Manual Instruction

Model 151

April 2005

palamides GmbH

Benzstraße 14 – 71272 Renningen

Tel: +49 (0) 7159 / 92570-0 – Fax +49 (0) 7159 / 92570-99

www.palamides.de

1

2

Contents

How it works......................................................................................................................7

1

2 Technical Data ..................................................................................................................9

3 Fundamental Safety Advice ............................................................................................11

4 Machine installation.........................................................................................................13

5 Description of the machine parts.....................................................................................16

6 Handling and Operation ..................................................................................................20

7 Setting up the machine....................................................................................................27

8 Optimisation menu ..........................................................................................................43

9 Quick set-up....................................................................................................................46

10 Quick Check....................................................................................................................47

11 Sensors, Pneumatics, Motors .........................................................................................49

Subject to change without notice

3

1

4

Subject to change without notice

How it works

We

Hereby declare that because of their design and construction, the machinery/devices

detailed below comply with the Health and Safety legislation of the EC-Machinery Directive.

This Declaration becomes invalid if an alteration is made which has not been agreed with

ourselves.

Product Automatic Delivery delta

1

Declaration of Conformity

Manufacturer Declaration

according to EC-Machinery Directive 98/37/EG, Annex II A

palamides GmbH

Benzstr. 14

71272 Renningen/Germany

Model 151, 152, 153

Serial number

Appropriate EC-Directives:

EC-Machinery Directive (98/37/EG)

EC-Low Tension Directive (73/23/EWG)

To comply the basic requirements we consulted the following appropriate standards:

EN 12100-1; EN 12100-2; EN 294

pr EN 1010 EN 60204-1

Date 16.10.2006

Signature (S. Palamides)

Identification of the

Signatory Managing Director

Sous réserve de modifications

5

1

How it works

Preface

You have acquired a technically superior industrial product in the delta automatic delivery

and by paying careful attention to the operating instructions, you will achieve the highest

levels of reliability and performance.

The delta is a fully automatic delivery system, which greatly rationalises the production

process behind the folding machine or saddle stitcher. Depending on the model, up to 5-up

work can be simultaneously processed in a very wide format range.

Sophisticated technical detailed solutions are responsible for the outstandingly high

production reliability. All sheets are measured at the infeed and, if necessary, are ejected.

The pile is bundled directly in the collection shaft using the patented operating process which

has been implemented in the delta.

Here, the most important aspect is not the bundling of the packages, but the rationalisation

achieved. By using a delta, one person can operate a folding machine rather than 2-3. With a

saddle stitcher, the work can easily be taken off the machine by the same operators who

load it.

• Rationalisation of the delivery process on saddle stitchers and folding machines.

• Makes use of the top running speed and performance of the producing machines

• Short setting-up times

• High efficiency due to the versatile application possibilities and the large format

range

• Pays for itself quickly

• Mark-free delivery (no smearing on freshly printed or sensitive sheets)

• Integrated pressing unit with main and pre-press rollers

• Ergonomically convenient working height for removing bundles

• By using different coloured bands per up-work, different versions (e.g. language

versions) can be easily distinguished.

These operating instructions should guide you in operating the stacking delivery correctly, in

complying with the safety regulations and in servicing the machine properly.

6

Änderungen vorbehalten

How it works

1 How it works

1.1 Area of application

The delta automatic delivery is primarily a fully automatic delivery system which greatly

rationalises the production process after a folding machine or saddle stitcher. The products

are counted and bundled in easily handled piles. Products such as advertising brochures,

mailings and signatures can be processed.

1.2 How it works

The delta automatic delivery is a fully automatic delivery system for cost-effective packaging

of pamphlets, signatures and brochures. Up to 5-up in a very large format range are

processed simultaneously. The exceptionally high production reliability is achieved through

sophisticated detailed solutions. As a result, all sheets are measured at the infeed and, if

necessary, ejected. The pressing unit, which is fitted as standard, together with the jogging

device, ensures that pile formation is neat and reliable. The pile is bundled directly in the

collection shaft using the patented operating process which has been implemented in the

delta. No slipping in the pile, whether unstable products or the smallest package, the delta

bundles reliably. Bundling is carried out using a choice of coated Kraft paper or PE film in

easily changeable magazines. The bundled packages are laid out on a package lift, which

conveys the packages to an ergonomically convenient working height.

1

Standard equipment

ELECTRONIC FORMAT MONITORING WITH WASTE SHEET DEFLECTOR

Incorrectly folded products are ejected.

ELECTRONIC CONNECTION TO MBO FOLDING MACHINES

Connection to the start/stop function, as well as the sheet call-up function

(24-pin design).

ELECTRONIC SHEET COUNTER

Counts the products irrespective of the production machine.

EQUIPMENT FOR PROCESSING MULTIPLE UP-WORK

delta up to 5-up, depending on model.

PRESSING DEVICE

Maximum 3.5t with pre and main pressing rollers.

Subject to change without notice

7

1

How it works

Options

SMALL FORMAT DEVICE

For processing products up to 90mm x 65mm.

STACKING LEVEL COMPENSATION 70MM

For forming tidy piles of spine stitched brochures and 4-sided folded products.

STACKING LEVEL COMPENSATION 150MM

For products which spread out heavily at the binding edge.

ANTISTATIC DEVICE

For improved processing of products laden with static.

AIR BLAST DEVICE

For smooth processing of difficult products on

Saddle stitchers and from layered folding.

SMALL PACKAGE DEVICE

For creating packages with a pile height of less than 20 mm

SADDLE STITCHER CONNECTION

For operation with saddle stitchers. An appropriate saddle stitcher plug to be

provided by the customer.

NAVIGATOR INTERFACE

For operation after MBO folding machines with Navigator control.

STAHL INTERFACE (10-PIN)

For operation after Stahl folding machines with 10-pin plug.

STAHL DIGITAL INTERFACE

For operation after Stahl digital folding machines

(only in connection with a 10-pin Stahl interface).

BARCODE RECOGNITION

For postcode sorting or for the collating function on digital printing machines.

PRINTER’S IMPRINT READER

For reliable separation of single book blocks in book-on-demand lines

CARD INSERTER

To supply a card for the upper and lower side of the pile, which is bundled with it.

8

Subject to change without notice

Technical Data

2 Technical Data

2.1 Formats

2

Minimum format

(without small package device)

Minimum format

(with small package device)

delta502

Infeed width x Infeed length

110mm x 95 mm

90 mm x 65 mm

max. for 1-up 510 mm x 305 mm

max. for 2-up 235 mm x 305 mm

delta703

max. for 1-up 760 mm x 305 mm

max. for 2-up 335 mm x 305 mm

max. for 3-up 235 mm x 305 mm

delta705

max. for 1-up 760 mm x 305 mm

max. for 2-up 335 mm x 305 mm

max. for 3-up 235 mm x 305 mm

max. for 4-up 175mm x 305 mm

max. for 5-up 148 mm x 305 mm

min. package height (without small package device) 20mm

min. package height

max. package height (

with small package device) 3mm

depends on product ) 150 mm

Performance Over 600 Packages/h per up-work

Over 60.000 Products/h per up-work

product)

(depends on

Speed 15-200m/min

Subject to change without notice

9

2

Technical Data

Noise level, measured according to EN 13023:2003 does not exceed 83dB(A)

(Measuring device B&K, Type 2221, Serial no. 16 95 9 64, microphone type

4176, no. 1718861, accuracy class 1, acoustic calibrator type 4230, serial no.

1678942

2.2 Connections

Elec. connection 6 KW

Compressed air

consumption

The supply of purified, dry compressed air (6 bar) is not included in delivery.

delta layout

350 ltr/min net, 6 bar, dry, filtered air supplied by the

customer

10

Subject to change without notice

Fundamental Safety Advice

3 Fundamental Safety Advice

3.1 Warning advice and symbols

This symbol means immediate, imminent danger to a person's life or health.

!

DANGER

!

WARNING

!

CAUTION

Ignoring this warning results in severe consequences for a person's health,

up to critical injury.

This symbol means possible, imminent danger to a person's life or health.

Ignoring this warning results in severe consequences for a person's health,

up to critical injury.

This symbol means a possible dangerous situation.

Ignoring this warning results in severe consequences for a person's health

and / or damage to property.

3

3.2 Permitted use

The "delta" Automatic Delivery intended solely as a delivery for folded brochures and spine

stitched brochures in paper processing companies. Any other or any additional use is not

regarded as a permitted purpose. “Palamides” is not liable for any damage arising from this.

3.3 Safety at work

1. At the time of supply, “palamides” Automatic Deliveries meet all safety-related

regulations. For this purpose, moving and rotating parts are covered with safety hoods,

which are mechanically, or rather, electrically locked in such a way that no unreasonable

interference with the operation exists.

2. It is extremely important with all safety related measures that the operating personnel

practice high safety levels and have remaining sources of danger pointed out to them

and/or impairment of the machine and other material assets cannot be excluded.

3. The machine may be operated only when in perfect technical condition. Faults which may

impair safety are to be removed immediately by trained personnel or personnel from the

manufacturer and/or supplier.

4. Before you operate the machine, read carefully through all the operating instructions,

including the safety and service conditions.

5. The operating instructions must always be handy near the machine.

6. If necessary, supplement the operating instructions with internal safety regulations, as

well as with legal accident prevention regulations.

7. If machine personnel changes frequently, make sure that all machine operators are

informed, or rather, trained in the previously mentioned points.

Subject to change without notice

11

3

Fundamental Safety Advice

8. Never remove the protective, or rather safety devices on the machine and never alter the

machine so that safety can no longer be guaranteed.

9. Only use tools which are in perfect condition and take care that no tools are

!

10. Pay attention to all safety and danger tips on the machine and keep these tips in a

legible / visible condition.

11. Report all audible / visible safety-related machine changes to the appropriate authority in

your works.

12. Operating personnel must have long hair tied back and may not wear loose clothing or

jewellery, including rings. There is a danger of injury should they get caught up or drawn

in.

13. When the machine is running, never try to clean it (rollers, belts), or to rectify faults or set

it up.

!

left lying on the machine after adjustment or maintenance work. Tools which

may fall into the machine can lead to serious consequences for both man

and machine.

14. Make sure that no other person switches the machine on while you are busy

on it - e.g. whilst setting up or during other work! >Danger< Therefore,

always press the EMERGENCY-OFF Button

15. Do not immediately switch the machine back on if it stops for some unknown reason.

Make sure first that the machine is in perfect condition and that no other person is busy

on the machine.

16. If you have to carry out extensive mechanical / electrical maintenance or repair work to

the machine, turn off the main switch and, if necessary, secure it with a padlock.

17. Never open the main control cabinet or lower service cabinet! Electric, or

!

18. Report any exposed cables or electrical connections to the appropriate authority in your

works.

!

!

rather, electronic work may only be carried out by relevant authorised

personnel or by the manufacturer’s or supplier’s personnel. >MORTAL

DANGER< with the control cabinet OPEN! With the control cabinet opened,

even with the main switch turned off, there is still electrical current on the

main terminal clamps!!!

19. According to the latest safety regulations, the machine must stop if one of

the safety hoods is opened. The hoods, which serve both as safety and

noise dampening hoods, contain electrical switches. These switches may

never be dismantled or bridged, as this would mean >DANGER<

and limb of the operator.

20. >DANGER<

necessary to ensure that the hoods are completely opened as far as they will

go.

In order to stop the hoods from closing themselves, it is

to the life

12

Subject to change without notice

Machine installation

4 Machine installation

4.1 Transport

Lifting load delta502 (incl. packing) at least 1400

Lifting load delta700 (incl. packing) at least 2t

Length of forks delta502 at least 1,20 m

Length of forks delta700 1,40 m

The packaging varies depending on the country being delivered to. However, the pallet has

the same design for all packaging variations.

The forks of the forklift truck must be positioned as shown in the photograph below because

of the centre of gravity. The machine must be moved carefully in order to prevent it from

tilting.

delta

4

Picture 1784-r

4.2 Unpacking

Remove the plastic packaging or the seaworthy crate from the machine. The machine is

secured and screwed down to the transport pallet by metal angled pieces. Remove the

screws so that the metal angle pieces (1) can be removed.

Check the machine for any transport damage. If there are any faults or damage, contact the

supplier or the transport company immediately, giving the machine description and serial

number.

Subject to change without notice

13

4

Machine installation

Metal angled pieces

(1)

(1)

Picture 8467

The machine can then be taken off the pallet using a forklift truck. The forks of the forklift

truck must be positioned as shown in the photograph below because of the centre of gravity.

The machine must be moved carefully in order to prevent it from tilting.

IP: Screw the adjustable feet (2) in the holes. The adjustable feet are part of the

T

accessories in the tool box delivered with the machine. They are screwed into the machine

frame.

View

Picture 1779

(2)

14

(2)

Picture 1782

Subject to change without notice

Machine installation

4.3 Cleaning

The machine must be cleaned with a soft cloth before commissioning. All bare metal parts

must be freed from rustproofer using a clean cloth.

4.4 Positioning the machine

The machine can be pushed into place and secured there using the adjusting feet.

4.5 Electrical connection

Check that the electrical supply meets requirements. Details about the distribution voltage,

frequency, fuse protection and connection specific to the country in question can be taken

from the wiring diagram. The wiring diagram is in the documentation folder.

4.6 Checks before first commissioning

4

4.6.1 Control box

During transport, it is possible that the screws on the electrical terminals are loosened. In

order to ensure trouble-free operation, it is necessary to tighten up the terminals of the relays

and contactors.

4.6.2 Safety hoods function

Before the machine is integrated into the production process, the function of every safety

hood switch must be checked, in order to ensure that the machine functions perfectly.

View

1

2

Picture 1725 Picture 1724

3

(1) Circuit breaker

hood press

(2) Circuit breaker

hood shaft

(3) Circuit breaker door Signals the controls that the door is open

Subject to change without notice

Signals the controls that the hood is open.

Signals the controls that the hood is open

15

5

Description of the machine parts

5 Description of the machine parts

5.1 Machine group designation

This chapter contains the designations for individual machine groups.

delta

1

2

3

4

5

6

7

8

Abb.1040841r

1 Upper band unwinding 5 Operating controls

2 Jogging gear 6 Pressing unit

3 Side loader 7 Round belts infeed

16

4 Lower band unwinding 8 Delivery

Package lift left and right side view

1

2

Abb.1601

1 Package lift ejector 2 Package lift table

Abb.1598

Subject to change without notice

Description of the machine parts

View to the front

5

1

2

5

3

Abb. 1040884

1 Upper band pressure shaft 4 Elevation table

2 Stacking level compensation 5 Dummy plate

3 Rear jogger 6 Contact pressure axle

3a Rear jogger adjustment 7 Complete adjusting frame

View to the back

6

3

4

3a

3

3a

3

Abb.1040868

Subject to change without notice

7

17

5

Description of the machine parts

View

1

2

3

4

Abb. 1040849

1 Upper belt contact pressure shaft 3 Stopper finger

2 Buffer spring 4 Support finger

View

1

2

18

Abb. 1040852

1 Shingling axle 2 Presssing unit

Subject to change without notice

Description of the machine parts

5.2 Self control mode

Usually, the machine operates at a folding machine or a saddle stitcher. Optional coupling

boxes are available for operation at this equipment. The machine is compatible with MBO as

standard. The 24-pin plug can be plugged directly into an MBO folding machine. If you wish

to work without the appropriate coupling, the machine can be operated using self control

mode.

OTE: There is no communication with the rest of the equipment in self control mode. The

N

rest of the equipment continues to run when there is a fault at the delivery. With self control

mode, the delivery must always be monitored.

Standard Self control mode

5

Abb.1744

Navigator inclusive Navigator self control mode

Abb.1743

Abb. 1617 Abb.1619

Subject to change without notice

19

6

Handling and Operation

6 Handling and Operation

6.1 Operating controls

The operating controls have the following functions:

• Operating the machine

• Adjusting the machine

• Information for machine operators

• Information for maintenance personel

• Information for service technicians

The machine is operated with the assistance of the menu guide on the display. If a key is lit

up, this option is activated. If the key flashes, it is waiting for input. The display shows which

inputs can be made. Confirm with enter. Repeatedly pressing the option key will lead back

to the main menu. Those authorised to service the machine and service engineers have

access to certain machine data via submenus.

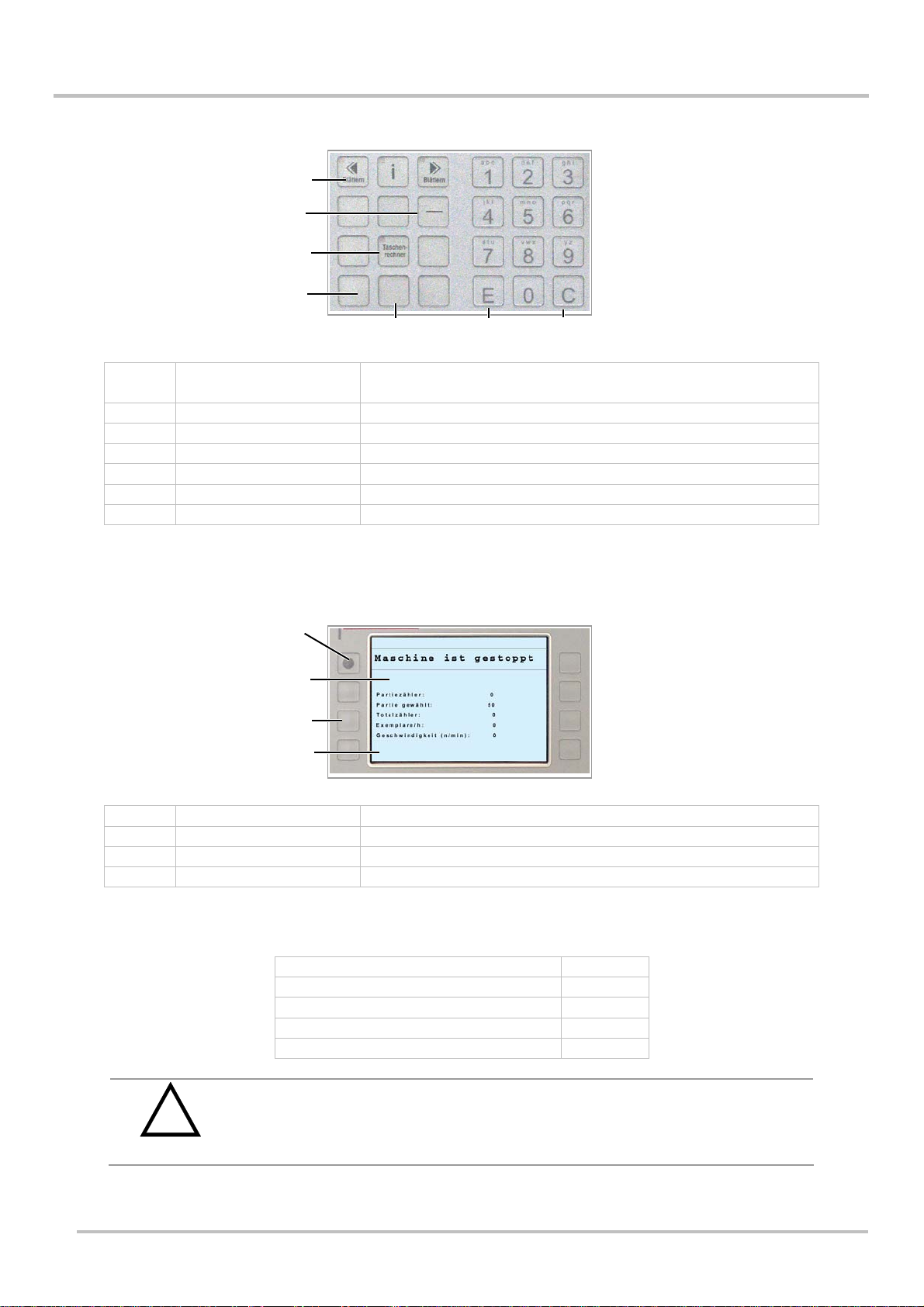

Group 2

Group 1

Group 3

Group 4

Abb.497

Group 1 Switching on and operating the machine

rotary switches - speed

Group 2 Function menu

Group 3 Display

Group 4 Numeric pad, keys for scrolling further menu

guide

20

ubject to change without notice

Handling and Operation

Group1 description

(1) Emergency-off Used to switch the equipment off immediately there is a

(2) Stop Switches the machine off.

(3) Start Starts the machine

(4) Sheet call-up

Only in connection

with an MBO folding

machine

(5) Single sheet

Only in connection

with an MBO folding

machine

(6) Speed press drive

with machine running

Inching mode

With machine stopped

(7) Preselect inching

mode

(with pressing unit

hood open)

(1)

(2)

dangerous situation. The switch locks when pressed and

the machine can only be restarted by pulling it out (turn the

button in a clockwise direction).

Note: Data is not deleted when the emergency-off button

is pressed. This means that, after re-starting, work

continues from the point where it stopped before the

emergency-off button was activated.

Deletes errors. This still shows on the display after

mechanical removal of a fault. The message is deleted by

pressing the stop button.

Note: Data is not deleted when the stop button is pressed.

This means that, after re-starting, work continues from the

point where it stopped before the stop button was

activated.

Note: After pressing the start button, the equipment needs

a few seconds until it is operational. During this time, any

products which may be moving through the machine will be

ejected via the waste sheet deflector.

Sheet call-up to the folding machine.

With MBO Navigator connection: Deletes errors on the

folding machine.

A single sheet can be called up from the folding machine

by pressing this key, e.g. for “calibration” mode.

The speed of the press drive can be altered by turning the

inching switch so that the machine can be aligned to the

speed of the folding machine.

Note: In inching mode, the press drive runs forwards or

backwards when the switch is activated in single sheet

mode. In shingled stream mode, only forwards.

Inching mode is enabled with the hood open by pressing

this key. Speed is reduced. Switch (6) lights up and is

enabled for inching mode

Note: Function 2. Only with open hood.

This inching mode is only enabled for the press drive.

(4) (5) (6) (7)

(3)

Abb.7677-2

6

Subject to change without notice

21

6

(5)

(6)

Group 2 description

(11)

Handling and Operation

(12)

(1)

(2)

(3)

(4)

(1) Set up All adjustments which are necessary for operation

are carried out in this menu

(2) Optimisation All adjustments which differ from the default values

are carried out in this menu.

(3) Manual mode The selected drives are operated manually in this

menu

(4) Service Service functions are accessed in this menu. Partly

password protected.

(5) Error The latest errors are shown on the display when this

button is pressed. Errors are described during

operation.

(6) Auto set up First calibrate! The shingling axle will run to the

calibrated sheet length by pressing the “auto set up”

key

(7) Home position /

remainder packing

(8) Calibration The small control light on the key flashes when this

(9) Inspection sheet 1. The waste sheet deflector ejects the next sheet.

(10) Language Choice of language

(11) Single sheet

Activates the single sheet

(12) Options All options offered by this machine are displayed

1. When the machine has stopped, it is brought to

the home position by pressing this key

2. When the machine has started, the function of this

key is remainder packing.

key is pressed. The next sheet that comes along will

be measured and taken as a reference. The light

goes out.

2. The key flashes if it is pressed approx. 3 sec. All

further sheets will be ejected until the key is pressed

again.

Alternates between “shingled stream” mode and

“single sheet” mode.

In single sheet mode the transport belt runs

continuously. In shingled stream mode the transport

belt only runs when products are fed in.

when this key is pressed. Optimisation of the options

can be carried out here.

(10)

(9)

(8)

(7)

Abb.491

22

ubject to change without notice

Handling and Operation

Group 4 description

6

(1)

(2)

(3)

(4)

(5)

(1) Scroll A flashing "scroll” key signals that further menu items are

available. These can be accessed by pressing the key.

(2) Minus Enters minus values

(3) Calculator

(4) Elevation table down Only works when the machine has stopped

(5) Manual welding Only works when the machine has stopped

(6) Enter Saves newly entered values

(7) Delete Deletes values called up

Group 3 description

Information which is normally standard and cannot be altered, appears on the display.

(6)

(7)

(1)

(2)

(3)

(4)

(1) Homepage Back to the homepage

(2) Status line

(3) Menu items Selection and display of menu items

(4) Standard info

Standard information:

Batch counter 0

Batch selected 50

Total counter 0

Examples / h 0

Speed (m/min) 0

Machine damage by pulling the power supply plug.

!

CAUTION

Electronic components can be damaged.

Only pull the power plug when the main switch is switched off..

Abb.1937-03

Subject to change without notice

23

6

Handling and Operation

6.2 Plan of the delta automatic delivery

The delta must be aligned to the folding machine so that the product stream is transferred

evenly and assigned to the relevant shafts. The height of the delivery must then be aligned

exactly to the height of the folding machine. The product stream must be conveyed to the

relevant shafts. The round belts must be parallel so that the products are not twisted..

Top view plan

6.3

5 2

1

Folding machine 4 Pre press roller

2

Round belt shaft 1 5 Main press roller

3

Round belt shaft 2 6 Shaft infeed

36 4

1

24

ubject to change without notice

Handling and Operation

6.4 Installing the automatic delivery

1. Place the machine in the middle in front of the folding machine.

2. Lock the adjusting feet (1). Spanner 12 (picture 1726)

Adjusting feet

6

1

Abb.1726

1. Establish power supply

2. Establish connection to the folding machine

3. Connect compressed air

!

CAUTION

Risk of stumbling over connecting cables and hoses.

Lay cables and hoses so that there are no places forming a tripping hazard

Subject to change without notice

25

6

Handling and Operation

Clamping lever

2

Abb.1040834

4. Open lever (2) on the delivery

5. Adjust delivery

6. Switch on main switch

Plan of the side view of the delivery

Brochure strikes the round belt opening exactly

26

ubject to change without notice

Setting up the machine

7 Setting up the machine

Setting the machine up for new jobs is described here. Each step is described in the order

that has proved itself in practise.

7.1 Infeed through the round belts

The round belts take the products from the folding machine or saddle stitcher.

For multiple up work, the products must be spread out. The angled infeed aligns the product

to the pile containers.

Note the sequence for adjustments:

1. upper round belt shaft 1

2. lower round belt shaft 2

3. upper round belt shaft 3

4. lower round belt shaft 4

7

Plan of the side view of the delivery

TOOLS REQUI4RED:

Allen key or screwdriver

Danger of being caught in running belts.

!

WARNING

Tools or fingers can be pulled in.

Let the belts run very slowly. Set the press drive at minimum speed for

this..

3

4

1

2

Subject to change without notice

27

7

Setting up the machine

Adjust upper round belts of shaft 1:

1. Loosen two infeed photocells BEX 02.01 and BEX02.02.

Ö Three belts are provided for each up-work as standard.

2. Open safety hood.

3. Set to inching mode and turn speed regulator.

4. Move the middle belt to the middle of the product.

Move both outer belts up to 20-30mm to the edge of the product.

View

Adjustment of the round belts

Upper round belt view

Abb.8879

1. Carry out this adjustment for each up-work of the product.

View

28

delta 3-up delta 5-up

Re-adjust the round belts for each up-work

ubject to change without notice

Setting up the machine

Adjust lower round belts of shaft 2:

1. Set the lower belts exactly below the upper belts.

Obere Rundriemen der Welle 3 einstellen:

Ö The products are driven along the course of the round belts. Set the round

1. Align belt (2) to the transport belt (1).

Ö see picture 1040837

2. Align both outside belts parallel to each other. In doing so, pay attention to the

number of grooves on round belt shaft 1.

3. Use the number of grooves to adjust both outer belts. This will ensure that the

product is not fed in at an angle.

Round belt adjustment

1

7

belts of shaft 3 so that there is an exact allocation to the relevant shaft.

2

Abb. 1040837

1 Transport belt 3 Photocell

2 Round belt

Wrong

Adjust lower round belts of shaft 4:

1. Place the lower belts exactly under the upper belts.

2. Repeat these steps for all up-works of the product.

3

Subject to change without notice

29

7

Setting up the machine

Position photocells

1. Fix the photocells between the round belts.

Ö On both outside streams

2. All belts must run freely.

3. Ensure that the round belts do not touch the photocells or their cables.

4. Ensure that there are no round belts under the photocell.

Ö The diode on the photocell does not light up

Adjustment for large formats

&

Round belts, large product, top view

For large formats, the products cannot be fed into the middle of the shaft.

The band is then no longer in the middle of the product. This has no

adverse effect on functionality.

7.2 Presse drive

The round belts and the folding machine must run at the same speed. This guarantees

trouble-free transfer of the products.

30

1. Adjust the speed using the press drive inching switch.

With the machine started

2. The difference in speed between the production machine and the delivery may

not be more than 10%.

3. Speed is shown in the display.

ubject to change without notice

Setting up the machine

7.3 Presssing unit

The pressing unit consists of pre and main pressing rollers. The pre-press rollers press any

trapped air out of the product. The main press rollers press the product with up to 3.5t.

7

Adjust pressing unit:

Adjust pressing unit

(4)

(3)

Abb.1735

1. Loosen all four star handles (1).

2. Open lever (2).

3. Put under 75% of the product (4).

4. Put under 50% of the product (3).

5. Carry out the adjustment on both sides

6. Close the lever

7. Re-tighten the star handles.

IP: Tighten only by hand

T

N

OTE: Check product for marking

(1)

(2)

Subject to change without notice

31

7

Setting up the machine

7.4 Sheet calibration

This function saves the linear measurement of the product being processed. All further

sheets are compared to this reference value. Photocells BEX2.1 und BEX2.2 measure the

sheet format.

1. Position infeed photocells BEX2.1 and BEX2.2 on the delivery above the

product.

2. Press the following sequence of keys.

1 Home position

2 Start

3 Calibrate, key flashes

4 Single sheet call-up

Control panel

Abb.491

Control panel

Abb.7677-2

(2)

(3)

(1)

(5)

(4)

32

7.5 Auto set up

The shingling axle adjusts automatically to the length of the product.

1. Press the following sequence of keys:

1 Calibrate sheet

2 Auto calibrate

ubject to change without notice

Setting up the machine

7.6 Shingling device

After the pressing unit, the products are taken over by the transport belts. The shingled

stream is formed at the shingling axle.

Shingle formation is automatically calculated and adjusted when the sheet is calibrated

The lower belts after the pressing unit can be adjusted in height. The shingling axle (2) is

adjusted to the product’s size using the “auto calibrate” function. The shingling axle can be

readjusted in the “manual function” menu. This takes place using the manual function key on

the operating controls. The upper / lower belt pressing force must be lowered for thick

products. This takes place by turning the shingling axle by up to +/-90°. The shingling axle

is supported eccentrically.

Adjust infeed angle:

7

Shingling axle

Abb.1616

1. Loosen knurled screw (1)

2. Adjust lower belts (2)

3. Tighten knurled screw

1

2

Subject to change without notice

33

7

Setting up the machine

Reduce upper/lower belt pressing force:

Shingling axle

2

1

Abb.8921

1. Loosen set screw (1)

2. Adjust the shingling axle (2) to the thickness of the product

3. Tighten set screw

7.7 Shaft infeed

Adjust upper belt:

In addition, the product can be fed by adjusting the upper belts.

1. Turn the knurled screw (4)

Ö The upper belt pressure shaft (3) is adjusted

Upper belt pressure shaft

4

34

3

Abb.1653

ubject to change without notice

Setting up the machine

Adjust support finger:

The product is additionally stabilised by raising the support finger so that it does not bend

into the shaft.

TIP: Important adjustment for smooth operation.

1. Lift the stop rocker (7) and let it engage

2. Loosen knurled screw (6)

3. Adjust the support finger (5) to the format

4. Loosen the stop rocker holder and locking button (8)

5. Engage the stop rocker back down

Support finger

7

7

8

5

6

Abb.1658

Subject to change without notice

35

7

Setting up the machine

Adjust pressure axle/ contact rollers:

1. Adjust the pressure axle (9) using the knurled screw (10)

Ö Adjust equally on both sides

Ö Loosen the set screw on the contact rollers (11)

Ö Adjust the contact rollers to the product

Ö Tighten set screw

Pressure axle / contact rollers

10

9

11

Abb.1654

Knurled screw contour pre-setting

36

3.2.a

ubject to change without notice

Setting up the machine

7.8 Shaftt

The products are stacked in the shaft and knocked-up by jogging plates. This ensures that a

tidy pile is formed. Two lateral jogging plates and the back jogger on the adjusting frame

undertake this function.

Adjust lateral jogging plates:

Two jogging plates are required per up-work.

Jogging plates

7

(1)

(1)

Abb.1654

1. Loosen lever (1)

2. Adjust both jogging plates to the height of the product

Ö The jogging plates are located in the narrowest position when the machine

stops

Set the adjusting frame to the product length:

(1)

Abb.1731

1. Loosen lever (1)

Subject to change without notice

(2)

37

7

Setting up the machine

2. Set the adjusting frame to the product width,

by turning the knurled screw (2)

Adjusting the angle of the rear jogging plate

(4)

(2)

(1)

Abb.1040864

1. Loosen both screws (1) using allen key no. 4.

2. Set the angle of the jogging plate to the products.

Ö by adjusting the lever (2).

3. Tighten both screws again (1).

38

ubject to change without notice

Setting up the machine

7.9 Delivery unit

By adjusting the side loader to the required delivery side, the machine automatically identifies

the delivery direction. Adjustable in 4 delivery directions.

Adjusting the side loader to the package lift

7

Abb.1040836

Package lift

Abb.1598

!

WARNING

(1)

Danger of being crushed by pusher moving upwards.

Tools or fingers can be pulled in.

Do not reach into open area (1).

Subject to change without notice

39

7

Setting up the machine

7.10 Adjustments at the operator controls

(3)

1 Home position 4 Single sheet call-up

2 Auto set up 5 Inching button

3 Set up 6 Calibrate

Changing values:

1. Select menu

2. Select function

3. Enter value

4. Confirm with “E”

5. if required, delete with “C”

(2)

(1)

(6)

(5)

Picture 497

(4)

40

Subject to change without notice

Setting up the machine

7.10.1 Batch counter

The batch amount is the number of products per package

1. Press the set-up key on the operator controls

Ö Enter the number of pieces in the batch and press “E”.

7.10.2 Stacking level compensation

Enter the amount at which the stacking level compensator should activate.

0 = switched off.

7.10.3 Sheet thickness

The destacking amount is calculated by entering the sheet thickness. The destacking

process repeats itself once the destacking amount is reached.

1. Measure the height of 10 sheets at the spine.

2. Press the set-up button on the operator controls and follow the instructions.

Reduce the value if the machine destacks too quickly

Increase the value if the machine destacks too slowly

7

Measuring device

Picture 1921

7.10.4 Total counter

Set by entering a user-defined value, or set to zero

7.10.5 Package lift cycles

Number of packaging cycles until the package lift starts.

7.10.6 Load default values

The factory settings for this menu are loaded by entering 1

7.10.7 Band type

The type of band can be selected here. Paper or PE.

Subject to change without notice

41

7

Setting up the machine

7.10.8 Jogging function in the packaging cycle

The jogging function during the packaging cycle can be blocked here

0 = normal

1 = continuous operation in the packaging cycle

7.11 Single sheet operation

Single sheet mode is recommended for sensitive or freshly-printed products, thick products

or a low folding speed.

Choose single sheet operation for products with a sensitive surface e.g. pages of books or

art printing. It is possible that these products could be marked during shingling or when the

stopper reaches into the shingled stream. Single sheet operation should also be chosen for

freshly-printed products. These products tend to rub against each other as the products are

pushed on top of each other during shingle formation.

The [shingled stream / single sheet] key alternates between these two operating modes.

Single sheet mode can be recognised by the transport belts running permanently.

7.12 Shingled stream operation

Shingled stream operation is suitable for non sensitive products, small formats or high

production speed, e.g. newspaper inserts, mailings, flyers.

The transport belt is timed with photocells BEX2.1 and BEX2.2 and only runs when products

are fed in. Shingle formation can be increased or decreased as required. This is carried out

in the optimisation menu.

42

Subject to change without notice

Optimisation menu

8 Optimisation menu

Adjustments which deviate from the default values can be made in the optimisation menu.

8.1 Package compression

Adjustment to package compression during production.

The values lie between -200 mm and +200 mm. The higher the value

the stronger the pressure on the package.

8.2 Intermediate position

The intermediate position starts after the last product in the stack has fallen on to the

elevation table. The intermediate position is required so that the pressing rails can be

retracted.

For products which spring open, it can be necessary to lower the intermediate position so

that there is enough room for the pressing rails to retract.

The setting range lies between -200 mm and +200 mm. Ideally, after reaching the

intermediate position, the upper edge of the package is approx. 20 mm under the pressing

rails.

8

8.3 Pressing rails earlier / later

After reaching the intermediate position, the pressing rails move to their working position.

The package can be pressed. Depending on the format, it could make sense to move the

pressing rails to the working position earlier or later. The smaller the value, the earlier the

pressing rails are started.

Pressing rails started too soon

Picture 932

Pressing rails started too late

Picture 933

8.4 Sheet gap (only in single sheet mode)

The sheet gap in single sheet mode can be adjusted here. Adjustment made in mm.

Subject to change without notice

43

8

Optimisation menu

8.5 Sheet fall time (only in single sheet mode)

The sheet fall time can be entered here. Enter in msec.

8.6 Shingling

Overlapping in the shingled stream can be adjusted in the shingling menu item. The values

can be varied from 40% - 90%. At 40%, the products will overlap 40%.

8.7 Stop

The stop time can be adjusted proportionally until the interruption in the shingled steam is

sufficient for the pressing rails to extend. Values can be set at 10% to 150%. Default value

75%.

8.8 Amount of folding errors

The number of recognised folding errors at which the machine will stop can be entered here.

0 = switched off.

8.9 Load default values

Default values are loaded by entering 1.

8.10 Tolerance

All products are measured by the delivery’s infeed photocell. Now, extra tolerance to the

reference value, which is measured by the calibrate key, can be entered in 0.1 mm. Products

which exceed this value + the tolerance value are ejected via the waste sheet deflector.

8.11 Jogging time

The jogging frequency can be adjusted here. The set time in msec. units corresponds to one

full phase.

8.12 Jogging motor

Jogging can be adjusted if required. The lower the value, the slower the jogging frequency.

All joggers, back joggers and side joggers are simultaneously set with this adjustment.

44

8.13 Pre-collection finger delay (not active on the delta705)

In the working position, extension of the pre-collection finger can be delayed with this

adjustment. Adjustment depends on the product and the speed. The greater this value, the

later the pre-collection finger retracts

Subject to change without notice

Optimisation menu

8.14 Stacking level compensation delay OUT (not active on the

As the elevation table returns from the intermediate position to the pressing unit, the flaps on

the stacking level compensator are reset. Resetting the stacking level compensator is

delayed by increasing this value.

This can be necessary for spines that spread out excessively at the spine.

8.15 Welding time

This adjustment determines for how long the band is welded. Band type is selected in the

option menu. Paper or plastic film. The welding time is chosen depending on the material.

8.16 Cooling time

This adjustment determines for how long the band is cooled. Band type is selected in the

option menu. Paper or plastic film. The cooling time is chosen depending on the material.

8.17 Sheet recognition

8

delta705)

In double stream, it could happen that products arrive offset in the delivery. Ejection of the

products can be cancelled by changing sheet recognition via a photocell.

8.18 Shingling belt speed (only in single sheet mode)

Constant speed for the shingling belt in m/sec. .

0 = automatic mode

Subject to change without notice

45

9

Quick set-up

9 Quick set-up

Short introduction for quickly setting-up the machine:

More detailed information can be found on the pages indicated.

9.1 Mechanical set-up

1. Set up machine to the previous machine and lock the adjusting feet Page 25

2. Adjust delivery’s height Page 25

3. Call up one product from the folding machine or saddle stitcher

and adjust round belts Page 20

4. Set infeed photocell Page 19

5. Adjust pressing unit Page 31

- Folding machine 1. Pre press roller 75%

2. Main press roller 50%

- Saddle stitcher 1. Pre press roller 125%

2. Main press roller approx. 100% or more

Controls:

1. Press calibrate key Page 37

2. Call up product

3. Press auto calibrate key Page32

6. Call up the product and allow it to run up to the shaft by

pressing the rocker switch. Page 37

7. Adjust lateral jogging plates to the product. Page 37

8. Adjust adjusting frame to the product width Page 34

9. Adjust support finger under the product edges. Page 34

46

9.2 Controls

1. Enter amount Page 39

2. Set total counter to zero Page 41

3. Select single sheet or shingled stream depending on

the product and speed. Page 42

4. Align the round belt’s speed on the folding machine

or saddle stitcher +/-. 10%. Page 30

Subject to change without notice

Quick Check

10 Quick Check

9 questions that you should ask yourself after set up.

10

1. Is the height of the delivery to the folding machine correct?

Plan

2. Are the brochures conveyed at an equally slanted angle?

3. Are the round belts running parallel to each other and are they adjusted

correctly to the product?

View

Subject to change without notice

47

10

Quick Check

4. Is the difference in speed between the folding machine and the automatic

bundling delivery less than 10%?

5. Are the infeed photocells free?

6. Have the pre and main pressing rollers been adjusted to the product

thickness?

View

7. Do the transport belts convey the shingled stream continuously without

faltering?

8. Are the shingled streams fed into the middle of the shafts?

View

9. Have the support fingers in front of the shaft been adjusted?

Upper round belts view

48

3.2.a

Subject to change without notice

Sensors, Pneumatics, Motors

11 Sensors, Pneumatics, Motors

11.1 The sensors used and their function

Article

No.

Description Functional principle Picture

11

61.00002 Reflection light

scanner TW1040mm

Reflection light

scanner with

background

shielding

B8, B9….

61.00025

61.00026

63.00117 Inductive proximity

Rotary pulse

encoder

switch

A transmitter sends out light in the

infrared range, which reflects from the

detected object and is sent back to the

receiver in the light scanner.

Objects, which are more than 40 mm

away are suppressed by this.

When an object is detected, the LED

on the scanner lights up and the output

returns 24V DC.

.

Rotary pulse encoders convert

rotational turns into impulses. These

signals can be evaluated so that

conclusions can be drawn about the

paths covered.

The encoders fitted by palamides are

equipped with two impulse tracks,

which also enable recognition of the

direction of rotation (left/right turning).

The second track (B-track) is placed at

90° to the A-track.

Encoders with 32 and 200 impulses

respectively are used on the delta. As

the sensors do not have any sort of

display, their function can be checked

under service / TPU counter.

If a metal part penetrates the working

area of the sensor, losses occur in the

eddy current of the magnetic field

shown by the sensor. These are

recognised by the sensor and it sends

a signal with 24V DC to its output.

At the same time its status is signalled

to the terminal by a LED. Generally,

the nearer the detected metal object is,

the quicker the sensor switches.

links rechts

Subject to change without notice

49

11

BE 5.09

BE 5.10

BE 4.01

BE 5.05

BE 5.07

BE 5.06

BE 5.08

BE 4.04

BE 4.02

Sensors, Pneumatics, Motors

11.2 Sensors

Delta sensors overview

BE 2.01

BE 2.02

BE 2.03

BE 2.02

BE 2.01

Abb.575-5

Delta sensors overview

BE 4.07

BE 4.08

BE 5.04

50

Abb.1589-r

Subject to change without notice

Sensors, Pneumatics, Motors

Sensors BEX 2.1 and BEX 2.2

Delivery

11

BEX2.1

BEX2.2

Abb.567

Sensor Position/ Description Function

BEX2.1 Sensor sheet measurement Count and measure sheets

BEX2.2 Sensor sheet measurement Count and measure sheets

Shaft encoder BEX 2.03

Press shaft encoder

BEX 2.03

Abb. 550

Sensor Position/ Description Function

BEX 2.03 Press shaft encoder The current rotational speed is sent to the controls

Subject to change without notice

51

11

BE4.01

Sensors, Pneumatics, Motors

Shaft encoder BE 4.01

Belt drive shaft encoder

Abb.552

Sensor Position/ Description Function

BE4.01 Belt drive shaft encoder Rotational speed control of the belt drive

Shaft encoder BE 4.02

Elevation table shaft encoder

BE4.04

BE4.02

52

Abb.565

Sensor Position/ Description Function

BE4.02 Elevation table shaft encoder Determines the position of the elevation table

BE4.04 Sensor Elevation table home position

Subject to change without notice

Sensors, Pneumatics, Motors

Sensor BE 4.05

Right side loader

BE4.05

Abb.07

Sensor Position/ Description Function

11

BE4.06

BE 4.05 Right side loader

BE 4.06 Left side loader

Sensor BE 4.07 und BE 4.08

Ejector shaft encoder

BE 4.07

Abb. 1030565

BE 4.08

Sensor Position/ Description Function

BE 4.07 Ejector in home position

BE 4.08 Ejector in operating

position

Subject to change without notice

53

11

Sensors, Pneumatics, Motors

Sensor 5.04

Package lift right side

Abb. 569

Sensor Position/ Description Function

BE 5.04 Package lift right side When activated, the package lift is located on the

right hand side

Sensor BE 5.05

Pressing rails

BE 5.05

54

Abb.570

Sensor Position/ Description Function

BE 5.05 Pressing rails in home position

Subject to change without notice

Sensors, Pneumatics, Motors

Sensor BE 5.08 and Sensor BE 5.06

Pressing rails

11

BE 5.08

BE 5.06

Abb.571

Sensor Position/ Description Function

BE 5.08 Welding die in operating position

BE 5.06 Pressing rails in operating position

Sensor BE 5.07

Welding die in home position

BE 5.07

Abb.578

Sensor Position/ Description Function

BE 5.07 Welding die in home position

Subject to change without notice

55

11

Sensors, Pneumatics, Motors

Sensors BE 5.09 and BE 5.10

Jogging plate sensors

BE 5.09

BE 5.10

Abb.580

Sensor Position/ Description Function

BE 5.09. Jogging plate narrowest position

BE 5.10 Jogging plate widest position

Sensors BE11, BE11.02 and BE11.04

Package lift

BE 11.04

BE 11.02

BE 11.01

56

Abb.1030537

Sensor Position/ Description Function

BE11.01 Package lift down

BE11.02 Package lift up

BE11.04 Slider operating position

Subject to change without notice

Sensors, Pneumatics, Motors

11.3 Cylinder

delta cylinder overview

Z7.1

11

Z9

Z11.1

Z10.1

Abb.575-5

delta cylinder overview

Z13

Z12.1

Z4

Z8

Z2.1/Z2.6 + Z5.1/Z5.2

Inside the machine

Z7.2

Abb.1589-r

Subject to change without notice

Z11.2

Z10.2

57

11

Sensors, Pneumatics, Motors

Waste sheet deflector cylinder

Open waste sheet deflector / pressing unit

Z13

Z12.1

Abb.550

Cylinder Position/ Description Function

Z12.1 Open pressing unit left

Z13 Waste sheet deflector

Stopper cylinder

Stopper cylinder

Z9

58

Abb.553

Cylinder Position/ Description Function

Z9 Stopper

Subject to change without notice

Sensors, Pneumatics, Motors

Cylinder shaft narrower/wider / small format

Shaft

11

Z2.1 – Z2.6

Cylinder Position/ Description Function

Z2.1-Z2.6 Small format option (pre-

Z5.1/Z5.2 Shaft narrower/wider

Ejector cylinder

Z5.1 / Z5.2

Abb.558

collection fingers)

Ejector

Abb.556

Cylinder Position/ Description Function

Z4 Ejector

Subject to change without notice

Z4

59

11

Sensors, Pneumatics, Motors

essing rails / welding die cylinder

Pressing rails / welding die t

Z2.1 – Z2.6

Cylinder Position/ Description Function

Z10.1 Welding die left

Z11.1 Pressing rails left

Band tensioner cylinder

Z5.1 / Z5.2

Abb.558

60

Abb.8560

Cylinder Position/ Description Function

Z8 Upper band tensioner

Subject to change without notice

Sensors, Pneumatics, Motors

Pressing rails / welding die cylinder

Package lift

Abb.1030574

Cylinder Position/ Description Funktion

11

Z15

Z14

YA11.05

YA11.04

Z15 Slider cylinder

Z14. Package table cylinder

YA11.04 Valve V10 Package lift upwards

YA11.05 Valve V11 Extend slider

Side loader cylinder

Right side loader

Z1

Abb.07

Cylinder Position/ Description Function

Z1 Side loader cylinder

Subject to change without notice

61

11

M5

Sensors, Pneumatics, Motors

11.4 Motors

Delta motors overview

Abb.575-5

Delta motors overview

M11

M2

M3

Behind control

cabinet

Abb.1589-r

M6.2

M4

62

M2 Press M5 Side jogger

M3 Belt drive M6 Shaft rear wall jogger

M4 Elevation table M11 Format adjustment

Subject to change without notice

Loading...

Loading...