Page 1

Pall WS08 Series Water Sensor

instruction booklet

SIWS08EN

WS08

AB

Page 2

Pall does not accept warranty and liability claims either upon this publication

or in case of improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors.

The content will be revised on a regular basis. These changes will be implemented

in later versions. The described products can be improved and changed at any

time without prior notice.

USA

FCC notice:

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the installation manual, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Caution:

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this device.

CANADIAN

ICES-003 notification:

This Device B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme

NMB-003 du Canada.

2

instruction booklet

Pall WS08 Series

Water Sensor

Because of developments in technology these data or procedures may

be subject to change. Consequently we advise users to review their

continuing validity annually. Part numbers appearing in this manual are

protected by the Copyright of Pall Europe Limited.

and Pall are trademarks of Pall Corporation.

Filtration. Separation. Solution is a service mark of Pall Corporation.

© 2008, Pall Europe Limited.

AB

Page 3

1. GENERAL 4

1.1 Symbol assertion 4

1.2 Safety instructions 4

1.3 Environmental information 4

2. PRODUCT DESCRIPTION 5

3. INSTALLA

TION 5

3.1 Installation of the housing 5

3.2 Installation of

the probe 5

3.2.1 General Safety instructions for installation 5

3.2.2 Installation of the probe directly in the process 6

3.2.3 Installation of the probe by utilizing the ball valve set 6

4. ELECTRICAL CONNECTIONS 8

4.1 Connection diagram 8

4.2 Connection diagram

alarm module / option 8

4.3 Connection configuration with plug connections / Option 8

5. OPERATING COMPONENTS 9

5.1 Circuit board 9

5.2 Display module

/ option 10

6. ALARM MODULE / OPTION 11

7. MAINTENANCE 12

7.1

Sensor replacement 12

7.2 Sensor pr

obe replacement / optional 12

7.3 Self-diagnostics and error messages 13

7.4 Replacement of sealing element 13

8. NETWORK 14

9. REPLACEMENT P

ARTS / ACCESSORIES 15

10. TECHNICAL DATA 16

1. GENERAL INFORMATION 17

2. INSTALLATION 17

3. ICONS ON THE TOOLBAR 18

3.1 File 18

3.2 Interfaces 18

3.3

Group 19

3.4 Transmitter 19

3.5 Information 20

4. ICON LIST 20

5. TA

BS 21

5.1 Analogue 21

5.2 Relay 21

5.3

Sensor / probe replacement 22

5.4 Information 23

6. OVERVIEW 24

6.1 How to set-up a new transmitter? 24

6.2 How to

read the configuration of a transmitter? 24

6.3 How to save the configuration in a transmitter? 24

DECLARATION OF CONFORMITY 25

Contents

HARDWARE

CONFIGURATION

SOFTWARE

3

instruction booklet

Pall WS08 Series

Water Sensor

AB

Page 4

1. GENERAL

The manual is a part of the scope of supply and serves to ensure proper handling and

optimum functioning of the instrument. For this reason, the manual must be read before

start-up.

In addition, the manual is for all personnel who require knowledge concerning transport,

setup, operation, maintenance and repair.

The manual must not be used for the purpose of competition without a written consent

from Pall and must also not be forwarded to third parties.

Copies for personal use are permitted.

All information, technical data and illustrations contained in these instructions are based

on information available at the time of publication.

1.1 Symbol assertion

This symbol indicates a safety instruction.

These safety instructions should always be followed carefully.

By not following these instructions injuries of persons or material damage

could happen.

Pall does not accept liability in the event of these

safety instructions being ignored.

This symbol indicates a note.

These notes should be observed to achieve optimum functioning

of the equipment.

1.2 Safety instructions

General Safety Instructions

• Excessive mechanical loads and incorrect usage should always

be avoided.

• In general, work on live components should be avoided and

when absolutely necessary should be performed by qualified

personnel only.

• Installation, electrical connection, maintenance and commissioning

should be performed by qualified personnel only.

Safety instructions for use of the alarm module

with voltages >50V

• To insulate the optional relay connections from the low-voltage side of

the water sensor, the partition provided for this purpose must be fitted

in the lower section.

• During operation of the instrument the modular housing must be

completely closed.

• The protection class of an opened housing corresponds to IP00 and

direct contact with components carrying dangerous voltages is therefore

possible. In general, work on live components should be avoided and

when absolutely necessary, should be performed by qualified personnel

only.

1.3 Disposal of Equipment

At the end of its life, the Water Sensor should be dismantled and disposed

of in accordance with all applicable local waste disposal laws and bylaws.

Where facilities exist, component parts of the unit may be recycled.

Details of the materials of construction are given on the product installation

drawing and if required, more detailed information regarding specific

items may be obtained from Pall or an approved agent.

If component parts of the equipment were previously contaminated with

the service fluid, an appropriate Manufacturer’s Safety Data Sheet (MSDS)

for the fluid should be obtained and read to ensure that contaminated

component parts are disposed of safely. Pall Europe Ltd., will meet it’s

obligations under the EU Directive on Waste Electrical and Electronic

Equipment (WEEE).

Hardware

4

instruction booklet

Pall WS08 Series

Water Sensor

AB

Page 5

Any product marked with the WEEE logo should be separated from other waste

streams to ensure that it can be recycled in an environmentally sound manner.

Pall Europe Ltd., accepts liability for New WEEE at the end of life and will dispose of

safely or recycle goods wherever possible. As defined in the Terms and Conditions

of Sale, Pall Europe does not accept any liability whatsoever for the remote collection,

shipping costs or packaging of returned goods. All costs associated with the return

of WEEE will be born by the customer.

Customers are responsible for the costs of shipping goods to the Central Collection

Point and Pall Europe Ltd accepts no liability whatsoever for any such costs.

Instructions to both customers and recyclers/treatment facilities regarding WEEE can

be found at www.Pall.com/weee.

2. PRODUCT DESCRIPTION

Pall Water Sensor series WS08 are specially designed for the measurement of water

content in oil.

The measured and the calculated values are available on two freely scaleable and

configurable analogue outputs. In addition, the relay output can be used for alarms and

process control (no relay available with RS485 options).

The modular housing enables a user-friendly operation and a quick

replacement of the sensor unit for service purposes.

3. INSTALLATION

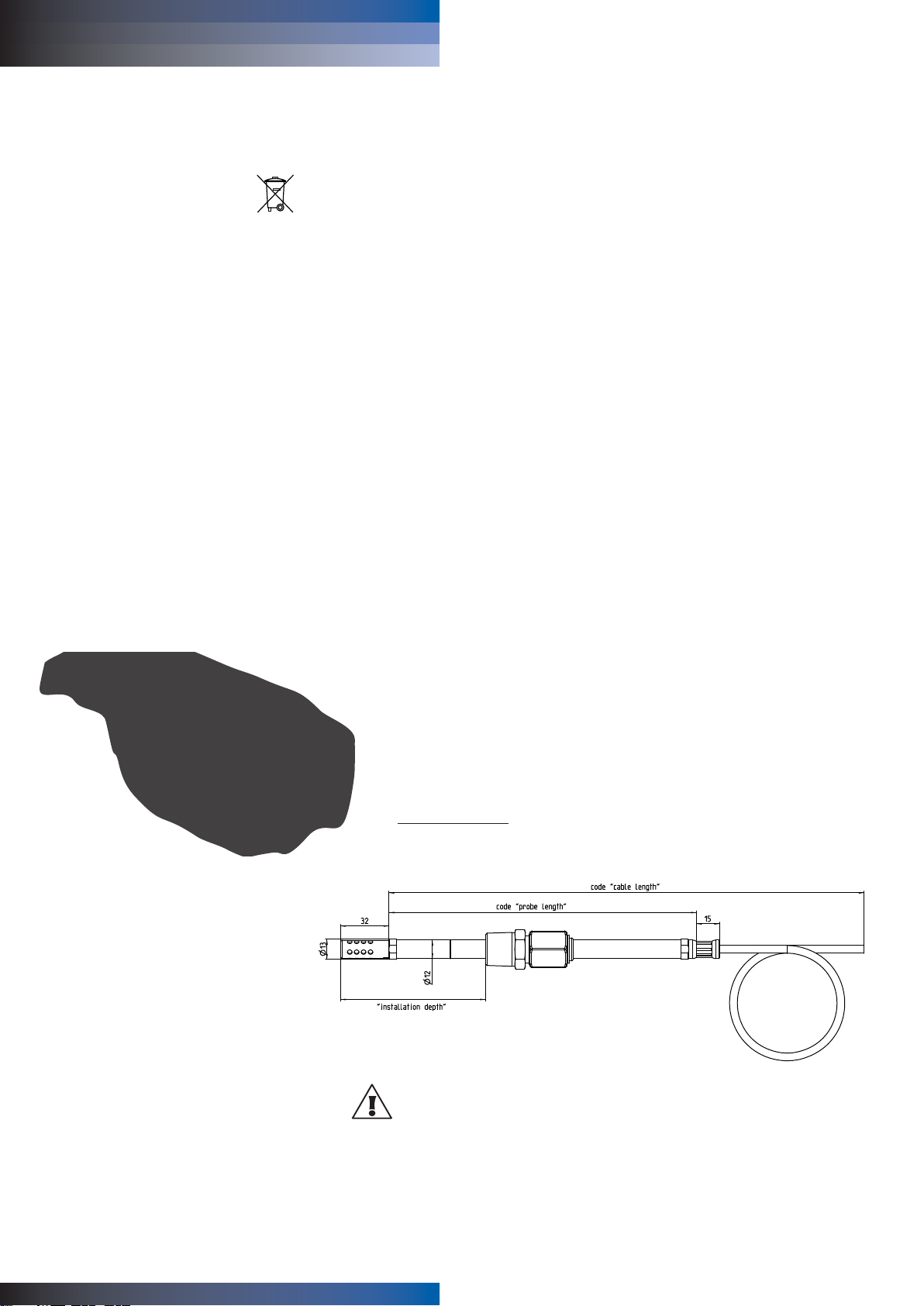

3.1 Installation of the housing

The necessary dimensions for the mounting holes can be found

in the drawing to the left.

3.2.1

General safety instructions for installation

The Water Sensor probe is designed for use with pressures up to 20 bar

(290 psi). Precautions therefor

e need to be taken when installing or

removing the probe to ensure that it is not ejected from the system at

high velocities. The design of the probe is such that only when the gland

is fully unscrewed can the probe be removed form the system.

Hardware

5

instruction booklet

Pall WS08 Series

Water Sensor

3.2 Installation of the probe

The probe should be located somewhere in the system where fluid will steadily

flow past the probe tip. A return line, or the wall of a reservoir are usually suitable.

Avoid locations where the fluid is frequently stagnant; also avoid places where

water or dirt/sludge could collect around the probe.

Installation depth: 100 mm probe 23 - 65 mm

200 mm probe 23 - 165 mm

AB

Page 6

Pall WS08 Series

Water Sensor

instruction booklet

6

Hardware

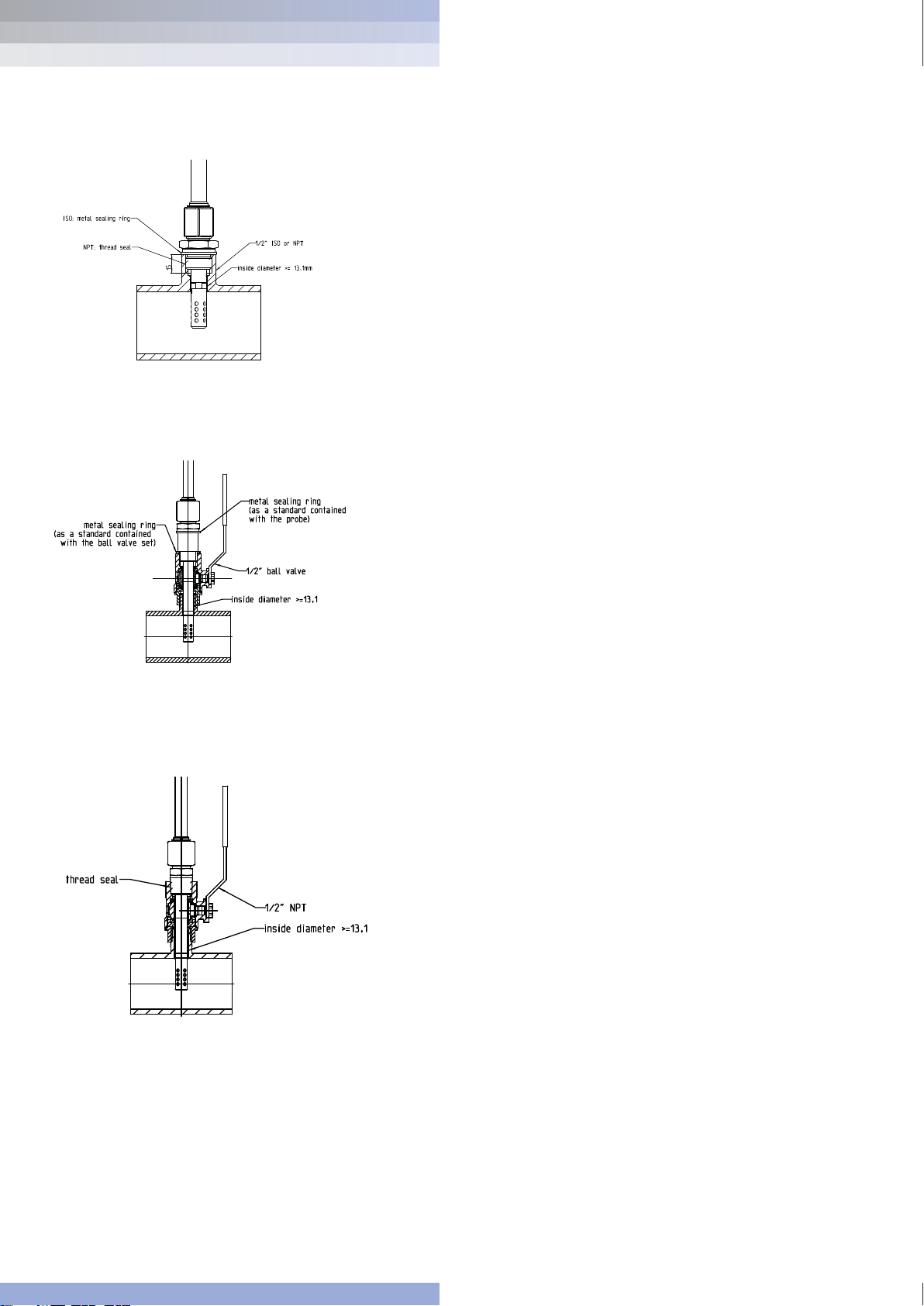

3.2.2 Installing a bushing/stub

The standard probe without ball valve requires either a ½” BSPP/ISO

or a ½“ NPT female bushing to be welded to the pipe or reservoir

where the probe is to be located. The NPT bush is required for the –

BO8 option probe. The long probe, when supplied with a ball valve,

requires a male threaded stub at the installation location. The

BSPP/ISO stub must be suitable for use with a bonded seal or metal

sealing washer.

Unless a suitable threaded port is already available, a ½” bush/stub

will need to be welded to the pipe or reservoir, the fluid having been

drained. Suitable cleaning/flushing procedures will be necessary once

the bushing/stub is fitted.

3.2.3 Installing the probe, without ball valve

Unscrew the gland-nut completely and check that the o-ring on the

cone of the gland is in good condition. If it is cut or damaged, replace

the o-ring.

Apply thread tape (-B08 option) to the thread of the nipple, or fit a

suitable seal ( C08 option, bonded seal or metal sealing washer). Fit

the nipple into the bush. Tighten sufficiently to ensure a fluid seal.

Slide the probe through the gland to locate the probe tip in the fluid

flow, and tighten the gland lock-nut onto the nipple to a torque of

30Nm (22 lbf ft). If a torque spanner is not available, firmly handtighten the nut, then spanner-tighten a further 50° (approximately 1

flat). Check that the probe is not free to slide in the gland – tighten

further if it can be moved by hand. Fill the system, pressurise to

normal working pressure, and check for leaks. For safety reasons,

keep away from the probe while the system is being pressurised, until

it is established that the probe will not be forced through the gland by

the pressure.

3.2.4 Installing the probe, with ball valve.

a) With the valve open, fit a suitable seal, or apply thread tape if

appropriate, and screw the valve onto the stub so that the handle

of the valve points away from the stub. Tighten sufficiently to seal

the joint. Close the valve, and fill/pressurise the system.

b) Unscrew the gland-nut completely and check that the o-ring on

the cone of the gland is in good condition. If it is cut or damaged,

replace the o-ring. Fit a suitable seal, or apply thread tape if

appropriate, and fit the nipple into the bush. Tighten the nipple

sufficiently to achieve a fluid seal. Screw the gland-nut onto the

nipple, sliding the probe back until the stop-ring contacts

the gland.

C08 option with ball valve

B08 option with ball valve

AB

Page 7

Pall WS08 Series

Water Sensor

instruction booklet

7

Hardware

c) Hand-tighten the gland nut until the probe is just free to slide/turn

within the gland, and slowly open the ball valve – there may be a

very slight leak of fluid around the gland-nut. Firmly and steadily

press the probe through the gland until the tip is in the flow of fluid.

Keeping the probe in position, tighten the gland-nut to 30Nm

(22 lbf ft). If a torque spanner is not available, firmly hand-tighten

the nut, then spanner-tighten a further 50° (approximately 1 flat).

Check that the probe is not free to slide in the gland – tighten

further if it can be moved by hand. Tightening the gland-nut should

eliminate the small leak which may occur during installation. For

safety reasons, keep away from the probe while the system is

being pressurised, until it is established that the probe will not be

forced through the gland by the pressure.

Note that a force of at least 1 kgf per bar of pressure (1.7 lbf per 10 psi)

is necessary to press the probe through the gland with the system

under pressure. Although the probe is designed for operation at up to

20 bar (290 psi) system pressure, it will be difficult to push the probe

through the gland and valve at pressures above about 4 bar (58 psi),

and there will be risk of damage to the probe. Ideally the system

should be depressurised to install the probe; the valve allows

installation/removal of the probe without draining the system.

3.3 Removal of the probe.

3.3.1 Removal of the probe, without ball valve.

a) Either completely isolate and depressurise the system where the

probe is located, or depressurise the whole system and drain it

until the fluid level is below the probe location.

b) Carefully loosen the gland nut, and having checked that there is no

residual pressure in the system, unscrew the gland-nut completely

and withdraw the probe.

3.3.2 Removal of the probe, with ball valve.

a) Depressurise the system. This is essential if the operating pressure

is above about 4 bar (58 psi), and recommended for lower pressures.

b) Carefully loosen the gland-nut – if the system is still pressurised,

apply a force along the probe to ensure that it is not forcibly pushed

back through the gland. Once the probe is free to move, withdraw it

through the gland until the stop-ring on the probe makes contact

with the gland. Close the valve. Do not force the valve closed if

there is a resistance, but investigate why the probe has not been

fully withdrawn.

c) Fully unscrew the gland-nut and withdraw the probe from the

valve assembly.

For reinstallation follow the instructions 3.2.2 or 3.2.3, omitting the

installation of the nipple, which should already be in place.

AB

Page 8

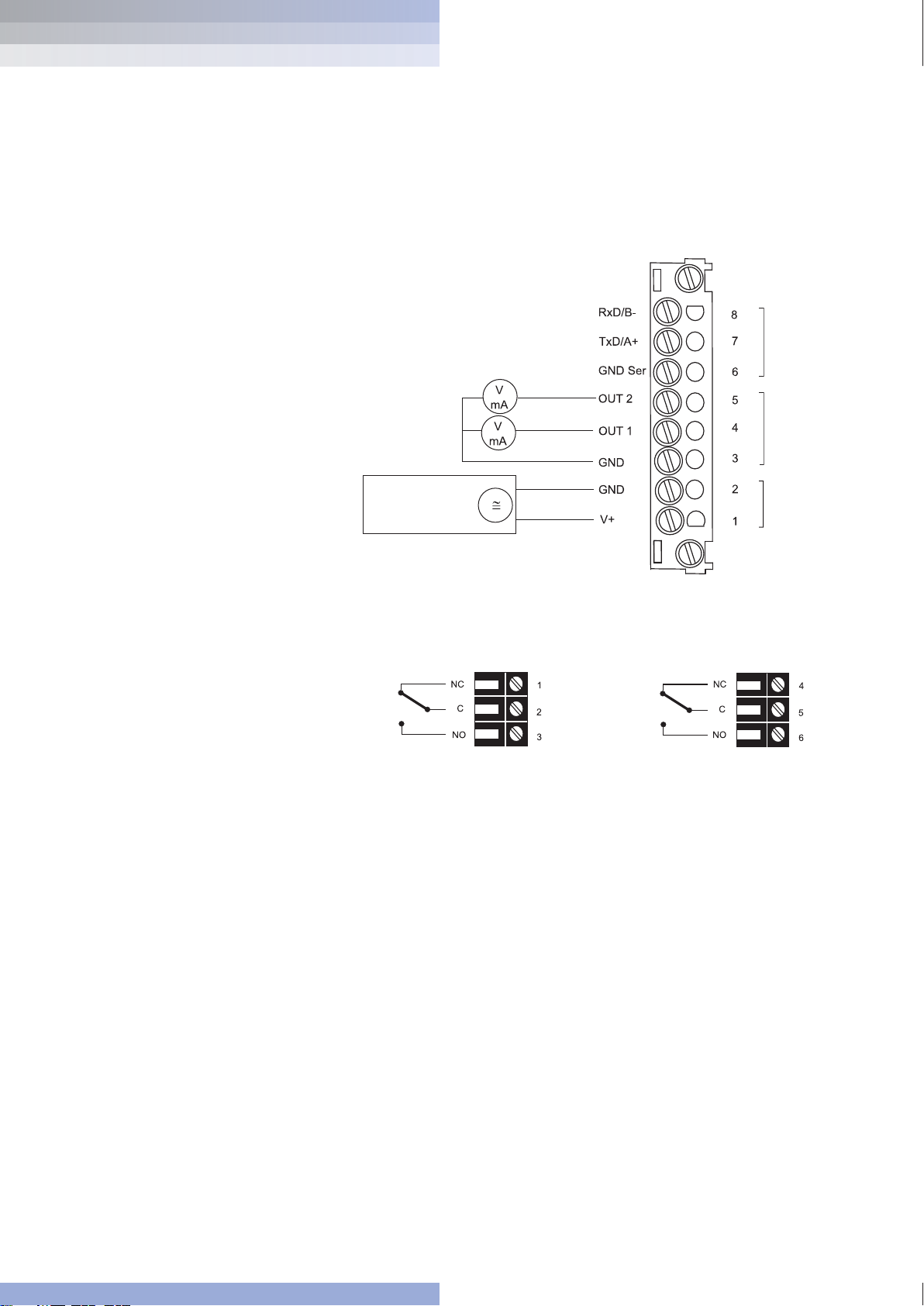

serial

data

output

analogue

output

supply

4.2 Relay connection diagram / Option

Rel 1

Rel 2

4. ELECTRICAL CONNECTIONS

Hardware

4.1 Connection diagram

instruction booklet

Pall WS08 Series

Water Sensor

8

AB

8 - 35 VDC

12 - 30 VAC

Page 9

4.3 Connection configuration with plug connections

4.4 Connection configuration of bottom part of the housing

with integrated power supply / 100...240V AC (option V01)

Description: Connection assignment:

GND-Ser 5

GND 4

Rxd/B- 3

V+ 2

Txd/A+ 1

The cable should be connected according to the number stamped in the

plug as shown in the above drawings.

Plug for RS485

connection

(front view)

Description: Connection assignment:

GND-Ser 5

GND 4

Rxd/B- 3

V+ 2

Txd/A+ 1

Plug for RS232

analogue output

(front view)

Description: Connection assignment:

GND-Ser 5

GND 4

Rxd/B- 3

Plug for 100-240V

metal housing

(front view)

Description: Connection assignment:

GND-Ser 5

GND 4

Plug for 100-240V

polycarbonate

housing

(front view)

External diameter of supply cable: 10-12mm (0.39-0.47”)

Maximum wire cross section: 1.5mm2 (AWG 16)

The protection of the supply cable against excess current and short-circuit

shall be in accordance with national and local codes.

Bottom and centerpeice of the housing shall be grounded!

Hardware

9

instruction booklet

Pall WS08 Series

Water Sensor

AB

Page 10

Pall WS08 Series

Water Sensor

instruction booklet

10

Hardware

1. Current / voltage output:

The default factory output setting is for current. The device can be

switched from current to voltage output using the configuration software

the two jumpers must be located as follows:

for current signals:

for voltage signals:

2. RS232 / RS485:

For the transition from RS232 to RS485 (network operation) these

jumpers must be removed.

3. Location of the network chip:

For refitting to RS485, an IC must be used (available as an option).

The notch on the chip must match the receiver slot!

4. Socket for optional display:

Pin connector for optional display.

5. Push-Buttons for calibration purposes:

See Hardware, chapter 7 “Maintenance

”

6. Diagnosis LEDs:

See Hardware, chapter 7 “Maintenance

”

5.1 Circuit board

After removal of the housing cover, the following operating

components on the circuit board may be accessed for adaptation

of the transmitter to the desired configuration. Each component is

discussed in more detail below.

5. OPERATING COMPONENTS

OUT2

OUT1

OUT2

OUT1

1. Current / voltage output jumpers

2. RS232 / RS485 jumpers

3. Location of the

network / RS485 chip

4. Socket for optional display

5. Push-button

6. Diagnosis LEDs

AB

I

I

U

U

Page 11

Pall WS08 Series

Water Sensor

instruction booklet

11

Hardware

SI SI US

T Temperature °C °F

%S % saturation % %

x Water content ppm ppm

1. MEASURED

VARIABLE:

2. UNITS: 3. MEASURED VARIABLE

SELECTION

5.2 Display module / Option

Press the ▲ or ▼ button

to select the desired

Measured Valve

1. Measured variable

2. Units

3. Measured variable selection and

4. Min / Max function

5. Measured values

6. Status line

4. MIN / MAX FUNCTION:

The WS08 Water Sensor can display the highest and lowest

measured value recorded since the last reset.

Highest measured value:

1. Select the desired measured variable.

2. To display the maximum value of the selected measured variable,

press the

▲

button for at least five seconds.

3.1. To reset the instrument to its normal operating status, press the

▲

button once again for five seconds.

3.2. If both buttons are pressed for at least five seconds while the

maximum value is displayed ➔ the “MAX” symbol disappears ➔

the maximum value will be deleted (Reset).

Lowest measured value:

1. Select the desired measured variable.

2. To display the minimum value of the selected quantity, press

the

▼

button for at least five seconds.

3.1. To reset the instrument to its normal operating status, press

the

▼

button once again for five seconds.

3.2. If both buttons are pressed for at least five seconds while the

minimum value is displayed ➔ the “MIN” symbol disappears ➔

the minimum value will be deleted (Reset).

AB

REL1

%S

aw: 0.38

38.2%

%S: 38.2%

%S: 38.2%

Page 12

Legend Minimum Maximum Unit

% saturation %S 0 100 %

Temperature T -40 (-40) 180 (356) °C (°F)

Water content x 0 99999 ppm

Note that the water content in ppm will not be displayed unless 4

constants, specific to the fluid, have been entered via the Configuration

software (see section 5.4 of the software description in this manual).

6. STATUS LINE:

- MIN; MAX: see point “MIN/MAX Function”

- CALIB LOW; CALIB HIGH: indicates the low or high humidity /

temperature calibration point.

- REL1 / REL2: Status Relay

- “ERROR 01....04”: see Hardware, chapter

7 “Self-diagnosis

and error messages

”

6. RELAY CONNECTION

The relay connection can be used for alarm and basic control functions.

Two relays are provided which can be configured using the configuration

software supplied (Note: Relays are not available with RS485 option).

The user thus has the option of setting the measured variable to be

monitored (%S, x, T) and the threshold hysteresis for each relay. (For

the procedure, see the Configuration Sofware, page 20 chapter 5.2

“Relay”)

max. switched voltage / max. switched current: 250 VAC / 6A

28 VDC / 6A

Minimum load: >100mA / 12V

The range over which the switching point of each relay can be adjusted

is given below:

5. DISPLAY RANGE:

The full range of each measured variable which can be displayed

is as follows:

Hardware

12

instruction booklet

Pall WS08 Series

Water Sensor

Legend Minimum Maximum Unit

% saturation %S 0 100 %

Temperature T -40 (-40) 180 (356) °C (°F)

Water content x 0 99999 ppm

AB

Page 13

%S: 38.2%

%S: 38.2%

Note, however, that the ppm output is not disabled if no ppm conversion constants

have been entered via the Configuration software (page 23, section 5.5).

If the Physical Quantity (see software, page 20, section 5.1) is set to ppm, but no

constants have been entered, the relay operation and appearance of REL legends

in the display will be unpredictable and meaningless.

Caution: The measured variable ppm (x) should only be used if

C1 to C4 constants have been loaded.

Switching relay 1:

Switching relay 2:

If relay 1 has tripped (ON),

then REL1 is displayed.

If relay 2 has tripped (ON),

then REL2 is displayed.

Hardware

13

instruction booklet

Pall WS08 Series

Water Sensor

ON

Relay status

Switching off

Switching on

Switching point

Hysteresis

OFF

ON

Relay status

Switching off

Switching on

Switching point

Hysteresis

OFF

AB

C

C

C

C

62

11

NC

1

12

2

3

NO

13

NC

11

1

12

2

NO

13

3

14

NC

4

15

5

6

NO

16

14

NC

4

15

5

NO

16

6

8°C

8°C

70

[ppm, %,°C/°F]

62

70

[ppm, %,°C/°F]

Page 14

• Sensor cleaning

Note: A reduction of the stabilisation time can be achieved by cleaning

the probe with n-Hexane resp. n-Heptane. Swirl the probe carefully in the

solvent then drip off and after that exhaust the air around the probe >0.5h.

Attention: Other solvents than above mentioned can corrode the

humidity sensor!!

• Fuse replacement (only with option V01)

7.1 Diagnostics

Self-diagnostics via the LEDs on the circuit board

(see section 5.1)

• Both LEDs off – no power to circuit board.

Check wiring and low voltage power supply

• Green LED flashing – circuit operating, microprocessor active.

• Green LED continuously on – electronic fault.

Contact Pall or your local supplier

• Red LED flashing – probe sensing element gaining moisture.

• Red LED continuously on – liquid water droplets on sensing element.

Allow the probe to dry out.

Note that during calibration operations using the buttons on the circuit

board, the significance of the LEDs being on, or flashing, is different from

the above. Humidity / Temperature Calibration using push buttons.

Self-diagnostics via messages on the display (when fitted)

• Error 1 – sensing element damaged. Contact Pall or your local supplier.

• Error 2 – liquid water on the sensing element. Allow the probe to dry out.

• Error 3 – temperature sensor open circuit or damaged. Contact Pall or

your local supplier.

• Error 4 – temperature sensor shorted. Contact Pall or your local supplier.

Definitions:

• Error

possible cause

➟ Measures / Help

• Display shows incorrect values

Error during re-adjustment of the transmitter

➟ Reset to factory calibration and repeat the calibration routine

Sensor defective

➟ Replace sensor

Output configured incorrectly

➟ PC - Software

• Transmitter failure

no supply voltage

➟ Check wiring and supply voltage

➟ only green LED is illuminated continuously

➟ Electronics defect

➟ contact the manufacturer

Hardware

7. MAINTENANCE

14

instruction booklet

Pall WS08 Series

Water Sensor

AB

Page 15

Hardware

15

instruction booklet

Pall WS08 Series

Water Sensor

8. NETWORK

Provided each of the WS08 Water Sensors has the RS485 communications option

fitted, up to 32 instruments can be connected to a single RS485 network. Full

details of networking WS08 Water Sensors, together with information on the

communications protocols, are given in a separate manual which will normally be

provided only when instruments fitted with RS485 communications are supplied.

The Pall manual corresponding to RS485 communications is titled:

“

Pall WS08 Series Water Sensor RS485 communications”

Network configuration:

Technical Data:

- Max. network size: 32 transmitters / COM-PORT of PC

- Max. network expansion: 1200m (3937ft) total length

- Transmission rate: 9600 Baud

Mounting notes:

Data cables: - minimum diameter of 4mm (0.16")

- 2-core twisted pair

- Typ. 50 pF/m, impedance 100 Ohm, non-shielded

- In accordance with the RS485 standard, cables

in category 5 (UTP), specified according to

EIA/TIA/ANSI 568, meet these requirements.

For high noise emissions, especially for large cable lengths, the use of shielded

cables is recommended. (Shield laid at GND)

1) Note: to enable optimum expansion, both ends of the network must be terminated with a

100 Ohm resistor.

2) Note: to adapt the RS232 interface on the PC to the RS485 network protocol, a signal converter

is required.

2 analogue

outputs

RS485

RS485

RS485

RS485

converter

RS232 (COM) interface

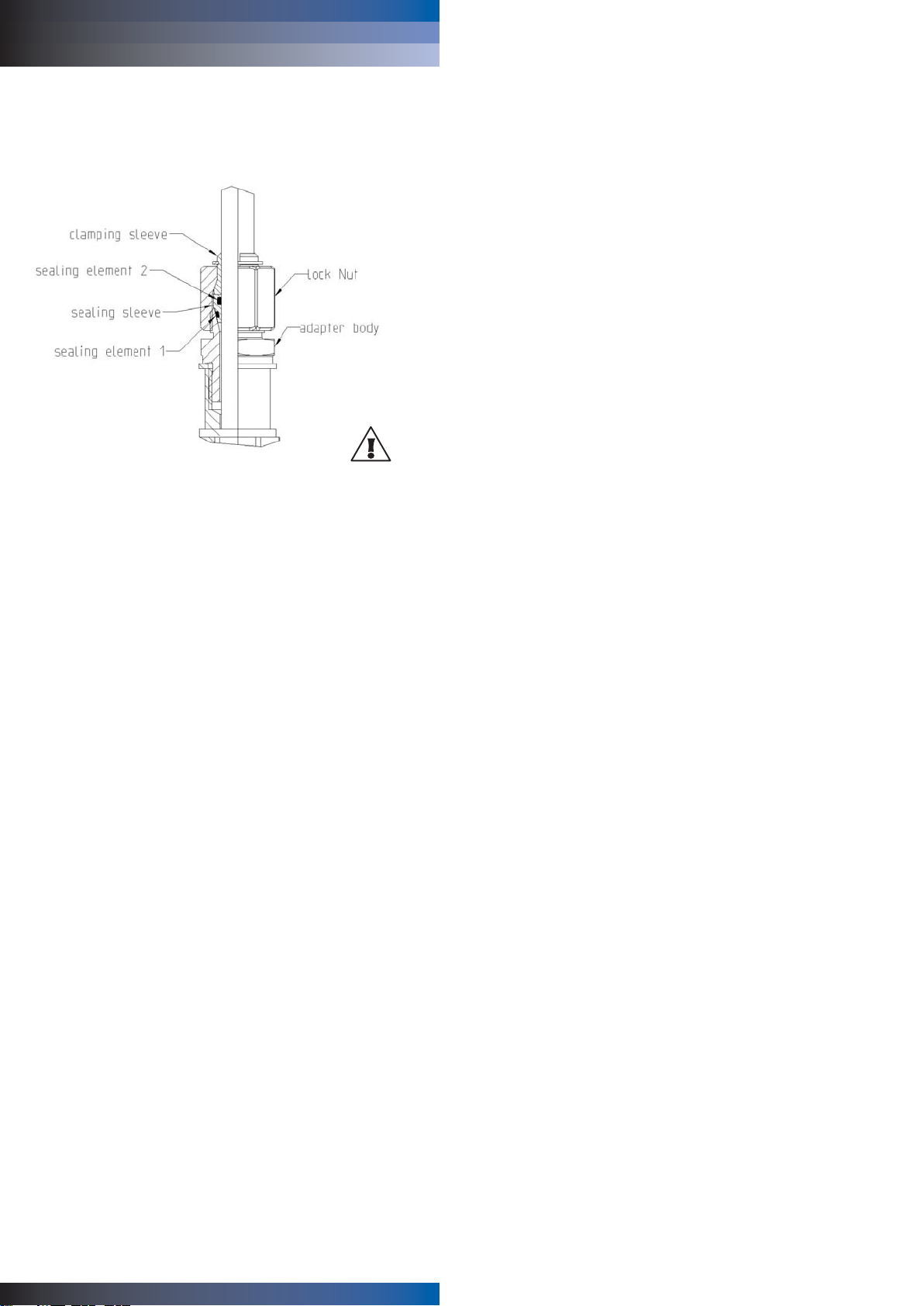

7.2 Replacement of sealing element1

In the event of sealing element wear or failure, replace with a

fluorocarbon sealing element 1 having 1.5 diameter and 13mm ID.

AB

1)

1)

2)

Page 16

9. REPLACEMENT PARTS / ACCESSORIES

Description Order Code

- LCD display and housing cover WS08D05-KIT

- RS232 interface cable, 3m WS08CA

- Ball valve set ISO (CO8 option) WSPV-KIT

- Sealing Element 1 HA050308

- Ball valve set NPT (BO8 option) WSPV-KIT-NPT

Plug connecors: For the network configuration, the following plug

connectors are also necessary:

- Y splitter: Siemens 6ES7 194-1KA01-0XA0

- Plug: Lumberg RSC 5/7

RS232/485 Converter: To adapt the RS232 interface on the PC to the RS485

network protocol, a signal converter.

Lumberg

RSC 5/7

Y splitter

Power supply +

Analog output

RS485

Network +

Power

supply

16

instruction booklet

Pall WS08 Series

Water Sensor

Hardware

AB

Page 17

17

instruction booklet

Pall WS08 Series

Water Sensor

10. TECHNICAL DATA

Saturation

Measuring range1 0...100%

Accuracy incl. hysteresis and nonlinearity in air ± 2% (0...90%RH) ± 3% (90...100%RH)

Response time at 20°C

(68°F) / t

90

typ. 10min in still oil

Temperature

Temperature sensor element Pt1000 (Tolerance class A, DIN EN 60751)

Working range sensing probe -40 ºC to 180 °C (-40°F to 356 °F)

Housing with display -20 ºC to 50 ºC (-4°F to 122 °F)

Housing without display -40 ºC to 60 ºC (-40ºF to 140 ºF)

Accuracy (typ.) +/- 0.5 ºC

Outputs

2

Two freely selectable and scaleable analogue outputs 0 - 5V Load Current < 1mA

0 - 10V Load Current < 1mA

4 - 20mA RL < 500 Ohm

0 - 20mA RL < 500 Ohm

General

Supply voltage Safety Extra Low Voltage 8 to 35 VDC

Safety Extra Low Voltage 12 to 30 VAC

Current consumption - 2x voltage output for 24V DC/AC: typ. 40mA

- 2x current output typ. 80mA

Pressure range sensing probe 0...20bar

System requirements for software WINDOWS 98 or later; serial interface

Serial interface for configuration

4

RS232C

Housing / Protection class polycarbonate / IP65; Nema 4

Cable gland M16 x 1.5 cable Ö 4.5 - 10mm

(0.18 - 0.39")

Electrical connection screw terminals up to max. 1.5mm

2

(AWG 16)

Electromagnetic compatibility according to EN61000-6-2 EN61000-6-3 ICES-003 ClassB

EN61326-1+A1+A2 FCC Part15 ClassB

Options

Display graphical LC display (128x32 pixels), with integrated pushbuttons

for selecting parameters and MIN/MAX function

Relay outputs 2 x 1 switch contact: 250V AC / 6A and 28V DC / 6A

threshold +

hysteresis can be adjusted with configuration software

1

refer to the working range of the humidity sensor! 4can be easily changed by software 4no data output

Hardware

AB

Page 18

CONFIGURATION SOFTWARE

LIMITATION OF LIABILITY

To the maximum extent permitted by applicable law, in no event shall Pall, its

employees or licensors or affiliates be liable for any lost profits, revenue, sales, data

or costs of procurement of substitute goods or services, property damage, personal

injury, interruption of business, loss of business information or for any special, direct,

indirect, incidental, economic, cover, punitive, special or consequential damages,

however caused and whether arising under contract, tort, negligence, or other theory

of liability arising out of the use of or inability to use the software, even if Pall or its

licensors or affiliates are advised of the possibility of such damages. Because some

countries/states/jurisdictions do not allow the exclusion or limitation of liability, but

may allow liability to be limited, in such cases, Pall, its employees’ or licensors’ or

affiliates' liability shall be limited to U.S. $50.

1. GENERAL INFORMATION

The configuration software was developed by Pall to allow fast and easy

configuration of individual transmitters.

This software tool is included in the scope of supply.

System requirements: MS WINDOWS 98

®

or higher; RS232 serial interface

2. INSTALLATION

Insert the CD-ROM supplied with the transmitter into the PC and open the set-up

application. Follow the instructions of the dialogue menus to set the desired language

and all other parameters for installation. At the end of the routine, the software is

installed and the Readme file or the program will be automatically opened.

Note:

Before any reinstallment or upgrade the older version must first be

uninstalled (the User will be notified during the installation routine and the process

will be interrupted automatically).

To remove the previous version, open the software folder in the system control panel.

All of the programs installed on your system are located here. Uninstall the WS08

Configurator by clicking on the appropriate button and then reinstall or upgrade.

Hardware

18

instruction booklet

Pall WS08 Series

Water Sensor

AB

Page 19

Configuration software

19

instruction booklet

Pall WS08 Series

Water Sensor

Note:

Within the Water Sensor Configurator software the word “transmitter”

is used to refer to the WS08 Water Sensor.

Users of this software should realize that “transmitter” and

“water sensor” can be used interchangeably.

3.1 File

Load: Loads a file with a saved transmitter configuration.

Save: Saves the current transmitter configuration in a file.

New Workspace: Opens a file for a new tree.

Open Workspace: Opens existing trees.

Save Workspace: Saves the current trees in an archive file.

Note:

The functions “Save Workspace” and “Open Workspace” apply to the

tree structure only, not to the configurations of individual transmitters!

3.2 Interfaces

Select: Selects the serial interface (COM port) for

communication with the transmitters.

Following functions are available:

use / do not use: Marked COM ports are greyed out and deactivated

for the configuration software (e.g. COM for

integrated Notebook Modem).

Note:

A disabled interface (shaded = do not use), can be enabled by clicking

on the “use” button.

3. ICONS ON THE TOOL BAR

AB

Page 20

3.3 Group

The icon “Group” provides the option of combining transmitters in

groups. A group may consist of transmitters used in the same

application, for instance assigned to a building.

New: Creates a group or adds another group into

an existing structure.

Delete: Deletes groups within a tree.

Rename: Changes the name of a transmitter group.

3.4 Transmitter

New transmitter:

A new transmitter is created in the tree.

This procedure requires the input of a number of parameters:

Group: Assigns a transmitter to a group.

Network: The check box network must be selected when

several WS08’s are operated in a network.

Network address: Input of the network address for the WS08

transmitter for unique assignment within the

network (see label on the transmitter housing).

For use only with RS485 equipped systems.

Interface: Selects the interface for connecting the transmitter

to the network. (For information on how to set up

a COM port, see Configuration Software, chapter

3.2 “Interfaces”).

Name: Assigns a meaningful name related to the

transmitter. This name is displayed in the tree

under the relevant group (e.g.: Clean Room).

Configuration software

20

instruction booklet

Pall WS08 Series

Water Sensor

AB

Page 21

21

instruction booklet

Pall WS08 Series

Water Sensor

Preferences: Displays the preferences for all transmitters that

have been set-up. The preferences may also be

changed here.

Delete transmitter: Deletes from the tree structure the selected

transmitters, or the selected groups.

Read: Reads and displays the configuration parameters

of the selected transmitter.

Read All: Reads the configuration for all transmitters.

Note:

Only those parameters that have the same value for all transmitters of

the network will be displayed. Other values are shaded and can not be

selected or changed.

Write: Writes the current configuration to

the selected transmitter.

Write All: Writes the current configuration to

all selected transmitters.

Set the configuration for a transmitter, then select the appropriate

network in the tree and write the configuration all transmitters of the

target group using the command “Write All”.

Warm Start: Resets and restarts the microprocessor of the

selected transmitter.

3.5 Information

Version: Displays the version number of the WS08

software currently installed and the contact

information for Pall.

4. ICON LIST

“Load File” (see Configuration Software, chapter 3.1 File)

“Save File” (see Configuration Software, chapter 3.1 File)

“New Transmitter” (see Configuration Software, chapter 3.4 Transmitter)

“Read Transmitter” (see Configuration Software, chapter 3.4 Transmitter)

“Save Transmitter” (see Configuration Software, chapter 3.4 Transmitter)

“Read All Transmitters” (see Configuration Software, chapter 3.4 Transmitter)

“Write All Transmitters” (see Configuration Software, chapter 3.4 Transmitter)

“Delete Transmitter” (see Configuration Software, chapter 3.4 Transmitter)

Configuration software

AB

Page 22

5.1 Analog

For the configuration of both analogue outputs.

Range: Using the drop-down input field, select either a

standardized output signal (0-5V, 0-10V, 0-20mA,

4-20mA) or a user-defined current/voltage output

range (upper and lower limits may be selected as

required between the limits indicated).

Physical Quantity: Selects the output physical quantities.

Highest /

Lowest Limit: Sets the desired scaling of the output. The limits

must fall within the operating range indicated above.

Units: Selects between SI or US units.

5.2 Relay

Used to set both alarm outputs.

Physical Quantity: Selects the physical quantity for each alarm output.

Switching

Point High: Sets the high switching point.

Hysteresis: Sets the switching hysteresis that should be

maintained each time the signal falls below the

upper switching limit.

Configuration software

5. TABS

22

instruction booklet

Pall WS08 Series

Water Sensor

Relay status

Switching off

Switching on

Switching point

Hysteresis

Note:

The word “TABS” refers to the selectable pages titled Analog, Relay,

Calibration and Information. These Tabs can be accessed by clicking on

the desired one.

AB

8°C

62

70

[ppm, %, °C/°F]

Page 23

Configuration software

23

instruction booklet

Pall WS08 Series

Water Sensor

5.3 Sensor / Probe Replacement

Note: For sensing elements and probe replacement, please contact

your local Pall representative.

Note: A reduction of the stabilisation time can be achieved by cleaning

the probe with n-Hexane resp. n-Heptane. Swirl the probe carefully in the

solvent then drip off and after that exhaust the air around the probe >0.5h.

Attention: Other solvents than above mentioned can corrode the

humidity sensor!!

1-point calibration Humidity:

Fast and easy calibration for accurate measurement results at a defined

working point (humidity point).

1) Stabilise the probe of the desired humidity for min. 30 minutes.

2) Click on the Humidity "1-point calibration" button. The measured

values will now appear in both input fields.

3) Replace the value in the input field "Humidity Reading" with the

reference humidity (value of the saline solution or display of HUMOR 20).

4) By clicking on "Save", the humidity reading for the transmitter will be

adjusted to the reference humidity.

5.4 Calibration

AB

Page 24

Pall WS08 Series

Water Sensor

instruction booklet

24

2-point calibration Humidity:

Calibration for accurate results over the entire measurement range.

1) Place the probe at the reference humidity (lower point).

2) Click on the Humidity 2-Point Calibration button.

(In a separate window, the measured values will appear in

both input fields)

3) Replace the value in the input field "Humidity Reading" with

the reference humidity. (Value of the saline solution or display

of HUMOR 20)

4) By clicking on "Save", the humidity reading of the transmitter will

be adjusted to the reference humidity. Now the 30-minute

stabilisation period starts.

5) Place the probe at the reference humidity (high point).

6) Before continuing wait till the 30-minute stabilisation period is over.

7) Replace the value in the input field "Humidity Reading" with the

reference humidity. (Value of the saline solution or display of HUMOR 20)

8) By clicking on "Save", the humidity reading of the transmitter will be

adjusted to the reference humidity.

9) The process is complete when the message "Two-point calibration

successful" appears.

1-point calibration Temperature:

If the working range is limited to a narrow temperature range, one-point

calibration will be sufficient within this working range.

1) Place the probe at the reference temperature and allow stabilisation

for approx. 30 minutes.

2) Click on the Temperature 1-Point Calibration button.

The measured value will appear in both input fields.

(see additional window)

3) Replace the value in the input field "Temperature Reading" with the

reference temperature.

4) By clicking on "Save", the temperature reading of the transmitter will

be adjusted to the reference temperature.

5) The process is complete when the message "Calibration Successful"

appears.

Factory Calibration:

Using the "Factory Calibration" button the user can reset all calibration

values back to their original factory setting. The "Factory Calibration"

button is located on the Calibration Tab (see photo at the start of section

5.4 Calibration).

Configuration software

AB

Page 25

Pall WS08 Series

Water Sensor

instruction booklet

25

5.6 Information

Here you will find information on the selected transmitter.

Serial number: Used to track the manufacturing data of

the transmitter.

Network address: Each transmitter is assigned a unique network

address at the factory for precise identification.

Type: Name of the transmitter series.

Humidity

Calibration Date: Provides information on the date of the last

humidity calibration, but only if the configuration

software was used.

Note: Calibrations performed directly on the circuit board are

not recorded!

Temperature

Calibration Date: Provides information on the date of the last

temperature calibration, but only if the

configuration software was used.

Note: Calibrations performed directly on the circuit board are

not recorded!

Firmware /

Version: Provides information on the software version

implemented in the transmitter (internal).

Configuration software

5.5 Parameter

Moisture content:

Enter the parameter C1, C2, C3 and C4 for calculation of the water

content x [ppm].

Note: The saturation content is PPM (parts per million) can be displayed if

the proper C1, C2, C3, & C4 constants have been loaded. It is important

to point out the constants vary for each oil manufacturer and oil type.

The user is cautioned not to experiment by entering arbitrary constants

since this will result in an inaccurate displayed PPM valve.

Contact your local Pall Corporation representative for more details.

Air pressure:

If a transmitter of the WS08 series is operated far above sea level or a

measurement is required at high process pressure, the prevailing ambient

pressure can be entered to increase the accuracy of the derived values /

computing funtions.

AB

Page 26

6.1 How to set-up a new transmitter/Water Sensor?

Note: Within the Water Sensor Configurator software the word

“transmitter” is used to refer to the WS08 Water Sensor.

Users of this software should realize that “transmitter” and

“water sensor” can be used interchangeably.

Menu “File” --> “New Workspace”

Assign a name to the file and select the location to save the file

Menu “Group” --> “New Group”

Assign and add a name, then click on “Finish”

Menu “Transmitter” --> “New Transmitter” or

Button “New Transmitter”

Select the group for the transmitter using the pull-down menu “Group”.

Specify the COM port (serial interface) of the PC / Notebook in the

pull-down menu “Interface”.

Enter the name for the transmitter in the “Name” field.

Complete the “New Transmitter” process by clicking on the

button “Add”.

6.2 How to read the configuration of a transmitter/Water Sensor?

The current configuration of the selected transmitter can be

read by clicking on the button “Read Transmitter” or by selecting

“Transmitter” --> “Read Transmitter”.

If the configuration is already loaded, the configuration data in the TABS can

be modified.

6.3 How to save the configuration in a transmitter/Water Sensor?

A modified configuration in the TABS can be saved to the selected

transmitter by clicking on the button “Save Transmitter” or by selecting

“Transmitter” --> “Save Transmitter”.

Configuration software

26

instruction booklet

Pall WS08 Series

Water Sensor

6. OVERVIEW

AB

Page 27

27

instruction booklet

Pall WS08 Series

Water Sensor

DECLARATION OF CONFORMITY

AB

Page 28

Pall WS08 Series

Water Sensor

instruction booklet

28

NOTES

AB

Page 29

Pall WS08 Series

Water Sensor

instruction booklet

29

NOTES

AB

Page 30

Because of developments in technology these data or procedures may be subject to change. Consequently

we advise users to review their continuing validity annually. Part numbers quoted above are protected by the

Copyright of Pall Europe Limited.

and Pall are trademarks of Pall Corporation.

Filtration. Separation. Solution is a service mark of Pall Corporation.

©2008, Pall Europe Limited.

June 2008. Printed in England. SIWS08EN

Pall Industrial Manufacturing

New York - USA

800 333 7255 toll free

+1 516 484 3600 telephone

+1 516 625 3625 fax

Portsmouth - UK

+44 (0)23 9230 3303 telephone

+44 (0)23 9230 2507 fax

Visit us on the web at www.pall.com

Pall Corporation has offices and plants throughout the world in locations including:

Argentina, Australia, Austria, Belgium, Brazil, Canada, China, France, Germany, India,

Indonesia, Ireland, Italy, Japan, Korea, Malaysia, Mexico, the Netherlands, New Zealand,

Norway, Poland, Puerto Rico, Russia, Singapore, South Africa, Spain, Sweden, Switzerland,

Taiwan, Thailand, United Arab Emirates, United Kingdom, United States, and Venezuela.

Distributors are located in all major industrial areas of the world.

AB

Loading...

Loading...