Pacific energy NEO 2.5 Installation And Operating Instructions Manual

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE HOMEOWNER

SERIAL #

INSTALLATION

SAFETY NOTICE

If this stove is not properly installed, a

house re may result. For your safety,

follow the installation instructions. Contact

local building or fire officials about

restrictions and installation inspection

requirements in your area.

TESTED and LISTED to CAN/ULC S627

AND UL 1482

Meets the Environmental Protection

Agency's July 1990 Particulate Emission

Standards

AND OPERATING

INSTRUCTIONS

071114-24 NEO25 5055.900

MODEL - NEO 2.5

SERIES - A

Contents

Safety .................................................................................................................... 3

Creosote Formation and Need for Removal .......................................................................3

Chimney Fires ..................................................................................................................... 3

In Case of a Chimney Fire ..................................................................................................3

Avoiding a Chimney Fire ..................................................................................................... 3

Operation .............................................................................................................. 4

Wood Selection...................................................................................................................4

How to Test Your Wood ....................................................................................................... 4

Lighting for the First Time ...................................................................................................4

Lighting a Fire ..................................................................................................................... 4

Normal Operation ...............................................................................................................4

Restarting After Extended or Overnight Burns ....................................................................5

Over Firing .......................................................................................................................... 5

Average Heat Output Calculation .......................................................................................5

Proper Draft ........................................................................................................................5

Ash Removal ......................................................................................................................5

Disposal of Ashes ............................................................................................................... 5

Storing Wood Beneath Unit ................................................................................................5

Maintenance ......................................................................................................... 6

Baffle Removal ....................................................................................................................6

Maintenance Checks ........................................................................................... 7

Assembly .............................................................................................................. 8

Crate Removal .................................................................................................................... 8

Side Panel Removal/Installation .........................................................................................8

NEO 2.5 Dimensions ...........................................................................................8

Ember Protection ................................................................................................. 9

Combustion Air .................................................................................................... 9

Residential Installation ..................................................................................... 10

Clearances ....................................................................................................................... 10

Chimney and Connector ................................................................................................... 10

Double-Wall Connector ..................................................................................................... 10

Single-Wall Connector(smoke pipe) .................................................................................10

Procedure ......................................................................................................................... 10

Mobile Home Installation .................................................................................. 14

Additional Requirements: .................................................................................................. 14

Clearances ....................................................................................................................... 14

Procedure:.........................................................................................................................14

Optional Blower ................................................................................................. 15

Blower Operation .............................................................................................................. 15

Optional Outside Air Adaptor ............................................................................................ 15

Troubleshooting ................................................................................................. 16

Replacement Parts - NEO 2.5 .......................................................................................... 17

Understanding & Operating Your Paci c Energy Stove ..................................................... 18

Firebrick Installation Instructions .................................................................... 19

Label .................................................................................................................................23

PLEASE SAVE THESE INSTRUCTIONS

NOTE: WE STRONGLY RECOMMEND THAT SMOKE DETECTORS BE INSTALLED.

If smoke detectors have been previously installed, you may notice that they are operating more frequently. This may be

due to curing of stove paint or fumes caused by accidentally leaving the re door open. Do not disconnect the detectors. If

necessary, relocate them to reduce their sensitivity.

SAFETY NOTICE: If this stove is not properly installed, a house re may result. For your safety, follow the installation

instructions. Contact local building or re officials about restrictions and installation inspection requirements in

you area.

Please read this entire manual before you install and use your new room heater. Failure to follow instructions may result in

property damage, bodily injury, or even death.

2 NEO25 071114-24

Safety

Creosote Formation and Need for

Removal

When wood is burned slowly, it produces tar and other organic

vapours, which combine with expelled moisture to form

creosote. The creosote vapours condense in the relatively

cool chimney ue of a slow burning re. As a result, creosote

residue accumulates on the ue lining. When ignited, this

creosote makes an extremely hot re. The chimney connector

and chimney should be inspected periodically (at least once

every two months) during the heating season to determine if

a creosote buildup has occurred. If creosote has accumulated

(3 mm. or more), it should be removed to reduce the risk of

a chimney re.

1. Highest smoke densities occur when a large amount of

wood is added to a bed of hot coals and the air inlet is

closed. The heated wood generates smoke, but without

ample air, the smoke cannot burn. Smoke-free, clean

burning requires small fuel loads, two or three logs at

a time or 1/4 to 1/2 of fuel load and leaving the air inlet

relatively wide open, especially during the rst 10 to 30

minutes after each loading, when most of the smoke

generating reactions are occurring. After 30 minutes or

so, the air inlet can be turned down substantially without

excessive smoke generation. Wood coals create very

little creosote-producing smoke.

2. The cooler the surface over which the wood smoke is

passing, the more creosote will be condensed. Wet or green

wood contributes signi cantly to creosote formation as the

excess moisture that is boiled off cools the re, making

it difficult for the tars and gases to ignite, thus creating

dense smoke and poor combustion. This moisture-laden

smoke cools the chimney, compounding the problem by

offering the smoke the ideal place to condense.

In summary, a certain amount of creosote is inevitable

and must be lived with. Regular inspection and cleaning is

the solution. The use of dry, seasoned wood and ample

combustion air will help to minimize the buildup.

In Case of a Chimney Fire

1. Prepare to evacuate to ensure everyone's safety. Have

a well understood plan of action for evacuation. Have a

place outside where everyone is to meet.

2. Close air inlet on stove.

3. Call local re department. Have a re extinguisher handy.

Contact your local municipal or provincial re authority for

further information on how to handle a chimney re. It is

most important that you have a clearly understood plan

on how to handle a chimney re.

4. After the chimney re is out, the chimney must be cleaned

and checked for stress and cracks before starting another

re. Also check combustibles around the chimney and

the roof.

- The services of a competent or certi ed installer, (certi ed

by the Wood Energy Technical Training program (WETT) - in

Canada, Hearth Education Foundation (HEARTH) - in U.S.A.,)

are strongly recommended.

Avoiding a Chimney Fire

There are two ways to avoid chimney res:

1. Do not let creosote build up to a point where a big chimney

re is possible.

2. Do not have res in the heater that may ignite chimney

res. These are hot res, such as when burning household

trash, cardboard, Christmas tree limbs, or even ordinary

fuel wood; (e.g.. with a full load on a hot bed of coals and

with the air inlet excessively open.)

Chimney Fires

The result of excessive creosote buildup is a chimney re.

Chimney res are dangerous. Chimney inside temperatures

can exceed 2000° F(1093˚C). This causes much higher

than normal temperatures in the chimney and on its exterior

surfaces. Thus ignition of nearby or touching combustible

material is more likely during a chimney re. Proper clearances

are critical during such a re.

Chimney res are easy to detect; they usually involve one or

more of the following:

-Flames and sparks shooting out of the top of the chimney

-A roaring sound

-Vibration of the chimney

071114-24 NEO25 3

Operation

CAUTION: Never use gasoline, gasoline type lantern fuel,

kerosene, charcoal lighter uid or similar liquids to start or

"freshen up" a re in this heater. Keep all such liquids well

away from the heater while it is in use.

CAUTION: Hot while in operation. Keep children, clothing

and furniture away. Contact may cause skin burns.

Your PACIFIC ENERGY heater is designed for many years of

trouble free operation. Over ring the appliance will shorten

the life of the product. Failure to recitify an over ring condition

can be hazardous and may void the manufacturer's warranty.

NOTE: Left and Right as referred to in this manual are

considered your left and right when facing the front of the

woodstove.

Wood Selection

This heater is designed to burn natural wood only. Higher

efficiency and lower emissions generally result when burning

air-dried seasoned hardwoods, as compared to softwoods or

to green or freshly cut hardwoods.

Wood should be properly air dried (seasoned) for six months

or more. Wet or undried wood will cause the re to smoulder

and produce large amounts of creosote. Wet wood also

produces very little heat and tends to go out often.

DO NOT BURN :

-Salt water wood * -Treated wood

-Wet or green wood -Coal/charcoal

-Garbage/Plastic * -Solvents

* These materials contain chlorides which will rapidly

destroy metal surfaces and void warranty.

Do not burn anything but wood. Other fuels, eg. charcoal,

can produce large amounts of carbon monoxide, a tasteless,

odourless gas that can kill. Under no circumstances should

you attempt to barbecue in this heater.

How to Test Your Wood

Add a large piece of wood to the stove when it has a good

large bed of coals. It is dry if it is burning on more than one

side within one minute. It is damp if it turns black and lights

within three minutes. If it sizzles, hisses and blackens without

igniting in ve minutes it is soaked and should not be burnt.

Lighting for the First Time

Curing of the Paint Finish

To achieve the best nish, the paint on your stove must be

baked on. When burning your stove for the rst 2-3 times it

is very important that the room be well ventilated. Open all

windows and doors. Smoke and fumes caused by the curing

process may cause discomfort to some individuals.

Lighting a Fire

WARNING: Never use chemicals or any other volatile

liquid to start a re.

1. Adjust air control to “High” position(all the way to the left)

and open door.

2. Place crumpled newspaper in the centre of the heater

and criss-cross with several pieces of dry kindling. Add

a few small pieces of dry wood on top.

3. Ignite the paper and close the door.

4. After the re has established itself, open the door and add

a few small logs. Close door.

5. Begin normal operation after a good coal base exists and

wood has charred.

Normal Operation

1. Set air control to a desired setting. If smoke pours down

across the glass (waterfall effect) this indicates you have

shut the control down too soon or you are using too low a

setting. The wide range control makes nding the desired

setting for your application easy. As every home's heating

needs vary (ie. insulation, windows, climate, etc.) the

proper setting can only be found by trial and error and

should be noted for future burns.

2. To refuel, adjust air control to “High” position(all the way

to the left), and give the re time to brighten. Open the

door slowly, this will prevent backpuffing or ame roll-out.

3. Use wood of different shape, diameter and length (

recommended 18"(457mm)). Load your wood and try

to place the logs so that the air can ow between them.

Always use dry wood.

4. Do not load fuel to a height or in such a manner that would

be hazardous when opening the door.

5. For extended or overnight burns, unsplit logs are preferred.

Remember to char the wood completely on "High" setting

before adjusting air control to the "Low" setting for overnight

burn.

WARNING: Always keep loading door closed when

burning. This heater is not designed for open door burning.

WARNING: No alteration or modi cation of the combustion

air control assembly is permitted. Any tampering will void

warranty and could be very hazardous.

WARNING: Do not use grates or andirons to elevate the

fuel. Burn directly on the re bricks. Replace broken or

missing bricks. Failure to do so may create a hazardous

condition.

4 NEO25 071114-24

Restarting After Extended or Overnight

Burns

1. Open door and rake hot embers towards the front of the

heater. Add a couple of dry, split logs on top of embers,

close door.

2. Adjust air control to high and in just a few minutes, logs

should begin burning.

3. After wood has charred, reset air control to desired setting.

4. To achieve maximum ring rate, set control to “High”

position(all the way to the left). Do not use this setting

other than for starting or preheating fresh fuel loads.

DO NOT OVERFIRE THIS HEATER: Attempts to achieve

heat output rates that exceed heater design speci cations

can result in permanent damage to the heater and chimney.

Over Firing

Over ring can be caused by operating the unit with the door

open, damage to door gaskets allowing excess air to enter

the rebox, the use of kiln dried lumber, mill ends or paper

waste and prolonged or continual use on a high burn setting.

Ash Removal

Caution: Ashes are to be removed only when the heater is cold.

Whenever ashes get 3(76mm) to 4(102mm) inches deep in

your rebox, and when re has burned down and cooled,

remove excess ashes. Leave an ash bed approximately 1"

(25 mm) deep on the rebox bottom to help maintain a hot

charcoal bed for future res.

Optional Ash Cleanout system: The ash dump handle is

located under the ash lip on the left hand side behind the lower

grill. To operate ash dump, lift and tilt the lower grill down, pull

handle out 1/2"(12mm) and turn clockwise. This will unlock

the ash dump and allow it to open. Hold handle open while

pulling ashes into the opening. Avoid large embers as these

still contain heat value. Release handle and push in to lock.

Ensure ash dump door is properly engaged. Fill the cavity

with the remaining ash level with the rebox oor. Lift and pull

out ashpan and discard ashes into metal container. Replace

ashpan and ensure it is seated properly.

Do not burn with ash dump door open. Doing so will

create a hazardous condition.

Average Heat Output Calculation

Seasoned wood has approximately 7500 BTU’s per pound.

The calculation is as follows:

Amount of wood in lbs. X 7500BTU’s

Burn rate in Hrs.

Experience will give you the right settings for proper combustion

and efficient burning. Remember the correct air inlet setting

is affected by variables such as type of wood, outside

temperature, chimney size and weather conditions. With

practice, you will become pro cient in operating your heater

and will obtain the performance for which it was designed.

X .8(80% Avg. Eciency)

Proper Draft

1. Draft is the force which moves air from the appliance up

through the chimney. The amount of draft in your chimney

depends on the length of the chimney, local geography,

nearby obstructions and other factors.

2. Too much draft may cause excessive temperatures in the

appliance. An uncontrollable burn or a glowing red stove

part or chimney indicates excessive draft.

3. Inadequate draft may cause backpuffing into the room

and plugging of the chimney. Smoke leaking into the room

through appliance and chimney connector joints indicates

inadequate draft.

Disposal of Ashes

Ashes should be placed in a metal container with a tight tting

lid. The closed container of ashes should be placed on a

non-combustible oor or on the ground, well away from all

combustible materials, pending nal disposal. If the ashes

are disposed of by burial in soil or otherwise locally dispersed,

they should be retained in closed container until all cinders

have thoroughly cooled. Other waste should not be placed

in this container.

Storing Wood Beneath Unit

It is possible to store wood between the stove pedestals,

underneath the unit. The wood must not extend further forward

than ush with the pedestals. Do not store paper or other stove

lighting devices within the pedestal area. Although storing

wood under the unit is possible it is not recommended. NOTE:

Refer to local re codes, CAN-B365 and NFPA 211 in the U.S..

WARNING: IF YOU CHOOSE TO STORE WOOD BENEATH

YOUR UNIT, EXERCISE EXTREME CAUTION WHEN

LOADING THE WOODSTOVE. EMBERS CAN FALL AND

MAY IGNITE WOOD BENEATH STOVE.

071114-24 NEO25 5

Maintenance

1. Burn cord wood only, dry and well seasoned. The denser

or heavier the wood when dry, the greater its heat value.

This is why hardwoods are generally preferred. Green or

wet wood will cause a rapid buildup of creosote. If you feel

it is necessary to burn wet or unseasoned wood, do so

only with the air inlet set open enough to maintain a good

strong re and fairly high chimney temperatures. Do not

attempt to burn overnight using green wood or wet wood.

Wet wood can cause up to 25% drop in heater output, as

well as contributing signi cantly to creosote buildup.

WARNING: Never use chemicals or any other

volatile liquid to start a re. Do not burn garbage, or

ammable uids such as gasoline, naptha, or engine

oil. We strongly recommend that smoke detectors be

installed.

2. Remove ashes frequently. Embers can roll out the door

and create a re hazard.

3. If glass becomes darkened through slow burning or poor

wood, it can readily be cleaned with replace glass cleaner

when stove is cold. Never scrape with an object that might

scratch the glass. The type and amount of deposit on the

glass is a good indication of the ue pipe and chimney

buildup. A light brown dusty deposit that is easily wiped off

usually indicates good combustion and dry, well-seasoned

wood and therefore relatively clean pipes and chimney.

On the other hand, a black greasy deposit that is difficult

to remove is a result of wet and green wood and too slow

a burning rate. This heavy deposit is building up at least

as quickly in the chimney.

WARNING: ONLY USE MATERIALS AND

COMPONENTS SUPPLIED BY MANUFACTURER

WHEN DOING MAINTENANCE OR

REPLACEMENTS.

4. DOOR GASKETS - The gasket used on this unit (7/8"

medium density berglass rope) requires only light

pressure to seal. This will prolong seal life. It is important

that the door seal be maintained in good condition.

Periodically inspect seals and replace if necessary. Follow

instructions included in the WODC.WDGKIT kit obtainable

from your nearest Paci c Energy Dealer.

5. DOOR GLASS - Do not slam loading door or otherwise

impact glass. When closing door, make sure that no logs

protrude to impact the glass. If the glass gets cracked or

broken, it must be replaced before using the stove.

Replacement glass can be obtained from your dealer.

Use 18"(457mm) x 10-1/4"(260mm) x 5 mm. Ceramic

glass only. Do not substitute with any other type.

To remove broken glass, remove the door gasket and then

undo the eight screws securing the gasket guides and glass

retainers. Remove all particles of glass . Be careful as they are

very sharp. Install new glass complete with gasket. Replace

glass retainers and gasket guides then install new door gasket

as per instructions provided with the door gasket kit.

CAUTION:

- do not overtighten, tighten screws very carefully

- do not clean glass when hot

- do not use abrasive cleaners on glass

6. The area where boost combustion air enters the rebox

must be kept clear of excessive ash buildup which will

block air ow. This area is at the front of the rebox.

7. Do not store wood within heater installation clearances, or

within the space required for fuel loading and ash removal.

Keep the area around the heater clean and free of loose

combustibles, furniture, newspapers, etc.

8. Establish a routine for the fuel, woodburning and

ring technique. Check daily for creosote buildup until

experience shows how often you need to clean to be safe.

9. Be aware that the hotter the re, the less creosote is

deposited. Weekly cleaning may be necessary in mild

weather, even though monthly cleaning is usually enough

in the coldest months when burning rates are higher.

10. Instruct all members of your family on the safe operation

of the heater. Ensure they have enough knowledge of the

entire system if they are expected to operate it. Stress the

section on chimney res and the importance of following

the steps outlined "In Case of Chimney Fire".

Baffle Removal

Chimney connector pipe should be disconnected from stove

to clean and inspect. Only if this is not possible should you

remove baffle assembly. CAUTION: Ceramic blanket insulation

is located on top of baffle. Do not use a vacuum in this area.

DO NOT OPERATE WITH BAFFLE ASSEMBLY OR

INSULATION REMOVED.

Remove retaining pin at the back top of the rebox, just under

the baffle. Lift baffle up and pull forward to disconnect from

the supply tube. Tilt baffle sideways to drop down and remove

from rebox. Re-install baffle assembly in reverse order.

WARNING: Sweep/Clean chimney with baffle installed or be

sure to plug the top of the baffle tube in the back of the rebox

before sweeping or cleaning. Failure to prevent ash or soot

from falling into the baffle tube will cause incorrect operation

and will lead to premature burn out of the tube or baffle.

6 NEO25 071114-24

Maintenance Checks

Check the following parts for damage such as cracks, excessive corrosion, burned out sections and excessive warping:

(See website for descriptions and more detail)

Some warping of the baffle is normal(up to 1/4” or 6mm). Replace if the baffle has permanent warping greater than this or

has signs of cracking or breakage.

Weekly:

- Firebrick - for cracking.

- Door Gasket - sagging, placement, damage.

Monthly:

- Brick rail tabs and brick rails.

- Air riser tube in the back of the rebox.

- Back side of airwash chamber - located in the upper front of rebox.

- Baffle locking pin.

- Boost tube cover - located in center of manifold, bottom front of rebox.

When Cleaning the

Chimney System:

- Top baffle board/blanket.

- Baffle.

- Brick Rails.

- Manifold - located in bottom front of rebox.

Blower:

- The blower should be cleaned out a minimum every six months by using a vacumn on the grill openings in the back and

bottom of the blower casing to remove any dust and debris.

- Please contact your dealer if you experience any of the damage listed above. Continuing to operate your stove with

broken parts may accelerate damage to other parts and may void your warranty

071114-24 NEO25 7

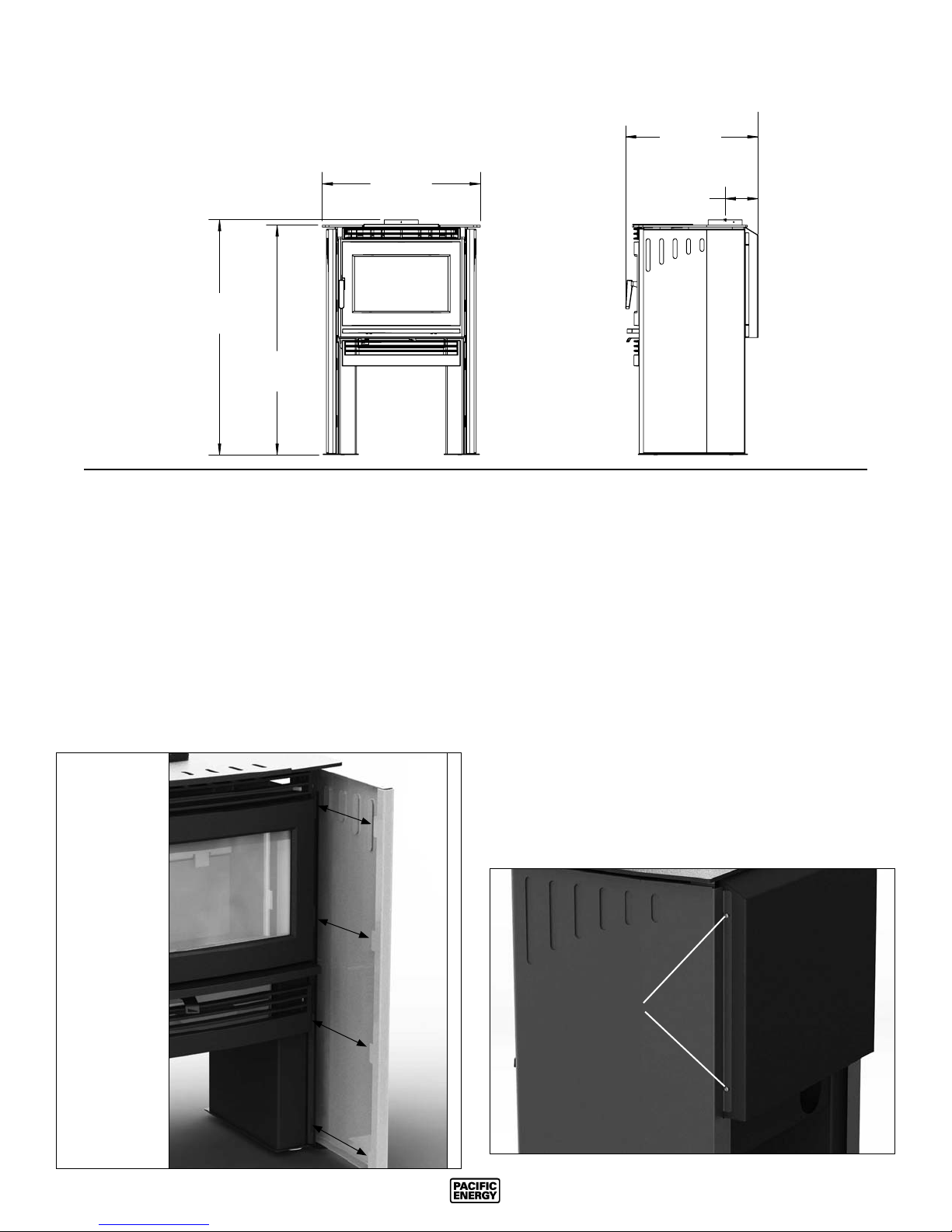

NEO 2.5 Dimensions

FIG. #1

29"

737mm

41"

1.04m

40 1/8"

1.02m

Side Panel Removal/Installation

Assembly

Crate Removal

1) To remove the panels, rst remove the screws that secure

the panel to the rear shield. Fig. #3

24 1/2"

622mm

6 1/8"

156mm

1) Carefully remove wood top and supports.

2) Remove plastic cover.

3) Using a 7/16"(12mm) wrench, remove lag bolts that secure

hold down brackets to bottom pallet.

4) Slide the hold down brackets away from the stove.

FIG. #2

2) Disengage the the tabs in the front of the panel by sliding

the panel forward away from the unit Fig. #2.

2) To install the panels, engage the tabs on the panel front

ange into the slots in the panel mounting bracket. Fig.

#2

3) Attach the panel to the rear shield. Secure with two screws.

Fig. #3

FIG. #3

SCREWS

8 NEO25 071114-24

Loading...

Loading...