Page 1

OPERATING INSTRUCTIONS

Pall®PCM500 Series Portable Fluid

Cleanliness Monitor

Page 2

PREFACE

The Pall PCM500 On-line Fluid Monitor has been developed to provide accurate and continuous information

on the cleanliness of aqueous solutions, hydraulic fluids and circulatory lubrication system fluids. Fluid

contamination levels monitored are then converted to the widely used contamination codes: ISO4406, SAE

AS4059 table 1 (NAS 1638) and AS4059 table 2. The result data can be exported to Flash Drive, Printer,

PC, PLC or network device..

The self-contained unit provides a portable fluid contamination monitor that can be used with a range of

fluids, including mineral oils and aqueous solutions. Fluid change procedures are included in this manual

and these help ensure the PCM500 monitor is adequately flushed prior to testing on an alternative fluid

application.

The contents of these operating instructions should be read before attempting any aspects of installation,

operation or maintenance.

The product has been tested and quality controlled in accordance with Pall standard procedures. The

customer should carefully inspect the product and ensure it is not damaged and or unsuitable for use. It is

the user’s responsibility to check actual operating conditions to ensure the PCM500 monitor is compatible

with the application and is operated within local safety codes.

NOTICE TO USERS

The PCM500 user manual is provided to assist users in maximising the benefits of the PCM500 portable

fluid cleanliness monitor.

As part of the continuous improvement process that Pall adopt in the development of technology and

satisfying customer requirements, this information or procedure may be subject to change.

Pall welcomes feedback from users who should contact their designated Pall Service Centre.

Please note the PCM500 is shipped to users with, a protective fluid, Rust veto NTP 32, which is miscible in

both aqueous liquids and oils. Please ensure the unit is flushed out before running tests. The unit should

be run for at least three full test cycles on the system fluid before performing a reliable test.

!

!

!

Important: Some fluids may react with Rust Veto to create gels,

which can result in functional issues within the PCM500. One

example is Mono Ethylene Glycol (MEG).

Please check with Pall if there is doubt over the compatibility of test

sample and Rust Veto transit fluid.

Important:

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

Important:

The PCM500W model is fitted with a sensor measuring relative humidity

in oil.

Do not use with water bearing fluids or permanent damage will occur.

2

Page 3

Contents

Section 1 Describes the environmental, mechanical and electrical aspects of the PCM500

monitor to include product specifications.

Section 2 Inspection, packaging and guidance note

Section 3 Description of the PCM500 monitors main items

Section 4 PCM500 principle of operation

Section 5 Pre-check and connection of the PCM500 to a fluid system

Section 6 General operation of the PCM500 monitor, including communications to

peripheral devices.

Section 7 Provides communication protocol for PLC control through RS232 Com port

Section 8 Details the fluid change procedure

Section 9 Describes the PCM500 monitor function codes, possible causes and corrective

actions.

Section 10 Spare parts list

Section 11 Covers the disposal of equipment

Appendix A Details the Pall PCM500 series worldwide aftermarket and calibration service.

Appendix B Details the Mesh Screen Manifold exchange procedure

MANUAL PART NUMBER ISSUE DATE

MA-PCM500 (Draft) 31/08/2015

3

Page 4

4

Page 5

WARNINGS, CAUTIONS AND NOTES

Care must be taken in referring to this manual so as to ensure adherence with all warnings,

cautions and important notes. These carry information related to the safety of personnel and

the integrity and satisfactory operation of plant.

WARNINGS: THESE ARE INSTRUCTIONS THAT DRAW

ATTENTION TO THE RISK OF INJURY OR DEATH.

Cautions: These are instructions that draw attention to the risk

of damage to the product, the process, the equipment or the

surroundings.

Important: These are instructions that draw attention to information

that will aid installation, operation or maintenance.

!

Labels affixed to PCM

Fuse

DC

F4A

H250

Caution label attached to Battery cover

VDC

Label indicating DC power and Fuse rating

Label indicating refer to manual

5

Page 6

Contents

Page

Preface 2

Declaration of Conformity 4

Warnings, Cautions and Notes 5

Section 1: PCM500 and PCM500W

Specification and Requirements

1.1 General Description 7

1.2 Fluid Environment 7

1.3 Ambient Environment 8

1.4 Electrical Requirements 8

1.5 Fluid System Connections 8

1.6 Product Specification 9

Section 2: PCM500/PCM500W Inspection

and Packaging. 10

Section 3: PCM500/PCM500W Description

of Monitor. 10

Section 4: PCM500/PCM500W Principles

of Operation

4.1 General Principles 11

4.2 HMI Control Panel 11

4.3 Test Sampling 11

4.4 Communication Panel 12

4.5 Power Schematic 12

4.5 Battery 13

Section 5: PCM500/PCM500W

Connecting the Monitor

5.1 Connection Options 14

5.2 Connections 15

5.2.1 High Pressure Line 15

5.2.2 Low Pressure Line 15

5.2.3 Reservoir Sampling 16

5.2.4 Bottle Sampling 16

5.3 Operational Checks 17

5.4 Installation Checks 17

Section 6: PCM500/PCM500W

Getting Started

6.1 General 17

6.2 System Requirements 17

6.3 Screen Button Description 18

6.4 The Screens Flow Chart 19

6.5 Example Screen 20

6.6 Start-up Sequence 20

6.7 Sampling 21

6.8 Test Point and Fluid Setup 23

6.9 Code Alarm Set-up 25

6.10 Data manager Screens 25

6.11 Tools Screens 27

Section 7: Interface Protocol – PLC

control through DB9 Serial Port 30

Section 8: PCM500 / PCM500W Fluid

Change Procedure 33

Section 9: PCM500 / PCM500W Function

Codes and Corrective Actions 34

Section 10: PCM500 / PCM500W Spare

Parts List 38

Section 11: PCM500 / PCM500W

Cleaning, Maintenance & Disposal of

Equipment 39

Appendix A: Calibration and Aftermarket

Services 40

Appendix B: PCM500/PCM500W Mesh

Manifold Exchange procedure 41

Pall World wide warranty 43

6

Page 7

Section 1: Pall PCM500 and PCM500W Fluid

Cleanliness Monitors

Specification and Requirements

1.1 General Description

The Pall PCM500/PCM500W is specifically developed as a portable diagnostic

monitoring device that provides an assessment of system fluid cleanliness. A fixed

display/controller allows for simple menu driven input of sample identification, monitor

configuration and data output in ISO4406, SAE AS 4059 Table 1 (NAS 1638) or SAE

AS 4059 Table 2 formats. The display/controller shows the test results, an option to

graph results and this data is automatically stored for subsequent trending and

evaluation. The self-contained design provides for a portable fluid contamination

monitor that can be used with a range of fluids including mineral oils and aqueous

solutions. Note: The PCM500W should not be used for aqueous solutions.

Fluid change procedures are included in this manual and these help to ensure the

PCM500 monitor is adequately flushed ready for an alternative fluid application

See Pall Datasheet M&EPCM500EN for full technical specification

The full technical specification is given below.

1.2 Fluid Environment

Operating Pressure range 0 to 315 bar (4,570 psi) maximum

Operating Viscosity range 1.5 to 450 Centistokes (30 to 2,200 SUS)

Operating System Mineral Oils 10C - 80ºC (50°F - 176°F)

Temperature Water Glycols 10ºC - 60ºC (50°F - 140°F)

Water Based Fluid 10ºC - 60ºC (50°F - 140°F)

Fuels 10ºC - 40ºC (50°F - 104°F)

Industrial Phosphate

Esters & Polyesters 10ºC - 80ºC (50°F - 176°F)

Be aware of possible danger associated with high oil temperatures and

exposed metal surfaces of the PCM500

Fluid Compatibility

Aqueous solutions having a pH <11.0, water glycols, high water based

fluids, petroleum based fluids, industrial phosphate esters, mineral oils

and synthetic fluids.

Do not use Acetone based fluid.

Seals Fluorocarbon (Viton)

WARNING: Health and Safety.

Observe caution when handling fluids and pay attention to instructions of

safe use in the Material Safety Data sheet and COSHH regulations.

Wear protective clothing if prescribed; e.g. safety gloves, clothing and

footwear.

Caution: Health and Safety.

Ensure there is adequate lighting to operate the equipment.

Observe local regulations for factory use.

7

Page 8

Section 1: Pall PCM500 and PCM500W Fluid

Cleanliness Monitors

Specification and Requirements

1.3 Ambient Environment

Operating Temperature range 5°C - 40°C (41°F - 104°F)

Storage Temperature range

(Monitor drained of fluid) -20°C to 55°C ( -4°F to 131°F)

Dust and water protection IP65 (NEMA 4)

Relative Humidity 95%rh non-condensing

Operating Altitude <2000 metres

WARNING: Do not use the PCM500 Series Monitor in an explosive

atmosphere

1.4 Electrical

External Mains Power Supply Unit Input 100 – 240 VAC (Auto Ranging)

(PSU) Accessory Frequency 50 – 60 Hz Single Phase.

Output 48V DC

Input Fuse Quick Blow, 4A 5x20mm (250V)

Optional Mains Supply Unit Input 100 – 240 VAC (Auto Ranging)

Frequency 50 – 60 Hz Single Phase.

Output 24VDC

Internal Battery 12VDC Lithium Ion rechargeable.

Battery Life Typically 35 - 40 samples depending on

cleanliness levels & oil viscosity

Communications USB 1 (Data Acquisition)

USB 2 (PC Setup of PCM)

USB 3 (Printer)

Ethernet Cat5 (Remote control & Data

Acquisition)

RS232C (PLC Control)

Voltage Free Contacts

(Alarm output – contact rating 1 Amp @

24VDC)

1.5 Fluid Connections

Inlet – 2 options High Pressure:

Hose with ¼” BSP female swivel fitting and Metric,

Imperial or NPT Test Point connector options.

Low Pressure:

Hose direct coupled on ¼” BSP female swivel fitting.

Sampling stalk (for bottle sampling)

Outlet M10 male fitted to 6mm OD. Clear plastic hose, with

straight adapter and cap.

8

Page 9

Section 1: Pall PCM500 and PCM500W Fluid

Cleanliness Monitors

Specification and Requirements

1.6 Product Specification

Weight 11 Kg (24 lb)

Dimensions 400 x 260 x 250 mm (15.75” x 10.2” x 10“)

Monitoring range ISO4406 11/9/7 to 23/21/17

Monitoring range SAE AS4059F Table 1

(NAS1638) 1 to 12

Monitoring range SAE AS4059F Table 2 >4µm: 1 to 12, >6µm: 1 to 12 and >14µm:

1 to 12

Accuracy ±1/2 ISO4406 Code

Water-in-Oil (PCM500W only) %rh. ± 2% at 5 to 95%rh (non-condensing)

(PPM switchable but requires C1, C2, 0 to 100% full range

C3 & C4 fluid constant input. Contact

PALL representative).

Enclosure Material and Flammability ABS UL94 V-0

Enclosure Gasket Seals Silicone Rubber

Noise Level <70 dBA

Foreseen misuse of equipment

Within this manual are cautions and warnings to highlight potential dangers associated

with operation of the PCM500. Here are a few points of note on misuse of the

equipment.

A danger to the user can arise from connecting the PCM500 to a pressured system

above the working limit, and / or, using an incorrect high-pressure connection.

Damage to the PCM500 can occur from using incompatible fluids.

A danger to the user and damage to the PCM500 can be from an incorrect mains

voltage supply.

9

Page 10

Section 2: Pall PCM500 and PCM500W

Fluid Cleanliness Monitors

Section 3: Pall PCM500 and PCM500W

Fluid Cleanliness Monitors

2.1 Inspection and Packaging

The PCM500 is shipped in a transportation

case. Use this case for re-shipping the PCM.

Visually inspect the case for signs of external

damage that may have occurred during

shipping and bring any damage to the

attention of the shipper.

Inspect the interior of the case for damage to

the contents as listed below. Compare the

contents of the case with the shipping papers

to assure all the content is present. If any

items are missing, contact Pall or an

approved agent.

The PCM500 package comprises of:

• Integrated PCM500 series monitor with

sample hoses

• Power supply unit

• Mains power lead

• PCM500 to PC communications cable

• PCM500 series Operating Instructions on

CD ROM

• PCM500 series Quick Reference Guide

• Fluid Sampling stalk

• High Pressure test point connector

(Choice of Imperial, Minimess or NPT)

• Certificate of Conformity

• Certificate of Calibration Verification

• Packing note checklist

3.1 Description of the Monitor

The PCM500 is designed and built for light

Industrial use while maintaining aesthetic

and user friendly ergonomics. See section 1

for full specification. The materials are

selected to meet the various fluid and

environmental conditions that the PCM500 is

likely to be subjected during operation.

As a self-contained unit, including sampling

hose and adapters, the user is able to

connect the PCM500 on-line or sample fluid

directly from a system reservoir without

breaking lines thereby avoiding extraneous

contamination.

The PCM500 cleanliness monitor provides

numerous display functions to assist the user

at all stages of operation and provides

function codes to warn of any problems with

both the PCM500 and system fluid.

1. HMI (display/controller)

2. Communication Ports

3. Robust case with carry handle.

4. Integral 12VDC battery

5. Printer storage compartment

6. Last Chance Filter Housing

7. Hose Storage

8. Mesh Screen block

9. Power input and Fuse

The instruments’ specific serial number and

calibration/service record sheet is also

included. It is important to keep this in a safe

place and return them with the unit for future

annual service requirements.

Caution: Health and Safety.

Ensure there is adequate

lighting to operate the

equipment.

Observe local regulations for

factory use.

❻

❼

❽

❾

❸

❶

❺

❹

❷

10

Page 11

Section 4: Pall PCM500 and PCM500W

External power connected and

Series Fluid Cleanliness Monitor

Principles of Operation

4.1 General Principles

Upon starting a test sequence the PCM500

will self-prime and perform internal checks on

the sample fluid condition. This is an

automatic part of the test time. After

approximately 30 seconds the PCM500 will

start the analysis. The screen will display a

progressive time bar for the duration of the

sampling period and identify the specific

stage in the monitoring cycle above the

progress bar.

During the analysis cycle the sample fluid is

presented to mesh screens in a specified

sequence, which captures contamination that

is larger than mesh pore size.

Particle concentrations are measured and

computed for each specific mesh.

BUTTONS:

• START/STOP/REPEAT (test)

• ON /OFF

The test Start/Stop button is active on

release. The ON button is active on

release but OFF requires pressing for 2 3 seconds to shut down.

Blue LED

On Off Flash On On

x

4.3 Test sampling

Green

LED

x No external power (battery

x PCM500 On - Operational /

Red Description

battery in charge mode.

only)

Standby

x Test in Progress

x Hardware/Sampling problem

detected

During the sampling sequence, data is

constantly analysed to identify any excessive

variance in temperature, viscosity, and

pressure to ensure results are not spurious.

The PCM500 will advise the user by function

codes, if any excessive variance occurs.

4.2 HMI Control Panel

The HMI LCD display is designed to provide

clear viewing of the screen menus and test

data. The test sample sequence is initiated

by use of the primary function keys. In edit

mode a keyboard is displayed on the screen,

which enables users to enter, or edit data

including sample points and fluid types.

There are three light emitting diodes (LED) to

indicate PCM500 operational status and two softtouch control buttons.

11

Page 12

4.4 Communications Panel

1

1 USB-A Socket 1 Text file upload/download from memory device

2 USB-B Socket PC connection for setup/control of PCM500

3 USB-A Socket 2 Printer connection

4 DB9 Female RS232 / PLC control (See section 7)

5 2-Pin Socket Voltage free contact. Relay

6 RJ45 Cat5 Ethernet 10/100 base

Screen indication of valid port connection

2

3

An indication of battery charge can be seen

in the lower right corner of the display.

4 5

U E PR

A row of four small boxes in the bottom right

corner of the display screen indicates when a

port connection is active.

U = USB-A 1

E = USB-A 2

R = RS232/PLC

P = Ethernet

External Supply

6

Align the red

dots and push

to connect

4.5 Power Schematic

The PCM500 is normally powered by a

battery located in the front of the unit behind

a plain panel. This has capacity at full charge

to power the monitor for an average of 40

tests (depending on oil viscosity). A power

supply unit (PSU), supplied as part of the

PCM500 package, allows the monitor to be

run from mains power and to charge the

battery.

!

Grip connector outer body and

pull straight to disconnect.

Important:

The PSU cable connection uses a

push – pull action on the outer body

and both connector and receptacle

align through a ‘red dot’ location mark.

DO NOT attempt to remove by rotating

the connector.

Important:

The monitor should not be operated

with the battery pack disconnected.

If a power outage occurs on mains

supply during testing the battery will

maintain power to the PCM to

prevent loss of data and allow for a

safe shut down

12

Page 13

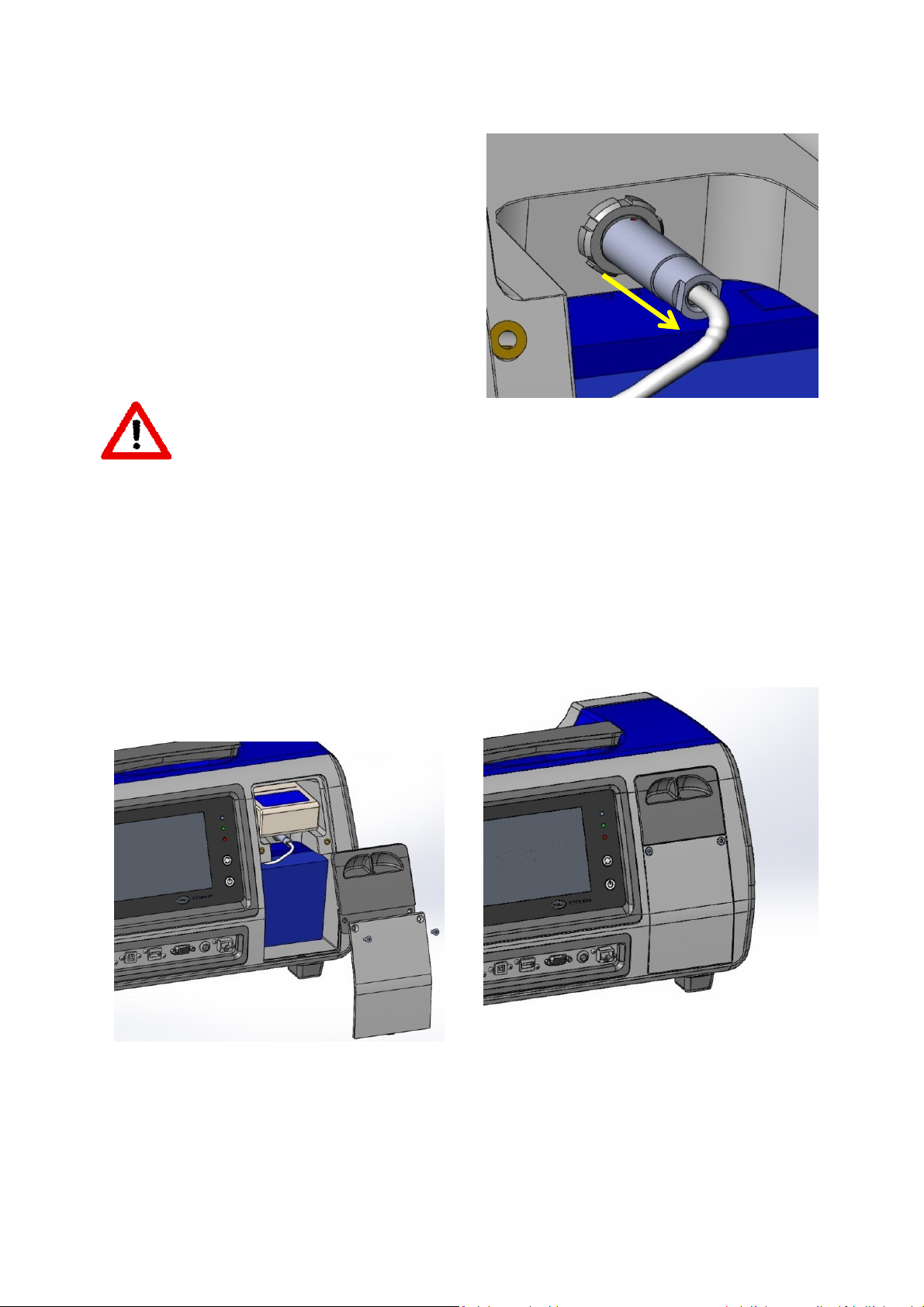

4.5 Battery

Important:

The monitor should not be

!

In the event of a battery replacement the

following procedure should be followed.

operated with the battery pack

disconnected. If a power outage

occurs on mains supply during

testing the battery will maintain

power to the PCM to prevent

loss of data and allow for a safe

shut down.

WARNING: Use only battery

packs supplied by the

manufacturer or Pall agent.

Serious damage will occur if a

battery of different chemistry or

specification is used.

4. The battery connector is removed by

pulling straight on the outer body. Do not

rotate the connector, otherwise damage

will result.

5. When connecting the new battery,

align the red dots between connector and

receptacle before insertion.

1. Ensure the PCM500 is OFF and the

external mains power supply disconnected.

2 . Remove the two M4x10 hex socket

screws from the battery cover and lift out the

cover and then the printer storage cover.

6. Replace the printer and battery covers

and fix with the M4 hex socket screws.

3. Remove the printer if present to allow full

access to the battery connector

13

Page 14

Section 5: Connecting the PCM500

5.1 Connection Options

A general checklist for the user before

starting is given in section 5.3 and also in the

‘Useful information’ quick reference card for

PCM500 unit.

PCM500 is configured for two hose

operation, inlet and return and these are

stored within the rear of the instrument. The

high-pressure hose is used for both high and

low-pressure sampling. Fluid entering the

PCM500 is filtered for contaminant larger

than 65µm diameter by a mesh cartridge

element (Last Chance Filter). This element is

user changeable. In the event of a blocking

filter, fluid entering the PCM will be restricted.

The PCM will detect a loss of fluid and

produce an error code and message on the

display.

Caution: In the interests of

safety, always remove the

end cap from the return line

before connecting the inlet

hose to high-pressure. If the

PCM Pressure Reduction Valve does not

regulate properly then excess outlet pressure

can escape through a relief-valve into the

return line.

NEVER LEAVE A PCM CONNECTED TO

HIGH-PRESSURE WITH THE RETURN

LINE CAPPED.

If the return line is capped or blocked and a

fault occurs with the Pressure Reduction

Valve, then to prevent damage to the internal

circuit a secondary relief valve will exhaust

through a diffuser element at the rear of the

PCM above the return outlet. It is important,

therefore, to be aware of a possible loss of

system fluid.

See the below image of diffuser location.

The sample take-off point in pressure

systems should be cleaned of contaminant

before connecting the PCM hose and in both

high and low pressure sampling modes the

return line must be unrestricted and allowed

to drain into a waste container or system

reservoir.

The PCM500 can be connected in various

ways. High-pressure mode is considered to

be the most appropriate to achieve

representative sampling.

It is important to note that due to the very

small bore through the high-pressure

connector it must be removed from the inlet

hose when sampling below 1 bar pressure. If

not, an error may occur through insufficient

fluid flow into the PCM.

When sampling a closed system, it is

advised to flush the PCM with one test to

waste to prevent cross contamination by fluid

remaining in the PCM from a previous test.

Safety Relief Exhaust Point

Caution:

Do not position the PCM that

makes it difficult to disconnect

power.

14

Page 15

5.2 Connection Options

5.2.1 High Pressure Line (>1 to 315 bar)

5.2.2 Low Pressure Line (0 - 1 bar)

<1 bar at test point: - remove HP connector and

couple hose direct.

15

Page 16

5.2 Connection Options

5.2.3 Reservoir Sampling (0 bar: - Direct coupled hose or use sampling stalk. Remove

high-pressure connector)

Note: Ensure sample point and hose connection are

cleaned before mating

5.2.4 Bottle Sampling (0 - 1 bar)

When sampling from a bottle or container, it is

advised to run a single test to waste with a

clean, compatible fluid (≤ ISO 12/10/8) and

remove any residual contaminant from the

PCM500. Depending on viscosity and

cleanliness, the PCM500 may require up to a

litre of fluid sample for a bottle test. Always

ensure the containers are thoroughly cleaned

prior to introducing a fluid sample..

When bottle sampling it is important to prevent

extraneous contaminant entering the sample,

such as may be found on the outer surface of

the HP hose connection. It is advised to use

the sampling stalk provided, which should be

kept in a clean condition.

In order to check the repeatability of

cleanliness results, a large sample (>3 Litre)

may be cycled into the same container and

averaged over a 3-test run for example.

16

Page 17

5.3 Operational Checks

5.4 Installation Checks

Preparation checks before going to the

installation to be sampled.

Caution: The PCM500

display touch sensitive

screen must not be pressed

with a sharp or pointed implement.

Finger contact is sufficient to operate the

display menu icons and keyboard.

Press and release the PCM500 start button

The Control panel green LED

will flash within a few seconds

and the PCM500 enters the

start-up phase. After a short period the

display will turn on and a screen will appear

with Pall logo. The next phase of start-up is

test firing of the internal valves (six clicks).

Following this the main menu screen is

visible.

If the PCM fails to power up on battery,

connect the external PSU and check the blue

LED on the front panel is ON. If not, check or

replace the input fuse with the correct value.

If the PCM fails to start, consult Pall.

First screen

At installation to be sampled

1) Access the hoses at the rear of the

PCM500.

2) Ensure the hose connectors are clean

and free from any visual contaminants.

3) Ensure the installation to be sampled is in

operation and has been running for a

minimum of 30 minutes prior to taking the

sample in order to distribute the

contamination as evenly as possible

within the fluid. This is necessary to allow

a representative fluid sample to be taken.

4) Connect the clear return line hose to the

system reservoir or suitable capacity

container ensuring cap is removed

5) Connect the black hose to the

appropriate sampling point. Check for

any leakage, rectify as required.

Warning: Ensure the

system operating pressure

is within the PCM500

monitor specified limitation of 315 bar,

4,570 psi maximum.

6) The PCM500 can now be switched on

and the screen sequence followed. The

specific procedure for start-up is detailed

in section 5.4 and section 6 ‘Getting

started’.

2. If the PCM500 has been used previously

with a different fluid to the new sample then

fluid change procedures detailed in section 7

should be adopted.

3. Switch off the PCM500 and you are now

ready to proceed to the installation to be

sampled.

Section 6: Getting Started

6.1 General

This section of the operating instructions

enables a new user to perform tests using

the PCM500 Cleanliness Monitor in a short

space of time. It does not instruct the user in

sampling techniques and the user should

consult Pall for guidance on recommended

sampling points.

6.2 System Components

• PCM500 Cleanliness Monitor

• Power Supply Unit

• Battery Pack

• Bluetooth / USB Printer (Option)

17

Page 18

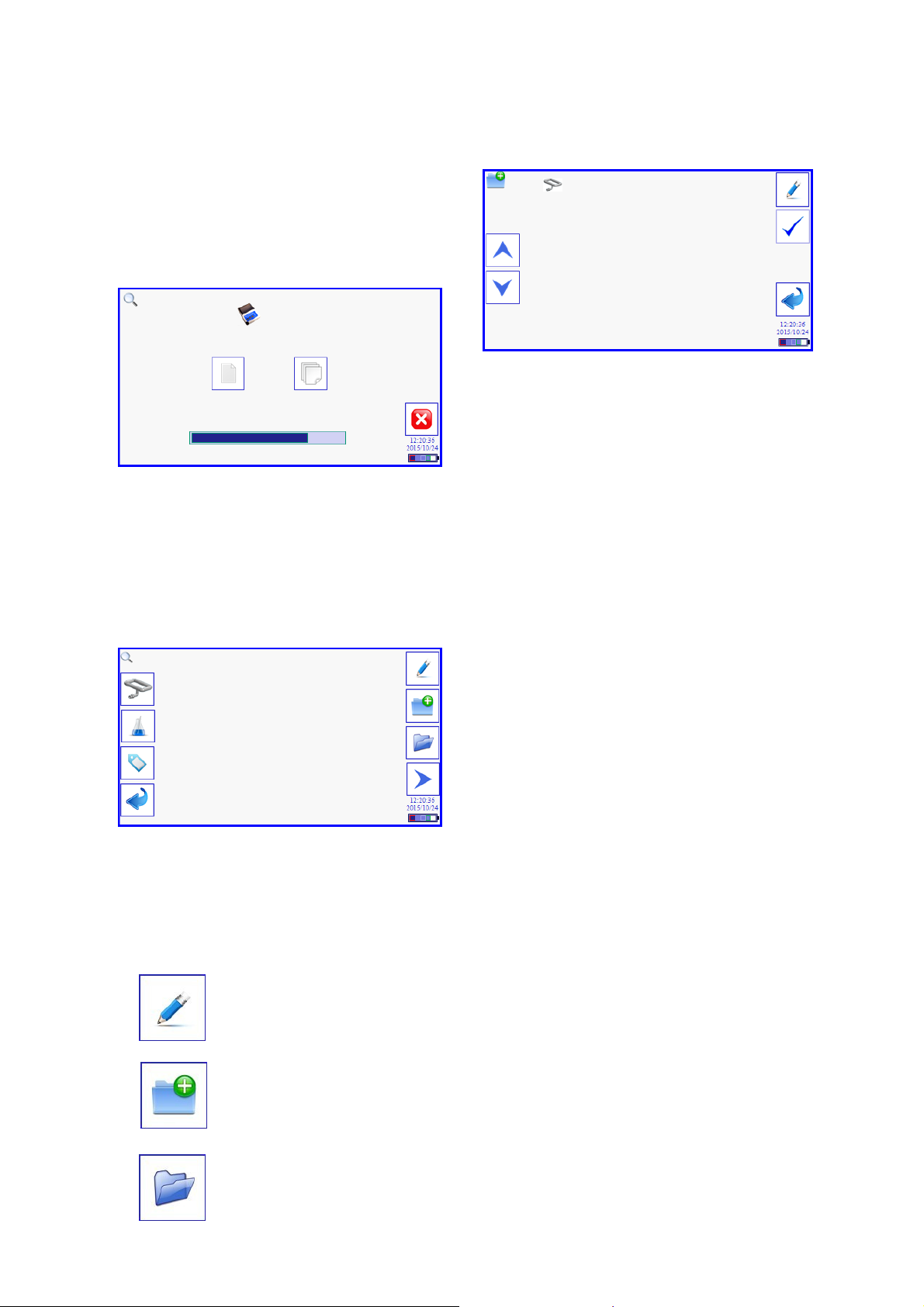

6.3 Button Descriptions

Main

Menu

Navigation

Editing &

Data

Warnings

Tools and

Functions

Communication

Testing

Home

Previous

Delete

Critical

Set Label

Export

Set-up

Confirm

Create

Warning

Clock

Bluetooth

Setup

Tools

Undo

Open

Shutdown

Date

Wi-Fi Setup

File Info Language

Cancel Up Down

Edit

Contact

Format

Comms

Port

Print

ISO 4406

Format

Forward Back

Temp.

Format

AS 4059

Format

Data

Management

Information

Test Point

Upload to

Flash Drive

PCM500

Spec

Fluid

Download

to PCM

Mesh

Settings

Test Label

Test Label

Battery

Data

Water in Oil Repeat

Result

Warning

Control

Panel

Select All

Comms.

Ports

Alarm Set-up

Graph

18

Page 19

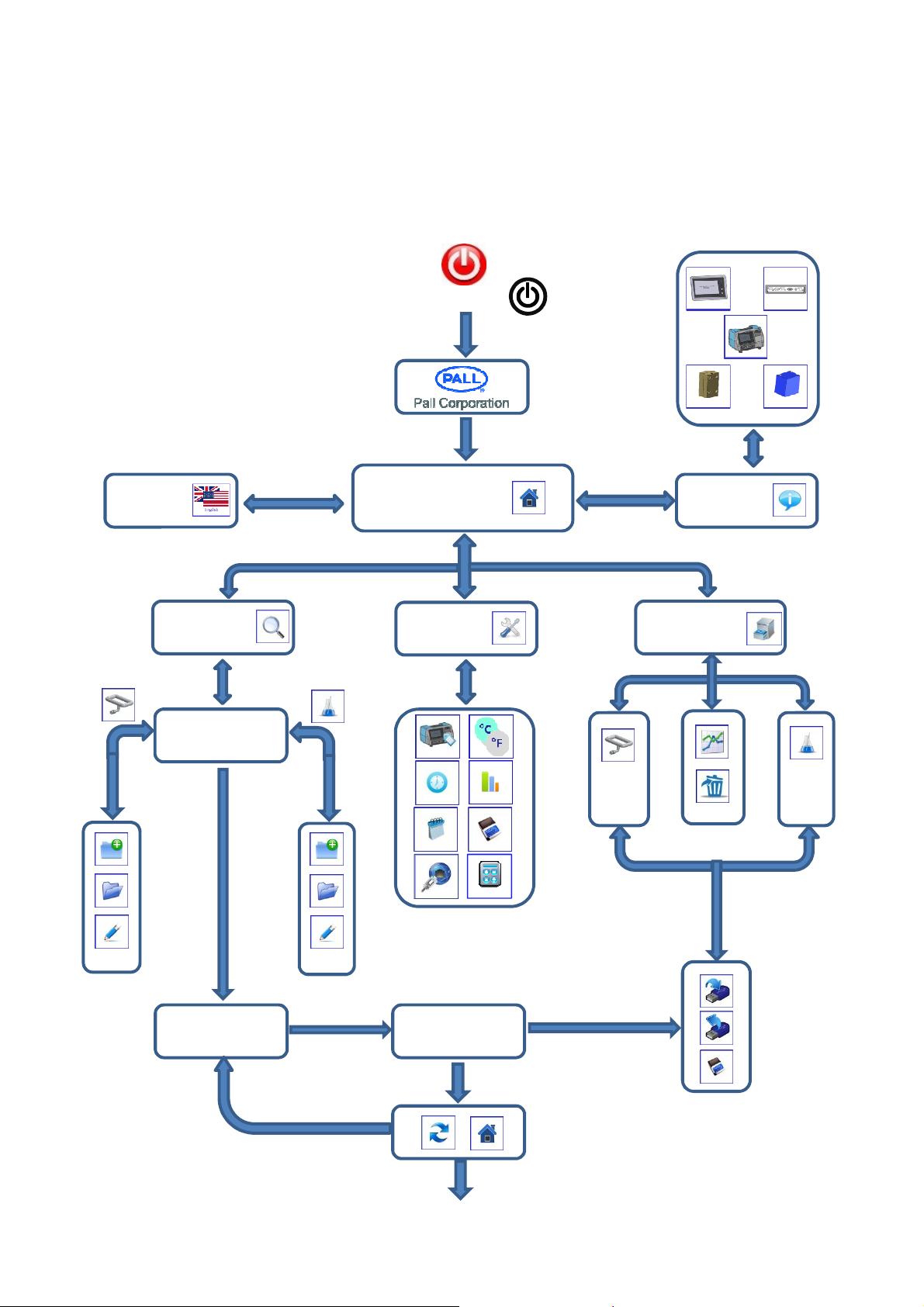

6.4 Display Flow Chart

The display flow chart can be used to help the new user become familiar with the PCM500

display operating sequence. The flow chart consists of a number of views using the

previous Icon listing to indicate their access within the screens.

START

Language

Current setup

Testing

MAIN MENU

Tools

Information

Data Manager

Test

Result

19

MAIN MENU

Page 20

6.5 Example Screen

The screen below is an example of those

that will be seen when using the PCM500.

An explanation of common keys is

incorporated here to prevent repetition.

The screens are structured into four main

groups; Testing, Tools, Data Manager and

Information. The home key will always return

the user to the main menu. There is a flag

icon that denotes the language setting. Use

this active icon to change language setting.

An example screen shot of the PCM500 main

menu:

If the PCM500 is out of calibration, requires

an annual service or other intervention a

warning screen will inform the user at startup. This is to ensure the user keeps the

PCM500 fully serviced and helps ensure the

integrity of the high-pressure part of the

instrument.

Calibration Expired

Mesh Test Limit Exceeded

Press the contact button to open a contact

details screen or proceed to home (Main

Menu).

PCM500W – SERIAL No. 2345

MESH TEST REMAINING: 1234

CALIBRATION DUE: 2016/10/24

CUSTOMER OR UNIT IDENTITY HERE

6.6 Start-up Sequence

Press and release the power on/off button

on the front panel. This will power-up the

PCM500 monitor and the green LED light will

flash for several seconds. Whilst the unit

powers up, the display will activate and the

following screens appear:

Splash screen

PALL CORPORATION

WWW.PALL.COM

Support / Contact Pall

Contact screen for technical support

In the event of a major fault the next screen

will appear and the PCM must be closed

down and the problem reported to your local

distributor or Pall Corporation.

HARDWARE FAULT

REFER TO MANUAL

20

Page 21

Main Menu Screen

PCM500W – SERIAL No. 2345

MESH TEST REMAINING: 1234

CALIBRATION DUE: 2016/10/24

CUSTOMER OR UNIT IDENTITY HERE

The main menu includes PCM500 serial

number, mesh test detail, calibration date,

and customer or unit identity if installed.

To the right hand side are buttons to access

menus for testing, tools, data manager and

information,.

6.7 Sampling

Sample can be on-line, from a reservoir, or

bottled oil sources. Refer to sections 1

‘Specifications and section 5.1 ‘Connection

Options’.

On Line or Tank Sampling Routine

From the main menu

press the test button

The user will be presented with a Test

Configuration screen. If the parameters are

correct then advance to the next screen

using the right arrow button. To edit or

change the setup select one of the top three

left hand buttons.

The time and date and a 5-stage battery

indicator is in the lower right corner.

To the bottom left is a button icon indicating

the languages that are available. Press to

select a different language.

Language select screen

Languages are installed for the following

countries.

• Denmark

• Finland

• Norway

• Sweden

• Netherlands

• Poland

• Portugal / Brazil

• Italy

• Germany

• France

• Spain

• USA / UK

Test Point screen:

TEST POINT NAME

FLUID NAME

TEST LABEL

Final Check Screen:

TEST POINT NAME

FLUID NAME

TEST LABEL

START

Check the parameters are correct then Start

test using RIGHT arrow button.

21

Page 22

Warm Up Screen example.

A single test result screen

If the sample fluid temperature is below the

value set in Test Point, the PCM will enter a

warm-up cycle which pumps fluid

continuously until the temperature measured

in the PCM circuit is at the target

temperature.

TEST POINT NAME

TEST 1 OF 3

WARM UP

24°C TARGET 45°C

WATER IN OIL 50%rh

Important: The PCM can

tolerate up to a 1°C per

!

minute change in sample

temperature during a

measurement cycle. It is

important, therefore, to stabilise PCM

temperature close to the system temperature

for measurement accuracy.

Once into the test measurement a progress

screen provides real-time test data. The test

can be cancelled at any time through the

Cancel button icon.

RESULT

TEST NAME: NEW OIL

TEST POINT: LUBE RESERVOIR

FLUID: 32 GRADE

CODE: ISO4406 21/18/14

WATER IN OIL 50%rh

TEMPERATURE: START 25°C END 26°C

TIME & DATE: 12:15 2015/10/24

WARNINGS:

NONE

Screen for multiple test results.

UP and DOWN buttons allow access to all

test results in the sequence. The results are

automatically saved to memory and can also

be viewed through the Data Manager

screens.

The options from the result screens above

are to transfer on USB; Print; Repeat the test

sequence or return to the Home screen.

RESULT 3 of 3

TEST NAME: NEW OIL

TEST POINT: LUBE RESERVOIR

FLUID: 32 GRADE

CODE: ISO4406 21/18/14

WATER IN OIL 50%rh

TEMPERATURE: START 26°C END 27°C

TIME & DATE: 12:30 2015/10/24

WARNINGS: NONE

The first measurement in the test cycle is

14µm particulate followed by the 6µm.

Temperature and Water-in-Oil (PCM500W)

data is provided and also details of the

previous result code, if a multiple test

sequence is running.

TEST POINT NAME

TEST 2 OF 3

6µm SAMPLING

24°C (MINIMUM IS 15°C)

WATER IN OIL 50%rh

LAST

TEST:

WARNINGS: NONE

Should any test parameters be exceeded

during a test a ‘Warnings Present’ label will

be shown at the bottom of the screen. These

will be recorded in the final test result detail

screen.

Transfer via USB will be to a Flash Drive /

Memory Stick connected to a USB-A port on

the COM port panel. Press the Tick button to

upload and a progress bar indicates the rate

of transfer. Press the Return button to go

back to the results screen.

Upload to Flash Drive?

22

Page 23

Print results screen

New Test point set-up

This follows the same control method as

USB transfer but there is an option to print

one or all results if multiple tests are

available. If one is selected then it will be that

currently open on the result screen.

3 RESULTS

PRINT ONE OR ALL

PRINTING RESULT 3 OF 3

6.8 Test Point & Fluid Setup

If a new Test Point or Fluid is to be created

for loading into the test setup or the current

settings require editing, this is done through

the Test Setup screens,

TEST POINT NAME

NEW TEST POINT

TEST POINT NAME = RESERVOIR

NUMBER OF TESTS = 3

MINIMUM TEMPERATURE (°C) = 10

CODE ALARM (ISO) = 18 / 16 / 13

TEMPERATURE ALARM (°C) = 70

WATER-IN-OIL ALARM (%rh) = 60

Use UP and DOWN arrows to select a

parameter and press EDIT for the following

action:

• Test Point name switches to qwerty

keyboard screen

• Number of tests, minimum temperature

and trigger time switches to calculator

screen

• Code alarm screen is determined by the

code format selected (Tools Screens)

• Temperature and water-in-oil alarm points

are edited on the calculator screen.

• Save the setup using the tick button.

• To return to test setup screen or, cancel

editing without saving use the Return

button.

FLUID NAME

TEST LABEL

For example, if either the Test Point or Fluid

buttons are pressed it activates a set of

options to the right of the screen. Using the

Test Label button will open the QWERTY

keyboard.

Edit key to change values in

Test Point and Fluid setup

Create New for Test Point or

Fluid

Open an existing Test Point or

Fluid setup

Important: The trigger period

!

The minimum set time is 7 minutes, which

includes the maximum allowable test period

and a 1 minute delay. e.g. Trigger time=7

min. test time=6 min. time from end

of test to the beginning of the next test = 1

min

If a test is started by external control, such as

from a PLC, then the trigger period can

remain at 0 minutes.

!

The PCM500W monitor must not be used

with water bearing fluids. The PCM500 does

not incorporate a water sensor

begins at the start of one test

to the beginning of the next.

Important: The water content

alarm is applicable to the

PCM500W monitor only.

23

Page 24

If a Test Point with the same name already

exists a warning screen will appear to

overwrite the old setup.

NEW TEST POINT

TEST POINT ALREADY

CREATED

REPLACE WITH NEW

SETTINGS?

Fluid setup screen

accessed through the Fluid

button.

• Select Fluid name to edit through the

QWERTY keyboard (enter/edit the name}.

• For PCM500W a water-in-oil entry is active

and toggles between %rh and PPM on the

press of the Edit button. If PPM is selected

then four absolute water constants appear for

editing. C1, C2, C3 and C4 are updated

using values supplied by Pall Corporation,

contact Pall for availability.

• Save the setup through the tick button and

use the Return button to go back to the Test

Point screen.

QWERTY Keybaord

Number Entry screen

Load a stored Test Point

From the OPEN button in Test point, select a

stored Test Point and make current by

pressing the TICK button.

NEW FLUID

FLUID NAME

%rh OR PPM

C1 CONSTANT (PPM)

C2 CONSTANT (PPM)

C3 CONSTANT (PPM)

C4 CONSTANT (PPM)

TEST POINTS

TEST POINT A

TEST POINT B

TEST POINT C

TEST POINT D

TEST POINT E

TEST POINT F

Load a stored Fluid

From the OPEN button in Fluids, select a

stored Fluid and make current by pressing

the TICK button.

24

Page 25

FLUIDS

FLUID A

FLUID B

FLUID C

FLUID D

FLUID E

FLUID F

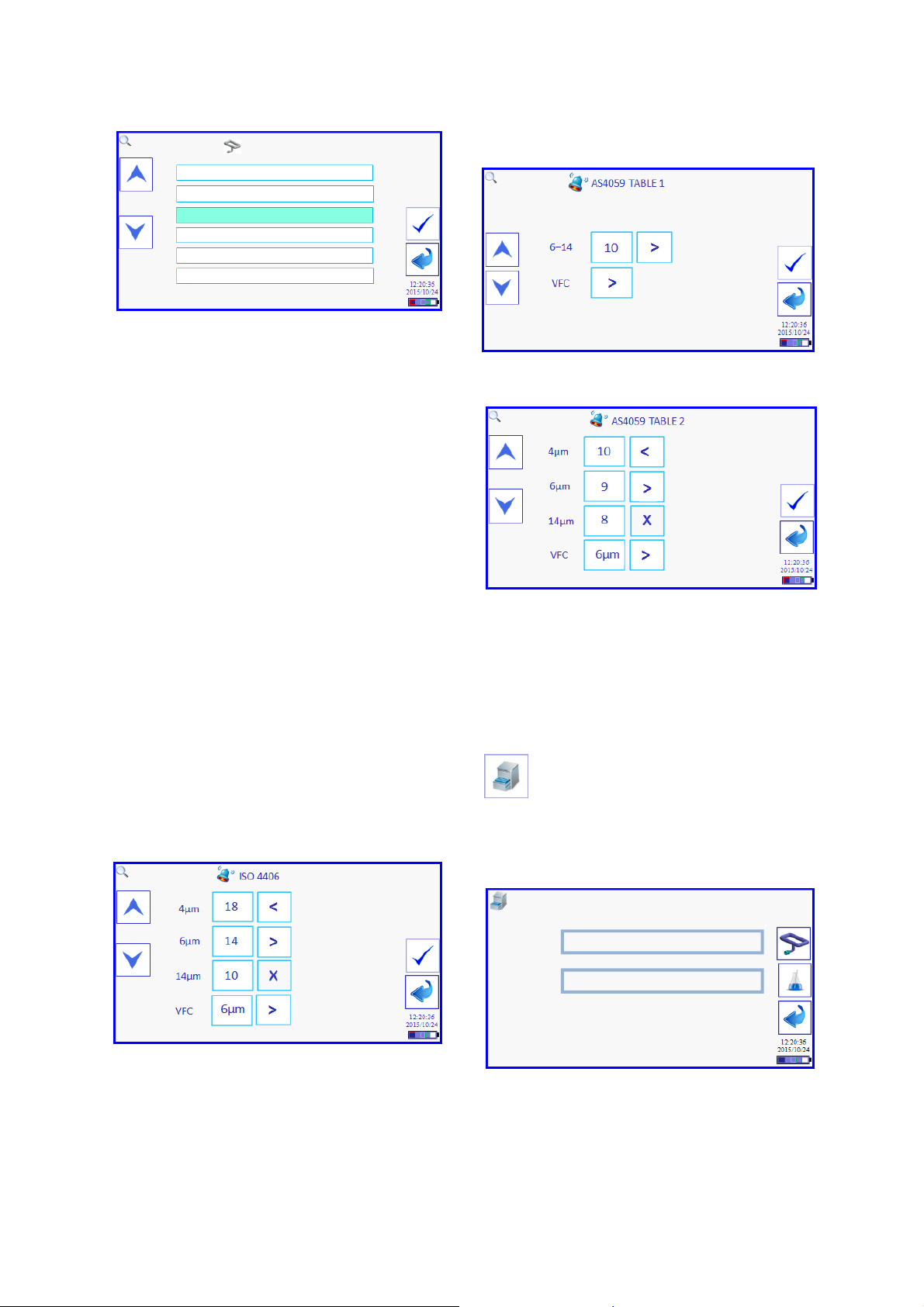

6.9 Code Alarm Setup

AS4059 Table 1

Each Test Point is allocated an alarm point

setup for the three coding standards and

whether a two or three-part code is selected.

The default alarms are set to maximum code

numbers and the user can adjust the code

alarms to their required limits.

If a different code standard is selected the

alarm points change to that standard also.

The VFC (Voltage Free Contact) is a two pin

socket on the PCM communication panel

(see section 4.4). A signal can be taken on

an alarm state to control the switching in or

out of a filtering system for example. In the

example below, the alarm is set to trigger if

6µm is greater than ISO 14 code. This could

signal the start of system filtration pumps.

To change a code number, touch to highlight

and use the UP and DOWN arrows.

To change an alarm action the options are <,

> and X (not applicable).

Example: ISO4406

AS4059 Table 2

6.10 Data Manager Screens

Any results saved on the PCM500 can be

viewed and managed using the data

manager. To get to the data manager press

the data manager button in the main menu.

The data manager displays the

current Test Point and Fluid.

Press the Test Point button to access data.

DATA MANAGER

TEST POINT B

RUST VETO NTP32

A list of all Test Points is now available to

Graph, Transfer or Delete.

25

Page 26

TEST POINTS

TEST POINT A

TEST POINT B

TEST POINT C

TEST POINT D

TEST POINT E

TEST POINT F

This button will graph all

results under a selected Test Point using the

current Code Format

Opening an individual Test

Point lists all tests under that

name. Single or All Test

Labels can be loaded to USB Flash Drive or

printed

TEST POINT B LABELS

RESERVOIR FILTER-IN

RESERVOIR FILTER-OUT

NEW OIL

NO LABEL (DEFAULT)

SAMPLE 2015-10-02

TEST RIG

TEST POINT B

TESTS

Flash Drive button will give a choice

of uploading or downloading Test

Point data

TEST POINTS

TEST POINT A

TEST POINT B

TEST POINT C

TEST POINT D

TEST POINT E

TEST POINT F

Upload to Flash Drive screen allows

individual or All Test Points for

selection.

Open an individual Test Label to view

individual tests. Then open and view the

result in detail

NEW OIL

DATE

TIME

RESULT

Individual Test detail can be uploaded to

Flash Drive or Printed. A flag to the side of a

test indicates a warning is attached

NAME: NEW OIL

TEST POINT: B

FLUID: MINERAL OIL

CODE: ISO4406 16/13/10

WIO (%rh): 50

TEMP (°C): START 25 END 26

DATE & TIME: 2015-10-25 14:15HRS

WARNING:

203 LOW BATTERY

RESULT

SELECT TEST POINT

TEST POINT A

TEST POINT B

TEST POINT C

TEST POINT D

TEST POINT E

TEST POINT F

26

Page 27

Deleting

Throughout the data management screens

there are several that include the delete

option. This includes Points; Names; Tests

and Fluids. To enable this action a password

must be entered. The default password

issued is DEL1 but this can be changed by

the user in the TOOLS screen.

Example:

On pressing the DELETE button under the

Test Label screen the screen header

changes. The user may now select Label(s)

by pressing the DELETE button and these

remain highlighted. When the selection is

complete the TICK button is pressed to go to

a password screen.

SELECT TO DELETE

RESERVOIR FILTER-IN

RESERVOIR FILTER-OUT

NEW OIL

NO LABEL (DEFAULT)

SAMPLE 2015-10-02

TEST RIG

The password is entered and TICK button

pressed

DELETE SELECTION?

DELETE FLUID OR TEST OR NAME OR POINT

6.11 Tools

• PCM Label (Edited through the QWERTY

screen)

• Code Format

• Remote Assistance

• Printer Test

• Calculator

• Temperature (Press to toggle between

Fahrenheit and Celsius)

• Date

• Time

This next screen is a last chance before the

data is removed. Pressing the TICK button

removes the selected data. To abort this

action the back arrow or Home button is

pressed.

PCM Label

This is entered through the

QWERTY keyboard and can be up

to 40 characters in length

UNIT IDENTIFIER IF REQUIRED

27

Page 28

Code Format

There are several options for Code format

within the three standards provided.

• ISO 4406 -/6µ/14µ (2-part)

• ISO 4406 4µ/6µ/14µ (3-part)

• AS4059 Revision F Table 1

• AS4059 Revision F Table 2 Size 6, and 14

• AS4059 Revision F Table 2 , Size 4, 6, &

14

Temperature

Temperature reporting is changed by simply

pressing the button to switch between

Fahrenheit and Celsius

Remote Assistance

Time

Time is set to a 24 hour clock and can also

be synchronised to a network clock using the

network clock button. The PCM must be

connected and logged on to a network first.

In manual mode use the left and right buttons

to select hours or minutes

Date

In the course of PCM operation a situation

may arise that requires the intervention of a

PCM Engineer to investigate operational

issues. The Engineer screen provides such

access. Pressing the Remote Assist button

opens a code input screen, in which, the user

enters an access code provided by the

remote Engineer.

Each PCM has its own IP address and to

enable remote access the PCM is connected

to the Internet through a Network or modem

on the Ethernet connection to allow a remote

Engineer to analyse diagnostic data.

REMOTE ASSIST PASSWORD

The date is set using the same screen

functions as in Time setting. Note: - date is

in the international standard format to ISO

8601

Press the Tick button to allow a remote

connection.

REMOTE ASSISTANCE

PCM IP ADDRESS

CO

DE

28

Page 29

Printer Test

To test a Bluetooth or USB connection

between PCM500 and Printer press the

Printer button. A progress screen will open to

show the two connection options. Press the

option required and a corresponding

progress bar indicates the communication

attempt between PCM and Printer. If a

connection is made the Printer will print a

‘Printer Detected’’ message.

TEST

Page 30

Section 7: Pall PCM500 Series Fluid

Cleanliness Monitors

Interface Protocol for PLC control using

DB9 Serial Port.

1. Hardware details

The RS232 settings are: 9600, 8, N, 1

Pin 2 TxD (Transmit Data)

Pin 3 RxD (Receive Data)

Pin 5 GnD (Ground)

Pin 2 and 3 must be crossed over when

using a PC.

C – PCM500 status:

0: The unit is in standby.

1: The unit has ended a test and it is

waiting to start a new test at the set time

interval.

2: The unit is currently performing a test.

D,E,F,G – Latest error codes if any. See

below for details.

[L] – Request last result

The latest valid result is transmitted via DB9

communications port. An example data string

appears like this:

2. Protocol between PCM500 and PLC (or

computer)

The commands available to the PLC or a

computer start and end with a square bracket

as follows:

[P] – “Ping” the unit to see the current status.

[L] – Request last result.

[S] – Start a test.

[A] – Abort a test.

Please note that the command letters are in

UPPER CASE; it will not work with

commands in lower case.

[P] – Ping

The purpose of this command is to verify the

PCM500’s current status.

When [P] is sent, the PCM500 responds with

a comma-separated string, terminated by a

carriage return and a new line.

e.g.

PCM,P,0,00,00,00,00

PCM

P 0 00 00 00 00

A B C D E F G

Where:

A - Label to identify that it is a valid

transmission from the PCM500

B - The P signifies that the transmission

doesn’t contain a result.

PCM, R, 2005/11/20 20:28:00, 1,2,00,00,

00,00,AST1: 11,50,22,10,Test1, 39648

PCM R 2005/11/20 20:28:00 1 2 000

A B C D E F G

0000AST1: 11 502210TEST1 39648

H I J K L M N O

Where:

A. Label sent by the PCM to signify start of

transmission.

B. The transmitted string is a result.

R=Result, A=Aborted test, P=Ping.

C. Date and time the test was performed.

D. Test number in the sequence.

E. Number of tests in the sequence.

F. Error codes (Hex) Byte 1. Hardware

problems. (see below).

G. Error codes (Hex) Byte 2. Sampling

problems. (see below).

H. Error codes (Hex) Byte 3. Sampling

problems. (see below).

I. Error codes (Hex) Byte 4. User defined

settings exceeded. (see below).

J. Result codes as selected on the unit (ISO,

AST1: (AS4059 Table1), or AST2:

(AS4059 Table2).

K. Viscosity.

L. Temperature.

M. Water In Oil (%SAT or PPM).

N. Test Label

O. Checksum.

30

0

Page 31

PCM500 Error codes

The codes are in hexadecimal format.

Byte Code Description

1 0x01 Very low battery

1 0x02 High pulse width

modulation

1 0x04 Viscometer

blocked

1 0x08 Low mesh

differential pressure

1 0x10 Pressure transmitter failure

1 0x20 Temp transducer failure

1 0x40 Internal controller failure

1 0x80 Internal error

2 0x01 Low battery

2 0x02 High line pressure

2 0x04 Low line pressure

2 0x08 Unstable temperature

2 0x10 Unstable viscosity

2 0x20 Unstable sampling

2 0x40 High mesh differential

pressure

2 0x80 Water in oil sensor failure

3 0x01 Water in oil

3 0x02 Memory full

3 0x04 6-micron mesh blocking

3 0x08 14-micron mesh blocking

3 0x10 Mesh test limit exceeded

3 0x20 Calibration period exceeded

3 0x40 Viscosity band mismatch

3 0x80 High viscosity differential

pressure

4 0x01 Solid contamination alarm

4 0x02 Water content alarm

4 0x04 Temperature alarm

4 0x08 Too much contaminant

4 0x10 Test aborted

4 0x20 Test sequence aborted

4 0x40 RESERVED

4 0x80 RESERVED

[S] – Starts a Test

The PCM500 is currently running a test:

the command is ignored.

The PCM500 is in standby: the test series

is initiated, with the maximum number of

tests as previously entered from the display.

The PCM500 is waiting between tests: a

test is initiated and the scheduled test is then

started at the appropriate time. The total

number of tests is decremented by one.

Once a test is started the results will be sent

to the PLC on completion of the test.

[A] – Abort test.

By sending [A], the entire test sequence is

aborted and the result string would appear

like this:

PCM, A, 2005/11/23

15:46:00,1,2,00,00,00,20,58695

The second string item is set to A (aborted),

and error Byte number 4 contains the “Test

sequence aborted” message (0x20). The

code field is NOT present.

Another example data-string is included

here following an aborted test due to the

PCM500 fluid return-line being dead-ended:

PCM, A, 2005/11/23 16:15:00,0,2,04,

02,30,20,51384

Byte1 = 04: Viscometer blocked

Byte2 = 02: High line pressure

Byte3 = 30: (10+20) Mesh test limit exceeded

(10) and Calibration period exceeded (20)

Byte4 = 20: Aborted test sequence.

(Byte3 has been artificially generated for the

benefit of the example.)

If the last test was requested then it would be

a result with the latest valid code.

PCM, R, 2005/11/23

10:22:00,2,2,00,00,00,00,AST1: 11,10323

The exact effect of this command depends

on the status of the PCM500 unit.

If a ping were issued it would include the

latest error codes.

PCM, P, 0,04,02,30,20

31

Page 32

3. Modes of Operation

a). – Test timing set on the PCM500

In the PCM500 Test Point setup, enter the

number of tests to be performed in a testcycle and also include any delay between

individual tests. A test sequence can then be

started from the PCM500 or from the PLC.

If an additional test is required, whilst in a

test-cycle delay period, then the PLC can

initiate this, without compromising the

existing delay in the test-cycle setting.

Please be aware, the delay period entered

will start from the beginning of a test.

b). – Test timing set by the PLC

In the PCM500 Test Point setup, enter the

number of tests to 1 (one) and enable the

PLC to start a test at the appropriate time.

.

32

Page 33

Section 8: Pall PCM500 and PCM500W

Fluid Cleanliness Monitors

Fluid Change Procedure

Important: Mixing of

incompatible fluids with Rust

!

meshes. One example is Mono Ethylene

Glycol (MEG).

Veto is likely to create gels

and block the PCM500

Important: The PCM500W

should not be used on waterbased fluids.

!

should be modified so as to reduce the

requirement for fluid changes. e.g. monitor

mineral oil during a 4 week period, followed

by 4 weeks monitoring water based fluids

Wet to dry Oil or vice versa:

If fluid changes are regular,

the monitoring programme

Contact Pall if there is doubt over the

compatibility of test sample and Rust Veto

transit fluid.

When Changing from mineral oil to water

based fluids or vice versa, a strict fluid

changeover procedure must be adhered

too.

The changeover fluid is “Rust veto NTP 32”,

which is miscible with both aqueous liquids

and oils. All changeover and flushing fluid

should be drained into a suitable waste

container and disposed of in accordance with

local Health and Safety legislation.

Mineral oil to water based fluids:

❶ Run a single test to waste using clean

Rust Veto NTP32 to flush out the mineral oil.

❷ Run a test to waste using the water based

fluid. Repeat testing until there are no traces

of Rust Veto NTP32 in the return line.

❶❶❶❶ When using PCM500W, stabilization

times can affect the water sensor accuracy

when sampling fluids of vastly differing water

content in short succession. The related

precautions, recommended guidelines and

test data related to this subject can be

located in appendix D of this operating

manual.

Important: The PCM500W

should never be used in

applications whose water

!

content is known to be at or

above 100% saturation.

Water based fluids to mineral oil:

❶ Run a single test to waste using clean

Rust Veto NTP32 to flush out the waterbased fluid.

❷ Run a test to waste using the mineral oil

sample. Repeat testing until there are no

traces of Rust Veto NTP32 in the return line.

33

Page 34

Section 9: Pall PCM500 and PCM500W

indicating high line pressure.

Ensure return hose is not

indicating low line pressure.

Remove, clean or replace

system sampled. Fluid

sample dilution/mixing.

Ensure system return line

Fluid Cleanliness Monitors

Function Codes, Possible Cause(s)

and Corrective Actions

Function codes either are flags only to indicate to the user an awareness of a borderline test

situation or curtail the test. An alarm will indicate registered function codes that can be

cancelled by pressing any key. A message will appear indicating the problem to the user.

Function codes generally occur during the warm up cycle first and while testing. There are

several different function messages incorporated into the PCM500.

Below is a list of these messages, possible causes and corrective actions.

Function

Code

201 Low Battery

101

202

203

102

204

205

206

PCM500

Condition

Very

Low Battery

High Line

Pressure

Low line

pressure

High Pulse

Width

Modulation

Unstable

temperature

Unstable

viscosity

Unstable

sampling

PCM500 Status Possible Cause Corrective Action

Unit gives warning of low

battery charge level at the

end of the test.

Unit gives warning of a very

low battery charge level at

the end of the test.

Unit halts the test and puts

error message on screen

Red L.E.D. on HMI panel

flashing on detection.

Unit halts the test and puts

error message on screen

Red L.E.D. on HMI panel

flashing on detection.

Unit halts the test and puts

error message on screen.

Red L.E.D. on HMI panel

flashing on detection.

Unit halts test and displays

error message on screen.

Red L.E.D. on HMI panel

flashing on detection.

Unit halts test and displays

error message on screen.

Red L.E.D. on HMI panel

flashing on detection.

Unit halts test and displays

error message on screen.

Red L.E.D. on HMI panel

flashing on detection.

Low voltage level

detected from internal

battery

Extra low battery level

detected

Blockage in hydraulic

circuit.

Fluid viscosity too

high. Pressure

transducer failure

No fluid. Last Chance

Filter (LCF) blocked.

Pump Malfunction.

Pressure transducer

failure.

Fluid viscosity too

high. Motor current

over set limit. Pump

malfunction.

Change >1deg /

minute. High oil

temperature. Low

temperature.

Fluid dilution. Large

temperature gradient

across PCM500

Aeration problem.

Pressure spikes in

See Unstable

viscosity.

Connect Power Supply

Unit (PSU) to a mains

power supply

Connect Power Supply

Unit (PSU) to a mains

power supply

Decrease fluid viscosity.

Contact Pall.

Check fluid supply and

inlet hose connection.

Pressure Relief Valve

Contact Pall.

Decrease fluid viscosity.

Contact Pall or an

approved agent

Operate Warm-up Cycle

refer to section 6.10.

Allow system fluid

temperature to stabilise

Operate Warm-up Cycle

refer to section 6.10.

Allow system fluid

temperature to stabilise

Ensure inlet hose is in

contact with system fluid.

is full of fluid.

blocked.

LCF.

34

Page 35

Section 9: Pall PCM500 and PCM500W

held programmer, refer to

and/or line pressure to

test and report error/warning

Warning message on screen.

received from pressure

(WIO) sensor

Fluid Cleanliness Monitors (continued)

Function Codes, Possible Cause(s)

and Corrective Actions

Function

Code

301 Water in Oil

302 Memory Full

103

207

104

PCM500

Condition

Viscometer

blocked

High mesh

differential

pressure

Low mesh

differential

pressure

PCM500 Status Possible Cause Corrective Action

Unit completes test.

Warning displayed on

screen.

Memory Full message will

appear on screen at start-up

and when test store

attempted.

PCM500 will abort current

test and display warning

message.

Red L.E.D. on HMI panel

flashing on detection.

PCM500 will abort current

message on the display

screen.

Red L.E.D. on HMI panel

flashing on detection.

PCM500 will abort current

test/cycle and report

error/warning message on

the display screen.

Red L.E.D. on HMI panel

flashing on detection.

Outside set limit

Internal store for test

data full

Viscometer orifice

blocked/blocking with

contaminant causing

differential viscosity

exceed operational

limits.

Mesh element

currently in the flow is

blocked/blocking with

contaminant causing

differential mesh

pressure to exceed

operational limits

Differential pressure

across mesh element

is below set limit.

Probable cause; hole

in the mesh, incorrect

direction of flow,

pressure transducer

failure.

Incorrect or no signal

Information only.

Upload test data to hand

Flush by testing with

clean, low viscosity oil.

Contact Pall or an

approved agent.

Flush by testing with

clean, low viscosity oil.

Contact Pall or an

approved agent

Contact Pall or an

approved agent

section 6.9

105

208

106

transducer

Water in Oil

(if applicable)

Temperature

transducer

Pressure

failure

failure

failure.

PCM500 will abort test.

Red L.E.D. remains ON

PCM500W will display

error/warning on successive

tests.

.

PCM500 will abort test.

Warning message on screen.

Red L.E.D. will remain ON

transducer during

calibration /

background check.

Incorrect output from

the sensor.

Incorrect output from

the transducer.

Contact Pall or an

approved agent

Contact Pall or an

approved agent

Contact Pall or an

approved agent

35

Page 36

Section 9: Pall PCM500 and PCM500W

specification, low fluid

Unit inoperative. Hold in this

Fluid Cleanliness Monitors (continued)

Function Codes, Possible Cause(s)

and Corrective Actions

Function

Code

107

303

304

305

306

308

PCM500

Condition

Internal

peripheral

micro-

controller

failure.

6-micron

mesh

blocking

14-micron

mesh

blocking

Mesh test

limit

exceeded

Calibration

period

exceeded

High

viscosity

differential

pressure

PCM500 Status Possible Cause Corrective Action

Error/warning message on

screen (if possible). Alarm

set. Hold in this state. Red

L.E.D. will remain ON..

PCM500 will abort current

test and display warning

message on screen. Red

L.E.D. flashing.

PCM500 will abort current

test and display warning

message on screen. Red

L.E.D. activated

Display warning message

on screen at PCM500 start-

up or at the end of current

test operation

Display warning message

on screen at PCM500 start-

up

Unit halts test and displays

error message on screen.

Red L.E.D. on HMI panel

flashing on detection.

No communication

with main controller.

Limits of ratio

between dP and dV

taken at the cycle

start have been

exceeded

Limits of ratio

between dP and dV

taken at the cycle

start have been

exceeded

Tests performed on

the same mesh set

above set limit.

12 month calibration

interval expired

Fluid viscosity out of

temperature

Contact Pall or an

approved agent

Flush by testing with

clean, low viscosity oil

Flush by testing with

clean, low viscosity oil

Contact Pall or an

approved agent for

service details

Contact Pall or an

approved agent for

service details

Reduce fluid viscosity.

Increase fluid

temperature at PCM500

state. Red L.E.D. will

108 Internal error

??? Comms error Ethernet

??? Comms error USB

remain ON..

Warning message on

display.

Possible hardware

failure

Contact Pall or an

approved agent

36

Page 37

Section 9: Pall PCM500 and PCM500W

conditions, stop button

Display warning message on

Display warning message on

Display warning message on

Fluid Cleanliness Monitors (continued)

Function Codes, Possible Cause(s)

and Corrective Actions

Function

Code

401

402

403

404

405 Test aborted

406

PCM500

Condition

Solid

Contaminatio

n Alarm

Water

Saturation

Alarm

High fluid

Temperature

Alarm

Contaminatio

n Too High

Test

sequence

aborted

PCM500 Status Possible Cause Corrective Action

screen. VFC relay activated.

screen. Red L.E.D. flashing

screen. Red L.E.D. flashing

Unit halts test and displays

error message on screen.

Red L.E.D. on HMI panel

flashing on detection.

Unit halts test and displays

warning message on screen.

Unit halts test sequence and

displays warning message

on screen.

Pre-set Solid

contamination level

exceeded

Pre-set Fluid water

saturation level

exceeded

Pre-set Fluid

temperature level

exceeded

Maximum Solid

contamination level

exceeded

Test aborted due to

one of the other

warning conditions,

remote message

received from COM

port, or glitch

generated in program

during debug file

creation

Test sequence

aborted due to one of

the other warning

pressed on control

panel, key pressed on

display or received an

abort test command

from PLC.

Repeat test to verify.

Investigate process.

Investigate cause of

elevated water contents

Investigate process,

reduce operating

Investigate process.

Dilute the sample with

Repeat test if possible.

Repeat test if possible.

NOTE: Refer to section 6 to review and / or amend your selected alarm levels

temperature

clean fluid

Coding:- 100 High priority warning

200 Medium priority warning

300 Low priority warning

400 User defined alarm

37

Page 38

Section 10: Pall PCM500 and PCM500W

Fluid Cleanliness Monitors

Spare Parts List

Part Number Description

PCM500.211 Power Supply Unit

PCM200.235A Mains Cable UK

PCM200.235B Mains Cable Europe

PCM200.235C Mains Cable USA

PCM200.235D Mains Cable Australasia

PCM200.235E Mains Cable Japan

PCM500.213ASS Battery Pack

PCM200.239 RS232 Communication Cable

PCM200.121 Last Chance Filter Element

PCM200.122 High Pressure Hose Assembly

PCM200.197 Low pressure Sampling Stalk

PCM200.154A Metric Test Point Connector

PCM200.154B Imperial Test Point Connector

PCM200.154C NPT Test Point Connector

500.470A

500.470B

PCM500.520A Printer Kit - UK

PCM500.520B Printer Kit - EUROPE

PCM500.520C Printer Kit - USA

PCM500.520D Printer Kit - AUSTRALASIA

PCM500.520E Printer Kit - JAPAN

PCM200.324 Printer Paper Roll (Pk.10)

PCM210.480 USB Cable

PCM500.600 Transit Case

PCM500.500 Replacement Mesh Manifold

Operating Instructions -

PCM500 CD ROM

Operating Instructions

PCM500 Quick Reference Card

38

Page 39

Section 11: Pall PCM500 and

PCM500W Fluid Cleanliness Monitors

Cleaning and Decontamination

As a matter of protection to the PCM

enclosure and safety to the user it is advised

to clean any fluid spills with suitable cleaning

materials and dispose of these safely.

Chemicals that may be harmful to the ABS

material itself should be removed

immediately.

Maintenance

Check the condition of the high-pressure

hose (PCM200.122) for signs of external

damage. This should be done before each

analysis session. If in doubt, contact your

Pall distributor or the manufacturer for advice

on a replacement part. Replacement is

carried out by a Pall service centre, where a

new hose installation is validated for

maximum operating pressure prior to

release.

Disposal of Equipment

At the end of its life, the monitor should be

dismantled and disposed of in accordance

with all applicable local waste disposal laws

and bylaws. Where facilities exist,

component parts of the unit may be recycled.

Details of the materials of construction are

given on the product installation drawing and

if required, more detailed information

regarding specific items may be obtained

from Pall or an approved agent.

If component parts of the equipment were

previously contaminated with the service

fluid, an appropriate Manufacturer’s Safety

Data Sheet (MSDS) for the fluid should be

obtained and read to ensure that

contaminated component parts are disposed

of safely.

The Last Chance Filter element is a user

serviceable part and can be accessed by

releasing the housing end plug. The element

is removed by inserting an M5 thread bolt

into the end cap and is then retracted.

Ensure no external contaminant enters the

housing before a new element is fitted.

39

Page 40

Appendix A: Pall PCM500 and

PCM500W Fluid Cleanliness Monitors

Calibration and

After Market Services

Calibration and Aftermarket Service

Pall PCM500 series fluid cleanliness

monitors are designed to provide trouble free

operation for many years. However, as for all

condition monitoring equipment, optimal

performance can only be achieved through

regular routine maintenance. To ensure your

PCM500 receives the maintenance

necessary, Pall provides a maintenance

package designed to increase the overall

effectiveness of the monitor. Pall

recommends returning the PCM monitor for

Service and Calibration annually. Mesh

replacement should be carried out when the

test limit is exceeded. The limit is variable

from 1000 to 3000 tests depending on fluid

sample cleanliness and viscosity.

Important: Pall recommends

returning the PCM monitor for

!

should be carried out when 3000 usage

points is exceeded.

Service and Calibration

annually. Mesh replacement

The annual service includes;

• Analysis of engineers diagnostic report

and rectification of any faults found

• Battery, Power supply and clock check

• Performance evaluation on calibration

fluid

• Software update to latest release level

• Check for oil leaks and rectification as

necessary

• Check condition of Last chance filter

• Low-pressure hose replacement

• Safety check of High-pressure hose.

Replaced at two year interval.

• Flush, strip and clean internal hydraulic

components

• Pressure Reduction Valve Assembly

check and reset

• Replace 6µm and 14µm meshes, O-ring

seals and flush housings

• Transducer calibrations

• Perform production validation procedures

• Software menu checks

• Return carriage to customer

Any additional work required is subject to

a separate written quotation.

Please contact Pall Aftermarket Division

or its approved agent for additional

information.

40

Page 41

Appendix B: PCM500.500 Mesh

Manifold Exchange Procedure

This procedure must be carried out in a clean

environment and great care taken to avoid

extraneous contamination entering the

PCM500. The mesh manifold should be

replaced once 3000 points are accrued and

to continue testing will produce a warning on

screen and recorded as error code 305 on a

test result until the mesh manifold is

replaced.

Every completed test is allocated points

between 1 and 3 depending on the severity

of fluid condition. As example, a low

contaminant, low viscosity sample will be

given 1 point, whereas a dirt laden, high

viscosity sample will be given 3 points. This

is to ensure the integrity of the mesh will

remain constant throughout the available

usage. It can be seen, therefore, that the

available tests range from 1000 to 3000

depending on sample condition.

1. Use an M5 socket driver to remove four

M5 Flange securing nuts.

2. Carefully remove the mesh manifold by

pulling on the outer body and place in

protective packaging that came with the

replacement mesh manifold. Do not use

mechanical grips that may damage the

housing.

3. The old O-ring seals may remain on the

main manifold stem connections.

Remove these to waste and dry up any

fluid spillage with the lint free wipes.

Mesh Manifold Removal

Procedure:

1. Place the PCM500 on a clean surface

and have adsorbent lint free paper wipes

available.

2. Ensure the PCM500 is switched OFF.

3. Cap off both hoses.

4. Remove the rubber manifold cover.

Mesh Manifold

access

Main manifold stem connections

4. Remove the Replacement Mesh Manifold

from its packaging and carefully remove

the protective tape covering the ports. The

O-rings may come away with the tape but

this is normal and it is advisable to fit all

four O-rings onto the main manifold stems

before fitting the mesh manifold.

41

Page 42

Appendix D: PCM500.500 Mesh

Manifold Exchange Procedure

Replacement Mesh Manifold – ‘O’-ring fitting

5. Slide the Mesh Manifold onto the four

bolts and push firmly onto the O-rings.

6. Fit the four M5 Flange nuts. Be very

careful not to cross thread onto the bolts.

7. Tighten the nuts to a maximum of 3

Newton-Metre.

8. Re-fit the rubber cover.

9. When the PCM500 is switched on it will

automatically detect the new mesh manifold

and reset the points total in program memory

to zero.

(+)

3Nm

42

Page 43

Pall PCM500 and PCM500W Fluid

Cleanliness Monitors

World-wide Warranty

Pall products are rigidly inspected during manufacture and on completion by a modern

Quality Control Department and are guaranteed for a period of one year from date of

commissioning, against defective materials and workmanship when properly installed and

operated at design conditions.

All parts proven to be defective within this period will be replaced free of charge FOB

England or original FOB point as applicable.

However, claims for damage or labour will not be allowed; nor can the seller’s equipment be

warranted of failure where the operating conditions are beyond the control of the seller or

beyond monitor specification. All claims must be accompanied by full particulars including

system conditions if applicable.

43

Loading...

Loading...