Pacific energy granville Installation And Operating Instructions Manual

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE HOMEOWNER

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life.

-- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

f i r e - p a r t s . c o m

- Do not touch any electrical switch; do

not use any phone in your building.

- Immediately call your gas supplier

from a neighbour’s phone. Follow the

gas supplier’s instructions.

- If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

Granville

Direct Vent Insert

SERIES A

INSTALLATION

AND OPERATING

INSTRUCTIONS

040805-24 GRNA # 5055.651

Contents

Caution .......................................................................................3

Safety .........................................................................................3

Maintenance ............................................................................... 3

Installation ................................................................................. 4

Clearances .................................................................................. 5

Venting .......................................................................................6

Rocker Switch ............................................................................7

Gas Supply .................................................................................8

Burner Removal ......................................................................... 9

Levelling Legs ...........................................................................9

Log Set .....................................................................................10

Surround Assembly ..................................................................12

Glowing Embers ......................................................................13

Louver Installation ................................................................... 13

f i r e - p a r t s . c o m

Glass Frame Installation ..........................................................13

Lighting Instructions................................................................14

First Fire ................................................................................... 15

Operation .................................................................................15

Primary Air Adjustment ...........................................................15

Optional Blower.......................................................................16

Optional Radiant Overlay ........................................................17

Replacement Parts....................................................................18

Burner Replacement Parts .......................................................20

Appendix A ..............................................................................21

Direct Vent Terminal Kit .................................................... 21

Vent Terminal Flashing Installation Guide ........................ 22

Safety Label ....................................................................... 23

IMPORTANT: When lit for the first time, the appliance will emit a slight odor for a couple of hours. This

is due to the curing of paints, sealants and lubricants

used in the manufacturing process. This condition is

temporary. Open doors and windows to ventilate

area. If optional fan kit has been installed, place fan

in the "OFF" position. Smoke and fumes caused by

the curing process may cause discomfort to some

individuals.

It is normal for fireplaces fabricated of steel to give

off some expansion and/or contraction noises during

the start up or cool down cycle. Similar noises are

found with your furnace heat exchanger or cook

stove oven.

040805-24 GRNA # 5055.651

2

Caution

Maintenance

FOR YOUR SAFETY - Do not install or operate your Pacific

Energy Granville Direct Vent Gas Insert without first reading

and understanding this manual. Any installation or operational deviation from the following instructions voids the

Pacific Energy Warranty and may prove hazardous.

This appliance and its individual shutoff valve must be disconnected from gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig.

(3.5 kPa)

This appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.5 kPa)

Note: When lit for the first time, the appliance will emit a

slight odour for a couple of hours. This is due to the curing of

paints, sealants and lubricants used in the manufacturing

process. This condition is temporary. Open doors and

windows to ventilate area. Smoke and fumes caused by the

curing process may cause discomfort to some individuals.

f i r e - p a r t s . c o m

Safety

Due to high temperatures, this gas appliance should be

located out of traffic and away from furniture and

draperies.

Children and adults should be alerted to the hazards of

high surface temperature and should stay away to avoid

burns or clothing ignition.

Young children should be carefully supervised when they

are in the same room as the appliance.

Clothing or other flammable material should not be placed

on or near the appliance.

Any grill, panel or door removed for servicing the unit

must be replaced prior to operating. Failure to do so may

create a hazardous condition.

Installation and repair should be done by a qualified

service person. The appliance should be inspected before

use and at least annually by a professional service person.

More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is imperative

that control compartments, burners and circulating air

passageways of the appliance be kept clean.

Caution: Turn off gas and electrical power supply and allow

ample time for unit to cool before servicing appliance. It is

recommended that this appliance and venting should be

inspected at least once a year by a qualified service person.

Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system and any gas

control which has been under water.

Annual Inspection:

a) Clean louvers and air passage ways of excessive lint

buildup from carpeting, bedding material, etc. The flow of

ventilation air must not be obstructed.

b) Inspect logs and burner assembly for lint and soot buildup.

If excessive buildup of soot is present, have a qualified service

person inspect and adjust unit for proper combustion. Clean

logs and burner with a vacuum cleaner, paying close attention

to burner ports.

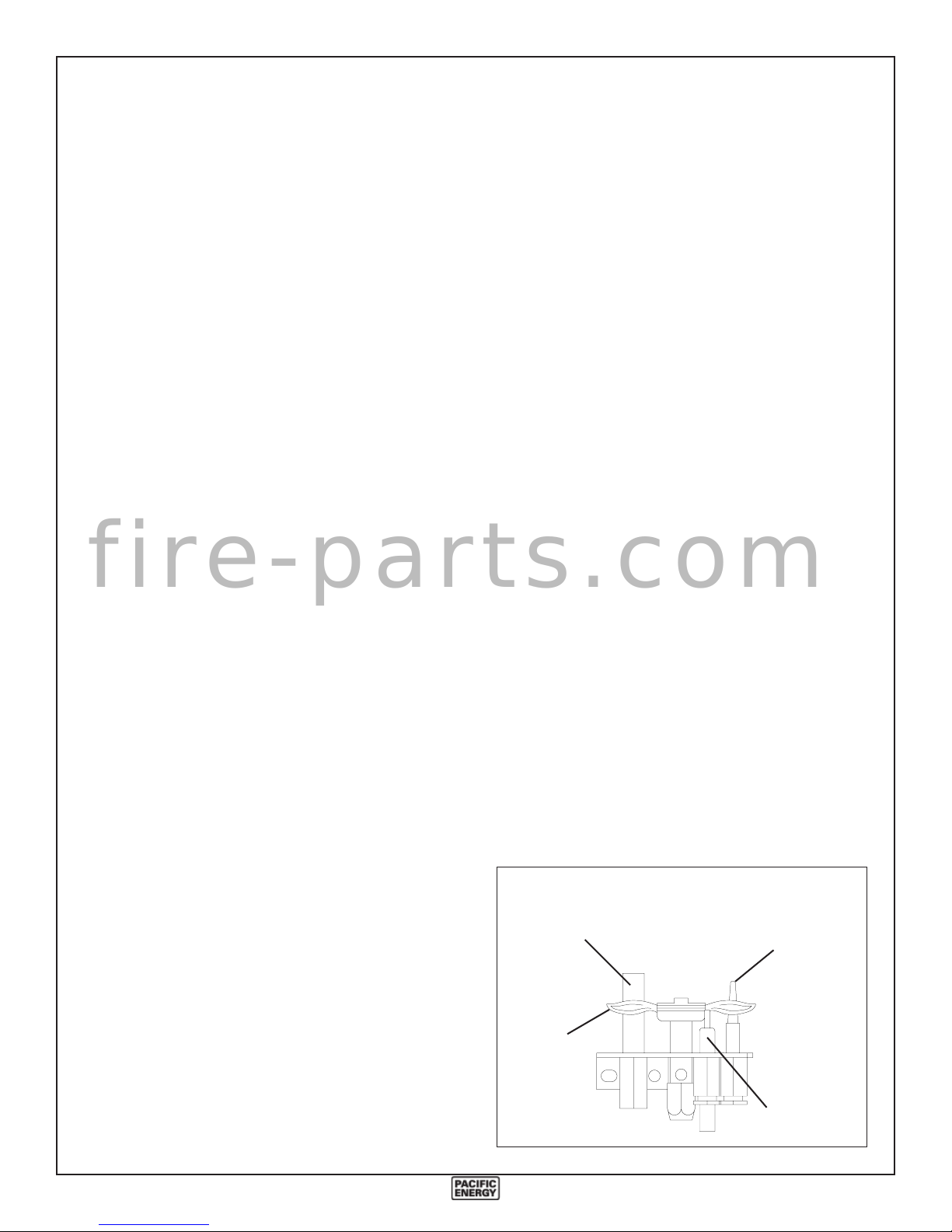

c) Check the pilot system for proper flame size and operation. Clean pilot free of lint or soot. (See Fig. #1)

d) Check that the vent pipe and vent terminal are open and

free from blockage or debris. If the venting system is disassembled for cleaning, it must be properly assembled and resealed.

e) Check glass panel gasket, replace if necessary. It is

important that the glass seal be maintained in good condition.

Note: The appliance area must be kept clear and free from

combustible materials, gasoline and other flammable vapours

and liquids.

Periodically:

a) Viewing glass may be cleaned with fireplace glass cleaner.

b) Exterior porcelain enamel finish may be cleaned with

soap and water.

Note: Never use abrasive cleaner to clean this appliance.

Do not clean glass when hot.

Fig. # 1

THERMOPILE

THERMOCOUPLE

It is Pacific Energy’s policy that no responsibility is

assumed by the Company or by any of its employees or

representatives for any damages caused by an inoperable,

inadequate, or unsafe condition which is the result, either

directly or indirectly, of any improper operation or

installation procedures.

040805-24 GRNA # 5055.651

PILOT

FLAME

ELECTRODE

3

Installation

The Granville Direct Vent Gas Insert installation and

venting must conform to the current CAN/CGA-B149.1

installation code (in Canada) or the National Fuel Gas

Code, ANSI Z223.1 -1988 (in the USA), and approved per

local codes. Only qualified (licensed or trained) personnel

should install this product.

Fig. # 3

A

28 3/8"

Existing Fireplace

5"

(Masonry or Factory Built)

The Granville Direct Vent Gas Insert is designed to be

installed into a masonry or a factory built zero clearance

fireplace. The masonry fireplace must be built according to

the requirements of the Standards for Chimneys, Fireplaces,

Vents and Solid Fuel Burning Appliances, NFPA 211 (Latest

Edition) or applicable National, Provincial, State or local

codes. The factory built zero clearance fireplace and its

chimney must be certified and meet applicable National,

Provincial, State or local codes.

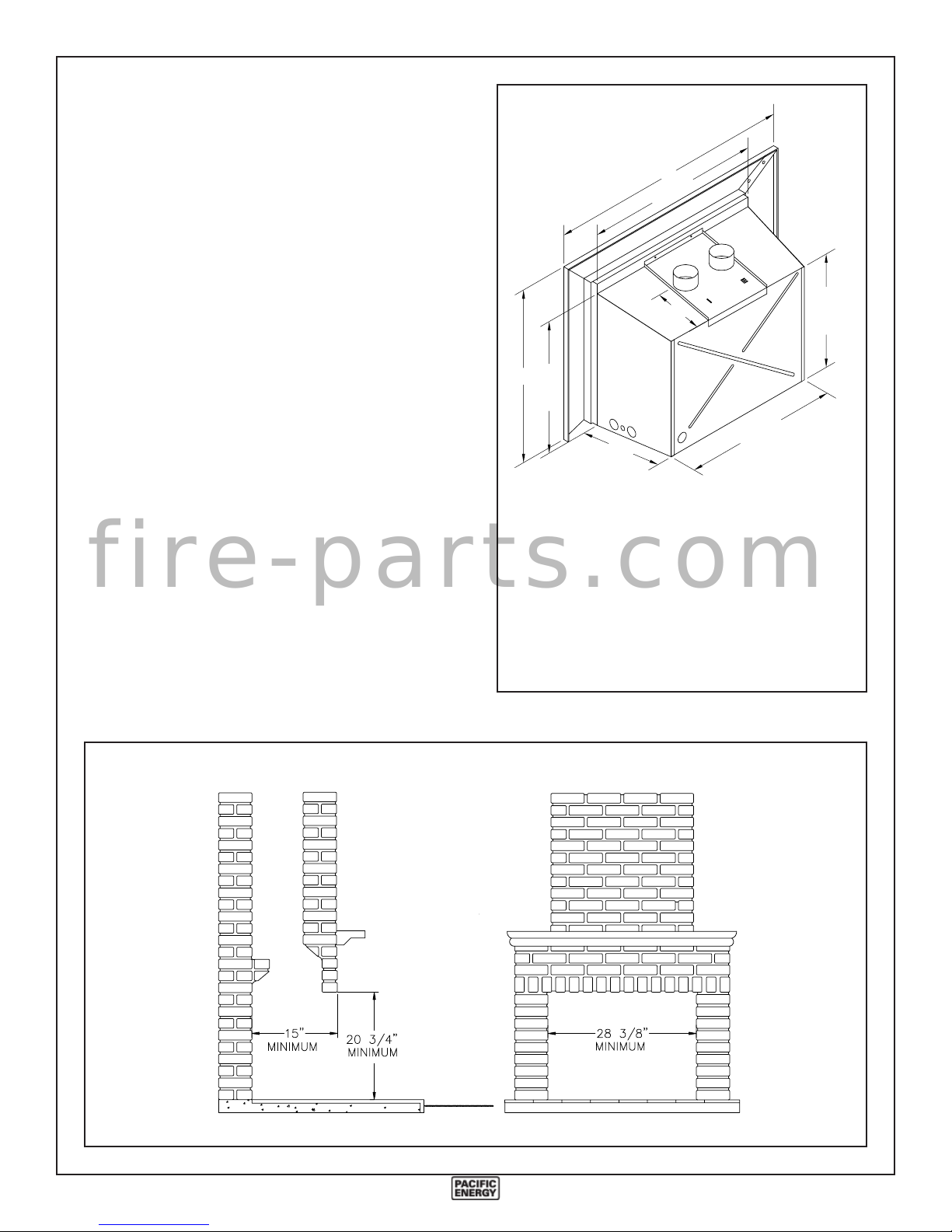

In order to sufficiently accommodate the Granville Direct

Vent Gas Insert, the minimum size of the fireplace should be

f i r e - p a r t s . c o m

28-3/8 inches wide, 20-3/4 inches high and 15 inches deep

(see Fig. #2).

The fireplace and its chimney should be swept and inspected.

The existing fireplace damper (if present) should be locked

open or removed completely if the opening is too small for two

- 3" flue liners to pass through.

B

20 3/4"

15"

Standard-size Surround

Plain and Embossed

Bevelled Panels .............. 38 1/2" wide x 27 1/4" high

Over-size Surround

Plain Flat Panels ............. 44 3/4" wide x 30 1/2" high

24 1/2"

AB

17 7/8"

Fig. # 2

040805-24 GRNA # 5055.651

4

Clearances

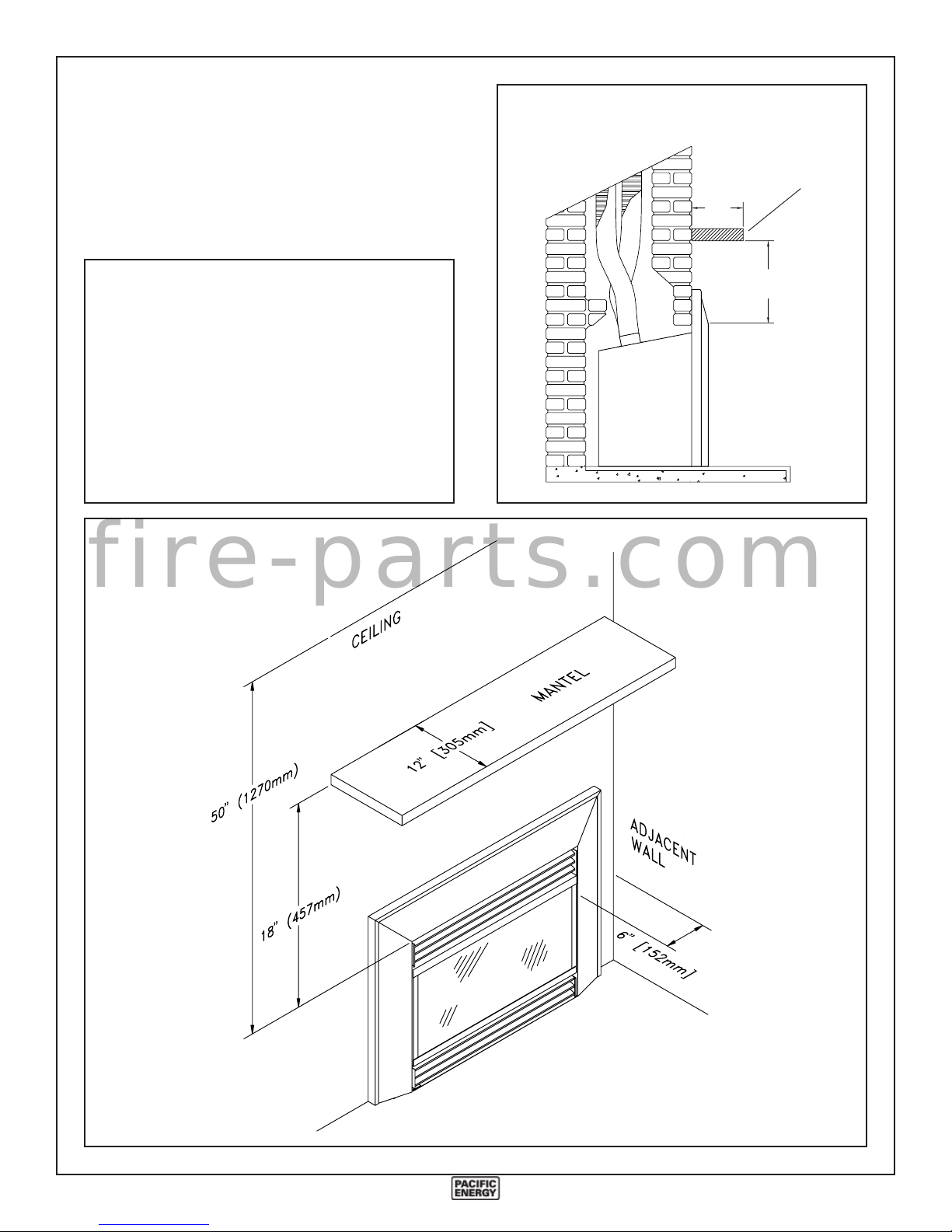

The minimum clearances from the appliance to combustible

surfaces are shown on Fig. #4 and #5. Adequate clearances

around air openings and air supplies are required.

Fig. # 5

12"

(305mm)

Mantel

MINIMUM CLEARANCES

18"

(457mm)

TO COMBUSTIBLES:

Adjacent sidewall: ....................... 6.0 in. (152 mm)

Ceiling to appliance: .................... 50 in. (1270 mm)

Mantel to appliance: .................... 18 in. (457 mm)

Maximum mantel extension: ....... 12 in. (305 mm)

Mantel top support

to appliance ................................... 18 in. (457 mm)

Mantel side support

to appliance ..................................... 6 in. (150 mm)

Fig. # 4

Gas Insert

f i r e - p a r t s . c o m

040805-24 GRNA # 5055.651

5

Venting

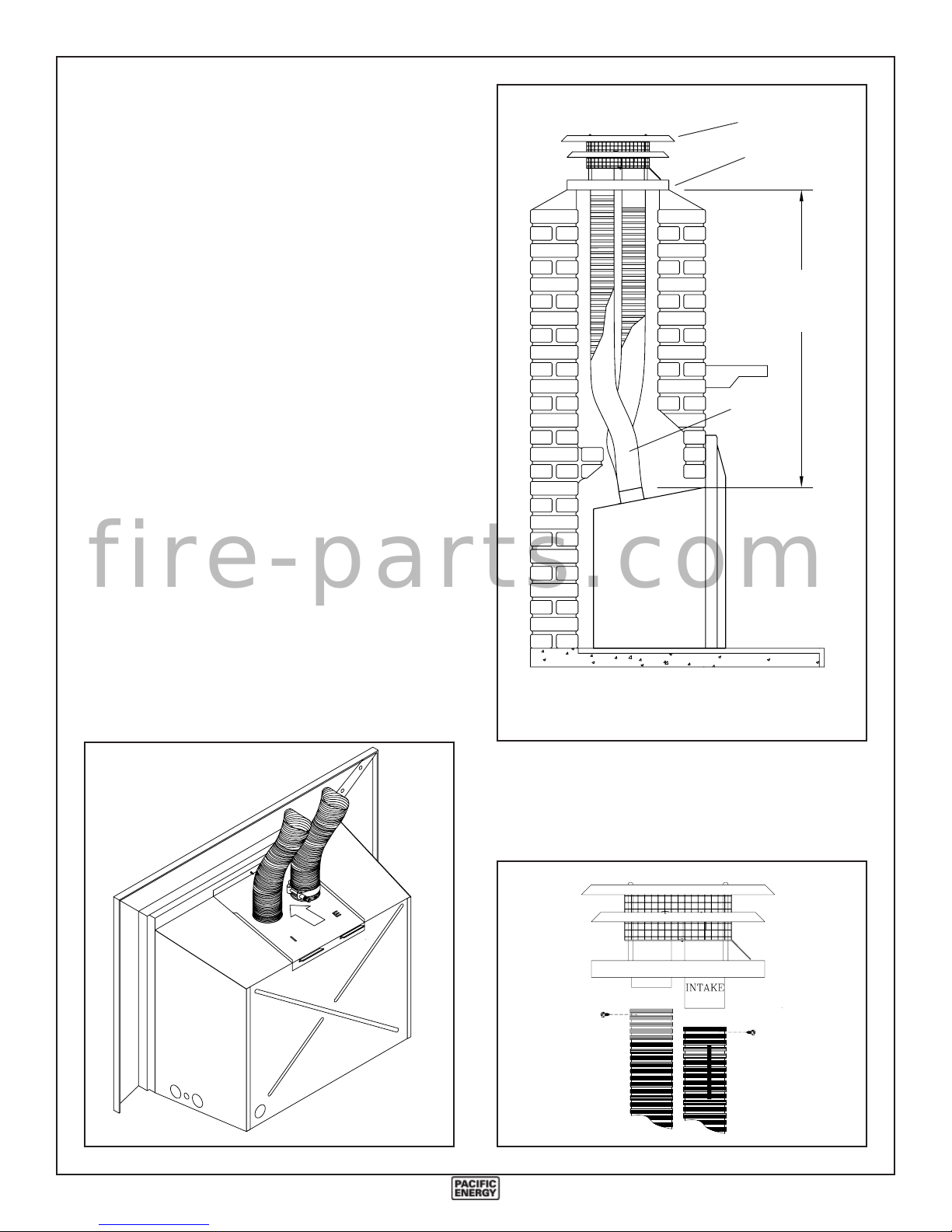

Fig # 7

Vent Terminal

Caution: Only Flex Liner kit (MIND.FL25) or an approved

gas vent flue liner and a Vent Terminal (MIND.VTTERM)

is approved for use with this appliance.

Also approved for use is Simpson Dura-Vent GS

termination kits, both Standard Vertical Termination cap

(#980) and the Extended Vertical Termination cap (#930)

in conjunction with the 3" Co-Linear Termination kit

(#923GK).

No other venting system or components may be used.

1) Measure chimney height and cut flex liner as required.

Mark one of the pipes to identify combustion air intake

pipe from flue outlet pipe.

2) Attach marked flex liner pipe to the intake side (longer

collar) of vent terminal. Seal and secure with sealant and

screws provided. Attach the other pipe to the outlet side of

vent terminal. Seal and secure with sealant and screws

provided.

3) Insert both flex liners from top of the chimney, down

through the damper opening.

4) The vent terminal is sized to fit most typical chimneys.

Before attaching vent terminal to top of chimney, apply a

bead of caulking to top of clay liner. Slip vent terminal

over liner and secure in place with lateral retaining bolts.

f i r e - p a r t s . c o m

5) For larger chimneys, an optional flashing is available

which may be cut and fitted to suit. The flashing attaches

to the underside of the terminal with four nuts provided.

Caulk the flashing in place to seal any gaps.

Gas Insert

Seal

Min. ........ 8' (2.4m)

Max. ....... 36' (10.9m)

3" Flex

Liner

The vent terminal must be sealed in place to prevent water

from entering the existing chimney.

Fig # 6

Note: The vent must be a minimum 8' long and

must not exceed a total length of 36'.

6) Remove the screw located above the top louver which

retains the vent connector plate on the appliance. Attach

ends of the flex liners to the collars on top of the connector

plate.

Fig # 8

040805-24 GRNA # 5055.651

6

Make sure the marked inlet pipe is attached to the inlet side

Fig # 9

(marked "I"), and the unmarked pipe is attached to the

outlet side (marked "E") of the connector plate.

7) Seal and secure inlet pipe with sealant and screws provided.

8) Slip the 3 1/2" pipe clamp loosely over the end of the flex

flue pipe. Slide the pipe over the collar (marked "E") of the

vent connector plate and clamp tightly in place. Secure in

place with screws provided. No additional seal is required.

9) Position vent connector plate over top of unit as the Insert

is pushed into the fireplace. Clip connector plate at the

back of the unit, tip down into position and attach in place

with screws previously removed. Leave the Insert extending a couple of inches out of the fireplace temporarily to

allow for proper surround placement.

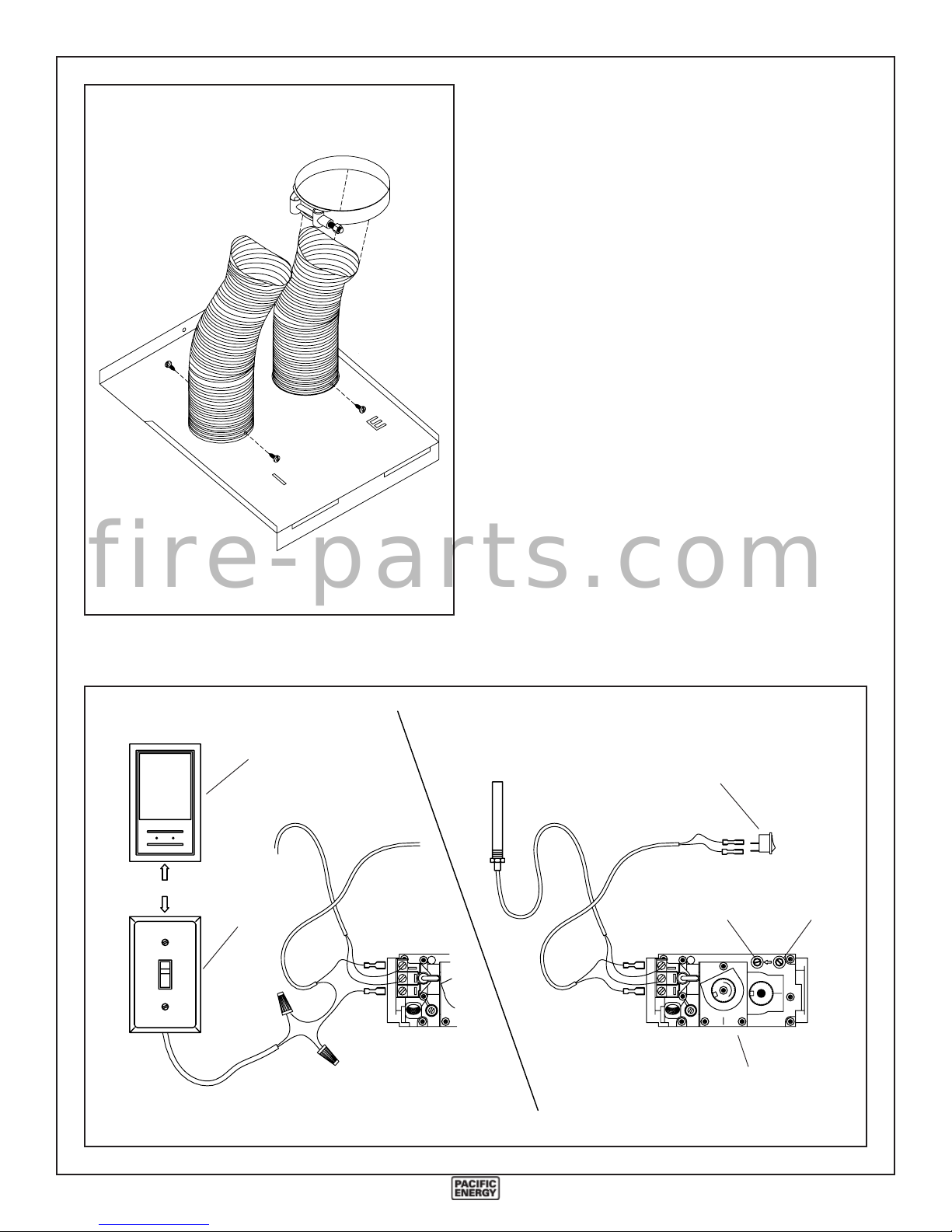

Rocker Switch

No electrical connection is required for the gas system

operation. The self generating pilot provides current for the

optional remote wall switch.

The installation of a wall switch allows for manual remote

operation of fireplace, and automatic operation with a wall

thermostat. Use a switch or thermostat rated for millivolts.

f i r e - p a r t s . c o m

Position the wall switch or thermostat so that a maximum of

25 feet of wiring from the switch to the fireplace is used. Use

18/2 thermostat wire. Connect the wall switch to the valve as

shown in Fig. #10.

Fig # 10

Thermostat

302010

Wall

Switch

Optional Wall Switch or Thermostat

Rocker Switch

Rocker Switch

(located top right corner of surround trim)

EA

F

O

F

P

I

L

T

O

N

O

Inlet

Pressure

Test Point

Manifold

Pressure

Test Point

THTP TH

TP

P

I

T

L

O

TP TPTH TH

L

O

H

I

P

I

T

L

O

Gas Valve

040805-24 GRNA # 5055.651

7

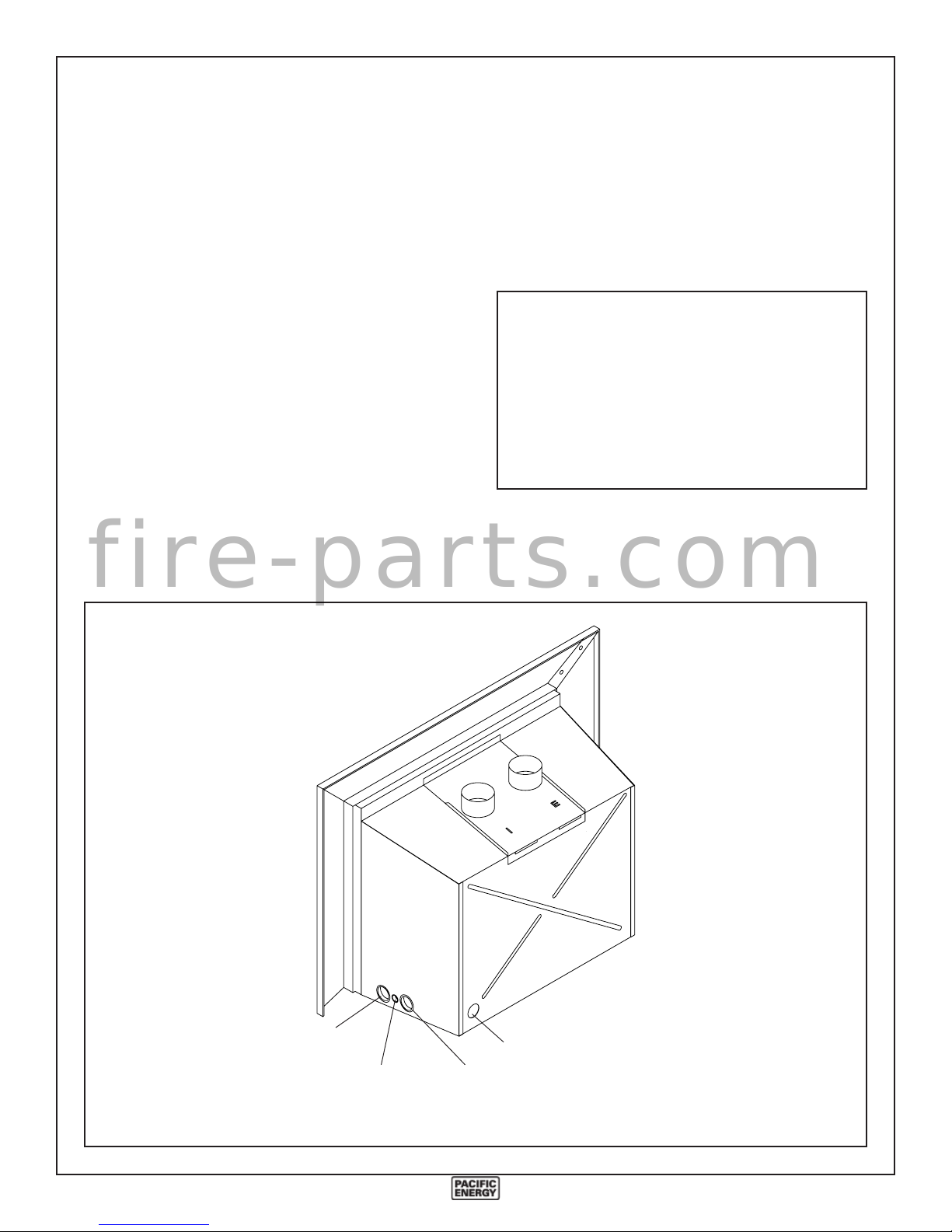

Gas Supply

Caution: The gas line should be installed by a qualified

service person in accordance with all building codes.

Consult local and/or national building codes before proceeding.

The gas valve inlet accepts a 3/8" N.P.T. fitting. Correct gas

line diameter must be used to assure proper operation.

The gas control is equipped with a capture screw type pressure

test port, therefore it is not necessary to provide an 1/8 inch

N.P.T. plugged tapping pressure port for checking gas pressure immediately upstream of the gas supply connection to the

appliance.

A knockout is provided at the bottom right rear of the appliance as an alternate entrance for a gas supply line (Fig. #11).

To use this entrance, remove the knockout from the rear of the

appliance. Remove the plastic bushing installed in the side and

reinstall into the hole at the rear of the appliance.

An optional 24" long flexible connector (part #

GASC.GASCON) may be used for easy gas connection. This

connector may exit the appliance through either the right front

or right rear access holes.

Correct gas pressure requirement:

Natural Gas Propane

Min. Pressure 5.0" wc 12.5" wc

(For purpose of input adjustment)

Max. Pressure 10.5" wc 13.0" wc

Manifold Pressure 3.8" wc 11.0" wc

f i r e - p a r t s . c o m

Fig # 11

Optional Blower

Cord Exit

Wire Harness

Rear Knockout

Gas Inlet

Exit

040805-24 GRNA # 5055.651

8

Loading...

Loading...