Page 1

UR310

EN

ENCNEN

CN

EN

DE

CN

EN

ES

DE

CN

EN

ES

DE

FR

CN

EN

ES

DE

FR

CN

IT

EN

ES

DE

FR

JP

CN

IT

KR

EN

ES

DE

FR

JP

CN

IT

UR310 Series

EN

UR310 Service Instructions

CN (Simplified) UR310 使用说明书

CN

(Traditional)

DE UR310 Wartungsanleitung

ES Instrucciones de mantenimiento de UR310

FR

Instructions de serviceUR310

IT Istruzioni d’uso e manutenzione per UR310

JN UR310アフターサービス説明書

KR UR310 서비스 지침 지침

中文

UR310使用說明書

ENGLISH

中文

(SIMPLIFIED)

中文

(TRADITIONAL)

DEUTSCHESPAÑOL

FRANÇAIS

ITALIANO

日本語

한국어

service instructions

M&ESIUR310c

Page 2

UR310

UR310 Series

RETURN LINE FILTERS service instructions

1 Specifications

Housing materials:

Head and Cover: Ductile cast iron

Tube: Carbon steel

Maximum operating pressure:

41 bar (600 psi)

Proof pressure:

62 bar (900 psi)

Minimum burst pressure:

165 bar (2400 psi)

Element burst pressure:

UE310 element 10 bard (150 psid) differential minimum

Operating temperature range:

-29° C to 120° C (-20° F to 250° F) with fluorocarbon seals

for petroleum based and specified synthetic fluids

60° C (140° F) maximum in HWCF, water-oil emulsion

or water glycol

Bypass valve setting options:

1.7 ± 0.2 bard (25 ± 3 psid) cracking pressure

4.5 ± 0.5 bard (65 ± 7 psid) cracking pressure

Non bypass

CAUTION:

Maximum surge flow should not exceed 1.3 times

normal flow.

Seals:

Fluorocarbon

The actual operating conditions should be checked by the

user to ensure that the element, housing and all seals are

compatible with the fluid and application, and are within local

safety codes. Please contact Pall or an approved distributor if

further information is required.

2 Receipt of equipment

The filter housing, and any optional equipment, are packed

individually for assembly by the customer. Unpack carefully

and ensure optional items are not mislaid in packaging to be

discarded.

3 General sources of information

3.1 For dimensions, operating parameters, assembly/

element part number, ordering information, notes,

performance data and specifications refer to datasheet.

3.2 This equipment has been assessed in accordance with

the guidelines laid down in the European Pressure

Directive 97/23/EC and has been classified within sound

engineering practice S.E.P. We hereby declare the

equipment meets the requirements of article 3, section

3, thus meeting the directive requirements. Under the

provisions of this directive the filter assembly is suitable

for use with group 2 fluids only.

3.3 Where under reasonably foreseeable conditions,

including external fires, the allowable limits could be

exceeded, suitable protective devices must be installed

by the customer within the connecting fluid system.

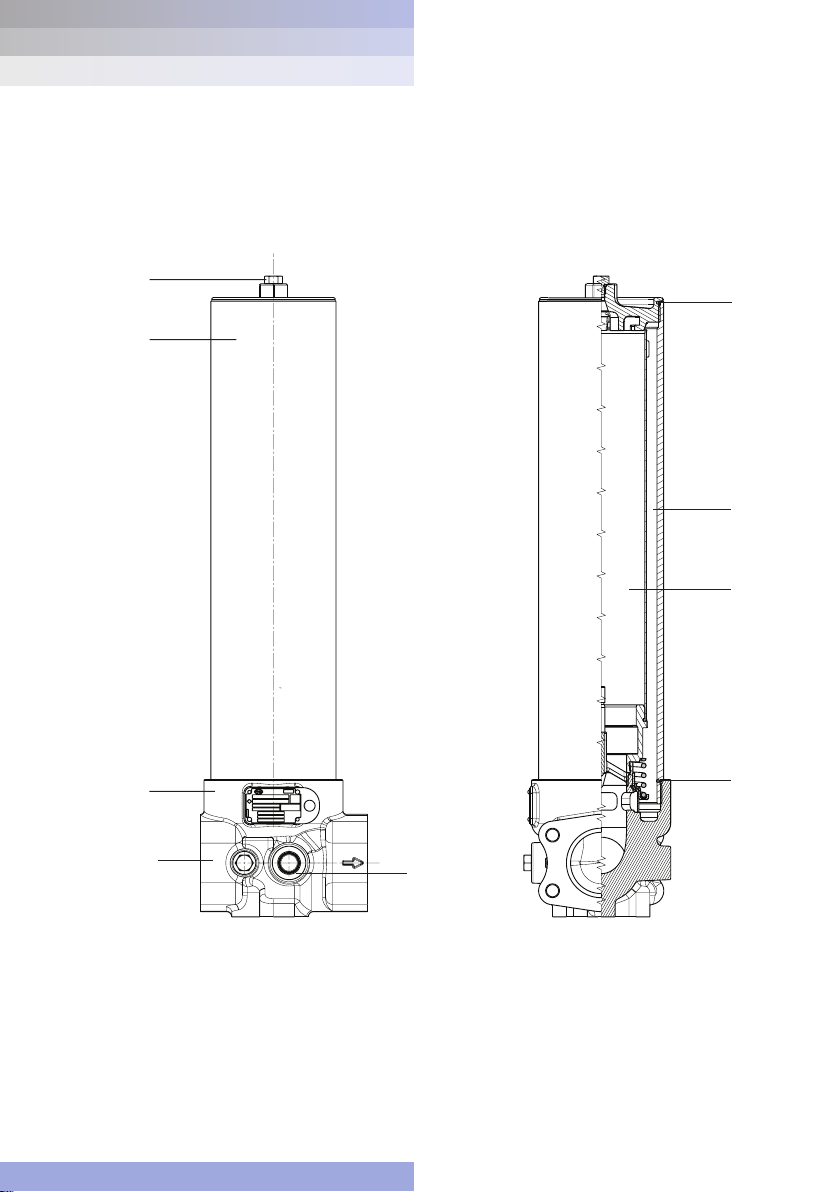

4 Installation of housing

4.1 The filter can be installed in any attitude, but for ease of

servicing, it is recommended that it be installed vertically

with the filter tube and cover pointing upwards (UR310) or

with the filter tube and cover pointing downwards (UR310H).

4.2 The minimum clearance required for element removal is

as follows:

4.2.1 UR310 series (cover service): 248mm (9.8") for

length 8, 383mm (15.1") for length 13, 553mm

(21.8") for length 20 and 1061mm (41.8") for

length 40 housings.

4.2.2 UR310H series (head service): 140.97mm (5.55")

for all lengths.

4.2.3 The UR310 Housing is supplied without a filter

element. For element installation and servicing

procedures, refer to Section 7.

4.3 Threaded differential pressure devices, when fitted,

must be torque tightened to 40 lbft or 54 Nm. All visual

indicators must be clearly visible.

NOTE: The UR310 head is supplied with a machined differential

pressure warning device port, fitted with a plastic shipping plug.

If no differential pressure warning device is ordered, the shipping

plug must be removed and replaced with a ‘B’ type blanking plug

(P/N HA9000-A104Z) and torque tightened to 40 lbft or 54 Nm.

NOTE: Never place the port plug in this port without first

installing uniform size -014 O-ring in lower O-ring groove,

otherwise a small bypass flow will result, allowing contaminant

downstream of the filter element.

CAUTION:

Never operate the filter unless a warning device port

is sealed.

4.4 Mount the filter assembly in position using 1/2" - 20UNF

- 2B (A or D ports) or M12 x 1.75 - 6H (C or F ports)

bolts in the holes on the head mounting pads. Torque

bolts to 20 - 25 lbft or 27 - 34 Nm.

4.5 Use a check valve downstream of the filter if there is a

possibility of reverse flow.

4.6 Install the filter housing using additional piping/valving to

allow complete filter assembly bypass if filter maintenance

is required without system shutdown. This series is not

available in a duplex or service bypass configuration.

CAUTION:

Reverse flow through filter element will cause damage.

NOTE: Piping supports should be provided as close as is

practicable to the port connections in order to minimize

external loads. This filter assembly must not be electronically

isolated from the users earthing system. This filter assembly

must be earthed by connecting the users earthing system to

one of the inlet/outlet connections.

4.7 Connect lines or hoses to housing inlet and outlet ports.

WARNING:

USE FITTINGS OR ADAPTORS COMPATIBLE WITH

PORTS SUPPLIED AS SHOWN BY PART NUMBER

ON NAMEPLATE AND NOTED IN DATA SHEETS:

USE OF INCORRECT FITTINGS OR ADAPTORS CAN

CAUSE FILTER HOUSING OR MANIFOLD FAILURE

RESULTING IN LOSS OF PRESSURE AND POSSIBLE

SYSTEM FAILURE OR PERSONAL INJURY.

2

Page 3

UR310

Pin 3

UR310 Series

RETURN LINE FILTERS service instructions

NOTE: Painting of the filter housing is optional. The coating

on the filter housing is a suitable painting base. Cover the

differential pressure warning device and nameplate if painting

of the housing takes place.

4.8 Bleed the filter

4.8.1 UR310 (cover service): Bleed the filter by opening the

vent plug (7) at the top of filter one and one-half turns.

Jog system and fill filter until all air bleeds through the

plug, then torque tighten plug to 12 ft/lb or 16 Nm.

4.8.2 UR310H (head service): Bleed the filter by opening the

vent plug (7b) on the head one and one-half turns. Jog

system and fill filter until all air bleeds through the plug,

then torque tighten plug to 12 ft/lb or 16 Nm.

Pressurize system fully and check for leaks; if leaks occur

refer to section 5.

CAUTION:

Failure to bleed the filter housing adequately will

increase the dissolved air content of the system fluid

which will shorten fluid life and may cause other

problems in the system.

5 Routine maintenance

5.1 Pall filters do not normally require special attention

except for periodic monitoring of the differential pressure

warning device. Schedule replacement of filter element

every six months or sooner, and have ample supply of

spare elements available.

5.2 If external leakage is noted, replace O-ring at leak. If

leakage persists, check sealing surfaces for scratches or

cracks; replace any defective parts.

5.3 Differential pressure devices actuate when the element

needs changing or because of high fluid viscosity in

‘cold start’ conditions. If ‘cold start’ conditions exist, see

Section 6.2 and 6.3.

5.4 A dirty system can quickly plug a new filter element,

especially with Pall high efficiency filter media. It may

require one or two initial element changes to stabilize

element life. If element life is short or differential

pressure is excessive, filter may be undersized; refer to

the sizing and selection section of the product literature

or contact your local Pall representative.

5.5 Make sure element change labels are clean and

undamaged. Replace illegible labels with the appropriate

new labels.

6 Differential pressure devices

Reference should be made to product literature for dimensions,

operating parameters, part numbering, ordering information

and specifications.

6.1 Differential pressure devices actuate when the element

needs changing or because of high fluid viscosity in

‘cold start’ conditions.

6.2 If stainless steel visual indicator is fitted and actuates

during ‘cold start’ (red button extends 5mm, 3/16"), reset

by depressing the button when the normal operating

temperature is reached. If indicator actuates after

resetting, replace element. If brass visual indicator

is fitted and actuates during ‘cold start’ (flag inside

indicator changes to red), it will automatically reset when

normal operating temperature is reached. If indicator

is still actuated after normal operating temperature is

reached, replace element.

NOTE: Option ‘P’ visual indicator has thermal lockout and

manual reset. No signal below 0° C (32° F), signal above

29° C (80° F).

3

6.3 Use of both positive indication (green light) and negative

indication (red light for dirty element) is recommended to

effectively monitor filter element life.

6.4 If the electrical switch actuates (e.g. red light comes on)

during cold start, continue operating until the signal (red

light) goes out as system warms to normal operating

temperature. This feature can be used as ‘warm up’

indication in operating procedures. If the warning signal

(red light) remains or appears when system is warm,

replace the filter element.

Electrical connections and ratings are dependent on

indicator chosen. Typical values only are shown below:

110 VAC = 4A (inductive),

220 VAC = 4A (inductive),

28 VDC = 3A (inductive),

48 VDC = 1A (inductive),

125 VDC = 0.25A (inductive),

Maximum inrush - 24 amps.

Underwriter’s lab. Inc. listed ratings of pressure switch

(Microswitch) options are:

4 amps at 250 VAC

0.25 amp resistive at 220 VDC

0.50 amp resistive at 110 VDC

Electrical differential pressure switch operation:

When preset differential pressure is exceeded continuity

switches from Normally Closed (NC) - Common to Normally

Open (NO) - Common.

When differential pressure decreases below pre-set value,

continuity returns to Normally Open (NO) - Common to

Normally Closed (NC) - Common.

4A (resistive)

4A (resistive)

5A (resistive)

1.5A (resistive)

0.5A (resistive)

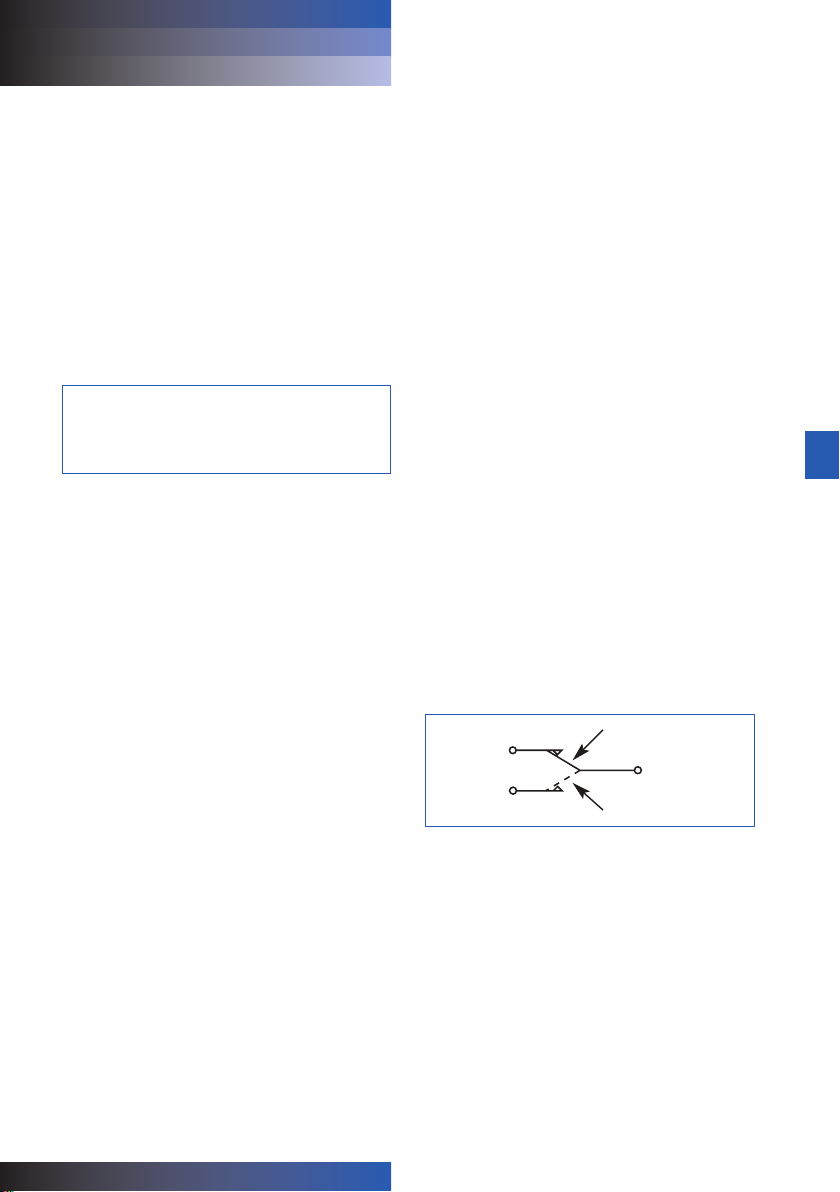

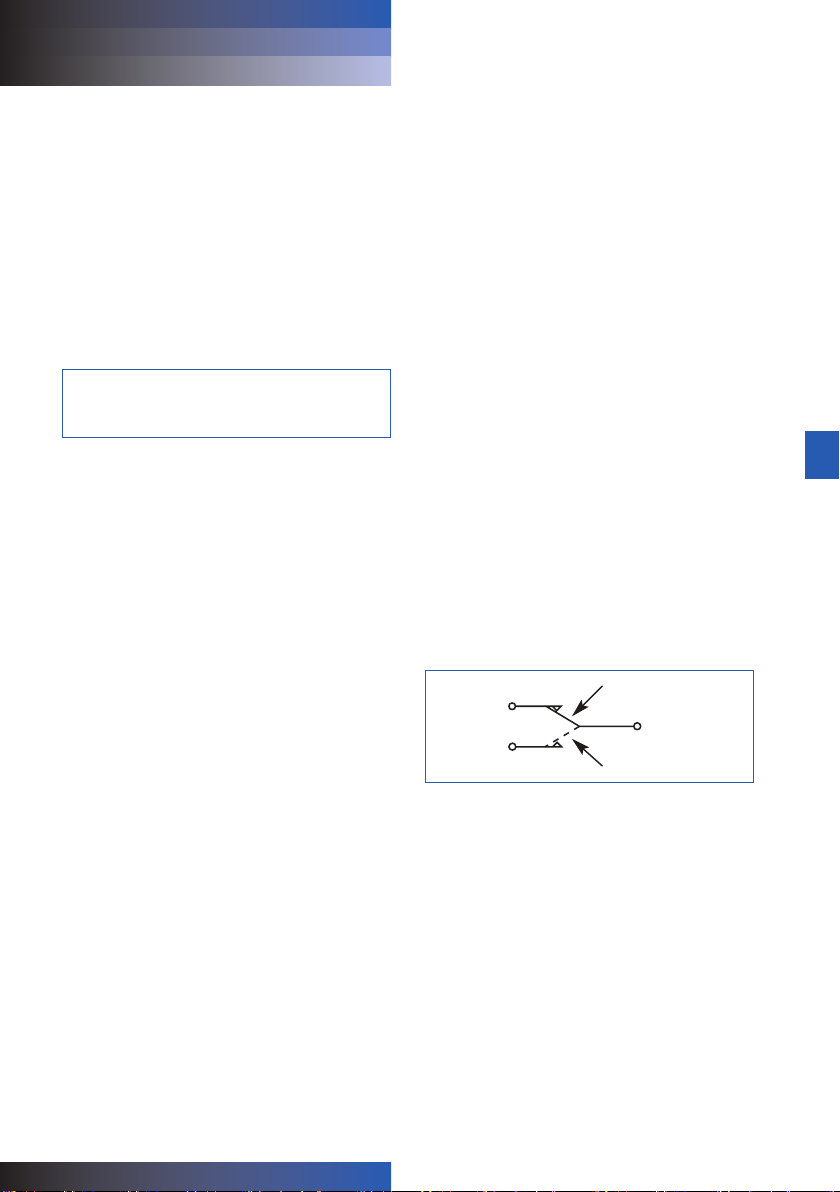

Figure 1 - Switch Circuit Diagram

NORMALLY

CLOSED

(NC) Pin 2

NORMALLY

OPEN (NO)

See individual indicator options for connection details.

LOW DIFFERENTIAL PRESSURE

COMMON

Pin 1

HIGH DIFFERENTIAL PRESSURE

ENGLISH

Page 4

UR310

UR310 Series

RETURN LINE FILTERS service instructions

7 Filter element servicing

During servicing, the external surfaces of the filter assembly

must be cleaned to remove any dust deposits.

Servicing must be conducted using suitable tools that do not

present a hazard.

Servicing must not be carried out when a potentially explosive

atmosphere is present.

CAUTION:

Filter elements should be replaced upon indication or

at specified intervals, six months maximum. Failure

to change the element will cause the filter to go

on bypass.

Refer to Service Parts List (Section 9) for item numbers for

applicable replacement element series. Remove and replace

element as follows:

7.1 Turn off and depressurize the system.

WARNING:

FAILURE TO DEPRESSURISE THE FILTER

BEFORE SERVICING ELEMENT COULD RESULT

IN EXPLOSIVE LOSS OF FLUID, DAMAGE TO

EQUIPMENT AND POSSIBLE PERSONAL INJURY.

7.2 For UR310 series (cover service):

Open vent plug (7) at the top of the filter one and

one-half turns.

Open drain plug (7b) on the filter head and drain fluid

into a suitable waste receptacle. Replace and torque

tighten drain plug to 12ft/lb or 16Nm. Unscrew and

remove cover (3) from tube (2) counter-clockwise when

viewed from above. It may be necessary to use a 1"

socket wrench on the hexagon on the cover (3) to

loosen the cover initially.

NOTE: The UR310 series assembly is equipped with Pall’s

‘Auto-Pull’ element extraction mechanism to facilitate element

removal. While removing the cap, tabs on the element endcap

lock into hooks in the cap and the element is automatically

pulled from the nipple.

7.3 For UR310H series (head service):

Open drain plug (7) at the bottom of the bowl assembly

(tube and cover) and drain fluid from the bowl into a

suitable waste receptacle. Replace and torque tighten

drain plug to 12 ft/lb or 16 Nm. Unscrew and remove the

bowl assembly (2 and 3) from head (1) counter-clockwise

when viewed from below. It may be necessary to use a 1"

socket wrench on the hexagon on the cover (3) to loosen

the cover initially.

7.4 Element replacement (UE310 Series): Remove filter

element (8), if already fitted, and carefully inspect the

interior surface (flow through the element is in-to-out) for

visible contamination. Normally no dirt should show, but

visible dirt or particles can be an early warning of

system component failure. Discard both the filter

element and its O-ring. The filter element is NOT

CLEANABLE. Any attempt to clean the filter element can

cause degradation of the filter medium and allow

contaminated fluid to pass through the filter element.

WARNING:

DO NOT ATTEMPT TO CLEAN OR RE-USE THE

ELEMENT.

ONLY USE GENUINE PALL REPLACEMENT FILTER

ELEMENTS. USE OF SUBSTITUTE ELEMENTS MAY

INVALIDATE PRODUCT WARRANTY.

7.5 DO NOT run the system without a filter element installed.

For UR310 series: check that the O-ring (4) between the

cover (3) and tube (2) is not damaged.

For UR310H series: check that the O-ring (5) between

the tube (2) and head (1) is not damaged.

Use the replacement filter as indicated by the part

number on the element endcap.

7.6 Lubricate element O-ring with clean system fluid.

Reinstall element in the shell assembly. Lightly lubricate

cover-to-head or tube-to-head (as applicable) O-ring

with clean system fluid and reassemble the housing until

thread bottoms. Hand tighten only.

7.7 Bleed the filter by filling the filter until all air bleeds

through the vent plug(7), then torque tighten the vent

plug to 12 lb/ft or 16Nm. Check for leaks as per

section 4.8.

7.8 After element change ENSURE DIFFERENTIAL

PRESSURE DEVICE IS RESET. Brass visual and

electrical and stainless steel electrical switches reset

automatically. When system reaches normal operating

temperature, check that the electrical switch and/or

visual warning button/flag has not actuated. If visual

indicator actuates due to a cold start condition, reset

again as per section 6.

8 Warranty, Limitation of Liability and

Remedies

THERE IS NO WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE WITH RESPECT

TO ANY OF THE PRODUCTS, NOR IS THERE ANY OTHER

WARRANTY EXPRESS OR IMPLIED, EXCEPT AS PROVIDED

FOR HEREIN.

For a period of twelve months from the date of delivery

from Seller or three thousand hours of use, whichever

occurs first (the “Warranty Period”), Seller warrants that

products manufactured by Seller when properly installed

and maintained, and operated at ratings, specifications and

design conditions, will be free from defects in material and

workmanship. By way of explanation and not limitation, the

Seller does not warrant the service life of the filter element

as this is beyond the Seller’s control and depends upon the

condition of the system into which the filter is installed.

Seller’s liability under any warranty is limited solely (in Seller’s

discretion) to replacing (FOB original ship point), repairing

or issuing credit for products that become defective during

the Warranty Period. Purchaser shall notify Seller promptly in

writing of any claims and provide Seller with an opportunity to

inspect and test the product claimed to be defective. Buyer

shall provide Seller with a copy of the original invoice for the

product, and prepay all freight charges to return any products

to Seller’s factory, or other facility designated by Seller. All

claims must be accompanied by full particulars, including

system operating conditions, if applicable.

4

Page 5

UR310

UR310 Series

RETURN LINE FILTERS service instructions

Seller shall not be liable for any product altered outside of

the Seller’s factory except by Seller or Seller’s authorized

distributor, and then, as to the latter, only for products which

have been assembled by the distributor in accordance with

Seller’s written instructions. Nor shall Seller be liable for a

product subjected to misuse, abuse, improper installation,

application, operation, maintenance or repair, alteration,

accident or negligence in use, storage transportation or

handling.

In no event will Seller be liable for any damages, incidental,

consequential or otherwise, whether arising out of or in

connection with the manufacture, packaging, delivery, storage,

use, misuse, or non use of any of its products or any other

cause whatsoever.

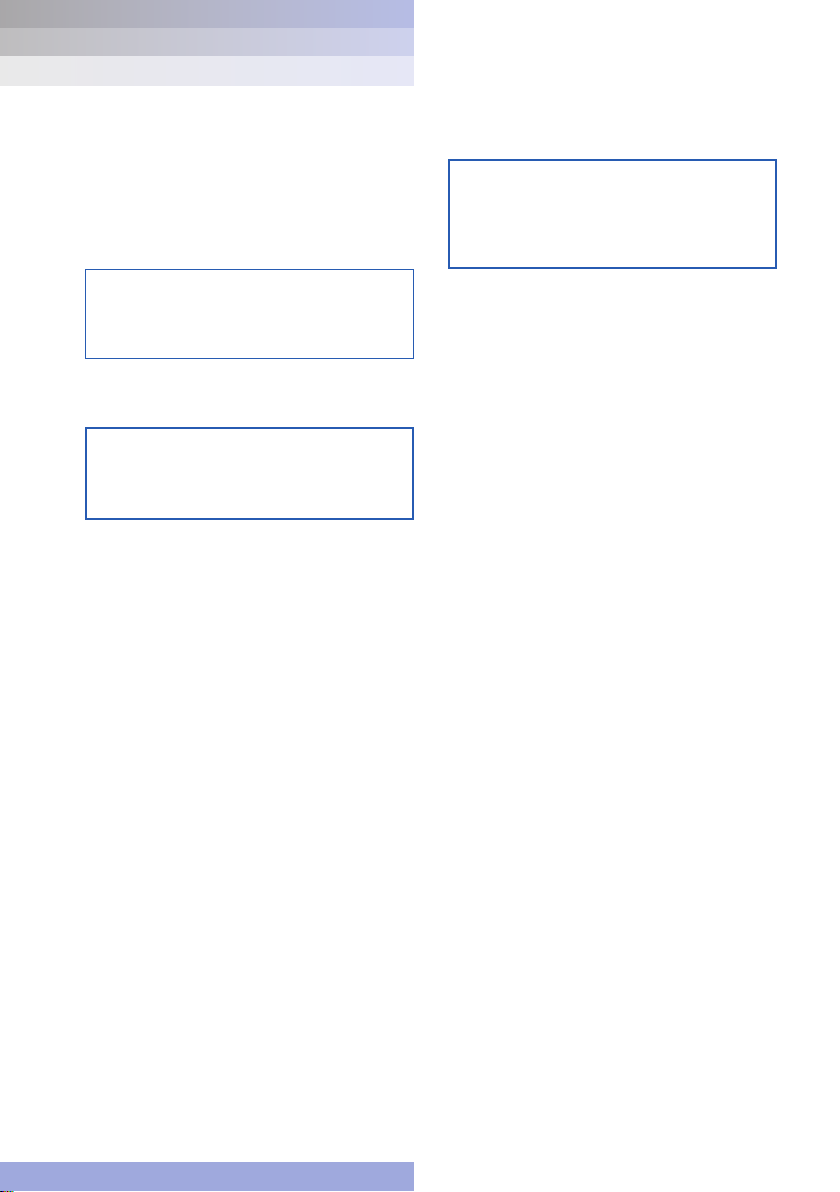

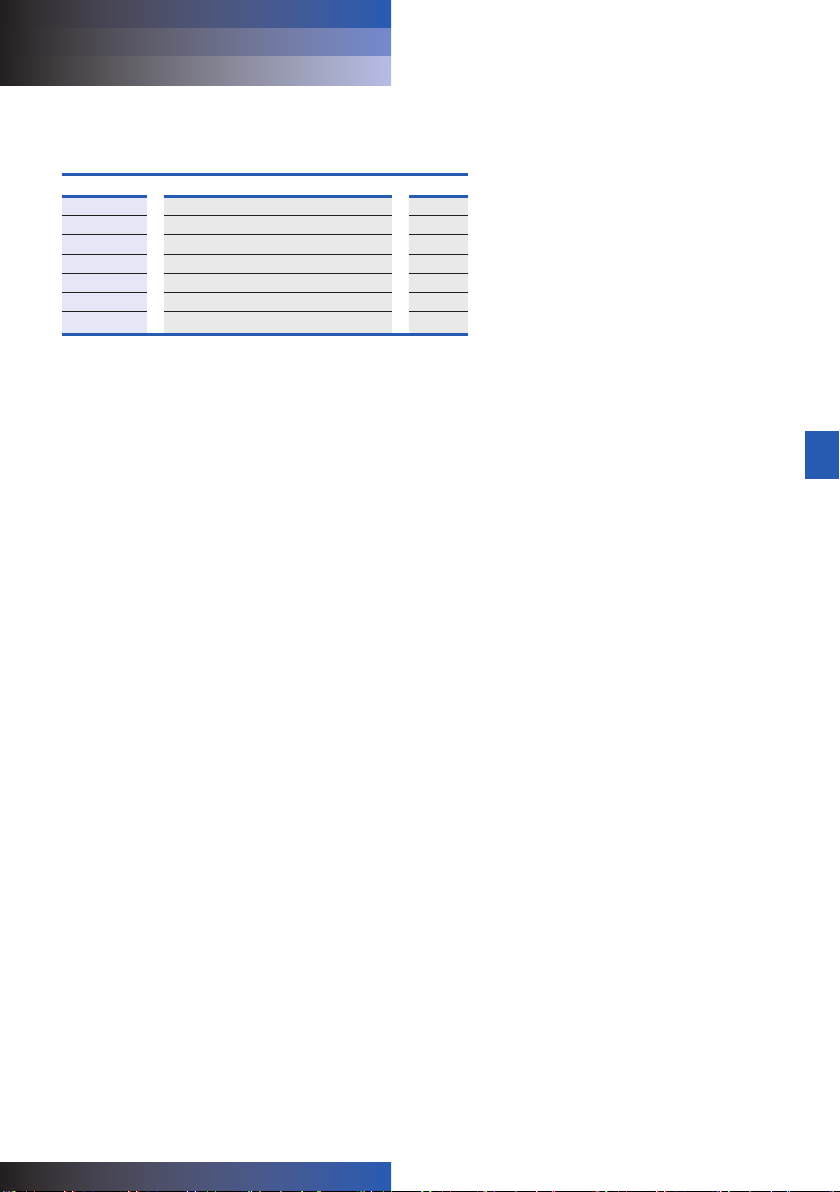

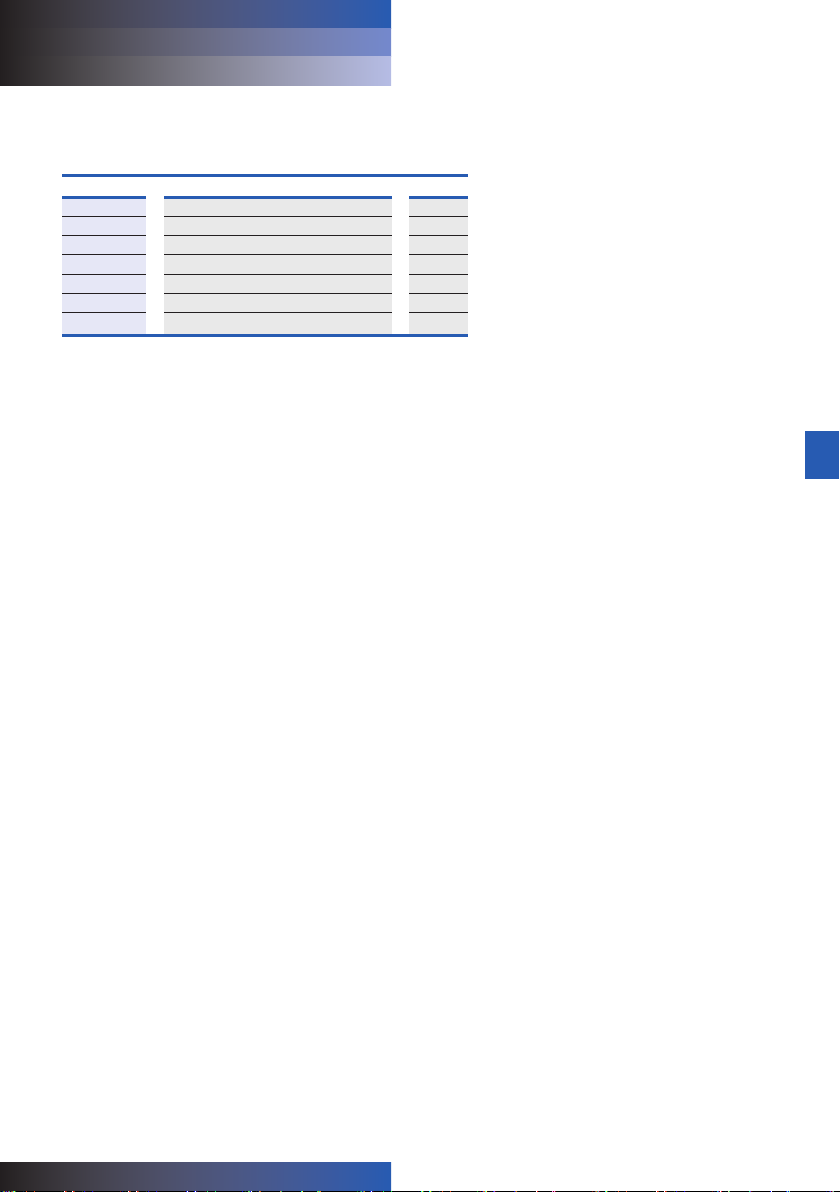

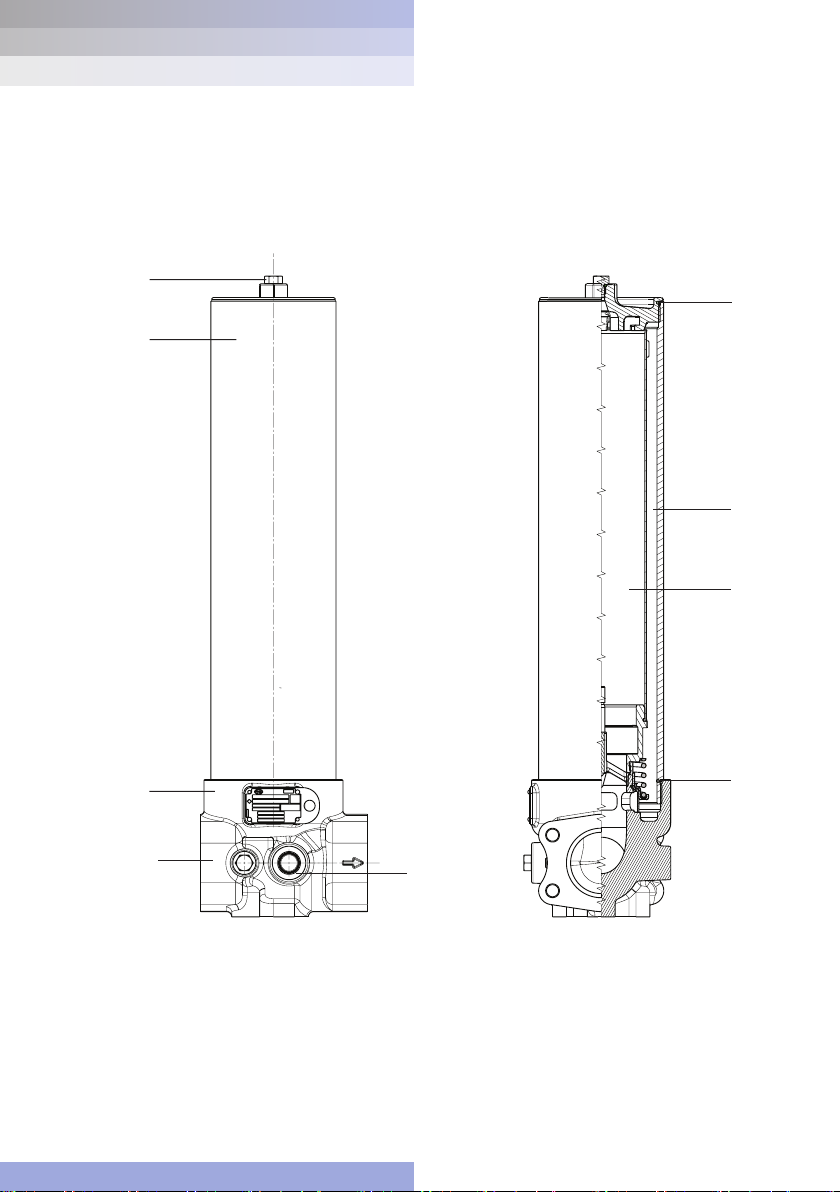

9 Parts List

List Description Quantity

1 Filter Head 1

2 Tube 1

3 Cover 1

4, 5 O-ring (cover-to-tube and head-to-tube) 2

6 Indicator or port plug kit (not shown) 1

7, 7b Vent/drain plug 2

8 Filter element 1

ENGLISH

5

Page 6

UR310

UH319

UH319 Series

service instructions

Figure 3

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

GG

Q

HIGH PRESSURE FILTERS

UR310 Series

RETURN LINE FILTERS service instructions

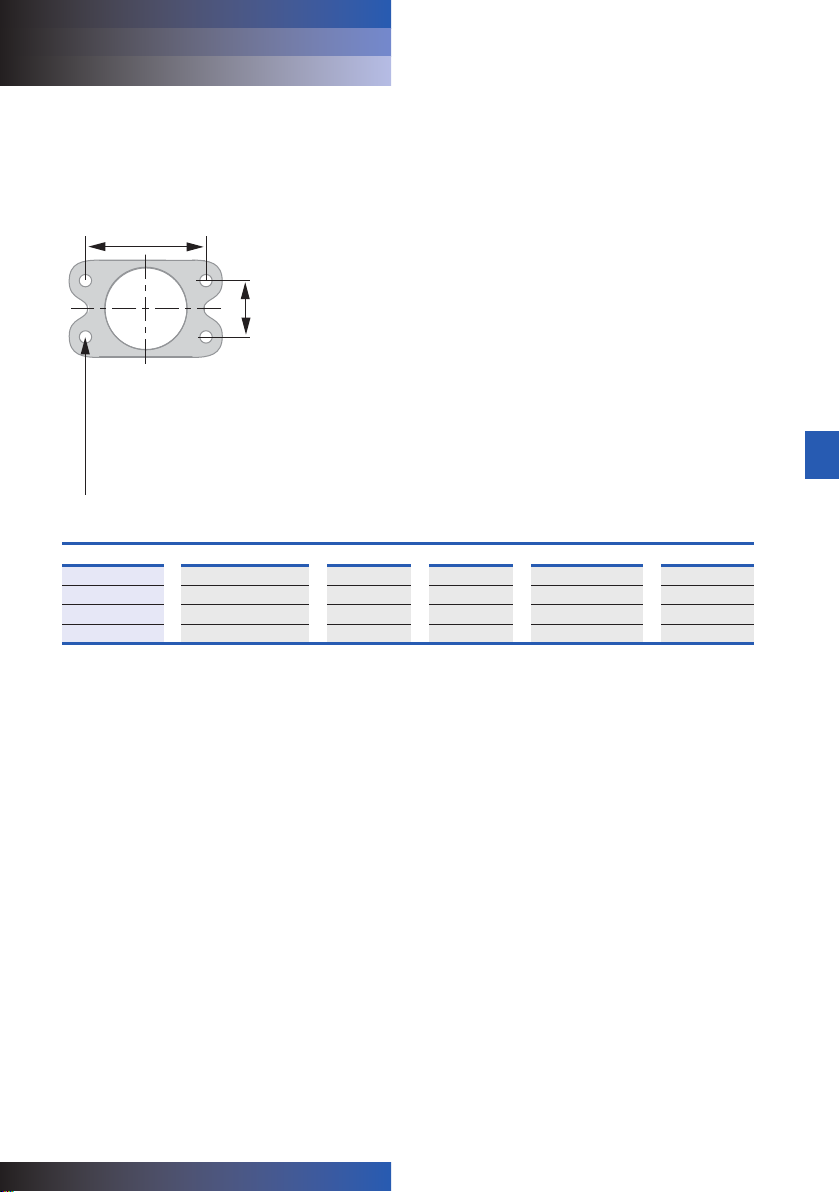

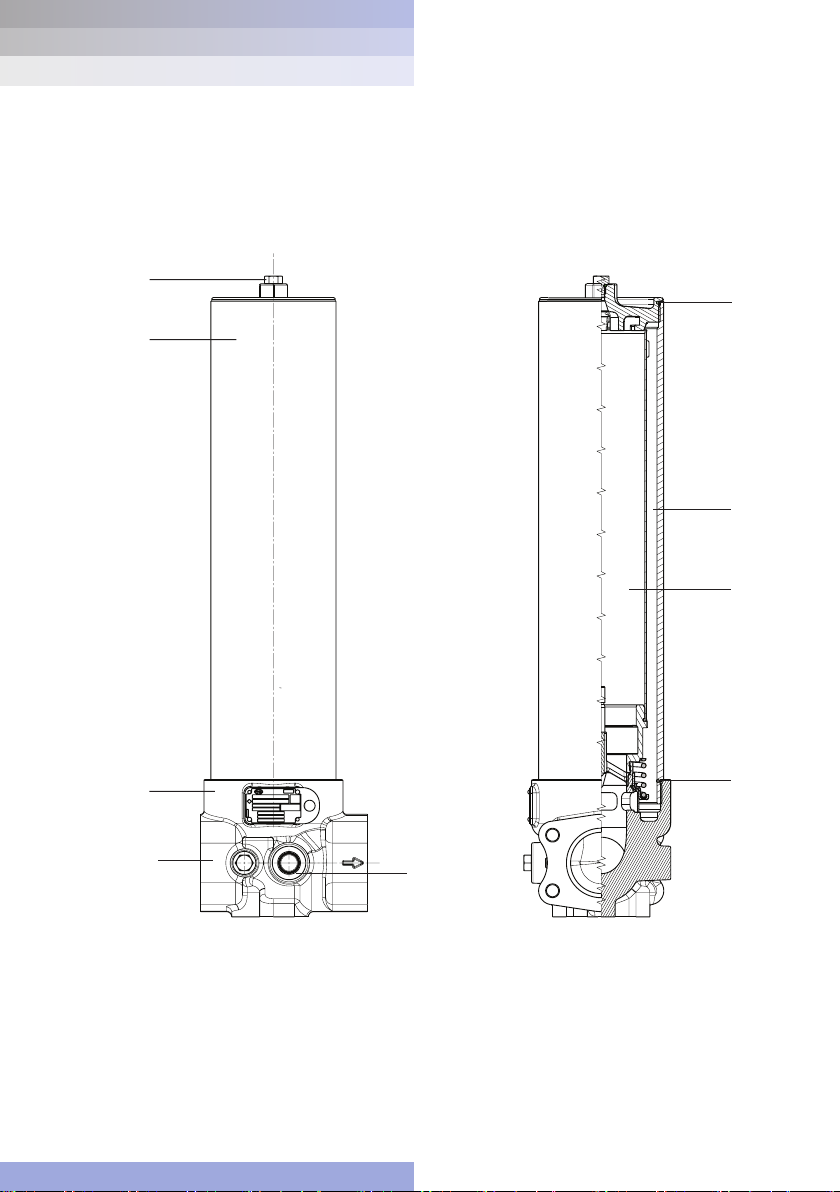

Figure 2

7

3

4

2

8

1

7b

6

6

5

Page 7

UR310

UH319

UH319 Series

service instructions

Figure 3

A

HIGH PRESSURE FILTERS

UR310 Series

RETURN LINE FILTERS service instructions

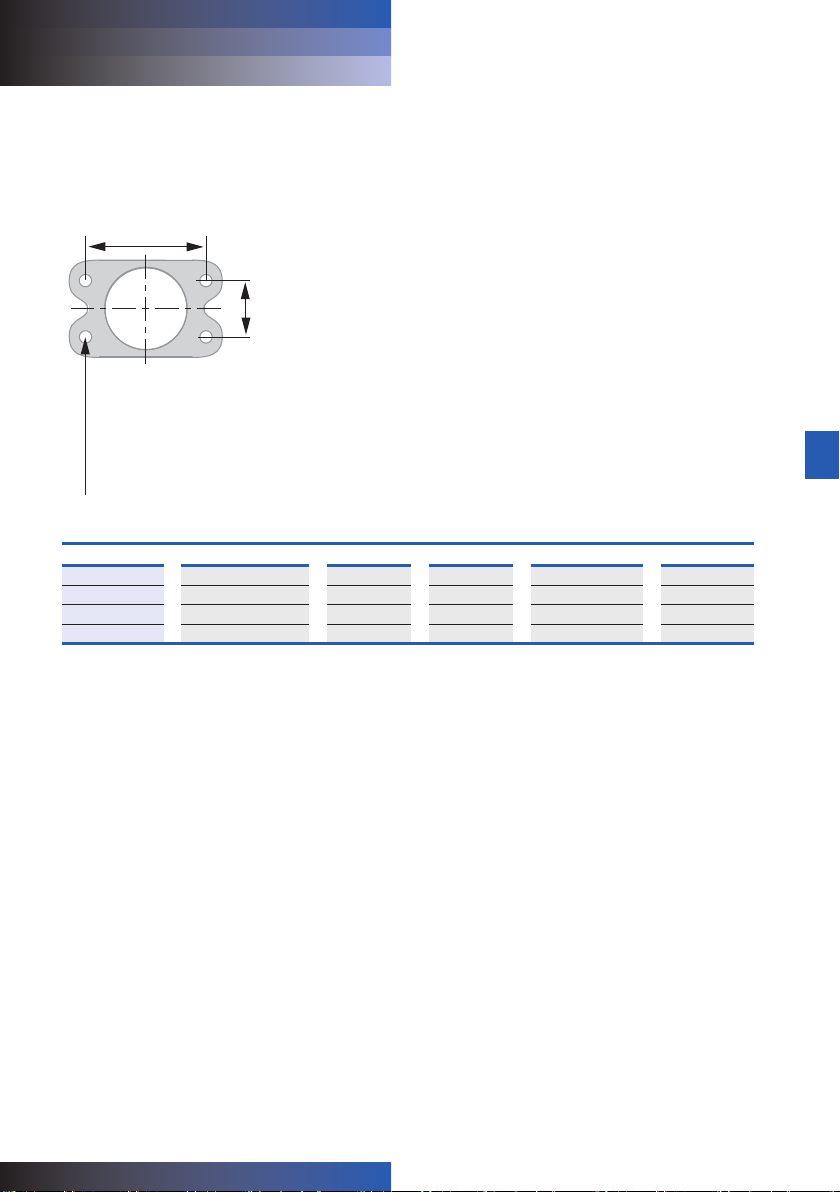

Figure 3

Q

GG

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

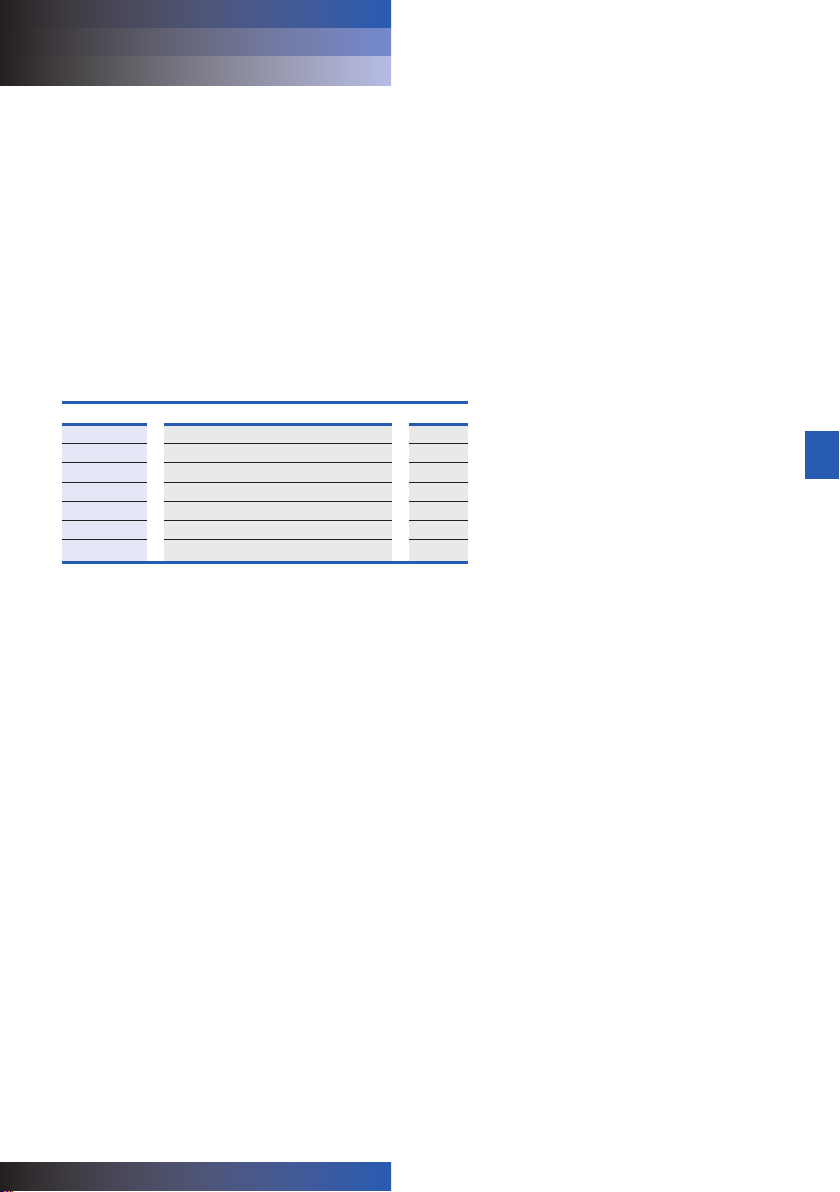

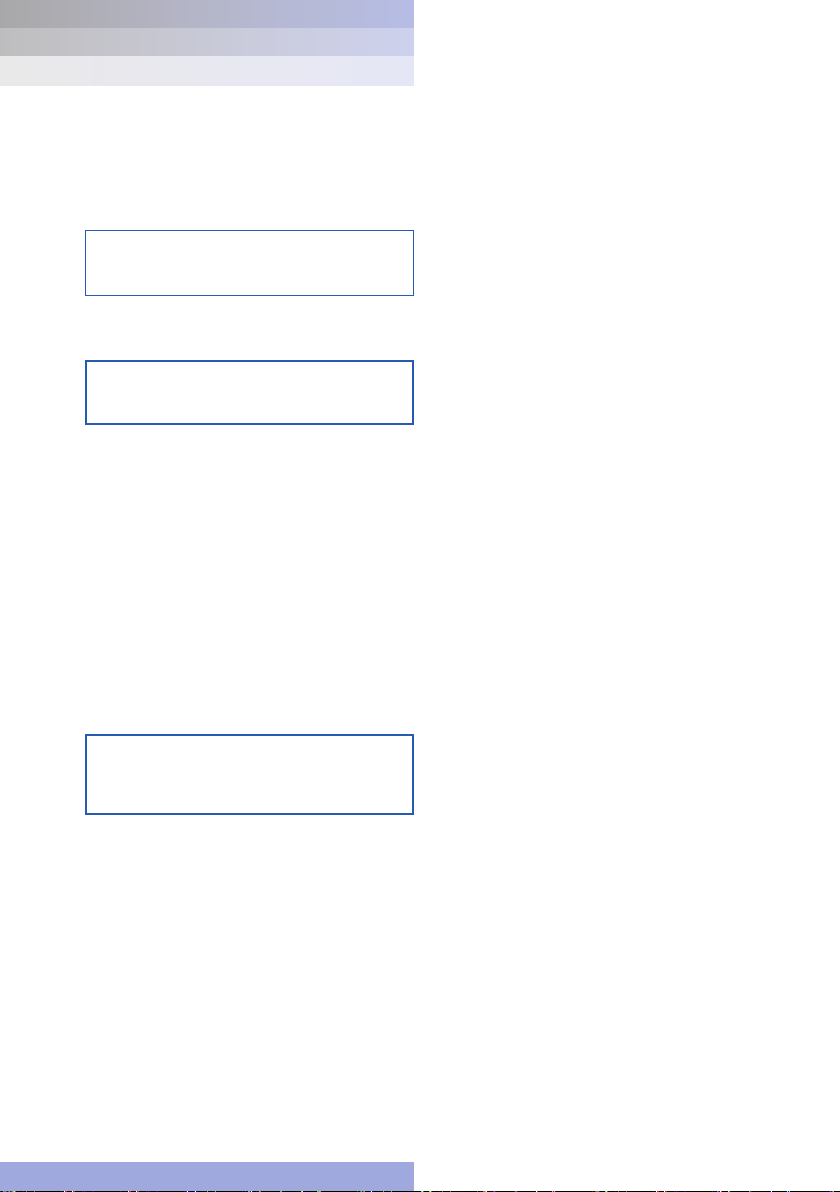

Flange Connection Details

Flange Code Nominal Tube Size GG Q Z Thread AA

D32 2" 1.688" 3.062" ½" - 13 UNC 1"

F32 2" 42.9 mm 77.8 mm M12 x 1.75 25 mm

D40 2½" 2.000" 3.500" ½" - 13 UNC 1"

F40 2½" 50.8 mm 88.9 mm M12 x 1.75 25 mm

ENGLISH

7

Page 8

UR310

RETURN LINE FILTERS

UR310 Series

service instructions

25 Harbor Park Drive

Port Washington, NY 11050

+1 516 484 3600 telephone

+1 800 289 7255 toll free US

Portsmouth - UK

+44 (0)23 9233 8000 telephone

+44 (0)23 9233 8811 fax

www.pall.com/contact

Visit us on the Web at www.pall.com

Pall Corporation has offices and plants throughout the world. For Pall representatives in your area, please go to www.pall.com/contact

Because of technological developments related to the products, systems, and/or services described herein, the data and procedures

are subject to change without notice. Please consult your Pall representative or visit www.pall.com to verify that this information

remains valid.

© Copyright 2019, Pall Corporation. Pall, and are trademarks of Pall Corporation.

® Indicates a trademark registered in the USA. Better Lives. Better Planet. and Filtration. Separation. Solution.SM are service marks

of Pall Corporation.

January 2019. Printed in England. M&ESIUR310c

Page 9

UR310

EN

CN

CN (Simplified) UR310使用说明书

UR310系列

中文

(SIMPLIFIED)

使用说明书

M&ESIUR310CN(S)c

Page 10

UR310

UR310系列

回流管过滤器 使用说明书

1 规格

滤壳材料:

过滤头和网盖:

滤管:

最高工作压力:

41巴(600 psi)

耐受压力:

62巴(900 psi)

最低爆破压力:

165巴(2400 psi)

滤芯爆破压力:

UE310滤芯最低压差 10巴 (150 psid)

工作温度范围:

带适合石油基和指定合成液体的碳氟化合物密封时,-29° C至

120°C(-20° F至250° F)

在HWCF、水油乳浊液或水乙二醇中最高60° C (140° F)

旁路阀设置选项:

1.7 ± 0.2巴(25 ± 3 psid)破裂压力

4.5 ± 0.5巴(65 ± 7 psid)破裂压力

无旁路

注意:

最低喘流不应超过正常流量的1.3倍。

密封材料:

碳氟化合物

用户应检查实际工作条件,以确保滤芯、滤壳和所有密封均适合

液体和应用且符合当地安全法规。如果需要其他信息,请联系颇

尔或批准的经销商。

球墨铸铁

碳钢

2 接收设备

滤壳和所有选装设备均单独包装,以供客户组装。请小心拆包以

免将选装零件留在将废弃的包装材料中。

3 一般信息源

3.1 对于尺寸、工作参数、总成/元件的零件号、订购信息、备

注、性能数据和规格,请参阅数据表。

3.2 本设备已经按照欧洲压力指令97/23/EC中制定的指导原则

评估并按照安全可靠的工程惯例(SEP)分类。我们在此声

明,设备满足第3条第 3节的要求,因而满足指令要求。根

据指令的条款,过滤器总成仅适用于第2组液体。

3.3 在可合理预见的条件下(包括外部火灾),可能超过容许

极限,客户必须在连接的液体系统中安装合适的保护装

置。

4 安装滤壳

4.1 过滤器可以在任何海拔高度安装,但为了便于维修,建议

垂直安装且滤管与过滤网盖朝上(UR310)或者滤管与过滤

网盖朝下(UR310H)。

4.2 拆下滤芯所需最小间隙如下所示:

4.2.1 UR310系列(网盖维护):248mm或9.8”(度

为8的滤壳);383mm或15.1”(长度为 13的滤壳)

;553mm或21.8”(长度为20的滤壳);1,061mm

或41.8”(长度为40的滤壳)。

4.2.2 UR310H系列(过滤头维护):140.97mm或5.55”

(所有长度的滤壳)。

4.2.3 UR310滤壳没有过滤器。对于滤芯安装和维修步

骤,请参阅第7节。

4.3 如有安装,带螺纹的压差设备必须拧至40 lbft或54 Nm。

所有可视指示器必须清晰可见。

注意:UR310过滤头配有加工成型的压差警告设备端口, 此端

口装有塑料装运堵头。如果未订购压差警告设备,必须拆下装运

堵头并换上B型堵塞器(P/N HA9000-A104Z),然后使用40 lbft或

54 Nm力矩拧紧。

注意:在下O型环凹槽中安装统一尺寸的 -014 O型环前,切勿

使用堵头堵住端口,否则,旁路将出现小水流,致使污染物流

到滤芯下游。

注意:

切勿操作过滤器,否则警告设备端口会闭合。

4.4 使用1/2” - 20UNF - 2B(A或 D端口)或M12 x 1.75 -

6H(C或F端口)螺栓将过滤器总成装在过滤头安装垫片

上。使用20 - 25 lbft或 27 - 34 Nm力矩拧紧螺栓。

4.5 如果可能回流,在过滤器下游安装止回阀。

4.6 如需在系统不停机时维护过滤器,请使用另一管道/阀门安

装滤罩,以使过滤器总成完全旁通。此系列不用于双路或

维修旁路结构。

注意:

从滤芯回流会导致过滤器损坏。

注意:建议尽量在离端口连接处近的位置安装管道支架,以将

外部负载降至最低。此过滤器总成不得与用户的接地系统电气隔

离。此过滤器总成必须通过以下方法接地:将用户的接地系统接

至入水/出水口连接处。

4.7 将管路或软管连接滤壳入水和出水口。

警告:

使用兼容所提供端口的接头或适配器,如铭牌和数据表中零

件号所示:使用错误接头或适配器可导致滤罩或歧管出现故

障,致使压力下降、系统出现故障或人员受伤。

10

Page 11

UR310

UR310系列

回流管过滤器 使用说明书

注意:可在滤壳上喷漆。滤壳上的涂层是合适的底漆。在外壳上

喷漆时,遮盖压差警告设备和铭牌。

4.8 将过滤器放气

4.8.1 UR310(网盖维护):将过滤器顶部的放气塞(7)拧开一圈

半对过滤器放气。慢慢运行系统并装满过滤器,直至所有

空气通过放气塞,然后使用12 ft/lb或16 Nm 力矩拧紧放气

塞。

4.8.2 UR310H(过滤头维护):将过滤头上的放气塞(7b)拧开一

圈半对过滤器放气。慢慢运行系统并装满过滤器,直至所

有空气通过放气塞,然后使用12 ft/lb or 16 Nm力矩拧紧

放气塞。

对系统完全加压并检查是否泄漏;如果泄漏,请参阅第5节。

注意:

滤罩未完全放气将增加系统液体中溶解的空气含量,从而缩

短液体寿命并导致系统中出现其他问题。

5 日常维护

5.1 除定期监测压差警告设备外,在正常情况下,颇尔过滤器

无需特别注意。安排最长每六个月更换一次滤芯并备足备

用滤芯。

5.2 如果发现从外部泄漏,请更换泄漏处的O型环。如果仍然

泄漏,请检查密封面是否划破或裂开;更换损坏的零件。

5.3 在需要更换滤芯或“冷启动”状态下液体粘度较高时,压差

设备发出警告。如果出现“冷启动”状态,请参阅6.2和 6.3

节。

5.4 脏污的系统可能很快堵塞新滤芯,特别是在使用颇尔高效

过滤介质时。此时,可能需要更换一次或两次原装滤芯,

以便保持滤芯的寿命。如果滤芯寿命短或压差较高,过滤

器可能不够大;请参阅产品手册中的尺寸和选择章节或联

系当地颇尔代表。

5.5 确保滤芯更换标签干净、未损坏。将字迹模糊的标签更换

为相应的新标签。

6 压差设备

对于尺寸、工作参数、零件编号、订购信息和规格,应参考产

品手册。

6.1 在需要更换滤芯或液体粘度“冷启动”状态下较高时,压差

设备发出信号。

6.2 如果不锈钢可视指示器(若安装)在“冷启动”时发出信号

(红色按钮弹起5mm3/16”),在达到正常工作温度时,

请按下按钮重置。如果指示器在重置后发出信号,请更换

滤芯。如果黄铜可视指示器(若安装)在“冷启动”时发出

信号(指示器内标志的变红),在达到正常工作温度时,

则会自动重置。如果指示器在达到正常工作温度后仍然发

出信号,请更换滤芯。

注意:‘P’可视指示器选件具有热锁定和手动重置功能。在0° C

(32° F)以下和29° C (80° F) 以上时,不会发出信号。

6.3 建议使用正指示(绿灯)和负指示(红灯,提示滤芯变

脏)有效监测滤芯的寿命。

6.4 如果电气开关在冷启动时发出信号(例如,红灯亮起),

则继续运行,直至信号(红灯)在系统升至正常工作温

度时消失。此功能可在运行过程中作为“预热”指示。如果

警告信号(红灯)仍存在或在系统升温后出现,请更换滤

芯。

电气连接和额定值取决于所选指示器。以下仅列出典型值:

110 VAC = 4A(感应式),

220 VAC = 4A(感应式),

28 VDC = 3A(感应式),

48 VDC = 1A(感应式),

125 VDC = 0.25A(感应式),

最高涌流 - 24安

Underwriter’s lab. Inc.列出压力开关(微动开关)选件的如下

额定值:

250 VAC下4安

220 VDC下0.25安(电阻式)

110 VDC下0.50安(电阻式)

电气压差开关运行:

在超过预设压差时,从“常闭(NC) - 共用地线”切换至“常开(NO)

- 共用地线”。

当压差降至预设值以下时,从“常开(NO) - 共用地线”恢复为“常闭

(NC) - 共用地线”。

4A(电阻式)

4A(电阻式)

5A(电阻式)

1.5A(电阻式)

0.5A(电阻式)

图1 - 开关电路图

常闭(NC)

引脚2

常开(NO)

引脚3

有关连接详情,请参阅各指示器选项。

压差低

压差高

共用地线

引脚1

中文

(SIMPLIFIED)

11

Page 12

UR310

UR310系列

回流管过滤器 使用说明书

7 滤芯维修

在维修时,必须洗去过滤器总成外表面上的所有灰尘。

必须使用不会产生危险的合适工具维修。

在空气可能引发爆炸时,切勿维修。

注意:

在提示或达到指定间隔(最长六个月)时更换滤芯。未更换

滤芯将导致过滤器不会有效过滤。

有关合适替换滤芯系列的零件号,请参阅备件清单(第9节)。

按以下步骤拆卸和更换滤芯:

7.1 关闭系统并减压。

警告:

在维修滤芯前未对过滤器减压可导致液体大量流失,使设备

损坏,人员也可能受伤。

7.2 UR310系列(网盖维护):

将过滤器顶部的放气塞(7)拧开一圈半。

打开过滤头上的排水阀(7b)并将液体排入合适的废物桶中。

更换排水阀并使用12ft/lb或16Nm力矩拧紧。从滤管(2)上逆

时针(从上往下看)拧下网盖(3)。首次拆卸时,可能需要

使用1”套筒扳手拧动网盖(3)上的六角螺钉。

注意:Ur310系列总成配有颇尔的‘自动抽拉’滤芯拆取装置以便

拆卸滤芯。拆下盖板后,滤芯底盖上的连接片卡入盖板上的钩子

中,滤芯被自动从接套中拉出。

7.3 UR310H系列(过滤头维护):

打开滤杯总成(滤管和网盖)底部的排水阀(7)并将滤杯中

的液体排入合适的废物桶中。更换排水阀并使用12 ft/lb或

16 Nm力矩拧紧。从过滤头(1)上逆时针(从下往上看)拧

下滤杯总成(2和3)。首次拆卸时,可能需要使用1”套筒

扳手拧动网盖(3)上的六角螺钉。

7.4 更换滤芯(UE310系列):拆下滤芯(8)(若已安装)并仔

细检查内表面(流进和流出滤芯)是否变脏。正常情况下

应没有污渍,但可见污渍或颗粒是系统组件故障的预警。

丢弃滤芯及其O型环。滤芯不可清洁。尝试清洁滤芯可导

致滤材性能下降,使脏污液体流过滤芯。

警告:

切勿尝试清洁或二次使用滤芯。

只能使用颇尔生产的替换滤芯。使用其他滤芯可能导致产

品保修失效。

7.5 未安装滤芯时,切勿运行系统。

UR310系列: 检查并确保网盖(3)和滤管(2)间的O型环(4)

未损坏。

UR310H系列: 检查并确保网盖(2)和滤管(1)间的O型环

(5)未损坏。

使用滤芯端盖上零件号标出的替换滤芯。

7.6 使用干净的系统液体润滑滤芯O型环。将滤芯重新装入滤

壳总成。使用干净的系统液体稍微润滑网盖与过滤头或滤

管与过滤头(若使用)间的O型环并重新组装滤壳,直至

拧到最后一圈螺纹。只能用手拧紧。

7.7 在过滤器中加满水以便放出气体,直至所有空气通过放气

塞(7),然后使用12 lb/ft或16Nm拧紧放气塞。按照4.8节内

容检查是否泄漏。

7.8 更换滤芯后,确保压差设备已重置。黄铜可视指示器、电

气开关和不锈钢电子开关自动重置。在系统达到正常工作

温度时,请检查并确保电气开关和/或可视警告按钮/标志

未发出信号。如果冷启动状态导致可视指示器发出信号,

请按照第6节内容再次重置。

8 保修、责任限制和补救措施

除非另有说明,我们不提供产品适销性或特定用途适用性的任何

保修,也不提供任何明示或暗示保证。

自销售方供货起十二个月或使用三千小时内(“保修期间”,以先

到者为准),在正确安装和保养以及按额定要求、规范和设计

条件使用的条件下,销售方保证销售方生产的产品没有材料和

工艺缺陷。作为说明而非限制,销售方对滤芯的使用寿命不提

供保证,因为这不在销售方的控制范围内且取决于安装过滤器

的系统条件。

销售方的保证责任仅限于更换(FOB原发货点)、维修保修期间

出现故障的产品(由销售方判定)或为其提供信用证。购买方要

尽快书面通知销售方提出索赔,并为销售方提供检验和测试涉及

缺陷的产品。购买方要为销售方提供产品发票原件复印件,预先

支付将产品退回销售方工厂或销售方指定地点产生的运费。所有

索赔都必须提供全部详情,包括适用的系统操作条件。

对于在销售方工厂外(销售方或销售方授权的经销商除外)改装

的任何产品,销售方概不负责;至于授权经销商改装的产品,销

售方仅对授权经销商按照其书面说明组装的产品负责。对于出现

误用、滥用、不当安装、应用、操作、保养或维修、改装以及使

用、储存、运输或搬运过失的产品,销售方概不负责。

对于与本产品生产、包装、交付、储存、使用、不当使用或未使

用相关的任何偶然、必然或其他损失,销售方概不负责。

12

Page 13

UR310

UR310系列

回流管过滤器 使用说明书

9 零件清单

列表

1

2

3

4、5

6

7、7b

8

描述

过滤头

滤管

网盖

O型环(过滤头与滤杯间)

指示器或塞子套件(未显示)

放气/排水塞

滤芯

数量

1

1

1

2

1

2

1

中文

(SIMPLIFIED)

13

Page 14

UH319

UH319 Series

service instructions

Figure 3

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

GG

Q

HIGH PRESSURE FILTERS

UR310

UR310系列

回流管过滤器 使用说明书

图2

7

3

4

2

8

1

7b

6

14

5

Page 15

UH319

UH319 Series

service instructions

Figure 3

A

HIGH PRESSURE FILTERS

UR310

UR310系列

回流管过滤器 使用说明书

图3

Q

GG

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

法兰连接详情

法兰代码

D32 2” 1.688” 3.062” ½” - 13 UNC 1”

F32 2” 42.9 mm 77.8 mm M12 x 1.75 25 mm

D40 2½” 2.000” 3.500” ½” - 13 UNC 1”

F40 2½” 50.8 mm 88.9 mm M12 x 1.75 25 mm

标称滤管尺寸

GG

Q

Z螺纹

AA

中文

(SIMPLIFIED)

15

Page 16

UR310

UR310系列

回流管过滤器 使用说明书

25 Harbor Park Drive

Port Washington, NY 11050

电话:+1 516 484 3600

美国免费电话:+1 800 289 7255

Portsmouth - UK

电话:+44 (0)23 9233 8000

传真:+44 (0)23 9233 8811

www.pall.com/contact

欢迎访问我们的网站:www.pall.com

颇尔公司的办事处和工厂遍布世界各地。如需了解颇尔当地代表,请访问www.pall.com/contact

由于所述产品、系统和/或服务不断采用新技术,数据和程序可能随时变更,恕不另行通知。请咨询您的颇尔代表或访问

www.pall.com,确认本资料信息是否有效。

© 版权所有2019,颇尔公司。Pall和 均是颇尔公司的商标。

®表示美国注册商标。Better Lives.Better Planet 以及 Filtration.Separation.Solution.SM均为颇尔公司的服务标志。

2019年1月。 英国印制。M&ESIUR310CN(S)c

Page 17

UR310

EN

CN

UR310系列

CN (Traditional)

中文

UR310使用說明書

中文

(TRADITIONAL)

使用說明書

M&ESIUR310CN(T)c

Page 18

UR310

UR310系列

返回管線過濾器 使用說明書

1 規格

外殼材質:

頭部及外罩:

管件:

最大操作壓力:

41 bar (600 psi)

驗證壓力:

62 bar (900 psi)

最小爆裂壓力:

165 bar (2400 psi)

濾芯爆裂壓力:

UE310濾芯至少10 bard (150 psid)壓差

操作溫度範圍:

-29° C 至 120° C (-20° F 至 250° F),有氟碳化合物密封時,

用於石油基及指定合成液體

最大60° C (140°F),HWCF、水油乳化液或水-乙二醇液體時。

旁通閥設定選項:

1.7 ± 0.2 bard (25 ± 3 psid)開啟壓力(cracking pressure)

4.5 ± 0.5 bard (65 ± 7 psid)開啟壓力(cracking pressure)

無旁通

注意:

最大湧升流量不得超過正常流量的1.3倍。

密封:

氟碳化合物

使用者須檢查實際操作條件,以確保元件、外殼及所有密封與

流體及應用相容,且符合當地安全規定。如需更多資訊,請洽詢

Pall或授權經銷商。

延性鑄鐵

碳鋼

2 收到設備

過濾器外殼及其他選購設備均為獨立包裝,待由客戶組裝。拆封

時應小心,並確保選購物品未遺落在欲丟棄的包裝內。

3 一般資訊來源

3.1 尺寸、操作參數、組件/元件料號、訂購資訊、注意事

項、性能資料及規格,參見規格表。

3.2 本設備已依據歐洲壓力指令97/23/EC規定之指導方針

進行評估,並已歸入完善的工程作業規範S.E.P (sound

engineering practice)中。設備符合第3條第3款要求,因此

符合指令要求,特此聲明。按本指令之規定,過濾器組件

僅適用於第2類(group 2)流體。

3.3 在合理可預見的情況下包含外部火災在內,可能超過允許

的極限值,客戶必須在相連的流體系統中安裝適當的保護

裝置。

4 安裝外殼

4.1 過濾器能以任何姿態安裝,但為方便維修,建議垂直安

裝,過濾器管件及外罩朝上(UR310)或過濾器管件及外罩朝

下。

4.2 取出元件所需之最小間距如下:

4.2.1UR310系列(從外罩維修):外殼長度8為

248mm (9.8”)、外殼長度13為383mm (15.1”)、

外殼長度20為553mm (21.8”)、外殼長度40為

1061mm (41.8”)。

4.2.2UR310H系列(從頭部維修):所有長度均為

140.97mm (5.55”)。

4.2.3提供的UR310外殼不含濾芯。濾芯安裝及維修程

序,參見第7章。

4.3 安裝螺紋壓差裝置時,必須鎖緊至扭力40 lbft 或 54 Nm。

所有目視指示必須清楚可見。

備註:UR310頭部出廠時附有機械加工的壓差警告裝置接口,並

裝有塑膠運輸塞。若未訂購壓差警告裝置,則必須取下運輸塞,

並安裝B型孔塞(blanking plug, P/N HA9000-A104Z),鎖緊扭力

為40lbft 或 54 Nm。

備註:務必先在下O形環凹構中安裝均勻尺寸的-014 O形環後,

才能將孔塞裝入此接口中,否則會形成少量旁通流,而導致濾

芯下游污染。

注意:

未將警告裝置接口密封前,切勿操作過濾器。

4.4 將1/2” - 20UNF - 2B(A或D接口)或M12 x 1.75 -6H

(C或F接口)螺栓置於頭部安裝板孔內,固定過濾器組件

的位置。螺栓鎖緊扭力為20 - 25 ft/lb 或 27 - 34 Nm。

4.5 若有反向流的可能性,則應在過濾器下游安裝止回閥。

4.6 若過濾器需要維護且不得關閉系統,則應利用額外的管

件/閥門安裝過濾器外殼,以便能旁通整個過濾器組件。

本系列不適用於雙工或維修旁路配置。

注意:

反向流通濾芯會造成損壞。

備註:管件支撐應儘可能靠近接口連接處,以將外部負荷降至最

低。本過濾器組件與使用者的接地系統之間不得為電氣隔離。必

須藉由將使用者的接地系統與其中一個入口/出口連接處連接,

將本過濾器組件接地。

4.7 將管線或軟管連接至外殼出口及入口接口。

警告:

使用與隨附接口相配的接頭或轉接頭,參見銘牌上之料號及

規格表所示:使用錯誤的接頭或轉接頭可能造成過濾器外殼

或歧管失效,導致壓力損失、系統故障或人員受傷。

18

Page 19

UR310

UR310系列

返回管線過濾器 使用說明書

備註:可選擇塗裝過濾器外殼,過濾器外殼的塗層是合適的底

漆。如欲進行外殼塗裝,則應先遮住壓差警告裝置及銘牌。

4.8 排空過濾器

4.8.1 UR310(從外罩維修):將過濾器頂部的通氣塞(7)旋開一

圈半,以排空過濾器。輕搖系統並填充過濾器,直到所有

空氣經由旋塞排出後,再以12ft/lb 或 16 Nm的扭力鎖緊旋

塞。

4.8.2 UR310H(從頭部維修):將頭部的通氣塞(7b)旋開一圈

半,以排空過濾器。輕搖系統並填充過濾器,直到所有空

氣經由旋塞排出後,再以12ft/lb 或 16 Nm的扭力鎖緊旋

塞。

將系統完全加壓檢查洩漏情況,如有洩漏,參見第5節。

注意:

若未能確實排空過濾器外殼,將造成溶解在系統流體內的空

氣量增加,進而縮短流體壽命並可能導致其他系統問題。

5 日常維護

5.1 Pall過濾器除定期監測壓差警告裝置外,一般不需要特別

注意。安排每六個月或更早更換濾芯,並備妥充足的備用

濾芯。

5.2 若發現外部洩漏,則更換洩漏處的O形環。若持續洩漏,

檢查密封表面是否有刮痕或裂縫,更換有瑕疵的零件。

5.3 當濾芯需要更換或因在「冷啟動」時高流體黏度的情況

下,則壓差裝置動作。若「冷啟動」狀態持續,參見6.2及

6.3節。

5.4 髒污的系統可能很快堵塞新濾芯,特別是在使用Pall高效

過濾介質時。一開始可能需要更換一次或兩次濾芯,以穩

定濾芯壽命。若濾芯壽命短或壓差過大,可能表示過濾器

尺寸過小,請參閱產品說明文件的尺寸選擇章節,或洽詢

當地Pall代表。

5.5 確認濾芯更換標籤乾淨且未受損。若標籤難以辨認,則應

更換適當的新標籤。

6 壓差裝置

應參閱產品說明文件中的尺寸、操作參數、料號、訂購資訊及

規格。

6.1 當濾芯需要更換或因在「冷啟動」時高流體黏度的情況

下,則壓差裝置動作。

6.2 若裝有不鏽鋼目視指示器且在「冷啟動」期間動作(紅色

按鈕延伸5mm、3/16”),則在達到正常操作溫度後按下

按鈕以復位。若指示器在復位後動作,則更換濾芯。若裝

有黃銅目視指示器且在「冷啟動」期間動作(指示器內的

旗標變成紅色),則會在達到正常操作溫度時自動復位。

若在達到正常操作溫度後仍處於動作狀態,則更換濾芯。

備註:‘P’目視指示器選購件具有溫度鎖定及手動復位。0° C (32°

F)以下無訊號,29° C (80° F)以上有訊號。

6.3 建議同時使用正常指示(綠燈)及異常指示(紅燈表示濾

芯變髒),以有效監測濾芯壽命。

6.4 若冷啟動期間電氣開關動作(例如亮紅燈),則繼續操作

直到系統加熱至正常操作溫度時,訊號(紅燈)消失。此

功能可作為操作程序中的「預熱」指示。若系統升溫後警

告訊號(紅燈)仍持續或出現,則更換濾芯。

電氣連接及額定值取決於選用的指示器。以下僅顯示典型數值:

110 VAC = 4A(電感),

220 VAC = 4A(電感),

28 VDC = 3A(電感),

48 VDC = 1A(電感),

125 VDC = 0.25A(電感),

最大湧升-24安培。

Underwriter’s lab. Inc.列名壓力開關(微動開關)的額定值選

項包括:

4安培,250 VAC時

0.25安培(電阻),220 VDC時

0.50安培(電阻),110 VDC時

電動壓差開關操作:

超過預設壓差時,連續性從常閉(NC)-共接點切換至常開(NO)

-共接點。

若壓差降至預設值以下,則連續性從常開(NO)-共接點切回至常

閉(NC)-共接點。

4A(電阻)

4A(電阻)

5A(電阻)

1.5A(電阻)

0.5A(電阻)

圖1、開關電路圖

ᐌ䭝(NC)

㝇2

ᐌ䭟(NO)

㝇3

詳細連接說明參見個別指示器選項。

ԢວᏂ

催ວᏂ

݅咲

㝇1

中文

(TRADITIONAL)

19

Page 20

UR310

UR310系列

返回管線過濾器 使用說明書

7 濾芯維修

維修時,必須清潔過濾器組件外部表面,以去除堆積的灰塵。

必須以不會造成危險的合適工具進行維修。

不得在可能爆炸的環境中進行維修。

適用更換濾芯系列之品項編號,參見維修零件表(第9節)。按

照以下說明取出並更換濾芯:

注意:

須依指示或按照規定的間隔時間(最長六個月)更換濾芯。

未更換濾芯將導致過濾器持續旁通。

7.1 關閉系統並降壓。

警告:

維修濾芯前若未先將過濾器降壓,可能導致流體爆炸損失、

設備受損及人員受傷。

7.2 UR310系列(從外罩維修):

將過濾器頂部的通氣塞(7)旋開一圈半。

打開過濾器頭部的排放塞(7b),並將流體排至合適的廢棄

物容器中。更換並鎖緊排放塞至12ft/lb 或 16Nm。從上

方觀看時,逆時針旋轉鬆開外罩(3)並從管件(2)取下。一

開始可能須使用一個1”的套筒扳手,以鬆開外罩(3)上的

六角螺栓。

備註:UR310系列組件配備Pall的「自動拉出(Auto-Pull)」濾芯抽

取機構,以便取出濾芯。取下護蓋時,濾芯端蓋上的扣環卡到護

蓋內的鉤子上,自動從短管中拉出濾芯。

7.3 UR310H系列(從頭部維修):

打開本體組件(管件及護罩)底部的排放塞(7),將本體內

的流體排放至合適的廢棄物容器中。更換並鎖緊排放塞至

12 ft/lb 或 16 Nm。從下方觀看時,逆時針旋轉鬆開本體

組 件 (2及3)並從頭部(1)取下。一開始可能須使用一個1”的

套筒扳手,以鬆開外罩(3)上的六角螺栓。

7.4 更換濾芯(UE310系列):若已裝有濾芯(8),取出並仔

細檢查內部表面(通過濾芯的流向為由內向外)是否有明

顯的污染情況。正常情況下不應出現髒污,但若發現髒污

或粒子可能是系統元件故障的早期警告。丟棄濾芯及O形

環。濾芯無法清潔。試圖清潔濾芯可能導致過濾介質劣

化,並使髒污的流體通過濾芯。

7.5 切勿在未安裝濾芯的情況下運轉系統。

針對UR310系列:確認外罩(3)與管件(2)之間的O形環(4)

未受損。

針對UR310H系列:確認管件(2)與頭部(1)之間的O形環(5)

未受損。

使用與濾芯端蓋上所示料號相同的濾芯進行更換。

7.6 使用乾淨的系統流體潤滑濾芯的O形環。將濾芯裝回殼體

組件內。用乾淨的系統流體略微潤滑外罩與頭部間或管件

與頭部間的O形環,並裝回外殼直到螺紋鎖到底。只能用

手鎖緊。

7.7 藉由填充過濾器以排空過濾器,直到所有空氣經由通氣塞

(7)排出,並以12 lb/ft 或 16Nm的扭力鎖緊通氣塞。按照

4.8節檢查洩漏。

7.8 更換濾芯後,確認壓差裝置復位。黃銅目視及電動與不鏽鋼

電動開關自動復位。當系統達到正常操作溫度時,確認電

動開關及/或目視警告鈕/旗標無動作。若目視指示器因

冷啟動狀態而動作,則按照第6節再次復位。

8 保固、責任限制及補救措施

就產品而言,除文中所述外,不保證任何特定用途之可售性

(MERCHANTABILITY)或合適性,亦沒有任何其他明示或暗示

之保證。

自賣方交貨日起12個月內或使用三千小時內,以先到者為準(

「保固期」),賣方保證由賣方製造的產品,在正確安裝及維護

並按照額定值、規格及設計條件操作之情況下,無任何材料及工

藝上的缺失。藉由以說明而非限制之方式,賣方無法保證濾芯的

使用壽命,因為此超出賣方的控制範圍,且取決於裝有過濾器之

系統的狀態。

針對保固期內有缺失的產品,賣方的保固責任僅限於更換(FOB

原始出貨地點)、檢修或給予折抵額度(由賣方自行決定)。買

方須立即以書面方式通知賣方任何事由,並讓賣方有機會檢驗及

測試宣稱有缺失的產品。買方須提供賣方產品正本發票的副本,

並預付將產品送回賣方工廠或賣方指定其他地點的所有運費。所

有事由必須隨附完整詳細說明,包含適用之系統操作情況。

賣方不為任何在賣方工廠以外、非賣方或賣方授權經銷商所做

的產品變更負任何責任,若為由授權經銷商變更者,則僅限於經

銷商按照賣方書面說明組裝之產品。賣方亦不為任何因誤用、濫

用、不當安裝、應用、操作、維護或檢修、變更、意外或疏於使

用、儲存、運輸或處理之產品負任何責任。

不論在任何情況下,賣方皆不為因任何產品之製造、包裝、交

貨、儲存、使用、誤用或未使用或任何其他原因造成之損害、事

故、後果或其他情況負任何責任。

警告:

切勿試圖清潔或重複使用濾芯。

只能更換PALL原廠濾芯。使用替代濾芯可能導致產品保固

失效。

20

Page 21

UR310

UR310系列

返回管線過濾器 使用說明書

9 零件表

編號

1

2

3

4, 5

6

7, 7b

8

說明

過濾器頭部

管件

外罩

O形環(頭部-本體之間)

指示器或接口孔塞套件(未顯示)

通氣/排放塞

濾芯

數量

1

1

1

2

1

2

1

中文

(TRADITIONAL)

21

Page 22

UH319

UH319 Series

service instructions

Figure 3

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

GG

Q

HIGH PRESSURE FILTERS

UR310

UR310系列

返回管線過濾器 使用說明書

圖2

7

3

4

2

8

1

7b

6

22

5

Page 23

UH319

UH319 Series

service instructions

Figure 3

A

HIGH PRESSURE FILTERS

UR310

UR310系列

返回管線過濾器 使用說明書

圖3

Q

GG

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

法蘭連接詳細說明

法蘭編號

D32 2” 1.688” 3.062” ½” - 13 UNC 1”

F32 2” 42.9 mm 77.8 mm M12 x 1.75 25 mm

D40 2½” 2.000” 3.500” ½” - 13 UNC 1”

F40 2½” 50.8 mm 88.9 mm M12 x 1.75 25 mm

標稱管件尺寸

GG

Q

Z螺紋

AA

中文

(TRADITIONAL)

23

Page 24

UR310

UR310系列

返回管線過濾器 使用說明書

25 Harbor Park Drive

Port Washington, NY 11050

+1 516 484 3600 電話

+1 800 289 7255 美國免費電話

Portsmouth - UK

+44 (0)23 9233 8000 電話

+44 (0)23 9233 8811 傳真

www.pall.com/contact

我們的網站:www.pall.com

Pall Corporation在全球都有辦公室和工廠。有關您所在地區的Pall Corporation 代表,請參閱網站:www.pall.com/contact。

由於文中提及的相關產品、系統及/或服務的技術開發其資料和程序可能變更,恕不另行通知。請洽詢您的Pall Corporation代表或

連結至www.pall.com,以確認本資訊是否仍有效。

© 版權2019,Pall Corporation、Pall及為Pall Corporation的商標。

® 表示美國註冊商標。Better Lives. Better Planet and Filtration. Separation. Solution.SM為 Pall Corporation的服務標章。

2019年1月。 英國印刷。M&ESIUR310CN(T)c

Page 25

UR310

EN

DE

CN

Baureihe UR310

DE UR310 Wartungsanleitung

DEUTSCH

Wartungsanleitung

M&ESIUR310DEc

Page 26

UR310

RÜCKLAUFFILTER

Baureihe UR310

Wartungsanleitung

1. Spezifikationen

Gehäusematerialien:

Kopf und Deckel: Kugelgraphitguß

Rohr: C-Stahl

Maximaler Betriebsdruck:

41 bar

Prüfdruck:

62 bar

Minimaler Berstdruck:

165 bar

Filterelementberstdruck:

UE310 Element, 10 bar Differenzdruck

Betriebstemperaturbereich:

-29° C bis + 120° C (-20° F bis 250° F) mit FKM-Dichtungen für

mineralische und synthetische Flüssigkeiten

maximal 60° C (140° F) bei HWCF, Wasser-Öl-Emulsionen bzw.

Wasser-Glykol Flüssigkeiten

Öffnungsdruck der Bypassventile:

Bypassöffnungsdruck 1,7 ± 0,2 bar

Bypassöffnungsdruck 4,5 ± 0,5 bar

Ohne Bypass

VORSICHT:

Der maximale Durchsatz sollte nicht mehr als das 1,3fache des normalen Volumenstroms betragen.

Dichtungen:

Fluorkautschuk (FKM)

Bitte prüfen Sie die vorhandenen Betriebsbedingungen

vor Einbau des Filters. Stellen Sie sicher, dass Gehäuse,

Filterelement und Dichtungen mit der Flüssigkeit verträglich

und für die Anwendung geeignet sind und den im Betrieb

geltenden Sicherheitsvorschriften entsprechen. Für weitere

Informationen wenden Sie sich bitte an Pall oder einen autorisierten Händler.

2 Anlieferung der Filter

Das Filtergehäuse und alles weitere Zubehör sind einzeln

verpackt und vom Kunden zu montieren. Bitte packen Sie die

Teile vorsichtig aus und vergewissern Sie sich, dass keine

Einzelteile in der Verpackung zurückgeblieben sind, bevor sie

diese entsorgen.

3 Allgemeine Informationen

3.1 Abmessungen, Betriebsdaten, Komplettfilter- und

Elementbezeichnungen, Bestellinformationen,

Anmerkungen, Leistungsdaten und Spezifikationen entnehmen Sie bitte dem Datenblatt.

3.2 Dieser Filter wurde nach den Richtlinien der

Europäischen Druckgeräterichtlinie 97/23/EC bewertet

und entspricht „guter Ingenieurpraxis“. Wir erklären, dass der Filter die Anforderungen von Artikel 3,

Abschnitt 3 erfüllt und somit den Normanforderungen

entspricht. Nach den Bestimmungen dieser Norm ist der

Komplettfilter daher nur für Flüssigkeiten der Gruppe 2

geeignet.

3.3 Wenn die zulässigen Grenzwerte unter vorhersehbaren

Bedingungen, einschließlich Bränden im Außenbereich,

überschritten werden könnten, müssen vom Kunden

geeignete Schutzeinrichtungen innerhalb des angeschlossenen Flüssigkeitssystems installiert werden.

4 Einbau des Gehäuses

4.1 Der Filter kann in jeder beliebigen Lage eingebaut werden,

aber zur Erleichterung der Wartungsarbeiten ist es empfehlenswert, den Filter senkrecht, mit dem Rohrkörper und

dem Deckel nach oben zeigend (UR310) bzw. nach unten

zeigend (UR310H) einzubauen.

4.2 Sehen Sie oberhalb des Deckels einen Mindestfreiraum

zum Elementwechsel vor:

4.2.1 Baureihe UR310 (Deckel-Betrieb): 248mm (9,8") für

4.2.2 Baureihe UR310H (Head Service): 141 mm für alle Längen.

4.2.3 Das UR310 Gehäuse wird ohne Filterelement geliefert.

4.3 Werden Differenzdruckanzeigen eingebaut, ziehen Sie diese

HINWEIS: Der UR310 Filterkopf wird mit einer

Differenzdruckanzeigenbohrung geliefert, die mit einem Transportstopfen

aus Kunststoff verschlossen ist. Wenn keine Differenzdruckanzeige

bestellt wurde, muss der Transportstopfen entfernt und durch einen

Blindstopfen des Typs ‚B‘ (Teilenummer HA9000A104Z) ersetzt werden,

der mit einem Drehmoment von 54 Nmangezogen werden muss.

HINWEIS: Vor Einbau eines Blindstopfens in diesen Anschluss sicherstellen, dass ein O-Ring der Größe 2-014 in die untere Ringnut einsetzt

ist. Andernfalls entsteht ein kleiner Bypass, wodurch Verschmutzung

auf die Reinseite des Filters gelangen kann.

4.4 Montieren Sie die Filtereinheit mit 1/2" - 20UNF - 2B

4.5 Bei Gefahr von Rückfluss installieren Sie nach dem Filter

4.6 Installieren sie das Filtergehäuse mit zusätzlichen

HINWEIS: Zum Minimieren der externen Belastungen sind

Rohrstützen in unmittelbarer Nähe zu den Anschlüssen zu installieren. Diese Filtereinheit darf nicht elektrisch vom Erdungssystem

des Kunden isoliert werden. Die Filtereinheit muss durch

Verbinden entweder des Eintritts- oder des Austrittsanschlusses

mit dem Erdungssystem des Kunden geerdet werden.

4.7 Schließen Sie die Rohrleitungen oder Schläuche an die

Gehäuse der Länge 8, 383mm (15,1") für Gehäuse

der Länge 13, 553mm (21,8") für Gehäuse der Länge

20 und 1061mm (41,8") für Gehäuse der Länge 40.

Informationen zum Einbau bzw. Wechsel des Elements

entnehmen Sie bitte Abschnitt 7.

bei der Montage mit einem Drehmoment von 54Nm an. Alle

optischen Anzeigen müssen gut sichtbar sein.

VORSICHT:

Nehmen Sie den Filter nur in Betrieb, wenn die

Differenzanzeigenbohrung verschlossen ist.

Schrauben (Anschlüsse ‚A‘ oder ‚D‘) oder M12 x 1,75 - 6H

Schrauben (Anschlüsse ‚C‘ oder ‚F‘) an den dafür vorgesehenen Bohrungen im Filterkopf. Ziehen Sie die Schrauben

mit einem Drehmoment von 30,5 +-0,5Nman.

ein Rückschlagventil.

Rohrleitungen und Ventilen, so dass im Fall von notwendigen Wartungsarbeiten an der Filtereinheit der gesamte Fluss

um die Filtereinheit herumgeleitet werden kann, ohne dass

das System abgeschaltet werden muss. Diese Baureihe ist

nicht als Duplex- oder Service-Bypass-Filter erhältlich.

VORSICHT:

Durchfluss der Filterelemente in umgekehrter Richtung

führt zur Beschädigung der Elemente.

Eintritts- und Austrittsanschlüsse an.

WARNUNG:

VERWENDEN SIE NUR VERBINDUNGEN ODER ADAPTER,

DIE ZU DEN MITGELIEFERTEN ANSCHLÜSSEN PASSEN,

DIE DURCH DIE TEILENUMMER AUF DEM TYPENSCHILD

SPEZIFIZIERT ODER IN DEN DATENBLÄTTERN

BESCHRIEBEN SIND. FALSCHE VERBINDUNGEN

ODER ADAPTER KÖNNEN ZUM VERSAGEN DES

FILTERGEHÄUSES ODER DES VERTEILERS FÜHREN.

DRUCKVERLUST UND MÖGLICHE SYSTEMAUSFÄLLE

ODER PERSONENSCHÄDEN SIND DIE FOLGE.

26

Page 27

UR310

ÖFFNER (NC

Pin

SCHLIESSER (NO

Pin

RÜCKLAUFFILTER

Baureihe UR310

Wartungsanleitung

HINWEIS: Das Filtergehäuse kann optional lackiert werden. Die Beschichtung des Filtergehäuses bietet eine

geeignete Grundschicht zum Lackieren. Kleben Sie die

Differenzdruckanzeige und das Typenschild vor dem Lackieren

des Gehäuses ab.

4.8 Entlüften Sie den Filter

4.8.1 UR310 (Cover Service): Öffnen Sie die

4.8.2 UR310H (Head Service): Öffnen Sie die

Beaufschlagen Sie das System vollständig mit Druck und

überprüfen Sie es auf Leckagen. Bei Undichtigkeiten gehen Sie

nach Abschnitt 5 vor.

VORSICHT:

Fehler bei der Entlüftung des Filters erhöhen den

Gehalt an gelöster Luft in der Systemflüssigkeit. Dies

hat kürzere Ölstandzeiten zur Folge und kann weitere

Probleme im System verursachen.

5 Routinewartung

5.1 Pall Filter erfordern normalerweise keinen besonde-

5.2 Bei äußeren Leckagen O-Ring an der Leckstelle erset-

5.3 Differenzdruckanzeigen sprechen an, wenn das

5.4 Ein verschmutztes System kann ein neues Filterelement,

5.5 Sorgen Sie dafür, dass die Elementwechseletiketten

6 Differenzdruckanzeigen

Für Abmessungen, Betriebsdaten, Teilenummern,

Bestellinformationen und Spezifikationen wird auf die

Produktliteratur verwiesen.

6.1 Differenzdruckanzeigen sprechen an, wenn das

Entlüftungsschraube (7) am Deckel des Filters um

eineinhalb Umdrehungen, und entlüften Sie das

Gehäuse. Lassen Sie das System langsam anlaufen und

befüllen Sie den Filter, bis die gesamte Luft durch die

Entlüftungsschraube ausgetreten ist. Ziehen Sie dann

dieSchraube mit einem Drehmoment von 16Nm fest.

Entlüftungsschraube (7b) am Kopf des Filters um eineinhalb Umdrehungen, und entlüften Sie das Gehäuse.

Lassen Sie das System langsam anlaufen und befüllen

Sie den Filter, bis die gesamte Luft durch die Schraube

ausgetreten ist. Ziehen Sie dann die Schraube mit einem

Drehmoment von 16 Nm fest.

ren Wartungsaufwand. Nur die Differenzdruckanzeige

muss regelmäßig überprüft werden. Planen Sie einen

Elementwechsel spätestens nach sechs Monaten ein und

halten Sie eine ausreichende Menge Ersatzfilter auf Lager.

zen. Falls die Leckage dadurch nicht beseitigt werden

kann, überprüfen Sie die Dichtflächen auf Kratzer oder

Risse und ersetzen Sie alle defekten Teile.

Filterelement gewechselt werden muss oder die Viskosität

der Flüssigkeit unter Kaltstartbedingungen hoch ist. Bei

Kaltstartbedingungen siehe Abschnitte 6.2 und 6.3.

vor allem ein Filterelement mit hocheffektiven Pall-

Filtermedien, schnell verblocken. Daher sind anfangs

möglicherweise ein oder zwei Elementwechsel erforderlich, bis sich die Elementstandzeit stabilisiert. Falls die

Standzeit der Elemente zu kurz oder der Differenzdruck

zu groß ist, müssen möglicherweise größere Filter eingesetzt werden; siehe Größen- und Auswahlkriterien im

Produktdatenblatt oder wenden Sie sich an Ihre örtliche

Pall-Vertretung.

sauber und unbeschädigt bleiben. Unleserliche Etiketten

müssen sofort durch entsprechende neue Etiketten

ersetzt werden.

Filterelement gewechselt werden muss oder die

Viskosität der Flüssigkeit unter Kaltstartbedingungen

hoch ist.

27

6.2 Falls eine optische Anzeige aus Edelstahl eingebaut

ist und während des Kaltstarts anspricht (roter Knopf

springt 5 mm heraus), drücken Sie den Knopf nach

Erreichen der normalen Betriebstemperatur wieder ein.

Spricht dann die Anzeige nach der Rückstellung wieder

an, wechseln Sie das Filterelement. Falls eine optische

Anzeige aus Messing eingebaut ist und während des

Kaltstarts anspricht (Anzeige wechselt auf rot), wird die

Anzeige nach Erreichen der Betriebstemperatur automatisch zurückgesetzt. Spricht die Anzeige nach Erreichen

der normalen Betriebstemperatur immer noch an, wechseln Sie das Element.

HINWEIS: Die optische Anzeige vom Typ ‚P‘ verfügt über eine

Kaltstartunterdrückung sowie eine manuelle Rückstellung. Kein

Signal unter 0° C; Signal über 29° C.

6.3 Zur effektiven Kontrolle der Filterstandzeit empfiehlt sich

der Einsatz von zwei Anzeigeleuchten (grünes Licht für

funktionierenden Stromkreis, rotes Licht für verschmutztes Filterelement).

6.4 Falls der elektrische Schalter unter Kaltstartbedingungen

anspricht (d.h. wenn das rote Licht aufleuchtet),

betreiben Sie das System weiter, bis das Signal (rotes

Licht) erlischt, da dann die normale Betriebstemperatur

erreicht ist. Diese Eigenschaft kann in den

Betriebsverfahren zum Anzeigen der „Aufwärmphase“

verwendet werden. Falls das Warnsignal (rotes Licht)

weiter leuchtet oder falls es bei Betriebstemperatur auftritt, ersetzen Sie das Filterelement.

Die elektrischen Anschlüsse und Daten hängen von der

ausgewählten Anzeige ab. Nachfolgend sind nur typische

Werte aufgeführt:

110 V Wechselstrom = 4A (induktiv),

220 V Wechselstrom = 4A (induktiv),

28 V Gleichstrom = 3A (induktiv),

48 V Gleichstrom = 1A (induktiv),

125V Gleichstrom = 0,25A (induktiv),

Max. Einschaltstromstoß – 24 A

Nennbelastungen der Druckschalter (Mikroschalter) nach

Underwriter's Laboratory:

4 A resistiv bei 250 V Wechselstrom

0,25 A resistiv bei 220 V Gleichstrom

0,5 A resistiv bei 110 V Gleichstrom

Funktion des elektrischen Differenzdruckschalters:

Wenn der vorgegebene Differenzdruck überschritten wird, wird

von Öffner (NC) - Allgemein auf Schließer (NO) - Allgemein

umgeschaltet.

Wenn der Differenzdruck unter den vorgegebenen Wert abfällt,

wird wieder von Schließer (NO) - Allgemein auf Öffner (NC) Allgemein zurückgeschaltet.

4A (resistiv)

4A (resistiv)

5A (resistiv)

1,5A (resistiv)

0,5A (resistiv)

Abbildung 1 - Verfahrensschema

)

2

3

Beachten Sie die Anschlussdetails der jeweiligen Anzeigenoptionen.

)

NIEDRIGER DIFFERENZDRUCK

ALLGEMEIN

Pin 1

HOHER DIFFERENZDRUCK

DEUTSCH

Page 28

UR310

RÜCKLAUFFILTER

Baureihe UR310

Wartungsanleitung

7 Filterelementwechsel

Während der Servicearbeiten muss die gesamte

Außenoberfläche der Filtereinheit gereinigt werden, um

Staubablagerungen zu entfernen.

Die Servicearbeiten müssen mit geeigneten Werkzeugen

durchgeführt werden, die keine Gefahr darstellen.

Im Fall einer potenziell explosiven Atmosphäre keine

Wartungsmaßnahmen durchführen.

VORSICHT:

Die Filterelemente sollten nach Ansprechen der

Anzeige oder in regelmäßigen Intervallen, spätestens

jedoch nach sechs Monaten, ausgewechselt werden.

Wenn die Filterelemente nicht rechtzeitig gewechselt

werden, arbeitet der Filter im Bypassbetrieb.

Die Teilenummern geeigneter Ersatzelemente können der

Service-Teileliste (Abschnitt 9) entnommen werden. Die

Elemente müssen folgendermaßen entfernt und ersetzt werden:

7.1 Schalten Sie die Anlage ab und druckentlasten Sie das

System.

WARNUNG:

WENN DAS FILTERGEHÄUSE NICHT VOR

DEM AUSWECHSELN DES FILTERELEMENTS

DRUCKENTLASTET WIRD, KANN ES ZU

EINER SCHLAGARTIGEN ENTSPANNUNG DER

FLÜSSIGKEIT KOMMEN, DIE ZU SACH- UND

PERSONENSCHÄDEN FÜHREN KANN.

7.2 Baureihe UR310 (Cap Service):

Öffnen Sie die Entlüftungsschraube (7) oben am Filter

um eineinhalb Umdrehungen.

Öffnen Sie die Ablassschraube (7b) am Filterkopf und

lassen Sie die Flüssigkeit in einen geeigneten Behälter

fließen. Ablassschraube wieder einschrauben und mit

einem Drehmoment von 16 Nm anziehen. Schrauben

Sie den Deckel (3) (von oben gesehen gegen den

Uhrzeigersinn) vom Rohrkörper (2) ab. Möglicherweise

wird für den Sechskant am Deckel (3) ein 1"

Steckschlüssel benötigt, um den Deckel zu lösen.

HINWEIS: Die Baureihe UR310 ist zur einfacheren Entnahme

des Filterelements aus dem Filtergehäuse mit dem Pall ‚AutoPull‘-Ausziehmechanismus ausgestattet. Beim Abschrauben

des Deckels greifen die Laschen der Elementendkappe in die

Haken im Deckel, und das Element wird automatisch von der

Aufnahme abgezogen.

7.3 Baureihe UR310H (Head Service):

Öffnen Sie die Ablassschraube (7) unten an der

Filterglocke (Rohrkörper und Deckel) und lassen Sie

die Flüssigkeit in einen geeigneten Behälter fließen.

Ablassschraube wieder einschrauben und mit einem

Drehmoment von 16 Nm anziehen. Schrauben Sie

die Filterglocke (2 und 3) (von unten gesehen gegen

Uhrzeigersinn) vom Filterkopf (1) ab. Möglicherweise

wird für den Sechskant am Deckel (3) ein 1"

Steckschlüssel benötigt, um den Deckel zu lösen.

7.4 Elementwechsel (Baureihe UE310): Entnehmen Sie das

Filterelement (8), falls bereits eines eingebaut ist, und

untersuchen Sie die innere Oberfläche (Element wird von

innen nach außen durchströmt) sorgfältig auf sichtbare

Verschmutzung. Im Normalfall ist keine Verschmutzung

zu sehen, sichtbare Schmutzpartikel können aber

schon ein erster Warnhinweis auf einen Schaden

einer Systemkomponente sein. Entsorgen Sie das

Filterelement einschließlich O-Ring. Das Filterelement

darf NICHT GEREINIGT WERDEN. Jeder Versuch, das

28

Filterelement zu reinigen, kann zur Zerstörung des

Filtermediums führen, so dass verschmutzte Flüssigkeit

auf die Reinseite gelangt.

WARNUNG:

NIEMALS DAS ELEMENT REINIGEN ODER

WIEDERVERWENDEN.

NUR ORIGINAL PALL-FILTERELEMENTE

VERWENDEN. DIE VERWENDUNG ANDERER

ELEMENTE KANN ZUM ERLÖSCHEN DER

PRODUKTGARANTIE FÜHREN.

7.5 Nehmen Sie das System AUF KEINEN FALL ohne

Filterelement in Betrieb.

Baureihe UR310: Untersuchen Sie den O-Ring

(4) zwischen Deckel (3) und Rohrkörper (2) auf

Beschädigungen.

Baureihe UR310H: Untersuchen Sie den O-Ring

(5) zwischen Rohrkörper (2) und Filterkopf (1) auf

Beschädigungen.

Verwenden Sie einen Filter mit der auf der Endkappe

des Elements angegebenen Teilenummer.

7.6 Benetzen Sie den O-Ring im Element mit sauberer

Systemflüssigkeit. Setzen Sie das Element in das

Stützrohr ein. Benetzen Sie den O-Ring zwischen Deckel

und Filterkopf bzw. Rohrkörper und Filterkopf ebenfalls

mit sauberer Systemflüssigkeit und schrauben Sie das

Gehäuse bis zum Anschlag wieder zusammen. Nur

handfest anziehen.

7.7 Entlüften Sie den Filter, indem Sie ihn füllen, bis die

gesamte Luft durch die Entlüftungsschraube (7) entwichen

ist. Dann die Entlüftungsschraube mit einem Drehmoment

von 16 Nm festziehen. Untersuchen Sie das System auf

undichte Stellen, wie in Abschnitt 4.8 beschrieben.

7.8 Stellen Sie nach dem Elementwechsel sicher, DASS

DIE DIFFERENZDRUCKANZEIGE ZURÜCKGESETZT

WIRD. Optische Anzeigen aus Messing und elektrische

Schalter aus Edelstahl stellen sich automatisch

zurück. Prüfen Sie nach Erreichen der normalen

Betriebstemperatur, ob der elektrische Schalter und/

oder der optische Anzeigenknopf/das Sichtzeichen nicht

angesprochen hat. Falls die optische Anzeige durch

Kaltstartbedingungen angesprochen hat, setzen Sie sie

gemäß den Anleitungen in Abschnitt 6 wieder zurück.

8 Garantie, Haftungsbeschränkungen und

Hilfsmaßnahmen

PALL SCHLIESST GEWÄHRLEISTUNGEN FÜR DIE

WIEDERVERKÄUFLICHKEIT UND DIE EIGNUNG DER

PRODUKTE FÜR EINEN BESTIMMTEN ZWECK AUS. PALL

ÜBERNIMMT KEINE VERTRAGLICHEN GEWÄHRLEISTUNGEN

ÜBER DIE HIER GENANNTEN GEWÄHRLEISTUNGEN HINAUS.

Der Gewährleistungszeitraum beträgt zwölf Monate ab dem

ursprünglichen Auslieferungsdatum vom Verkäufer oder

dreitausend Betriebsstunden, je nachdem, welcher Fall

zuerst eintritt („Garantiezeit“). Der Verkäufer haftet dafür,

dass die vom Verkäufer hergestellten Produkte, wenn

sie richtig installiert und gewartet sowie entsprechend

den Auslegungsbedingungen, Spezifikationen und

Konstruktionsmerkmalen betrieben werden, frei von

Material- und Herstellungsfehlern sind. Erläuternd wird darauf

hingewiesen, dass der Verkäufer unter anderem auch nicht

für die Standzeit der Filterelemente haftet, da sie außerhalb

der Einflussmöglichkeiten des Verkäufers liegt und von den

Betriebsbedingungen des Systems abhängig ist, in dem die

Elemente installiert werden.

Page 29

UR310

RÜCKLAUFFILTER

Baureihe UR310

Wartungsanleitung

Die Verantwortung des Verkäufers unter den

Garantiebedingungen ist darauf beschränkt, dass er die

Produkte, die während der Garantiezeit einen Fehler

aufweisen, nach eigenem Ermessen ersetzt (FOB ursprüngliche

Lieferanschrift), repariert oder dem Käufer den Wert des

Produkts erstattet. Der Käufer hat den Verkäufer über seine

Garantieansprüche sofort schriftlich zu benachrichtigen und

dem Verkäufer die Möglichkeit einzuräumen, das betroffene

Produkt zu inspizieren und zu testen. Der Käufer hat dem

Verkäufer eine Kopie der Originalrechnung zuzuschicken und

das Produkt mit Vorauszahlung aller Transportkosten an die

Fabrik des Verkäufers oder an eine andere vom Verkäufer

bestimmte Stelle zu versenden. Alle Ansprüche müssen

umfassende Informationen über den Einsatz des Produkts,

einschließlich gegebenenfalls der Betriebsbedingungen im

System beinhalten.

Der Verkäufer haftet nicht für Defekte in einem Produkt,

das außerhalb der Fabrik des Verkäufers - mit Ausnahme

von Veränderungen durch den Verkäufer oder einen vom

Verkäufer autorisierten Vertragshändler - geändert wurde,

und im letzteren Fall auch nur dann, wenn das Produkt den

schriftlichen Anweisungen des Verkäufers entsprechend vom

Vertragshändler zusammengesetzt wurde. Der Verkäufer haftet

auch nicht im Falle von unsachgemäßer und missbräuchlicher

Verwendung, unsachgemäßer Handhabung bei Installation,

Anwendung, Bedienung, Wartung und Reparatur sowie

bei Veränderungen, Unfällen oder fahrlässiger Benutzung,

Lagerung, Transport oder Handhabung.

Unter keinen Umständen haftet der Verkäufer für zufällige

Schäden, Folgeschäden oder andere Schäden, unabhängig

davon, ob sie in Zusammenhang mit der Herstellung,

Verpackung, Lieferung, Lagerung, Benutzung, Missbrauch

oder Nichtbenutzung seiner Produkte oder aus einer beliebigen

anderen Ursache eingetreten sind.

9 Teileliste

Pos. Beschreibung Anzahl

1 Filterkopf 1

2 Rohrkörper 1

3 Deckel 1

4, 5 O-Ring (zwischen Deckel und Rohrkörper

6 Differenzdruckanzeige oder Blindstopfen

(nicht dargestellt) 1

7, 7b Entlüftungs-/Ablassschraube 2

8 Filterelement 1

bzw. Filterkopf und Rohrkörper) 2

DEUTSCH

29

Page 30

UR310

UH319

UH319 Series

service instructions

Figure 3

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

GG

Q

HIGH PRESSURE FILTERS

RÜCKLAUFFILTER

Abbildung 2

7

3

Baureihe UR310

Wartungsanleitung

4

2

8

1

7b

6

30

5

Page 31

UR310

UH319

UH319 Series

service instructions

Figure 3

A

HIGH PRESSURE FILTERS

Baureihe UR310

RÜCKLAUFFILTER

Abbildung 3

Q

GG

Z

4 HOLES FULL THREAD DEPTH AA

4 Gewindebohrungen mit Gewindetiefe AA

4 huller med gevind, dybde AA

4 taladros pasantes roscados. Profundidad A

4 täyskierteistä reikää, syvyys AA

4 trous taraudés de profondeur AA

4 fori completamente filettati profondità AA

4 tapgaten (met draad over volle diepte)

4st fästhål. Gänga "Z". Min gängdjup "AA"

Flanschverbindungen

Flansch-Code Rohrdurchmesser GG Q Z Gewinde AA

D32 2" 1,688" 3,062" ½" - 13 UNC 1"

F32 2" 42,9 mm 77,8 mm M12 x 1,75 25 mm

D40 2½" 2,000" 3,500" ½" - 13 UNC 1"

F40 2½" 50,8 mm 88,9 mm M12 x 1,75 25 mm

(nominal)

Wartungsanleitung

DEUTSCH

31

Page 32

UR310

RÜCKLAUFFILTER

Baureihe UR310

Wartungsanleitung

25 Harbor Park Drive

Port Washington, NY 11050

+1 516 484 3600 Telefon

+1 800 289 7255 gebührenfrei (USA)

Portsmouth - GB

+44 (0)23 9233 8000 Telefon

+44 (0)23 9233 8811 Fax

www.pall.com/contact

Besuchen Sie uns im Internet unter www.pall.com

Pall Corporation besitzt Niederlassungen und Werke weltweit. Pall-Vertretungen in Ihrer Region finden Sie unter www.pall.com/contact.

Aufgrund der technischen Entwicklungen der hier beschriebenen Produkte, Systeme und/oder Dienstleistungen können die Daten

und Verfahren ohne Vorankündigung jederzeit geändert werden. Bitte sprechen Sie Ihre Pall-Vertretung an oder sehen Sie unter

www.pall.com nach, ob diese Informationen noch aktuell sind.

© Copyright 2019, Pall Corporation. Pall, , und Athalon sind Marken der Pall Corporation.

® bezeichnet eine in den USA eingetragene Marke. Better Lives. Better Planet. und Filtration. Separation. Solution.SM sind

Dienstleistungsmarken von Pall Corporation.

Januar 2019. Produziert in Großbritannien M&ESIUR310DEc

Page 33

UR310

EN

ES

DE

CN

Series UR310

ES Instrucciones de mantenimiento de UR310

ESPAÑOL

Instrucciones

de mantenimiento

M&ESIUR310ESc

Page 34

UR310

FILTROS DE LÍNEA DE RETORNO

Series UR310

instrucciones de mantenimiento

1 Especificaciones

Materiales de la carcasa:

Cabezal y Cuerpo: hierro Fundido Dúctil

Tubo: acero al carbono

Presión máxima de funcionamiento:

41bar (600psi)

Presión de prueba:

62bar (900psi)

Presión mínima de rotura:

165bar (2400psi)

Presión de rotura del elemento:

Elemento UE310 10 bard (150 psid) diferencial mínimo

Rango de temperatura de funcionamiento:

-29° C a 120° C (-20° F a 250° F) con sellos de fluorocarbono

para fluidos en base petróleo y sintéticos específicos

60° C (140° F) máximo en HWCF, emulsión agua-aceite o

agua-glicol.

Opciones de ajuste de la válvula de bypass:

1,7 ± 0,2 bard (25 ± 3 psid) presión de apertura

4,5 ± 0,5 bard (65 ± 7 psid) presión de apertura

Sin bypass

PRECAUCIÓN:

El flujo máximo no debe superar 1,3 veces el flujo

normal.

Juntas:

Fluorocarbono

El usuario deberá verificar las condiciones reales de

funcionamiento a fin de garantizar que el elemento, la

carcasa y todos las juntas sean compatibles con el fluido y

la aplicación, y que cumplan con los códigos de seguridad

locales. Comuníquese con Pall o un distribuidor autorizadosi

necesita más información.

2 Recepción del equipo

La carcasa filtrante y cualquier equipo opcional se embalan

individualmente para que el cliente las monte. Desembale con

cuidado y asegúrese de que los artículos opcionales no se

pierdan en el embalaje que se va a desechar.

3 Fuentes generales de información

3.1 Para las dimensiones, los parámetros operativos, el

número de pieza del montaje/elemento, la información

de pedido, las notas, los datos de rendimiento y las

especificaciones, consulte la hoja de datos.

3.2 Este equipo se ha evaluado de acuerdo con las

directrices establecidas en la Directiva Europea de

Presión 97/23/CE y se ha clasificado dentro de las

buenas prácticas de ingenieríaS.E.P. Declaramos que

el equipo cumple con los requisitos de la sección 3 del

artículo 3, por tanto cumpliendo con los requerimientos

de la directiva.Según las disposiciones de esta

directiva, el conjunto delfiltro solo es adecuado para

uso con fluidos del grupo 2.

3.3 Cuando sea previsible la superación de los límites

permitidos bajo determinadas condiciones especiales,

como incendios externos, el cliente deberá instalar los

dispositivos de protección adecuados en el sistema de

conexión del fluido.

34

4 Instalación de la carcasa

4.1 El filtro se puede instalar en cualquier posición, pero

para facilitar el mantenimiento, se recomienda que

se instale verticalmente con el tubo y la tapa del filtro

apuntando hacia arriba (UR310) o con el tubo y la tapa del

filtroapuntando hacia abajo (UR310H).

4.2 El espacio libre mínimo que se requiere para retirar el

elemento es como se indica a continuación:

4.2.1 Serie UR310 (mantenimiento de la cubierta): 248 mm

4.2.2 Serie UR310H (mantenimiento de cabeza): 140,97mm

4.2.3 La carcasa UR310 se suministra sin elemento

4.3 Los dispositivos de presión diferencial roscados, cuando

NOTA: La cabeza UR310 se suministra con un puerto de

dispositivo de aviso de presión diferencial mecanizado, equipado

con un tapón de envío de plástico. Si no se solicita un dispositivo

de aviso de presión diferencial, el tapón de envío debe retirarse y

reemplazarse con un tapón obturador tipo ‘B’ (Ref. HA9000-A104Z)

y apretarse con un torque de 40 lbft o 54 Nm.

NOTA: Nunca coloque el tapón de puerto en este puerto sin

instalar primero la junta tórica de -014 de tamaño uniforme en

la ranura inferior de la junta tórica; de lo contrario, se producirá

un pequeño flujo de derivación, lo que permitirá el paso de la

contaminación aguas abajo del elemento filtrante.

4.4 Monte el conjunto del filtro en su posición utilizando

4.5 Si existe la posibilidad de un flujo inverso use una válvula

4.6 Instale la carcasa del filtro utilizando tuberías/válvulas

NOTA: Los soportes de tubería deben proporcionarse lo más

cerca posible de los puertos de las conexionespara minimizar

las cargas externas. Este conjunto filtranteno debe estar aislado

electrónicamente del sistema de puesta a tierra del usuario. Este

conjunto filtrante debe conectarse a tierra conectando el sistema de

puesta a tierra del usuario a una de las conexiones de entrada/salida.

4.7 Conecte las líneas o mangueras a los puertos de entrada

(9,8 pulg.) para longitud 8, 383 mm (15,1 pulg.) para

longitud 13, 553 mm (21,8 pulg.) para longitud 20 y

1061 mm (41,8 pulg.) para carcasas de longitud 40.

(5,55 pulg.) para todas las longitudes.

filtrante. Para los procedimientos de instalación y

mantenimiento de elementos, consulte la Sección 7.

estén instalados, deben apretarse con torque a 40 lbft

o 54 Nm. Todos los indicadores visuales deben ser

claramente visibles.

PRECAUCIÓN:

No utilice el filtro a menos que el puerto del dispositivo

de aviso de presión diferencial esté sellado.

pernos de 1/2 pulg. - 20UNF - 2B (puertos A o D) o

M12 x 1,75 - 6H (puertos C o F) en los orificios de las

almohadillas de montaje de la cabeza. Apriete los pernos

a 20-25 lbft o 27- 34 Nm.

de retención aguas abajo del filtro.

adicionales para permitir un bypasscompletodel conjunto

del filtro si es necesario el mantenimiento del filtro sin

parar el sistema. Esta serie no está disponible en una

configuración de dúplex o bypassde servicio.

PRECAUCIÓN:

El flujo inverso a través del elemento filtrantecausará daños.

y salida de la carcasa.

ADVERTENCIA:

UTILICE LAS CONEXIONES O ADAPTADORES

COMPATIBLES CON LOS PUERTOS INDICADOS EN LAS

REFERENCIAS DE LA PLACA DE CARACTERÍSTICAS Y

DESCRITOS EN LAS HOJAS DE DATOS: EL EMPLEO DE

CONEXIONES Y ADAPTADORES INCORRECTOS PUEDE

PROVOCAR FALLOS EN LA CARCASA DEL FILTRO O

EN EL COLECTOR CUYO RESULTADO PODRÍA SER

UNA PÉRDIDA DE PRESIÓN, UN FALLO GENERAL DEL

SISTEMA O LESIONES PERSONALES.

Page 35

UR310

NORMALMENTE

CERRADO (NC)

Pin

NORMALMENTE

ABIERTO (NA)

Pin

FILTROS DE LÍNEA DE RETORNO

NOTA

Elrevestimiento de la carcasa del filtro es una base de pintura

adecuada. Cubra el dispositivo de aviso de presión diferencial

y la placa de identificación si se va a pintarla carcasa.

4.8 Purgue el filtro

4.8.1 UR310 (mantenimiento a través de la tapa): Purgue el

4.8.2 UR310H (mantenimiento a través de la cabeza): Purgue

Presurice el sistema completamente y revise si hay fugas; Si se

producen fugas, consulte la sección 5.

PRECAUCIÓN:

Si no se purga adecuadamente la carcasa del filtro,

aumentará el contenido de aire disuelto en el fluido del

sistema, lo que acortará la vida útil del fluido y puede

causar otros problemas en el sistema.

5 Mantenimiento de rutina

5.1 Los filtros Pall normalmente no necesitan atención

5.2 Si se observa una fuga externa, reemplace la junta tórica

5.3 Los dispositivos de presión diferencial se activan

5.4 Un sistema con suciedad puede taponar rápidamente

5.5 Deberá verificarse que las etiquetas de sustitución del

6 Dispositivos de presión diferencial

Deberá consultarse la documentación del producto para

obtener más información acerca de dimensiones, parámetros

de funcionamiento, referencias, realización de pedidos y

especificaciones.

6.1 Los dispositivos de presión diferencial se activan

6.2 Si el indicador visual de acero inoxidable está instalado

: La pintura de la carcasa del filtro es opcional.

filtro girando el tapón de purga (7) en la parte superior

del filtro una vuelta y media. Arranqueel sistema y llene

el filtro hasta que todo el aire salga a través del tapón,

después apriete el tapón a 12 ft/lb o 16 Nm.

el filtro girando el tapón de ventilación (7b) en la cabeza

una vuelta y media. Arranque el sistema y llene el filtro

hasta que todo el aire salga a través del tapón, después

apriete el tapón a 12 pies / lb o 16 Nm.

especial, excepto para el control periódico del

dispositivo de aviso de presión diferencial. Programe

el reemplazo del elemento de filtro cada seis meses

o antes, y tenga disponible un amplio suministro de

elementos de repuesto.

en la fuga. Si la fuga persiste, revise las superficies de

sellado en busca de rasguños o grietas; Reemplace

cualquier pieza defectuosa.

cuando el elemento necesita cambiarse o debido a la

alta viscosidad del fluido en condiciones de “arranque

en frío”. Si existen condiciones de “arranque en frío”,

consulte las secciones 6.2 y 6.3.

un elemento filtrante nuevo, especialmente con medios

Pall de alta eficacia. Puede ser necesario realizar uno o

dos cambios de elemento antes de estabilizarse la vida

útil del mismo. Si la vida útil del elemento es muy corta

o si la presión diferencial es excesiva, es posible que el

filtro sea demasiado pequeño; véase el apartado sobre

tamaños y selección en la documentación del producto

o consultar al representante local de Pall.

elemento permanezcan limpias e intactas. Sustituya las

etiquetas ilegibles por etiquetas nuevas apropiadas.

cuando el elemento necesita cambiarse o debido a la

alta viscosidad del fluido en condiciones de “arranque

en frío”.

y se activa durante el “arranque en frío” (el botón rojo

se extiende 5 mm, 3/16"), reinicie presionando el botón

cuando se alcance la temperatura de funcionamiento

normal. Si el indicador se activa después de reiniciar,

35

Series UR310

instrucciones de mantenimiento

reemplace el elemento. Si el indicador visual de latón

está instalado y se activa durante el “arranque en

frío” (el indicador interior cambia a rojo), se reiniciará

automáticamente cuando se alcance la temperatura

normal de funcionamiento. Si el indicador sigue

funcionando después de alcanzar la temperatura normal

de funcionamiento, reemplace el elemento.

NOTA: El indicador visual de la opción “P” tiene bloqueo

térmico y reinicio manual. No hay señal por debajo de 0° C

(32° F), pero si señal por encima de 29° C (80° F).

6.3 Se recomienda utilizar el indicador positivo (luz verde)

y el indicador negativo (luz roja para elemento sucio) a

fin de controlar de forma eficaz la vida útil del elemento

filtrante.

6.4 Si se activa el interruptor eléctrico (es decir, se enciende

la luz roja) durante el arranque en frío, siga operando

hasta que la señal (luz roja) se apague cuando el

sistema se calienta hasta alcanzar la temperatura

normal de funcionamiento. Esta función se puede usar

como una indicación de ‘calentamiento’ durante el

funcionamiento. Si la señal de advertencia permanece

encendida o aparece cuando el sistema está caliente,

reemplace el elemento filtrante.

Las conexiones eléctricas y las características nominales

dependen del indicador elegido. Los valores típicos se

muestran a continuación:

110 VAC = 4A (inductivo),

220 VAC = 4A (inductivo),

28 VDC = 3A (inductivo),

48 VDC = 1A (inductivo),

125 VDC = 0,25A (inductivo),

Irrupción máxima: 24 amperios.

Listado de valores nominales para las opciones del interruptor

de presión (Microswitch) de Underwriter’s lab. Inc.:

4 amperios a 250 VAC

0,25 amperios resistivo a 220 VCC

0,50 amperios resistivo a 110 VCC

Funcionamiento del interruptor de presión diferencial

eléctrico:

Si se supera la presión diferencial predefinida, el interruptor de

continuidad cambia de Normalmente Cerrado (NC) - Común a

Normalmente Abierto (NO) - Común.

Cuando la presión diferencial disminuye por debajo del valor

preestablecido, la continuidad vuelve de Normalmente abierto

(NO) - Común a Normalmente cerrado (NC) - Común.

Figura 1: diagrama del circuito del interruptor

2

3

Consulte las opciones de indicadores individuales para detalles

de conexión.

4A (resistivo)

4A (resistivo)

5A (resistivo)

1,5A (resistivo)