Painless Performance 60506, 60507 User Manual

P/N 60506 & 60507

1997-98 GM LS1 FUEL INJECTION WIRE

HARNESS INSTALLATION INSTRUCTIONS

P/N 60508 & 60509

1999-02 GM LS1 FUEL INJECTION WIRE

HARNESS INSTALLATION INSTRUCTIONS

Sixth Edition November 17, 2005

PAINLESS PERFORMANCE PRODUCTS

2501 Ludelle Street - Fort Worth, Texas 76105-1036 - (800) 423-9696

Manual P/N 90520

Copyright © Oct. 2001

TABLE OF CONTENTS

1.0 INTRODUCTION.......................................................................................................................... 1

2.0 ABOUT THESE INSTRUCTIONS............................................................................................... 1

3.0 TOOLS NEEDED.......................................................................................................................... 2

4.0 PRE-INSTALLATION AND HARNESS ROUTING GUIDELINES........................................... 2

4.1 TRANSMISSION FUNCTION...................................................................................... 2

4.2 GET TO KNOW THE ENGINE THAT YOU ARE USING........................................... 3

5.0 GENERAL INSTALLATION INSTRUCTIONS.......................................................................... 4

5.1 GROUNDING THE VEHICLE....................................................................................... 4

5.2 ROUGH INSTALLATION............................................................................................... 5

5.3 HARNESS ATTACHMENT........................................................................................... 5

5.4 TERMINAL INSTALLATION INSTRUCTIONS.......................................................... 5

6.0 GM LS1 SYSTEM WIRE HARNESS INSTALLATION.............................................................. 6

6.1 CONTENTS OF THE WIRE HARNESS KIT................................................................ 6

6.2 SPECIFIC CIRCUIT CONNECTIONS........................................................................... 5

6.3 ENGINE GROUP INSTALLATIONS............................................................................... 10

6.4 TAIL SECTION INSTALLATIONS................................................................................. 15

7.0 TROUBLE-SHOOTING INSTRUCTIONS................................................................................... 16

7.1 THE "CHECK ENGINE" LIGHT................................................................................... 16

7.2 RETRIEVING TROUBLE CODES FROM THE COMPUTER..................................... 17

7.3 WHEN TO CALL "PAINLESS WIRING" TECH LINE................................................ 17

LIST OF FIGURES

Figure 6.1 Diagnostic Link Connector (DLC) & Check Engine Light ............................................. 6

Figure 6.2 Brake Switch Connection ............................................................................................... 7

Figure 6.3 Brake Switch Relay......................................................................................................... 8

Figure 6.4 Gear Indicator Switch ..................................................................................................... 8

Figure 6.5 Air Pump & Air Solenoid Relays .................................................................................. 10

Figure 6.6 Canister Purge Solenoid ................................................................................................. 10

Figure 6.7 Canister Vent Solenoid ................................................................................................... 10

Figure 6.8 Air Pump Connection ..................................................................................................... 10

Figure 6.9 Air Bleed Solenoid.......................................................................................................... 10

Figure 6.10 Fuel Pump Relay Connector............................................................................................ 10

Figure 6.11 EGR Valve....................................................................................................................... 12

Figure 6.12 Knock Sensor Connector.................................................................................................. 12

Figure 6.13 Oxygen Sensors ................................................................................................................ 13

Figure 6.14 MAP Sensor .................................................................................................................... 13

Figure 6.15 CMP Sensor .................................................................................................................... 13

Figure 6.16 CKP Sensor .................................................................................................................... 13

Figure 6.17 Injectors 1, 3, 5, 7............................................................................................................. 13

Figure 6.18 Injectors 2, 4, 6, 8 ............................................................................................................ 13

Figure 6.19 TPS Sensor ...................................................................................................................... 14

Figure 6.20 IAC................................................................................................................................... 14

Figure 6.21 MAF Sensor .................................................................................................................... 14

Figure 6.22 Driver Side Coil Connector.............................................................................................. 14

Figure 6.23 Passenger Side Coil Connector......................................................................................... 14

Figure 6.24 ECT Sensor....................................................................................................................... 14

Figure 6.25 IAT Sensor........................................................................................................................ 15

Figure 6.26 VSS (4L60E)...................................................................................................................... 16

Figure 6.27 Transmission Connection (4L60E)………........................................................................ 16

Figure 6.28 Transmission Connections (T56 manual).....…................................................................. 16

Figure 7.1 Fuse Identification.............................................................................................................. 16

LIST OF TABLES

Table 4.1 Compatible Parts.............................................................................................................. 3

Table 6.1 Dash Section Connections................................................................................................ 9

Table 6.2 Engine Section Connections............................................................................................. 11

Table 6.3 Tail Section Connections.................................................................................................. 15

ii

1.0 INTRODUCTION

We at Painless Performance Products believe you have purchased the most up-to-date and easiest to install

automotive fuel injection harness on the market. All components to this harness are new. All harnesses are tested

for faults before they leave the factory floor. This harness is designed for easy installation, even if you have no

electrical experience.

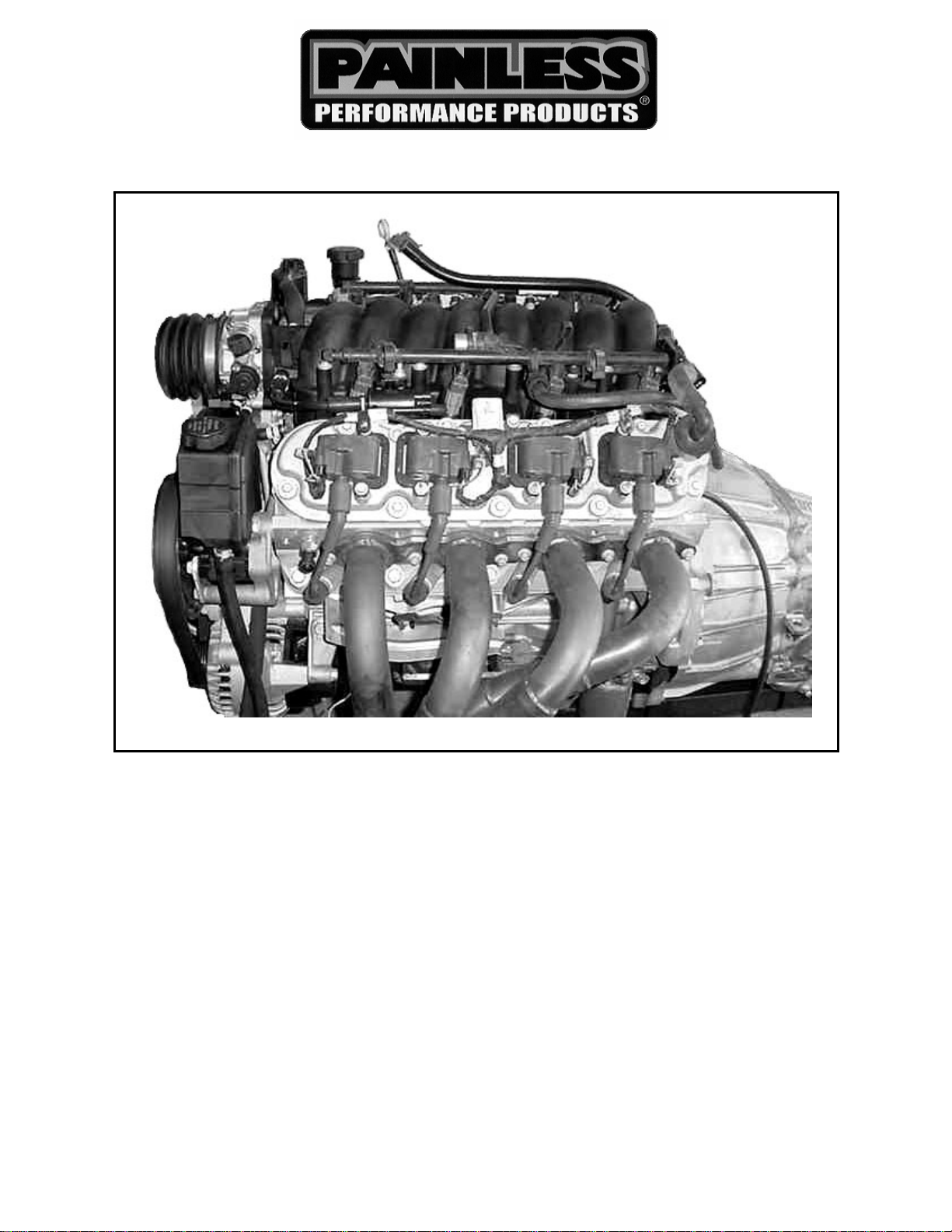

The 60506-7 harness is designed to be a complete wiring system for the fuel injection system on General Motors

1997-98 LS1 injected engines and to control the 4L60E automatic or T56 manual transmission using the 1998

computer Service #16238212. The 60508-9 harness is designed to be a complete wiring system for the fuel injection

system on a 1999-02 LS1 with a T56 manual or a 4L60E automatic transmission. Factory computers from 1999-02

Camaros or Firebirds, equipped with the LS1, may be used with this harness. These computers were service number

9354896 or 12200411. These harnesses include all wiring that is needed by the computer to run and control the fuel

injection system and transmission. A module has been included to bypass the vehicle anti theft system (VATS)

incorporated in the computer from the factory. This harness along with the VATS module included in the kit will get

the LS1 engine and transmission up and operating. It is recommended that you have the computer reprogrammed to

remove anything in the original factory programming that relates to a device or devices that are not being used in

your particular vehicle.

NOTE: Most likely the check engine light will come on and stay on when using a computer with the original factory

programming. This is normal and is why we recommend that the computer be reprogrammed.

NOTE: Most remanufactured computers come without any programming in them and must be programmed before

they can be used.

NOTE: The program in your computer must match the transmission that you plan on using. You cannot run a 4L60E

transmission with a computer programmed for a T56.

Usually, the computer, relays and fuse block can easily be mounted under the dash. Most of the wiring in the harness

has been pre-terminated to the proper connector and all wire has been GM color-coded. All wiring is TXL, 600 volt,

and 125 degree centigrade with cross-link insulation.

These fuel injection system harnesses have been divided into the following three major groups:

ENGINE GROUP Includes wiring for the fuel injectors, ignition system, and sensors.

DASH GROUP Includes ignition feed wire, assembly line diagnostic link (DLC) connector,

check engine light, computer connectors, brake switch wiring, gear shift indicator wiring,

tachometer wiring, VATS, fuse block, fuel pump relay connector

(These emission sections are not included in the 60508-9 harnesses) air pump, air bleed,

canister purge, canister vent, air pump and air solenoid relays.

TAIL GROUP Includes VSS wiring, transmission wiring and a power wire for the fuel pump

.

2.0 ABOUT THESE INSTRUCTIONS

These instructions provide information for the installation of the 60506, 60507, 60508 & 60509 LS1 fuel injection

harness kits. The contents of these instructions are divided into the following major sections:

1.0 INTRODUCTION

2.0 ABOUT THESE INSTRUCTIONS

3.0 TOOLS NEEDED

4.0 PRE-INSTALLATION AND HARNESS ROUTING GUIDELINES

5.0 GENERAL INSTALLATION INSTRUCTIONS

6.0 GM LS1 FUEL INJECTION HARNESS KIT

7.0 TROUBLE-SHOOTING INSTRUCTIONS AND TROUBLE CODES

Sections are further divided into Paragraphs and Steps. Throughout, the Figure numbers refer to illustrations and

the Table numbers refer to information in tables. These are located in or near the sections or paragraphs to which

they correspond. Always pay careful attention to any notes or any text labeled CAUTION.

1

3.0 TOOLS NEEDED

In addition to your regular tools, you will need, at least, the following:

Crimping tool NOTE: USE A QUALITY TOOL TO AVOID OVER-CRIMPING.

Wire stripper

Continuity tester CAUTION: DO NOT USE A TEST LIGHT TO TEST THE COMPUTER OR SENSOR

WIRING. YOU WILL DAMAGE THE COMPUTER.

Electric drill

1 5/8" Hole saw (for the rubber grommet in the firewall)

4.0 PRE-INSTALLATION AND HARNESS ROUTING GUIDELINES

The installation of your harness kit will consist of two parts:

~ The physical routing, positioning, and securing of the harness, wire groups, and individual wires and

connectors.

~ The proper electrical connection of the individual circuits.

We cannot tell you how to route the harness in your automobile. That depends a great deal upon the particular make

of the automobile and what extent you want to secure and conceal the harness. We do offer some general guidelines

and routing practices starting in Paragraph 5.3, general installation instructions in Section 5.0, and precise

instruction concerning the electrical connections you will have to make beginning in Section 6.0. To help you begin

thinking through the installation of your wire harness, read the following sections:

4.1 TRANSMISSION FUNCTION

If you are using the T56 transmission, read Paragraph 4.1.1, then skip to the note at the end of the page. If you are

using the 4L60E, then skip Paragraph 4.1.1, and start at paragraph 4.1.2.

4.1.1 If you are using a T56 transmission, tape off and store the purple and pink (brake switch) wires,

the orange/black and black/white (gear indicator switch) wires in the dash group and the 13position (transmission) round connector in the tail section. Plug in the skip shift solenoid, reverse

lockout solenoid and vehicle speed sensor connector to the transmission as shown in Figure 6.28.

We have included a wire to turn on a skip shift light if you are planning on using one. This wire is

white/black and provides a ground to the skip shift light. You must connect power to the other side

of the light.

4.1.2 If you ARE going to use a 4L60E transmission, tape off and store the skip shift light wire, skip

shift solenoid and reverse lockout solenoid connectors. You must use the vehicle speed sensor

(VSS), correct brake switch and a gear indicator switch. These are necessary to make the

transmission work correctly. The brake switch should be closed (electrically connected) when the

brakes ARE NOT being applied and open (not electrically connected) when the brakes ARE

being applied. This is the opposite of a standard brake light switch. If you are using a pressure

brake switch, a SPDT relay must be installed to unlock the converter when the brakes are applied.

NOTE: Emission devices

The 60506-7 harnesses have provisions for the emission devices. We have rolled up the canister

purge, canister vent, air pump and air bleed solenoid wiring in the dash section and it may be left

there if these items are not to be used. If you plan on using these items you will need to route these

wires out to the engine compartment. Secure the wires to the main harness using the tie wraps

supplied.

The 60508-9 harnesses have no emission wiring included.

2

4.2 YOU SHOULD GET TO KNOW THE PARTICULAR ENGINE YOU ARE USING:

NOTE: The 1997-02 LS1 engine had four oxygen sensors from the factory. We have included

provisions for only two oxygen sensors, which include one on the driver side and one on the

passenger side of the engine. We have removed the two rear oxygen sensors since they

originally where behind the catalytic converters and most people don’t want to run more

than two oxygen sensors. This system has two rectangular connectors at the computer.

4.2.1 PPPI recommends the use of the following parts. See Table 4.1A for 60506-7 or 4.1B for 60508-

9. These will meet all requirements and are compatible with PPPI harnesses. The numbers given

are GM and AC Delco part numbers. You must use the computer listed on table 4.1 with our

harness.

4.2.2 Familiarize yourself with the harness by locating each of the harness groups and by looking at the

connectors on the wire ends.

4.2.3 Decide where and how the computer, fuse block and relays will be mounted. PPPI wire harness

kits are designed to mount either under the dash or in the kick panel on the passenger side. They

must be no further apart than the wiring will allow (approx. 18 inches).

4.2.4 A good exercise is to lay out the wire harness on the floor beside your vehicle and identify all the

connectors and wires.

4.2.5 You will want to route the harness through and around open areas. Inside edges provide extra

protection from hazards and also provide places for tie wraps, clips and other support.

4.2.6 Route the harness away from sharp edges, exhaust pipes, and the hood, trunk and door hinges.

4.2.7 Plan where harness supports will be located. Use a support approximately every 6 inches unless

the harness routes under the floor carpet.

4.2.8 Allow enough slack in the harness at places where movement could possibly occur (body to frame,

frame to engine, etc.).

4.2.9 The wires should be bundled into harness groups. Use tape, nylon ties or poly split loom.

LS1 Fuel Injection Harness (97 - 98) Part # 60506 & 60507

Main Computer…………………Service #16238212

Fuel Pump Relay………………..Delco# 15-8240

Brake Switch…………………….Delco# D850A

Gear Indicator Switch…………...Delco# D2286A

Intake Air Temperature………….Delco# 213-243

MAF Sensor……………………..Delco# 213-353

Engine Coolant Temperature……GM# 12551708

Oxygen Sensor (Pass. Side)……..Delco# AFS97

Oxygen Sensor (Drvr. Side)……..Delco# AFS98

TPS Sensor………………………Delco# 213-912

MAP Sensor…………………..…Delco# 213-331

Idle Air Control Motor…………..GM# 17113391

Table 4.1A 60506-7 Compatible Parts

Knock Sensors…………………...Delco# 213-362

EGR Valve……………………….Delco# 214-5597

Coils………………………….…..Delco# D580

Cam Position Sensor……………..Delco# 213-355

Crankshaft Position Sensor………Delco# 213-354

Air Pump…………………………Delco# 215-353

Air Pump Relay………..………...Delco# 15-8426

Air Solenoid Relay………………Delco# 15-8426

Air Bleed Solenoid………………GM# 1997201

Canister Purge Solenoid…………GM# 1997278

Canister Vent Solenoid…………..GM# 24574755

VSS(4L60E Only)……………….Delco# 213-328

3

LS1 Fuel Injection Harness (99 - 02) Part # 60508 & 60509

Main Computer…………………Service #9354896

Service #12200411

Fuel Pump Relay………………..Delco #15-8240

Brake Switch…………………….Delco #D850A

Gear Indicator Switch…………...Delco #D2286A

Intake Air Temperature………….GM #12160244

Delco #213-243

MAF Sensor……………………..GM #25179711

Engine Coolant Temperature……GM #5326388

Delco #213-953

Oxygen Sensor (Pass. Side)……..GM #25312196

Delco #AFS97

Oxygen Sensor (Drvr. Side)……..GM #25312197

Delco #AFS98

TPS Sensor………………………GM #17123852

Delco #213-912

MAP Sensor…………………..…GM #16212460

Delco #213-331

Idle Air Control Motor…………..GM #17113391

Knock Sensors…………………...GM #10456603

Delco# 213-362

Coils………………………….…..GM #12558948

Delco# D580

Cam Position Sensor……………..GM #12561211

Delco# 213-363

Crankshaft Position Sensor………GM #12560228

Delco# 213-354

VSS(4L60E Only)……………….Delco# 213-328

Table 4.1B 60508-9 Compatible Parts

5.0 GENERAL INSTALLATION INSTRUCTIONS

CAUTION:

~ DO NOT DISCONNECT THE BATTERY OR THE COMPUTER CONNECTORS WHILE THE

IGNITION IS ON.

~ DO NOT SHORT ANY WIRES IN THIS HARNESS TO GROUND (WITH THE EXCEPTION OF

LABELED GROUND WIRES) OR DAMAGE TO THE COMPUTER WILL RESULT.

~ GIVING OR RECEIVING A "JUMP START" MAY DAMAGE THE COMPUTER.

~ DO NOT USE A TEST LIGHT WHEN TESTING COMPUTER SENSORS OR COMPUTER

CIRCUITS. DAMAGE TO THE COMPUTER WILL RESULT!

~ WHEN ROUTING THE WIRES FOR THE VEHICLE SPEED SENSOR (IF USED) MAKE

CERTAIN THAT THEY ARE AT LEAST 12 INCHES AWAY FROM ANY IGNITION WIRING

(SPARK PLUG WIRES, ETC.).

Notes:

~ There is a normal, small current drain on these fuel injected systems.

~ Each connector in this harness is different and will not fit in the wrong place. NEVER FORCE ANY

CONNECTOR.

~ When connecting the plugs to the computer USE EXTREME CARE

the computer are or become bent.

~ The fuel pump and pressure regulator you are using MUST

PSI

(pounds per square inch). If using a higher pressure pump you must add an inline regulator to

bring the pressure down to the 55-60 range since the LS1 fuel system does not have a built-in

regulator on the fuel rail as in many earlier GM fuel injection systems.

5.1 GROUNDING THE VEHICLE

A perfectly and beautifully wired automobile will nevertheless have problems if everything is not properly grounded.

Don't go to the effort to installing a quality wire harness only to neglect proper grounding.

Note: The installer of this harness is responsible for all ground wires not provided with this part.

5.1.1 Connect a ground strap or cable (minimum of a 4 Ga. wire) from the negative battery terminal to

the chassis (frame).

5.1.2 Connect a ground strap (minimum of a 4 Ga. wire) from the engine to the chassis (frame). DO

NOT RELY UPON THE MOTOR MOUNTS TO MAKE THIS CONNECTION.

5.1.3 Connect a ground strap from the engine to the body.

to make sure none of the pins in

maintain a constant pressure of 55-60

4

Loading...

Loading...