Pacific energy Classic Gas, Super 27 Gas Installation And Operating Insctruction Manual

IMPORTANT:

THESE INSTRUCTIONS ARE TO

REMAIN WITH THE

HOMEOWNER

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or loss of life.

-- Do not store or use gasoline or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

--WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbour’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

--Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

This appliance may be installed in an

aftermarket permanently located,

manufactured (mobile) home, where not

prohibited by local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

Classic Gas

and

Super 27 Gas

SERIES A

DIRECT VENT HEATER

INSTALLATION

AND OPERATING

INSTRUCTIONS

251104-24 CLGA-A 5056.423

Contents

CAUTION ....................................................................................... 3

SAFETY ......................................................................................... 4

MAINTENANCE............................................................................. 4

BASE KIT INSTALLATION ........................................................... 5

DOOR KIT INSTALLATION ........................................................... 5

GAS SUPPLY ................................................................................ 6

FLOOR PROTECTION................................................................... 6

ATTACHMENT TO FLOOR ........................................................... 6

CLEARANCES .............................................................................. 6

VENTING REQUIREMENTS ......................................................... 7

WALL TERMINATION VENTING .................................................. 8

ROOF TERMINATION VENTING .................................................. 9

VENT RESTRICTOR ADJUSTMENT ......................................... 10

VENT TERMINAL CLEARANCES.............................................. 11

GLOWING EMBERS .................................................................... 12

INPUT RATE CONVERSION ...................................................... 13

PROPANE CONVERSION .......................................................... 14

LOG SET ...................................................................................... 15

LIGHTING INSTRUCTIONS ........................................................ 16

FIRST FIRE .................................................................................. 16

OPERATION ................................................................................ 17

PRIMARY AIR ADJUSTMENT .................................................... 17

OPTIONAL WALL SWITCH OR THERMOSTAT ........................ 18

OPTIONAL BLOWER .................................................................. 19

REPLACEMENT PARTS - Classic Gas ..................................... 20

REPLACEMENT PARTS - Super 27 Gas................................... 21

REPLACEMENT PARTS - Burner Assembly............................ 22

RATING LABEL........................................................................... 23

2

Important: When lit for the first time, the appliance

will emit a slight odour for a couple of hours. This is

due to the curing of paints, sealants and lubricants

used in the manufacturing process. This condition is

temporary. Open doors and windows to ventilate

area. If optional fan kit has been installed, place fan

in the "OFF" position. Smoke and fumes caused by

the curing process may cause discomfort to some

individuals.

It is normal for fireplaces fabricated of steel to give off

some expansion and/or contraction noises during the

start up or cool down cycle. Similar noises are found

with your furnace heat exchanger or cook stove oven.

CAUTION

FOR YOUR SAFETY - Do not install or operate your Pacific

Energy heater without first reading and understanding this

manual. Any installation or operational deviation from the

following instructions voids the Pacific Energy Warranty and

may prove hazardous.

This appliance and its individual shutoff valve must be

disconnected from gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psig. (3.5 kPa).

This appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.5 kPa).

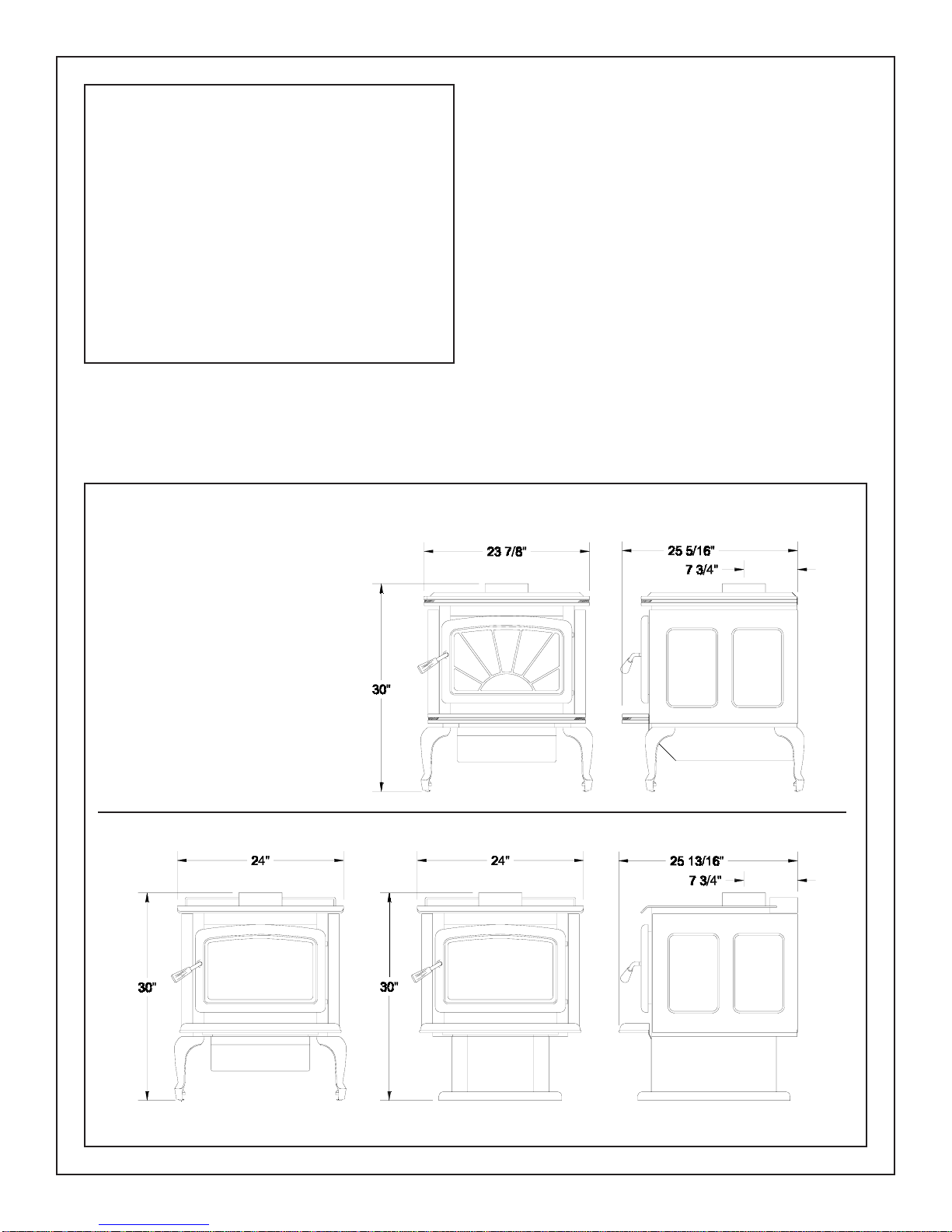

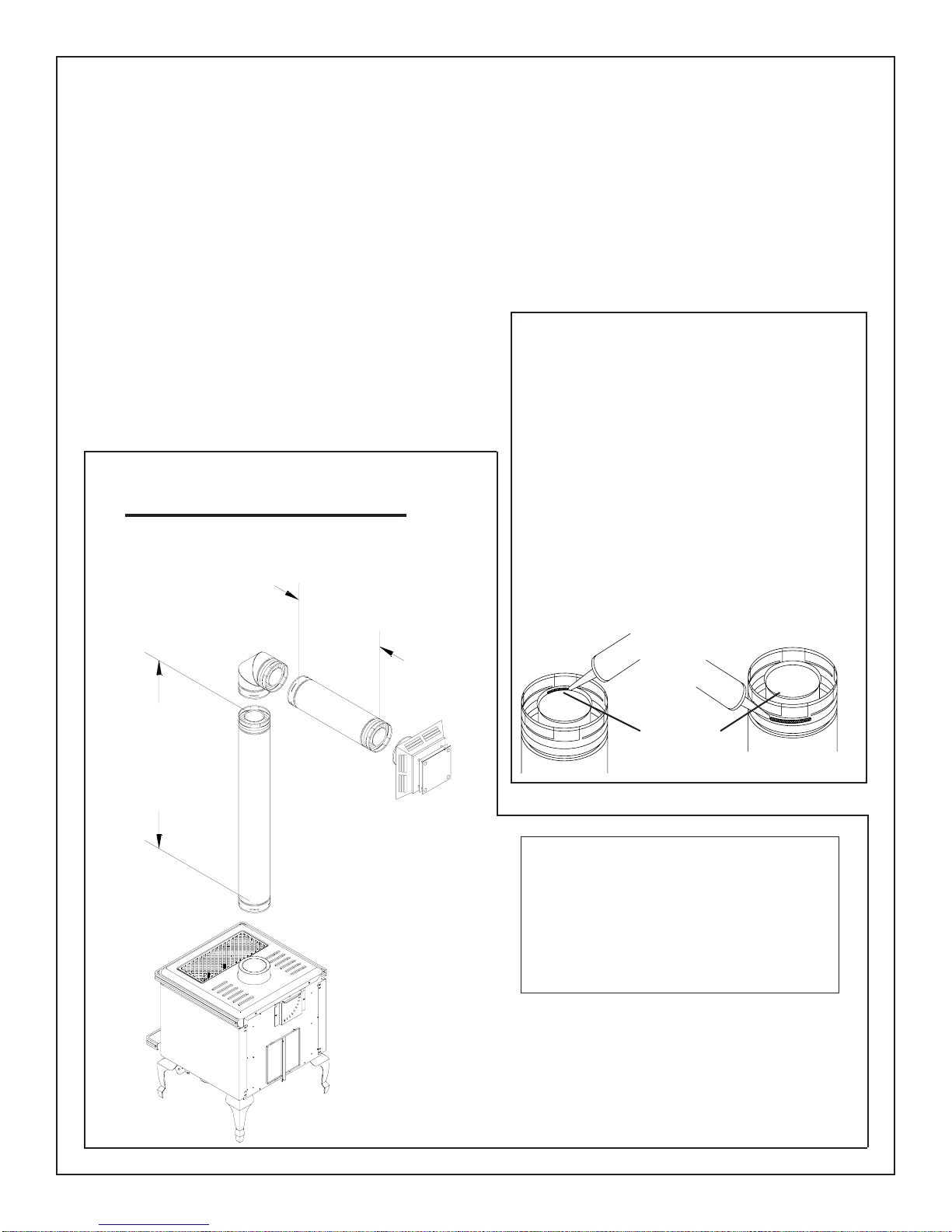

Fig # 1

Classic Gas

Super 27 Gas

Leg Model Pedestal Model

3

SAFETY

MAINTENANCE

• Due to high temperatures, this gas appliance should be

located out of traffic and away from furniture and draperies.

• Children and adults should be alerted to the hazards of

high surface temperatures and should stay away to avoid

burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothing or other flammable material should not be

placed on or near the appliance.

• Under no circumstances should this fireplace be

modified. Any grill, panel or door removed for servicing the

unit must be replaced prior to operating. Failure to do so

may create a hazardous condition.

• Installation and repair should be done by a qualified

service person. The appliance should be inspected before

use and at least annually by a professional service person.

More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is imperative

that control compartments, burners and circulating air

passageways of the appliance be kept clean.

It is Pacific Energy’s policy that no responsibility is assumed

by the Company or by any of its employees or

representatives for any damages caused by an inoperable,

inadequate, or unsafe condition which is the result, either

directly or indirectly, of any improper operation or

installation procedures.

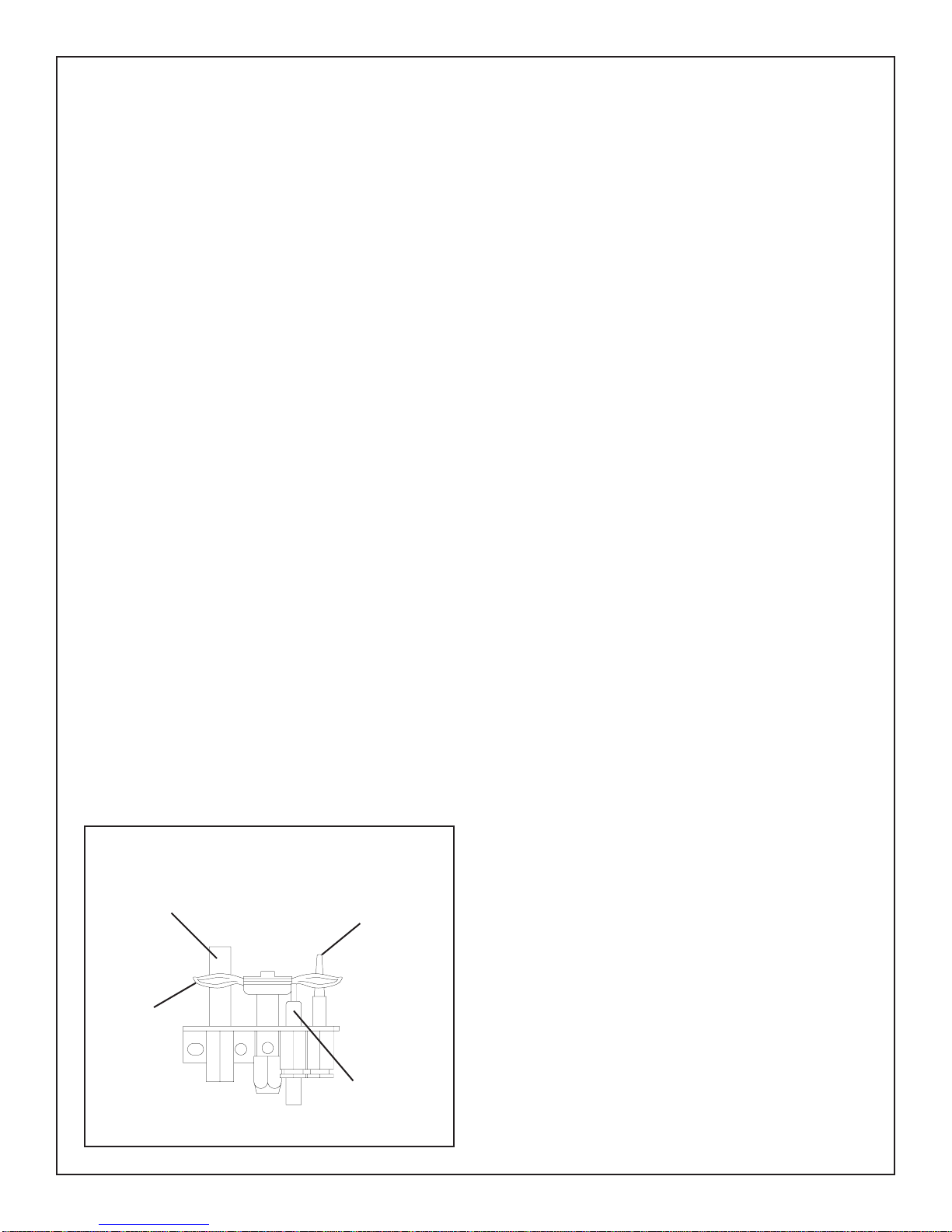

Fig. # 2

Caution: Turn off gas and electrical power supply and allow

ample time for unit to cool before servicing appliance. It is

recommended that this appliance and venting should be

inspected at least once a year by a qualified service person.

Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system or gas

control which has been under water.

Door Glass

Warning: Do not operate appliance with glass panel

removed, cracked or broken. Replacement of glass should

be done by a licensed or qualified service person.

Do not strike or otherwise impact the glass in anyway that may

cause it to break. If the glass becomes cracked or broken, it

must be replaced before using the fireplace. Replacement

glass can be obtained from your nearest Pacific Energy

dealer. The size required is 9 1/8" x 15 5/8" x 5 mm. Use

ceramic glass only. Do not substitute with any other type.

To remove broken glass, undo the four retaining screws and

remove the frame, noting position for re-assembly. Remove

all particles of glass. Be careful as they are very sharp. Install

new glass complete with gasket. Replace frame and screws.

Annual Inspection:

a) Clean air passage ways of excessive lint and dust buildup

from carpeting, bedding material, etc. The flow of ventilation

air must not be obstructed.

b) Inspect logs and burner assembly for lint and soot buildup. If excessive build-up of soot is present, have a qualified

service person inspect and adjust unit for proper combustion.

Clean logs and burner with a vacuum cleaner, paying close

attention to the ports on the burner.

c) Check the pilot system for proper flame size and operation.

Clean pilot free of lint and dust. (See Fig. #2)

d) Check that the vent pipe and vent terminal are open and

free from blockage or debris. If the venting system is

disassembled for cleaning, it must be properly assembled

and re-sealed.

e) Check door and glass panel gasket, replace if necessary.

It is important that the glass and door seal be maintained in

good condition.

Note: The appliance area must be kept clear and free from

combustible materials, gasoline and other flammable vapours

and liquids.

THERMOPILE

PILOT

FLAME

4

THERMOCOUPLE

Periodically:

a) Viewing glass may be cleaned with fireplace glass cleaner.

b) Exterior finish may be cleaned with mild soap and water.

Caution:

- do not use abrasive cleaners on glass or any other part of this

appliance.

- do not clean glass when hot.

ELECTRODE

BASE KIT INSTALLATION

Crate removal

1) Carefully remove crate top, side supports and plastic

cover bag.

2) Leave the unit on the pallet.

Leg Kit (Classic Gas model only)

1) Remove the 1/2" nuts and washers from the studs on the

bottom corners of the stove using a 3/4" wrench. Save nuts and

washers for later use.

2) Remove the lag bolts that secure the unit hold down

brackets to the pallet.

2) Remove the hold down brackets and discard.

3) Position the legs onto the studs.

4) Place 1/2" washer over the studs and secure in place

with 1/2" nut previously removed.

4) Remove the unit from the pallet and install.

Pedestal Kit (Super 27 Gas model only)

1) Remove the ash lip assembly and pedestal from the

shipping box.

2) Align ash lip assembly mounting screws into slots of the

pedestal door and secure in place.

3) Using a 3/4" wrench, remove the 1/2" nuts and washers

from the studs on the bottom corners of the stove. Save

nuts and washers for later use.

4) Lift the unit off the hold down brackets and carefully

place unit on its back, taking care to not damage the

restrictor positioning panel located on the back of the

unit.

5) Align the pedestal mounting holes with the studs on the

stove.

6) Secure the pedestal to the stove with the 1/2" nuts and

washers previously removed.

7) Carefully place the unit in an upright position.

DOOR KIT INSTALLATION

1) Remove door from packing box and inspect.

2) Position door onto hinge pins located on the right side

of the firebox opening.

3) Latch door closed by lifting safety catch and rotating

door handle counter-clockwise till latched.

Fig. # 3

Leg Adapter (Super 27 Gas model only)

1) Remove the ash lip and adapter from the shipping box.

2) Align the ash lip mounting slots with the studs on the front

control access door. Secure in place with 1/4" nuts.

3) Using a 3/4" wrench, remove the 1/2" nuts and washers

from the studs on the bottom corners of the stove. Save

nuts and washers for later use.

4) Lift the unit off the hold down brackets and carefully

place unit on its back, taking care to not damage the

restrictor positioning panel located on the back of the

unit.

5) With the control access door facing up, align the adapter

mounting holes with the studs on the stove bottom.

6) Position the legs on to the studs.

7) Place 1/2" washer over the studs and secure legs in

place with 1/2" nut previously removed.

8) Carefully place the unit in an upright position.

5

GAS SUPPLY

CLEARANCES

Caution: The gas line should be installed by a qualified

service person in accordance with all building codes.

Consult local and/or national building codes before

proceeding.

Correct gas line diameter must be used to assure proper

operation. The gas control is equipped with a captured screw

type pressure test point, therefore it is not necessary to provide

a 1/8 inch N.P.T. plugged tapping pressure test port for

checking gas pressure immediately upstream of the gas

supply connection to the appliance.

The gas valve inlet accepts a 3/8" N.P.T. fitting. For leg model

units, it is recommended to use the optional flex gas connector

(#GASC.GASCON). Route the gas connector inside the

adapter to the rear. Fasten connector to the right side near the

back with the bracket. Alternately, the gas supply line may

enter through the 4" diameter hole located in the base of the

leg adapter. This will allow the installation of the optional

blower kit.

Correct gas pressure requirements:

Natural Gas Propane

Min. Pressure 5.0" wc 11.5" wc

(For purpose of input adjustment)

Max. Pressure 10.5" wc 13.0" wc

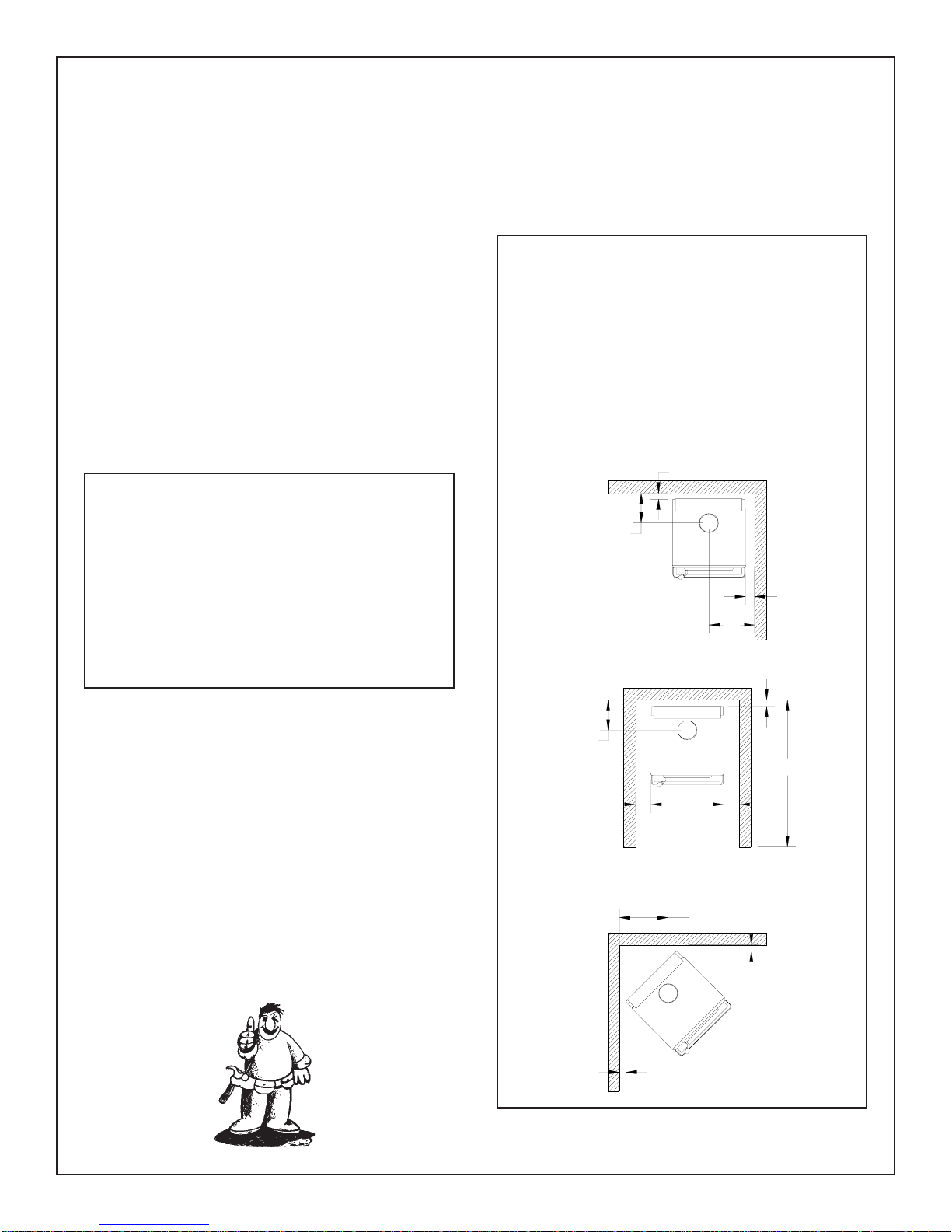

The minimum clearances from the appliance to combustibles

are shown on Fig. #4. Adequate clearances around air

openings and combustion air supplies are required.

Fig. # 4

Minimum Clearance

to Combustibles

Sidewall to Appliance 3 in. (76 mm)

Rearwall to Appliance 2 in. (51 mm)

Corner to Appliance 2 in. (51 mm)

Alcove sidewall to Appliance 5 in. (127 mm)

Alcove minimum width 34 in. (864 mm)

Alcove maximum depth 48 in. (1.2 m)

Alcove minimum height 61 in. (1.5 m)

2"

9 3/4"

3"

Manifold Pressure

Maximum 3.8" wc 11.0" wc

Minimum 1.1" wc 2.9" wc

FLOOR PROTECTION

Both, the Classic Gas and Super 27 Gas Heaters, may be

installed directly on a combustible floor. If the appliance is to

be installed directly on carpeting, combustible floor tile or

other combustible material other than wood flooring, the

appliance shall be installed on a metal or wood panel

extending the full width and depth of the unit.

ATTACHMENT TO FLOOR

Mobile Home installations require that the appliance be firmly

attached to the structure. Once the appliance is in it's final

location, secure the unit in place through holes in the pedestal

base. The holes are located on the left and right hand side of

the base.

9 3/4"

15"

2"

48"

5"

ALCOVE HEIGHT

61" MINIMUM

15 3/4"

2"

5"

2"

6

VENTING REQUIREMENTS

The heater installation and venting must conform with local

codes or, in the absence of local codes, with the current

Canadian Installation Code, CAN/CGA-B149.1 (in Canada)

or the current National Fuel Gas Code, ANSI Z223.1 (in the

USA). Only qualified (licensed or trained) personnel should

install this product.

The Classic Gas and Super 27 Gas Heaters are tested and

certified for use with SIMPSON DURA-VENT DIRECT VENT

GS pipe or SECURITY CHIMNEYS SECURE VENT system.

Vent components approved for use are listed in Figure 4. Kits

for venting either through the wall or vertically through the roof

are available from the vent system manufacturer or your

nearest Pacific Energy Authorized Dealer.

Before installing the vent system, the installer should read

these instructions to ensure proper installation requirements

are maintained. Follow vent pipe manufacturer's instructions

for assembly and installation.

NO OTHER VENTING SYSTEMS OR COMPONENTS MAY

BE USED.

CAUTION: UNDER NO CONDITION SHOULD

COMBUSTIBLE MATERIAL BE CLOSER THAN 1 INCHES

FROM ANY VERTICAL OR HORIZONTAL VENT SECTIONS.

Connections between each vent system component must be

tightly joined and sealed, and secured with sheet metal

screws at each joint.

Consult your local Building Codes before beginning the

installation.

Vent Pipe Sealant

SIMPSON DURA-VENT DIRECT VENT GS pipe: All

vent pipe sections must be sealed. Run a 1/8 inch

wide bead of sealant around the male end of the outer

pipe and female end of the inner pipe as shown

below, and twist-lock the vent pipe sections together.

Fig # 5

WALL TERMINATION

Minimum Installation

Horizontal Run

*

Minimum

Vertical Rise

2 Feet

Maximum

1 Foot

SECURITY CHIMNEYS SECURE VENT system: If

only one elbow is used in the vent system, sealant is

not required. Simply twist-lock the vent pipe sections

together. If more than one elbow is used, apply

sealant to inner sleeve of all elbows. Run a 1/8 inch

wide bead of sealant around the female end of the

inner pipe of elbow as shown below, and twist-lock

the vent pipe sections together.

Inner

Pipe Joint

Sealant

Outer

Pipe Joint

Minimum Maximum

Vertical Rise Horizontal Run

2 Feet 1 Foot

3 Feet 2 Feet

4 Feet 3 to 10 Feet

A minimum vertical rise of 2 feet is

*

required for any wall termination. For

horizontal runs greater than 1 foot,

increase vertical rise equally. At 4 feet

of vertical rise, horizontal run may be

up to 10 feet.

7

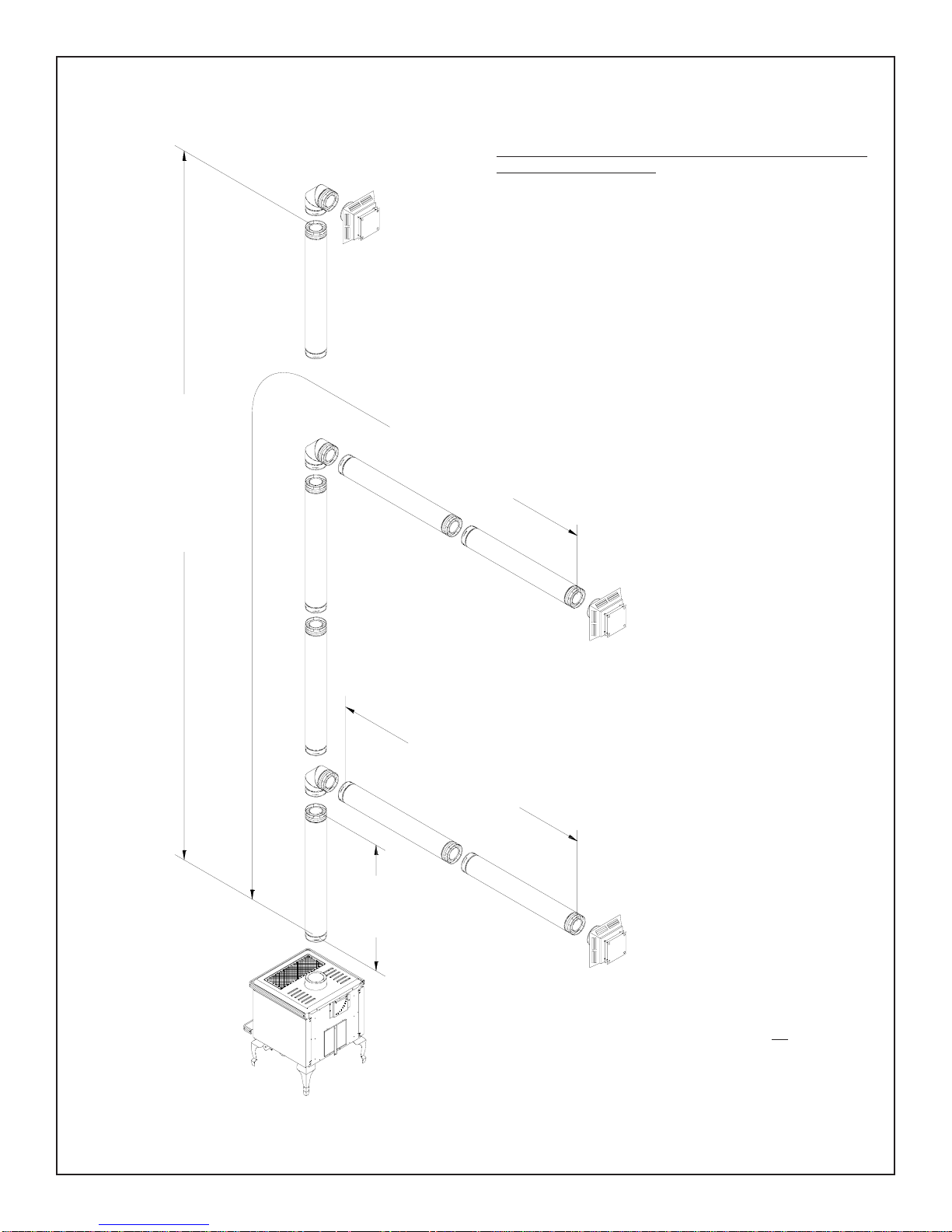

Fig. # 6

Maximum

Vertical Rise

40 Feet

*

Maximum

Vent Length

40 Feet

WALL TERMINATION VENTING

A minimum vertical rise of 2 feet is required for any wall

termination (see Fig. #5).

For horizontal runs greater than 1 foot, increase vertical rise

equally. At 4 feet of rise, the horizontal run may increase up

to and must not exceed 10 feet. A maximum of two 90° or 45°

elbows may be used. If more than 2 elbows are used, reduce

horizontal run by 2 feet for each additional set of elbows.

For optimum performance and flame appearance, keep the

vent length to a minimum. Connections between each vent

component must be tightly joined and sealed. A horizontal run

of vent must have a 1/4 inch rise for every 1 foot of run towards

the termination.

*

Horizontal Run

Minimum Rise

4 Feet

Maximum

10 Feet

Total horizontal run must not exceed 10 feet.

*

Use a maximum of one 90° elbow or two 45°

elbows. If more than 1 elbow is required,

reduce horizontal run by 2 feet for each

additional 90° elbow and 1 foot for each

additional 45° elbow.

8

Loading...

Loading...