Pacific energy A, Fairfield Operating Instructions Manual

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life.

-- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch; do

not use any phone in your building.

- Immediately call your gas supplier

from a neighbour’s phone. Follow the

gas supplier’s instructions.

- If you cannot reach your gas supplier,

call the fire department.

-- Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE

HOMEOWNER

SERIES A

VENTED GAS FIREPLACE

HEATER

INSTALLATION

AND

OPERATING

INSTRUCTIONS

Fairfield

Gas Insert

090701-24 Fairfield-A 5056.425

Printed in Canada

Pacific Energy Fireplace Products Ltd.

Box 1060, Duncan, BC V9L 3Y2

Phone: 250-748-1184

Web site: http://www.pacificenergy.net

f i r e - p a r t s . c o m

2

Contents

Caution ...................................................................................................... 3

Maintenance .............................................................................................. 4

Installation................................................................................................. 5

Clearances ................................................................................................. 6

Venting....................................................................................................... 7

Gas Supply ................................................................................................ 7

Blocked Vent Shut-off System ................................................................. 8

Draft Inspection ........................................................................................ 8

Surround Assembly .................................................................................. 9

Log Set ..................................................................................................... 10

Glowing Embers ..................................................................................... 12

Levelling Legs ......................................................................................... 12

Glass Frame Installation ........................................................................ 12

Louver Installation ................................................................................. 13

Optional Radiant Overlay ..................................................................... 13

Lighting Instructions .............................................................................. 14

First Fire .................................................................................................. 15

Operation................................................................................................. 15

Primary Air Adjustment ........................................................................ 15

Burner Removal...................................................................................... 16

Propane Conversion ............................................................................... 17

Optional Blower ...................................................................................... 18

Replacement Parts .................................................................................. 20

Burner Replacement Parts .................................................................... 22

Label ........................................................................................................ 23

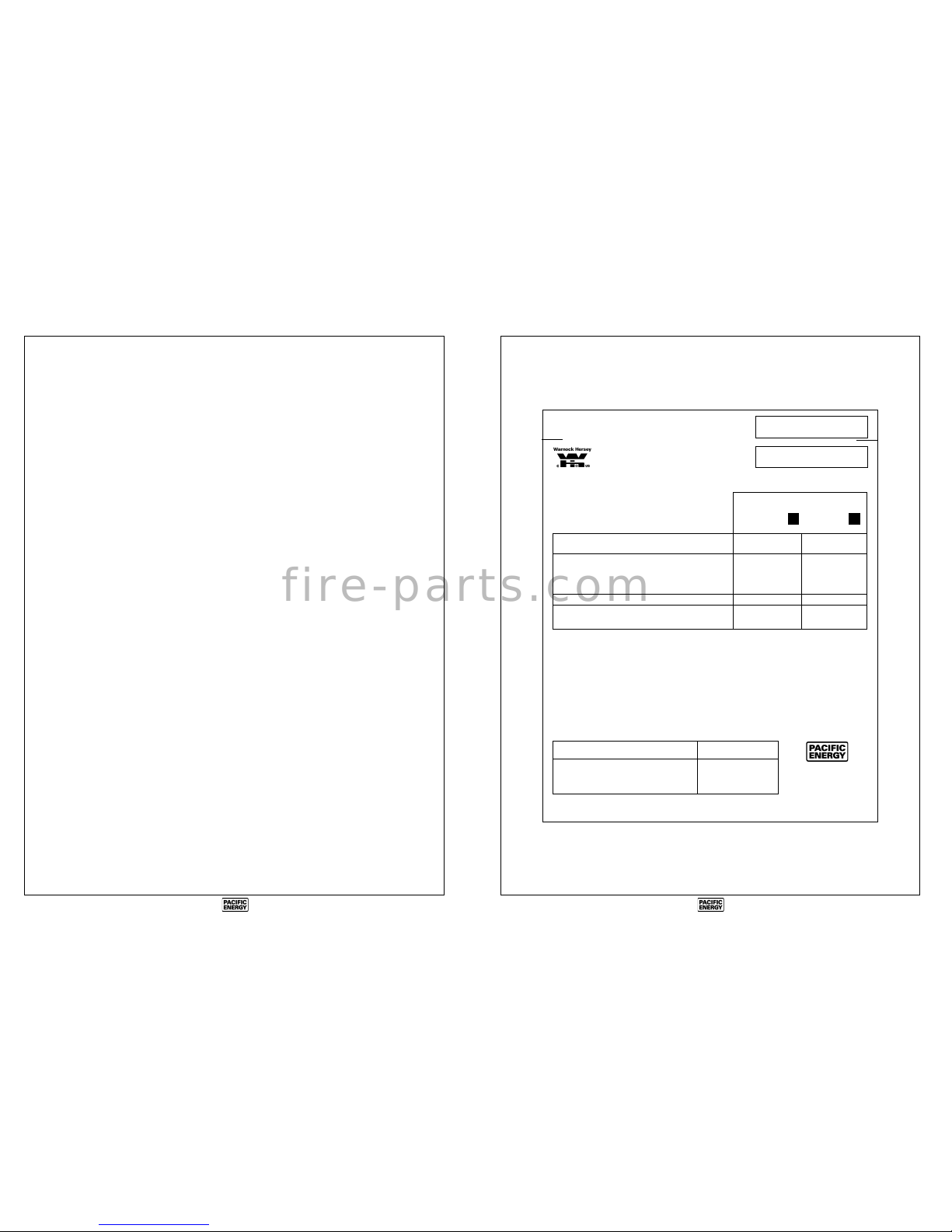

23

FOR USE WITH/ NATURAL GAS/ LP-GAS/

EN CASE D’EMPLOI AVEC:

DU GAZ NATUREL

DU GAZ LP

Minimum supply pressure / Pression minimum d’alimentation: 5.0 in/wc / 5.0 po/c.e. 12.5 in/wc / 12.5 po/c.e.

(For the purpose of input adjustment/dans le but de regler l’alimenation) (1.25 kPa) (3.11 kPa)

Manifold pressure / Pression de la tuyauterie: 3.8 in/wc / 3.8 po/c.e. 11.0 in/wc / 11.0 po/c.e.

(.95 kPa) (2.74 kPa)

Orifice Size / Diametre de l’injectuer: # 45 (2.08 mm) # 55 (1.32 mm)

Input BTU/hr (kW) / Puissance à l'entrée BTU/h (kW) : Max.: 21,000 (6.2) Max.: 21,000 (6.2)

Min.: 10,500 (3.1) Min.: 10,500 (3.1)

Optional components: Blower Kit (MINB.BLOW) / Éléments facultatifs: Ventilateur (MINB.BLOW)

Blower electrical rating: 115v, 60hz, 0.5 A / Normes electriques du ventilateur: 115v, 60hz, 0.5 A

This appliance equipped for altitudes 0-4500 ft. (0-1370 m) / Cet unité est concu pour des altitudes variant entre 0- 4500

pieds (0-1370 m). Also certified for installation in a bedroom or a bedsitting room / Aussi certifié pour installation dans

une chambre à coucher ou une salle de séjour.

This appliance needs fresh air for safe operation and must be installed so there are provisions for adequate combustion

and ventilation air. Par mesure de securite, cet appareil doit etre installe de facon a assurer un approvisionnement

suffisant d’air de combustion et de ventilation. This vented gas fireplace is not for use with air filters. Ne pas utiliser de

filtre à air avec foyer au gaz à évacuation.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage.

Refer to the owner’s information manual provided with this appliance. For assistance or additional information, consult a

qualified installer, service agency or the gas supplier.

This appliance must be installed in accordance with local codes, if any; if not, follow the current CAN/CGA-B149

(Canada) or ANSI Z223.1 (USA). Cet appareil diot etre installe conformement aux exigences des codes locaux. S’il

n’existe aucun code local, se conformer a la norme CAN/CGA-B149 en vigueur.

Left and Right side are determined when facing the front of the appliance.

Les cotes droit et gauche se determinent en se mettant devant l’appareil et en lui faisant face.

INSTALL IN SOLID FUEL BURNING FIREPLACE / N'INSTALLER QUE DANS UN FOYER NON COMBUSTIBLE

MINIMUM CLEARANCES TO COMBUSTIBLES / Fireplace Insert /

DEGAGEMENT DES MATIERES INFLAMMABLES Encart de la cheminée

Adjacent Sidewall / Mur du côté adjacent : 9.5 in. / 9.5 po. (241 mm)

Ceiling / Plafond : 38 in. / 38 po. (965 mm)

Mantel to Appliance / Du manteau al’appareil : 9 in. / 9 po. (229 mm)

Max. Mantel Extension / Extension max. dmanteau : 12 in. / 12 po. (305 mm)

Facing Side and Top / : 1 in. / 1 po. (25 mm)

040701 5050.7203 1-FFGA

PACIFIC ENERGY

FIREPLACE PRODUCTS LTD.

PO Box 1060, Duncan,

British Columbia, V9L 3Y2

MODEL / MODELE: FAIRFIELD - INSERT

SERIES / SERIE: A

ANSI Z21.88-1999b / CAN 2.33-M99 Vented Gas Fireplace

Heaters, CAN/CGA-2.17 -M91 Gas-Fired Appliances For Use

At High Altitudes

REPORT NO.

476-1936-00

L18582

VENTED GAS FIREPLACE HEATER - NOT FOR

USE WITH SOLID FUEL

FOYER AU GAZ À ÉVACUATION - NE PAS

UTILISER AVEC DU COMBUSTIBLE SOLIDE.

CERTIFIED FOR CANADA AND U.S.A. / CERTIFIÉ POUR CANADA ET U.S.A.

WH

WH

DO NOT REMOVE OR

COVER THIS LABEL

MADE IN CANADA / FABRIQUE AU CANADA

This Appliance is Equipped For Use With /

Cet Appareil est Équipé Pour Utilise Avec :

NATURAL GAS

GAZ NATUREL

LP-GAS

LP GAZ

Label

f i r e - p a r t s . c o m

3

IMPORTANT: When lit for the first time, the

appliance will emit a slight odor for a couple of

hours. This is due to the curing of paints, sealants and lubricants used in the manufacturing

process. This condition is temporary. Open doors

and windows to ventilate area. If optional fan

kit has been installed, place fan in the "OFF"

position. Smoke and fumes caused by the curing

process may cause discomfort to some individuals.

It is normal for fireplaces fabricated of steel to

give off some expansion and/or contraction

noises during the start up or cool down cycle.

Similar noises are found with your furnace heat

exchanger or cook stove oven.

Caution

FOR YOUR SAFETY - Do not install or operate your

Pacific Energy Fairfield Gas Insert without first reading and

understanding this manual. Any installation or operational

deviation from the following instructions voids the Pacific

Energy Fireplace Products Warranty and may prove hazardous.

This appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psig (3.5 kPa).

This appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa).

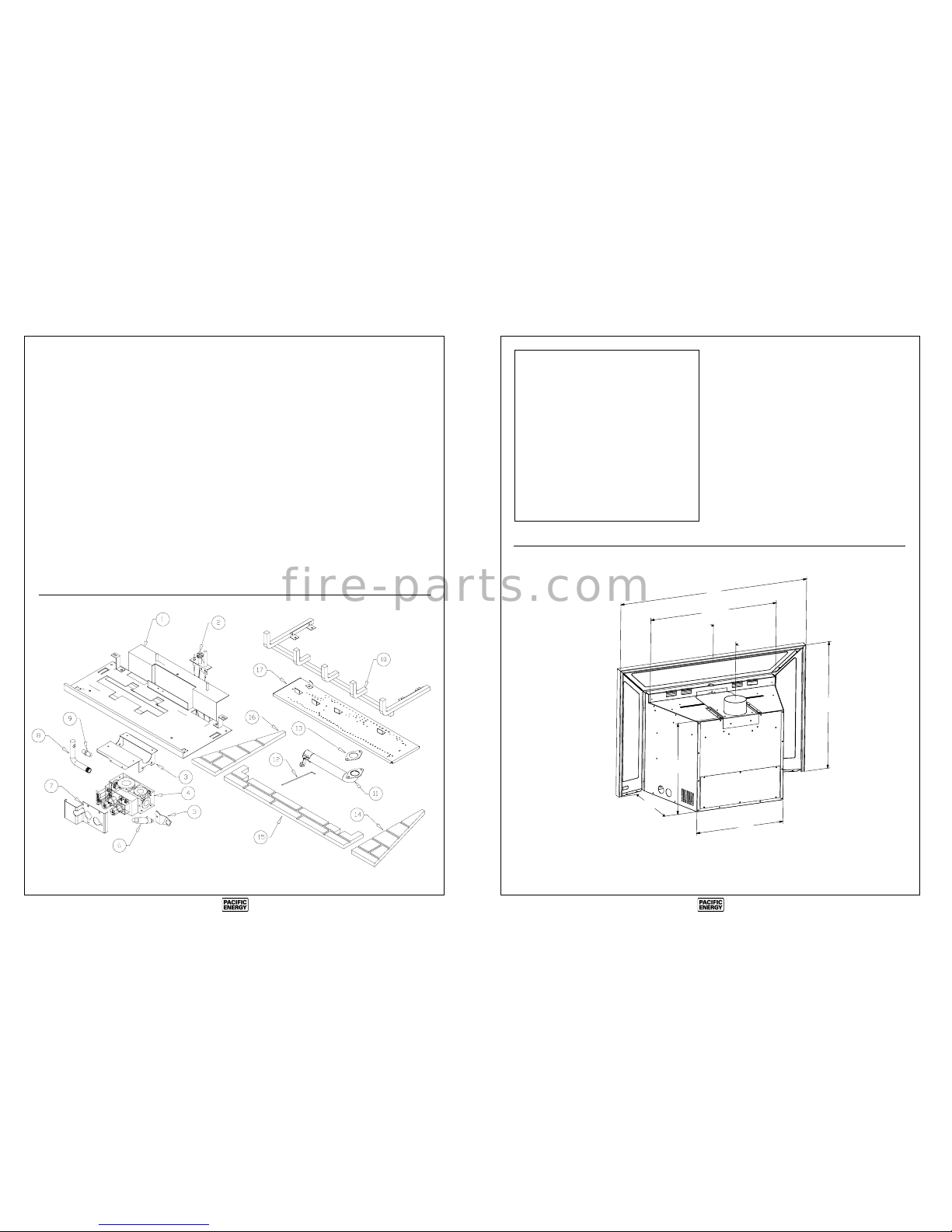

Standard-size Surround Assembly, Plain and Embossed Bevelled Panels ............. 37" wide x 25" high

Over-size Surround Assembly, Plain Flat Panels ................................................... 43" wide x 28" high

A B

Fig. # 1

A

10" to 14"

24 3/4"

B

17"

12 5/8"

17 7/8"

22

Burner Replacement Parts

See Fig. # 41

(WHEN ORDERING, INCLUDE PART NUMBER WITH DESCRIPTION)

ITEM DESCRIPTION PART NO. ITEM DESCRIPTION PART NO.

1 ...........Burner Plate Assembly ....................BRNA.2915

2 ...........Pilot Assembly, NG ..............................5009.157

.............Electrode Assembly c/w Wire ............ 5009.5001

.............Thermopile ................................................... 5010

.............Thermocouple ...........................................5010.3

.............Pilot Supply Tube c/w Fittings ........... 5003.0001

.............Pilot Orifice, NG ..................................... 5003.17

.............Pilot Orifice, LP .................................... 5009.169

3 ...........Valve Bracket ...............................................1983

4 ...........Gas Valve, NG ........................................ 5007.05

5 ...........Igniter Bracket ..............................................1984

6 ...........Igniter ........................................................ 5016.5

7 ...........Valve Cover ................................. MIND.186201

8 ...........Manifold .................................................. 5012.51

9 ...........Burner Orifice, NG (#45) .......................5021.34

.............Burner Orifice, LP (#55) ........................ 5021.35

10 .........Andiron Assembly ...................... BRNA.198531

11 .........Venturi Tube Assembly .............. BRNA.501131

12 .........Air Shutter Rod ............................................ 1752

13 .........Venturi Tube Gasket .................................... 5012

14 .........Brick Panel, Right ................................. 5094.245

15 .........Brick Panel, Front ................................. 5094.226

16 .........Brick Panel, Left ...................................5094.244

.............Brick Panel Set ....................................5094.2451

17 .........Burner Pan Assembly ...................... BRNA.1987

All parts may be ordered from your nearest Pacific Energy Gas Stove dealer. Contact Pacific Energy for the location of the dealer

nearest you.

Fig. # 41

f i r e - p a r t s . c o m

4

Safety

• Due to high temperatures, this gas appliance should be

located out of traffic and away from furniture and draperies.

• Children and adults should be alerted to the hazards

of high surface temperature and should stay away to

avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothing or other flammable material should not be

placed on or near the appliance.

• Any grill, panel or door removed for servicing the unit

must be replaced prior to operating. Failure to do so may

create a hazardous condition.

• Installation and repair should be done by a qualified

service person. The appliance should be inspected before

use and at least annually by a professional service person.

• More frequent cleaning may be required due to excessive lint from carpeting, bedding material, etc. It is imperative that control compartments, burners and circulating air passageways of the appliance be kept clean.

It is Pacific Energy’s policy that no responsibility is assumed

by the Company or by any of its employees or representatives

for any damages caused by an inoperable, inadequate, or

unsafe condition which is the result, either directly or indirectly, of any improper operation or installation procedures.

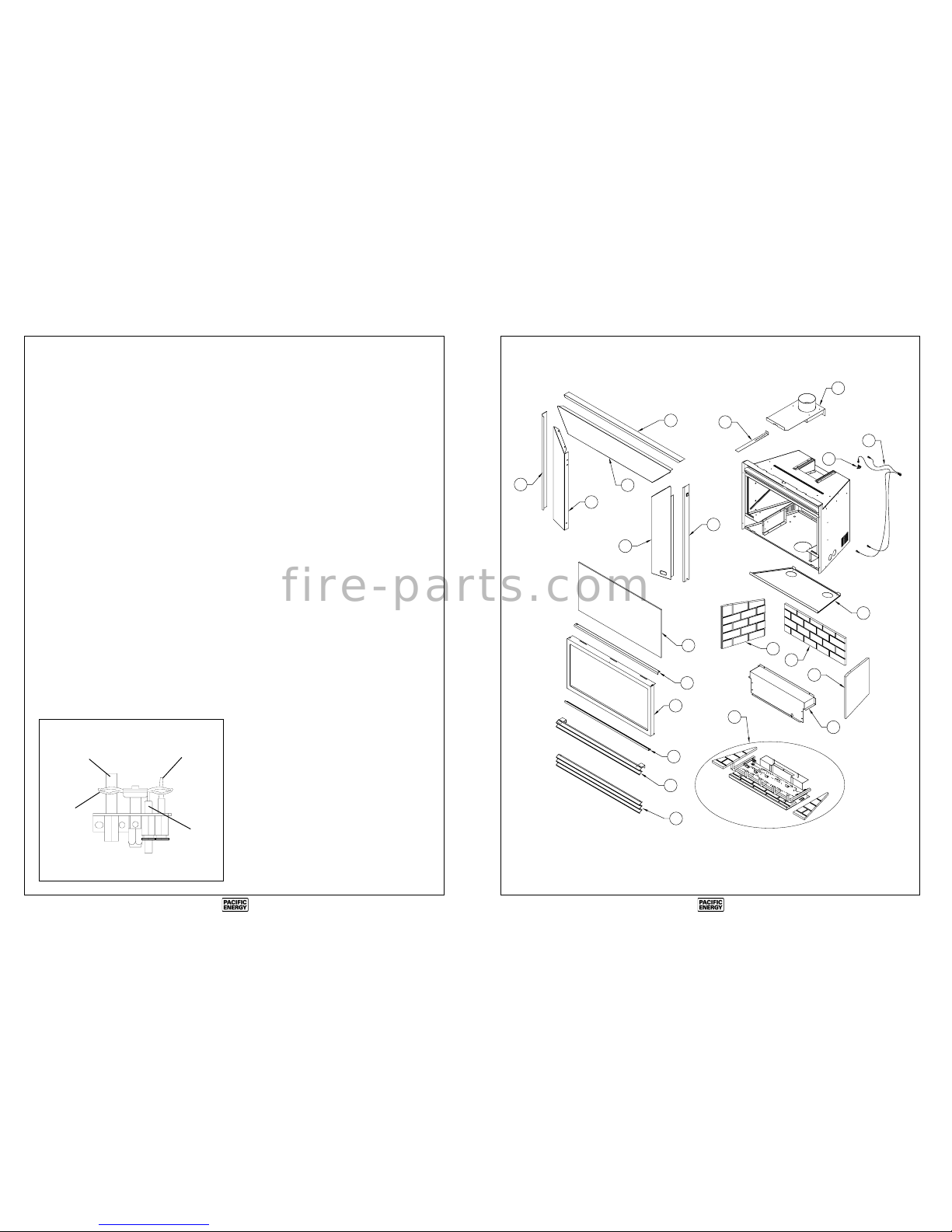

Fig. # 2

THERMOCOUPLE

THERMOPILE

PILOT

FLAME

ELECTRODE

Maintenance

Caution: Turn off gas and electrical power supply and allow

ample time for unit to cool before servicing appliance. It is

recommended that this appliance and venting should be

inspected at least once a year by a qualified service person.

Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system and any

gas control which has been under water.

Glass Panel:

Warning: Do not operate appliance with glass panel re-

moved, cracked or broken. Replacement of the glass panel

should be done by a licensed or qualified service person.

Do not strike or otherwise impact the glass in anyway that

may cause it to break. If the glass becomes cracked or broken,

it must be replaced before using the fireplace. Replacement

glass can be obtained from your nearest Pacific Energy

dealer. The size required is 12 1/8" x 24 1/4" x 5mm. Use

ceramic glass only. Do not substitute with any other type.

To remove broken glass, fold down the front bottom louver

to access the window latches.

Disengage the over-center latches by pulling each lever down

and forward. Grasp the sides of the frame and swing the

bottom out to clear. Lift up and forward to disengage from the

top. Remove all particles of glass. Be careful as they are very

sharp. Install new glass complete with gasket. Replace frame.

Annual Inspection:

1) Clean louvers and air passage ways of excessive lint

buildup from carpeting, bedding material, etc. The flow of

combustion and ventilation air must not be obstructed.

2) Remove glass frame assembly and log set. Inspect logs

and burner assembly for lint and soot buildup. If excessive

buildup of soot is present, have a qualified service person

inspect and adjust unit for proper combustion. Clean logs and

burner with a vacuum cleaner, paying close attention to

burner ports.

3) Check the pilot system for proper operation (See Fig. #2).

4) Check that the chimney flue and its outlet are open and

free from blockage or debris.

5) Check glass panel gasket, replace if necessary.

Note: The appliance area must be kept clear and free from

combustible materials, gasoline and other flammable vapors

and liquids.

Periodically:

a) Viewing glass may be cleaned with glass cleaner.

b) Exterior porcelain enamel finish may be cleaned with soap

and water.

Note: Never use abrasives to clean this appliance.

21

Fig. # 40

3

1

4

5

9

7

6

8

2

19

19

17

18

16

19

15

10

13

14

11

13

12

f i r e - p a r t s . c o m

Loading...

Loading...