Palintest

®

Potalab

®

+

(C)

Advanced Portable Water Quality

Laboratory (Physico-Chemical)

Wagtech

®

ZI PTW 10010C

Palintest

®

2

Who We Are

Over the last 20 years the Wagtech®name has become synonymous with water testing

in the most extreme circumstances and remote locations.

Developed for a range of applications, from long term surveillance to rapid response testing

in an emergency, the Wagtech

®

kits provide a robust solution to testing key water quality

parameters in the field.

Acquired by Palintest

®

in 2011, the manufacture and support of the Wagtech®portable

water quality laboratory range has now been integrated into the Palintest®product family.

Further information regarding the Wagtech®product range can be found at: www.palintest.com

Contents

Chapter Page

1

2

3

4

5

6

7

8

Kit Layout

Introduction

Photometer 7500

Compact Turbimeter

Digital pH Meter

Digital Conductivity Meter

Digital Arsenator

Appendix 1 - Reagents and Consumables

4

8

9

31

38

42

51

53

3

4

Potalab®+ (C) Water Test Kit - Layout

Fig 1. Potalab®+ (C) Physico-Chemical test kit layout.

Coloured circles indicate the chapter colour in which their use is explained.

1

Kit Layout

Function Equipment

Kit Layout

1

Parameter Testing Using

Photometer 7500

Turbidity Measurement Compact Turbimeter

pH Measurement Digital pH Meter (+ electrode)

Conductivity Measurement Digital Conductivity Meter (+ electrode)

Arsenic Testing Digital Arsenator

1

Photometer 7500 BT

2

Cuvettes (+ under Photometer)

3

Reagent Tablets (Chlorine DPD) ‘DPD1 & 3’

4

Reagent Tablets (Fluoride)

5

Reagent Tablets (Ammonia)

6

Reagent Tablets (Nitrate) ‘Nitratest’ and Tube (6a)

7

Reagent Tablets (Nitrite) ‘Nitricol’

9

10

Turbidity Standard & Cuvettes

11

Silicon Oil

12

13

14

15

Reagent Tablets (Sodium Borohydride A2)

16

Reagent Powder (Sulphamic Acid)

17

Filter Paper Holders (Black & Red)

18

Arsenator Filter Papers

Other Items Dilution Tube

22

23

Tube Brush & Lint Free Cloth

24

Dilution Tube - Sample Bottle Inside

25

Instruction Manual

5

6

Potalab®+ (C) Water Test Kit - Layout

Fig 2. Potalab®+ (C) Physico-Chemical test kit with instruments removed to show equipment beneath.

Coloured circles indicate the chapter colour in which their use is explained.

1

Kit Layout

Function Equipment

Kit Layout

1

Parameter Testing Using

Photometer 7500

Turbidity Measurement Compact Turbimeter

pH Measurement Digital pH Meter (+ electrode)

Conductivity Measurement Digital Conductivity Meter (+ electrode)

Arsenic Testing Digital Arsenator

Other Items

1

Photometer 7500 BT

2

Cuvettes (+ under Photometer)

8

Photometer Cap (under Photometer)

9

10

Turbidity Standard & Cuvettes

12

13

14

19

Conical Flask (under Arsenator)

20

In-Filter Arsenic Trap (under Arsenator)

21

pH Buffer and Conductivity Solutions

(under Arsenator)

7

2

Introduction

8

2.0 Introduction

Ideally suited to longer term surveillance and professional monitoring, the Potalab®+ (C) Advanced

Portable Water Quality Laboratory provides portable analysis of a wide and comprehensive range of key

drinking water quality parameters where the most important factor is to obtain laboratory levels of accuracy.

Built for physico-chemical water testing, the Potalab

®

+ (C) is the most advanced portable water

quality laboratory available today.

3.0 Introduction

Photometer 7500 BT

3

The Palintest Photometer 7500 Bluetooth

is a direct-reading, waterproof photometer for

determining key water quality parameters for

drinking water, wastewater and process water

samples. Designed for both portable and

laboratory use, the Photometer 7500 Bluetooth

should always be used with genuine Palintest

reagents for optimal performance.

The fundamental operating technique applied to

the Photometer 7500 Bluetooth is based on the

principles of optical absorbance and scattering

of visible light.

Optical absorbance techniques are based on the use

of Palintest (spectro)photometric reagents, creating

visible colours with specific analytes upon reaction.

The intensity of colour produced is measured with

the Photometer 7500 and the data compared to

the stored calibration data to deliver the final result.

Optical scattering techniques produce small

particles to scatter the source beam, the amount

of scatter providing a result for the concentration

of parameter under test.

For more information regarding the science behind

both photometric and turbidimetric analysis

technology please visit www.palintest.com/know.

The Photometer 7500 is provided with

programmed methods for a comprehensive range

of water quality parameters. Upon choosing a test

the instrument automatically selects the required

parameters for accurate analysis including

wavelength and reaction time. Upon completion

of the test optional follow-on tests are available

and results can be converted to alternative units

of expression e.g. mg/l to ppm, N or NH

.

3

The Photometer 7500 Bluetooth offers a choice of

connectivity to download all or selected results and/or

upload up to 30 User Defined Tests. Choose from

Bluetooth 4.0 wireless connectivity or USB connection.

Bluetooth 4.0 (also known as Bluetooth SMART or Low

Energy) connection allows seamless data exchange

using the Palintest Aqua Pal app, available for iOS

and Android devices. See Section 3.11 for more details.

USB connection via the port located at the rear

of the instrument provides a choice of either

‘Hard Disk’ mode or serial communication mode.

See Section 3.4 for more details.

The Photometer 7500 Bluetooth offers a choice

of either mains power via the USB port or using

three 1.5V ‘AA’ batteries (supplied).

The Photometer 7500 Bluetooth is supported

with a two year warranty and a full range of

service, calibration and technical support. Support

resources are available at www.palintest.com

relating to both products and applications.

3.1 Quick Start

Photometer 7500 Layout

Adaptive Cuvette Holder

(do not insert finger!)

LCD screen

with backlight

Numerical keys

for Hotkey

operation and

text entry

USB

Port

Light

Cap

Navigation

Keys

On/

Off

Photometer 7500 Interface

The LCD screen features a selectable backlight

with the screen separated into four clear, easy

to read zones:

1

2

3

4

9

3

Photometer 7500 BT

10

1 Mode or Test Identification.

2 Dialogue screen - prompts and choices will be

displayed as a list. Select using up/down arrows.

3 Info Panel - displays status icons, date/time

and Sample/Operator ID

4 Action select - choices are displayed as a row.

Use left/right arrows to select.

Info Panel Icons

3.2 Taking a Sample

The first critical step in any analysis is taking a

representative sample. When selecting a sample point

a number of care points are recommended as follows:

• Ensure the sample point is safe to access and

follow all relevant/required precautions

• When sampling from a tap or outlet, remove

any attachment and clean the tap/outlet with

a dry cloth before allowing the tap/outlet to

run for 1 minute prior to sample collection

• When sampling from a river or stream take the

sample as near as possible to the main flow and

not too close to the edge where the water may be

still and unrepresentative of the sample as a whole

• Rinse any sample container repeatedly with

the sample to prevent any cross contamination

from previous samples

• Once collected the sample must be processed

immediately or as quickly as possible, especially

for highly reactive species such as chlorine for

example. The use of a portable field test kit

makes this possible. However if the delay

between sample collection and analysis is likely

to be several hours chill the sample to preserve

and prevent potential microbiological growth

• Samples containing solid particles can interfere

with photometric analysis. Either allow solids

to settle and decant the clear liquid or filter

the sample prior to analysis

3.3 Starting up the Instrument

Power Supply

The Photometer 7500 Bluetooth is designed to

be powered either from alkaline batteries or via

the USB port.

When operating on battery power, the battery

level is indicated on the Info Panel. A minimum

voltage of 3.0V is needed to operate the

photometer and a flashing battery symbol

indicates a critically low battery. Change batteries

immediately or switch to alternative USB power.

The Photometer 7500 Bluetooth will automatically

power down when power is no longer capable

of providing acceptable performance.

To power via the USB port, use the supplied

cable connected either to the mains adaptor

or a PC. The USB icon will appear when the USB

connection is made and battery power will no

longer be consumed.

The Photometer 7500 Bluetooth has a back-up

battery mounted internally to save instrument

settings and data during power loss and

instrument idle periods.

Replacing Batteries

The battery compartment is located on the base

of the instrument and secured by four screws.

Remove the cover and install a complete set of

new batteries, observing the correct polarity as

indicated. Use 3 x 1.5V ‘AA’ alkaline batteries

or equivalent. See Section 3.9 for more details.

To avoid corrosion damage through leakage,

remove batteries from the instrument if it is

to be stored or left unused for a long period.

Start-up Screen

Description

Battery status

Bluetooth connected

Bluetooth on, not connected

Upper/lower case text/number entry

Hotkey Entry Mode Enabled

USB connected

Hard Drive/COM port mode

Icons

Photometer 7500 BT

3

The default start-up screen on power up is the

‘Choose a Test’ screen.

To access the Mode menu press the left arrow

key to highlight ‘Menu’ and OK.

To choose a test use the up/down arrows to scroll

through the list and press OK on the desired parameter.

Mode Screen

The Photometer 7500 has four operating modes

as follows:

Choose a Test

The Choose a Test mode is the standard operating

mode for taking photometer readings and is the

default start-up screen on power up. See Section

3.5 for more information.

Hotkey Test List

Assign up to 10 of the most frequently used tests

for single button access when in Hotkey mode,

indicated by the icon in the Info Panel. More

information on how to set up and use Hotkey

mode can be found in Section 3.4.

System Mode

Personalise your Photometer 7500 Bluetooth and

manage stored data within the System mode.

Options include setting Operator/Sample IDs,

interrogating the result log and defining the

instrument operating conditions. See Section

3.4 for further information.

Check Standard Mode

Validate performance of your Photometer 7500

Bluetooth using Palintest Check Standards.

See Section 3.7 for more information.

3.4 System Mode

Personalise your Photometer 7500 Bluetooth

and access the data log via the System Mode.

Scroll up or down using the appropriate keys to

see all available options. The options and available

settings are as follows:

Log

The Photometer 7500 Bluetooth has an internal

data log for up to 500 data points. The data is

stored automatically upon completion of the test

and automatically overwrites the oldest result when

the memory is full. The data log is unaffected by

power on/off.

Each data point is stored in a comma-separated

values (CSV) format and consists of date,

time etc.

Selecting Log offers two choices:

View - to view individual data points use the

up/down keys. Data is stored in chronological order

with the most recent result shown by default.

Scroll through results using the up/down arrows.

Select Back to return to the previous menu.

11

3

Photometer 7500 BT

12

Clear - the entire log can be deleted from the

Photometer 7500 Bluetooth if the instrument is

not locked (see System Lock). Selecting Clear

produces the following screen:

Data can be downloaded via either Bluetooth

(see Bluetooth Log Transfer) or USB connection

(see USB Interface).

Operator ID

The Photometer 7500 Bluetooth offers the option

to create up to 12 unique alphanumeric Operator

IDs. Operator IDs are added to the result data

automatically but deleting IDs does not affect the

result log.

To create a new Operator ID, select Operator ID

and use the up/down keys to select a blank field.

Select New and press OK.

Alphanumeric characters are entered/edited using

the 0-9 keys or the up/down keys. Press and hold

the 1 key to toggle between upper case, lower

case and numeric characters.

After entering a character, the cursor automatically

moves to the next position if no key is pressed.

Alternatively press the right key.

Up to 10 characters can be added for Operator IDs,

including spaces.

To edit characters use the left/right keys to select

the desired character. Press and hold the left key

to delete the character or change the character

using the entry mode.

When the Operator ID is correct press the OK key

to create the ID and return to the Operator ID

list. The new Operator ID will be displayed in the

Operator list.

Choose the Operator ID to be used by scrolling

through the list and pressing the OK key on the

desired choice. The instrument will return to the

System menu.

To modify or delete an existing Operator ID,

highlight the ID and select Edit. Choose either

Edit to modify the existing entry or Delete to

remove it from the list.

Photometer 7500 BT

3

Sample ID

The Photometer 7500 Bluetooth offers the option

to create up to 24 unique alphanumeric Sample IDs.

Sample IDs are added to the result data automatically

but deleting IDs does not affect the result log.

To create a new Sample ID, select Sample ID

and use the up/down keys to select a blank field.

Select New and press OK.

Alphanumeric characters are entered/edited using

the 0-9 keys or the up/down keys. Press and hold

the 1 key to toggle between upper and lower

case characters.

After entering a character, the cursor automatically

moves to the next position if no key is pressed.

Alternatively press the right key.

Up to 10 characters can be added for Sample IDs,

including spaces.

To edit characters use the left/right keys to select

the desired character. Press and hold the left key

to delete the character or change the character

using the entry mode.

new Sample ID will be displayed in the Sample list.

Choose the Sample ID to be used by scrolling through

the list and pressing the OK key on the desired choice.

The instrument will return to the System menu.

To modify or delete an existing Sample ID, highlight

the ID and select Edit. Choose either Edit to modify

the existing entry or Delete to remove it from the list.

Bluetooth

The Photometer 7500 Bluetooth features the

latest Bluetooth 4.0 (also known as Bluetooth

Low Energy or Bluetooth SMART) for wireless

communication with external devices.

The Palintest Aqua Pal app provides seamless data

exchange with the Photometer 7500 Bluetooth,

provides data trend analysis and user-defined

action limits for key parameters.

Additional data management functionality is provided

by the Palintest Portal (www.palintestportal.com).

Uploaded data can be shared with colleagues

and customers within your User Group(s) and

integrated into customised reports. See Section

3.11 for more information on the Aqua Pal app

and the Palintest Portal.

When the Sample ID is correct press the OK key to

create the ID and return to the Sample ID list. The

There are four options available in the Bluetooth menu:

• Bluetooth Communications ON - activate the

Bluetooth and make the Photometer 7500

Bluetooth visible for connection/pairing

• Bluetooth Communications OFF

• Bluetooth Log Transfer - transfer historical log

data to the Aqua Pal app when connected

to a remote device

• Bluetooth Device ID - create a unique device

name for the Photometer 7500 Bluetooth to

discriminate between multiple connections

13

3

Photometer 7500 BT

14

Bluetooth Communication On

Select this option to enable Bluetooth

communications allowing the instrument to be

paired with a suitable Bluetooth SMART enabled

device. Visit www.palintest.com\know for more

information regarding available/suitable Bluetooth

SMART devices.

The Bluetooth icon is shown in the Info Panel

when Bluetooth is enabled. Connection status

is shown as follows:

indicates the Bluetooth is activated

and connected to an external device

indicates the Bluetooth is activated

but the Photometer 7500 Bluetooth

is not connected to an external device

Bluetooth Communication Off

Selecting this option disables the Bluetooth

communications module. The Bluetooth icon

is not visible on the Info panel.

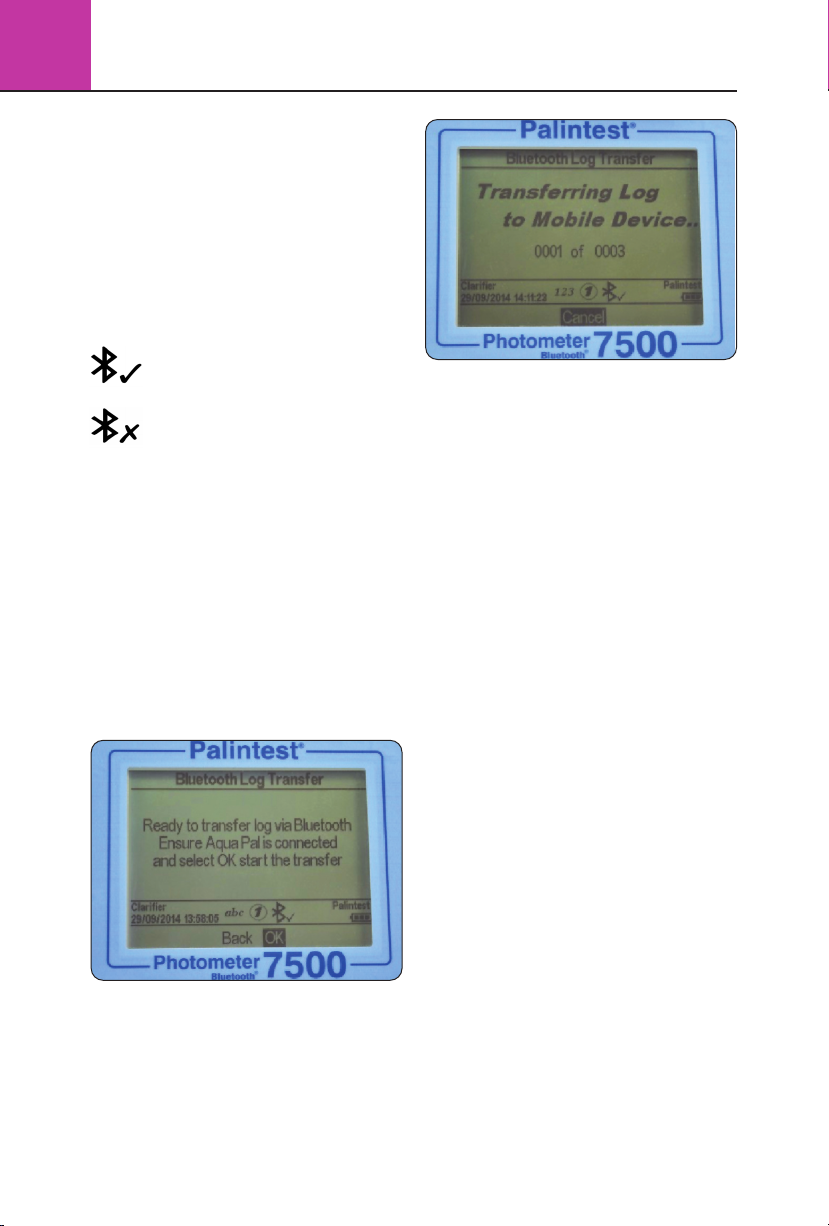

Bluetooth Log Transfer

Selecting this option transfers all or a selected

group of results stored in the log to the paired

mobile device.

The Photometer 7500 Bluetooth will validate the

paired connection and confirm readiness to transfer.

Transferring selected data will require specification

of the result log window e.g. from result 40

to result 100 to be transferred selectively.

Press OK to transfer the data log. The data will

transfer in series. Each data point is validated by

the Aqua Pal app prior to upload of the next.

If the connection is lost the Photometer 7500

Bluetooth will prompt for re-connection. If

connection is not required or possible press Exit

to disable Bluetooth and cancel the log transfer.

The message ‘Log transfer is complete’ will be

shown when all data points have been uploaded

successfully. Press OK to return to the previous menu.

Bluetooth Device ID

A number of Photometer 7500 Bluetooth instruments

may be available to connect to a remote device,

although only one active connection is possible at

any time. A user-defined Bluetooth Device ID ensures

simple pairing between the desired Photometer

7500 Bluetooth and the Palintest Aqua Pal app.

Creating and/or editing Bluetooth Device ID is

identical to Operator and Sample ID creation.

USB Interface

The waterproof USB interface provides both

communication between the Photometer 7500

Bluetooth and a PC and an alternative mains

power source via the adaptor.

When connected the USB icon will appear, replacing

the battery icon in the Info Panel, as power will

be preferentially drawn from the external source.

The USB data interface has a choice of two

operating modes - Hard Drive and COM Port. The

current status of the USB connection is shown on

the Info panel when the USB lead is connected.

Toggle between COM Port and Hard Disk mode in the

System -> USB menu by selecting the desired option.

The USB connection supports software update and

data download through a simple ‘drag and drop’

approach when operated in Hard Disk mode.

Photometer 7500 BT

3

Hard Drive

The instrument appears as a removable hard drive

when connected to a PC in Hard Disk mode. Upon

connection the remote drive will have the

following files included:

• 7500_***.afx.*** where * represent

version numbers of software - this is

the operating software for the Photometer

7500 Bluetooth

• Log.txt - the data log file stored in a

comma separated value (csv) format

Operating software or calibration library can

be updated by dragging a new version to the

instrument - contact support@palintest.com

for new software if this option is required. Any

updates to operating software will be notified

via the www.palintest.com\know portal.

Downloading the result log is carried out by dragging

the LOG.txt to the local desktop and opening the file

with any program that can open CSV format files.

earlier models of Palintest instruments. In this mode,

the PC requires installation of a USB virtual COM

Port driver, available from www.palintest.com/know,

and the availability of software operating as a

virtual com port.

A large number of third-party software systems

are available to provide data upload and remote

control of testing using the COM port mode.

Please contact your local Palintest representative

for more details.

Test Selection Method

The Photometer 7500 Bluetooth offers two

distinct methods of selecting test parameters Phot Number Entry Mode or Hotkey Entry Mode.

Phot Number Entry Mode is active by default.

Switching to Hotkey mode is carried out by

enabling Hotkey Entry Mode in the Test Selection

Method menu.

Select Hotkey Entry Mode and press OK. If ‘Hotkey

Entry Mode’ is enabled, the icon is displayed

on the Info panel.

Only one Test Selection Method is permitted at

any time.

For more information regarding extracting and

opening result logs using the Hard Disk mode

visit www.palintest.com/know.

COM Port

The instrument behaves as if connected to the PC

serial port via RS232 when connected in COM Port

mode, allowing remote control from an external

software system and data upload. This allows

backwards compatibility with software written for

Phot Number Entry Mode

All methods/calibrations (including User Defined

Tests) are identified by a unique three-digit ID

Phot Number. When operating in Phot Number

Entry Mode, access the test of choice quickly by

typing the three-digit number when in either the

Choose a Test screen or any result screen.

For example, to access the Phot 002 Total

Alkalinity test press ‘002’, ‘02’ or just ‘2’ to

load the method instantly.

15

3

Photometer 7500 BT

16

Hotkey Entry Mode

This option provides single button access to the

ten most frequently used tests by assigning each

to a unique position on the numerical keypad.

To assign a test to a specific Hotkey (0-9), firstly

ensure that ‘Hotkey Mode’ is enabled. This is

shown by the indicator on the Info Panel.

Select the Hotkey Test List from the Mode menu.

The ten available positions are listed along with

assigned or empty slots.

Select the Hotkey to assign (0-9) and use the

up/down arrows to highlight the required

parameter/method from the Choose a Test list.

Press OK and the test will be assigned to the

defined number.

Units

The Photometer 7500 Bluetooth offers the choice

of result expressed in mg/l, ppm, mmol/l, µmol,

g/l and µg/l.

Changing the result units will not affect the result log.

Dilution Factor

When samples are above the test range, indicated

by >> on the result screen, a dilution procedure can

be used. Setting Dilution Factor to On will prompt

the Photometer 7500 Bluetooth to automatically

request the dilution factor when carrying out a test.

Change the dilution factor by using the up/down

arrows or manually type the dilution factor. The

instrument will automatically correct the result

for the dilution and display the corrected result

(which will also be stored in the result log).

The maximum dilution factor permitted is 99.

If the calculated result exceeds the available number

of permitted characters >> will be displayed

NOTE: do not use sample dilution when

measuring pH or alkalinity.

Photometer 7500 BT

3

System Lock

To prevent unauthorised or inadvertent changes

to the System settings or log deletion a four digit

code can be used to lock several options.

The default code is set to 6812. To change the

System Lock code follow the on-screen prompts

to choose a memorable four digit number.

When the System Lock is applied, the items accessible

within the System Mode are limited until the unlock code

is entered. Access is limited to viewing the result log,

adjusting the backlight, contrast and Bluetooth settings.

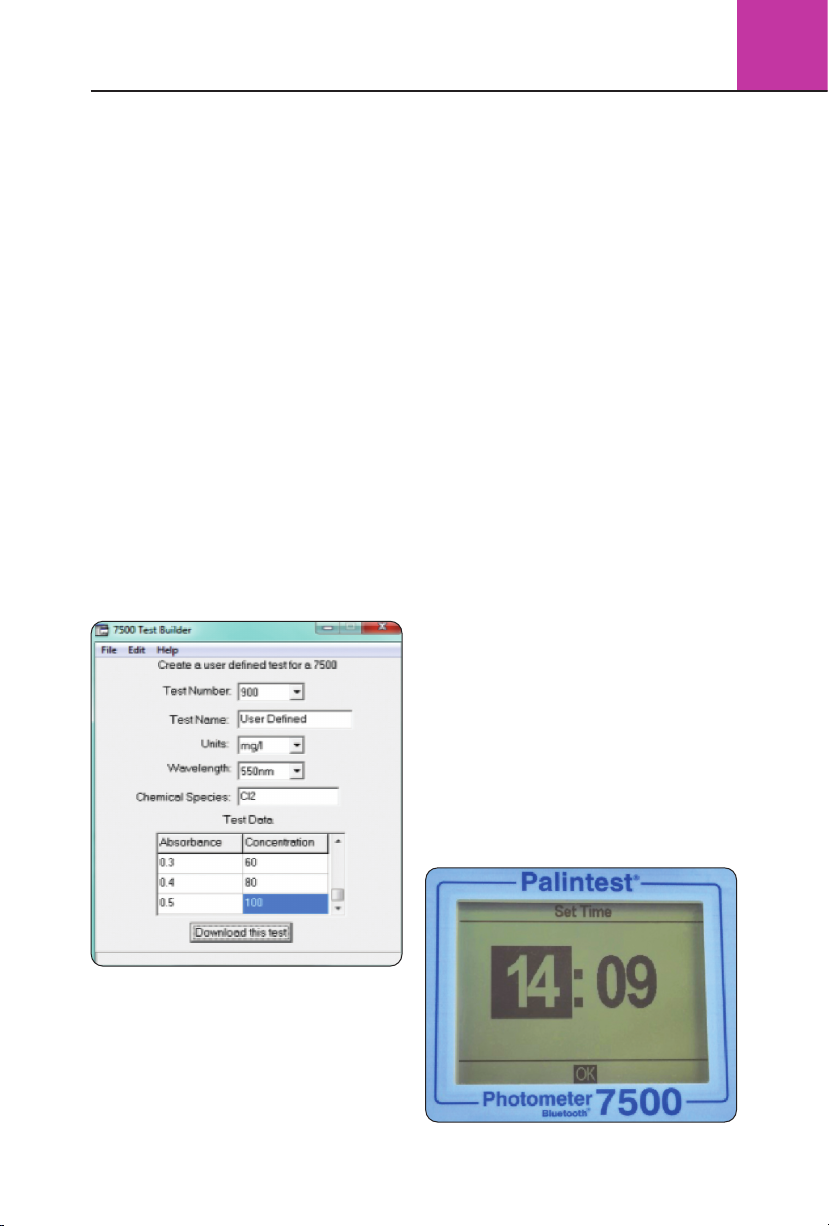

User Defined Tests

In addition to the many available calibrations/

methods, the Photometer 7500 Bluetooth provides

additional capability for up to 30 User Defined

Tests. A User Defined Test is built using a table of

calibration data consisting of up to 10 data pairs

of absorbance and concentration.

Download or request a copy of Usertestbuilder.exe

(suitable for Windows operating systems) from

our websites to define the details and calibration

data as shown below:

Alternatively save the test data as a *.txt file and

drag and drop onto the Photometer 7500 Bluetooth.

User Defined Tests are stored in Phot Numbers 900 - 929

to avoid confusion with standard Palintest calibrations.

Press OK once the test has been uploaded

to view the test in the User Defined Test list.

A number of options are available within

the Edit User Defined Test menu:

BACK return to the previous menu

ADD add additional User Defined Tests

EDIT upload new data for the selected test

DELETE remove the test from the instrument

For more information regarding creation and

upload of User Defined Tests please visit

palintest.comknow

Accessing User Defined Tests can be carried out by

assigning to Hotkeys (if enabled), scrolling through

the list of tests or entering the required Phot Number.

Language

Select the desired local language for operation,

choosing from English, French, Spanish, German,

Italian and Chinese (Mandarin). The selection of

language will also adjust appropriate tests and

units to local convention as required.

Set Time/Set Date/Date Format

All test results are recorded automatically in the

Data Log and appended with date and time (plus

additional information). Date and time are stored on

an internal clock, supported by a coin cell battery.

To correct the time select Set Time from the

System menu.

Use the up/down keys to adjust the hour; press

the right key to select and adjust the minutes.

Connect the Photometer 7500 Bluetooth to the

PC using the USB cable provided, ensuring the

instrument is set to Hard Drive mode.

Once data is complete press “Download this test”

to transfer the method details and calibration.

The Photometer 7500 Bluetooth will respond

with Test Data Accepted.

17

3

Photometer 7500 BT

18

Press OK when the correct time is set.

To correct the date select Set Date from the

System menu.

Use the up/down keys to adjust the day/month/year,

using the left/right keys to select the field.

Press OK when the correct date is set.

The Date Format can be set to DD/MM/YYYY or

MM/DD/YYYY as required. To select the required

format highlight the desired choice and press OK.

Time Out

When operating using battery power the

Photometer 7500 Bluetooth provides automatic

power-off as a power-saving measure. Three

settings are provided:

Normal 5 minutes

Long 15 minutes

Off (disables Time Out)

The time intervals begin after the last key is pressed

or activity takes place.

Time Out is automatically disabled when the

instrument is powered by USB supply and during

a Bluetooth data log transfer.

Back Light

The instrument display features a high intensity

backlight to support use in low light conditions.

The backlight is designed to use minimal energy

but activating the Backlight will naturally consume

battery power more rapidly. The settings available

for Backlight are:

Backlight Auto-Dim Backlight activates on any

key press and dims after

15 seconds automatically.

Backlight On Backlight is on permanently

Backlight Off Backlight is off permanently

LCD Contrast

In addition to the Backlight, the default contrast

setting for the display can be adjusted using the

up/down keys when light conditions are difficult.

The display provides a sequence of alternating

squares to give visual indication of the correct

settings to apply.

When complete/acceptable press the OK key.

Version

The serial number of the instrument and the

software version are displayed. The instrument

serial number will be required for technical

support and servicing/warranty and can also

be found on the base of the instrument.

3.5 Analysing Samples

The Photometer 7500 Bluetooth provides simple,

accurate and reliable analysis of key drinking

water, wastewater and process water parameters.

Selecting the required parameter and performing

the test are supported through on-screen prompts

and comprehensive test instructions.

The principle of photometric testing is based on the

absorption or scattering of a measured intensity

Photometer 7500 BT

3

of incident light compared to the light intensity

reaching the detector array. The light intensity is

determined as Transmittance (%T) or Absorbance (A)

and compared to calibration tables stored within the

Photometer 7500 Bluetooth. The stored calibration

tables convert %T or A to results in a variety of

units (mg/l, ppm etc.) as defined in Section 3.4.

Calibration tables are defined by Palintest based

on the measurement of reference standards using

Palintest reagents. To achieve the best quality

results there are a small number of care points:

1 Always use the provided light cap to prevent

ambient light affecting the results.

2 Ensure Sample and Blank cuvettes are clean, dry

and inserted correctly into the sample chamber,

using the allocated orientation mark to align.

3 Always blank the instrument with untreated

sample prior to analysis.

Additional guidance is provided in Section 3.8

Photometric Testing Hints and Tips

Selecting Test Parameters

The Photometer 7500 Bluetooth offers a number

of choices to select the parameter to test:

Phot Number Entry - use the numeric keypad

to enter the unique Phot Number to directly

access any programmed calibration (including

User Defined Tests). This method will not be

available if the Photometer 7500 Bluetooth is

operating in Hotkey Entry Mode.

Hotkey Entry - use the numeric keypad to

directly access up to 10 of the most commonly

used tests. When operating in this mode the Info

panel will display the icon and Phot Number

Entry mode will be disabled.

Choose a Test - available in either Phot Number

Entry or Hotkey Entry modes, the full list of test

parameters is available by selecting Choose a Test

and scrolling using the up/down keys. When the

desired parameter is highlighted, press the OK

key to access the method. Tests are presented in

Phot Number order.

When the required test is selected the Photometer

7500 Bluetooth automatically selects the correct

wavelength and sets additional method parameters

as required.

Test method protocols are defined in detail in the

Palintest Phot Book, supplied with the Photometer

7500 Bluetooth, including the reagents and

accessories that may be required.

When a test is selected, the Photometer 7500

Bluetooth screen will display a number of screens

and options to guide the user through the testing

process, as described in the following pages.

Dilution Factor

If selected in the System menu, the initial screen will

request the defined Dilution Factor to apply to results.

If Dilution Factor is not active this screen will not

be shown.

Results shown on the final screen have automatically

been corrected for dilution prior to display. Corrected

results will also be stored in the log.

Blanking the Photometer 7500 Bluetooth

Blanking the photometer is a key first step in

photometric analysis, effectively removing the

potential entrained sample colour and minor amounts

of turbidity from calculation of analytical results.

To blank the photometer, prepare a Blank cuvette

using untreated sample i.e. sample that has not

been reacted with any reagents. If the sample is to

be diluted or physically treated (filtered for example)

before analysis, use the same dilution/treatment

for the Blank cuvette.

When accessing the test method the Photometer

7500 Bluetooth will request the user to

Insert Blank.

19

3

Photometer 7500 BT

20

Insert the Blank cuvette and press OK.

The Photometer 7500 Bluetooth will determine

the absorbance due to the sample colour at

all wavelengths simultaneously and store in

temporary memory for use in analysis.

Upon successful blanking the Photometer 7500

Bluetooth will automatically move to the Insert

sample stage of the analytical method.

If the sample is too highly coloured to support

effective blanking and subsequent analysis the

error message “Error 9 is caused by the blank

cuvette being too dark. Check the correct cuvette

is being used”.

Ensure the blank cuvette is being used, not the

sample plus reagent cuvette. Sample colour can

be reduced by dilution with clean water; the

dilution selected should take account of the

expected concentration of parameter under test.

Blank results are stored in the temporary memory

of the Photometer 7500 Bluetooth and will be

used for all subsequent tests until:

• The instrument is powered down (temporary

memory is lost/deleted)

• A new Blank reading is taken - this option is

available on accessing any subsequent test at

the base of the screen. Repeat the blanking

process if the sample changes significantly

or a new sample is under test

• Some tests use a reversed blanking process

where a coloured blank cuvette may be required.

When changing between standard tests and

‘reverse blank’ test, a new blank sample will be

requested by the Photometer 7500 Bluetooth

If the blank value generated in this step is not

detectable an error message will be displayed

“Error 7 is caused by too much ambient light. Try

using the light cover provided with the instrument”.

See Section 3.8 Photometric Testing Hints and

Tips for more advice regarding effective blanking.

Reading Results with the

Photometer 7500 Bluetooth

Assuming a suitable blank has been recorded,

the next step of the photometric analysis process

is to carry out the reading step.

Photometer 7500 BT

3

Prepare a Sample cuvette following the method

instructions provided in the Palintest Phot Book.

Select Read at the base of the screen and press OK.

At the Insert sample prompt, insert the sample

cuvette ensuring it is clean and dry and oriented

correctly using the location mark.

Press OK to begin the measurement process.

The screen will display Reading...

At the completion of the measurement process

the result is displayed on screen.

Timer

Many photometric methods require a reaction time

to develop optimise sensitivity, the recommended

time period being documented in the Palintest Phot

Book and included as part of the method parameters

programmed into the Photometer 7500 Bluetooth.

Tests requiring a reaction time will have the option to

select an automatic timer to count down the reaction

time required. While in the Insert sample screen use

the right key to move the cursor to highlight Timer.

The programmed reaction time will be displayed.

Press OK to Start the countdown.

Three options will be displayed:

Stop cancel the countdown timer

Exit exits the countdown screen and

returns to the Insert sample

screen. The countdown will

continue and the current time can

be seen by selecting Timer. At the

end of the countdown an audible

alarm will sound to indicate the

sample is ready to read. Select

OK to read the sample manually.

Exit and Read exits the countdown screen and

automatically reads the sample

at the completion of the allocated

time period.

Changing Result Units of Expression

Many chemical species have a number of

alternative units that can be used for reporting

results e.g. Phosphate can be expressed as

PO

or P for example.

4

21

3

Photometer 7500 BT

22

Where alternative units of expression for results

are available the ▲▼ symbols will be displayed

next to the current result units. Use the up/down

arrows to change the units of expression as

required. Values are modified automatically.

Results stored in the log will be in the units

selected on screen, changing the chemical species

will add an entry to the log showing the updated

result and species parameter selected.

Follow-on Tests

A number of photometric methods have additional

optional methods that can be applied, known as

Follow-on Tests e.g. Phot 008 Total Chlorine follows

Phot 007 Free Chlorine. Follow-on methods are

usually either based on further reagent addition to

the sample just measured for sequential parameters

or used to correct for potential/known interferences.

Follow-on tests are clearly defined in the Palintest

Phot Book and, if available, are accessed via the

Follow-on option located at the right hand side

of the options.

To access the Follow-on test, highlight Follow-on

and press OK. The next method is automatically

loaded and operated in the usual manner.

NOTE: if no viable result is produced during the first

stage of a sequential test method, the Follow-on

option will be automatically removed.

For correction methods, the data log will store

the corrected result automatically along with all

other results in the sequence.

All Follow-on methods have unique allocated Phot

Numbers but not all can be directly accessed.

Follow-on methods that cannot be directly

accessed are not listed in the Choose a Test list

for Hotkey Entry but will be available following

a viable result in the initial test stage.

3.6 7500 Test Methods

Fluoride

Range: 0-1.5mg/l (ppm) F

Colour change: Colourless - Red/Yellow

1 Fill test cuvette with sample to the 10ml mark.

2 Add one Fluoride No 1 tablet,

crush and mix to dissolve.

3 Add one Fluoride No 2 tablet,

crush and mix to dissolve.

4 Stand for 5 minutes.

5 Take photometer reading.

Chlorine-Free

Range: 0-5.00mg/l (ppm) Cl

2

Colour change: Colourless - Purple/Red

1 Rinse test cuvette with sample leaving

two or three drops in the tube.

2 Add one DPD 1 tablet, crush tablet and then

fill the test tube with sample to the 10ml mark.

Mix to dissolve tablet fully and ensure no

particles remain.

3 Take photometer reading immediately.

The result may drift on standing.

4 Retain test solution if the Total Chlorine

Follow-On Test is required.

Photometer 7500 BT

3

Chlorine-Total

Range: 0-5.00mg/l (ppm) Cl

Colour change: Purple/Red from Free Chlorine

Test increases in intensity

Carry out this test on the solution

remaining from the Free Chlorine test.

1

Add one DPD 3 tablet, crush and mix to dissolve.

2 Stand for two minutes to

allow full colour development.

3 Take photometer reading after

two minutes have elapsed.

Note: To obtain Combined Chlorine residual

subtract Free Chlorine result from Total Chlorine result:

Combined Chlorine =

Total Chlorine - Free Chlorine

2

Nitrate

Range: 0-20mg/l (ppm) N

Colour change: Colourless - Red

1 Take a clean Nitratest Tube (PT 526). Using the

Measuring Syringe (PT 361) add 1ml of sample.

Fill the Nitratest Tube to the 20ml mark with

deionised water.

2 Add one level spoonful of Nitratest Powder and

one Nitratest tablet. Do not crush the tablet.

Replace screw cap and shake tube well for exactly

one minute then allow contents to settle.

3

Then, either: Invert tube gently 2 or 3 times and

then allow to stand for at least two minutes to

ensure complete settlement. Remove screw cap and

wipe around top with a clean tissue. Decant clear

solution into test cuvette, filling to the 10ml mark.

or: Using the Palintest Filtration Set (PT 600) filter

a portion of the solution through a GF/B filter

paper into a test cuvette filling to the 10ml mark.

4

Add one Nitricol tablet, crush and mix to dissolve.

5 Stand for 10 minutes.

6 Take photometer reading.

Ammonia

Range: 0-1.00mg/l (ppm) N

Colour change: Yellow - Green

1 Fill test cuvette with sample to the 10ml mark.

2 Add one Ammonia No 1 tablet and one

Ammonia No 2 tablet, crush and mix to dissolve.

3 Stand for 10 minutes.

4 Take photometer reading.

3.7 Calibration/Validation

Your Photometer 7500 Bluetooth is delivered with

a calibration certificate validating the performance

of the instrument as it leaves Palintest.

We recommend annual service and calibration

of all photometric instruments in normal use.

The Photometer 7500 Bluetooth also includes an

automatic routine to validate analytical performance

using certified Palintest Check Standards. Accessed

via the Mode menu, the Check Standard Mode

provides a field method of ensuring your instrument

is operating within defined specifications and also

a troubleshooting method for unexpected results.

Every Palintest Check Standards set is supplied with

certified values expressed as %T (Transmission), derived

from traceable reference materials. Acceptable tolerances

are defined on the certificate and are automatically

specified within the Photometer 7500 Bluetooth.

Check Standard Mode

Access Check Standard Mode from the Mode screen.

Highlight Check Standard Mode and press OK.

Nitrite

Range: 0-0.5mg/l (ppm) N

Colour change: Colourless - Red

1 Fill test cuvette with sample to the 10ml mark.

2

Add one Nitricol tablet, crush and mix to dissolve.

3 Stand for 10 minutes.

4 Take photometer reading.

23

3

Photometer 7500 BT

24

Two choices are offered:

Enter Check use the up/down keys to

Standard Values adjust the displayed values

to match the certificate

Check Standard insert the Check Standards

Measurement in the defined order to

generate a validation report

Enter Check Standard Values

Each standard has two values assigned, for two

individual wavelengths.

Use the up/down keys to adjust the values to match

the certificates, following the order defined on the

display. Press OK when the correct value is shown

and the prompt will forward to the next value.

Upon completion the message Check Standard

Values assigned successfully will be displayed.

Press OK to return to the Check Standard Mode menu.

Check Standard Measurement

Follow the on-screen prompts to insert the Check

Standards in the defined order. The Photometer

7500 Bluetooth will automatically measure the

Transmittance at the required wavelength.

Upon completion of the sequence the results are

displayed on screen with pass or fail status.

If the Check Standard Mode reports a failure,

see Section 3.9 Troubleshooting for guidance or

contact your local Palintest supplier.

3.8 Photometric Testing Hints and Tips

Photometric analysis is a very powerful technique,

providing accurate analysis of a wide range

of critical drinking water, wastewater and

environmental parameters.

A complete guide to the science behind photometric

(also known as colorimetric) analysis can be found

in the Know portal at www.palintest.com/know/

Palintest has focused on simplifying the test

methods and equipment used for this technique

but there are still a number of ways to ensure the

results you generate are as accurate as possible:

1 Always use genuine Palintest reagents when

using the programmed test methods. Each

parameter has a unique calibration which

has been generated using Palintest reagents.

Alternative reagents may follow the same

general methodology but can differ

substantially in formulation and colour

generated thereby rendering the calibration

and hence results inaccurate.

2 Always correct for the blank value - any

inherent colour in the sample (which may not

be visible to the naked eye) will offset the

result if the blank step is omitted. If the sample

colour is too intense for the photometer to

blank use dilution with deionised water to

reduce the intensity. Remember to dilute the

sample to the same extent for analysis.

3 Always respect the reaction time specified

within the instructions. Some methods

produce instant colour whereas others require

a reaction time to reach full development.

Taking a reading before the reaction time

has elapsed may lead to low results.

4 The presence of solids, either large or in the

form of turbidity, can adversely affect the

quality of results by preventing incident light

from reaching the detector. The blanking step

can reduce the impact of turbidity interference

but large solid particles must be removed prior

to analysis. Solids can be removed by filtration

prior to analysis or, if the solids are settleable

and will not lie in the optical path, allowing

them to settle in the photometer cuvette can

be acceptable.

Photometer 7500 BT

3

5 Calibration curves relate transmission/

absorbance to concentration to provide result

data but not all calibration ranges are linear.

Frequently at higher concentrations the curve

‘flattens’ leading to higher potential variability

in results. If greater accuracy is required than

can be achieved on neat samples then dilution

can be used to improve performance.

6 Ensure the photometer cuvette is clean, has

no droplets on the outside and not excessively

scratched. Good technique is to wipe the outside

surface of the cuvette prior to inserting into

the optical chamber to prevent contamination

of the optical system.

7 Always use good quality, genuine Palintest

cuvettes. Use the orientation mark to ensure

repeatable positioning of the cuvette.

8 Maintain the cleanliness of the optical chamber

by only inserting clean cuvettes. If the chamber

becomes fouled or sample is spilled the base

can be removed for cleaning access. Clean the

optical chamber with a soft cloth. Do not use

abrasive chemicals or scouring agents.

9 Always use the light cap provided to prevent

ambient light affecting results. This is especially

relevant when operating in strong sunlight or

other light conditions.

10 Ensure your Photometer 7500 Bluetooth is

operating effectively by using Palintest Check

Standards and the Check Standard Mode (see

Section 3.7 Calibration/Validation) and having the

photometer serviced and calibrated at regular

intervals. Calibration is recommended at 12

month intervals for normal usage and can be

provided by your local Palintest distributor.

3.9 Troubleshooting

The Photometer 7500 Bluetooth features selfdiagnostic software and hardware to optimise

performance and battery life. The Info Panel

indicates the status of the Photometer 7500

Bluetooth and any specific fault conditions are

defined and displayed on screen.

Optical Errors

I have an Error 9 message

Error 9 is caused by the blank cuvette being too

dark to allow the blanking step to be carried out.

Check that the correct cuvette is being used i.e. ensure

the sample cuvette is not being used for blanking.

If the sample is too highly coloured or contains

significant solids, dilute and repeat the blanking step.

If the problem persists and the blank cuvette is not

the issue, clean the optical chamber by removing

the access cover and cleaning with a soft cloth.

Do not use corrosive or abrasive chemicals.

I have an Error 7 message

Error 7 is caused by too much ambient light

reaching the detector. Use the light cover

provided with the instrument.

Check Standard Issues

How do I maintain my Check Standards?

Check Standards are manufactured to precise

values/tolerances, certified against traceable

reference materials and provided in sealed

cuvettes. Do not decant or remove the sealed

cap from the Check Standard.

Ensure the Check Standard cuvettes are clean

and dry using lint-free cloths before inserting

into the optical chamber.

Insert the Check Standard aligning the orientation

arrow towards the front of the optical chamber.

Values assigned to calibration standards are

defined at 20-25°C. Extremely high or low

ambient temperatures can affect Check Standard

results so ensure standards are at the defined

temperature to effectively validate.

Check Standards have a two year shelf-life, after

which the colours will no longer be valid. Please

dispose of the expired standards after this period

according to the MSDS.

My Check Standard validation has failed

Photometers may fail the Check Standard validation

step due to the requirement for service/calibration.

Contact your local Palintest partner for service

and support.

Ensure the Check Standards are inserted correctly,

using the orientation mark to align and inserted

fully. Use the light cap to prevent any ambient

light interference.

Service/calibration is recommended at annual

intervals in normal operation.

25

3

Photometer 7500 BT

26

Bluetooth Issues

The Photometer 7500 Bluetooth features

the latest Bluetooth SMART connectivity.

I can’t connect the Photometer

7500 Bluetooth to my device

Ensure your device is Bluetooth SMART ready.

Previous versions of Bluetooth (also known

as Bluetooth Classic) will not connect to the

Photometer 7500 Bluetooth. Check your device

specification or visit www.bluetooth.com

to see the latest list of SMART ready devices.

I can’t download my results

to my connected device

The Info Panel will show the connected status

of the Photometer 7500 Bluetooth. Ensure the

connected icon is displayed.

If more than one remote device is running the

Aqua Pal app, check that the correct device is

connected to the Photometer.

The connected device is indicated at the base

of the Aqua Pal results screen.

I can’t upload my data

to the Palintest Portal

Ensure you have a reliable internet connection

to exchange data with the Palintest Portal. Once

uploaded data can be shared within your secure

user group and downloaded for report generation.

Bluetooth Error Messages

The Photometer 7500 Bluetooth communicates

seamlessly with the Palintest Aqua Pal app. In the

event of any errors the Photometer 7500 Bluetooth

will display either of the following messages:

The Photometer 7500 Bluetooth is not receiving a

response from the Palintest Aqua Pal app but the

remote device is connected. This will appear 10s

after a result transmission has started and no

valid response has been received.

Re-start the Aqua Pal app and select Retry.

When the Bluetooth connection to the remote

device the following message is shown:

Check the Bluetooth has not been inadvertently

deactivated in the mobile device settings.

NOTE: the Photometer 7500 will not appear as

a ‘paired device’ in the settings of a Bluetooth

SMART device.

Battery/Power Issues

My batteries are running out too quickly

Use good quality batteries and always replace

the batteries completely when indicated on the

Info Panel. The battery compartment is located

underneath the Photometer 7500 Bluetooth and

secured by four screws.

Remove the battery cover and replace batteries

as a set.

Refit the battery cover ensuring the cover is tight

enough to prevent water ingress. Do not overtighten

as this will damage the screw housings.

The Photometer 7500 Bluetooth has a number

of power-saving features such as auto-dim of

the backlight and automatic power down after

inactivity (See Section 3.4). Activating these features

will prevent power being used unnecessarily.

Bluetooth can also be de-activated if not required.

Using the USB port to provide power will

automatically prevent battery power being consumed

when mains or external power is available.

My photometer will not switch on

The Info Panel provides an ongoing indication of

power available from the battery supply. When the

voltage available falls below 3.0V the Photometer

7500 Bluetooth will not switch on as the available

power will not be sufficient to provide effective

photometric testing.

Use the USB cable to provide an alternative

power supply. If the photometer still fails to

switch on, contact your local Palintest partner

for service support.

My USB power supply is not working

Ensure your PC is not operating in power save

mode or the mains supply is not isolated.

Replace the cable with an alternative to ensure

the cable is not faulty.

USB Connection Issues

I cannot download my data

Check the USB mode is set to Hard Disk, not COM

port mode. In Hard Disk mode the data can be

‘dragged and dropped’ as with a conventional

memory stick and is available in CSV format.

Opening CSV data files can be accomplished by a

number of text editing or spreadsheet programs.

Where do I find the COM port drivers?

The latest drivers are available at

www.palintest.com

COM port drivers are provided for Windows

operating systems (Windows Vista, XP and 7).

Care and Maintenance

The Photometer 7500 Bluetooth contains no userserviceable parts internally. User maintenance is

only recommended for cleaning of the optical

chamber, changing batteries and validating

performance using the Check Standard Mode.

Cleaning the Optical Chamber

The optical chamber has been designed to

support removal and cleaning with a lint-free

cloth as required by removal of the access cover.

Photometer 7500 BT

Access

Cover

Screws

Do not use any of the following agents

when cleaning this optical chamber:

• Abrasive cloths

• Corrosive chemicals

• Any organic solvents

Do not overtighten the screws on re-assembly

to avoid damaging the access cover.

Replacing the Batteries

Remove the four retaining screws from the

battery cover and gently prise the cover free.

Battery

Cover

Access

Screws

Replace all batteries at the same time.

Ensure on replacing the battery cover that

the gasket is correctly located to prevent any

water ingress. Tighten the screws carefully

but do not overtighten.

3

27

3

Photometer 7500 BT

28

3.10 Technical Specifications

Instrument Type Dual light source photometer offering direct-reading of

pre-programmed test calibrations, Absorbance and Transmittance

Optical System

Optical Source Dual LED sources with optical filters

Optical Detectors Silicon photodiodes

Peak Wavelengths 450nm, 500nm, 550nm, 570nm, 600nm, 650nm

Wavelength Selection Automatic

Bandwidth ±5nm

Range 1 - 100%T (0-2.3 Abs)

Accuracy ± 1.0% T

User Interface

Display 320 x 240 pixel LCD with contrast adjustment

Backlight Timed, on key press with auto-dim and off

User Interface On-screen prompts available in English, French, Spanish,

German, Italian, Turkish and Mandarin (Chinese).

Keypad Numeric keypad with assignable Hotkeys. Four navigation keys and OK key

Physical

Size (W x L x H) 150 x 250 x 70mm

Weight 975g

IP Rating IP67

Power Supply

Batteries 3 x 1.5v ‘AA’ batteries

Lifetime 40 hours (typical use, backlight off, ‘AA’ alkaline cells)

Mains 5V DC, 900mA delivered via USB port

Power Management Auto-switch off (user selectable between 5-15 minutes on battery) or continuous operation

Power Saving User control for Backlight and Bluetooth to minimise battery consumption

Test Methods

Tests Available Pre-programmed for Palintest tablet reagent and Tubetests

®

format tests

Also operates in Absorbance and Transmittance modes

User Defined Tests Up to 30 user calibrations can be entered. Up to 10 points per calibration

Test Selection Phot number entry, Hotkey or selection from a list

Test Cuvettes 12-20mm OD with automatic cuvette centering

Result Units g/l, mg/l, ppm, mmol/l, µmol/l, µg/l, ppb

Blanking Automatic blanking at all wavelengths. Blank value

stored in memory until power off or new blank recorded

Connectivity

USB USB Type B Connector. Waterproof connector available

Wireless Palintest Bluetooth SMART profile

Data Management

Instrument Memory Non-volatile storage

Memory Capacity Up to 500 data sets. Each data set includes date, time, Sample ID,

Operator ID, method number, method name, result, units

Sample IDs Up to 24 at any time

Operator IDs Up to 12 at any time

Data Download To computer via USB using Hard Disk or COM port mode. Wireless Bluetooth SMART

download, either instantly or as a data batch, using a connected device running

the Palintest Aqua Pal app. Optional Palintest Portal data management available

Data Output Format Plain text

Software Upload Software update by ‘drag and drop’ in USB Hard Disk Mode

Photometer 7500 BT

3

3.11 Palintest Aqua Pal App

and the Palintest Portal

What is the Aqua Pal App?

Generating reliable and accurate water test

data is only part of the process of managing

drinking water, wastewater, process water and

environmental compliance.

Collating the data quickly and sharing with

other members of the team can be the difference

between effective control and failing to adhere

to local regulatory standards.

Connecting to the Aqua Pal App

Enable Bluetooth on the Photometer 7500

Bluetooth. The icon will appear on the Info Panel

showing Bluetooth is on but not connected.

Open the Aqua Pal app and log in using your

registration credentials. Choose whether to

use automatic or manual result addition.

The Palintest Aqua Pal app is intrinsic in the

process of storing, sharing and managing data

produced by the Photometer 7500 Bluetooth

and also allows for additional data to be added

manually for the Big Data experience.

The Aqua Pal app is available for both iOS and

Android (version 4.3 or later) devices that are

equipped with Bluetooth SMART connectivity.

On first use the Aqua Pal app will require a

registration step for both the app and the secure

Palintest Portal. An internet connection is required

to process the request as it will involve a second

stage authentication via the provided email address.

Once the sign up process is completed the Aqua

Pal app and Palintest Portal are ready to go.

To connect the Photometer 7500 Bluetooth press

the ‘+’ symbol in the top right hand corner of

the device screen. This will produce the list of all

locally advertising Bluetooth SMART devices.

29

3

Photometer 7500 BT

30

Select the Photometer 7500 Bluetooth you wish

to connect (see also Section 3.4 - Adding Device

Name) and Aqua Pal will link. The Info Panel

will display the connected Bluetooth icon.

Previously connected instruments are

stored in the app for future selection.

Once connected, data can either be uploaded

automatically (if selected) or direct from the

log (all or a selected group).

Manual data entry is also possible for results

generated with non-Bluetooth instruments or

external devices such as TDS meters, flow meters

or level sensors.

Connecting with the Palintest Portal

Also included with the Aqua Pal app is

the secure Palintest Portal found at

https://palintestportal.com

Data stored in the Aqua Pal app can be uploaded

to the Palintest Portal when an internet connection

is available.

Data stored within the portal can be shared with

team members using the User Group functionality.

Simply assign team members to the User Group

and they can view data generated by logging

in to the portal.

Results stored within the portal can be filtered

by date, sample ID, Operator ID and parameter.

Data can be viewed graphically over time with

the status (in spec, nearing limit, out of spec)

being indicated by a simple colour key.

Further Information

The full guide to the Aqua Pal app and the Palintest

Portal are available at www.palintest.com

and available for download from the Palintest

Know portal.

4.0 Introduction

The Compact Turbimeter is the latest addition to the Palintest

Compact Meter range which includes photometers for chlorine,

ozone, chlorine dioxide and ammonia.

The Turbimeter operates according to the ISO 7027 method

for measurement of turbidity, utilising two NIR light sources

at 860nm as part of the QuadoptiX™ optical system.

The Turbimeter is provided with accessories and

standards to support effective use of the instrument.

For technical support or to report issues with this

product please contact Palintest or your supplier.

Compact Turbimeter

4

4.1 QuadoptiX™ Technology

The Palintest Compact Turbimeter utilises

QuadoptiX™ technology for turbidity

measurement - a sophisticated optical approach

designed to ensure turbidity measurements

are as accurate and repeatable as possible in

even the most challenging circumstances.

Turbidity measurements are carried out by analysis

of light scattered at 90° to the incident light

(nephelometric measurement) at levels below 40NTU.

Above 40NTU the recommendation is to measure

also at 180° to ‘compensate’ the 90° readings.

QuadoptiX™ technology uses two independent

sources and two independent detectors to provide

effectively four entirely autonomous measurement

systems in the same instrument, allowing multiple

validation of all results for greater accuracy.

4.2 Start-up and Start Page

To switch the unit ‘on’, press the POWER button

and release. An audible beep will confirm the

instrument is on. Switch ‘off’ by holding the

POWER button for 1 second.

The LCD screen is provided with a backlight option

that can be set to on/off in the ‘System’ menu

(see Section 4.4). The initial default setting is ON.

After initialisation, the Start page will appear

and display, initially defaulted to Mode screen

and showing three options:

1 Reading - Select the mode to measure

turbidity or suspended solids (see Section 4.5).

2 Calibration - Choose either SDVB, Total

Suspended Solids or to Restore the factory

calibration values (see Section 4.7).

3 System - view or set Log (result and calibration),

Operator ID, Sample ID, Units, Language, Set Time,

Set Date, Date Format, Software Version and

switch the backlight on/off (see Section 4.4).

The option to change the Start page is available in the

‘System’ menu, allowing the user to choose to start

in the default mode above, normal measurement

mode or the last measurement mode used.

Navigation through Menus is carried out using

the Up/Down buttons, using the ‘OK’ button

to select or the ‘Back’ button to return up a level.

4.3 Battery Life/Replacement

Your Compact Turbimeter is supplied with fresh

batteries that will be suitable for at least 150 hours

of use. Changing batteries is carried out through

the compartment on the rear of the instrument.

Two ‘AA’ 1.5V batteries are required. Current

battery status is displayed on the screen to

assist in power management.

The Turbimeter has an auto-off function to save

power, automatically switching off the meter

after five minutes of inactivity.

A back-up battery is located on the PCB to

store all user data including the last mode used

for reading. Replacing the AA batteries will not

lead to settings or calibration data being lost.

If battery power is insufficient for effective analysis

the Turbimeter screen will show Error 110:

Battery Low and advise to change batteries.

The battery icon will also show ‘Empty’ status.

If battery power is insufficient for any operation

the Turbimeter screen will show Error 111:

Battery Critical and automatically shut down.

31

4

Compact Turbimeter

32

4.4 System Menu

The System menu allows the user to set the

Compact Turbimeter preferences and review

results and calibration data.

4.4.1 Log

Select ‘Results’ or ‘Calibrations’.

Once the log has been chosen, select ‘View’ or ‘Clear’.

The ‘Readings’ log holds up to 100 data points

with date, time, Sample ID, Operator ID, Reading

Mode and Result.

The oldest result will automatically be

overwritten when the log is full.

The ‘Calibrations’ log stores the date, time,

method and Operator ID (if set) for the last

12 good calibrations.

To view data select ‘View’ and use the

Up/Down buttons to scroll in either direction.

Use ‘Clear’ in either log to delete the entire log.

Select ‘Clear’ then ‘Yes’ in the following screen

to delete.

4.4.2 Operator ID

Optionally select or edit the username using

alphanumeric characters.

To create a new Operator ID select a blank

line and press ‘OK’.

Press ‘New’ to create the ID.

Use the Up/Down buttons to Show/Change characters.

When the correct character is shown, press and

hold the [+] key for one second to move to the

next character.

Correct mistakes by holding the [Del] key for

one second. Complete the process by pressing

‘Done’ briefly. Select ‘OK’ to accept the entry

or ‘Edit’ to modify the entry.

To modify or delete an existing Operator ID,

highlight the ID and select ‘Edit’ Choose either

‘Edit’ to modify the existing entry or ‘Delete’

to remove it from the list.

Deleting the Operator ID will not affect results

stored in the log. Up to 12 Operator IDs can be

stored and recalled from memory as required.

To return to the System menu, either select the

Operator ID required using ‘OK’ or highlight a

blank entry (if one is available) and press ‘Back’.

4.4.3 Sample ID

Optionally set the Sample ID using the same

method as Operator ID.

Up to 24 Sample IDs can be stored and

recalled as required.

Both Operator ID and Sample ID are stored

in the log with result and calibration data.

4.4.4 Units

Results can be displayed in NTU, FTU and FNU.

4.4.5 Language

Select English, French, German, Spanish or Italian

and press ‘OK’ to switch to alternative languages.

4.4.6 Set Time

Increase/decrease the time by using the Up/Down

buttons. When the correct time is shown select ‘OK’.

4.4.7 Set Date

Increase/decrease the date by using the Up/Down

buttons. When correct select ‘OK’.

4.4.8 Date Format

Select DD/MM/YYYY or MM/DD/YYYY as required.

4.4.9 Version

The serial number of the instrument and the

software version will be displayed.

The instrument serial number is required for

support and warranty claim.

4.4.10 Backlight

Select either ‘Off’ or ‘On’ as required. The

Compact Turbimeter will maintain the current

status until changed.

4.4.11 Start Page

The ‘Start Page’ allows the user to define a choice

of initial screens/modes on powering the Compact

Turbimeter. To change start page, highlight the

favoured choice for initial screen - Mode Menu,

Normal Reading Mode or Last Reading Mode.

The new Start Page choice will appear when the

instrument is next powered on.

Compact Turbimeter

4

4.4.12 LCD Contrast

The default setting is appropriate for all but the

most challenging light conditions but, should it

become necessary, the contrast setting for the

LCD screen can be manually adjusted.

Use the Up/Down buttons to adjust the image

on screen until the alternating shapes are clearly

visible and press ‘Back’.

4.5 Reading Menu

When taking readings ensure the cuvette is free

from dirt, dust and condensation using the supplied

lint free cloths.

Ensure the light cap is in place to prevent stray

light from adversely affecting readings. If no light

cap is fitted or the sample cuvette is not correctly

inserted Error 107: Blanking Error will be reported.

Microscopic scratches on the sample cuvette

will refract light and can lead to higher than

expected values.

To prevent scratches having an impact apply a thin

film of silicone oil (provided) to the sample cuvette.

Select the ‘Reading’ menu and choose from:

Normal - This mode reads the turbidity of the

sample in approximately eight seconds with an

audible beep at the start and finish of measurement.

Average - Selecting this mode prompts a further

choice of Short Average (3 readings), Medium

Average (6 readings) and Long Average (12

readings). Averaging readings is extremely useful for

turbidity measurement where particles are in motion

or where extremely high accuracy is required.

Continuous-Capture

This mode allows continuous reading of sample

turbidity until measurement is manually interrupted.

This mode will support cuvette indexing and

settling studies on rapidly settling samples.

Total Suspended Solids

The relationship between turbidity and suspended

solids can be approximated with correlated data.

The QuadoptiX™ bench provides the performance

required to produce reliable data for suspended

solids, based on calculated factors (slope and

offset) for turbidity versus suspended solids.

Default factors are not possible due to the unique

variety of size, shape and reflectivity of individual

sample matrices.

Calculated factors will provide a rapid qualitative

value for Total Suspended Solids that will be relevant

until process conditions change. This reading

mode will only become active upon a site specific

calibration being stored in the Compact Turbimeter.

4.6 Taking Readings

Normal Mode

Choose ‘Reading’ mode, select ‘Normal’

and press ‘OK’.

Insert the sample with the orientation

mark facing forward and press ‘Read’.

A beep will sound at the start and end

of measurement.

Result is displayed and stored in the results log

with date, time, Operator ID and Sample ID.

(NOTE: See the ‘System’ section for details

of the result log).

Average Mode

Choose ‘Reading’ mode, select ‘Average’

and press ‘OK’.

Select the number of readings required for the

averaging function:

Short Average - 3 consecutive readings

Medium Average - 6 consecutive readings

Long Average - 12 consecutive readings

Insert the sample with the orientation mark

facing forward and press ‘Read’.

The instrument will beep at the start and end of

measurement cycle. Result is displayed on the

screen and stored in the log with time, date,

Operator ID and Sample ID.

Continuous-Capture Mode

Choose ‘Reading’ mode, select ‘ContinuousCapture’ and press ‘OK’.

Insert the sample with the orientation mark

facing forward and press ‘Read’.

A beep will occur at the start and end of each

measurement cycle.

To store data in the log, press

(repeat as required). To cease measurement,

press ‘Back’ at any time.

‘Capture’

33

4

Compact Turbimeter

34

To index a cuvette, insert the sample cuvette

with the orientation mark facing forward.

Systematically rotate the sample cuvette 45°

at a time and record the position of the lowest

value. This is the optimal cuvette alignment for

low turbidity measurement.

Total Suspended Solids

This mode will only be active if a site calibration has

been stored within the Turbimeter. Once a calibration

has been created (via the ‘Calibration’ menu) the site

ID can be used to recall the site specific relationship

between turbidity and suspended solids.

Choose ‘Reading’ mode, select ‘Total Suspended

Solids’ and press ‘OK’. Highlight the Site ID for

the Site/Sample under investigation using the

Up/Down arrows. The calibration data will be

recalled automatically.

Insert the sample with the orientation mark facing

forward and press ‘Read’. A beep will occur at

the start and end of each measurement cycle.

Result is displayed on the screen in mg/l and

stored in the log with time, date, Operator ID

and Sample ID.

4.7 Calibration Menu

The Compact Turbimeter is delivered with a stored

calibration carried out on primary Formazin

standards and validated as part of the production

process. For field use, a set of calibration