PACSystems RX3i, RX7i User Manual

PACSystems™ RX3i

GFK-2419M Ethernet Network Interface Unit

March 2009

The PACSystems RX3i Ethernet NIU, IC695NIU001,

makes it possible to use PACSystems RX3i and Series

90-30 I/O remotely on an Ethernet network. Once set up

by configuration, data exchange is completely automatic.

System control can be provided by any GE Fanuc master

device capable of exchanging Ethernet Global Data. The

Ethernet NIU automatically provides the controller with

status information in each exchange. The application

program logic in the controller can monitor this status data,

and issue appropriate commands to the Ethernet NIU.

An RX3i Ethernet NIU station consists of:

▪ an RX3i Universal Backplane (IC695CHS0xx)

▪ an RX3i power supply (IC695PSxxxx)

▪ the RX3i Ethernet NIU (IC695NIU001)

▪ one or more RX3i Ethernet modules (IC695ETM001)

▪ proprietary application software

▪ PACSystems RX7i and RX3i controllers can send

selected COMMREQs to the RX3i ENIU via Ethernet

Global Data. The ENIU executes the COMMREQs and

returns the results to the controller.

▪ During EGD configuration, RX3i Ethernet interfaces are

identified by their Backplane/Slot location.

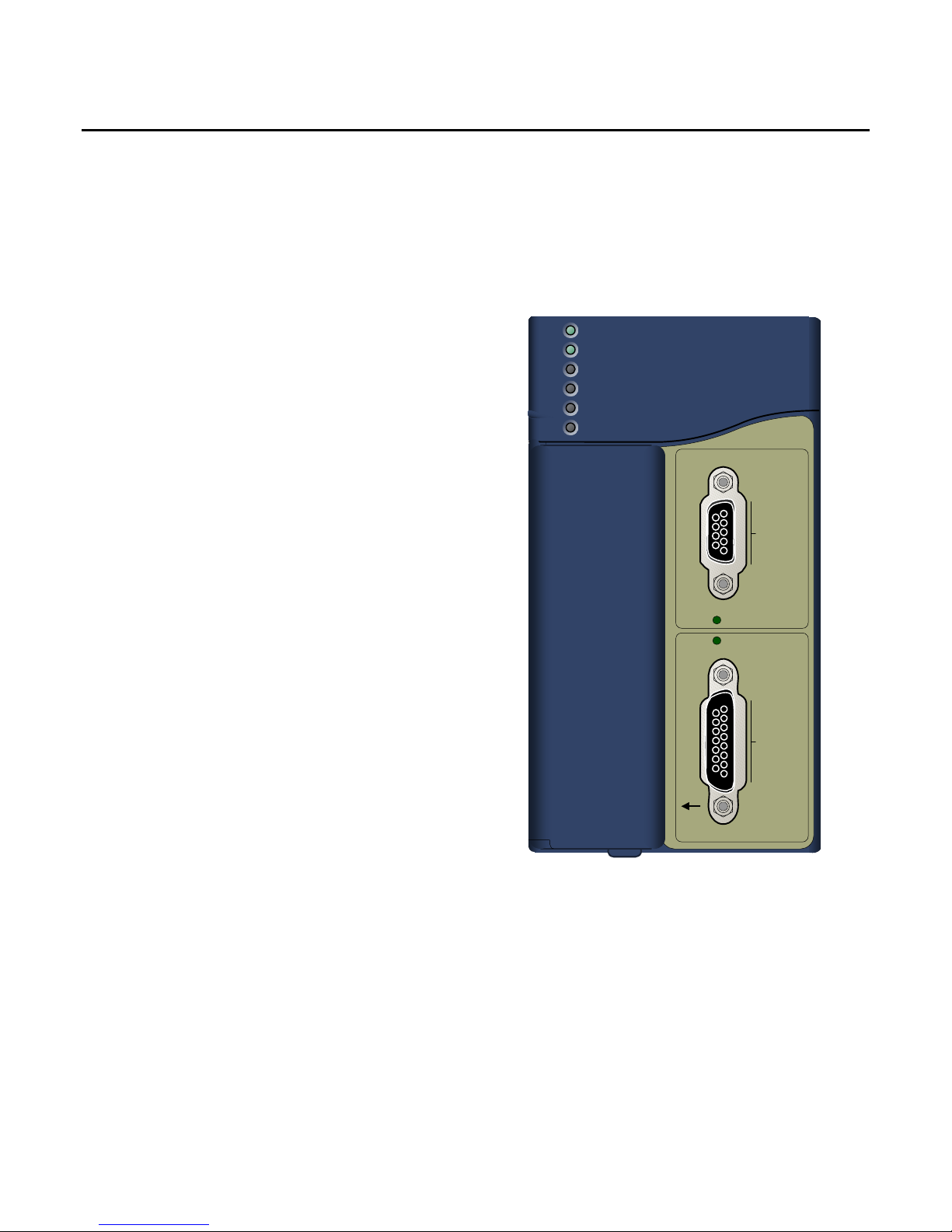

NIU OK

NIU SCANNING I/O

OUTPUTS ENABLED

I/O FORCE

BATTERY

SYSTEM

FAULT

RESET

RUN I/O

STOP

RUN OUTPUT DISABLE

ENABLE

IC695NIU001

NIU001

COM 1

▪ Optional Series 90-30 expansion backplanes.

▪ PACSystems RX3i and/or Series 90-30 modules, as

appropriate for the application.

The Ethernet NIU is compatible with the same types of

modules, backplanes, and other equipment as a

PACSystems RX3i CPU. For a list of compatible products,

see the PACSystems RX3i Hardware and Installation

Manual, GFK-2314.

This module requires Machine Edition Logic Developer

software, version 5.51 or later.

COM1 ACTIVE

COM1 ACTIVE

Ethernet NIU Features

▪

20Kbytes of optional local logic. Supports all

languages except C programming.

▪ 10 Mbytes of built-in flash memory for local user data

storage.

▪ Battery-backed calendar clock.

▪ In-system upgradeable firmware.

▪ Two serial ports: an RS-485 serial port and an

RS-232 serial port.

▪ Supports Ethernet communications via the backplane-

based Ethernet Interface module (IC695ETM001)

▪ Data exchange using Ethernet Global Data (EGD)

▪ TCP/IP communication services using SRTP

▪ Comprehensive station management and diagnostic

tools

▪ Supports operation with redundant controllers

COM 2

BATT

Ethernet Global Data Features

The Ethernet NIU communicates with its controller via

Ethernet Global Data exchanges. One exchange is used to

send outputs to the ENIU and another exchange is used to

send inputs back to the controller. The ENIU supports

receiving outputs from redundant controllers. By sending the

EGD exchange to a group address both controllers can

receive the inputs. Up to 1300 bytes of outputs can be sent to

a set of ENIUs from a controller. Each ENIU can send up to

1300 bytes of inputs to the controller.

A typical system might consist of a controller with five ENIUs.

The controller sends 1300 bytes of outputs and each ENIU

2 RX3i Ethernet NIU

T

C

GFK-2419M

sends 100 bytes of inputs to the controller. This typical

system would have its I/O updates occur in less than 25

milliseconds. If the controller scan time is greater than 25

milliseconds, the update occurs at the controller’s scan

rate. This performance timing is a guideline, not a

guarantee, and assumes that there is no other traffic on

the Ethernet link to the I/O. More performance data for

other system configurations can be found in the Ethernet

NIU Manual, GFK-2196A or later.

ENIU COMMREQ Feature

The ENIU supports selected COMMREQs that are sent to

it by a “C” block application in a PACSystems Rx7i or RX3i

controller. Ladder code is written in the RX7i or RX3i to

interface to the “C” block which results in COMMREQ

commands being sent via a EGD Exchange to the ENIU.

The ENIU executes the COMMREQ and sends the results

back to the RX7i or RX3i via another EGD exchange.

The following COMMREQs are supported:

▪ Modbus Master – function codes 1, 2, 3, 4, 5, 6, 7, 15,

16, 17

▪ Genius – enable/disable outputs, switch BSM, clear

fault, clear all faults, assign monitor, read diagnostic

▪ PROFIBUS Master – Commreqs 1, 2, 4, 5, 6

▪ Motion (DSM314/DSM324) – load parameters

▪ High Speed Counter – Data command

▪ DeviceNet Master – Commreqs 1, 4, 5, 6, 7, 9

▪ Analog Module – HART Protocol Commreqs

Operation, Protection, and Module

Status

Operation of this module can be controlled by the threeposition RUN/STOP switch or remotely by an attached

programmer and programming software. Program and

configuration data can be locked through software

passwords. The status of the NIU is indicated by the eight

NIU LEDs on the front of the module. (See “LED

Operation”).

Battery

A three-cell lithium battery pack (IC698ACC701) is

installed as show below. The battery maintains data

memory when power is removed and operates the

calendar clock. Program and initial values are always

loaded from flash when the ENIU powers up. When

replacing the battery, be sure to install a new battery

before disconnecting the old one. If a new battery is

installed when no battery is currently installed, the new

battery must be installed while the CPU has power.

Otherwise, the CPU may not power up. If that happens,

remove the battery, power-cycle the

CPU, then reinstall the battery.

Disposal of lithium batteries

must be done in accordance with

federal, state, and local

regulations. Be sure to consult

with the appropriate regulatory

agencies before disposing of

batteries.

To avoid loss of RAM memory

contents, routine maintenance

procedures should include

scheduled replacement of the NIU’s

lithium battery pack. For information

on estimating battery life, refer to

the PACSystems NIU Reference

Manual, GFK-2222.

RESE

A

B

Installation

It is the responsibility of the OEM, system integrator, or end

user to properly install the control system equipment for safe

and reliable operation. Installation should not be attempted

without referring to the PACSystems RX3i Hardware and

Installation Manual, GFK-2314.

1. Make sure that backplane power is off.

2. Install the NIU module in backplane 0. The NIU requires

two slots and can use any slots except the highest

numbered (rightmost) slot. It is recommended that the

ENIU be located in slots 2 and 3. For more information

about choosing a slot for the ENIU, see below.

3. Turn on power. The module should power up. When the

NIU has successfully completed initialization, the NIU OK

LED stays on and the NIU SCANNING I/O and EN LEDs

are off.

4. To save battery life, do not connect the battery for the first

time until the ENIU is installed in the backplane and the

backplane powered on. The battery may then be

attached to either of the two terminals in the battery

compartment. Once that is done, the ENIU may be

powered down and normal battery back up operation will

begin.

Backplane Locations for the ENIU

1. The A/C Power Supply (IC695PSAx40) for the RX3i is a

doublewide module whose connector is left-justified as

viewed when installed in a backplane. It cannot be

located in slot 11 of a 12-slot backplane or slot 15 of a

16-slot backplane. No latch mechanism is provided for

the last (rightmost) slot in a backplane, so it is not

RX3i Ethernet NIU 3

GFK-2419M

possible to place the power supply in the second to

last slot.

2. The RX3i ENIU (IC695NIU001) is a doublewide

module whose connector is right justified as viewed

when installed in a backplane. The ENIU is

referenced for configuration and application logic by

the leftmost slot occupied by the entire module, not by

the slot the physical connector is located in. For

example, if the ENIU has its physical connector

inserted in slot 3, the module occupies slots 2 and 3

and the ENIU is referenced as being located in slot 2.

▪ The ENIU may be located in slot 0 with its

connector in slot 1.

▪ The ENIU cannot be located in slot 11 of a 12-

slot backplane or in slot 15 of a 16-slot

backplane, because its connector cannot be

installed in the slot reserved for an expansion

module.

3. When migrating a Series 90-30 ENIU system to a

PACSystems RX3i ENIU, maintaining the slot 1

location of the ENIU means that only a singlewide

power supply may be used in slot 0. Either DC power

supply can be used (IC695PSD040 or

IC695PSD140). Therefore, if the application must

maintain a slot 1 ENIU and uses an AC power-supply,

the RX3i system must have the RX3i AC powersupply located in a slot to the right of the RX3i ENIU

in slot 1.

Locating the ENIU in a Slot Other than 1

Before deciding to place the ENIU in a slot other than slot

1, it is important to consider the possible application

migration issues that could arise, as explained below.

Application Program

For Service Request #15 (Read Last-Logged Fault Table

Entry) and Service Request #20 (Read Fault Tables), the

location of ENIU faults is not the standard 0.1 location, but

the slot the ENIU is located in (see above). Logic that

decodes fault table entries retrieved by these service

requests may need updating.

COMMREQs directed to the ENIU (e.g. those directed to

the serial ports of the ENIU) will need to be updated with

the correct ENIU slot reference.

Fault Tables

Faults logged for the ENIU in the fault table will not in the

standard 0.1 (backplane.slot) location, but will reflect the

ENIUs actual slot.

Series 90 Controllers

Remote Series 90 controllers that use SRTP Channels

COMMREQs expect the ENIU to be in slot 1 or slot 2. To

support communications with Series 90 SRTP clients such as

Series 90 controllers using SRTP Channels, the RX3i

internally redirects incoming SRTP requests destined for

{backplane 0, slot 1} to {backplane 0, slot 2}, provided that the

ENIU is located in backplane 0 slot 2 (and the remote client

has not issued an SRTP Destination service on the

connection to discover the backplane and slot of the ENIU).

This special redirection permits Series 90-30 applications that

expect the power supply to be located leftmost and the ENIU

to be located to the right of the power supply to function.

Attempts to establish channels with ENIUs in slots other than

1 or 2 will fail if initiated from Series 90 controllers.

HMI and External Communication Devices

All external communication devices that interact with the ENIU

should be checked for compatibility with ENIU slot locations

other than slot 1. Problems may arise with, but are not limited

to, initial connection sequences and fault reporting. Machine

Edition View users should select “GE SRTP” as their

communications driver – it can communicate with an ENIU in

any slot.

Programmer Connection

The programmer can communicate with the NIU via serial port

1, serial port 2, or the backplane-based Ethernet interface.

Connecting a programmer via an Ethernet TCP/IP network

requires a CAT5 standard Ethernet cable with RJ-45

connectors.

Before connecting the programmer and ENIU to the Ethernet

TCP/IP network, set the IP address using the Initial IP

Address software tool. After setting the IP address, connect

the RX3i and the computer running the programming software

to the Ethernet Interface. For detailed information on

programmer connection via Ethernet TCP/IP, refer to the

TCP/IP Ethernet Communications for PACSystems User’s

Manual, GFK-2224.

Hardware Configuration

The slot location of the ENIU must be updated in the

hardware configuration to reflect the ENIU’s true location.

4 RX3i Ethernet NIU

GFK-2419M

Firmware Upgrades

The ENIU uses non-volatile flash memory for storing the

operating system firmware. This allows firmware to be

updated without disassembling the module or replacing

EPROMs.

To install a firmware upgrade, connect WinLoader to the

NIU RS-232 or RS-485 serial port. When connecting

directly to the NIU, there is no need to specify the

Backplane/Slot location. For upgrades to Intelligent Option

modules (the IC695ETM001, for example), which are

performed indirectly via the NIU serial port, you must

specify a backplane/slot location.

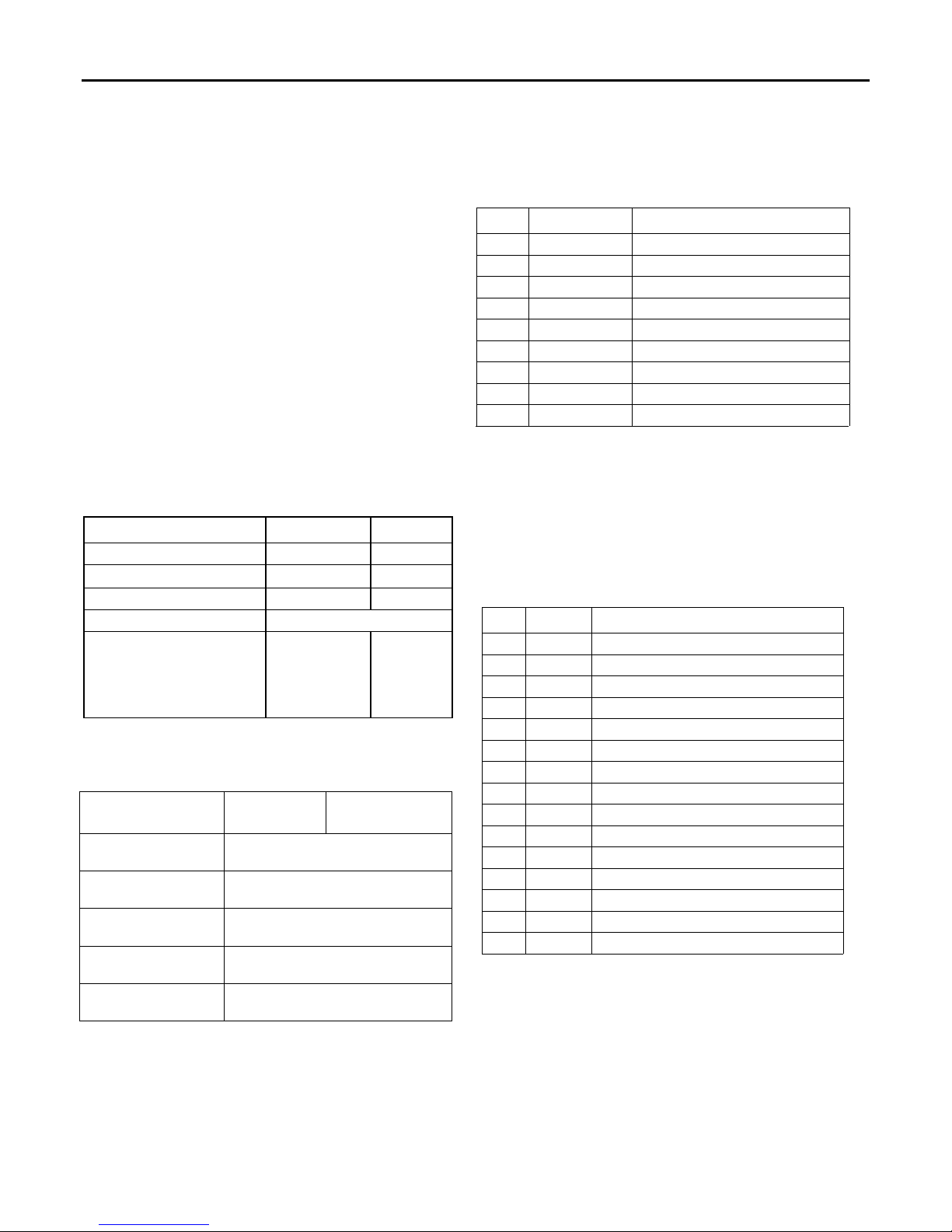

Serial Ports

The NIU has two independent, on-board serial ports,

accessed by connectors on the front of the module. These

ports provide serial interfaces to external devices.

Protocols Supported

Protocol Port 1 Port 2

RTU (slave) Yes Yes

SNP Slave Yes Yes

Serial I/O * Yes Yes

Firmware Upgrade ENIU in STOP/No I/O mode

Message Mode

(C Runtime Library

Functions:

serial read, serial write,

sscanf, sprintf)

* Modbus Master is supported in application code in Serial

I/O mode.

Serial Port Baud Rates

Protocol

Modbus RTU Slave

protocol

Message 1200, 2400, 4800, 9600, 19.2K,

Firmware Upgrade

via Winloader

SNP Slave 1200, 2400, 4800, 9600, 19.2K,

Serial I/O 1200, 2400, 4800, 9600, 19.2K,

Port 1

Port 1 (COM1) is RS-232 compatible. It has a 9-pin,

female, D-sub connector with a standard pin out. This is a

DCE (data communications equipment) port that allows a

Yes Yes

Port 1

(RS-232)

1200, 2400, 4800, 9600, 19.2K,

38.4K, 57.6K, 115.2K

38.4K, 57.6K, 115.2K

2400, 4800, 9600, 19.2K, 38.4K,

57.6K, 115.2K

38.4K, 57.6K, 115.2K

38.4K, 57.6K, 115.2K

Port 2

(RS-485)

simple straight-through cable to connect with a standard ATstyle RS-232 port. The COM1 Active LED provides the status

of serial port activity.

Port 1 RS-232 Signals

Pin Signal Description

1* NC No Connection

2 TXD Transmit Data

3 RXD Receive Data

4 DSR Data Set Ready

5 0V Signal Ground

6 DTR Data Terminal Ready

7 CTS Clear To Send

8 RTS Request to Send

9 NC No Connection

* Pin 1 is at the bottom right of the connector as viewed from the

front of the module.

Port 2

Port 2 (COM2) is RS-485 compatible. Port 2 has a 15-pin,

female D-sub connector. This port supports the RS-485 to

RS-232 adapter (IC690ACC901). This is a DCE port. The

COM2 Active LED provides the status of serial port activity.

Port 2 RS-485 Signals

Pin Signal Description

1* Shield Cable Shield

2 NC No Connection

3 NC No Connection

4 NC No Connection

5 +5VDC Logic Power**

6 RTS(A) Differential Request to Send

7 0V Signal Ground

8 CTS(B‘) Differential Clear To Send

9*** RT Resistor Termination

10** RD(A‘) Differential Receive Data

11 RD(B‘) Differential Receive Data

12 SD(A) Differential Send Data

13 SD(B) Differential Send Data

14 RTS(B) Differential Request To Send

15 CTS(A’) Differential Clear To Send

* Pin 1 is at the bottom right of the connector as viewed from

the front of the module.

** Pin 5 provides isolated +5VDC power (300mA maximum)

for powering external options.

*** Termination resistance for the RD A’ signal should be

connected on units at the end of the line. To make this

termination, connect a jumper between pins 9 and 10

inside the 15-pin D-shell.

Loading...

Loading...