Pacific energy SUMMIT INSERT - B Nstallation And Operating Instructions

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE HOMEOWNER

SAVE THESE INSTRUCTIONS

SAFETY NOTICE

If this stove is not properly installed, a house

re may result. For your safety, follow the

installation directions. Consult local building

or officials about restrictions and installation

SERIAL #

inspection requirements in your area.

TESTED and LISTED

to ULC S628 / UL 1482

Meets the U.S. Environmental Protection

Agency's July 1990 Particulate Emission

Standards

Summit

Wood Insert

INSTALLATION

AND OPERATING

INSTRUCTIONS

190112-24 SINB.BODY 5055.5112

MODEL:

SUMMIT INSERT

SERIES - B

NOTE:

WE STRONGLY

RECOMMEND THAT

SMOKE DETECTORS BE

INSTALLED.

If smoke detectors have been previously installed, you may notice that

they are operating more frequently.

This may be due to curing of stove

paint or fumes caused by accidentally

leaving the re door open. Do not

disconnect the detectors. If necessary, relocate them to reduce their

sensitivity.

SAFETY NOTICE:

If this stove is not

properly installed, a

house re may result.

For your safety, follow the installation

instructions. Contact

local building or re

officials about restrictions and installation

inspection requirements in your area.

Please read this entire manual before

you install and use your new room

heater. Failure to follow instructions

may result in property damage, bodily

injury, or even death.

Contents

Safety ............................................................................................ 3

Clearances ................................................................................... 3

Masonry or Factory Built Fireplace ........................................................ 3

Mantel Clearances ................................................................................. 5

Dimensions .................................................................................. 5

Installation .................................................................................... 6

Fireplace Speci cations ......................................................................... 6

Into a Masonry Fireplace ....................................................................... 6

Full Flue Liner - (Required in Canada) .................................................. 7

Direct Flue Connection .......................................................................... 7

Into a Factory Built Fireplace ................................................................. 8

Combustion Air ...................................................................................... 8

Surround Assembly and Installation ...................................................... 9

Fan Speed Controller Relocation ..........................................................11

Operation .................................................................................... 13

Wood Selection.....................................................................................13

How to Test Your Wood .........................................................................13

Lighting the Fire ....................................................................................13

Normal Operation .................................................................................13

Restarting After Extended or Overnight Burns ......................................13

More Wood, More Heat .........................................................................14

Proper Draft ..........................................................................................14

Ash Removal ........................................................................................14

Disposal of Ashes .................................................................................14

Blower ......................................................................................... 14

Blower Operation ..................................................................................14

Electrical Supply ...................................................................................14

Creosote ..................................................................................... 15

Formation and Need for Removal .........................................................15

Chimney Fires .......................................................................................15

In Case of a Chimney Fire ....................................................................15

Avoiding a Chimney Fire .......................................................................15

Maintenance ............................................................................... 16

Baffle Removal ......................................................................................16

Appendix A ................................................................................. 17

Understanding & Operating Your Paci c Energy Stove .........................17

Troubleshooting ....................................................................................18

Firebrick Installation .................................................................. 19

Replacement Parts .................................................................... 20

Label .................................................................................................... 23

2 SINB.BODY 190112-24

”

Safety

Clearances

Please read this entire manual before installation

and use of this wood burning insert. Failure to follow

these instructions could result in property damage,

bodily injury or even death.

We strongly recommend that smoke detectors be installed.

If smoke detectors have been previously installed, you may

notice that they are operating more frequently. This may be

due to curing of stove paint or fumes caused by accidentally

leaving the re door open. Do not disconnect the detectors.

If necessary, relocate them to reduce their sensitivity.

SAFETY NOTICE: If this stove is not properly installed, a

house re may result. For your safety, follow the installation directions. Consult local building or re officials

about restrictions and installation inspection requirements in your area.

NATIONAL

FIREPLACE

INSTITUTE

CERTIFIED

www.nficertified.org

We recommend that our products be

installed and serviced by professionals

who are certified in the U.S. by the

National Fireplace Institute (NFI)

or in Canada by Wood

Energy Technical

Training (WETT)

Wood Energy

Technical Training

www.wettinc.ca

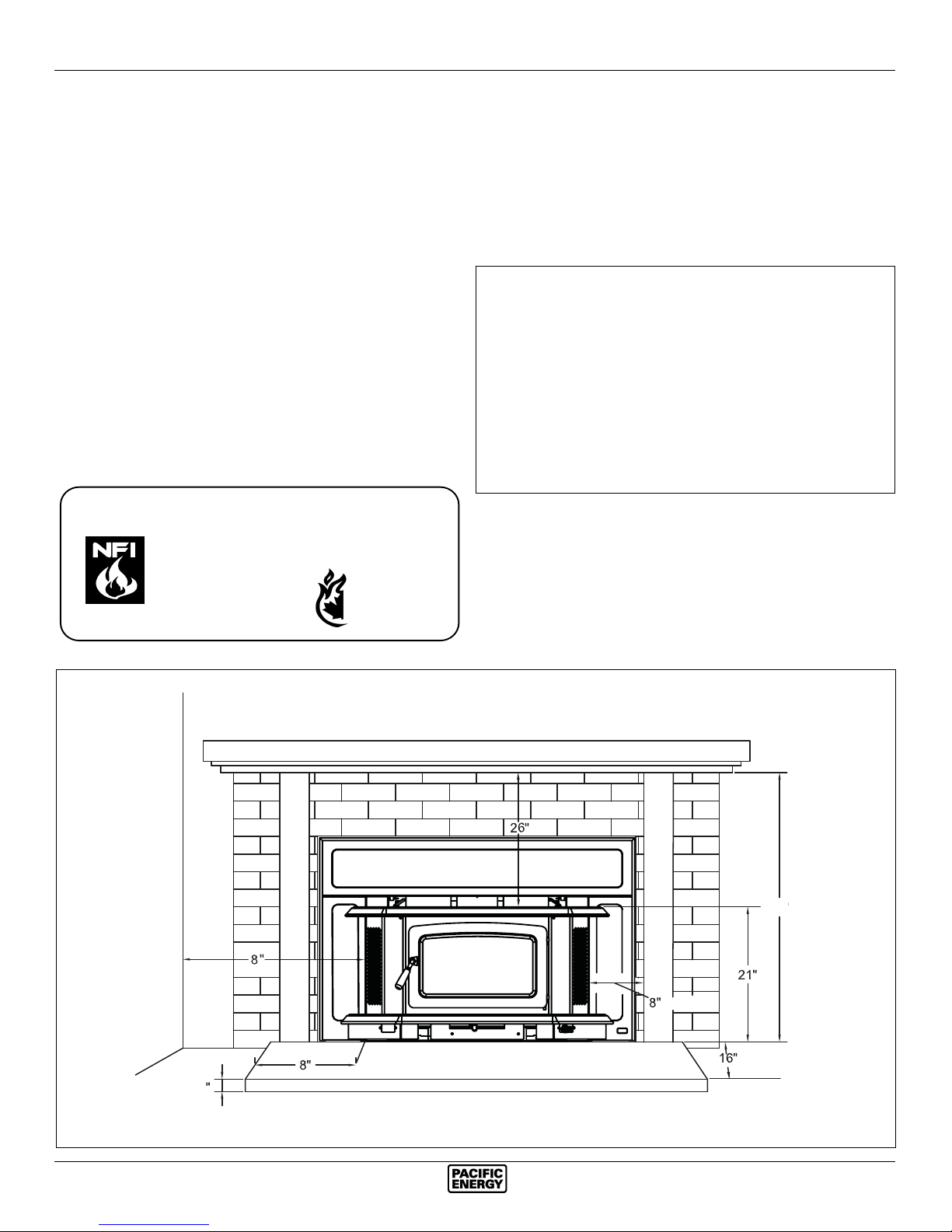

Masonry or Factory Built Fireplace

The minimum required clearances to surrounding combustible materials when installed into a masonry or factory built

replace are listed below and in gure #1.

Minimum Clearances to Combustibles

(Measured From Insert Body)

Adjacent Sidewall ..........................8 in. (203 mm.)

Mantel ..........................................26 in. (660 mm.)

12" Mantel with Shield .................20 in. (508 mm.)

(with part # SINB.MSMBKA)

Top Facing ................................... 26 in. (660 mm.)

with Mantel Shield .......................20 in. (508mm)

(with part # SINB.MSMBKA)

Side Facing (1.5 in. extension) ...... 8 in. (203 mm.)

CAUTION: Unit hot while in operation. Parts of the appliance, especially the external surfaces, will be hot to touch

when in operation. Keep children, clothing and furniture

away. Contact may cause skin burns.

Fig. # 1

Adjacent Wall

Mantel or Top Facing

Side Facing

47

Fireplace

Hearth

3

SINB.BODY 190112-24 3

Fireplace hearth requirements: (Measured without the insert)

The non-combustible replace hearth must be raised 3” above an adjacent combustible oor and extend 16” in front and

*

8” beyond each side of the existing replace opening. A non-combustible hearth that extends a minimum 20-1/2” in front

of the replace opening may be ush to an adjacent combustible oor.

MINIMUM FIREPLACE

OPENING AND HEARTH

DIMENSIONS

16”

18”

23 1/8”

28”

26”

18”

Non-combustible replace

hearth

8”8”

3”

*

3”

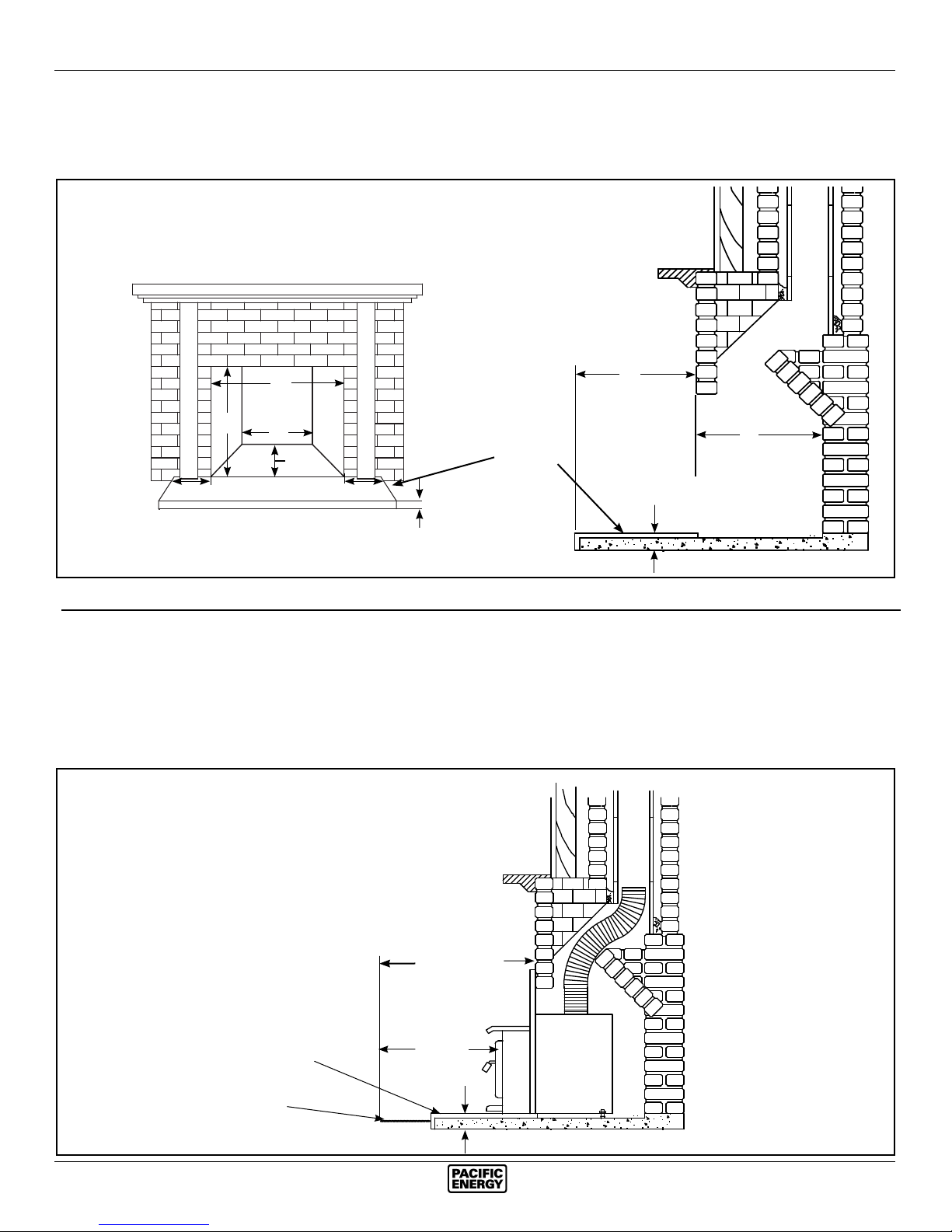

Ember protection:

Combustible oor in front of the replace insert must be protected from hot embers by non-combustible material extend-

**

ing 16” (USA) and 18” (CANADA) to the ring side and 8” to other sides of the unit.

Consult CAN/CSA-B365 Installation Code for Solid-Fuel-Burning appliances and equipment in Canada, and N.F.P.A.

211 Standard for chimneys, replaces, vents and Solid-Fuel-Burning appliances in USA.

MINIMUM EMBER

PROTECTION

DIMENSIONS

Non-combustible hearth

Non-combustible oor

covering

4 SINB.BODY 190112-24

22 1/2” USA

24 1/2” CANADA

16” USA

**

18” CANADA

3”

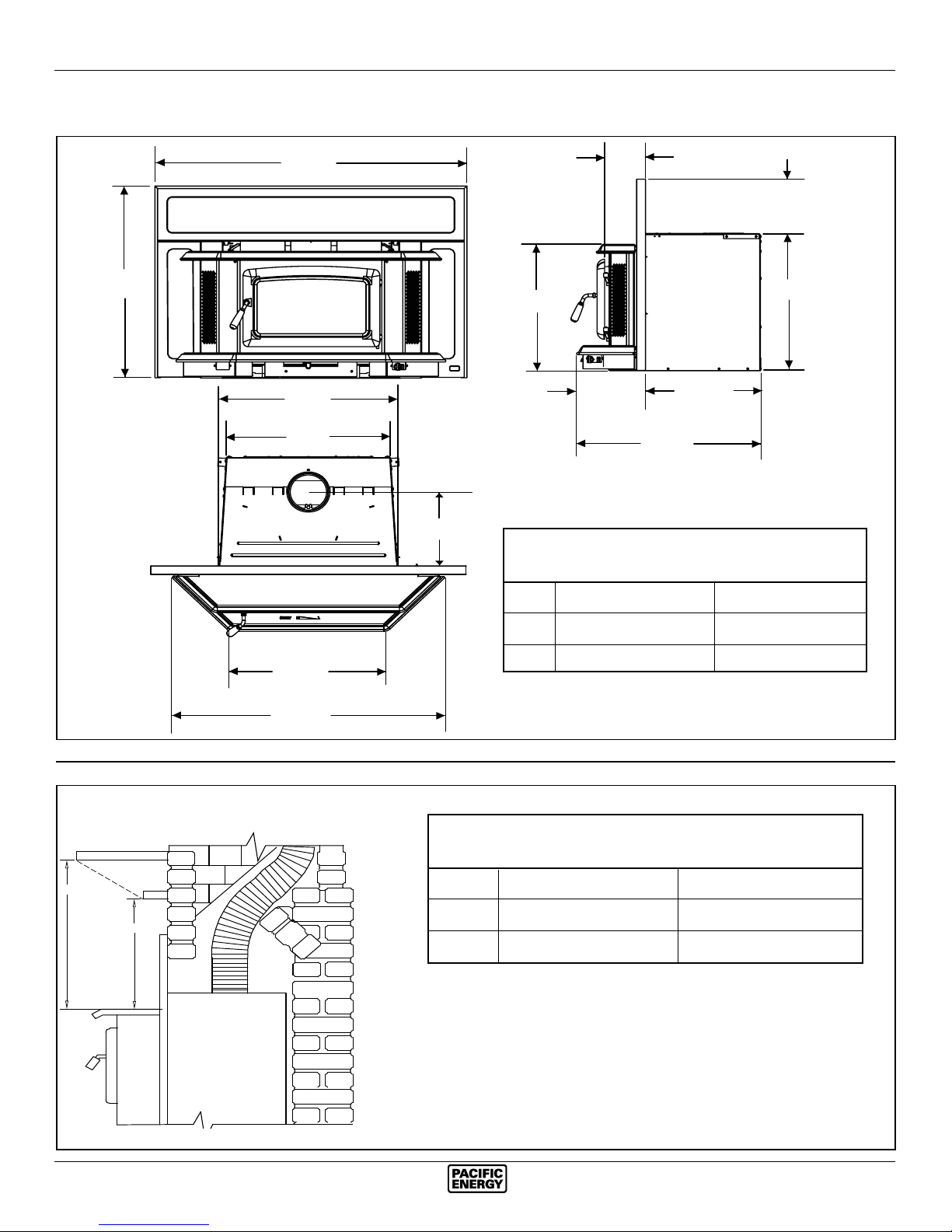

Dimensions

B

A

27 9/16”

25 3/8”

12 1/4”

6 5/8”

9 1/8”

21”

10 7/8”

18”

28 7/8”

22 15/16”

SURROUND DIMENSIONS

REG. SURROUND O/S SURROUND

Mantel Clearances

12"

A

4"

B

23 5/16”

40 7/8”

A 48 3/4” 52 3/4"

B 32 1/16” 34 1/16"

MANTEL CLEARANCE

CHART

WITHOUT SHIELD WITH SHIELD

A 26” 20"

B 23 1/2” 18"

SINB.BODY 190112-24 5

Installation

Your Insert is designed to be installed into a masonry or factory built zero-clearance replace. The masonry replace

must be built according to the requirements of the Standard

of Chimneys, Fireplaces, Vents and Solid Fuel Burning appliances, N.F.P.A. 211 (Latest Edition) or applicable National,

Provincial, State or local codes. The installation shall conform

to CAN/CSA-B365, Installation Code for Solid-Fuel-Burning

Appliances and Equipment. The factory built zero-clearance

replace and its chimney must be listed per UL 127 or ULC

S610 standards.

Warning: Under no circumstances is this heater to be installed

in a makeshift or "temporary" manner.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVICING ANOTHER APPLIANCE.

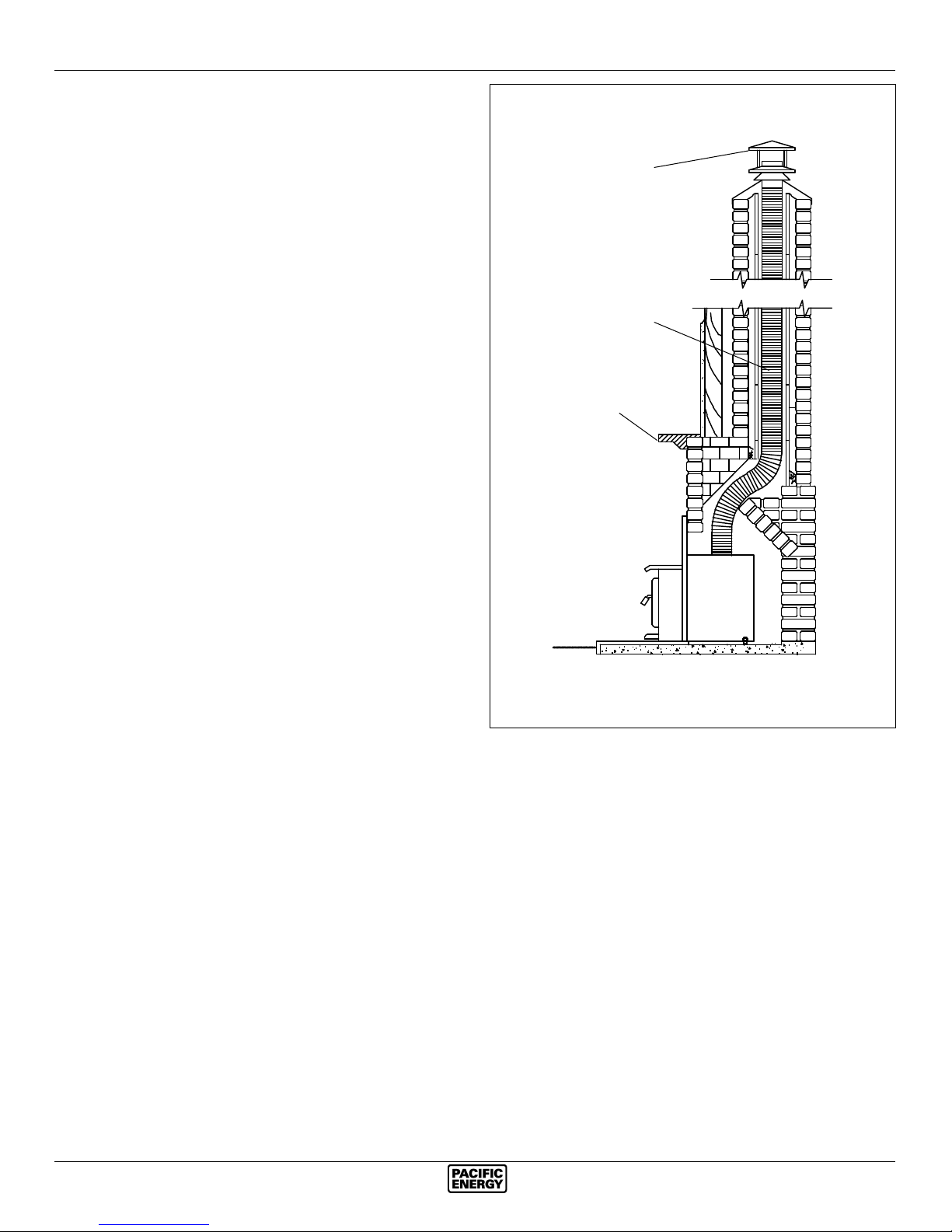

Fig. # 2

Stainless Steel

Rigid or Flex Liner

Full Flue Liner

Rain Cap

Fireplace Speci cations

Your replace is required to have the following minimum

sizes:

WIDTH (at front) 28" (711 mm)

WIDTH (at rear) 26" (660 mm)

HEIGHT 23-1/8" (587 mm)

DEPTH 18" (457 mm)

Chimney height 15' (minimum).

A metal tag is provided and is to be fastened to the back

wall of the replace, if the replace has been modi ed

to accommodate the insert.

Into a Masonry Fireplace

Inspect your replace for cracks, loose mortar or other physical defects. If repairs are required, they should be completed

before installing your insert.

The replace chimney must be suitable for wood burning use.

Check for creosote build up or other obstructions, especially if

it has not been in use for some time. Have chimney swept.

The existing replace damper is to be locked open or removed

completely.

WARNING: Do not remove bricks or mortar from your

existing replace.

Exception: Masonry or steel, including the damper plate,

may be removed from the smoke shelf and adjacent damper

frame if necessary to accommodate a chimney liner, provided

that their removal will not weaken the structure of the replace

and chimney, and will not reduce protection for combustible

materials to less than that required by the National Building

Code.

Mantel or

Top Facing

Positive Flue Connection(In U.S.A. only): where a throat

blocker plate and a short connector pipe is used.

Note: A clean-out door may be required under local codes,

when a positive ue connection is used. Consult local

codes.

Paci c Energy highly recommends the use of a full

liner as the safest installation and providing optimum

performance. When connected to a full liner, the Insert

is able to draft correctly and will prevent problems such

as difficult start-ups and smoking out the door.

The Insert must be installed in accordance with local and or

national building codes. The two methods of ue connection

that are acceptable in most areas are:

Full Flue Liner: (Fig.2, Required in Canada) where a stainless

steel rigid or exible liner extends from the Insert ue collar

to the top of the chimney.

6 SINB.BODY 190112-24

Full Flue Liner - (Required in Canada)

1) Measure the chimney height from the top of the existing

ue to the oor of the hearth. This will allow extra length

of liner for ashing and rain cap.

2) Feed the stainless steel liner from top of the chimney,

through the damper area and into the replace cavity.

Attach a stove connector to the bottom of the liner.

3) Remove bay top and both right & left blower covers

(Fig #4 & 6).

4) Remove casing top by removing screws on each casing

side and pulling top forward(Fig. #5).

5) Push insert into replace. Use the rear adjustment legs to

level insert. (NOTE: Adjustment legs are located in bottom

rear of insert)

6) Measure, trim and shape a top ashing to t the existing

chimney ue. Plan for a 1” to 1-1/2” overlap on each side.

Place ashing over top of the liner and seat rmly against

the tile.

7) Caulk around liner with high temp stove cement and insert

into collar. Screw in fasteners to secure.

8) Attach a rain cap to the end of the liner. A storm collar

may be used if desired.

9) Reattach casing top with screws previously removed.

Consult your local Dealer about relining your replace

chimney.

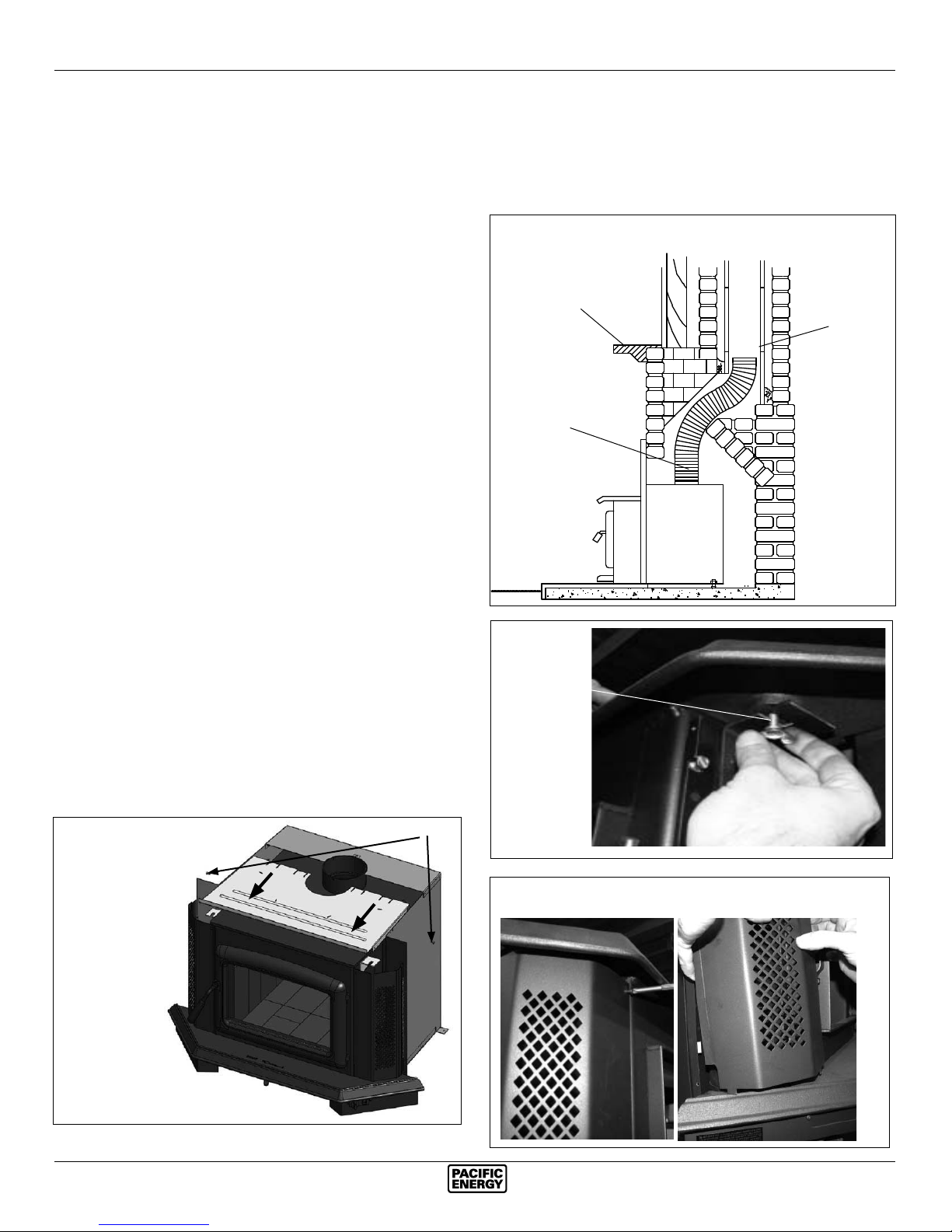

Direct Flue Connection (USA only)

Fig. # 3

Mantel or

Top Facing

6" Stainless Steel

Rigid or Flex Liner

Direct Flue Connection

Chimney

Flue Liner

1) Measure from the rst chimney ue liner tile to the top of

the Insert. Allow extra length of liner to insert into ue

tile.

2) Feed the stainless steel liner through the damper area

and into the rst chimney ue tile. Seal around pipe.

Note: A clean-out door may be required under local codes,

when a direct ue connection is used. Consult local codes.

3) Remove bay top and both right & left blower covers

(Fig #4 & 6).

4) Remove casing top by removing screws on side and pulling top forward(Fig. #5).

5) Push insert into replace. Use the rear adjustment legs

to level insert.

6) Attach connector pipe to stove collar.

7) Reattach casing top and fasten.

Fig. # 5

SCREWS

Fig. # 4

“Wing” Screw

Fig. #6

SINB.BODY 190112-24 7

Into a Factory Built Fireplace

Your Insert may be installed into a factory built replace (size

permitting) with the following requirements:

1) Inspect your replace for damage or other physical defects. The replace must be in good working condition.

If in doubt about its condition, seek professional advice.

Check for creosote build up or other obstructions inside

the chimney, especially if it has not been in use for some

time. Before installing, clean your chimney system thoroughly.

2) A full stainless steel rigid or exible ue liner meeting

type HT requirements (2100°F) per UL1777 (U.S.) or

ULC S635 (Canada) must be used for both safety and

performance. The liner must be securely attached to the

Insert ue collar and the chimney top.

3) The surround must be sealed to the replace front or the

damper area around the chimney liner must be sealed

to prevent room air entering the chimney cavity of the

replace.

4) The air ow within and around the replace must not be

altered by the installation of the Insert (i.e. no blockage of

louvers or cooling air inlet or outlet ports). This includes

the circulating air chambers in a steel replace or metal

heat circulator.

5) Alteration of the replace in any manner is not permitted

with the following exceptions:

a: external trim pieces which do not affect the operation

of the replace may be removed and stored on or within

the replace for re-assembly if the Insert is removed.

b: the chimney damper may be removed to install the

liner.

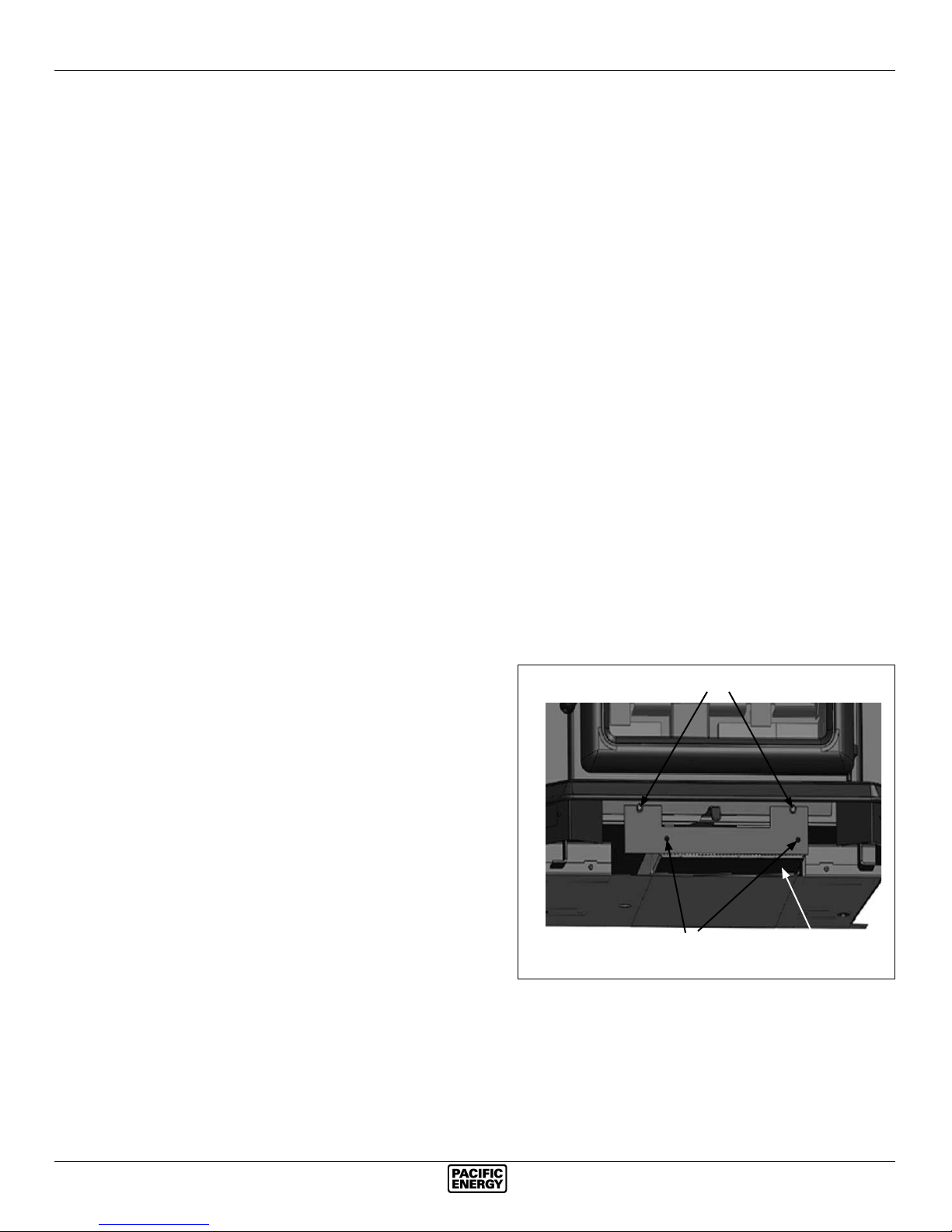

Combustion Air

Consult local building codes regarding combustion air supply. Intake or combustion air can be supplied to the Insert in

one of two ways:

1) Outside air supply: Remove cover from ash clean out in

existing replace. Place a rodent screen in place of the

cover. Install the Insert as described in the "Installation"

section, making sure not to cover the opening of the air

inlet. When installation is complete, seal surround to replace and anywhere else air may enter. This will ensure

combustion air is drawn from outside the house and into

the 9" x 2" intake at the lower rear of the appliance.

2) Room air supply: Loosen the two hex head bolts slightly

(DO NOT REMOVE) Remove the two screws in the cover

plate and remove, slide the cover box out and discard. Replace cover plate and tighten hex head bolts. Fig. #7).

Fig. # 7

HEX HEAD BOLTS

SCREWS

COVER

BOX

8 SINB.BODY 190112-24

Loading...

Loading...