paladin FFC LAF5690, FFC LAF5671, FFC LAF5689, FFC LAF5672, FFC LAF5694 Operator And Parts Manual

...

Click Here To View

Item at

www.GapPower.com

OPERATOR’S AND PARTS MANUAL

POWER RAKE

SERIAL NUMBER: ___________________

MODEL NUMBER: ___________________

800-456-7100 I www.paladinattachments.com 2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright ©

Manual Number: MR25661

Models: LAF5647, LAF5671, LAF5689;

LAF5648, LAF5672, LAF5690;

LAF5660, LAF5676, LAF5694;

LAF5696, LAF5697 & LAF5698

Date: March 2014

Rev. 2

Notes

TABLE OF CONTENTS

PREFACE ............................................................................................................... 2

OWNER AND OPERATOR SAFETY INFORMATION

SAFETY STATEMENTS ............................................................................... 3

SAFETY PRECAUTIONS ............................................................................. 3-5

SAFETY SIGNS ............................................................................................ 6-7

SPECIFICATIONS ................................................................................................... 8-9

MOUNTING ............................................................................................................. 10

HYDRAULIC CONNECTION .................................................................................. 11

SET UP ................................................................................................................... 12

OPERATION ........................................................................................................... 13

MAINTENANCE ..................................................................................................... 14-15

SERVICE ................................................................................................................. 16

STORAGE ............................................................................................................... 17

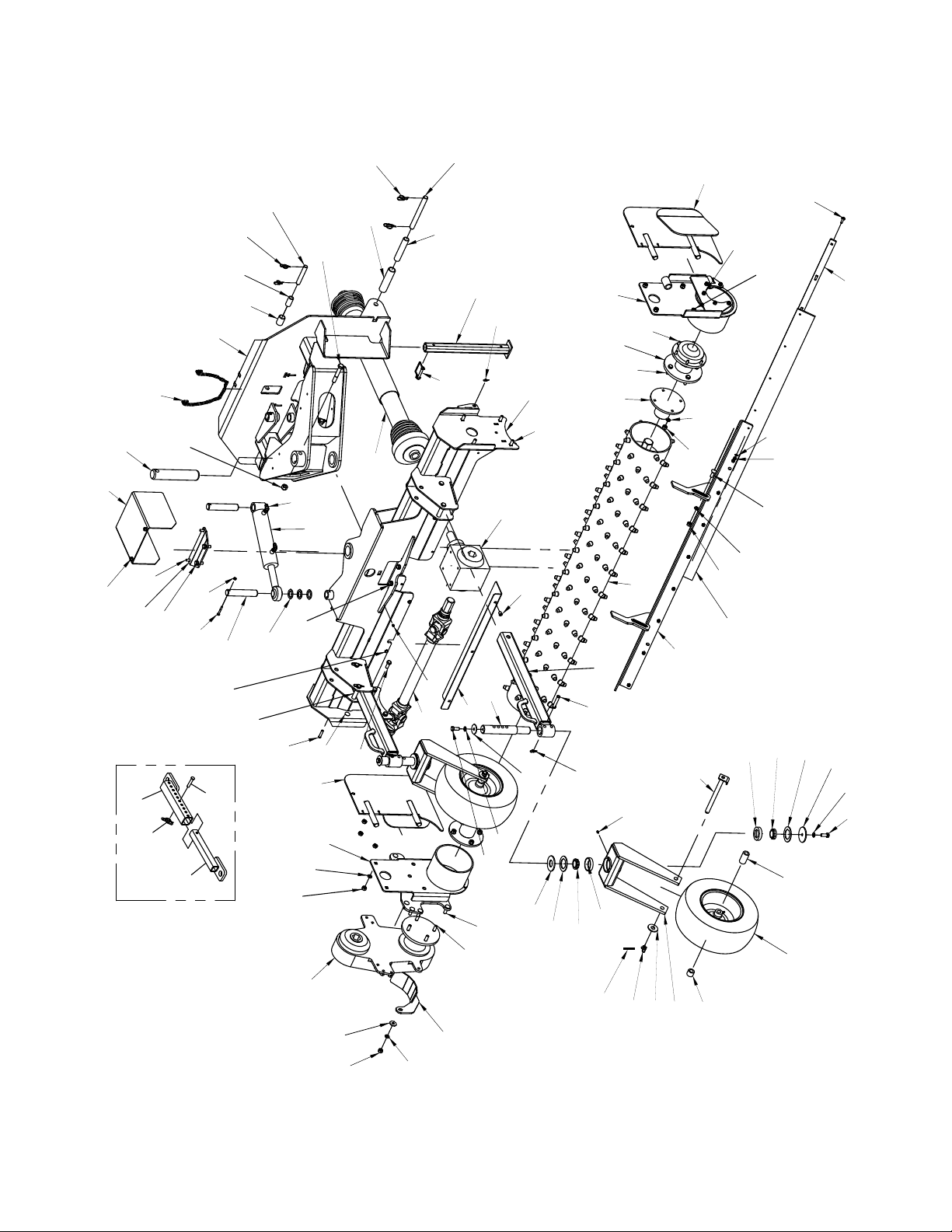

POWER RAKE PARTS ILLUSTRATION ................................................................. 18, 20 & 22

POWER RAKE PARTS LIST ................................................................................... 19, 21 & 23

PTO POWER RAKE PARTS ILLUSTRATION ........................................................ 24, 26 & 28

PTO POWER RAKE PARTS LIST .......................................................................... 25, 27 & 29

HYDRAULIC ANGLE KIT PARTS ILLUSTRATIONS AND LISTS .......................... 30

WARRANTY ............................................................................................................. 31

MR25661

1

PREFACE

GENERAL INFORMATION

This product was carefully designed and manufactured to give you many years of dependable service.

Only minor maintenance (such as cleaning and lubricating) is required to keep it in top working condition.

Be sure to observe all maintenance procedures and safety precautions in this manual and on any safety

decals located on the product and on any equipment on which the attachment is mounted.

WARNING! Never let anyone operate this unit without reading the “Safety Precautions”

and “Operating Instructions” sections of this manual. Always choose hard,

level ground to park the vehicle on and set the brake so the unit cannot roll.

Unless noted otherwise, right and left sides are determined from the operator’s control position when facing

the attachment.

NOTE: The illustrations and data used in this manual were current (according to the information

available to us) at the time of printing, however, we reserve the right to redesign and change the

attachment as may be necessary without notication.

BEFORE OPERATION

The primary responsibility for safety with equipment falls to the operator. Make sure the equipment is

operated only by trained individuals that have read and understand this manual. If there is any portion of

this manual or function you do not understand, contact your local authorized dealer or manufacturer to

obtain further assistance. Keep this manual available for reference. Provide this manual to any new owners

and/or operator’s

SAFETY ALERT SYMBOL

This is the “Safety Alert Symbol” used by this industry. This symbol is used to

warn of possible injury. Be sure to read all warnings carefully. They are included

for your safety and the safety of others working with you.

SERVICE

Use only manufacturer replacement parts. Substitute parts may not meet the required standards.

Record the model and serial number of your unit on the cover of this manual. The parts department

needs this information to insure that you receive the correct parts.

SOUND AND VIBRATION

“Sound pressure levels and vibration data for this attachment are inuenced by many different parameters;

some items are listed below (not inclusive):

• prime mover type, age, condition, with or without cab enclosure and conguration

• operator training, behavior, stress level

• job site organization, working material condition, environment

Based on the uncertainty of the prime mover, operator, and job site, it is impossible to get precise machine

and operator sound pressure levels, or vibration levels for this attachment.”

NOTE: A list of all Paladin Patents can be found at http//www.paladinbrands.com/patents.asp.

2

MR25661

SAFETY STATEMENTS

THIS SYMBOL BY ITSELF OR WITH A WARNING WORD THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING

YOUR PERSONAL SAFETY OR THE SAFETY OF OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

DANGER THIS SIGNAL WORD IS USED WHERE SERIOUS INJURY OR DEATH WILL

RESULT IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

WARNING THIS SIGNAL WORD IS USED WHERE SERIOUS INJURY OR DEATH

COULD RESULT IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

CAUTION THIS SIGNAL WORD IS USED WHERE MINOR INJURY COULD RESULT IF

THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

NOTICE NOTICE INDICATES A PROPERTY DAMAGE MESSAGE.

GENERAL SAFETY PRECAUTIONS

WARNING! READ MANUAL PRIOR TO INSTALLATION

Improper installation, operation, or maintenance of this equipment could result in

serious injury or death. Operators and maintenance personnel should read this manual,

as well as all manuals related to this equipment and the prime mover thoroughly

before beginning installation, operation, or maintenance. FOLLOW ALL SAFETY

INSTRUCTIONS IN THIS MANUAL AND THE PRIME MOVER'S MANUAL(S).

READ AND UNDERSTAND ALL SAFETY STATEMENTS

Read all safety decals and safety statements in all manuals prior to operating or

working on this equipment. Know and obey all OSHA regulations, local laws,

and other professional guidelines for your operation. Know and follow good work

practices when assembling, maintaining, repairing, mounting, removing, or

operating this equipment.

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions and operations before operating.

Visually inspect your equipment before you start, and never operate equipment that

is not in proper working order with all safety devices intact. Check all hardware to

ensure it is tight. Make certain that all locking pins, latches, and connection devices

are properly installed and secured. Remove and replace any damaged, fatigued, or

excessively worn parts. Make certain all safety decals are in place and are legible.

Keep decals clean, and replace them if they become worn and hard to read.

MR25661

3

GENERAL SAFETY PRECAUTIONS

GENERAL SAfETy PRECAUTIONS

Always wear proper safety glasses, goggles, or a face shield when driving pins in or

out, or when any operation causes dust, ying debris, or any other hazardous mate-

rial.

Do not work under raised booms without supporting them. Do not use support mate-

rial made of concrete blocks, logs, buckets, barrels, or any other material that could

suddenly collapse or shift positions. Make sure support material is solid, not de-

cayed, warped, twisted, or tapered. Lower booms to ground level or on blocks. Lower

booms and attachments to the ground before leaving the cab or operator’s station.

Hydraulic uid under pressure can penetrate the skin and cause serious injury or

death. Hydraulic leaks under pressure may not be visible. Before connecting or dis-

connecting hydraulic hoses, read your prime mover’s operator’s manual for detailed

instructions on connecting and disconnecting hydraulic hoses or ttings.

• Keep unprotected body parts, such as face, eyes, and arms as far away as

possible from a suspected leak. Flesh injected with hydraulic uid may develop

gangrene or other permanent disabilities.

• If injured by injected uid, see a doctor at once. If your doctor is not familiar with

this type of injury, ask him to research it immediately to determine proper treat-

ment.

• Wear safety glasses, protective clothing, and use a piece of cardboard or wood

when searching for hydraulic leaks. DO NOT USE yOUR HANDS!

SEE ILLUSTRATION.

WARNING! PROTECT AGAINST FLYING DEBRIS

Always wear proper safety glasses, goggles or a face shield when driving pins in or

out, or when any operation causes dust, flying debris, or any other hazardous material.

WARNING! LOWER OR SUPPORT RAISED EQUIPMENT

Do not work under raised booms without supporting them. Do not use support

material made of concrete blocks, logs, buckets, barrels or any other material that

could suddenly collapse or shift positions. Make sure support material is solid, not

decayed, warped, twisted, or tapered. Lower booms to ground level or onto blocks.

Lower booms and attachments to the ground before leaving the cab or operator’s

station.

WARNING! USE CARE WITH HYDRAULIC FLUID PRESSURE

Hydraulic fluid under pressure can penetrate the skin and cause serious injury or

death. Hydraulic leaks under pressure may not be visible. Before connecting or

disconnecting hydraulic hoses, read your prime movers operator’s manual for detailed

instructions on connecting and disconnecting hydraulic hoses or fittings.

• Keep unprotected body parts, such as face, eyes, and arms as far away as

possible from a suspected leak. Flesh injected with hydraulic fluid may develop

gangrene or other permanent disabilities.

• If injured by injected fluid, see a doctor at once. If your doctor is not familiar with

this type of injury, ask him to research immediately to determine proper treatment.

• Wear safety glasses, protective clothing, and use a sound piece of cardboard or

wood when searching for hydraulic leaks. DO NOT USE YOUR HANDS!

SEE ILLUSTRATION.

CARDbOARD

HyDRAULIC HOSE

OR fITTING

MAGNIfyING GLASS

4

MR25661

GENERAL SAFETY PRECAUTIONS

WARNING! DO NOT MODIFY MACHINE OR ATTACHMENTS

Modifications may weaken the integrity of the attachment and may impair the function,

safety, life, and performance of the attachment. When making repairs, use only the

manufacturer’s genuine parts, following authorized instructions. Other parts may be

substandard in fit and quality. Never modify any ROPS (Roll Over Protection Structure)

or FOPS (Falling Object Protective Structure) equipment or device. Any modifications

must be authorized in writing by the manufacturer.

WARNING! SAFELY MAINTAIN AND REPAIR EQUIPMENT

• Do not wear loose clothing, or any accessories that can catch in moving parts.

If you have long hair, cover or secure it so that it does not become entangled in

the equipment.

• Work on a level surface in a well-lit area.

• Use properly grounded electrical outlets and tools.

• Use the correct tool for the job at hand. Make sure they are in good condition

for the task required.

• Wear the protective equipment specified by the tool manufacturer.

WARNING! SAFELY OPERATE EQUIPMENT

Do not operate equipment until you are completely trained by a qualified operator in

how to use the controls, know its capabilities, dimensions, and all safety requirements.

See your machine's manual for these instructions.

• Keep all step plates, grab bars, pedals, and controls free of dirt, grease,

debris, and oil.

• Never allow anyone to be around the equipment when it is operating.

• Do not allow riders on the attachment or the prime mover.

• Do not operate the equipment from anywhere other than the correct operators

position.

• Never leave equipment unattended with the engine running or with this

attachment in a raised position.

• Do not alter or remove any safety feature from the prime mover or this attachment.

• Know your work site safety rules as well as traffic rules and flow. When in

doubt on any safety issue, contact your supervisor or safety coordinator for an

explanation.

WARNING! KNOW WHERE UTILITIES ARE

Observe overhead electrical and other utility lines. Be sure equipment will clear them.

When digging, call your local utilities for location of buried utility lines, gas, water, and

sewer, as well as any other hazard you may encounter.

MR25661

5

SAFETY SIGN LOCATIONS

RDL3123

The diagram on this page shows the location of the decals used on the FFC Power Rake.

The decals are identified by their part numbers, with reductions of the actual decals located on

the following page. Use this information to order replacements for lost or damaged decals. Be

sure to read all decals before operating the attachment. They contain information you need to

know for both safety and product longevity.

RDL3123

50-10017

50-0724

Serial # Tag

RDL3123

RDL3100

RDL3314

RDL3100

50-10017

6

RDL3314

50-0724

Serial # Tag

INSTRUCTIONS

• Keep all safety signs clean and legible.

• Replace all missing, illegible, or damaged safety signs.

• Replacement parts for parts with safety signs attached must also have safety signs

attached.

• Safety signs are available, free of charge, from your dealer or from FFC.

PLACEMENT OR REPLACEMENT OF SAFETY SIGNS

1. Clean the area of application with non-flammable solvent, and then wash the same area

with soap and water.

2. Allow the surface to fully dry.

3. Remove the backing from the safety sign, exposing the adhesive surface.

4. Apply the safety sign to the position shown in the diagram above and smooth out any

bubbles.

MR25661

SAFETY SIGNS

PART #50-0724

WARNING! HIGH PRESSURE FLUID

PART #50-10017

WARNING! READ MANUAL

PART #RDL3100

WARNING! STAND CLEAR

PART #RDL3314

DANGER! ROTATING SHAFT

PART #RDL3123

WARNING! PIVOTING ATTACHMENT

MR25661

7

PRIME MOVER SPECIFICATIONS

IMPORTANT Exceeding any of the maximum recommended prime mover specifications

CAN result in damage to this product and

WILL void all FFC warranties.

DESCRIPTION SPECIFICATIONS

Weight of Prime Mover without Power Rake 11,000 lbs. maximum

Operating Capacity of Prime Mover's Loader 4,500 lbs. maximum

Lift Capacity of Prime Mover's Loader 9,000 lbs. maximum

Hydraulic Pressure Output 3,500 psi maximum

Rear Ballast As required to maintain full prime mover stability.

(Note the Shipping Weight on the specifications page,

then see the operator’s manual(s) for your prime mover,

loader, and quick-attach for ballasting needs.)

TRACTOR REQUIREMENTS

The PTO Drive Units are designed for use with tractors that are equipped with an 1.38"-6 spline rear

power take-off (PTO), 540 rpm only.

The tractor must also provide for 3-point hitch attachment Category I or II. The tractors rated drawbar

PTO horsepower on a 3-point should be no less than 25 HP and no more than 100 HP.

NOTE: In order to maintain steering control, ballast may need to be added to you tractor.

To determine whether or not to add the ballast, refer to your tractor's operator's manual.

POWER RAKE SPECIFICATIONS

Model

Number

LAF5648 (MANUAL)

LAF5648H (HYDRAULIC)

LAF5672 (MANUAL)

LAF5672H (HYDRAULIC)

LAF5690 (MANUAL)

LAF5690H (HYDRAULIC)

LAF5660 (HYDRAULIC)

LAF5696 (MANUAL)

LAF5676 (HYDRAULIC)

LAF5697 (MANUAL)

LAF5694 (HYDRAULIC)

LAF5698 (MANUAL)

Overall

Width

60.63"

60.63"

82.75"

82.75"

100.75"

100.75"

68.13"

68.13"

84.13"

84.13"

102.13"

102.13"

Overall

Height

30.31"

30.31"

30.31"

30.31"

30.31"

30.31"

38.75"

38.75"

38.75"

38.75"

38.75"

38.75"

Overall

Depth

72.5"

72.5"

72.5"

72.5"

72.5"

72.5"

95"

95"

95"

95"

95"

95"

Shipping

Weight

870 lbs.

905 lbs.

1000 lbs.

1035 lbs.

1075 lbs.

1110 lbs.

1150 lbs.

1115 lbs.

1220 lbs.

1185 lbs.

1290 lbs.

1255 lbs.

8

MR25661

MR25661

9

POWER RAKE MOUNTING

WARNING! READ MANUAL PRIOR TO INSTALLATION

Improper installation, operation, or maintenance of this equipment could result in

serious injury or death. Operators and maintenance personnel should read this

manual, as well as all manuals related to this equipment and the prime mover

thoroughly before beginning installation, operation, or maintenance. FOLLOW ALL

SAFETY INSTRUCTIONS IN THIS MANUAL AND THE PRIME MOVER'S

MANUAL(S).

Loaders

1. Place this product on a firm, level surface that is large enough to safely accommodate this

product, your prime mover and all workers involved in the mounting process.

2. Refer to the operator’s manual(s) for your prime mover, loader, and quick-attach and follow the

mounting instructions contained therein.

3. Carefully raise the loader arms or three point linkage and cycle the tilt cylinders or lower

link arms to check clearances and to verify that all mounting procedures have been

successfully completed.

IMPORTANT Lubricate all grease fittings before connecting this product to your prime

mover's hydraulic system. Refer to POWER RAKE MAINTENANCE page and

follow the instructions.

3 Point Hitch Category 1 or 2

1. Place this product on a firm, level surface that is large enough to safely accommodate this

product, your tractor, and all workers involved in the mounting process. Making sure this

product is in the operating position and level will facilitate in selecting the proper mounting

holes.

2. Read and understand the Operation and Maintenance manual for your tractor before installing

this product.

3. Remove the top link on your tractors’ 3 point and drive the tractor backwards in to position to

connect the lower links to the attachment mounting ears. The ears have a combination

category 1 & 2 hitch pin installed so you need to make sure the outer pin matches your tractors’

category. Select a hole position on the mounting ears that aligns or is a little above the lower

link points with the tractor link arms fully lowered and connect the arms.

4. The upper link cylinder provided with this product requires a category #2, 1” diameter pin to

attach to the tractors’ upper link point. If you have a category #1 tractor you will have to bush

the pin up to category #2. It is important that when you pin the rod end of the cylinder to the

tractors’ upper link point there is between 4” and 5” of exposed cylinder rod. If you have less

the bucket will not roll back enough and if you have more the bucket will not dump properly.

Move the cylinder pin hole position on the mounting ears until you attain the recommended

amount of exposed cylinder rod.

IMPORTANT Lubricate all grease fittings before connecting this product to your prime

mover's hydraulic system. Refer to POWER RAKE MAINTENANCE page and

follow the instructions.

10

MR25661

POWER RAKE HYDRAULIC CONNECTION

READ AND UNDERSTAND ALL SAFETY STATEMENTS

Read all safety decals and safety statements in all manuals before beginning any

Power Rake hydraulic connection. Know and obey all OSHA regulations, local laws, and

other professional guidelines for your operation. Know and follow good work practices

when assembling, maintaining, repairing, mounting, removing, or operating this

equipment.

Loaders

1. Disconnect the hydraulic hose quick couplers (or purchase locally, if not supplied) from one

another and attach the quick couplers to your prime mover as per the instructions in your prime

mover's operator's manual.

2. Carefully raise the loader arm and cycle the tilt cylinders or lower link to check hose clearances

and to check for any interference.

3. If your Power Rake is equipped with a hydraulic angling kit (LAF5640/LAF5650), connect the two

eye terminal wire ends (black = positive / white = negative) to the prime mover battery. The

angle cylinder is activated by the toggle switch ONLY when the drum is turning clockwise [viewed

from the left end]. The toggle switch box is magnetized and should be placed on a convenient

steel surface in the cab of the prime mover. If your unit is equipped with a quick connect wire

harness for the prime mover joystick refer to owner's manual for proper installation and operation.

4. Cycle the hydraulic cylinder(s) on this product several times from fully retracted to fully extended

until all air has been completely removed from the cylinder(s).

3 Point Hitch Category 1 or 2

1. Both the hydraulic drive and the PTO drive require one set of auxiliary hydraulics.

Purchase proper couplers and hoses and attach to the tractor per the instructions in your tractors’

operators manual.

2. Carefully raise the link arms and cycle the upper link cylinder to check hose clearances,

interferences, and acceptable range of motion to operate the Power Rake.

NOTICE When shipped, the hydraulic cylinder(s) on this product contained air or an air-

fluid mixture. The orifices beneath the port(s) of the cylinder barrels will restrict

the exit of that air. Failure to remove all the air from the hydraulic cylinder(s) can

cause uneven, jerky cylinder movement when the hydraulic controls are being

operated and unwanted cylinder movement when the controls are not being

operated.

WARNING! Do not lock the auxiliary hydraulics of your prime mover in the "ON" position.

Failure to obey this warning could result in death or serious injury.

MR25661

11

POWER RAKE SETUP

SAFETY FIRST! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS

BEFORE BEGINNING ANY POWER RAKE SETUP!

1. Roller

The roller and power rake [front to back] should be positioned level with the ground. To adjust,

raise or lower the gauge wheels and/or use the prime mover’s tilt cylinder. For a 3-point mounting,

the upper link needs to be adjusted in or out.

To allow the roller to penetrate the ground deeper, raise the gauge wheels. During operation, depth

control can be adjusted further by tilting the power rake back to raise the gauge wheels, allowing

more roller penetration.

2. Deflectors

Under average conditions, the normal gap between the roller and deflector should be about 1.25”.

This gap can be adjusted by loosening the two carriage bolts that hold the deflector and adjusting

it up or down in the square cornered slot. A wider opening will allow more dirt and rock to pass

through. DO NOT let the roller hit the deflector. The gap should be consistent all across the

deflector and this can be verified by either measuring or matching height marks on the two tabs

that protrude up through a slot in the deflector support area.

3. Endplates

The endplates contain the material in front of the roller while clean material passes between the

roller and deflector. With the endplates mounted in the working position and the power rake parallel

with the prime mover’s tires, material can be moved along, filling in low spots.

Hydraulic drive unit endplates can be mounted to the front or back of the power rake, depending on

raking direction. When moving the endplates from front to back, move the left one to the right side

and the right one to the left side. Pin the top bushing only to secure the endplates. For PTO drive

units the endplate mounting is limited to containment when traveling forward only.

The endplates can be stored by using the top front bushing and storage tab or tabs on the

mainframe.

4. Angle

Set the rake straight for conditioning and collecting debris.

Angle the rake for windrowing debris or fill. Angling is also used to change grade.

12

MR25661

POWER RAKE OPERATION

POWER RAKE OPERATION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS

(pages 2–5 of this manual) BEFORE BEGINNING ANY POWER RAKE

OPERATION

WARNING

Failure to obey the following procedures could result in death or serious injury.

Never lift this product above:

• the operators eye level OR

•

to a height where visibility is obstructed, whichever is lower.

WARNING! Failure to obey the following procedures could result in death or serious

injury.

• Never lift this product above (a) the operator’s eye level or (b) to a height

where visibility is obstructed, whichever is lower.

1. Never raise the Power Rake more than a few inches off the ground when traveling from job

site to job site.

2. For the roller to operate effectively, it must rotate in the opposite direction of the prime mover

wheels [see figure below]. Roller direction is controlled by prime mover hydraulic controls or

PTO shaft. PTO shaft rotation cannot be reversed and results in roller rotation shown in the

lower illustration.

3. Normal operating ground speed is between 3 and 5 mph. In heavy rock, reduce speed to 1 to

3 mph.

4. For hydraulic drive, normal operating rpm of the roller is approximately 170. If operating in

heavy rock, reduce speed as appropriate. For PTO drive the drum rpm is constant at 211 at

540 PTO rpm.

5. Operating depth will determine how much dirt is carried ahead of the roller. Ideal depth will

vary from skimming the surface to about 3” deep.

6. When making the first windrow, the level of dirt may be halfway up the deflector. After moving

the windrow two or three times, the level of dirt may be to the top of the deflector. Try to

prevent material from flowing over the top of the deflector. Volume and density of material will

dictate how many times a windrow can be moved.

7. The following are common operating applications:

Application Roller Position Endplate Position Hydraulic Float Position*

Pulverizing topsoil Angled or Straight Stored Rigid

Debris Removal Angled or Straight Windrow or Collect Float

Finish Grading Straight Collect Float

Spreading Fill and Topsoil Angled Windrow Rigid

Changing Grade Angled Windrow Float

Thatching existing Grass Area Straight Stored Rigid

*See your prime mover’s manual for whether or not your loader has hydraulic float capabilities. For

models with 4-bar linkages, remove the clevis pin (part # 96) to float. (pins may be stored in the

middle position holes of the back plate ribs.) For PTO drive models connect the upper link at the

slotted mast hole.

Roller Rotation Travel Direction

8. When adjusting the gap between the roller and deflector; a wider opening will allow more dirt

and rock to pass through. For finer raking, reduce the gap.

9. Tires: check the air pressure of your tires before each use. Maintain recommended tire

pressure to maintain a consistent, even grade.

MR25661

13

POWER RAKE MAINTENANCE

GENERAL INFORMATION

Regular maintenance is the key to long equipment life and safe operation. Maintenance requirements

have been reduced to the absolute minimum. However, it is very important that these maintenance functions be

performed as described below.

1. Park your prime mover on a level surface with this product properly attached.

2. Place your prime mover’s transmission in “Park” and engage the parking brake.

3. Lower this product onto preplaced blocking.

4. Shut off your prime mover’s engine, remove the starter key, wait for all moving parts to come to a stop,

and relieve all pressure in the hydraulic lines (refer to your prime mover's operator's manual for

instructions on how to relieve hydraulic pressure). On PTO drive models disconnect the driveline.

WARNING! Do not use blocking made of concrete blocks, logs, buckets, barrels or any other

material that could suddenly collapse or shift positions. Do not use wood or steel

blocking that is warped, twisted, or tapered. Failure to obey this warning could result in

death or serious injury.

BEFORE EACH USE

• Make sure all shielding is in place.

• On PTO drive models check driveline for wear.

• Make sure that all nuts and bolts are in place and properly tightened.

• Make sure that all other fasteners are in place and are performing their specified function.

• Make sure that tires are inflated to maximum load pressure indicated on tire. Do not over inflate.

• Make sure that all hydraulic fittings are tightened to specifications and that there are no leaks in any

fittings or hoses. (SEE THE HYDRAULIC CONNECTION SECTION).

• Make sure that all safety signs are in place, are clean, and are legible.

(SEE THE SAFETY SIGN SECTION).

• Replace any damaged parts and excessively worn parts.

AFTER EVERY 10 HOURS OF USE ON PTO DRIVE MODELS

• Grease roller bearing (48” and PTO drive models only). Grease all u-joint cross bearings.

The main frame shaft guard must be removed to grease the hex driveline.

WEEKLY

• Lubricate all pivot points, PTO driveline guard, and PTO driveline telescoping shafts.

FOR PTO DRIVE – AFTER 50 HOURS OF USE AND THEN EVERY 1000 HOURS OR ANNUALLY

• Drain the 90 degree gearbox and the spur gear case of lubricant and refill with 80-90 W gear lube with

an EP rating of GL-5 minimum. (Approximately 41 oz. For the 90 degree gearbox and 63 oz. For the

spur gear case.)

ANNUALLY

Repack the bearings in the wheels as described in steps 1-4 below.

1. Make sure that there is no weight on the wheels. If the wheels are partially supporting the weight of this

product, restart your prime mover and move the loader and/or dump cylinders. Repeat the specified

shutdown procedure.

2. Remove each wheel using two wrenches and remove the bearing components from the wheels.

3. Clean the bearing components, and then use a high quality waterproof grease to repack the bearing

components & hub.

4. Reassemble all components using a new seal.

14

MR25661

MAINTENANCE

MAINTENANCE RECORD

Use this log to record maintenance performed on the attachment.

Date

Maintenance Procedure

Performed

Performed

by

Comments

MR25661

15

POWER RAKE SERVICE

IMPORTANT When replacing parts use only factory approved replacement parts.

Manufacturer will not claim responsibility for use of unapproved parts or

accessories and/or other damages as a result of their use.

Removing Wire, Twine, Weeds, etc. that are Wrapped Around the Roller

1. Park your prime mover on a level surface with this product properly attached.

2. Place your prime mover’s transmission in “Park” and engage the parking brake. On PTO

models make sure PTO is disengaged.

3. Lower this product onto preplaced blocking that will support the motor guards of this product so

that the teeth are not in contact with the ground.

WARNING! Do not use blocking made of concrete blocks, logs, buckets, barrels or any other

material that could suddenly collapse or shift positions. Do not use wood or steel

blocking that is warped, twisted, or tapered. Failure to obey this warning could

result in death or serious injury.

4. Shut off your prime mover’s engine, remove the starter key, wait for all moving parts to come to

a stop, and relieve all pressure in the hydraulic lines.

5. Disconnect the hydraulic lines from your prime mover and connect the two ends to each other.

For PTO drive disconnect the PTO driveline. This should permit the roller to rotate freely.

6. Pull the material from the roller while allowing it to rotate.

ALTERNATE METHOD FOR SKID STEER LOADERS

If your prime mover is equipped with safety stops for the lift arms of the loader that can be activated

from the operator’s position or if the safety stops must be activated from outside the operator’s position

and a second person is present, then the method above may be replaced with these steps:

1. Park your prime mover on a level surface with this product properly attached.

2. Place your prime mover’s transmission in “Park” and engage the parking brake.

3. Disconnect the hydraulic lines from your prime mover and connect the two ends to each other.

This should permit the roller to rotate freely.

4. Fully raise the lift arms and fully extend the tilt cylinders to the fully dumped position.

5. Shut off your prime mover’s engine, remove the starter key, wait for all moving parts to come to

a stop, and relieve all pressure in the hydraulic lines.

6. Pull the material from the roller while allowing it to rotate.

Replacing Deflector Strips

1. Perform steps 1 through 5 above.

2. Remove worn strip by removing bolts and nuts that secure the strip.

3. Replace the strip, making sure the steel backing strip is re-installed.

IMPORTANT: For PTO Drive Models genuine FFC replacement parts must be used to

service the PTO driveline.

16

MR25661

POWER RAKE STORAGE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS

BEFORE BEGINNING ANY POWER RAKE STORAGE

1. Disconnect hydraulic hoses from prime mover. Install dust plugs or couple hoses together, as

appropriate.

2. Disengage your Power Rake from the prime mover. Be sure your Power Rake rests in a stable

position for storage.

3. Be sure your power rake is stored on a hard, level surface.

WARNING! Block equipment securely for storage.

WARNING! Keep children and bystanders away from storage area.

MR25661

17

POWER RAKE PARTS ILLUSTRATION

59

59

47

56

55

23

92

91

90

95

94

70

34

26

27

36

37

66

37

36

31

55

5

50 50

24

45

39

25

27

45

55

52

55

59

4

41

40

63

61

53

35

2

68

18

43

42

93

14

95

94

96

16

44

73

38

43

20

6

69

38

7

48

71

57

9

66

62

65

64

33

30

68

49

28

54

51

60 19

8

58

32

2129

8

50

74

58

67

49

22

1

17

46

55

75

72

11

55

59

12

3

59

55

10

15

13

59

18

MR25661

POWER RAKE PARTS LIST

ITEM QTY.

varies (1) (2) (2) 13-50860 Motor Mount

1

2

3

4

5

6

7

8

9

*10

*11

*12

13

14

15

16

17

18

**19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

varies (1) (2) (2) 13-50865 Motor Plate

2 13-50866 Wheel Arm

1 13-51048 Not Used Not Used Bearing Mount (for 48" model)

1

1

varies

2 Not Used LAF4075 Bulkhead Jam Nut #10

1

1

2 03-4618 Hydraulic Adapter 10FB-12MB

varies (2) (4) (4) P276200 Hydraulic Adapter 10MB-10MJ

2 Not Used LAF4656 Hydraulic Tee Bulkhead Run 10MJ-10MJ-10MJ

varies (1) LAF4655 (2) LAF4678 (2) LAF4678 Hydraulic Motor

2

2 Not Used LAF4657 (48) LAF4682 (57) Hydraulic Hose .5" x Length noted 10FJ-10FJ

2

1 LAF5600 Mounting Frame

1

2

1

1

1 LAF5613 Right Side Shield

2

2

4

1

2

1

2

2 LAF5616 LAF5632 LAF5635 Deflector Support

1

2

1

4

LAF5647

LAF5648

48"

13-50861

(3)

LAF4514 (92)

Not Used

LAF5609

LAF5608

LAF5606

LAF5618

LAF5610

LAF6808

LAF5671

LAF5672

72"

Not Used Not Used

(6) (6) LAF3412

LAF4680 (96) LAF4680 (96)

LAF4682 (57) LAF4709 (66)

LAF5633 LAF5603

LAF5631 LAF5605

Not Used Not Used

LAF5630 LAF5626

LAF5634 LAF5627

Not Used Not Used

LAF5689

LAF5690

90" DESCRIPTION

LAF2817

LAF2818

03-3859

03-3860

LAF5602

M6817

P850620

LAF5625

LAF5628

LAF5629

LAF5636

LAF5638

P760500

Axle Shaft Assembly (for 48" model)

Position Tube (Female)

Position Tube (Male)

Shroud Gusset Protector

Hydraulic Quick Coupler Female 12FB

Hydraulic Quick Coupler Male 12FB

Hydraulic Hose .63" x Length noted 10FJ-12MB

Hydraulic Hose .5" x Length noted 10FJ-10FJ

Pivot Pin

Drum Deflector

Main Frame (Hydraulic Drive)

Dust Guard (for 48" model)

Wheel Caster Fork

Wheel Caster Washer (top)

Wheel Bearing Seal

Drum Weldment

Drum Deflector Strap

Pivot Frame

Wheel Caster Washer (bottom)

Left Side Shield

Wheel Post

Rotor Bearing (for 48" model)

Bearing Race

NOTE: All parts are the same as the LAF5690 except for those parts numbered under the other models.

*ITEM may vary per Prime Mover -- Contact FFC for correct item.

**For Floating Models (LAF5647, LAF5671 & LAF5689) see part numbers 90-96.

MR25661

19

POWER RAKE PARTS ILLUSTRATION

59

59

47

56

55

23

92

91

90

95

94

70

34

26

27

36

37

66

37

36

31

55

5

50 50

24

45

39

25

27

45

55

52

55

59

4

41

40

63

61

53

35

2

68

18

43

42

93

14

95

94

96

16

44

73

38

43

20

6

69

38

7

48

71

57

9

66

62

65

64

33

30

68

49

28

54

51

60 19

8

58

32

2129

8

50

74

58

67

49

22

1

17

46

55

75

72

11

55

59

12

3

59

55

10

15

13

59

20

MR25661

POWER RAKE PARTS LIST

ITEM QTY.

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

4 P760300 Tapered Roller Bearing Cone

2 LAF9715 Pin 1.25" x 6.5" (1) .281 Hole

2 M10463 Axle Bolt .75"-16 x 9.5" Fine Thread Hex

2 M16107 Wheel and Tire Assembly

2 M16108 Axle Spacer Long

2 M16109 Axle Spacer Short

2

1 RHW1112 Grade 5 Hex Head Cap Screw .31" x 2.5"

4 P100805 Grade 5 Hex Head Cap Screw .5" x 1.25"

varies (4) (8) (8) RHW1406 Grade 5 Hex Head Cap Screw .5" x 1.75"

6

1 RHW1612 Grade 5 Hex Head Cap Screw .63" x 4"

varies

20

1 RHW5162 Grade 5 Flat Washer .31" USS

12 RHW5432 Grade 5 Flat Washer .5" SAE (quantity may vary)

2 P850612 Grade 5 Flat Washer .75" USS

varies (13) (19) (25) P851105 Grade 5 Lock Washer .31"

40

6 RHW6602 Not Used Not Used Grade 5 Lock Washer .63" (for 48" model)

2

varies

varies

1

2

4 RHW7999 Grade 5 U-Bolt .5" x 4.25" x 4.03"

2

2

4

3

1

4

3

2 RHW8136 Washer .5" x 2" OD x .093" Thick

3

1

1

2

1

LAF5647

LAF5648

48"

RHW1603

(12)

(13)

(32)

LAF5671

LAF5672

72"

Not Used Not Used

(18) (24) P104506

(19) (25) RHW7101

(36) (36) RHW7401

LAF5689

LAF5690

90" DESCRIPTION

07-3022

RHW2405

P851108

RHW7003

RHW7602

P158000

07-1044

RHW8068

RHW8069

07-3112

RHW8098

RHW8115

RHW8133

RHW8150

RHW8613

RHW8614

RHW8616

RHW8618

Grade 8 Hex Head Cap Screw .25" x 2"

Grade 5 Hex Head Cap Screw .63" x 1.75"

Grade 5 Carriage Bolt .31" x 1.5"

Grade 5 Carriage Bolt .5" x 1.5"

Grade 5 Lock Washer .5"

Grade 5 Lock Nut .5"

Grade 5 Hex Nut .31" (quantity may vary)

Grade 5 Hex Nut .5"

Grade 5 Nylock Nut .63"

Grade 5 Hex Slotted Nut .75"-16 Plated

Grade 2 Cotter Pin .13" x 1.5"

Lynch Pin .25" x 1.56" (1.31" Usable)

Clevis Pin .75" x 4" (3.73" Usable)

Grease Zerk .25" self-tapping (28 tpi)

Grade 2 Fender Washer .08" x .31" x 1.5"

Rue Ring Cotter Pin .75" Heavy

Rue Ring Cotter Pin .5" Heavy

Clevis Pin .5" x 2.75" (2.53" Usable) Plated

Weld Plate for .88" Hose (not used on all models)

Cover Plate for .88" Hose (not used on all models)

Hose Cradle for .88" Hose (not used on all models)

Hose Spring (not used on all models)

NOTE: All parts are the same as the LAF5690 except for those parts numbered under the other models.

MR25661

21

POWER RAKE PARTS ILLUSTRATION

59

59

47

56

55

23

92

91

90

95

94

70

34

26

27

36

37

66

37

36

31

55

5

50 50

24

45

39

25

27

45

55

52

55

59

4

41

40

63

61

53

35

2

68

18

43

42

93

14

95

94

96

16

44

73

38

43

20

6

69

38

7

48

71

57

9

66

62

65

64

33

30

68

49

28

54

51

60 19

8

58

32

2129

8

50

74

58

67

49

22

1

17

46

55

75

72

11

55

59

12

3

59

55

10

15

13

59

22

MR25661

POWER RAKE PARTS LIST

ITEM QTY.

90

91

92

93

94

95

96

4 LAF5619 Link Arm

1

1 LAF5641 Back Plate

8 LAF5643 Bushing

8 P101020 Grade 5 Hex Head Cap Screw .63" x 5"

8

2 RHW8148 Clevis Pin .63" x 4.75"

LAF5647

48"

LAF5671

72"

LAF5689

90" DESCRIPTION

LAF5639 Mounting Frame

RHW7603

Grade 5 Lock Nut .63"

NOTE: All parts are the same as the LAF5689 except for those parts numbered under the other models.

MR25661

23

PTO POWER RAKE PARTS ILLUSTRATION

4

25

6359

24

81

82

MANUAL ANGLE

52

35

4860

65

80

45

61

29

83

44

4658

41

69

40

75

69

57

38

74

64

48

60

23

67

36

66

37

26

49

34

18

48

54

68

60

21

76

72

11

33

53

12

42

71

73

27

43

31

20

30

49

67

32

47

14

10

64

60

5

51

59

63

64

15

60

43

64 60

58

62

53

42

7

8

12

16

13

60

48

70

39

50

22

2

3

53

48

17

28

60

24

19

55

64

60

1

MR25661

78

77

56

6

9

PTO POWER RAKE PARTS LIST

ITEM QTY.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

1 13-50412 PTO Gear Box Guard Weldment

2

1 LAF4516 Hydraulic Cylinder 2.5" x 7.5" x 1.25" Shaft

1 LAF5602 Pivot Pin

1 LAF5613 Right Side Shield

2

2

2

2 M6817 Wheel Caster Fork

2

2

4 LAF5625 Wheel Bearing Seal

2 LAF5629 Wheel Caster Washer (bottom)

1 LAF5687 LAF5632 LAF5635 Deflector Support

1 LAF5688 LAF5633 LAF5603 Drum Deflector

1

1 LAF5636 Left Side Shield

2

1

1

1

1

1

1 LAF5664 Spacer Plate

1

1

2

1

1

2

1

1 LAF5680 LAF5681 LAF5682 Drum Weldment

1

1

1

2

2

1

2

LAF5660

56"

LAF5692

LAF5661

LAF5667

LAF5683

LAF5676

72"

LAF5634 LAF5627

LAF5662 LAF5663

LAF5668 LAF5669

LAF5684 LAF5685

LAF5694

90" DESCRIPTION

P261350

M16109

M16108

M16107

M10463

P850620

LAF5638

LAF5644 Spur Gear Case

LAF5645

LAF5646

07-10124

LAF5665

LAF5670

13-51051

LAF5677

LAF5678

13-51049

LAF8350

LAF9010

LAF9429

LAF9430

LAF9431

LAF9432

Hydraulic Elbow 90° 6MB-6MJ

(Cylinder Seal Kit = LAF4017)

Axle Spacer Short

Axle Spacer Long

Wheel and Tire Assembly

Wheel Axle

Wheel Caster Washer (top)

Drum Deflector Strap

Wheel Post

Bearing Assembly

90° Gear Box

PTO Drive Shaft

Hex Drive Line

Clutch Guard

Shaft Guard

Wheel Arm

Gear Case Mount

Mounting Frame

Hub Mount

Bearing Mount

Main Frame

Jack Stand

Chain .125" GR 30 (26 Links)

Bushing 1.13" x .13" x 5.56"

Pin .88" x 8.38"

Pin .75" x 4.75"

Bushing 1.44" x .13" x 5.56"

NOTE: All parts are the same as the LAF5694 except for those parts numbered under the other models.

MR25661

25

PTO POWER RAKE PARTS ILLUSTRATION

4

25

6359

24

81

82

MANUAL ANGLE

52

35

4860

65

80

45

61

29

83

44

4658

41

69

40

75

69

57

38

74

64

48

60

23

67

36

66

37

26

49

34

18

48

54

68

60

21

76

72

11

33

53

12

42

71

73

27

43

31

20

30

49

67

32

47

14

10

64

60

5

51

59

63

64

15

60

43

64 60

58

62

53

42

7

8

12

16

13

60

48

70

39

50

22

2

3

53

48

17

28

60

26

19

55

64

60

1

MR25661

78

77

56

6

9

PTO POWER RAKE PARTS LIST

ITEM QTY.

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

1 LAF9433 Top Link Bushing

1 P126250 Top Link Bushing

4 P760500 Bearing Race

4

2 LAF9715 Pin 1.25" x 6.5"

2 07-3022 Grade 8 Hex Head Cap Screw .25" x 2"

varies (2) (3) (4) RHW1105 Grade 5 Hex Head Cap Screw .31" x 1"

5

11 P100805 Grade 5 Hex Head Cap Screw .5" x 1.25"

8

1

varies (7) (9) (12) P104506 Grade 5 Carriage Bolt .31" x 1.5"

2 RHW2205 Grade 5 Carriage Bolt .38" x 1"

13 RHW2405 Grade 5 Carriage Bolt .5" x 1.5"

2 07-3709 Grade 5 Carriage Bolt .5" x 1.75"

2

2 P850612 Grade 5 Flat Washer .75" USS

3

varies

7

34

2

varies (9) (9) (12) RHW7101 Grade 5 Hex Nut .31"

7

23

1

1

3

2

6

4 RHW8130 Rue Ring Cotter Pin .88" Heavy

2

2

2

2

4

varies

2

2

LAF5660

56"

(12)

(2)

LAF5676

72"

(15) (19) P851105

(3) (4) RHW8642

LAF5694

90" DESCRIPTION

P760300

P100605

RHW1406

RHW1612

RHW5462

P855120

P851106

P851108

RHW7003

RHW7201

RHW7401

RHW7602

RHW8079

07-3112

RHW8114

RHW8115

RHW8133

RHW8136

RHW8150

RHW8225

RHW8227

P158000

07-1044

Tapered Roller Bearing Cone

Grade 5 Hex Head Cap Screw .38" x 1.25"

Grade 5 Hex Head Cap Screw .5" x 1.75"

Grade 5 Hex Head Cap Screw .63" x 4"

Grade 5 Flat Washer .5" USS

Machinery Bushing .135" x 1.25" ID

Grade 5 Lock Washer .31"

Grade 5 Lock Washer .38"

Grade 5 Lock Washer .5"

Grade 5 Lock Nut .5"

Grade 5 Hex Nut .38"

Grade 5 Hex Nut .5"

Grade 5 Nylock Nut .63"

Snapper Pin .38" x 2.75" (2.5" Usable)

Grease Zerk .25" self-tapping (28 tpi)

Rue Ring Cotter Pin .38" Regular

Rue Ring Cotter Pin .75" Heavy

Rue Ring Cotter Pin .5" Heavy

Washer .5" x 2" OD x .093" Thick

Clevis Pin .5" x 2.75" (2.53" Usable) Plated

Clevis Pin .38" x 1.75" (1.53" Usable) Plated

Clevis Pin .75" x 3.5" (3.25" Usable) Plated

Rivet Nut .31"-18 .027-.150 Grip Range

Grade 5 Hex Slotted Nut .75"-16 Plated

Grade 2 Cotter Pin .13" x 1.5"

NOTE: All parts are the same as the LAF5694 except for those parts numbered under the other models.

MR25661

27

PTO POWER RAKE PARTS ILLUSTRATION

4

25

6359

24

81

82

MANUAL ANGLE

52

35

4860

65

80

45

61

29

83

44

4658

41

69

40

75

69

57

38

74

64

48

60

23

67

36

66

37

26

49

34

18

48

54

68

60

21

76

72

11

33

53

12

42

71

73

27

43

31

20

30

49

67

32

47

14

10

64

60

5

51

59

63

64

15

60

43

64 60

58

62

53

42

7

8

12

16

13

60

48

70

39

50

22

2

3

53

48

17

28

60

28

19

55

64

60

1

MR25661

78

77

56

6

9

PTO POWER RAKE PARTS LIST

FOR MANUAL ANGLE MODELS (See list below -- which replace the cylinder.)

LAF5696

ITEM QTY.

80

81

82

83

NOTE: All parts are the same as the LAF5698 except for those parts numbered under the other models.

1 LAF2818 Position Tube (male)

1

1 RHW8133 Rue Ring Cotter Pin .5" Heavy

1 RHW8150 Clevis Pin .5" x 2.75" (2.53" Usable) Plated

56"

LAF5697

72"

LAF5698

90" DESCRIPTION

LAF2817 Position Tube (female)

MR25661

29

HYDRAULIC ANGLE KITS PARTS ILLUSTRATION & LISTS

9

5

1

FROM B

3

12

16

FORWARD

PTO DRIVE HYDRAULIC

ANGLE KIT # LAF5695

8

15

M2

B

1

2

FROM A

A

6

13

L2

TO REAR

2

4

14

11

10

TEE

7

EXISTING HOSE

KIT # LAF5650

FOR 60" & 72" POWER RAKES

KIT # LAF5640

FOR 48" POWER RAKE

ITEM QTY.

1

2

3

4

5

6

7

8

2

2 P276458 P276458 Hydraulic Adapter 10MJ-12MB

2 P261350 P261350 P261350 Hydraulic Elbow 90° 6MB-6MJ

1 LAF4417 Hydraulic Elbow 90° 10MJ-10FJ

1

1 LAF4660 LAF4660 Solenoid Operated Control Block Assembly

1 LAF4657 (48") LAF4681 (22") Hydraulic Hose .5" x (length noted) 10FJ-10FJ

1 LAF9441 LAF9441 Wire Assembly 9'

9

10

11

12

13

14

15

16

2 P100505 P100505 Grade 5 Hex Head Cap Screw .31" x 1.25"

2 P851105 P851105 Grade 5 Lock Washer .31"

1 LAF4516 LAF4516 LAF4516 Hydraulic Cylinder 2.5" x 7.5" x 1.25" Shaft

2 03-2140 03-2140 Hydraulic Adapter 6MJ-6MB

1 LAF5659 LAF5659 Shield

2 LAF4093 LAF4093 Hydraulic Elbow 90° 6FJ-6MJ

3 P855120 P855120 P855120 Machine Bushing

LAF5640

PART #

LAF4308

LAF5650

PART #

LAF4308

LAF4719

LAF4658

Contact FFC to obtain correct

LAF5695

PART # DESCRIPTION

Hydraulic Hose .38" x 19" 6FJ-6FJ

Hydraulic Hose .5" x 72" 10FJ-10MB

Hydraulic Hose .63" x 72" 10FJ-12MB

Wire Harness with Box for Rotating Cylinder

30

MR25661

Limited Warranty

Except for the Excluded Products as described below, all new products are warranted to be free from defects

date the product is rst leased or rented, or (iii) the date that is six (6) months after the date of shipment by Paladin

speci ed by Paladin Light Construction, with freight PRE-PAID by the claimant, to allow Paladin Light Construction

WITHOUT LIMITATION THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

THE REPAIR OR REPLACEMENT, OF THE PARTICULAR PRODUCT ON WHICH ANY CLAIM OF LOSS OR

in material and/or workmanship during the Warranty Period, in accordance with and subject to the terms and

conditions of this Limited Warranty.

1. Excluded Products. The following products are excluded from this Limited Warranty:

(a) Any cable, part that engages with the ground (i.e. sprockets), digging chain, bearing, teeth, tamping

and/or demolition head, blade cutting edge, pilot bit, auger teeth and broom brush that either constitutes or is part

of a product.

(b) Any product, merchandise or component that, in the opinion of Paladin Light Construction1, has been

(i) misused; (ii) modi ed in any unauthorized manner; (iii) altered; (iv) damaged; (v) involved in an accident; or (vi)

repaired using parts not obtained through Paladin Light Construction.

2. Warranty Period. The Limited Warranty is provided only to those defects that occur during the Warranty

Period, which is the period that begins on the rst to occur of: (i) the date of initial purchase by an end-user, (ii) the

Light Construction as evidenced by the invoiced shipment date (the “Commencement Date”) and ends on the date

that is twelve (12) months after the Commencement Date.

3. Terms and Conditions of Limited Warranty. The following terms and conditions apply to the Limited Warranty

hereby provided:

(a) Option to Repair or Replace. Paladin Light Construction shall have the option to repair or replace

the product.

(b) Timely Repair and Notice. In order to obtain the Limited Warranty, (i) the product must be repaired

within thirty (30) days from the date of failure, and (ii) a claim under the warranty must be submitted to Paladin Light

Construction in writing within thirty (30) days from the date of repair.

(c) Return of Defective Part or Product. If requested by Paladin Light Construction, the alleged

defective part or product shall be shipped to Paladin Light Construction at its manufacturing facility or other location

to inspect the part or product.

Claims that fail to comply with any of the above terms and conditions shall be denied.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

AND ANY WARRANTY BASED ON A COURSE OF DEALING OR USAGE OF TRADE.

IN NO EVENT SHALL PALADIN LIGHT CONSTRUCTION BE LIABLE FOR CONSEQUENTIAL OR SPECIAL

DAMAGES.

IN NO EVENT SHALL PALADIN LIGHT CONSTRUCTION BE LIABLE FOR ANY LOSS OR CLAIM IN AN

AMOUNT IN EXCESS OF THE PURCHASE PRICE, OR, AT THE OPTION OF PALADIN LIGHT CONSTRUCTION,

DAMAGE IS BASED. THIS LIMITATION OF LIABILITY APPLIES IRRESPECTIVE OF WHETHER THE CLAIM

IS BASED ON BREACH OF CONTRACT, BREACH OF WARRANTY, NEGLIGENCE OR OTHER CAUSE AND

WHETHER THE ALLEGED DEFECT IS DISCOVERABLE OR LATENT.

LIMITATIONS AND EXCLUSIONS.

1

Attachment Technologies Inc., a subsidiary of Paladin Brands Holding, Inc. (PBHI) is referred to herein as Paladin Light

Construction.

February 10, 2010

MR25661

31

Loading...

Loading...