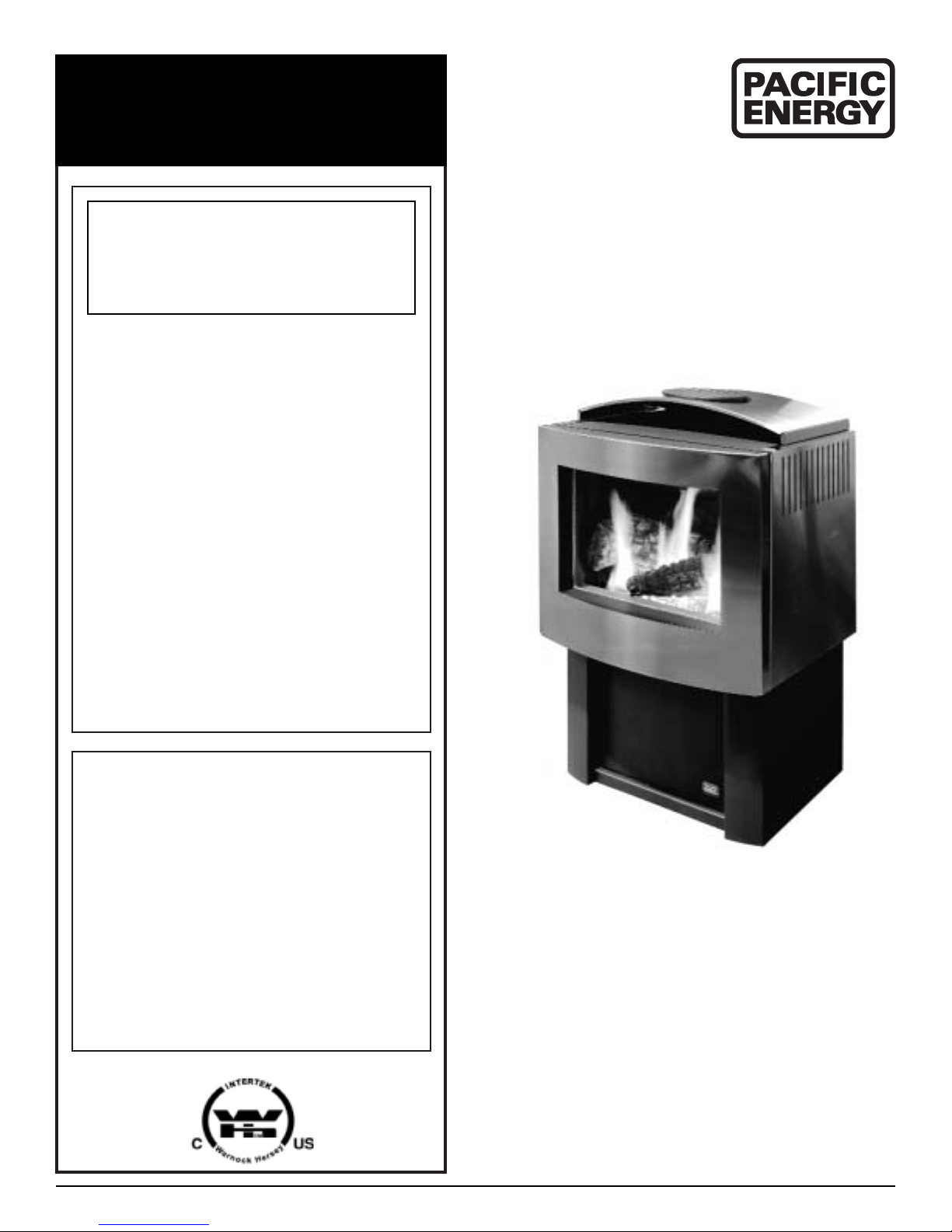

Pacific energy fusion gas, A Installation And Operating Instructions Manual

070905-28 FSGA 5056.4221

INSTALLATION

and

OPERATING

INSTRUCTIONS

fusion gas

DIRECT VENT

FREESTANDING STOVE

Series A

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE HOMEOWNER

– Do not store or use gasoline or

other flammable vapours and

liquids in the vicinity of this or

any other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electrical

switch; do not use any phone in

your building

•Immediately call your gas supplier

from a neighbour’s phone. Follow

the gas supplier’s instructions

• If you cannot reach your gas

supplier, call the fire depar tment

– Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

This appliance may be installed in

an aftermarket permanently

located, manufactured home (USA

only) or mobile home, where not

prohibited by local codes.

This appliance is only for use with

the type of gas indicated on the

rating plate. This appliance is not

convertible for use with other

gases, unless a certified kit is

used.

WARNING: If the information in

these instructions is not followed

exactly, a fire or explosion may

result causing property damage,

personal injury or loss of life.

2

070905-28 FSGA 5056.4221

CAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GAS SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FLOOR PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ATTACHMENT TO FLOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TOP OR REAR VENT CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

VENTING REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

WALL TERMINATION VENTING- with no vertical rise . . . . . . . . . . . . . . . .10

WALL TERMINATION VENTING- with vertical rise . . . . . . . . . . . . . . . . . .11

ROOF TERMINATION VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

VENT TERMINAL CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

VENTING SYSTEM COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

REMOVAL OF WINDOW FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

REMOVAL OF RIGHT HAND SIDE PANEL . . . . . . . . . . . . . . . . . . . . . . . . .15

ADJUSTMENT OF TOP VENT DAMPER . . . . . . . . . . . . . . . . . . . . . . . . . . .16

LOG SET INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

LIGHTING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

FIRST FIRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

MANUAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

OPTIONAL REMOTE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

OPTIONAL BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

PROPANE CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-23

BODY REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

BURNER REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

SAFETY LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Contents

3

070905-28 FSGA 5056.4221

FOR Y OUR SAFETY

Do not install or operate your Pacific

Energy heater without first reading

and understanding this manual. Any

installation or operational deviation

from the following instructions voids

the Pacific Energy Warranty and may

prove hazardous.

This appliance and its individual

shutoff valve must be disconnected

from gas supply piping system during

any pressure testing of that system at

test pressures in excess of 1/2 psig.

(3.5 kpa).

This appliance must be isolated from

the gas supply piping system by

closing its individual manual shutoff

valve during any pressure testing of

the gas supply piping system at test

pressures equal to or less than 1/2

psig. (3.5 kPa).

This appliance must not be

connected to a chimney flue serving

a separate solid-fuel burning

appliance.

If the optional blower is installed, this

appliance must be electrically grounded in accordance with local codes or,

in the absence of local codes, with

the National Electrical Code,

ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.1.

Important: When lit for the first time, the appliance will emit a slight

odour for a couple of hours.This is due to the curing of paints, sealants

and lubricants used in the manufacturing process.This condition is

temporary. Open doors and windows to ventilate area. If optional fan kit

has been installed, place fan in the "OFF" position. Smoke and fumes

caused by the curing process may cause discomfort to some

individuals.

It is normal for fireplaces fabricated of steel to give off some expansion

and/or contraction noises during the start up or cool down cycle. Similar

noises are found with your furnace heat exchanger or cook stove oven.

Caution

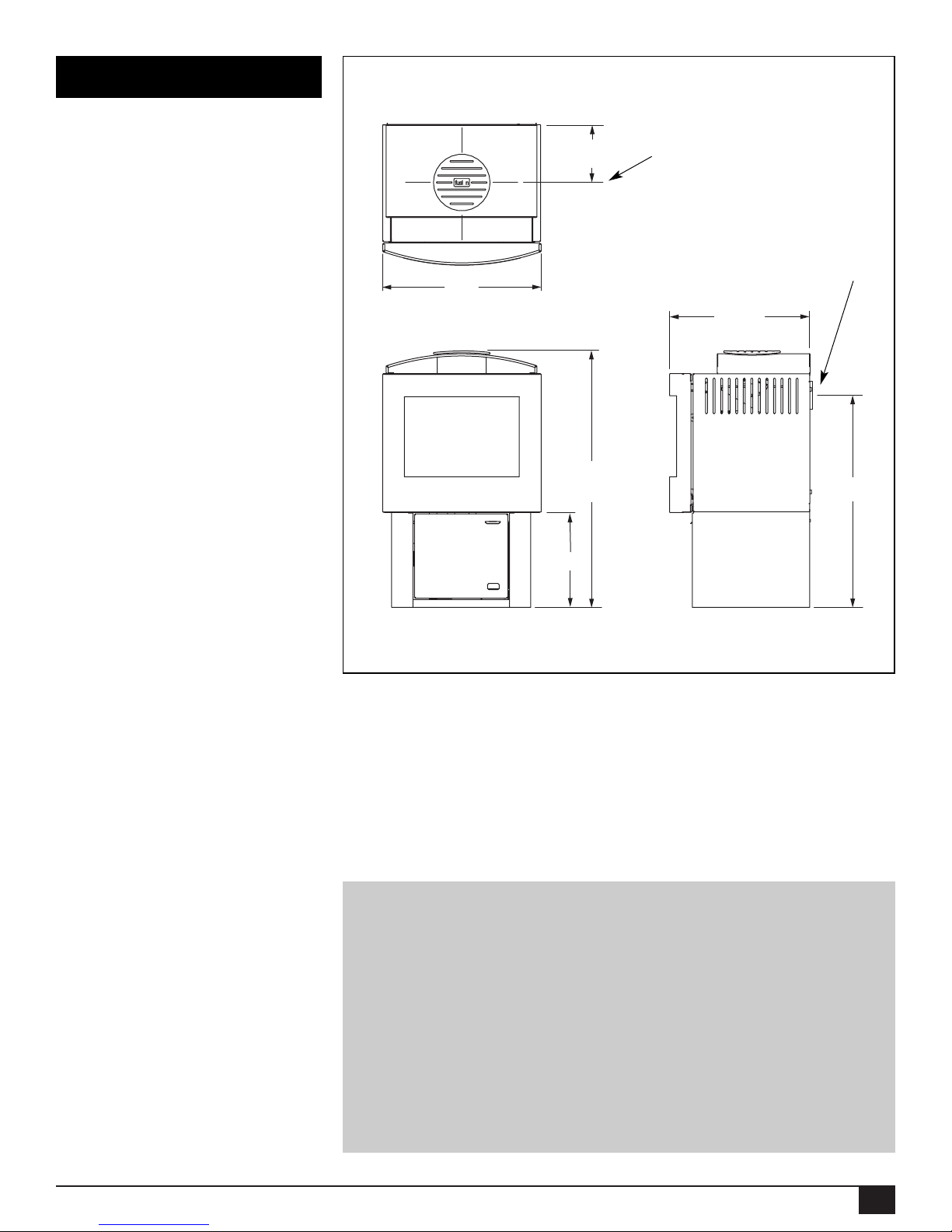

Fig. #1

7 5/8”

34”

18 5/8”

12 9/16”

26 7/16”

21”

Stove Dimensions

Center of top flue outlet

Center of rear

flue outlet

4

070905-28 FSGA 5056.4221

• Due to high temperatures, this gas

appliance should be located out of

traffic and away from furniture and

draperies.

• Children and adults should be

alerted to the hazards of high surface

temperatures and should stay away

to avoid burns or clothing ignition.

• Young children should be carefully

supervised when they are in the

same room as the appliance.

• Clothing or other flammable material

should not be placed on or near the

appliance.

• Under no circumstances should this

fireplace be modified. Any grill, panel

or door removed for servicing the unit

must be replaced prior to operating.

Failure to do so may create a

hazardous condition.

• Installation and repair should be

done by a qualified service person.

The appliance should be inspected

before use and at least annually by a

professional service person. More

frequent cleaning may be required

due to excessive lint from carpeting,

bedding material, etc. It is imperative

that control compartments, burners

and circulating air passageways of

the appliance be kept clean.

It is Pacific Energy’s policy that no

responsibility is assumed by the

Company or by any of its employees

or representatives for any damages

caused by an inoperable, inadequate,

or unsafe condition, which is the

result, either directly or indirectly, of

any improper operation or installation

procedures.

Caution: Turn off gas and electrical

power supply and allow ample time

for unit to cool before servicing

appliance. It is recommended that

this appliance and venting should be

inspected at least once a year by a

qualified service person.

Do not use this heater if any part has

been under water.Immediately call a

qualified service technician to inspect

the heater and to replace any part of

the control system or gas control,

which has been under water.

Door Glass

Warning: Do not operate appliance

with glass panel removed, cracked

or broken. Replacement of glass

should be done by a licensed or

qualified service person.

Do not strike or otherwise impact the

glass in anyway that may cause it to

break. If the glass becomes cracked

or broken, it must be replaced before

using the fireplace. Replacement

glass can be obtained from your

nearest Pacific Energy dealer. Use

ceramic glass only. Do not substitute

with any other type.The size required

is 12 3/16” x 17 1/4” x 5 mm.

To remove broken glass, see page 11

for window removal instructions.

Remove all particles of glass. Be

careful, as they are very sharp. Install

new glass complete with gasket and

frame.

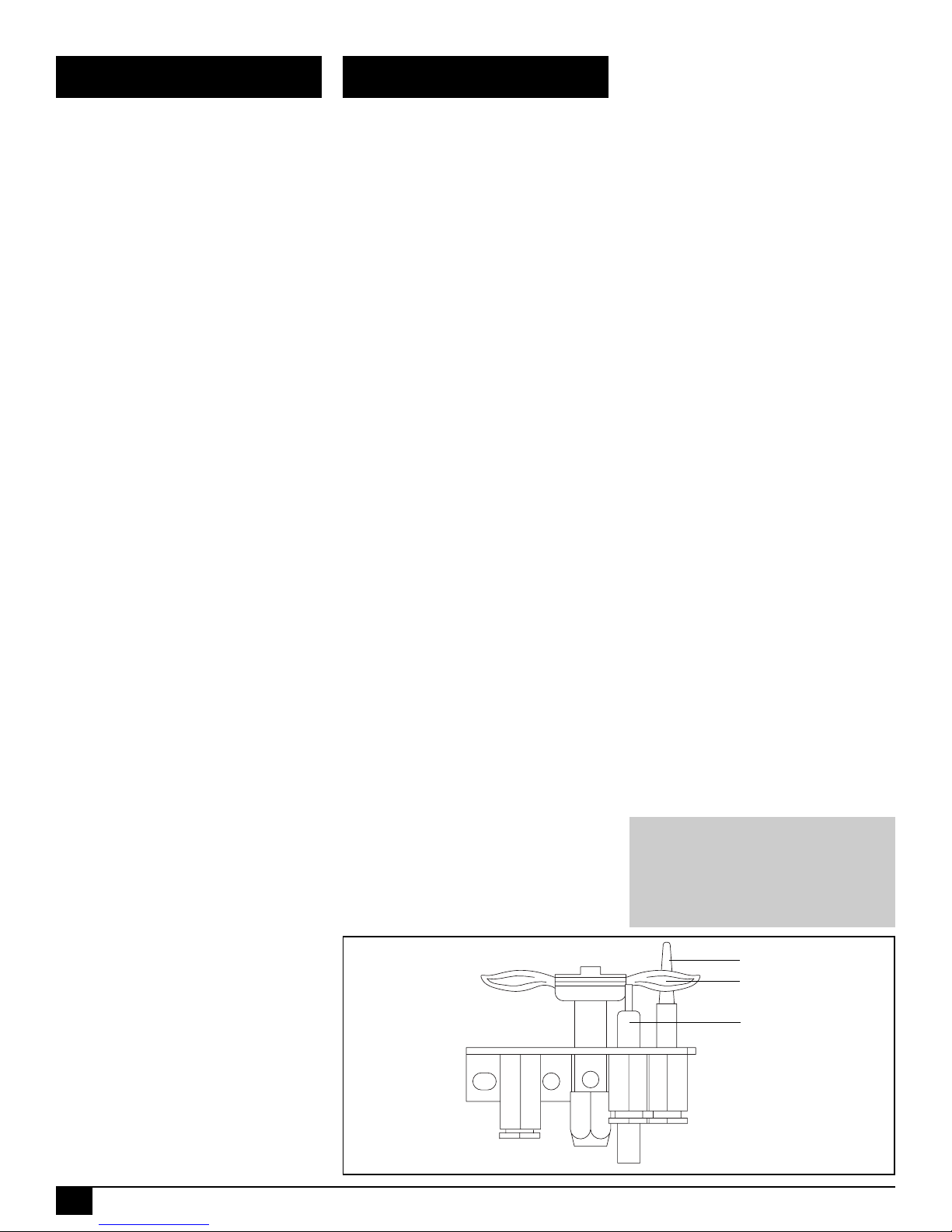

Annual Inspection:

a) Clean air passageways of

excessive lint and dust buildup from

carpeting, bedding material, etc.

The flow of ventilation air must not

be obstructed.

b) Inspect logs and burner

assembly for lint and soot build-up.

If excessive build-up of soot is present, have a qualified service person

inspect and adjust unit for proper

combustion. Clean logs and burner

with a vacuum cleaner, paying close

attention to the ports on the burner.

c) Check the pilot system for proper

flame size and operation. Clean

pilot free of lint and dust.

(See Fig. #2)

d) Check that the vent pipe and

vent terminal are open and free

from blockage or debris. If the

venting system is disassembled for

cleaning, it must be properly

assembled and re-sealed, as per

vent manufacturers instructions.

e) Check door and glass panel

gasket, replace if necessary. It is

important that the glass and door

seal be maintained in good

condition.

Note: The appliance area must be

kept clear and free from

combustible materials, gasoline and

other flammable vapours and

liquids.

Periodically:

a) Viewing glass may be cleaned

with fireplace glass cleaner.

b) Exterior finish may be cleaned

with mild soap and water.

Safety Maintenance

Fig. #2

THERMOCOUPLE

ELECTRODE

PILOT FLAME

Caution:

Do not use abrasive cleaners

on glass or any other part of

this appliance.

Do not clean glass when hot.

5

070905-28 FSGA 5056.4221

Gas Supply

Floor Protection

Clearances

Attachment

to Floor

In the state of Massachusetts, only a

licensed plumber and gas fitter may

install this product. Correct gas line

diameter must be used to assure

proper operation.

The gas control is equipped with a

captured screw type pressure test

point, therefore it is not necessary to

provide a 1/8 inch N.P.T. plugged

tapping pressure test port for

checking gas pressure immediately

upstream of the gas supply

connection to the appliance.

The gas valve inlet accepts a 3/8"

N.P.T. fitting.

Mobile Home installations require that

the appliance be firmly attached to

the structure. Once the appliance is in

its final location, secure the unit in

place through holes in the pedestal

base.The holes are located on the

left and right hand side of the base.

The Fusion Gas stove may be

installed directly on a combustible

floor.If the appliance is to be installed

directly on carpeting, combustible

floor tile or other combustible material

other than wood flooring, the

appliance shall be installed on a

metal or wood panel extending the

full width and depth of the unit.

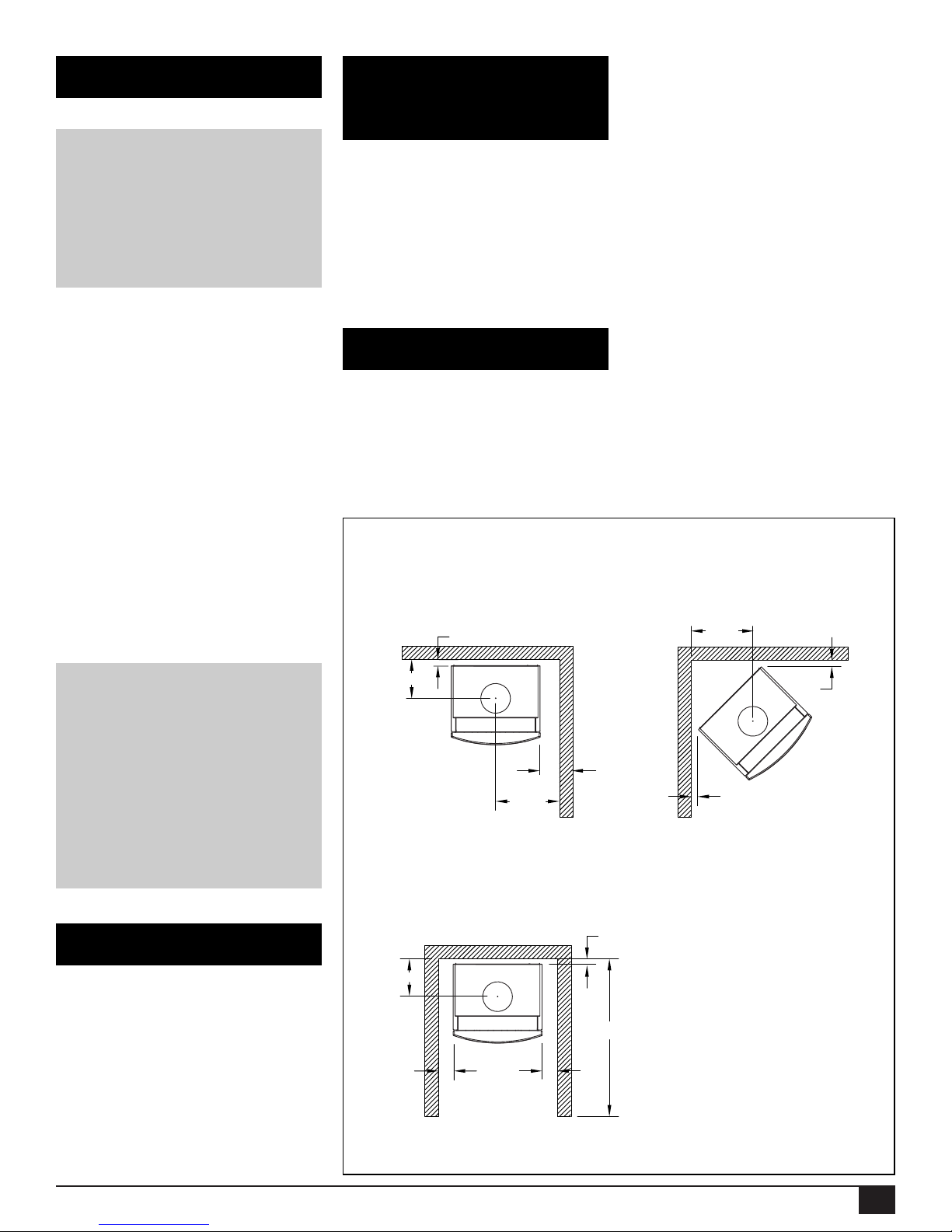

The minimum clearances from the

appliance to combustibles are shown

on Fig. #3. Adequate clearances

around air openings are required.

Sidewall to Appliance 6 in (152 mm)

Rearwall to Appliance 1 in (25 mm)

Corner to Appliance 1 in (25 mm)

Alcove Sidewall to Appliance 6 in (152 mm)

Alcove minimum width 33 in (838 mm)

Alcove maximum depth 48 in (1219 mm)

Alcove minimum height 46 in (1168 mm)

Minimum Clearances to Combustibles

Correct gas pressure requirements

Natural Gas Propane

Min. Pressure 5.0” WC 11.5” WC

(For purpose of

input adjustment)

Max. Pressure 13.9” WC 13.9” WC

Manifold Pressure

Maximum 3.8” WC 10.5” WC

Minimum 0.7” WC 1.6” WC

13 3/4”

1”

1”

Fig. #3

Caution:

The gas line should be installed

by a qualified service person in

accordance with all building

codes. Consult local and/or

national building codes before

proceeding.

1”

8 5/8”

16 1/2”

6”

8 5/8”

1”

6”

ALCOVE HEIGHT

61” MINIMUM

6”

48”

6

070905-28 FSGA 5056.4221

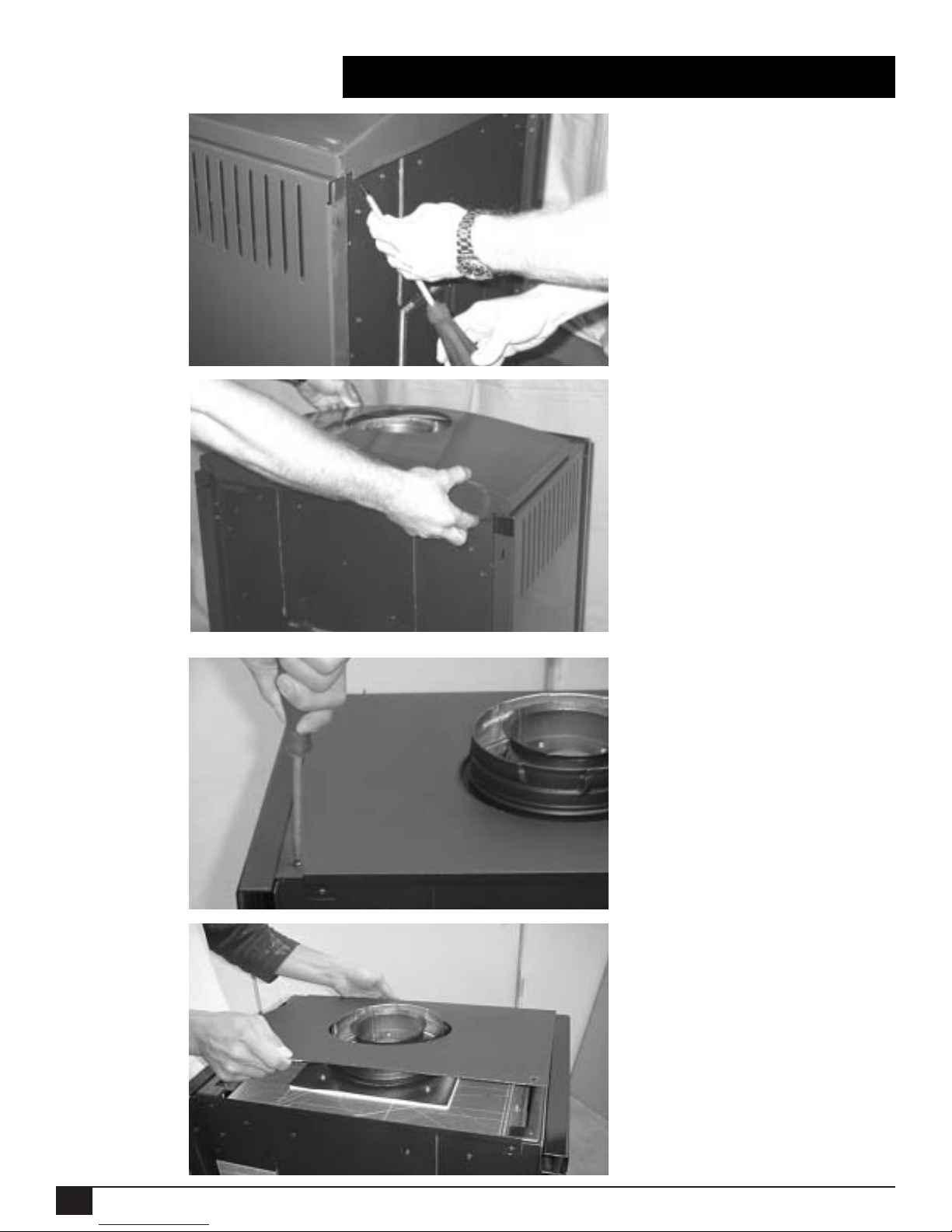

Top or Rear Vent Conversion

1) Remove the two screws securing

the air deflector to the rear of the

stove (Fig.#3.01), remove the air

deflector and store it in a safe place

(Fig. #3.02).

2) Remove the two screws that

secure the top plate in place

(Fig. #3.03). To remove the top plate,

lift it from the back and slide it forward slightly to unhook it from the

brackets at the front (Fig.#3.04).

The fusion gas stove is set up in the

factory as a top vent.To convert to

rear vent, use the following procedure. Please read the instructions

carefully before converting the appliance:

Fig. #3.01

Fig. #3.02

Fig. #3.03

Fig. #3.04

7

070905-28 FSGA 5056.4221

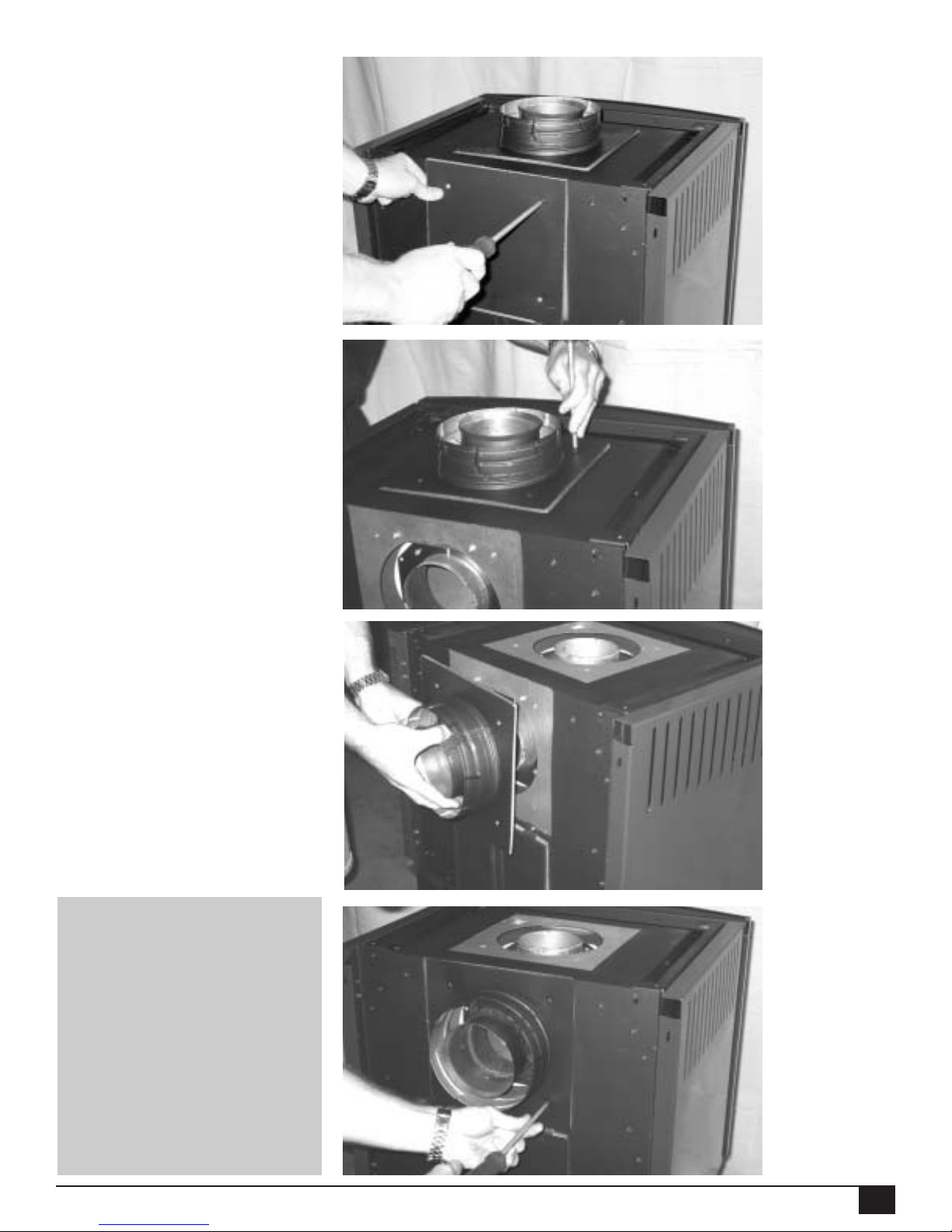

IMPORTANT:

Take care not to damage the

gaskets on the vent adapter

and flue outlet cover plate

during the procedure. Inspect

the gaskets carefully before

reinstalling, if the gasket on

either piece is damaged, it

will need to be replaced

before continuing.

3) Remove the four screws that fasten the vent cover to the back of the

appliance, and remove the vent cover

(Fig. #3.05).

4) Remove the four screws securing

the vent adapter to the top of the

stove (Fig #3.06).Pull the vent

adapter off and attach it to the rear

flue outlet. Press fir mly to ensure a

positive, snug connection (Fig.#3.07)

and use four screws to fasten it in

place (Fig. #3.08).

Fig. #3.05

Fig. #3.06

Fig. #3.07

Fig. #3.08

8

070905-28 FSGA 5056.4221

5) Place the vent cover from step 3

over the top flue outlet (Fig. #3.09)

and use four screws to fasten it in

place (Fig. #3.10).

6) Replace the top plate by hooking

the front flange over the mounting

brackets (Fig.#3.11) pull it firmly

towards the rear of the appliance and

fasten it down at the back with two

screws (Fig #3.12).

Fig. #3.09

Fig. #3.10

Fig. #3.11

Fig. #3.12

9

070905-28 FSGA 5056.4221

7) Place the air deflector back on the

top of the appliance and align it so it

is spaced evenly from either side.

Fasten the air deflector to the rear

bracket using two screws (Fig. #3.13).

8) Place the optional cast iron Fusion

Gas Trivet into the outlet of the air

deflector.Take care to not scratch the

finish on the top of the appliance (Fig.

#3.14). Adjust the cap so that the

logo reads left to right when facing

the front of the appliance, and the

radius matches the top of the air

deflector.

Fig. #3.13

Fig. #3.14

Loading...

Loading...