Painless Performance 10309 Instructions Manual

Wire Harness Installation

Instructions

Manual #90571 PART 1

For Installing:

#10309 Basic Customizable Nostalgia All Black

Chassis Harness – 17 Circuit

Painless Performance Products recommends you, the installer, read this

installation manual from front to back before installing this harness. Due

to the variables in modifications that can be done to vehicles, reading

this manual will give you considerable insight on the proper installation

of this harness.

Perfect Performance Products, LLC

Painless Performance Products Division

2501 Ludelle Street

Fort Worth, TX 76105-1036

800-423-9696 phone – 817-244-4024 fax

Web Site: www.painlessperformance.com

E-Mail: painless@painlessperformance.com

If you have any questions concerning the installation of this harness, feel

free to call Painless Performance Products' tech line at 1-800-423-9696.

Calls are answered from 8am to 5pm central time, Monday thru Thursday,

8am to4:30pm Fridays, except holidays.

We have attempted to provide you with as accurate instructions as

possible, and are always concerned about corrections or improvements

that can be made. If you have found any errors or omissions, or if you

simply have comments or suggestions concerning these instructions,

please write us at the address above, send us a fax at (817) 244-4024 or email us at painless@painlessperformance.com. We sincerely appreciate

your business.

Perfect Performance Products, LLC shall in no event be liable in contract

or tort (including negligence) for special, indirect, incidental, or

consequential damages, such as but not limited to, loss of property

damage, or any other damages, costs or expenses which might be claimed

as the result of the use or failure of the goods sold hereby, except only the

cost of repair or replacement.

90571 Installation Manual

January 14, 2014

Copyright 2013 by Perfect Performance Products, LLC

2

CAUTION: BEFORE THE REMOVAL OF YOUR ORIGINAL HARNESS

AND/OR THE INSTALL OF YOUR NEW PAINLESS HARNESS, DISCONNECT

THE POWER FROM YOUR VEHICLE BY REMOVING THE NEGATIVE OR

POSITIVE BATTERY CABLE FROM THE BATTERY.THE BATTERY IS NOT

TO BE CONNECTED UNTIL THE PAINLESS HARNESS HAS BEEN

INSTALLED AND TESTED.

A full color copy of these instructions can be found online at

http://www.painlessperformance.com/InfoSearch/manuals.php

If your vehicle has an existing harness, you will want to retain it for the

possible re-use of various pigtails & connector housings particular to

your application. During the removal process, avoid making any

unnecessary cuts.

This harness is universal in nature, meaning, all ends are left open to

allow you to cut wire to length and install the appropriate connection.

The package of terminals included with the harness will enable you to

make connections.

Only printed wires will have a 900-series number. These 900-series

numbers are used to identify various wires and circuits in the wiring

diagrams that are a part of these instructions.

In the event that there are unused or unconnected wires, the ends of all

wires labeled in this instruction manual as “POWER” or wires printed

with “B+” in the description, will need to have the ends terminated with

an insulated terminal or taped. Doing so will prevent the wires shorting

and causing harness failure or fire.

3

TABLE OF CONTENTS

PAGE # SECTION

6 INTRODUCTION

7 CONTENTS

8 SMALL PARTS

9 TOOLS NEEDED

10 PRE-INSTALLATION GUIDELINES

11 INSTALLING FACTORY TERMINALS

12 GROUNDS

15 FUSE BLOCK

Horn relay

Flashers

16 Fuse Identification

17 Relays & Switches

18 Fuse Block Mounting

20 FUSE BLOCK HARNESS ROUTING

22 COMPONENT OUTPUT HARNESS ROUTING

24 HEADLIGHT SECTION CONNECTIONS

Left/Driver Side Headlight

26 Headlight w/ Pigtails

28 Left Turn/Park Light

29 Horn

Right Turn/Park Light, Right Headlight

31 ENGINE / IGNITION SECTION

Coil/ignition

32 Ballast Bypass

33 Tachometer

35 Engine Sending Units/Switches

Coolant Temperature

37 Oil Pressure, Choke

39 START/CHARGE SECTION

Alternator

40 Charge Indicator Light

42 GM SI Series Alternators

43 GM CS-130 Alternators

45 GM CS-130D Alternators

47 GM Externally Regulated Alternator

48 Ford Externally Regulated Alternator

49 Ford Internally Regulated Alternator (3G)

50 MOPAR Externally Regulated Alternator

52 MIDI Fuse

54 Starter

4

Schematics, Diagrams, & Photos

PAGE # SECTION

6 NOTES diagram

7 CONTENTS photo

9 JAW STYLE CRIMPERS picture

11 TERMINAL INSTALLATION pictures

13 GOOD & BAD GROUND SOURCE diagrams

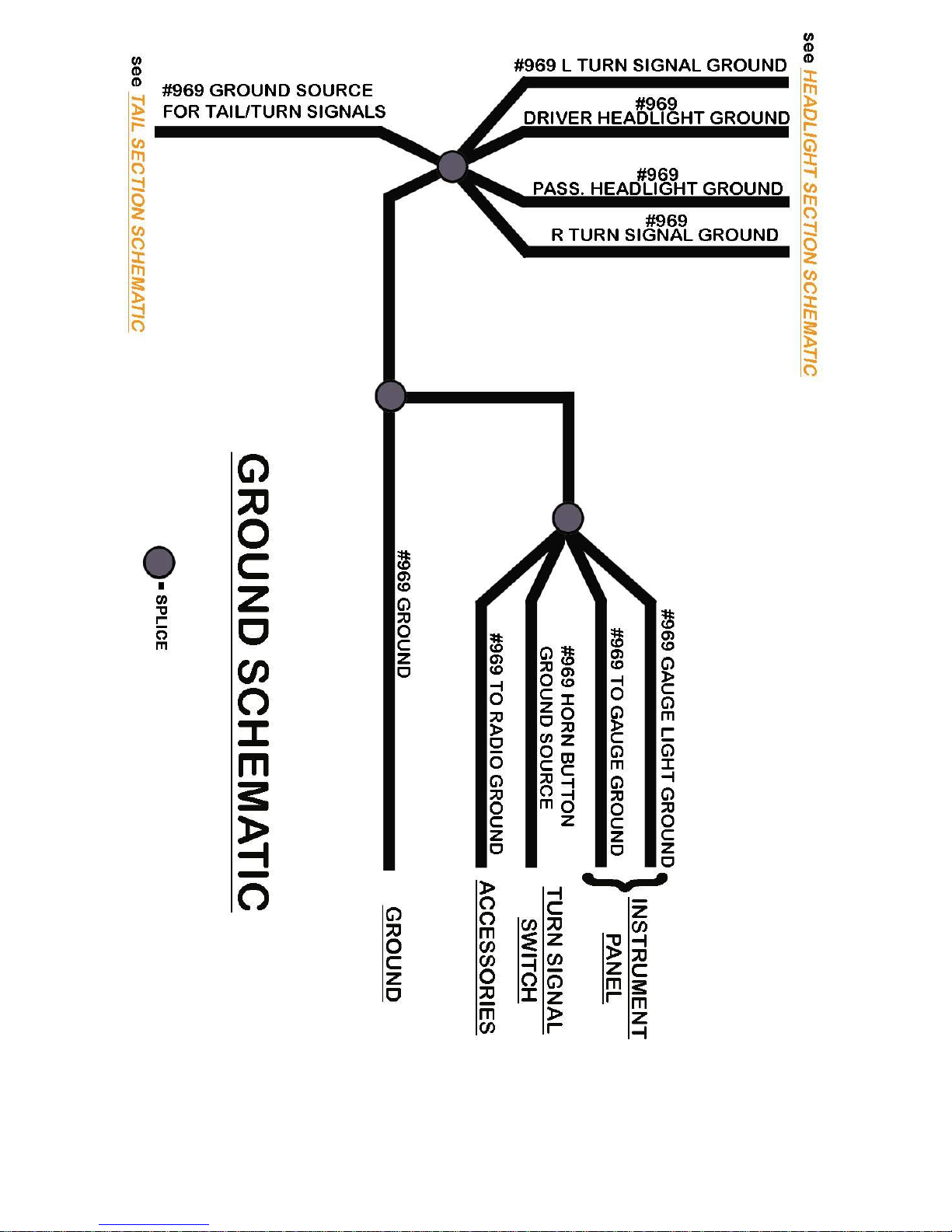

14 GROUND SCHEMATIC

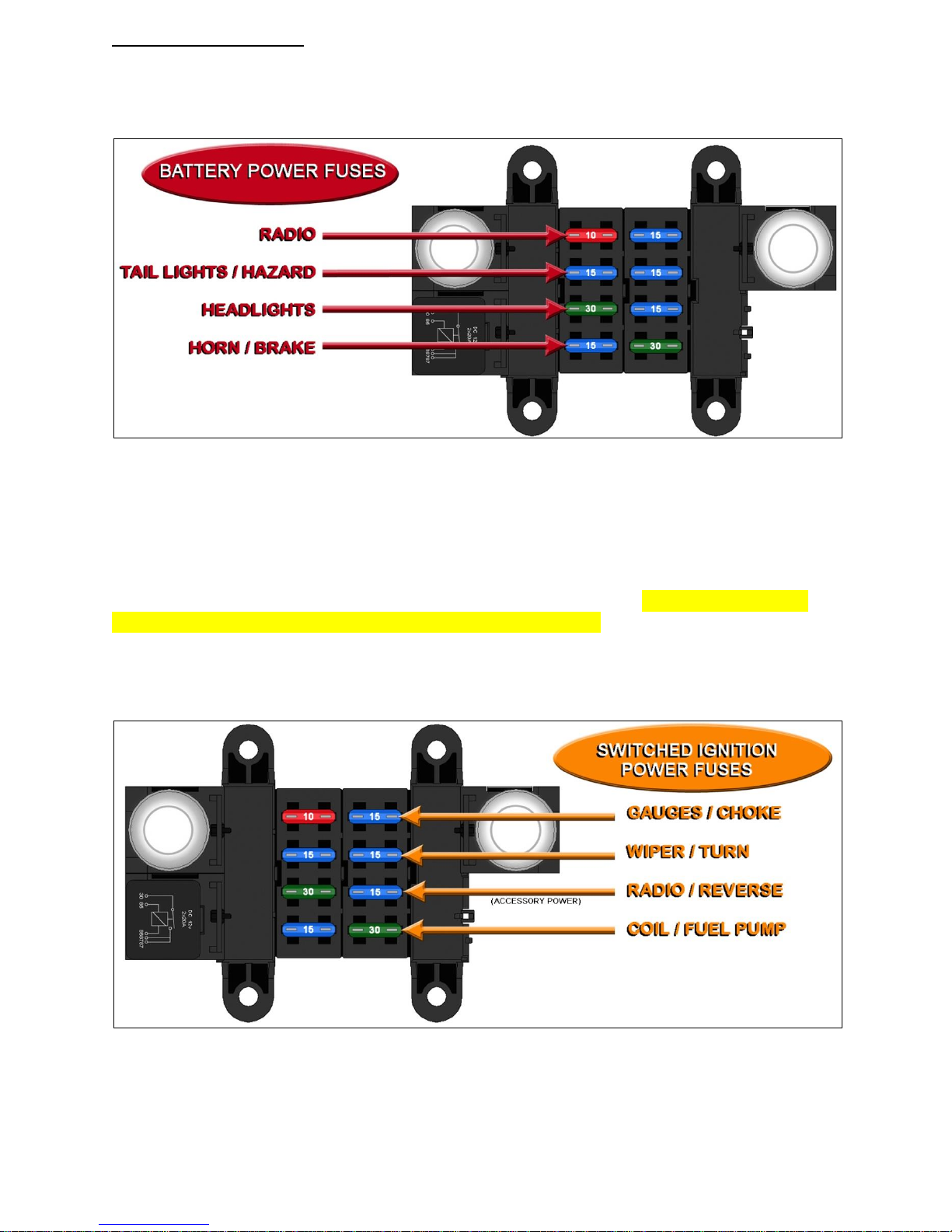

16 FUSE IDENTIFICATION diagrams

18 FUSE BLOCK MOUNTING photos

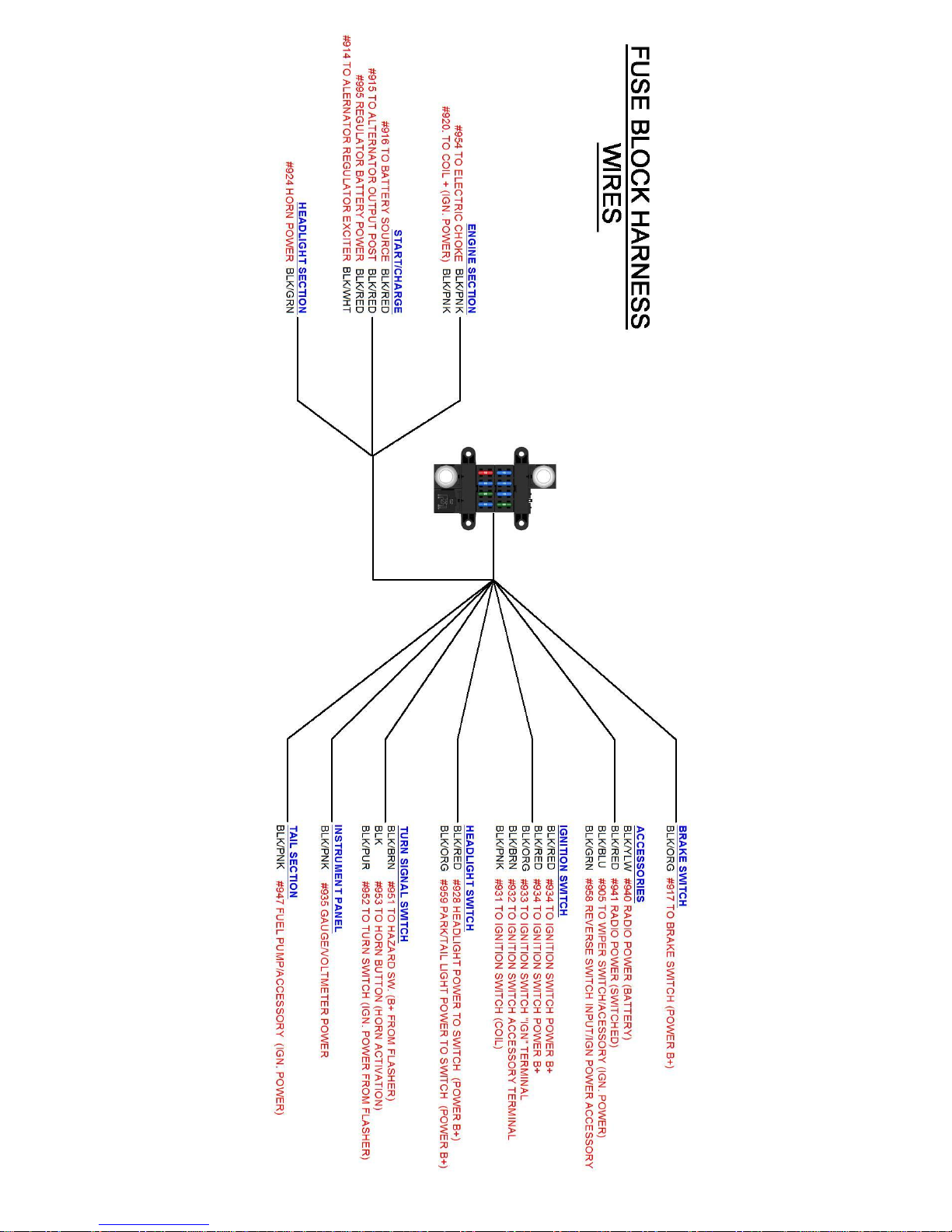

19 FUSE BLOCK HARNESS diagram

20 FUSE BLOCK HARNESS ROUTING diagram

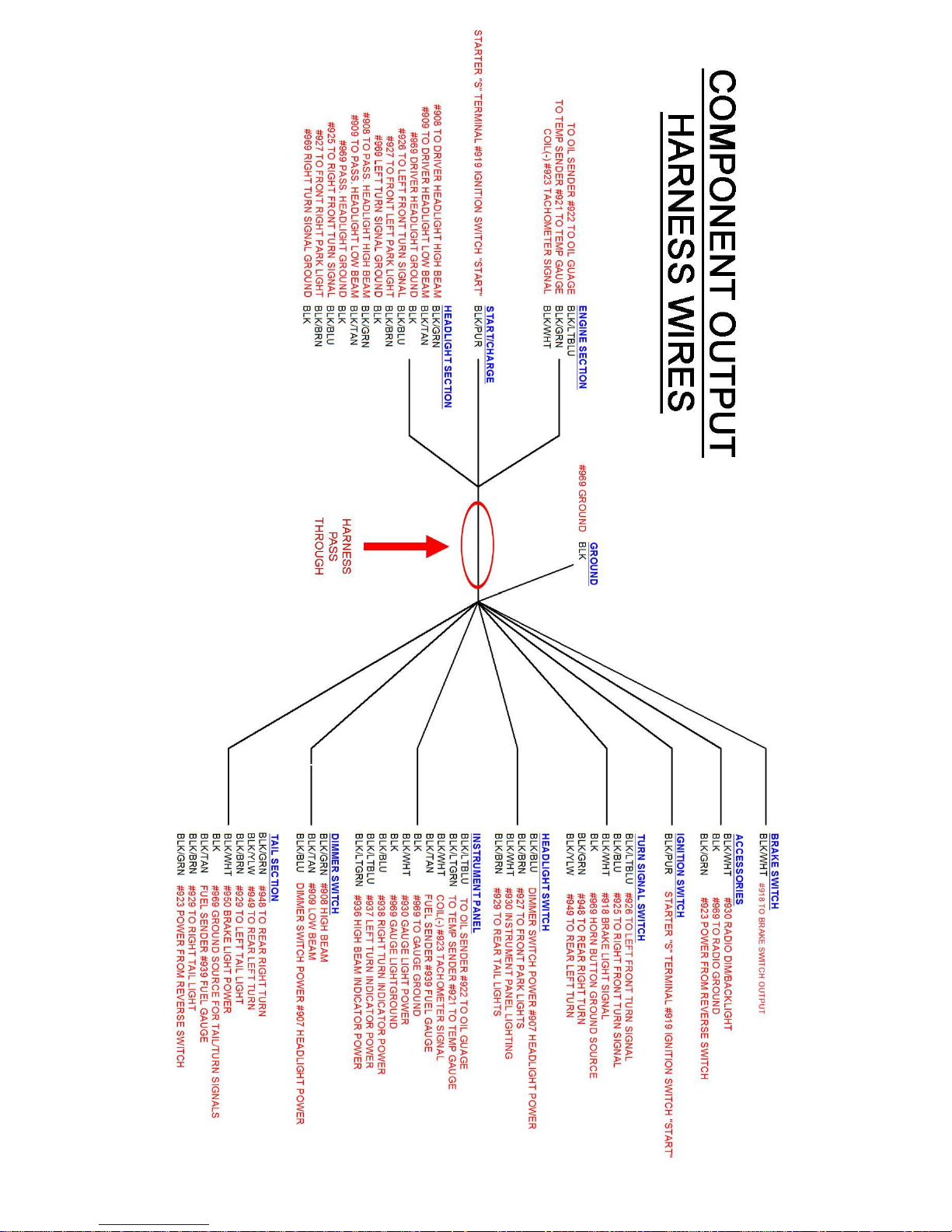

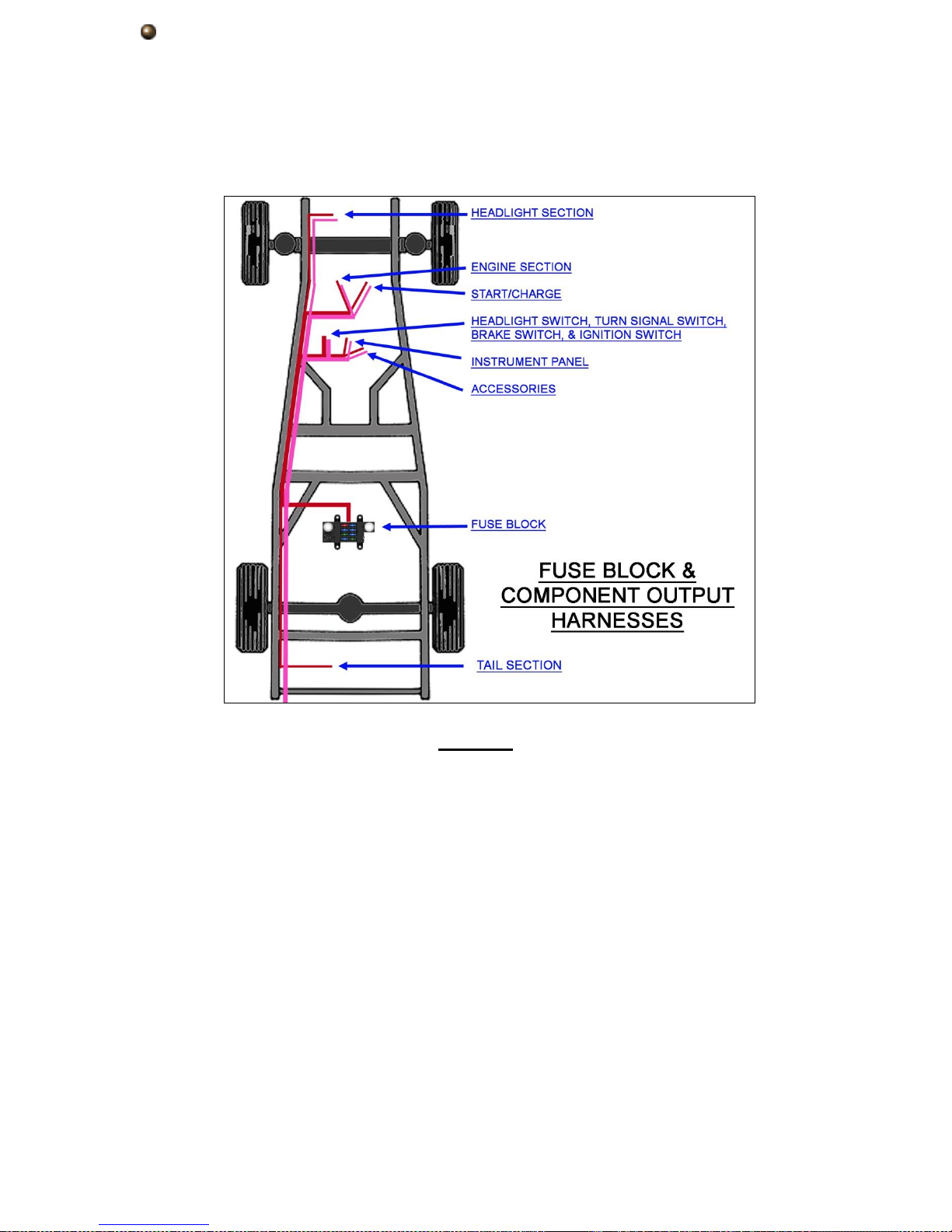

21 COMPONENT OUTPUT HARNESS diagram

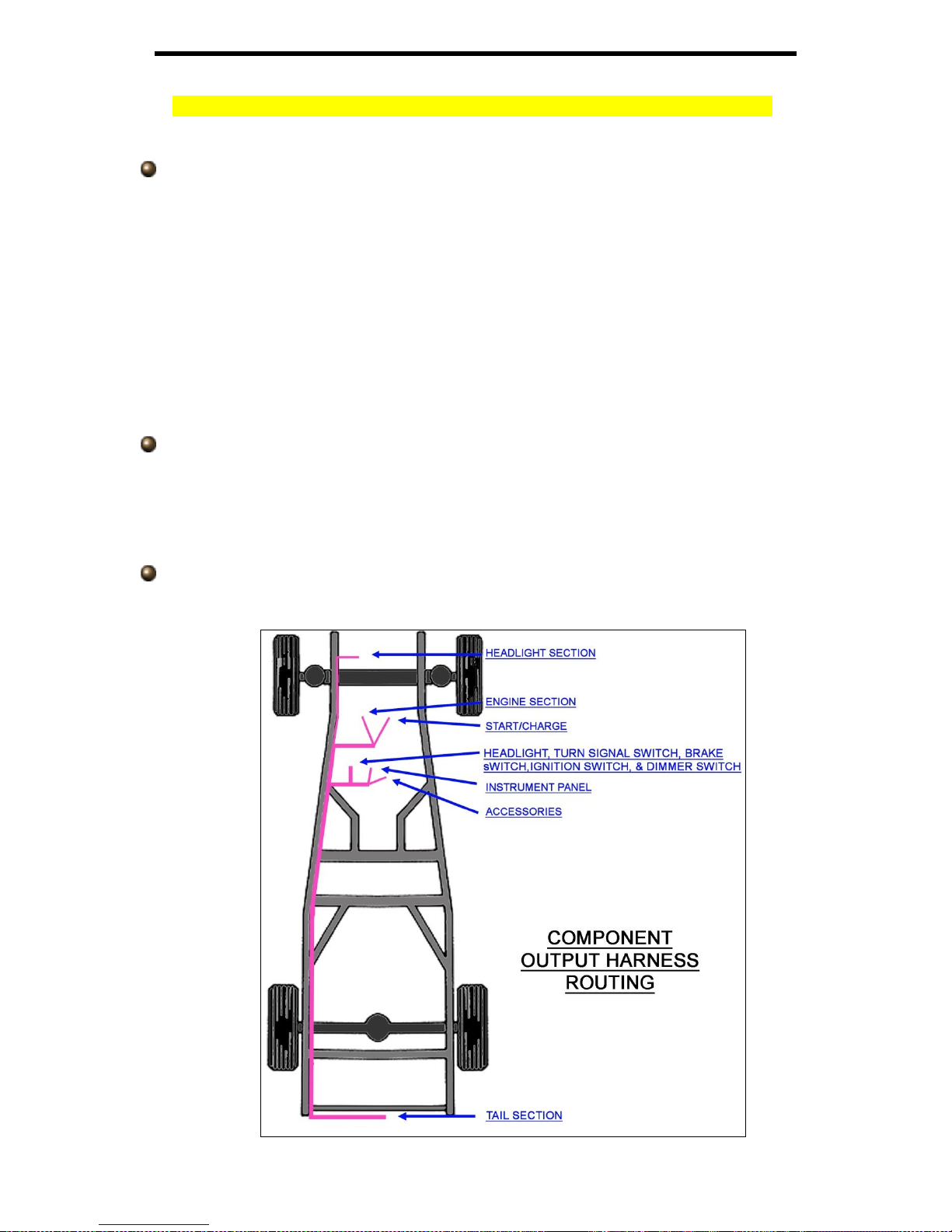

22 COMPONENT OUTPUT HARNESS ROUTING diagram

23 COMPONENT & FUSE BLOCK HARNESSES TOGETHER diagram

25 HEADLIGHT CONNECTOR PIN OUT photo

30 HEADLIGHT SECTION SCHEMATIC

34 COIL CONNECTIONS diagram

BALLAST RESISTOR CONNECTIONS diagram

MSD CONNECTIONS diagram

35 HEI COIL ON CAP CONNECTIONS photo

38 ENGINE SECTION SCHEMATIC

39 CHARGE INDICATOR LIGHT diagram

43 GM SI SERIES ALTERNATOR diagram

44 GM CS-130 ALTERNATOR diagram

46 GM CS-130D ALTERNATOR diagram

47 GM EXTERNALLY REGULATED ALTERNATOR diagram

49 Ford EXTERNALLY REGULATED ALTERNATOR diagram

50 Ford INTERNALLY REGULATED ALTERNATOR (3G) diagram

51 MOPAR EXTERNALLY REGULATED ALTERNATOR diagram

52 MIDI FUSE MOUNTING photo

53 BATTERY POWER/MIDI FUSE SCHEMATIC

55 GM STARTER diagram

56 FORD STARTER SOLENOID diagram

57 MOPAR STARTER RELAY diagram

58 MOPAR “SR14” RELAY diagram

5

INTRODUCTION

Thank you for your purchase of a Painless Performance product. These

instructions along with the Painless harness have been designed to allow you, the

installer, the cleanest and easiest install possible.

During the course of reading this manual you will notice wire colors with a slash,

as an example Black/White. This indicates a wire with a stripe. The first color is the

main color of the wire and the color after the slash is the stripe color. In the case of the

example, Black/White indicates a black wire with a white stripe.

Do not let the length of this instruction manual intimidate you. Much of the

information contained in this manual is helpful information about each wire, where the

wire comes from, where it goes, why a component needs it, etc. In many cases, there

are multiple schematics as well as alternate connection options for the same

wire/connection point due this being a universal harness. You will find that the actual

install portions of this manual are pretty straight forward and easy to follow.

The install portions are noted with a round bullet note, as seen here.

Individual components and sections are labeled with printed tags for easy

identification. As this harness is all black, conventional GM color code was followed

based on the stripe found on the wire. These colors, along with the schematic diagrams

found throughout this manual and the printed circuit numbers and description printed on

the wire, will help you identify the different circuits during installation and later on if

additions to the overall system are necessary.

As you read through the installation manual prior to actual installation, use the

blank areas titled NOTES in each section and in the back of the manual to list

components you are connecting to on your vehicle, factory or manufacturer wires that

are coming from the component, then list their function/ power requirement. You can

then use the text in the manual and the wire index in the back of the manual to identify

the wire and circuit number in the Painless harness that will connect to that requirement.

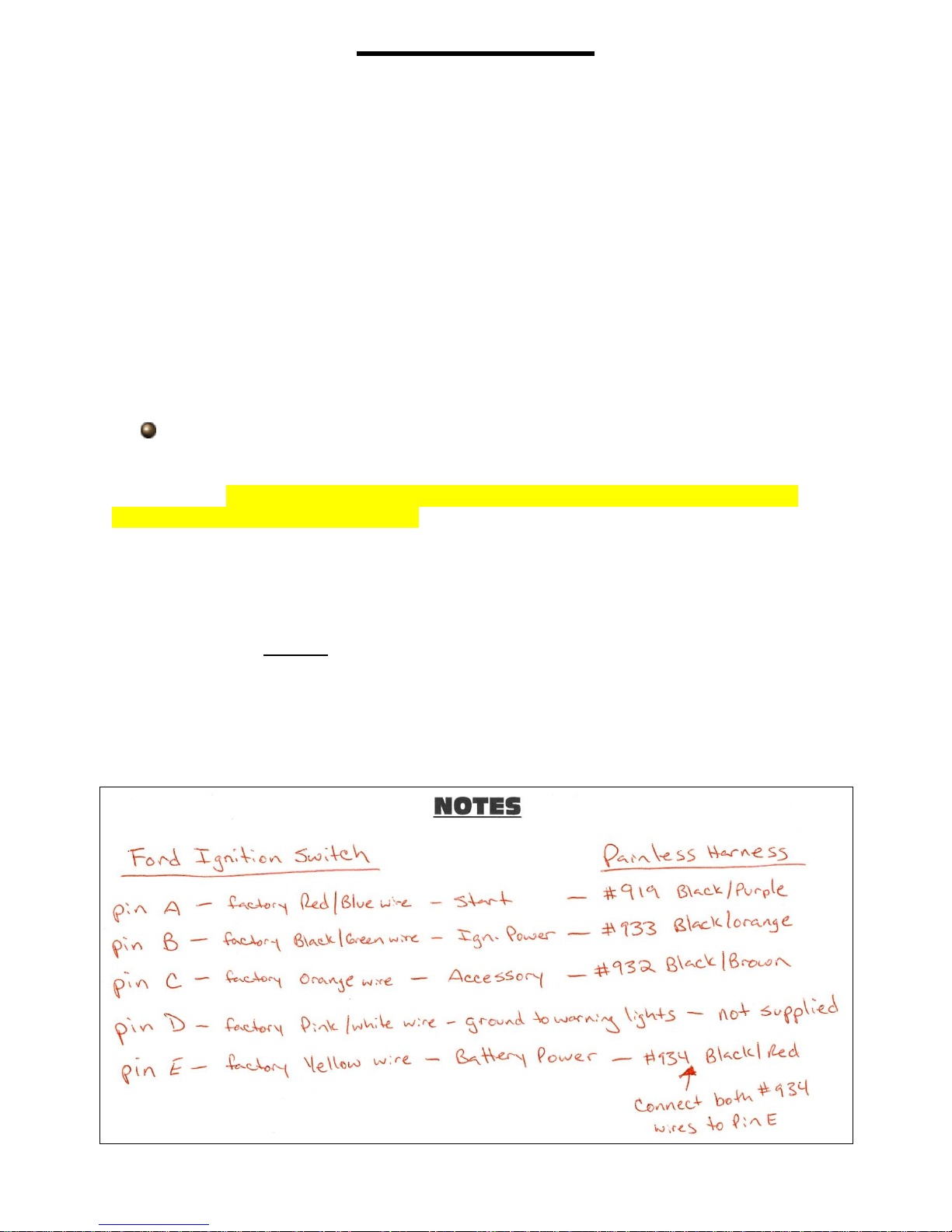

For example, a dash mounted 60’s-70’s Ford ignition switch:

6

Planning connections beforehand will give you a better understanding of what

needs to be routed, if any additional wires may need to be added, and how to make the

best use of any extra circuits provided in the Painless harness.

CONTENTS OF THE PAINLESS WIRE HARNESS KIT

Refer to the Contents Figure (below) to take inventory. See that you have

everything you’re intended to have in this kit. If you find that anything is missing or

damaged, please contact the dealer where you obtained the kit or Painless

Performance at (800) 423-9696.

The Painless Wire Harness Kit should contain the following:

Power Supply Harness Harness, with the fuse block pre-installed

Output supply harness

3 rolled wires: Red, Black/Yellow, and Black/Red

Parts Kits: (1) insulated loose piece terminals kit (1) un-insulated terminal kit

3 bag kits: Alternator bag, heat shrink bag, a bag w/ zip ties and other parts

This manual: parts #1 and #2

CONTENT FIGURE- All of the parts in the Painless kit

7

You may be wondering… “Why two harnesses in this kit instead of just one

grouped together like most harnesses?”

You will notice one harness has a fuse block pre-installed. This will be known in

this manual as the FUSE BLOCK HARNESS. This harness contains all of the power

wires to components like the headlight switch, turn signal switch, brake switch etc. and

also supplies power to the fuse block from the battery. This harness has extra length

built in to allow the fuse block to be mounted up to 10’ away from major components like

the headlight switch and the ignition switch.

The secondary harness, or COMPONENT OUTPUT HARNESS, contains wires

from individual switches and sending units to the components they operate. As an

example: all the wires from the turn signal switch to the turn indicators, oil/temp/fuel

sending units to the gauges, and headlight switch out to the exterior lights. Since the

majority of this harness involves connections made to components of the dash, we are

given a common reference point since most dashes are slightly forward of the center of

the vehicle. This allows this secondary harness to have shorter lengths than the fuse

block harness but still provide ample length for just about any install. These shorter

lengths result in less waste when you route and cut these wires to length.

SMALL PARTS

Included with the Painless harness are parts kits containing miscellaneous

terminals, fuses, screws, and nuts. Many of the terminals are non-insulated and will

require heat shrink to be applied after the terminal has been properly crimped. Heat

shrink has been supplied.

These non-insulated terminals follow the same “old-school” traditional feel of this

nostalgia harness; colored insulated terminals would seem out of place. When crimping

these terminals, take notice to the split in the terminal. Make sure the smooth side of the

jaw on the crimper goes towards this split.

One small bag kit, labeled ALTERNATOR, contains

all of the components for an inline fuse installation and

alternator connections. This fuse is to isolate the battery

from the alternator and Painless harness. These parts

include the base with cover, fuse, mounting screws and ring

terminals.

“Umbrella” style zip ties have been provided for you

to attach the Painless harness to the inner fender, core

support, and/or frame. These zip ties fit into ¼” holes left

behind by factory plastic retainer loops or those created with

a drill by the installer.

8

Remember, as the zip ties are installed and the harness is routed, wrap the tie

around the harness and LOOSELY tie the harness. Make sure you leave enough room

to pull and push the harness as you make your connections. Only when all connections

have been made will you tighten the zip ties.

TOOLS NEEDED

In addition to your regular hand tools, you will need, at least, the following tools:

Wire Crimping and Stripping Tools:

This style of hand crimper can be purchased from just about any local auto parts store,

home improvement store or can also be

purchased online. You will need this style

of crimper to crimp the heat shrinkable and

non-heat shrinkable insulated terminals

included in the small parts kit.

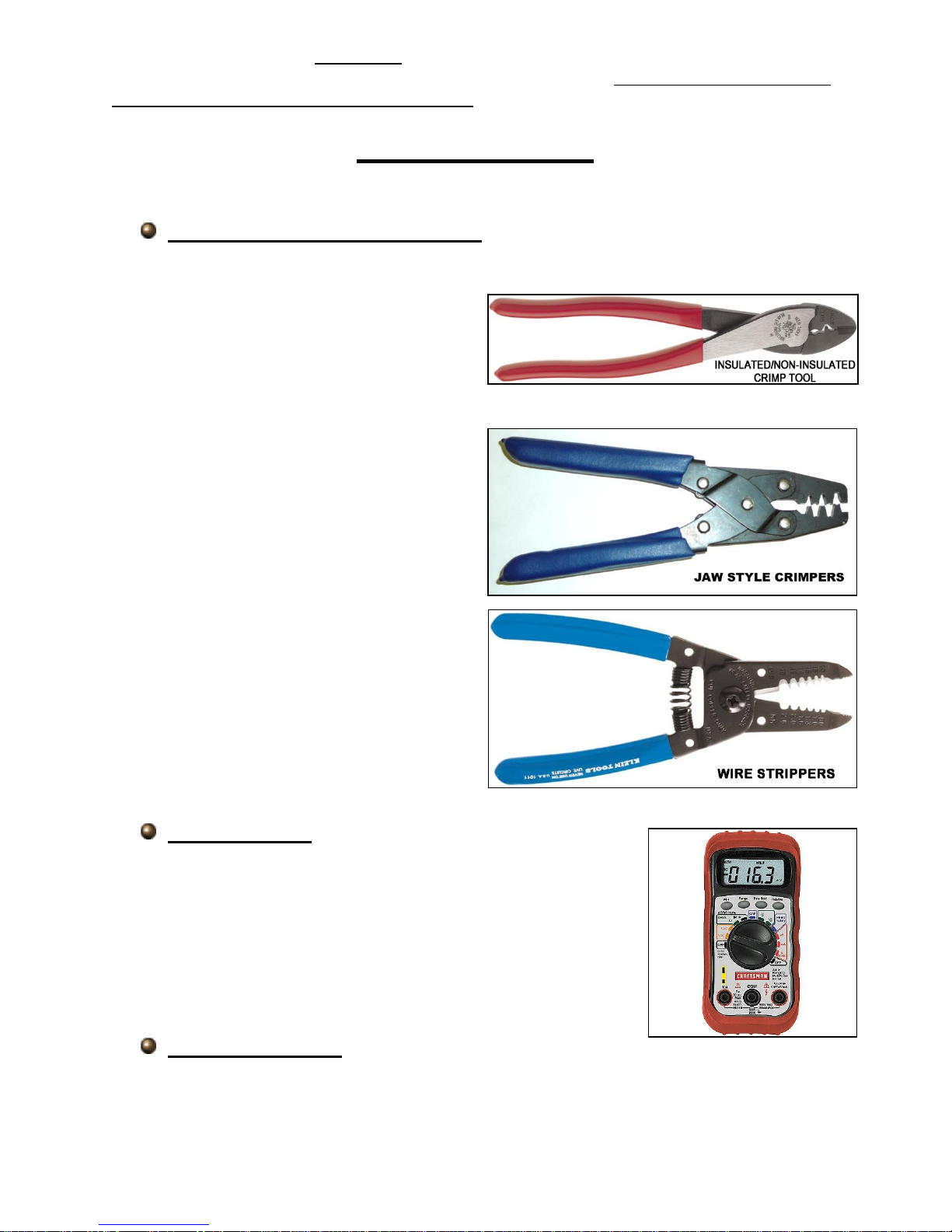

Another style of crimpers are “Jaw

Crimpers” or “Roll Over Crimpers”. These

crimpers will crimp factory style, uninsulated terminals. These types of

terminals are provided in the kit for

connections to an HEI distributor,

headlights and factory style alternator. If

none can be found locally, these crimpers

can be found using Painless part # 70900.

A good set of wire strippers are required to

strip wire properly. This style of wire

stripper is ideal for this harness install

because of its ability to properly strip wire

gauges 10 to 20.These are available from

just about any local auto part store,

electrical supply shop, home improvement

store or can be purchased online.

Volt/Ohm Meter:

A Volt/Ohm meter is always a good tool to have on hand when

installing any type of electrical components into any vehicle.

Most basic units provide the two functions required to diagnose

electrical issues seen during a harness install. These two

functions are the ability to read DC Voltage and electrical

continuity or Ohms. They can be purchased from any home

improvement store, local hardware store and electrical supply

shop and online.

Electric Drill & Bits:

A drill and bits are needed in order to use the screws provided with the kit for the MIDI

fuse holder and the fuse block mounting.

9

Heat Gun:

Very useful to shrink the heat-shrinkable terminals found in the

parts kit.

Small (10 amp or less) Battery Charger

See TESTING THE SYSTEM located on page 145.

Factory Wire Schematic

This isn’t absolutely necessary; however, having one handy is

good practice with any electrical job.

PRE-INSTALLATION GUIDELINES

The installation of your wire harness mainly consists of two parts:

• The physical routing and securing of the wire harness, wires, and groups.

• The proper connection of the individual circuits.

These two major tasks are not separate steps, but are combined. That is, you will

route some wires and make some connections, route more wires and make more

connections. Harness routing will depend greatly on mounting locations of things such

as gauges, shifters, lighting lenses/headlights, etc. Harness routing also depends a

great deal on fuse block mounting location and to the extent you want to secure and

conceal the harness. This aspect will be more prominent in the ENGINE SECTION

wiring, where much of the harness is usually visible.

The best pre-installation practice is to become familiar with the harness by

locating each of the harness sections. A good way to do this is by laying out the wire

harness on the floor and identifying each of the section labels found on the harness as

you read through the manual. The wire index in the back of the second manual will help

to quickly identify each wire in these sections.

During the install, wires should be

bundled into groups. Use nylon ties, split loom,

or tape. Exposed wires of the engine

compartment and wires running to the rear of

the vehicles may need some sort of wiring loom

or covering. Painless offers Power Braid Kit part

#70920 and ClassicBraid #70970 to fill this

need. These kits include everything you will

need to add extra protection to your new

harness.

10

INSTALLING FACTORY STYLE TERMINALS

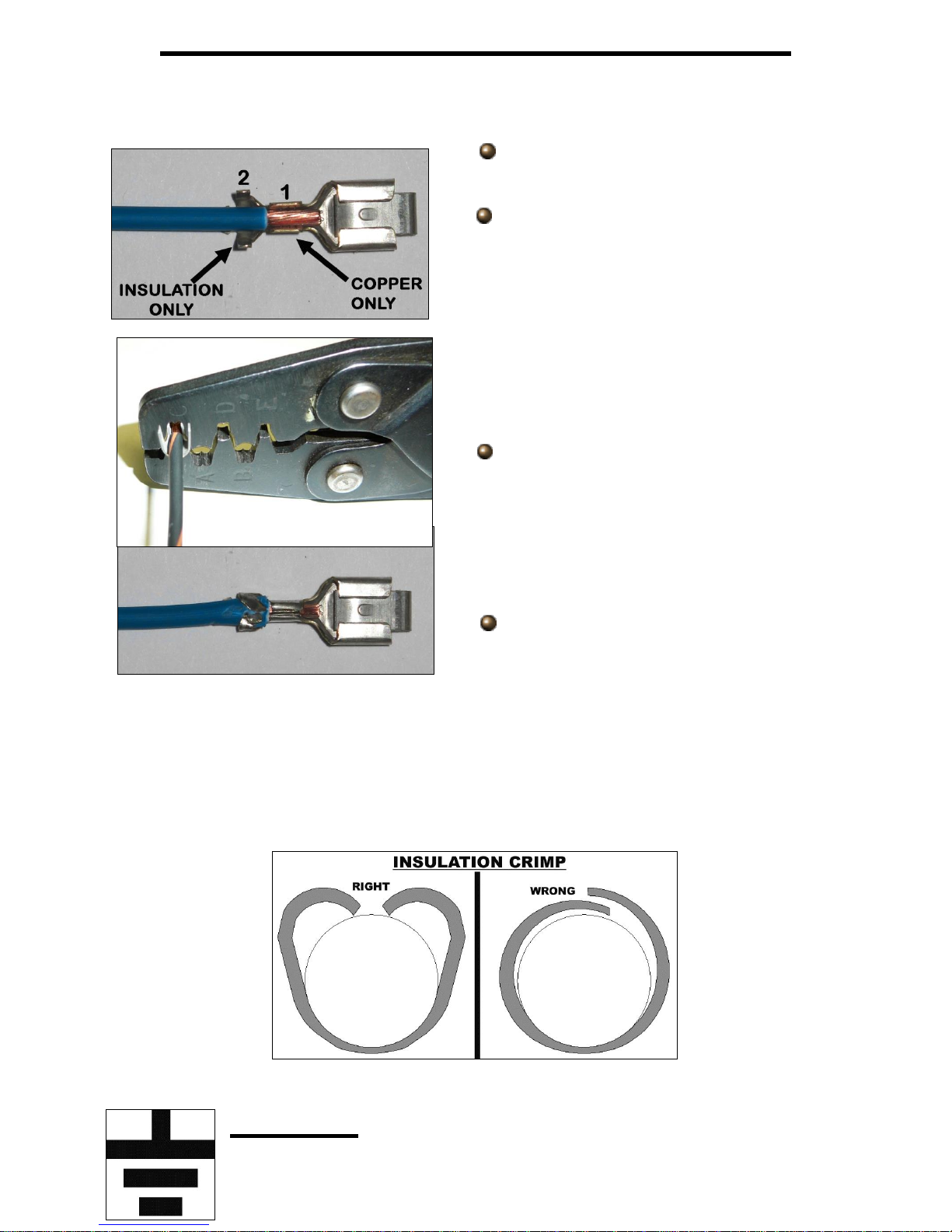

In the parts kit you will see different non-insulated male and female terminals.

These terminals are for factory style connections and require roll over crimpers.

Strip about ¼” of insulation off of the

wire.

Insert the wire into the terminal. There

are 2 terminal straps on the terminal. For

instructional purposes, we will label them 1 and

2. Strap 1 crimps the exposed copper stands of

the wire, while strap 2 crimps the wire

insulation. Make sure your strip length is long

enough to ensure only copper strands are

crimped by Strap 1, but make sure it is short

enough that only insulation is crimper by Strap

2. The photo to the left best demonstrates this.

Using the appropriate jaw on the

crimpers, crimp Strap 1. The appropriate jaw

depends on the wire gauge as well as the

terminal stiffness. If you are unsure which jaw

to use, you can always start with the biggest

and work your way down until you get a tight

crimp.

With Strap 1 crimped you can move

onto crimping the insulation strap, Strap 2.

Place Strap 2 into the appropriate jaw of the

crimpers. This jaw will be larger than the one

used to crimp the first strap. Crimp down on Strap 2 making sure the strap folds

downward into the wire, and not overlapping itself, refer to the drawing below.

Overlapping could cause problems with the terminal fitting into the factory

connector.

Grounds

11

Throughout this instruction manual and when looking at the Painless harness you

will see the word GROUND, maybe you’ve seen the ground symbol on wire diagrams?

What exactly is a ground and why do you need it?

You’ve probably noticed the large cable coming

from the negative side of your battery going down to the

sub frame or to the engine. This cable allows voltage to

get back to the battery through the metal of the sub

frame and all the other metal pieces bolted to the frame.

It is also important to have ground cables going from the

sub frame to the engine and from the sub frame to the

body. Painless offers part # 40140, seen in the photo, to

supply proper grounds back to the battery.

A ground is simply the common path voltage takes back to the battery. A ground,

or chassis ground as it is often called, is any bare metal surface found on the vehicle

which is in turn connected back to the frame/negative side of the battery through

mounting points and ground straps. They are needed in order for the voltage current to

have some place to go.

There are two ways components are grounded in vehicles: through mounting and

through wire connection.

Some grounds are supplied though the mounting of the metal housings in which bulbs

are installed, like turn signal or tail light housings. Components with plastic housings or

non conductive housings, like headlights which are glass, get their grounds through

wires from the chassis harness.

To help avoid grounding problems, all the ground wires in the Painless harness

are connected together through a series of splices. All of these splices connect to a

large 10 gauge wire found in the COMPONENT OUTPUT HARNESS, see the Ground

Schematic on page14.

On light housings that ground through the mounting and for the harness ground

wire connection point make sure that all mounting points are clean by removing all dirt,

corrosion, or paint. This is especially important for cars that have recently been painted

as paint build up will cause grounding issues. 80 grit or courser sandpaper should be all

that’s needed to properly clean grounding points.

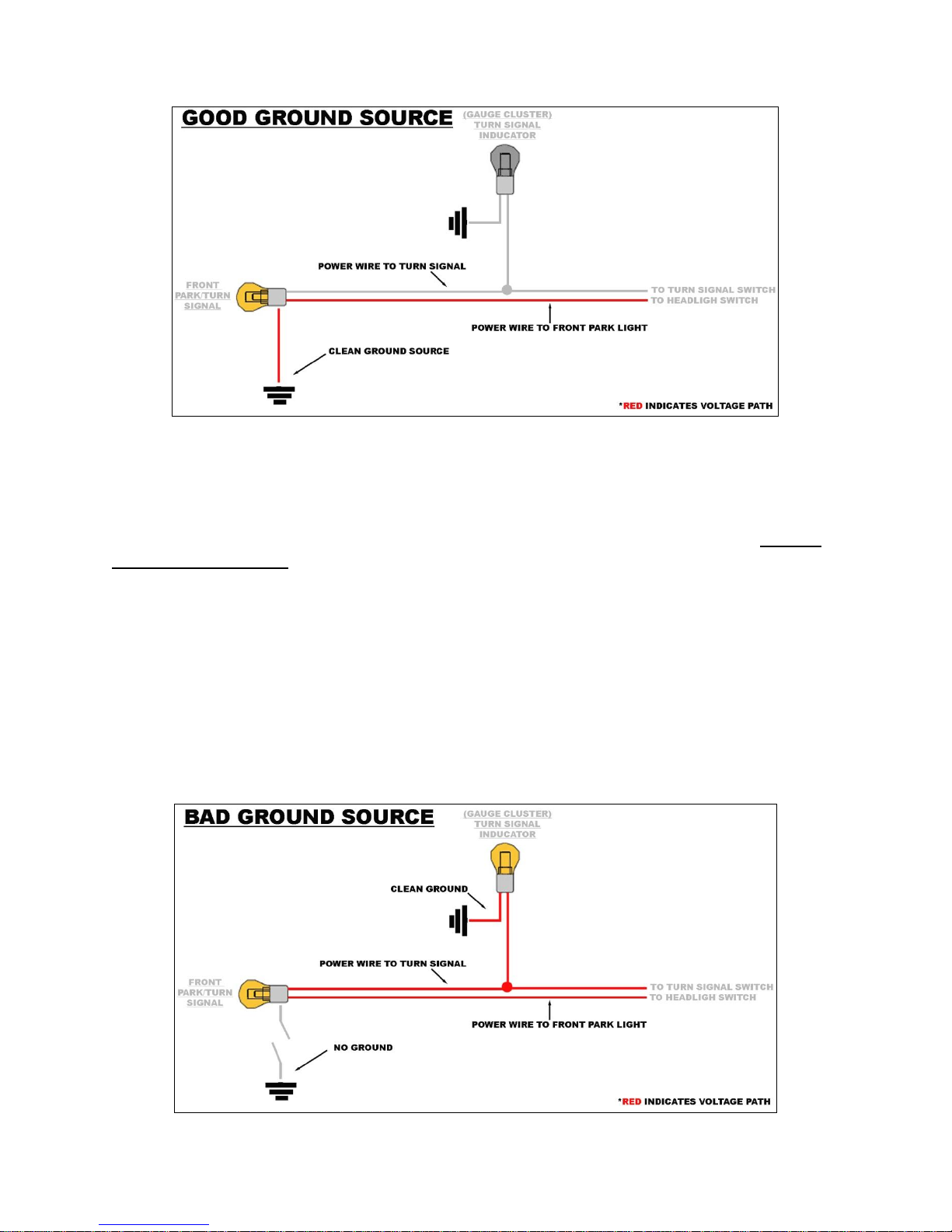

Why are clean grounds important?

As an example we will use a front turn signal that also functions as a park light.

Follow the red line from right to left in the diagrams on the next page. This red line

indicates the path electrical current takes when everything is properly grounded and as

represented in the second diagram, when the ground is bad; notice which bulbs

illuminate when good and bad grounds are present.

In our park light example with a good ground source, current travels from the

headlight switch to the park light bulb. Since the bulb is properly grounded, current

12

passes cleanly through the bulb causing it to illuminate and the current exits the bulb

through the ground source back to the battery. The ground allows everything to work

properly without any issues.

When a ground isn’t connected or is contaminated with dirt, corrosion, or paint,

the voltage will find the easiest path to ground, which is represented in the diagram

below.

Current travels from the headlight switch to the park light bulb, but wait; there is

no ground at the bulb. Since the ground it would normally use is not there, the current

will find another way to get to ground and back to the battery. When this happens,

things that should not have power receive power coming from the park light bulb. Since

the turn signal wire also goes to the bulb, the current will travel out of the bulb through

the turn signal wire. Notice in the diagram that a bad ground at the front park light can

cause issues on the interior of the vehicle at the turn signal indicator on the dash. In this

case, the turn signal indicator light is illuminated when it shouldn’t be. Also, since this

one power source which was only supposed to power 1 bulb is not powering 2 bulbs,

both bulbs may be dimmer than they would have been if everything was grounded

properly. This is one of the problems with diagnosing a bad ground; they can cause

issues throughout the entire vehicle.

13

14

FUSE BLOCK

The Painless harness contains an 8 circuit fuse block that uses modern ATC

blade style fuses. This fuse block allows the convenience of having both flashers (turn

signal and hazard), as well as the horn relay, to be mounted in one location.

Horn Relay

On the fuse block you will find a horn

relay, which replaces the factory core

support/firewall mounted horn relay found

on older vehicles. The fuse block mounted

horn relay uses a standard 30 amp SPST

relay and is ground activated from a wire in

the Turn Signal Switch group of wires of the

fuse block harness. Replacement relays for

the horn relay can be found at any auto

parts store or by ordering Painless part

number #80131.

Flashers

The two flashers simply switch

power off and on going to the turn

signal switch and hazard switch. The

flasher found next to the horn relay is

the hazard flasher. The flasher on the

side of the fuse block by itself is the

turn flasher.

How a flasher functions is

simple. Power is switched off and on

according to heat built in the resistance wire inside the flasher. As soon as power is

drawn through the flasher, as when the turn signal or hazard switch is activated, the

resistance wire heats up and makes contact with the output side of the flasher. This

contact passes power through the flasher, into the switch and to the turn signal lamp(s).

Once this contact has been made, the resistance wire is no longer resisting any voltage,

so it begins to cool; this cooling causes the flasher to lose contact.

This loss of contact means that there is no longer any voltage going to the

switch, causing the turn signal light to turn off. Once contact is lost, the resistance wire

begins heating up and the entire process starts over again until the turn signal switch or

hazard switch is disengaged.

Some L.E.D. turn signals do not draw enough

voltage to activate a typical thermal flasher. If you are using

L.E.D. turn signals, and your turn signals do not work

properly and you are certain everything is connected

properly, a no load flasher will be required; Painless part

number #80230.

15

Fuse Identification

The following two diagrams and information will detail each fuse and which

components/circuits each fuse powers.

The drawing above shows all the battery power fuses. These fuses are powered

by a wire that comes from the large power splice, seen on page 53. All of these battery

power fuses fuses will have power at all times.

The drawing below shows all the switched ignition fuses. These fuses are

powered by wires coming from the ignition switch (wires #931, #932, and #933) and will

have power depending on what position the ignition switch is in. None of these fuses

should have power when the ignition is in the OFF position. The “RADIO / REVERSE”

fuse is powered by the wire intended to connect to the accessory terminal on the

ignition switch as noted in the drawing. The ignition switch section, page 79 of the

second manual, will go into further detail about power supplied to these fuses.

Fuse labels have been provided to allow labeling the fuse block for future

reference.

16

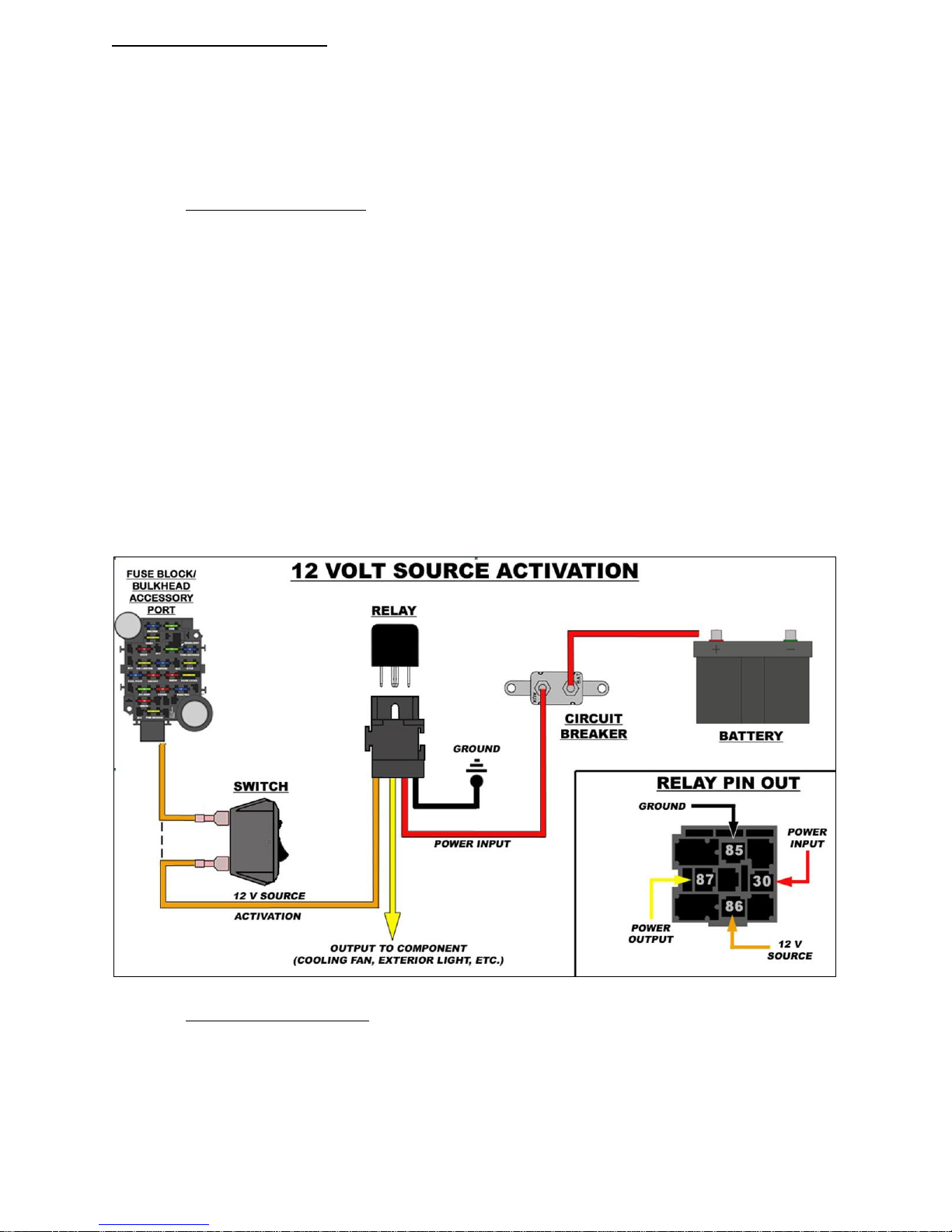

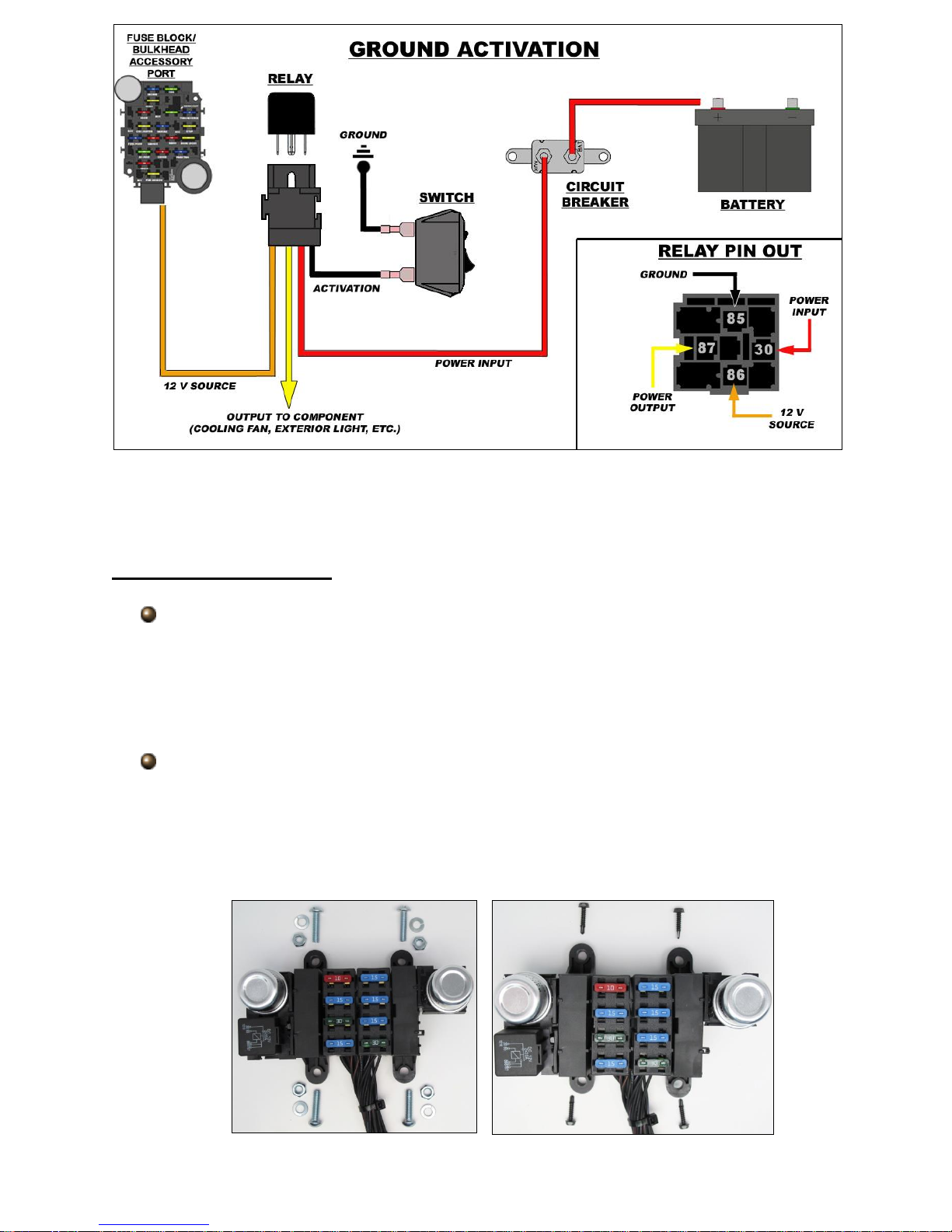

Relays and Switches

All ACCESSORY wires found in this harness can support up to 15 amps.

Components requiring more amperage will need to be connected to a relay. An

ACCESSORY wire can be used as a 12 volt activation source or 12 volt source for

ground activation in these circumstances. Take a look at Painless part #’s 30107 &

30108 to fill your relay needs.

A 12 volt activated relay is constantly grounded and will send power out of the

output side of the relay to the component being powered when 12 volts is applied to the

relay, as the name implies. The 12 volt source can be wired directly to the relay or

interrupted by a switch, as shown in the 12 VOLT SOURCE ACTIVATION drawing.

Wiring directly to the relay, as indicated by the dashed line, would be used in the

case of wiring a water pump relay, or any other high amperage component you

would want to run continuously while the key is in the on position. In these cases,

make certain the 12 volt wire you are using is an Ignition Switched 12 volt wire and

not a battery constant hot.

The 12 volt activation wire can also be wired to a switch to offer the user OFF/ON

capabilities. These are the situations a battery constant power source would be

used. This would allow a component to be turned OFF or ON without the key in the

ON position. However, unless a lighted switch is being used, a ground activated

relay may work better to avoid running power through the switch.

A ground activated relay is just the opposite of the 12 volt activated relay, 12

volts (battery constant or switched) is supplied uninterrupted and the ground wire is

switched. The Horn Relay pre-wired in the Painless harness is a Ground Activated

Relay. Another example of this method is a thermostat operated fan relay. In this case

however, a thermostatic switch would replace the switch in the drawing below. Like

mentioned before, ground activation method is best used when a component is

operated by an unlit switch from the interior of the vehicle.

17

In the event that a toggle/rocker switch is being used without a relay, make sure

the amperage of the component you are powering does not exceed the capabilities of

the switch. Switch failure will occur.

Fuse Block Mounting

Locate the harness with the fuse block pre-installed.

To begin mounting the fuse block, you will need to find a suitable location that will

allow easy access in the event you have to replace a fuse, and also allow enough

length for the wires to reach things like the ignition switch, headlight switch, etc. Make

sure this area in out of the elements and in an area that will not get wet.

Mount the fuse block to the mounting location in one of the following 2 ways:

1) Drilling holes using a ¼” drill bit and using the four bolts, nuts and washers

supplied

2) Using the four self tapping screws and a ¼” nut driver on a drill.

18

19

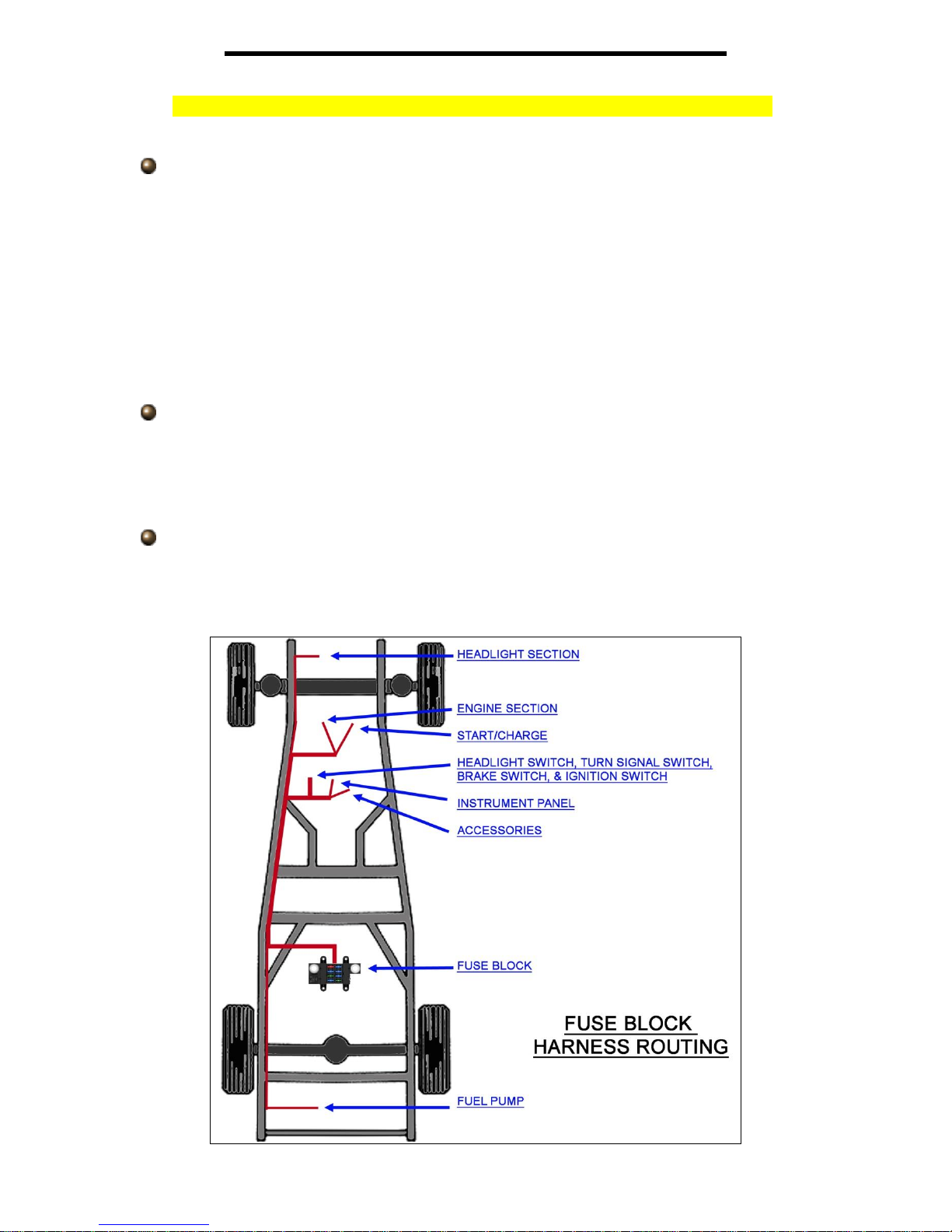

FUSE BLOCK HARNESS ROUTING

Loosely route all of the following wire groups to their designated connection

points. NO CONNECTIONS OR CUTTING WILL TAKE PLACE AT THIS TIME. A

complete layout of the Fuse Block Harness can be found on the previous page.

Route the 3 sections intended for engine compartment connection towards the

front of the vehicle. These sections are labeled “ENGINE SECTION”,

START/CHARGE, and HEADLIGHT SECTION”.

Multiple grommets have been provided to allow pass through of the firewall/floor

board. Use the grommet that best fits an existing hole or one created by you, the

installer.

If you are using a hydraulic brake switch mounted on or near the master cylinder,

the wire labeled “BRAKE SWITCH” will also be grouped and routed with these

wires.

Route the wires intended for dash mounted components/switches towards their

connection points on the dash at this time. These will be groups labeled “TURN

SIGNAL SWITCH”, “HEADLIGHT SWITCH”, “IGNITION SWITCH”,

“ACCESSORIES”, “INSTRUMENT PANEL”, AND “BRAKE SWITCH” (if it wasn’t

already routed to the engine compartment)

A single wire labeled “TAIL SECTION” is a power wire intended to connect to an

electric fuel pump or wire can also be used for something else, can be routed at

this time to its connection point. See page 95 of the second manual for more

information on this wire.

20

21

COMPONENT OUTPUT HARNESS ROUTING

Loosely route all of the following wire groups to their designated connection

points. NO CONNECTIONS OR CUTTING WILL TAKE PLACE AT THIS TIME. A

complete layout of the Component Output Harness can be found on the previous page.

On the Component Output harness, locate the area seen circled in red in the

schematic on the previous page. This area will be the portion of the Component

Output Harness that passes through the firewall/floor board towards the front of

the vehicle.

At this time route the following groups of wires towards their locations in the front

of the vehicle: “ENGINE SECTION”, START/CHARGE, and HEADLIGHT

SECTION”

If you are using a hydraulic brake switch mounted on or near the master cylinder,

the wire labeled “BRAKE SWITCH” will also be grouped and routed with these

wires.

Route the wires intended for dash mounted components/switches towards their

connection points on the dash at this time. These will be groups labeled “TURN

SIGNAL SWITCH”, “HEADLIGHT SWITCH”, “IGNITION SWITCH”,

“ACCESSORIES”, “INSTRUMENT PANEL”, AND “BRAKE SWITCH” (if it wasn’t

already routed to the engine compartment)

Route the large bundle of wires labeled “TAIL SECTION” to the rear of the

vehicle.

22

With both harnesses now routed you can begin using the small 4” zip ties

provided in the kit to tie the two harnesses together to create one harness. The

drawing below shows that if routed correctly both harnesses should be close , if

not side by side or one top of each other, making tying them together rather

easy. If your harnesses are routed on different sides of the vehicle, tie the

harnesses together where they meet at common connection points, such as the

dash mounted switches.

NOTES

23

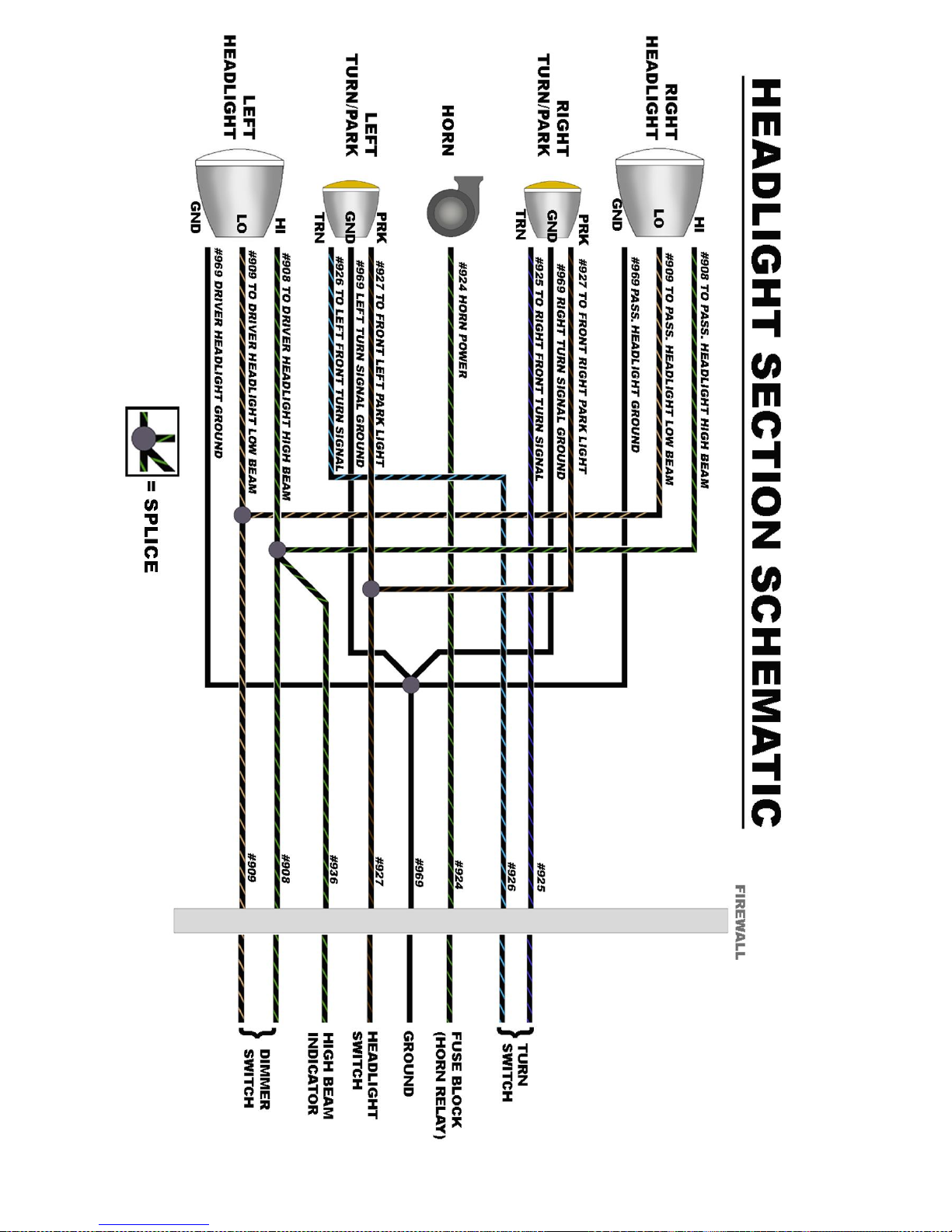

HEADLIGHT SECTION CONNECTIONS

The HEADLIGHT SECTION of this Painless Harness includes all power and

ground wires needed to properly hook up both driver and passenger side headlights,

and left and right front turn & park/marker lights. There is also a power wire from the

fuse block mounted horn relay to power a horn. All wires in the Headlight Section can

be seen in the Headlight Section Schematic on page 30.

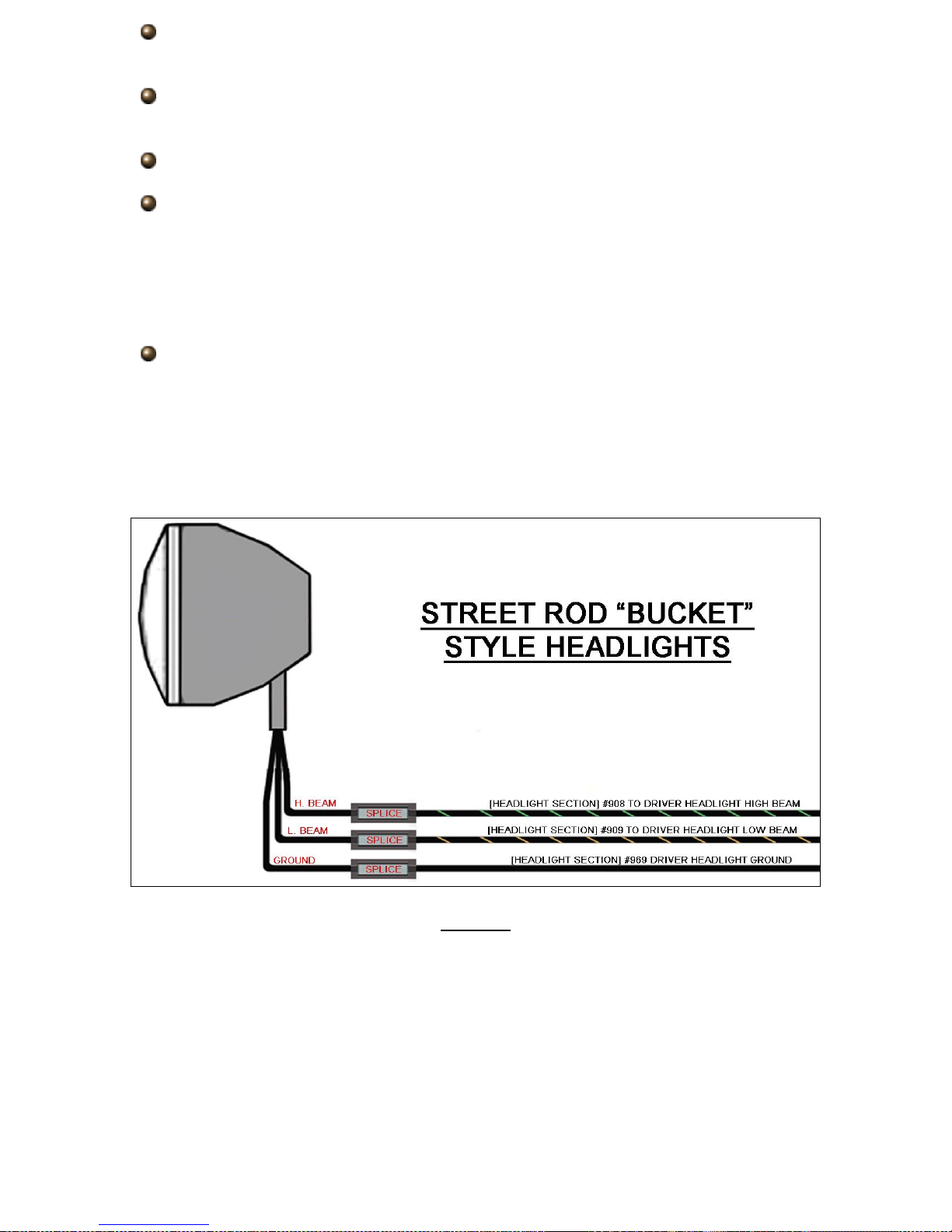

Left/Driver Side Headlamp

Your first connection in the Headlight Section will be the Left/Driver side

Headlamp. Three wires make up the connection to the Left Headlamp, they are:

Black/Green: 14 gauge wire, printed [HEADLIGHT SECTION] #908 TO DRIVER

HEADLIGHT HIGH BEAM, this wire will provide power to the high beam filament of the

head lamp. This wire goes into a splice with a wire going to the right headlamp and also

to a wire going to the high beam indicator in the dash and to the dimmer switch. This

wire will have power when the dimmer switch is in the high beam position and the

headlight switch is in the headlight ON position.

Black/Tan: 14 gauge wire, printed [HEADLIGHT SECTION] #909 TO DRIVER

HEADLIGHT LOW BEAM, this wire will provide power to the low beam filament of the

head lamp. This wire goes into a splice with a wire going to the right headlamp and also

to a wire going to the dimmer switch. This wire will have power when the dimmer switch

is in the low beam position and the headlight switch is in the headlight ON position.

Black: 14 gauge wire, printed [HEADLIGHT SECTION] #969 DRIVER HEADLIGHT

GROUND , this wire provides a ground source for the headlamp. This wire is tied into

the integrated ground circuit and can be seen in the Ground Schematic on page 14.

24

The connection of these three wires will depend on the style headlights you are

using in your application…

3 prong, Sealed Beam/ Sealed Beam Halogen/ H4 halogen

Connectors and terminals have been provided in the parts kit to allow proper

connection to these 3 prong headlights.

Locate the terminals and connector seen in the photo below. Please be aware

these terminals look just like smaller narrower terminals provided in the kit; you

will need the larger terminals for this connection. These terminals will be in the

same compartment as the connectors.

Route the 3 wires for left/driver side headlamp connection to the back of the

headlamp. Removing the headlamp may be necessary and is recommended to

ensure the terminals of the headlamp are not damaged during connection; they

are easily bent if the connector is not installed correctly.

Cut the 3 wires to length and strip ¼” of insulation from all 3 wires.

Using a set of roll over crimpers, as shown on page 11, crimp a terminal onto

each wire.

Insert all three wires in the connector according to photo above.

25

Plug the connector onto the prongs of the headlamp. Make sure the connector is

inserted straight onto the prongs as these prongs will easily bend making a

proper connection difficult.

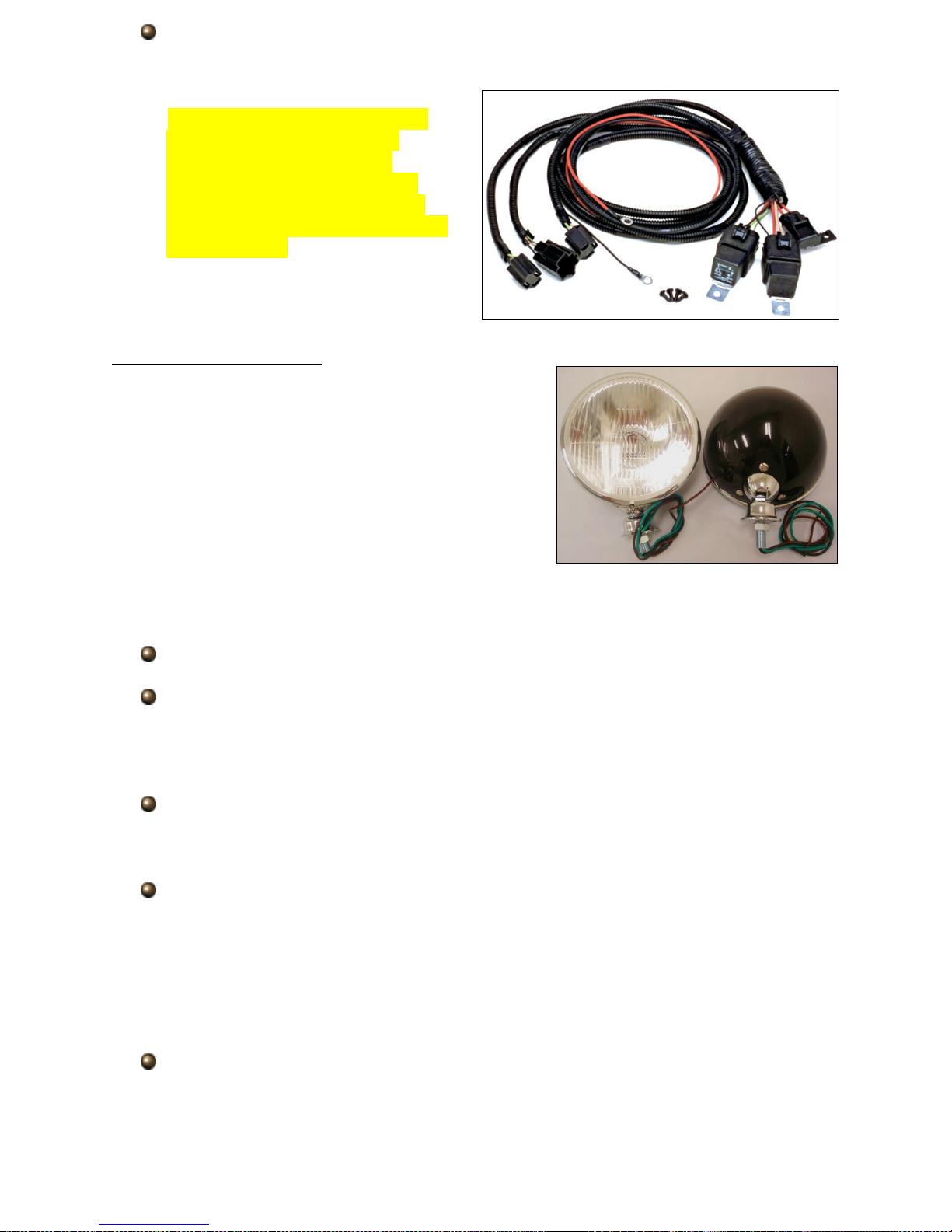

If halogen bulbs are being used

Painless recommends using

Painless part # 30815. This

headlight relay kit is needed to

avoid overloading the headlight

switch with the higher demands of

halogen bulbs.

Headlights with Pigtails

In order to make the appropriate connections

consult the manufactures instructions of the

headlights you are using to identify each wires

function. If you do not have instructions, or know

the manufacturer of the lights on your vehicle, you

can test a light using your vehicles battery.

On units that have 3 wires, in almost all

cases there will be a black wire, this is typically a

ground, while the other two colored wires are obviously the power for the high and low

beams. Units with 5 or 6 wires also have turn/park light features.

Touch one of the colored wires to the positive side of the battery.

With the colored wire touching the positive side, now touch the black wire, or both

black wires if your lamp also has turn/park, to the negative side. You may see a

couple sparks upon connecting to the negative side but this is normal. The light

should now be on, take notice to how bright the light is.

Remove both wires from the battery and repeat this process with the other

colored wire(s). First to the positive side, and then the ground(s) to the negative

side.

Whichever wire on the positive side on the battery made the light(s) brighter is

the high beam power wire or turn signal if your lamps have this option. Write this

down in the notes section at the back of this manual for future reference.

In some cases headlamps will have a Green, Brown or Tan, and Black wire

coming from them, like shown in the photo above. This is a common GM style color

code meaning: Black = ground, Brown or Tan= low beam, Green= high beam.

Connection of the #908, #909, & #969 wires of the Painless harness will be made

using the nickel plated splices provided in the parts kit along with pieces of heat

shrink.

26

Each wire, coming from the headlight bucket as well as the Painless Harness will

be cut to length and have ¼” of insulation stripped from them.

Connect the splice to each of the 3 wires on the Painless harness, taking the split

on the splice into consideration as shown on page 8.

With the splice crimped, slide a piece of heat shrink onto each wire.

Insert the wires from the headlight bucket into the splice that corresponds with

the wires function:

High Beam wire to the Painless Black/Green wire printed #908

Low Beam wire to the Painless Black/Tan wire printed #909

Ground wire to the Painless Black wire printed #969

With the wires now crimped, slide the heat shrink over the splice and apply heat

with a heat gun* to shrink it down and make a weather resistant connection.

*Some may opt to use a small soldering torch or even a cigarette lighter to

accomplish this. This is not advised as it tends to overheat the heat shrink

causing it to bubble or crack. Use caution to prevent overheating if using any kind

of flame.

NOTES:

27

“Left Turn/Park Light”

The Left Turn/Park Light of the

Painless harness consists of 3 wires,

These wires are:

Black/Brown: 18 gauge wire, printed

[HEADLIGHT SECTION] #927 TO

FRONT LEFT PARK LIGHT, is the power

source for the park light. This wire is

spliced to the other #927 wire in the Head

Light Section and also with a #927 wire

going to the Headlight Switch. This wire

will have power anytime the headlight switch is in the Park/Tail Lights ON or Headlights

ON position.

Black/Light Blue: 18 gauge wire, printed [HEADLIGHT SECTION] #926 TO LEFT

FRONT TURN SIGNAL, this wire is the turn signal power. This wire goes into a splice

with the Black/Light Blue wires going to the left turn indicator light and to the wire

coming from the turn signal switch. This wire will have interrupted switched power from

the turn signal flasher any time the left turn signal is activated and the ignition is in the

ON position and interrupted battery power from the hazard flasher any time the hazard

switch is in the ON position.

Black: 18 gauge wire, printed [HEADLIGHT SECTION] #969 LEFT TURN SIGNAL

GROUND, this wire provides a ground source for the turn/park lamp. This wire is tied

into the integrated ground circuit and can be seen in the Ground Schematic on page 14.

If your light has a dual filament bulb and only 2 wires, you will not connect the

black #969 wire. Your light socket grounds though the mounting of the lens/bucket. If

this is the case, #969 can be removed from the harness or connected to the frame or

any other clean ground source.

If your light has a single filament bulb, your lens will only act as a turn signal.

#927 will not have a connection point; check your local laws to see if front park lights

are required, you could be in violation of the law without them. If you can run without the

front park lights, both #927 wires, along with the other wire going to the headlight switch

splice to these can be removed from the Painless harness

The #926, #927, & #926 will be connected to the wires coming from the Turn

/Park light with splices and heat shrink. If you are unsure of which wires is the

park light and turn signal, follow the instructions given on page 25 for testing the

function of each wire. The brighter of the two functions (park and turn signal) will

be the turn signal function. If your lens or bucket only has 2 wires and is a dual

filament bulb, the testing will have to be done with the lens/ bucket mounted to

the vehicle for proper grounding.

NOTES

28

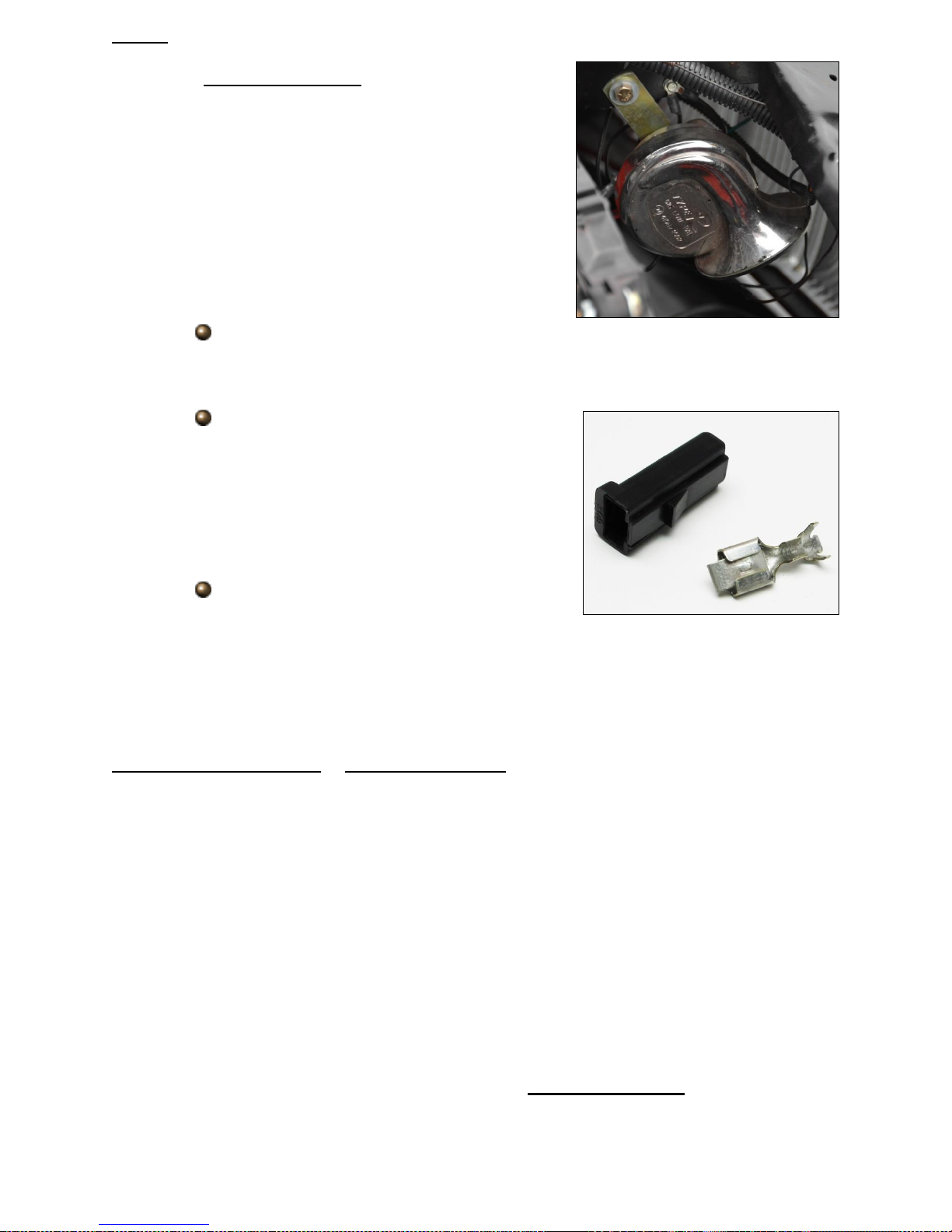

“Horn”

The Headlight Section has a single wire

dedicated for connection to a horn. *Most horns

ground through their mounting and only require a

power connection. This wire is:

Black/Green: 16 gauge wire, printed [HEADLIGHT

SECTION] #924 HORN POWER, this is a power wire

that comes from the fuse block mounted horn relay

which is ground activated by the horn button on the

steering column. This wire will only have power when

the horn button is pressed.

Route the #924 wire to the horn. If you have to pass this wire through any

metal surfaces, you will find small grommets in the parts kit to protect the

wire.

If you have a tab on the horn, locate the

terminal and connector, seen to the right,

provided in the parts kit.

Ring terminals and heat shrink have been

provided for those with “screw” or “post &

nut” connections.

If your horn has a wire to connect to, then

a splice and heat shrink will be needed.

*If your horn requires a ground wire, use a piece of scrap wire that was cut from

the any of the black #969 ground wires on the driver side headlight or turn/park light

connections to connect the ground on the horn. Using a ring terminal from the parts kit,

attach the other end of the ground wire to a chassis ground source on the vehicle.

“Right Turn/Park Light” & “Right Headlamp”

The connections mentioned above all connect in the same manner as those on

the left/driver side. The only difference you will find is the Turn signal wire for the right

turn signal has a different color stripe that one used for the left turn signal. The right

Turn signal will be:

Black/ Blue: 18 gauge wire, printed [HEADLIGHT SECTION] #925 TO RIGHT FRONT

TURN SIGNAL, this wire is the turn signal power. This wire goes into a splice with the

Black/ Blue wires going to the right turn indicator light and to the wire coming from the

turn signal switch. This wire will have interrupted switched power from the turn signal

flasher any time the left turn signal is activated and the ignition is in the ON position and

interrupted battery power from the hazard flasher any time the hazard switch is in the

ON position.

This concludes all of the connections in the Headlight Section of the engine

harness. Go back and inspect the harness layout and once satisfied it is free of moving

parts and sharp edges tighten any loose zip ties.

29

30

Loading...

Loading...