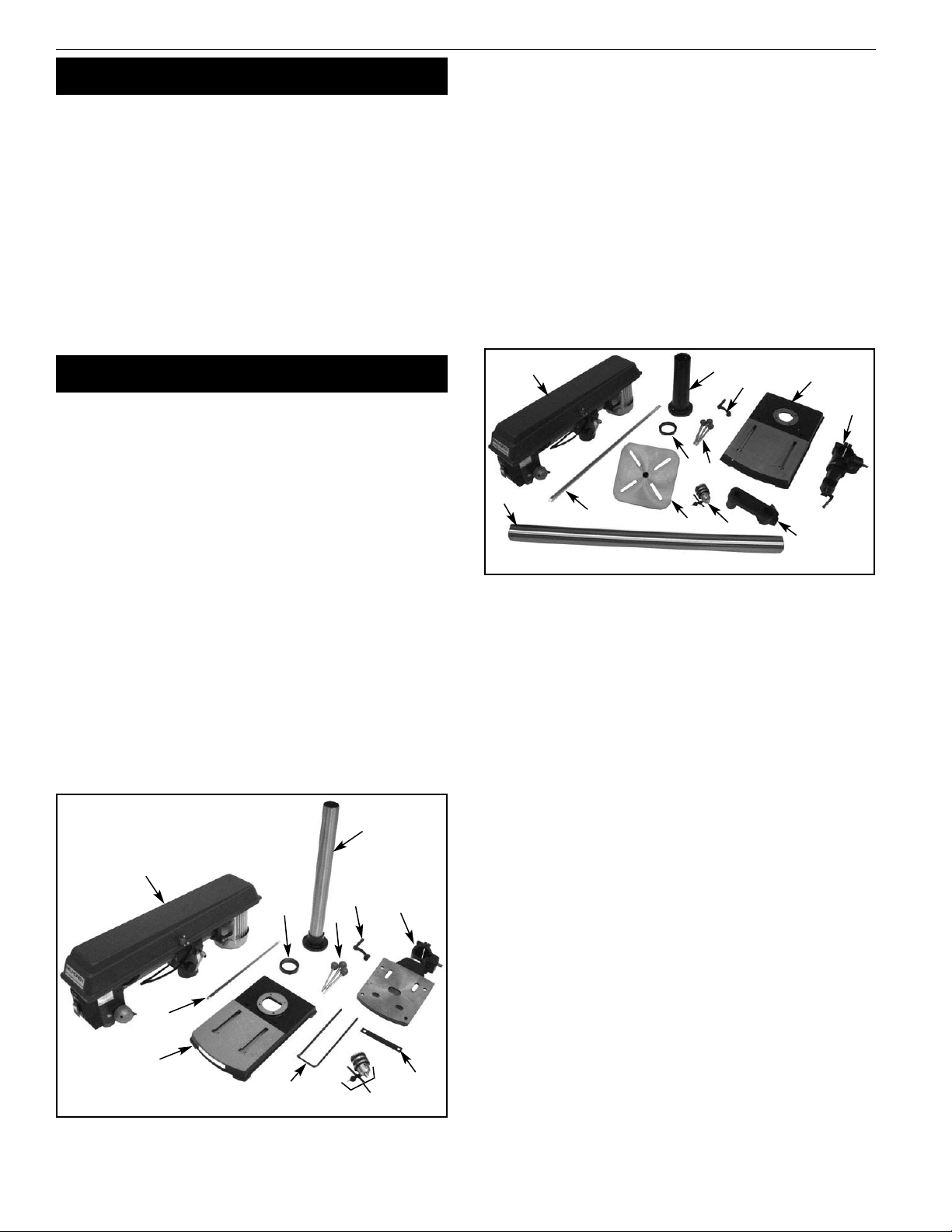

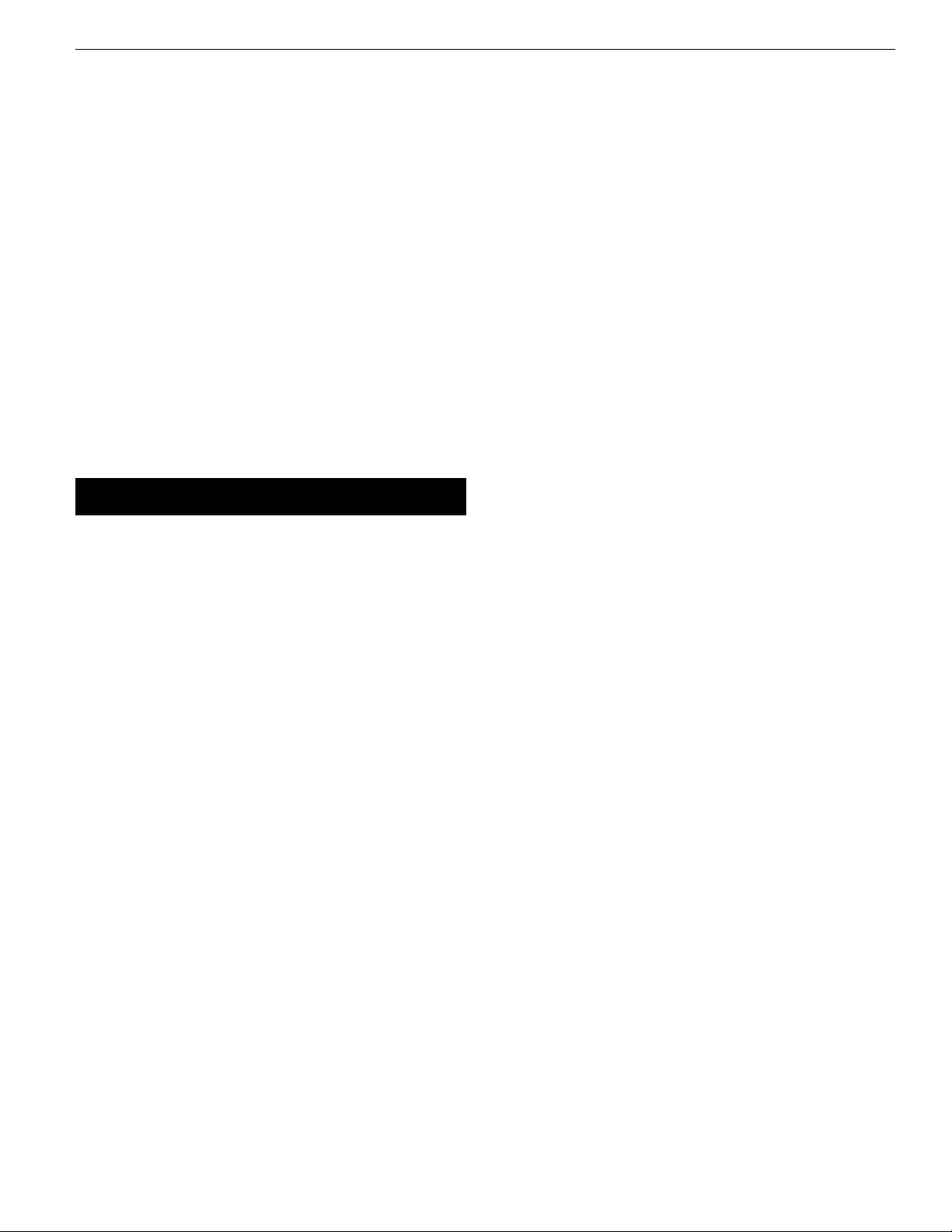

Drill press is shipped unassembled. Locate and identify the following assemblies and loose parts (Refer to Figures 1 and 2):

MODEL 80341A BENCH DRILL PRESS

A Head Assembly

B Column Assembly

CBase

D Table and Bracket Assembly with Worm Gear

E Quill Feed Handle (3)

F Table Crank Handle

G Retaining Ring

HRack

I Drill Chuck with Key

JYoke

KStrap

Not Shown: Chuck arbor, Drift key, Lock handle, Shoe, M10 x 30 Hex

head bolts (2), M10 Flat washers (2), M10 Hex nuts (2), M8 x 30 Hex

head bolts (4), M8 Flat washers (4), M8 Lock washers (4), and 3mm

and 4mm hex wrenches.

MODEL 80342A FLOOR DRILL PRESS

A Head Assembly

B Column

C Column Flange

DBase

E Table Arm and Bracket Assembly with Worm Gear

F Extension Arm

G Table

H Drill Chuck with Key

I Table Crank Handle

J Quill Feed Handle (3)

K Retaining Ring

LRack

Not Shown: Chuck arbor, Drift key, Lock handle, Shoe, M10 x 40 Hex

head bolts (4), M8 Flat Washers (4), M8 Lock washers (4), and 3mm,

4mm and 5mm hex wrenches.

IMPORTANT: The tool has been coated with a protective coating.

In order to ensure proper fit and operation the coating must be

removed. Remove coating with mild solvents such as mineral spirits and a soft cloth. Nonflam mable solvents are recommended.

After cleaning, cover all exposed surfaces with a light coating of oil.

Paste wax is recommended for table top.

CAUTION: Never use highly volatile solvents. Avoid getting clean-

ing solution on paint as it may tend to deteriorate these finishes.

Use soap and water on painted components.

SPECIFICATIONS

MODEL 80341A

Chuck size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16mm, 3JT

Spindle taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MT2

Spindle travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.15”

Quill diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.85”

Quill collar diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.16”

Column diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.36”

Speeds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 575-3520

Swing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33”

Head tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°L, 90°R

Table size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7

/8 x 9”

Table slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

/2”

Base size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1

/8 x 163/4”

Base working surface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1

⁄2 x 9”

Drilling capacity (cast iron) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

/8”

Distance, spindle to table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1

/4-15”

Distance, spindle to base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22”

Overall height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37”

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 lbs

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

/2 HP, 115 V, 1725 RPM, 4.8 Amps

2

Palmgren Operating Manual & Parts List 80341A & 80342A

Figure 1 – Model 80341A Unpacking

D

E

F

H

J

K

I

C

B

A

G

Figure 2 – Model 80342A Unpacking

D

L

E

F

H

J

K

I

C

B

A

G

3

UNPACKING (CONTINUED)

MODEL 80342A

Chuck size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16mm, 3JT

Spindle taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MT2

Spindle travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.15”

Quill diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.85”

Quill collar diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.16”

Column diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.76”

Speeds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 575-3520

Swing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33”

Head tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°L, 90°R

Table size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3

⁄8 x 103⁄8”

Table slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

/2”

Base size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 x 23

3

/4”

Base working surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7

⁄8 x 123⁄8”

Drilling capacity (cast iron) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

/8”

Distance, spindle to table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30”

Distance, spindle to base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50”

Overall height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65”

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 lbs

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

/2 HP, 115 V, 1725 RPM, 4.8 A

SAFETY RULES

PROPOSITION 65 WARNING: Some dust created by power

sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to the state of California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other

masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures vary, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved, properly fitting

face mask or respirator when using such tools.

Before any work is done, carefully read the cautions listed. Working

safely prevents accidents.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves, neck-

ties, rings, bracelets or other jewelry which may get caught in

moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses which comply with United States ANSI

Z87.1. Everyday glasses have only impact resistant lenses. They

are NOT safety glasses.

• Wear face mask or dust mask if cutting operation is dusty.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

WORK AREA SHOULD BE READY FOR JOB

• Keep work area clean. Cluttered work areas and work benches

invite accidents.

• Do not use power tools in dangerous environments. Do not use

power tools in damp or wet locations. Do not expose power

tools to rain.

• Work area should be properly lighted.

• Proper electrical outlet should be available for tool.

Three-prong plug should be plugged directly into properly

grounded, three-prong receptacle.

• Extension cords should have a grounding prong, and the three

wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof. Use

padlocks, master switches or remove switch keys to prevent

any unintentional use of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Read operating instructions manual for specific maintaining

and adjusting procedures.

• Keep tool lubricated.

• Use sharp cutters and keep the tool clean for safest operation.

• Remove adjusting tools. Form the habit of checking that adjust-

ing tools are removed before turning on the machine.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

• Check for damaged parts. Check for alignment of moving parts,

binding, breakage, mounting and any other condition that may

affect a tool’s operation.

• Damaged parts should be properly repaired or replaced. Do

not perform makeshift repairs. (Use the parts list provided to

order replacement parts.)

KNOW HOW TO USE TOOL

• Use the right tool for the job. Do not force tool or attachment

to do a job for which it was not designed.

• Disconnect tool when changing accessories such as bits, cut-

ters and the like.

• Avoid accidental start-up. Make sure switch is in OFF position

before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Handle workpiece correctly. Secure work with clamps or vise.

Leave hands free to operate machine to protect hands from

possible injury.

• Never leave a tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is tipped

or if cutter is unintentionally contacted.

• Keep hands away from moving parts and cutting surfaces.

• Know your tool. Learn its operation, application and specific

limitations.

• Feed work into a bit or cutter against the direction of rotation

of bit or cutter.

• Turn the machine off if it jams. A cutter jams when it digs too

deeply into the workpiece. (The motor force keeps it stuck in

workpiece.)

• Use recommended accessories. Refer to page 13. Use of

improper accessories may cause risk of injury to persons.

• Clamp workpiece or brace against column to prevent rotation.

• Use recommended speed for drill accessory and workpiece

material.

WARNING:Think Safety! Safety is a combination of operator

common sense and alertness at all times when drill press is being

used.

Palmgren Operating Manual & Parts List 80341A & 80342A

ASSEMBLY

Refer to Figures 3 - 12 and 22.

MOUNT COLUMN ASSEMBLY TO BASE (80341A)

Refer to Figures 3 and 23.

• Place base on flat level surface.

• Mount column assembly to base using four hex head bolts, lock

washers and flat washers.

• Push supporting yoke (Ref. No. 6) into holes at rear of base (Ref.

No. 1) with bent portion of yoke facing down.

• Use strap, washers, bolts and nuts (Ref. Nos. 2 - 5) to secure yoke

in position.

MOUNT COLUMN ASSEMBLY TO BASE (80342A)

Refer to Figure 4.

• Place base on flat level surface.

• Mount column flange to base using four hex head bolts, lock

washers and flat washers.

• Insert column into flange. Push column down until it seats in

flange. Secure column in position with the two set screws.

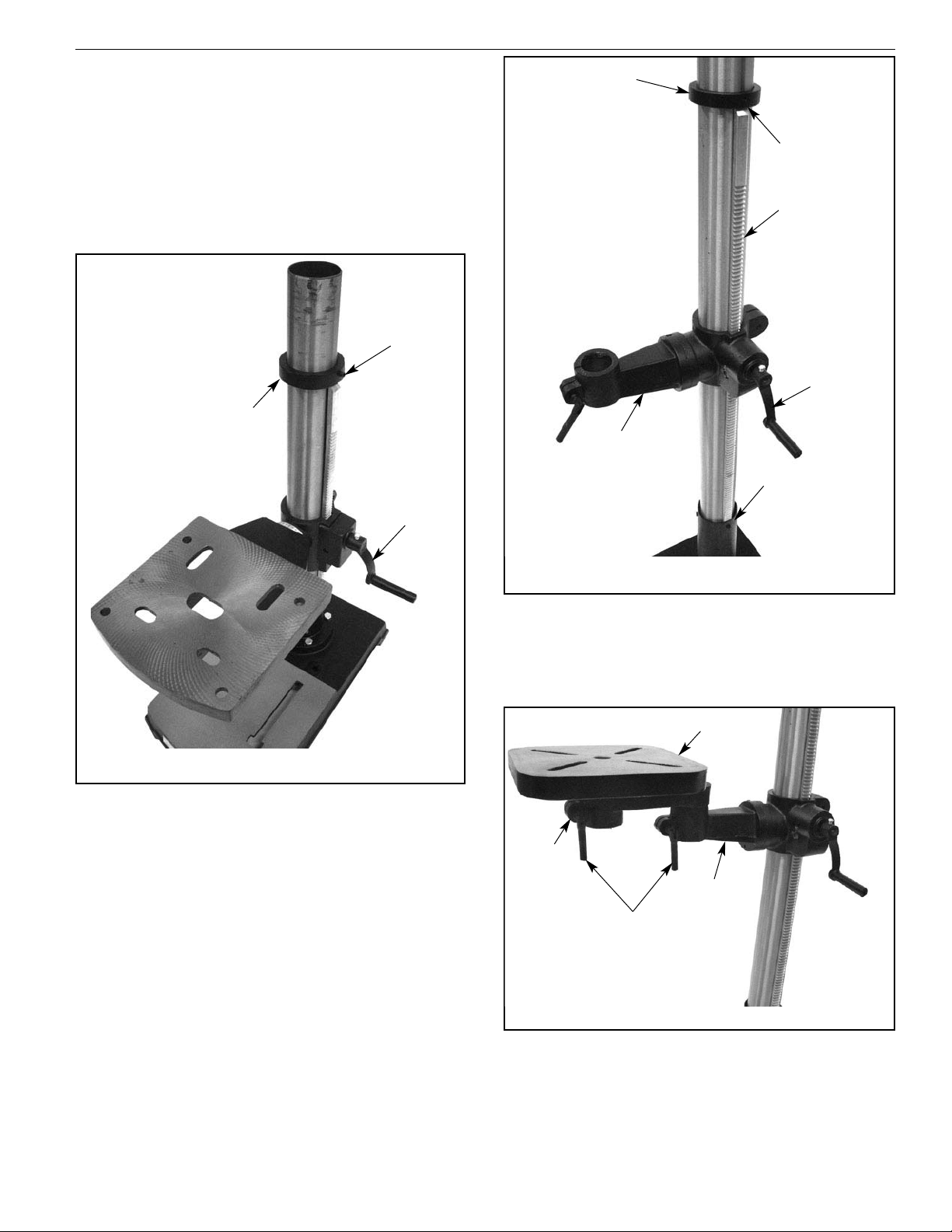

MOUNT TABLE BRACKET ASSEMBLY (80341A)

Refer to Figures 5 and 6, page 4 and 5.

• Make sure worm gear is in the table bracket and engages pin-

ion teeth.

• Place rack inside table bracket. Slide rack into the slot in the

bracket so that rack teeth engage the pinion gear in the bracket.

Large non-machined portion of rack should be at top.

4

Palmgren Operating Manual & Parts List 80341A & 80342A

Column

Flange

Rack

Table Bracket

Assembly

Figure 5 – Position Table Bracket Assembly on Column

Figure 3 – Mount Column Assembly to Base (80341A)

Hex Head Bolts

Column Assembly

Base

Figure 4 – Mount Column Flange to Base

Column

Hex Head Bolts

Set Screw

Flange

Base

Palmgren Operating Manual & Parts List 80341A & 80342A

5

ASSEMBLY (CONTINUED)

• Slide table bracket assembly with rack over column. Place bot-

tom end of rack inside beveled edge of column flange. See

Figure 5, page 4.

• Slide retaining ring over column with beveled edge down.

Position ring against top of rack so that rack is in beveled edge

of ring. Secure ring with set screw.

• Rotate table assembly around column. Adjust ring as necessary

to prevent binding of rack.

• Attach crank handle onto worm gear shaft. Secure handle with

screw, tighten screw on flat of worm gear shaft.

MODEL 80342A

Refer to Figures 7 and 8.

• Make sure worm gear is in the table bracket and engages pin-

ion teeth.

• Place rack inside table bracket with large, unmachined portion

of rack to the top. Slide rack onto the slot in the bracket so that

rack teeth engage the pinion gear in the bracket.

• Slide table bracket assembly with rack over column. Place bot-

tom end of rack inside beveled edge of column flange. See

Figure 7.

• Slide retaining ring over column with beveled edge down.

Position ring against top of rack so that rack is in beveled edge

of ring. Secure ring with set screw.

• Rotate table assembly around column. Adjust ring as necessary

to prevent binding of rack.

• Attach crank handle onto worm gear shaft. Secure handle with

screw, tighten screw on flat of worm gear shaft.

• Insert the extension arm into the table arm bracket assembly.

NOTE: The table can be installed directly to the table arm

bracket assembly.

• Insert the table into the extension arm.

• Tighten locking handles to secure table, extension arm and

bracket.

Figure 6 – Attach Retaining Ring, Crank Handle and

Locking Handle

Retaining Ring

Set Screw

Crank Handle

Figure 8 – Attach Extension Arm and Table

Bracket

Extension

Arm

Locking Handle

Tab le

Figure 7 – Attach Bracket, Rack, Retaining Ring and Crank

Handle

Retaining Ring

Set Screw

Bracket

Rack

Column Flange

Crank

Handle

6

Palmgren Operating Manual & Parts List 80341A & 80342A

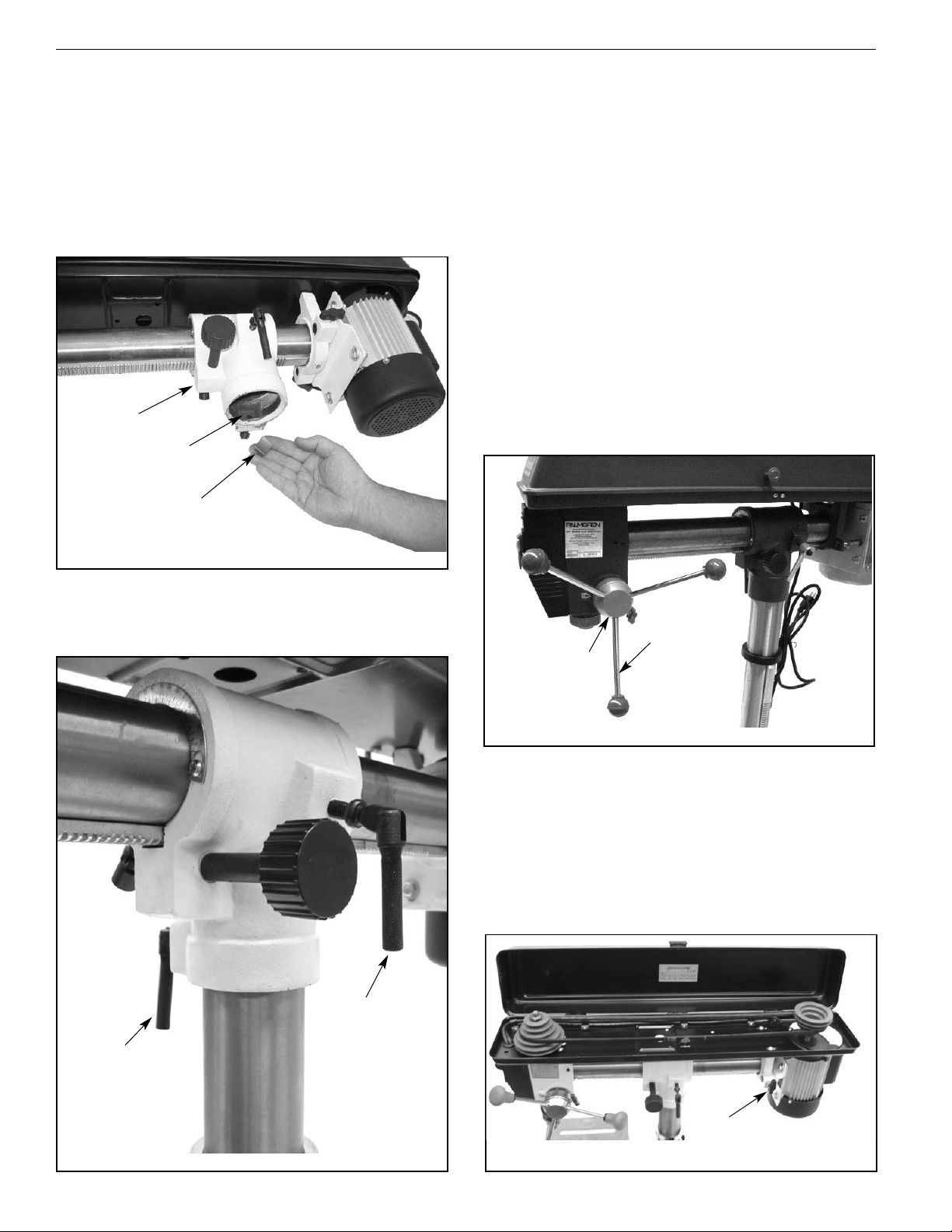

ASSEMBLY (CONTINUED)

MOUNT HEAD ASSEMBLY

Refer to Figures 9 and 10.

WARNING: Although compact, the drill press head assembly is

heavy. Two people are required to mount the drill press head

assembly onto the column.

• Place locking shoe into the cavity in the ram bracket.

WARNING: Do not install the head assembly onto column unless

the locking shoe is in place. The head assembly cannot be properly

secured to the column without locking shoe.

• Slide drill press head assembly onto top of column.

• Position head so that it is centered over base.

• Secure head assembly into position by tightening the locking

handles (see Figure 10).

MOUNT CHUCK AND ARBOR

Refer to Figure 22, page 12.

• Be sure spindle, arbor and chuck tapers are clean and dry. Make

sure quill is completely retracted.

• Use the provided chuck key (Ref. No. 1) to adjust the jaws of the

chuck (Ref. No. 2) until they are recessed inside the drill chuck

body.

• Place drill chuck on a workbench face down. Arbor (Ref. No. 80)

has a short taper and a long taper. Place short taper into top of

drill chuck and tap with a rubber or wooden mallet.

• Slide arbor into the spindle (Ref. No. 4) while slowly rotating

drill chuck. Spindle has a rectangular pocket in which the tang

fits into. Once tang is oriented correctly, drill chuck will not

rotate without turning the spindle.

• Tap the end of drill chuck with a rubber or wooden mallet to

seat it into the spindle.

• Use a hammer to carefully tap chuck securely onto the spindle.

MOUNT QUILL FEED HANDLES

Refer to Figure 11.

• Thread the three quill feed handles into the threaded holes on

the pinion hub.

ADJUST V-BELT TENSION

Refer to Figure 12.

• Open the pulley cover and loosen both motor lock knobs (one

on each side of the head).

• Push motor back to apply tension to v-belt.

• Correct tension is obtained when the v-belt can be flexed

approximately

3

/8” at belt midpoint using finger pressure.

• When correct tension is obtained, secure motor in position by

tightening motor lock knobs.

Figure 10 - Secure Head Assembly

Head Angle

Locking Handle

Head Rotation

Locking Handle

Figure 11 - Install Quill Feed Handles

Pinion Hub

Quill Feed Handle

Figure 12 - Adjust V-belt Tension

Motor

Lock

Knob

Figure 9 – Place Locking Shoe Into the Cavity in Ram Bracket

Ram Bracket

Cavity

Locking Shoe

Loading...

Loading...