Pacific energy Estate Installation And Operating Instrictions

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE

HOMEOWNER

FOR YOUR SAFETY

WARNING: If the information in this manual

is not followed exactly, a fi re or explosion

may result causing property damage,

personal injury or loss of life.

-- Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity

of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbour’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fi re department.

--Installation and service must be performed

by a qualifi ed installer, service agency or

the gas supplier.

This appliance may be installed in an aftermarket permanently located, manufactured (mobile) home, where not prohibited

by local codes.

SERIES H

This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases, unless a certifi ed kit is

DIRECT VENT FIREPLACE

INSTALLATION

AND OPERATING

INSTRUCTIONS

250505-36 ESTATE_H 5055.8.B

TOP VENT

OUTLET LOCATION

REAR VENT

OUTLET LOCATION

CONTENTS

CAUTION ..............................................................................................................3

INSTALLATION REQUIREMENTS .......................................................................4

CHASE INSULATION ...........................................................................................5

FRAMING WITHOUT SCREEN DOOR ................................................................6

FRAMING FOR SCREEN DOOR .........................................................................7

HEARTH EXTENSION ........................................................................................7

TOP OR REAR VENT ........................................................................................... 8

VENT ADAPTER INSTALLATION ........................................................................8

VENTING ...............................................................................................................9

ROOF TERMINATION VENTING AND VENT RESTRICTOR ............................ 10

VENT CONNECTION .......................................................................................... 11

VENT EXTENSION .............................................................................................12

VENT TERMINAL INSTALLATION ..................................................................... 13

ROOF VENT TERMINAL INSTALLATION ......................................................... 14

OPTIONAL VENTING ......................................................................................... 16

OPTIONAL SNORKEL VENT TERMINAL .........................................................19

MANUFACTURED (MOBILE) HOME .................................................................20

GAS SUPPLY ...................................................................................................... 20

WALL SWITCH OR THERMOSTAT ...................................................................20

BURNER REMOVAL ...........................................................................................21

OPTIONAL BRICK PANELS INSTALLATION ................................................... 21

LOG SET ASSEMBLY ........................................................................................22

OPTIONAL BLOWER ......................................................................................... 24

SCREEN DOOR INSTALLATION ....................................................................... 25

LIGHTING INSTRUCTIONS ..............................................................................26

FIRST FIRE ......................................................................................................... 27

OPERATION .......................................................................................................27

FLAME ADJUSTMENT .......................................................................................27

REPLACEMENT PARTS ....................................................................................28

BURNER REPLACEMENT PARTS ....................................................................29

APPENDIX A .......................................................................................................30

Louver Installation Guide ...........................................................................30

Wall Termination Kit ....................................................................................31

Roof Termination Kit ...................................................................................32

5' Vent Pipe Kit ............................................................................................ 33

10' Vent Pipe Kit .......................................................................................... 34

Safety Label .................................................................................................35

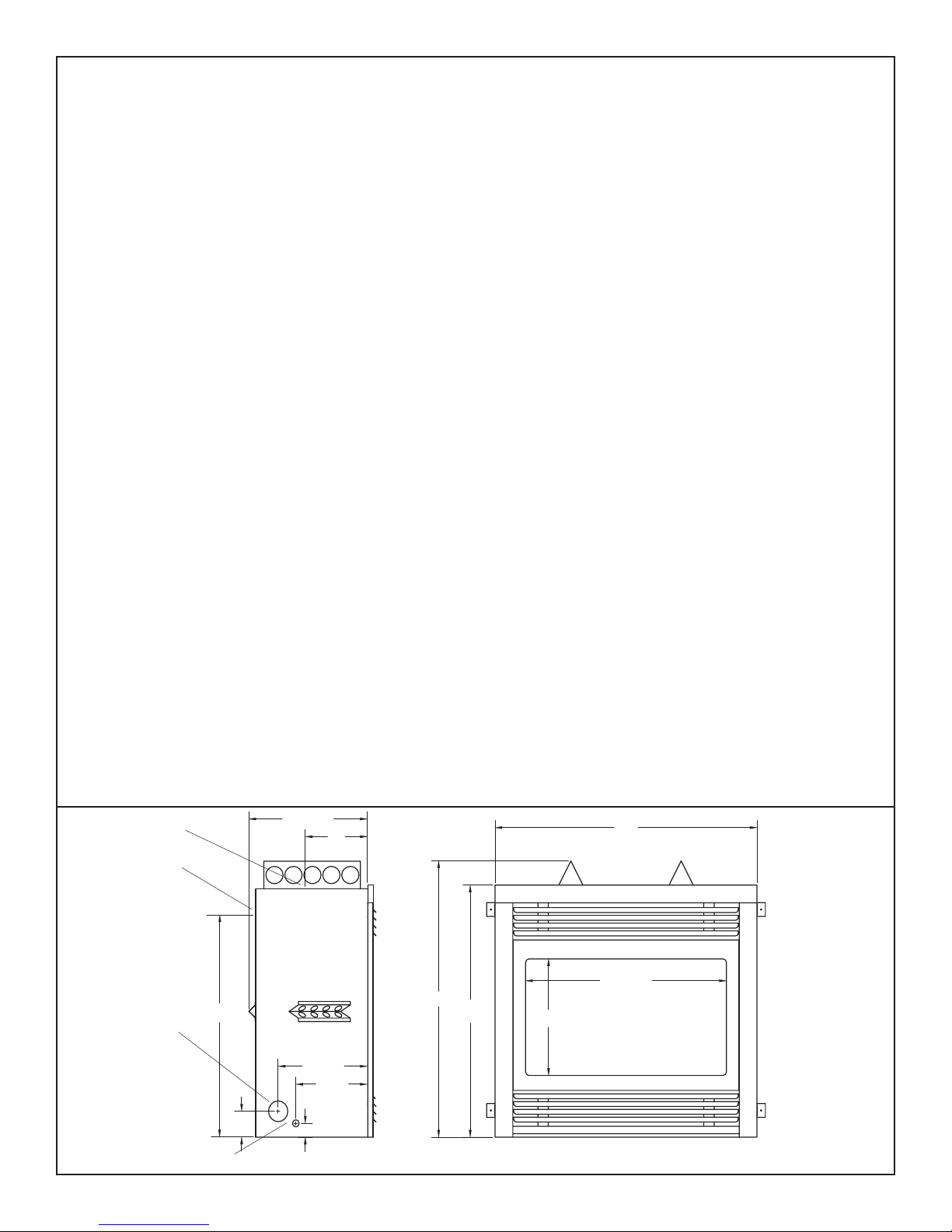

17 1/4"

9"

38"

GAS INLET

ACCESS HOLE

2 ESTATE_H 250505-36

31 1/2"

ELECTRICAL

ACCESS HOLE

3 3/4"

12 15/16"

10 3/8"

2"

40"

36 1/2"

29 1/8"

16 7/8"

CAUTION

MAINTENANCE

FOR YOUR SAFETY - Do not install or operate your Paci c Energy

Gas Stove without rst reading and understanding this manual. Any

installation or operational deviation from the following instructions voids

the Paci c Energy Gas Stove Warranty and may prove hazardous.

This appliance and its individual shutoff valve must be disconnected

from gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig. (3.5 kPa)

This appliance must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig. (3.5 kPa)

Note: When lit for the rst time, the appliance will emit a slight odour

for a couple of hours. This is due to the curing of paints, sealants

and lubricants used in the manufacturing process. This condition is

temporary. Open doors and windows to ventilate area. Smoke and

fumes caused by the curing process may cause discomfort to some

individuals.

SAFETY

Due to high temperatures, this gas appliance should be located

out of traf c and away from furniture and draperies.

Children and adults should be alerted to the hazards of high

surface temperature and should stay away to avoid burns or

clothing ignition.

Young children should be carefully supervised when they

are in the same room as the appliance.

Clothing or other ammable material should not be placed

on or near the appliance.

Any grill, panel or door removed for servicing the unit must

be replaced prior to operating. Failure to do so may create a

hazardous condition.

Installation and repair should be done by a quali ed service

person. The appliance should be inspected before use and at

least annually by a professional service person. More frequent

cleaning may be required due to excessive lint from carpeting,

bedding material, etc. It is imperative that control compartments,

burners and circulating air passageways of the appliance be

kept clean.

It is Paci c Energy’s policy that no responsibility is assumed

by the Company or by any of its employees or representatives

for any damages caused by an inoperable, inadequate, or unsafe

condition which is the result, either directly or indirectly, of any

improper operation or installation procedures.

Caution: Turn off gas and electrical power supply and allow ample

time for unit to cool before servicing appliance. It is recommended

that this appliance and venting should be inspected at least once a

year by a quali ed service person.

Do not use this heater if any part has been under water. Immediately

call a quali ed service technician to inspect the heater and to replace

any part of the control system and any gas control which has been

under water.

Glass Panel:

Warning: Do not operate the appliance with the glass panel removed,

cracked or broken. Replacement of the glass panel should be done

by a licensed or quali ed service person. Do not strike or otherwise

impact the glass in anyway that may cause it to break. If the glass

becomes cracked or broken, it must be replaced before using the

replace. Replacement glass can be obtained from your nearest

Paci c Energy dealer. The size required is 31-1/4" x 19" x 5mm. Use

ceramic glass only. Do not substitute with any other type.

To remove broken glass, fold down the front bottom louver to access

the screw retaining the decorative window trim overlay if installed.

Remove the screw and swing the bottom out to clear. Lift to disengage from the top and remove. Place on a smooth surface to avoid

scratching.

Disengage the over-center latches by pulling each lever down and

forward. Grasp the sides of the frame and swing the bottom out to

clear. Lift up and forward to disengage from the top. Place the glass

frame assembly in a safe place to avoid damage. Remove all particles of glass. Be careful as they are very sharp. Install new glass

complete with gasket. Replace frame and screws.

Annual Inspection:

a) Clean louvers and air passage ways of excessive lint buildup from

carpeting, bedding material, etc. The ow of combustion and ventilation air must not be obstructed.

b) Remove glass panel and log set. Inspect logs and burner assembly for lint and soot buildup. If excessive buildup of soot is present,

have a quali ed service person inspect and adjust unit for proper

combustion. Clean logs and burner with a vacuum cleaner, paying

close attention to burner ports.

c) Ensure pilot is free of lint and dust. Check the pilot system for

proper ame size and operation. (See Fig. #1)

d) Check that the vent pipe and vent terminal are open and free from

blockage or debris. If the venting is disassembled for cleaning, it must

be properly assembled and resealed. Refer to VENTING section for

proper procedure.

e) Check glass panel gasket, replace if necessary. It is important

that the glass seal be maintained in good condition

Note: The appliance area must be kept clear and free from combustible

materials, gasoline and other ammable vapours and liquids.

Periodically:

a) Viewing glass may be cleaned with replace glass cleaner.

b) Exterior nish may be cleaned with soap and water.

Caution:

- do not use abrasive cleaners on glass or any other part of the

replace.

- do not clean glass when hot

Fig. # 1

250505-36 ESTATE_H 3

THERMOPILE

PILOT FLAME

THERMOCOUPLE

ELECTRODE

INSTALLATION REQUIREMENTS

The Estate Fireplace installation and venting must conform

to the current CAN/CGA-B149 installation code (in Canada) or

the National Fuel Gas Code, ANSI Z223.1 -1988 (in the USA), and

approved per local codes. Only quali ed (licensed or trained)

personnel should install this product.

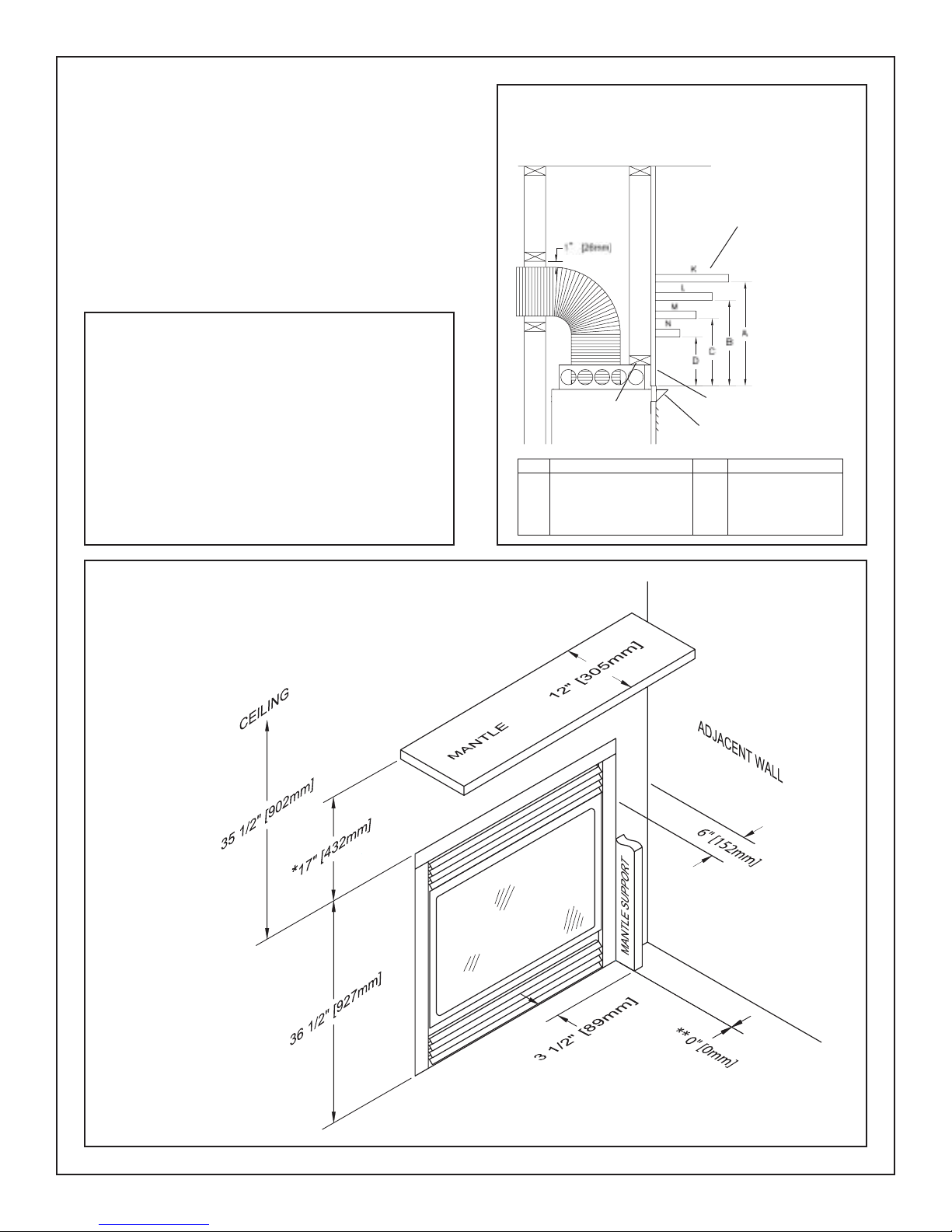

Fig. # 3

MANTEL CLEARANCES

WITH MANTEL SHIELD

The Estate Fireplace is designed to be framed at zero clearance

to combustible material with conventional lumber. Ensure framing

dimensions are maintained during construction.

NOTE: If a screen front is installed, cement board will be required on

the front face, see required clearances on the following page, and the

Screen Front Framing Section.

Minimum Clearances to Combustibles:

Side standoffs .......................................0 in. (0 mm)

Back standoffs ......................................0 in. (0 mm)

Top standoffs ........................................0 in. (0 mm)

Adjacent sidewall: .................................6 in. (152 mm)

Ceiling to appliance: .....................35 1/2 in. (902 mm)

Mantel to appliance: ...........................17 in. (432 mm)

Maximum mantel extension: ...............12 in. (305 mm)

With Mantel Shield ..........................See Figure # 3

Mantel support (3 1/2" wide max.) ........0 in. (0 mm)

Pacifi c Energy Vent pipe ......................1 in. (25 mm)

Simpson Dura-Vent GS pipe ......... 1-3/4 in. (45 mm)

Fig. # 2

Clearance without

*

mantel shield

COMBUSTIBLE MANTEL

HEADER

Ref. Mantel Width Ref. Clearance

K 12" (305 mm) A 17" (432 mm)

L 9 1/4" (235 mm) B 14" (356 mm)

M 6 5/8" (168 mm) C 11" (279 mm)

N 4" (102 mm) D 8" (203 mm)

FINISHED WALL

MANTEL SHIELD

**Allow 1/2" for

Screen Door Installations

4 ESTATE_H 250505-36

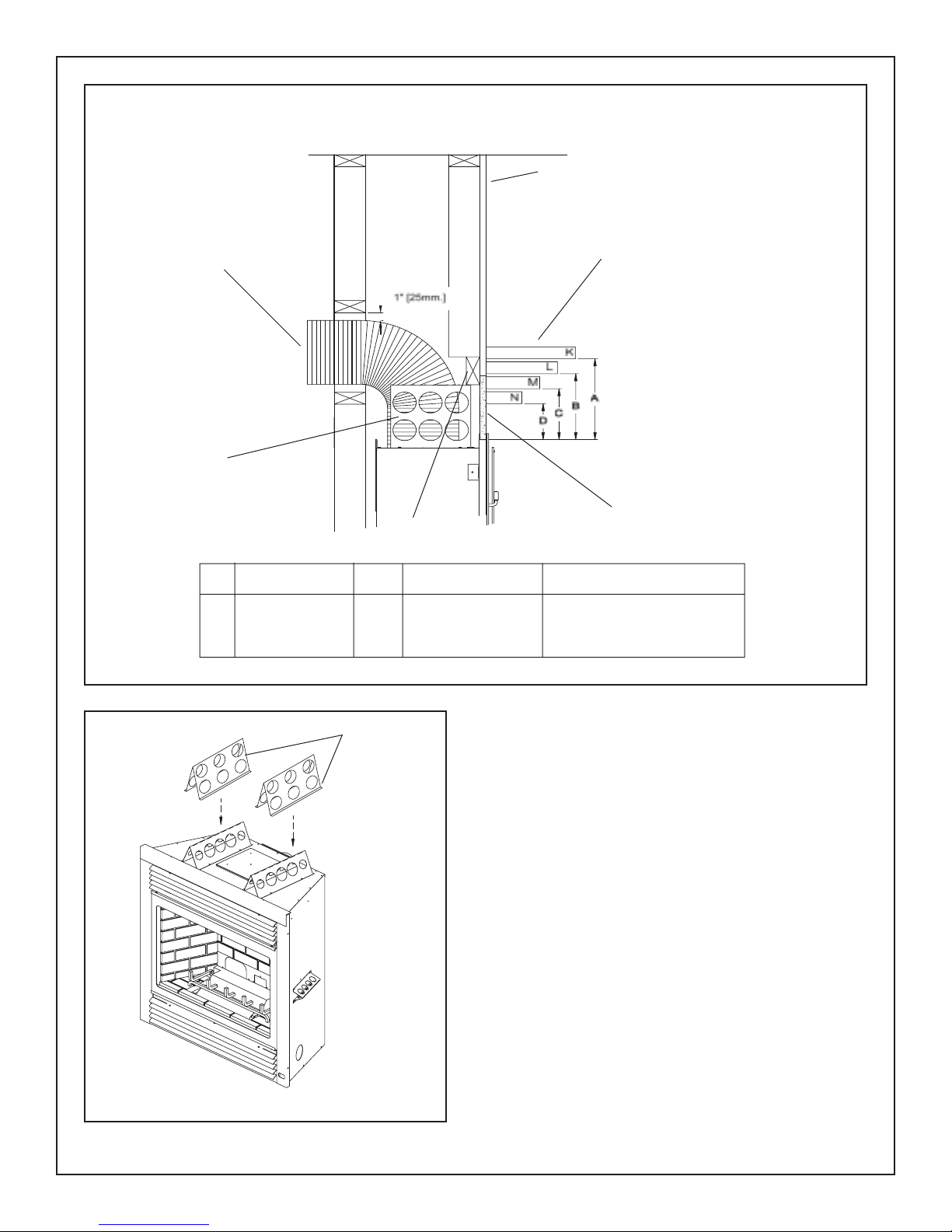

Fig. # 3a

MANTEL CLEARANCES

WITH OPTIONAL SCREEN FRONT

FINISHED WALL

TOP OR

REAR

VENTING

TOP

EXTENDED

STANDOFF

HEADER

Ref. Mantel Width Ref. Clearance Clearance

Top Edge of Screen Top Edge of Unit

K 12" (305 mm) A 16 1/4" (413 mm) 17 (432 mm)

L 9 1/4" (235 mm) B 13 1/4" (337 mm) 14" (356 mm)

M 6 5/8" (168 mm) C 10 1/4" (260 mm) 11 " (280 mm)

N 4" (102 mm) D 7 1/4" (184 mm) 8" (203 mm)

COMBUSTIBLE

MANTEL

8" HIGH

CEMENT BOARD

MANDATORY WITH

SCREEN DOORS

Fig. # 3b

Top

Extended

Standoffs

OPTIONAL SCREEN DOOR

TOP STANDOFFS

The Estate Fireplace is shipped with the short top standoffs in place

and the extended top standoffs loose. If the Optional Screen Door

is to be installed, the short standoffs must be replaced with the

extended standoffs.

1) Remove the four screws attaching each top standoff in place

and remove the standoffs.

2) Position extended top standoffs in the same place and attach

with the four screws.

CHASE INSULATION

When installing this replace against a non-insulated exterior wall

or chase, it is recommended that the outer walls be insulated to

same degree as other exterior walls. Do not place the replace

directly against the insulation. Cover the insulation and plastic

vapour barrier with a solid surface, such as drywall (sheetrock).

Consult local codes.

250505-36 ESTATE_H 5

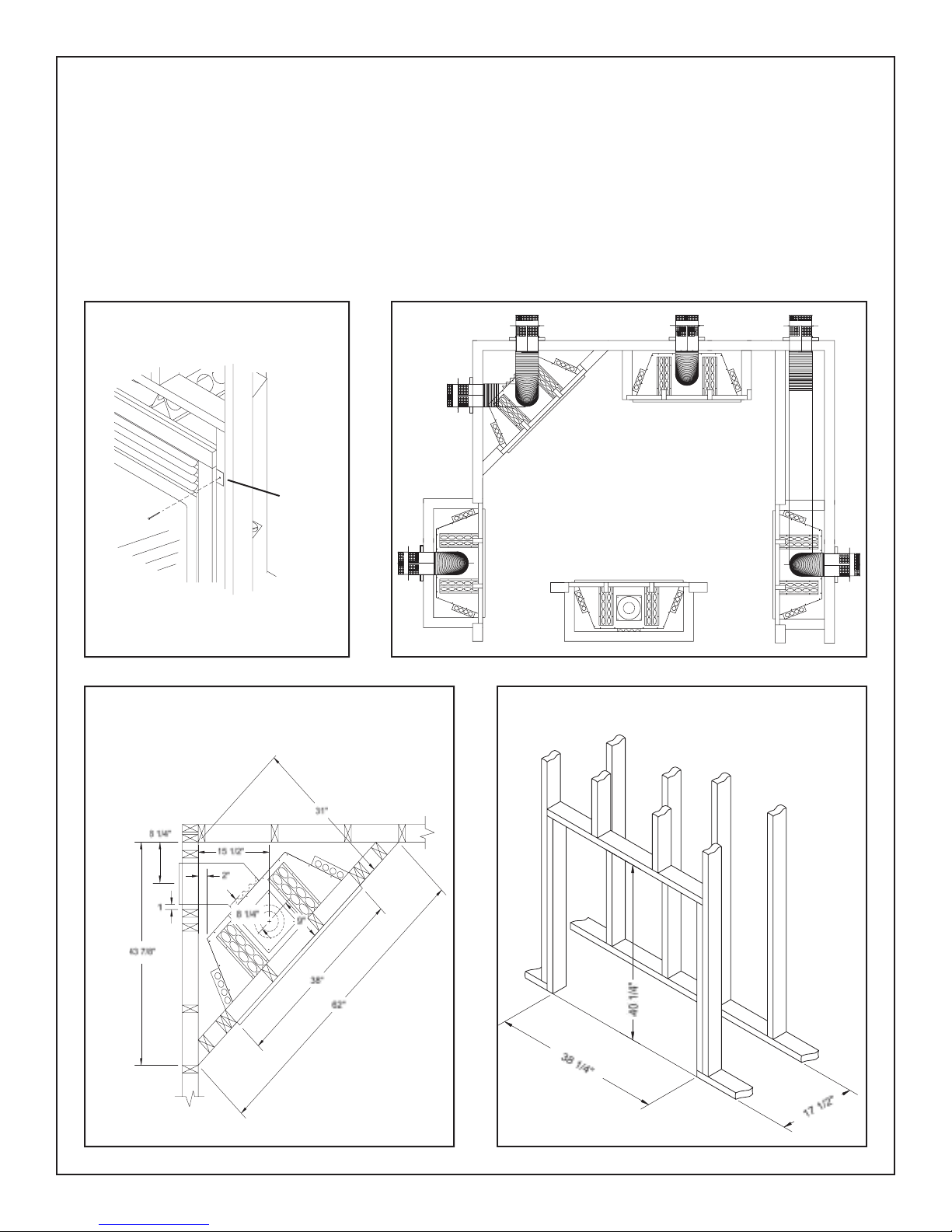

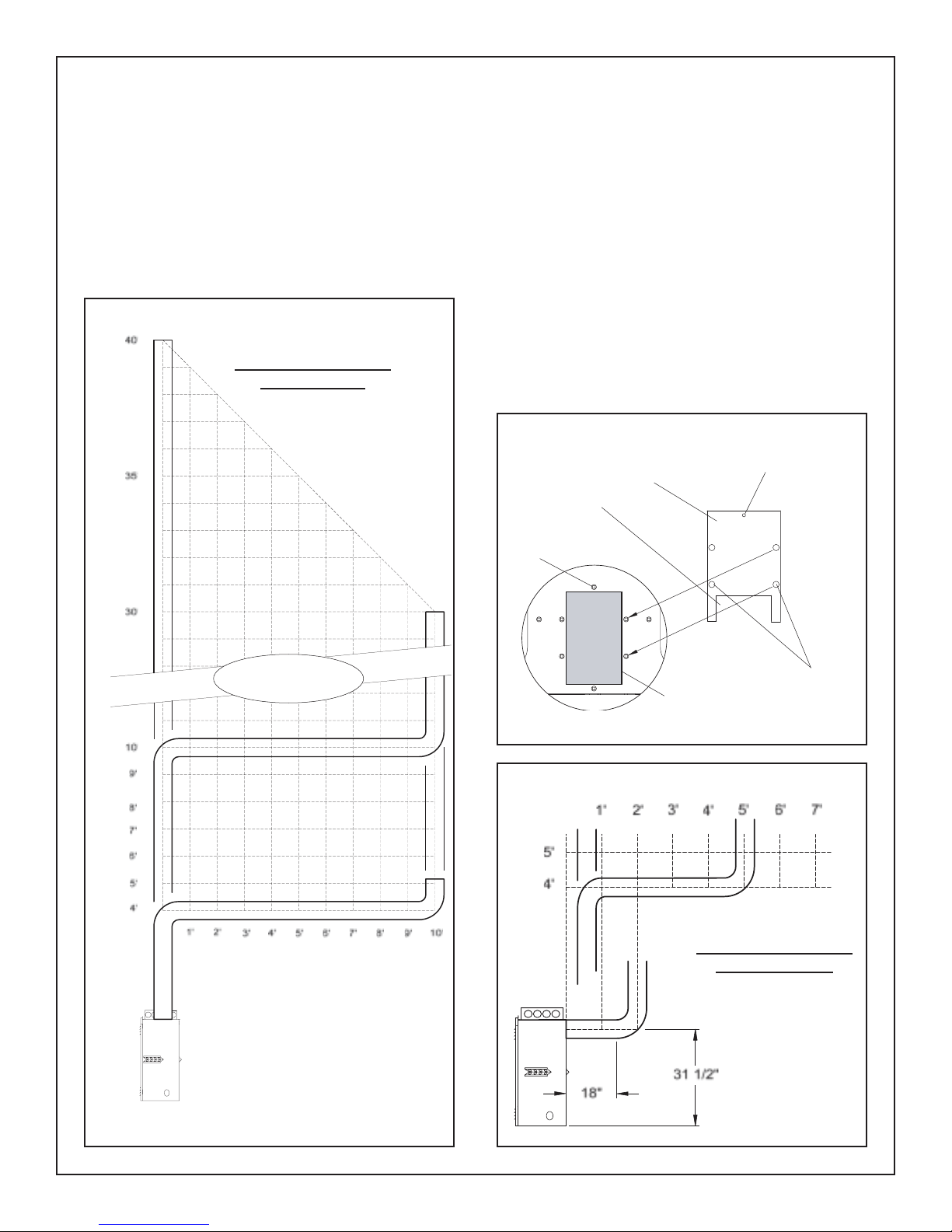

FRAMING WITHOUT SCREEN DOOR

In planning the installation for the Estate Fireplace, it is necessary to

determine where the unit is to be installed, location of vent system

and where gas supply piping may be plumbed. It may be installed

into an existing wall, a corner, a built-in wall or a wall projection. (see

Fig. # 5) Due to high temperatures, do not locate this appliance in

areas of high traf c or near furniture or draperies.

Once the nal location has been determined, frame a minimum

opening of 38-1/4 inches wide, 40-1/4 inches high and 17-1/2 inches

deep with conventional 2 x 4 lumber. (see Fig. # 6 and # 7) It may

be preferred to frame the replace after it is positioned and the vent

system is installed. Heavier construction may be required for some

Fig. # 4

NAILING

TAB S

Fig. # 5

installations, consult local building codes for speci c requirements.

Ensure framing dimensions are maintained during construction.

Bend out the two nailing tabs on each side and secure the replace

to framing with screws or nails. (see Fig. # 4) The tabs will allow

for a 3/4 inch thick nishing wall. The wall may be nished up to the

replace facing with combustible material. (see Fig. # 3)

The minimum clearances from the appliance to combustible surfaces

are shown on Fig. # 2 and # 3. Adequate clearances around air openings and combustion air supplies are required. If installing a screen

front, see required clearances in that section.

Examples of

Common Installation

Locations

Fig. # 6

CORNER FRAMING

DIMENSIONS

Fig. # 7

FRAMING DIMENSIONS

6 ESTATE_H 250505-36

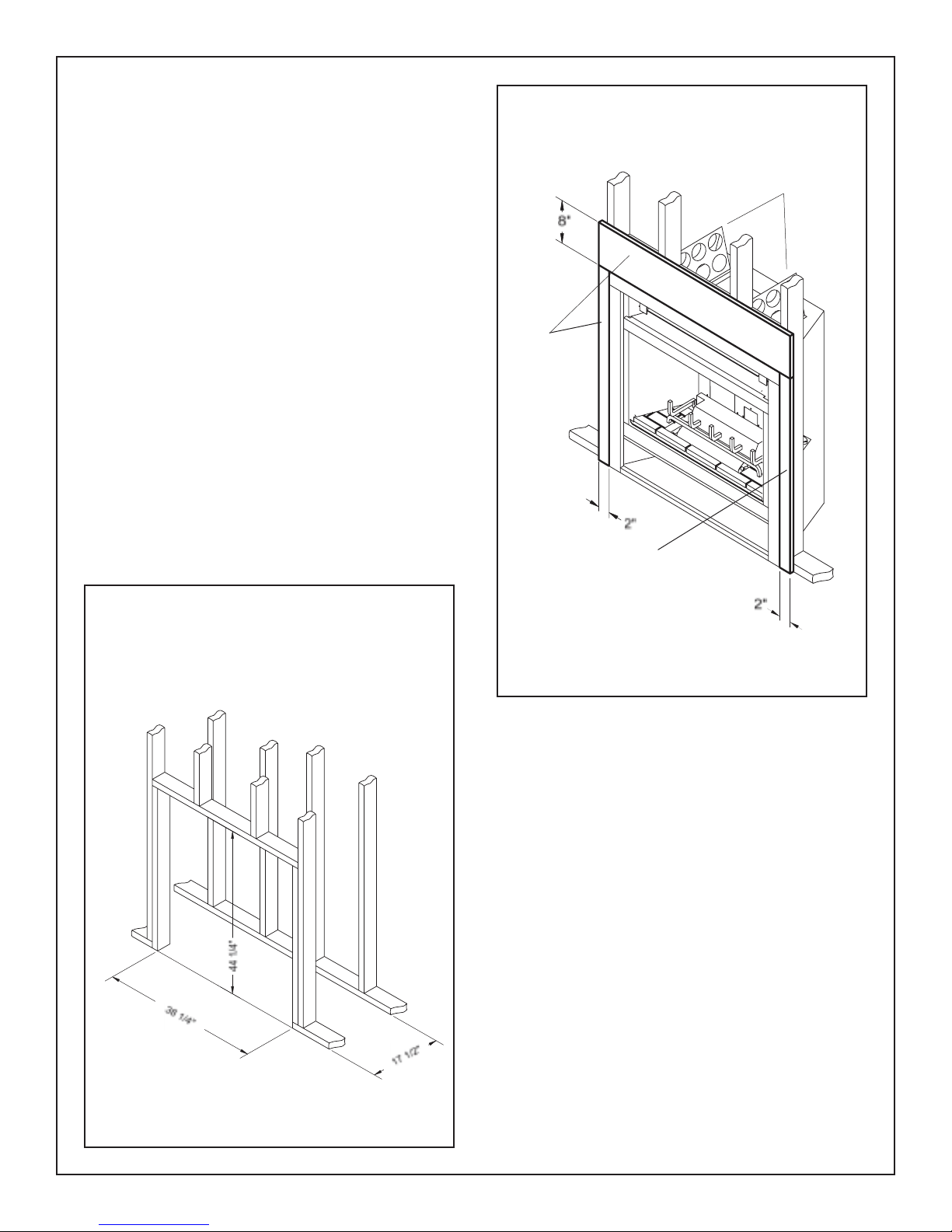

FRAMING FOR SCREEN DOOR

In planning the installation for the Estate Fireplace, it is necessary to

determine where the unit is to be installed, and where the location of

vent system and gas supply piping may be plumbed. Various installations are possible, such as, into an existing wall, a corner, a built-in

wall or a wall projection (see Fig. #5). Due to high temperatures, do

not locate this replace in areas of high traf c or near furniture or

draperies.

Once the nal location has been determined, frame a minimum

opening of 38-1/4 inches wide, 44-1/4 inches high and 17-1/2 inches

deep with conventional 2 x 4 lumber (see Fig. #6 & 7a). It may be

preferred to frame the replace after it is positioned and the vent

system is installed. Heavier construction may be required for some

installations, consult local building codes for speci c requirements.

Ensure framing dimensions are maintained during construction.

Bend out the two nailing tabs on each side and secure the replace

to framing with screws or nails (see Fig. #4). The tabs will allow for

a nishing wall up to 3/4 inch thick, if thicker, unit must be spaced

outwards accordingly.

Due to higher temperatures with the Screen Door, concrete board (or

other non-combustible material) must be used to sheet in the front of

the replace. The concrete board must extend 8" above and 2" down

the side of the unit. See gure #7b. Standard sheetrock (drywall) may

be used beyond this and up to the sides of the replace.

Fig. #7b

Concrete

Board

CONCRETE BOARD DETAIL

Extended

Top Standoffs

Fig. # 7a

FRAMING DIMENSIONS

OPTIONAL SCREEN DOOR

Concrete

Board

Concrete board (or other non-combustible material)

must extend 8" above and 2" down the side of the unit.

The minimum clearances from the appliance to combustible surfaces

are shown on Fig. # 2 & 3a. Adequate clearances around air openings

and combustion air supplies are required.

Refer to the replace installation manual supplied with the unit for

additional requirements.

HEARTH EXTENSION

The Estate replace is designed to be installed on a combustible

oor. A noncombustible hearth extension is not required for this

model. If one is desired, the hearth extension must be ush to the

bottom of the replace.

250505-36 ESTATE_H 7

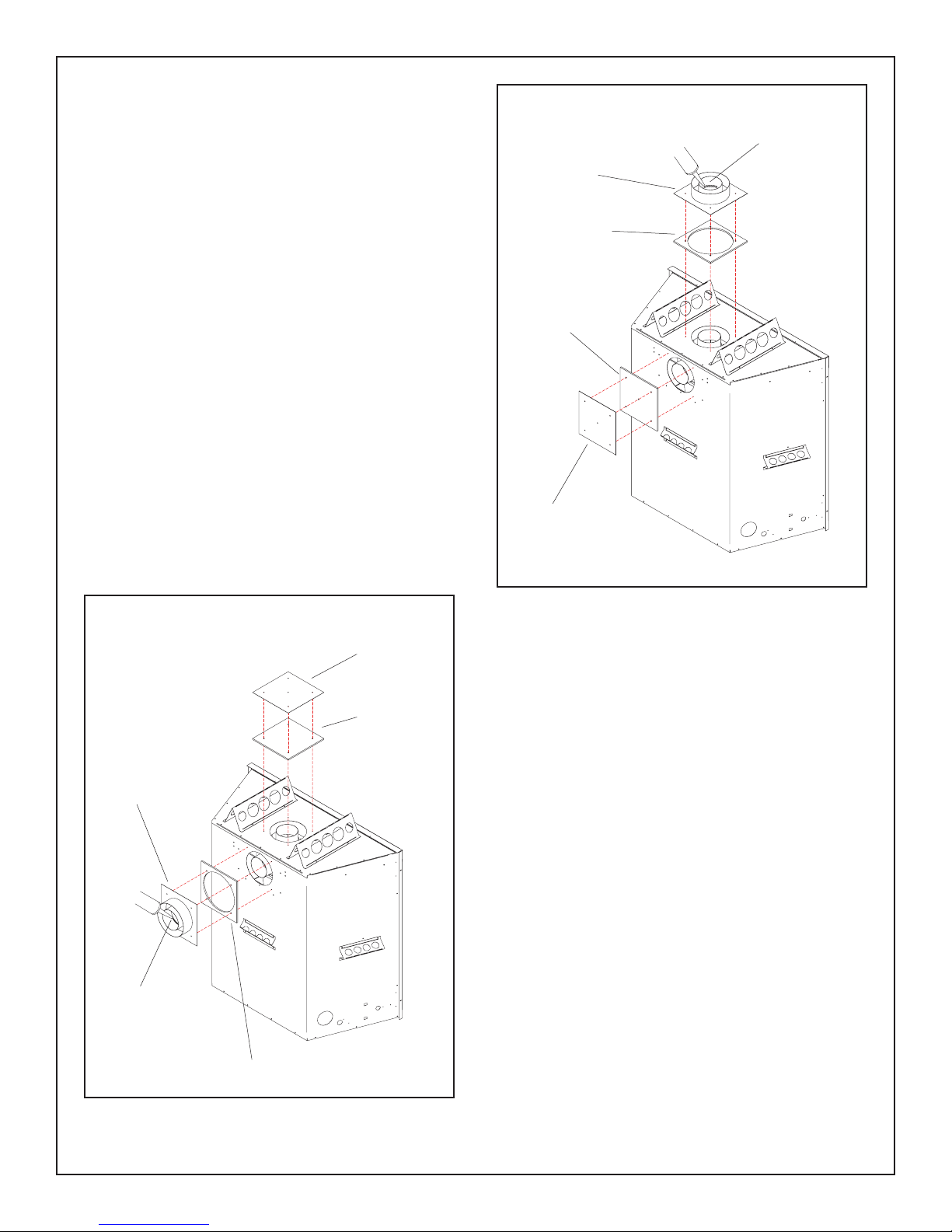

TOP OR REAR VENT

Caution: The vent outlet not being used for venting must be blocked

with the vent cover plate and gasket.

The Estate is capable of top or rear vent applications. The replace

is factory set for top vent application (see Fig. #8a).

If you choose to use this appliance in a rear vent application you

must re- install the vent cover plate and gasket on the top vent outlet

(see Fig. #8b).

Vent cover plate removal and installation.

Fig. # 8a

Black Sealant

Vent Adapter

Adapter Gasket

1) Remove the ve # 8 x 1/2" sheet metal screws that attach the

vent cover plate to the rear of the appliance. Remove the cover

plate and gasket. Be careful not to damage the gasket.

2) Remove the four screws around the top vent outlet.

3) Place the gasket and vent cover plate over the top vent outlet.

4) Secure in place with screws previously removed (see Fig.

#8b).

Fig. # 8b

Vent Cover

Plate

Vent Cover

Gasket

Vent Cover

Gasket

Vent Cover

Plate

VENT ADAPTER INSTALLATION

The Estate replace easily adapts to use either the Paci c Energy Flex

Vent, or the Simpson Dura-Vent GS venting system. Each system

requires a speci c vent adapter. Use the Paci c Flex Vent adapter

(ENCD.PEADPT) or the Dura-Vent adapter (ENCD.DVADPT).

Vent Adapter

Black Sealant

Adapter Gasket

8 ESTATE_H 250505-36

Supplied with each adapter is a ceramic gasket (# 5068.2761) that

must be used.

Installation:

The adapter 4" pipe must be sealed to the replace 4" vent outlet. Failure

to seal this joint may cause the replace to not operate properly.

1) Apply a bead of black sealant (supplied with the replace) to the

inside of the ared end of adapter (See Figs. #8a &8b).

2) Place the gasket and vent adapter over the vent outlet and align

with attachment holes.

3) Secure in place with the four #8 x 1/2” sheet metal screws previously removed.

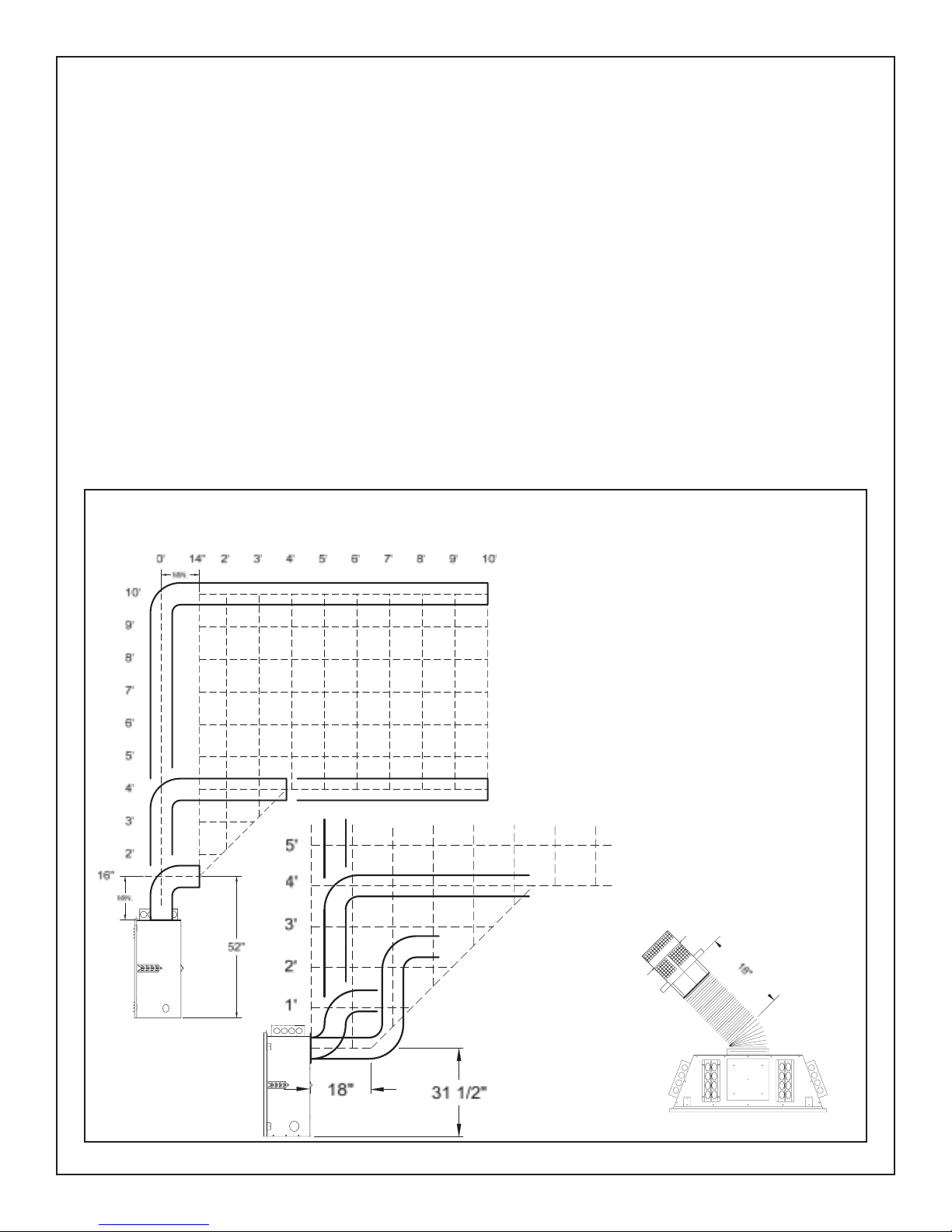

VENTING

Before installing venting for this unit, the installer should read these

instructions to ensure that the proper vent con guration has been

selected.

Use only Paci c Energy vent kits #:

GASC.WALKIT - Wall Termination Kit

ESTD.ROTKIT - Roof Termination Kit

ESTD.VP05 - 5' Vent Pipe Kit

ESTD.VP10 - 10' Vent Pipe Kit

Standard roof ashing or ashing listed below may be used.

ESTD.ROFLAT - Flat Roof Flashing ( at roof)

ESTD.ROADJ - Adjustable Roof Flashing (1/12 to 7/12 pitch)

ESTD.ROSTP - Steep Roof Flashing (8/12 to 12/12 pitch)

Vent system components approved for use with the Estate Fireplace

are shown in Figure # 9 and Appendix A. The Estate Fireplace is

also tested and certi ed for use with SIMPSON DURA-VENT DIRECT

VENT GS pipe (see Optional Venting section).

NO OTHER VENTING SYSTEMS OR COMPONENTS MAY BE

USED.

Various combinations of vertical and horizontal runs may be used.

Refer to Figures # 8c, 8d, & 8f for details. For optimum performance

and ame appearance, keep the vent length to a minimum. Connections between each vent system component must be tightly joined

and sealed, and secured with sheet metal screws at each joint. A

horizontal run of vent must have a 1/4" rise for every 2 ft.of run towards the termination.

Fig. # 8c

PACIFIC ENERGY

WALL TERMINATION VENTING

HORIZONTAL RUN

CAUTION: UNDER NO CONDITION SHOULD COMBUSTIBLE

MATERIAL BE CLOSER THAN 1 INCH FROM THE VERTICAL

AND HORIZONTAL SECTIONS OF THE PACIFIC ENERGY VENT

SYSTEM OR 1-3/4 INCHES FROM THE SIMPSON DURA-VENT

DIRECT VENT GS SYSTEM.

Exterior wall opening:

IMPORTANT: Before cutting an opening in an exterior wall, ensure

correct vent terminal location by referring to the clearance speci cations noted on Figure #13.

It is preferred to cut an opening between two building framing members to avoid any extra framing. Consult your local building codes

prior to proceeding. The vent kit will accommodate a maximum wall

thickness of 11-1/2 inches.

Having determined the vent terminal location, cut and frame an opening of 10-1/2 inches. The opening may be round or square. Minimum

distance from the nished oor to the centre of the opening in a at

wall is 52 inches, and 59-1/4 inches in a corner installation for top

vent, or 31-1/2" for rear vent. Height of the opening will vary with

each installation. As the horizontal vent run increases, so does the

minimum vertical rise.

NOTE: The vent must not exceed

a total length of 20 feet. Any combination of rise and run may be

used but must be constrained to

the boundaries of this chart. For

each additional 90° elbow, reduce

vent length by 2 feet. For each

additional 45° elbow, reduce vent

length by 1 foot.

VERTICAL RISE

NOTE: The minimum top exit vent

length is a combination of 16" rise

and 14" run. For longer venting

confi gurations, the rise and run

must be constrained to the boundaries of this chart.

1' 2' 3' 4' 5' 6' 7'

NOTE: At 31 1/2" up, the maximum horizontal rear exit vent

length is 18" with a 45° elbow

(see below).

250505-36 ESTATE_H 9

PACIFIC ENERGY

ROOF TERMINATION VENTING AND VENT RESTRICTOR

NOTE:

The vent must be a minimum 4' long and must not exceed

a total length of 40'. Any combination of rise and run may be used

but must be constrained to the boundaries of the charts shown in

Figs. #8d & 8f.

Fig. # 8d

ROOF TERMINATION

TOP VENTING

Included with the unit is a Vent Restrictor. This item is used for air

ow regulation when the vent height is 25 ft. or more. Installation of

this restrictor ensures proper ame appearance for the wide variety of

vent con gurations. If the ames are bent forward and have excessive

movement, the vent restrictor is required.

Refer to the Burner Removal section for installation location of the

restrictor (see Fig. #21). Remove the glass front, and the two rear

logs. Remove the one top mounting screw shown in Fig. #8e, place

the restrictor over the hole, and replace the one screw.

Fig. # 8e

MOUNTING SCREW

HOLE

RESTRICTOR AIR

OPENING

MOUNTING SCREW

VENT RESTRICTOR

VERTICAL RISE

Vent Restrictor

required above

25 ft.

HORIZONTAL RUN

NOTE: The vent must not exceed a

total length of 40 feet. Any combination

of rise and run may be used but must

be constrained to the boundaries of this

chart. For each additional 90° elbow,

reduce horizontal vent length by 2 feet.

For each additional 45° elbow, reduce

horizontal vent length by 1 foot.

Fig. # 8f

VERTICAL RISE

AIR INLET OPENING

AT FIREBOX BACK.

PLACE RESTRICTOR

DIRECTLY OVER

THIS OPENING

HORIZONTAL RUN

ROOF TERMINATION

REAR VENTING

SCREW

CLEARANCE

HOLES

NOTE: The vent

must have a minimum of 4' rise

10 ESTATE_H 250505-36

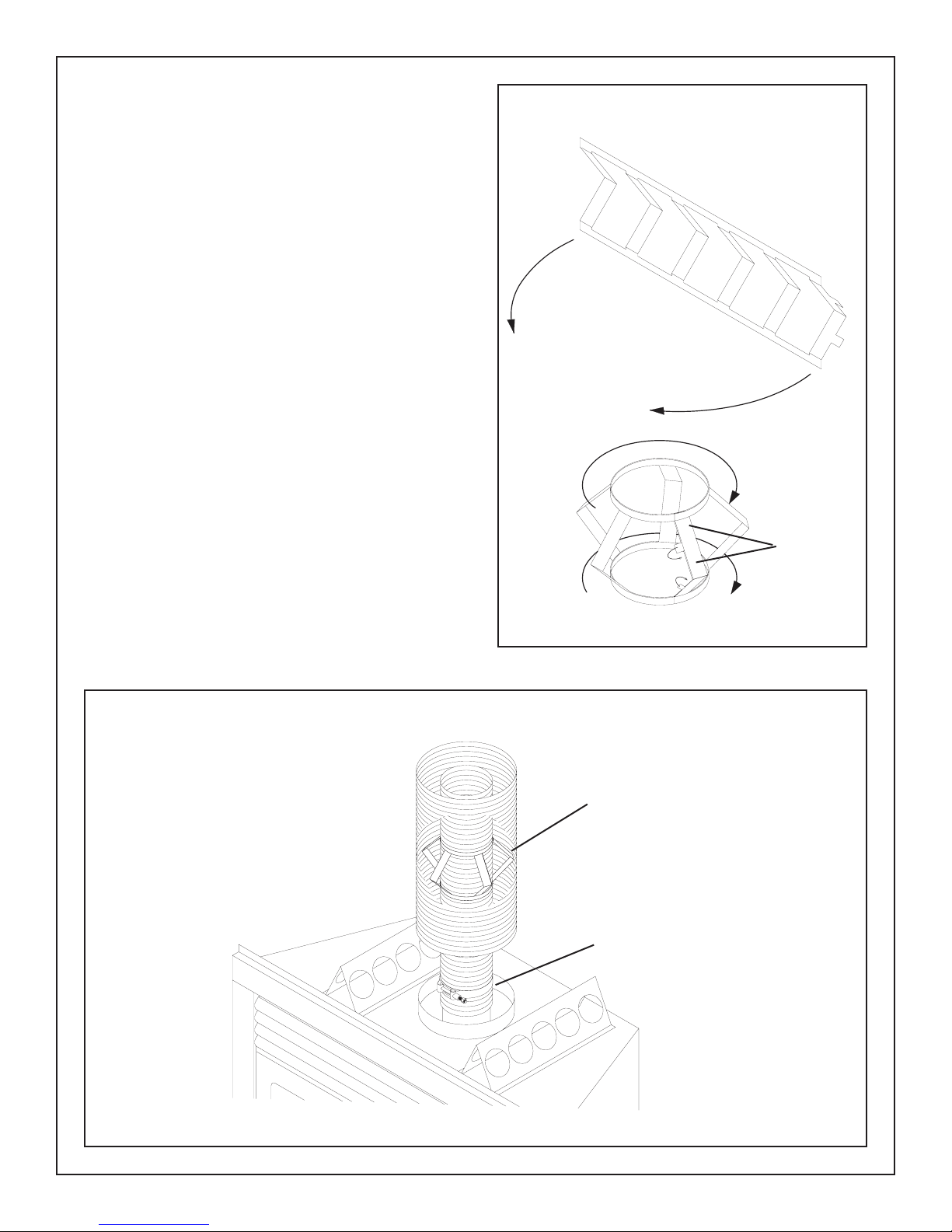

VENT CONNECTION

Note: This section refers only to Paci c Energy ex vent.

Attaching the venting to the unit before framing begins is preferred.

Once the replace is in position proceed to attach the venting. (see

Fig # 9)

The exible vent pipe may be stretched to accommodate various

lengths of venting. Stretch and/or cut to length as required.

The 4 inch exible inner pipe must be centred inside the 8 inch pipe

with pipe spacers provided. Pipe spacers should be installed at

maximum 2 foot intervals. (see Fig. # 10) Spacers may have to be

closer if pipe is bent 90°.

1) Bend pipe spacer around the 4 inch inner pipe. With ends of

spacer overlapped, bend locking tabs into place. (see Fig. # 10)

2) Slip the 4 1/2 inch pipe clamp loosely over the inner ex pipe.

Slide the pipe a minimum 1 1/2 inches over the inner sleeve collar of

the appliance. Clamp tightly in place (see Fig. # 9). No additional

seal is required. Secure in place with screws provided.

3) Slip the 8 inch outer ex pipe onto the larger collar and secure

in place with screws provided. Seal the joint with high temperature

sealant provided.

Fig. # 10

BEND TABS

OVER

Fig. # 9

PIPE SPACER

PIPE CLAMP

250505-36 ESTATE_H 11

Loading...

Loading...