Pacific Wolverine PF7 Installation Manual

Wolverine PF7

Edger Sander

OWNERS MANUAL & OPERATING INSTRUCTIONS

MAY 2010 REF. 69 PART # 000510

From Serial Number

04453 (110 Volt)

PACIFIC

NORTH AMERICAN SAFETY INSTRUCTIONS

USE AND APPLICATION

WARNING: This floor sanding machine must be grounded.

This floor-sanding machine shall be grounded while in use to protect the operator from electric

shock. The machine is provided with a three-conductor cord and a moulded three-contact

grounding type attachment plug to fit the proper grounding type receptacle. The Green (or

Green and Yellow) conductor in the cord is the grounding wire. Never connect this wire to other

than the grounding pin of theattachment plug.

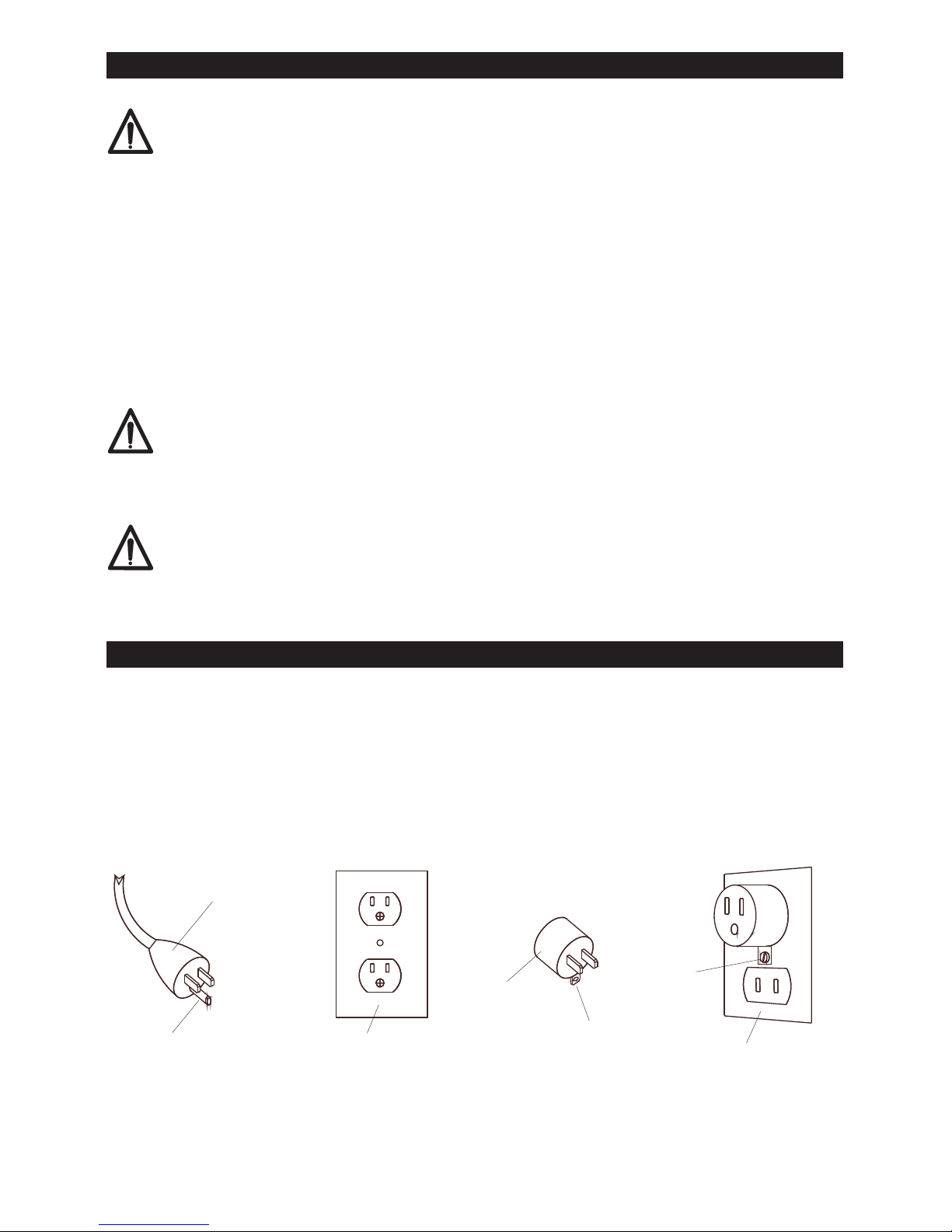

This floor-sanding machine is provided with an attachment plug as shown in sketch A. It is

intended for use on a nominal 120 volt circuit. If a properly grounded receptacle as shown in

sketch A is not available, an adaptor as shown in sketch 'C' should be installed as shown in sketch

B if the outlet box that houses the receptacle is grounded. Be sure to fasten the grounding tab with

a metal faceplate screw.

Floor sanding can result in an explosive mixture of fine dust and air. Use floor-sanding machine

only in a well-ventilated area freefrom any flame or match.

Moving Parts - to reduce the risk of injury, unplug the machine before replacing abrasive sheets

or carrying out any form ofadjustment or servicing.

WARNING:

WARNING:

Risk of explosion.

Of potential injury.

This machine is intended for commercial use connected with the laying and maintaining of wooden floors and

decks.

These types of surfaces may be found both in commercial andhousehold environments.

ATTACHMENT PLUG

SKETCH ‘C’

METAL

SCREW

COVER OF GROUNDED

OUTLET BOX SKETCH ‘B’

ADAPTER

GROUNDING

MEANS

COVER OF GROUNDED

OUTLET BOX SKETCH ‘A’

GROUNDING PIN

Manufactured in UK © Hiretech

CONTENTS

WARNING

MAINS CABLE WIRING - PLUG

SPARE PARTS

SPECIFICATION

SAFETY

SET UP

PREPARATION

OPERATION

FLOOR SANDING TECHNIQUE

FLOOR TYPES

i

i

I

1

1

Assembly and Transport 2

Installing Abrasive Disc 2

2

2,3

Drum Floor Sander 4

Edger Sander 4

Hand Sanding 4

Sanding Plank & Strip Floors 4

Parquet & Block Floors 4

6

General 7

Visual Inspection 7

Dust Control System 7

Drive 7

Lubrication 7

Care of Motor 7,8

Sanding Pad Removal & Replacement 8

Sanding Pad Trimming 9

Adjusting the Castors 10

Electrical Testing 10

11

12

13

14

ABRASIVE PAPER GUIDE

SERVICE AND ROUTINE MAINTENANCE

TROUBLE SHOOTING

WOLVERINE PARTS DRAWING

WOLVERINE PARTS LIST

WOLVERINE CIRCUIT DIAGRAM

SERVICE & REPAIR 16

WARNING

MAINS CABLE WIRING - PLUG

For safe operation of this machine, readand understand all instructions. Look for the‘warning/caution’symbol.

This symbol means that if you do not follow the instructions injury can occur to the operator and

damage to themachine and floor may result.

Pacific Floor Care reserves the right to make changes or improvements to it's products without prior notice.

i

NORTH AMERICA

BLACK

WHITE

GREEN

BRASS

TERMINAL

SILVER

TERMINAL

SPARE PARTS

Use Pacific Floor Care genuine spare parts only for service and repair. Use of non-approved parts will void the product

warranty. See the back cover of this manual for the terms and conditions of the Pacific Floor Care Limited Warranty.

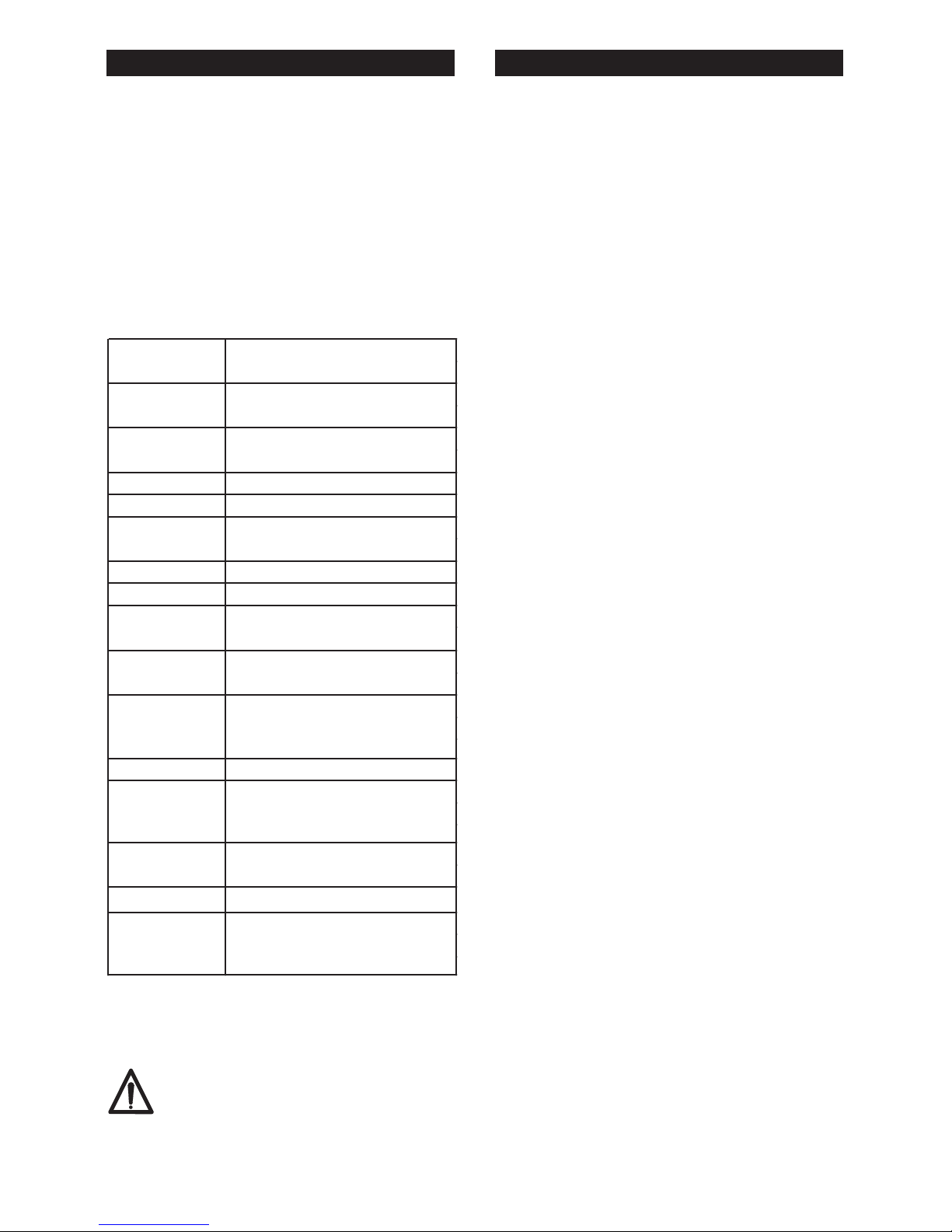

SPECIFICATION

The Pacific Wolverine PF7 Edger Sander will sand

hard and soft wood floors, cork and composition

floors and any solid wood surface that requires rapid

sanding and leveling to a fine finish. Ideal for

confined areas such as closets and stair treads the

will sand right up to the edge of

a floor without damage to the base (skirting) board.

Completely self contained with a high efficiency dust

pick-up the is a high

performance sander suitable for professional and

home owner use.

Pacific Wolverine PF7

Pacific Wolverine PF7

SAFETY

1. For safety it is recommended that a residual

current circuit breaker (ground fault interrupter)

is used with this machine.

2. Check the operating voltage is correct and that

the machine is switched OFF (O) before

connecting to the power supply.

3. Never attempt to lock the switch in the ON (I)

position with tape or by any other means.

4. Always disconnect from the power supply when

changing the abrasive disc, servicing the floor

sander, replacing the dust bag or leaving the

machine unattended.

5. Always replace the dust bag (paper type) or

empty the dust bag (cloth type) when the dust in

the bag reaches the ‘MAX’ line or when the

machine is left unattended.

6. Never dispose of or empty the contents of the

dust bag into a fire or incinerator.

7. Never reuse the paper dust bag or use a non

standard bag. Cloth type bags must be in good

condition with no holes.

8. Always wear a dust mask when using the floor

sander, handling the dust bag or cleaning the

machine after use.

9. Wearear protection when using the floor sander.

10. Ensure adequate ventilation of the work area to

avoid the formation of a combustible mixture of

flying dust and air.

11. Never smoke when using or servicing the floor

sander or when handling the dust bag.

12. Never expose the machine to rain or damp.

Always store in a dry place.

13. Stop the floor sander immediately if damage to

the machine or abrasive disc is suspected.

14. Never allow the powercable to come into contact

with the sanding disc when the floor sander is in

operation. If the power cable becomes damaged

and the inner conductors are exposed switch the

power OFF and remove the plug before

attempting to move the machine. The cable must

be replaced by an authorized agent or qualified

electrician using genuine Pacific Floor Care

spare parts only.

15. Keep hands, feet and loose clothing away from

all moving parts of the machine.

16. Punch down or remove all nails, screws, tacks

and other fixings from the floor before sanding to

prevent contact with the sanding disc.

17. Never use the machine above waist height as

control will be lost.

18. Keep children and pets clear atall times.

19. If the machine should fail to operate refer to the

fault finding guide on page 8.

1

CAUTION - read the following Safety

and Operational notes before using your

.PacificWolverine PF7 Edger Sander

Noise: 100 dBa at 1metre (3’ 3")

Switch: Bias Off, double pole.

Motor RPM: 13,000

Disc RPM: 3,000

Moving Pa rts: Sealed for life ball bearings.

Weight: 16.4kg (36.2lbs)

0.04 M² H Aeq8

(8 Hr. RMS )

7" (178") dia. x 7/8“ (22mm) dia.

centre hole. 24 to 120 grit fibre or

paper back.

Abrasive:

Continuous heavy duty AC/DC self

cooling 4 brush.

7" (178mm) dia. Metal backed and

rubber bonded.

High impact ABS with bronze bush.

Hardened steel alloy pinion and

large diameter aluminium bronze

drive gear.

Seated oversize vacuum fan,

disposable paper dust or cloth

bag.bags

Disc Guard:

Drive:

110/120 V 50/60 Hz

220/240 V 50/60 Hz

110/120 V 8A

220/250 V 5A

Average

Load Current:

110/120 V 15A

220/250 V 8A

Dust Pickup:

Vibration:

Power Supply:

Off Load

Current:

Motor:

Sanding Pad:

SET UP

Assembly and Transport

Installing Abrasive Disc

1. Always carry the floor sander by the two handles

with the bag frame in the up position and the

power cable stowed around the bag frame.

Protect the sanding disc with an abrasive disc

and ensure that the clamp bolt is secure. Ensure

that the floor sander is secure and cannot move

when being transported in a vehicle. The floor

sander is heavy. Take care when lifting and

carrying the machine.

2. To prepare the floor sander for use place the

machine on the floor and remove the cable from

the bag frame. Check that the cable is in good

condition and that all fittings are secure.

3. Lower the dust bag support frame and fit a paper

dust bag following the instructions printed on the

bag. Do not reuse or use a non standard bag. If a

cloth type bag is used ensure that it is tied securely

around the dust outlet and that the bag is in good

condition with no holes.

4. To dismantle the floor sander reverse procedure

2 to 3 above.

1. Ensure the power cable is disconnected from the

power supply.

2. Tip the floor sander upside down and rest the

machine on it's top and handles.

3. Remove the Wrench Ref.61 from the clips inside

the skirt of the floor sander situated in between

the castors and remove the Bolt Clamp Ref.59

and Washer Clamp Ref.58 from the center of the

sanding disc.

4. Select a suitable grade of abrasive disc (see

Abrasive Paper Guide on page 5).

5. Place the bolt clamp through the center of the

washer clamp and abrasive disc and carefully

thread the bolt into the sanding disc.

6. Using the wrench, tighten the bolt clamp

ensuring that the abrasive disc is centered and

the washer clamp is properly located. The bolt

should be secure but do not try to over tighten.

Heavy grit abrasive discs will seat down as you

tighten the bolt so take care to ensure the washer

CAUTION - never fit more than one

abrasive disc . If more than one abrasive

disc is fitted the setup of the sander will

be affected and the clamp bolt and

washer and sanding pad will be

damaged.

clamp is properly located. Heavy grit abrasive

discs may not lie flat on the sanding disc, this is

quite normal and the abrasive disc will flatten

immediately upon operation.

7. Do not use damaged or incorrectly sized

abrasive discs under any circumstance, damage

will result to the machine and floor.

1. Where possible remove all furniture from the

area or room. The Pacific Wolverine PF7 Edger

Sander features an efficient dust pickup, however,

some dust will escape. Protect all vulnerable

furnishings with dust sheets.

2. Remove all tacks, staples and other unwanted

fixings from the floor. Failure to do so will result

in damage to the abrasive disc and sanding disc.

3. Punch all nails below the surface of the floor

using a suitable nail punch and hammer. Any

screws used to fix boards should be counter sunk

below the surface. During sanding, any nails or

screws that become exposed must be punched or

counter sunk further.

4. Firmly fix all loose boardsor blocks.

5. Remove heavy wax, grease and dirt deposits by

hand.

6. Sweep and vacuum the floor thoroughly to

remove dirt and discarded fixings.

7. Ensure good ventilation by opening windows.

8. If sanding a work bench or similar work piece

follow the instructions above to prepare it ready

for sanding. Make sure that the work piece is

secure. Never use the floor sander above waist

height.

Note: Use Pacific Floor Care genuine floor sander

abrasives for the best sanding performance and

finish.

1. Move the floor sander to the location of your

work.

2. Make sure the switch is in the OFF (O) position

then connect the power cable to a suitable power

supply ideally located behind or to one side of

the machine and work area.

3. Weara dust mask and ear defenders.

4. Kneel behind the machine on one knee (use knee

pads to protect knees) and hold both handles

with the power cable held in the right hand in a

small loop and then pass the cable over the right

PREPARATION

OPERATION

2

shoulder. Tilt the floor sander back so that the

sanding disc does not touch the floor or work

piece.

5. Switch ON by pushing the ON/OFF switch to (I)

position and hold in place with your thumb. To

switch OFF (O), release the pressure on the

switch and it will automatically return to the OFF

position.

6. Now lower the floor sander slowly forward so

that the abrasive disc comes into contact with the

floor or work piece. At the same time move the

machine in a sideways motion so when the

abrasive disc comes into contact with the work

surface it is moving to one side. This will ensure

that the sander does not dwell in one position

and damage the floor or work piece.

i. Always ensure that the floor sander is

moving when in operation and the

sanding disc is in contact with the floor.

ii. Never lift the back of the machine when

sanding.

iii. Never apply pressure to try to increase the

rate of sanding. Damage to the floor or

work piece will occur.

iv. Never bounce or drop the floor sander on

to the floor or work piece, always lower the

machine gently.

v. Never dwell in one place, move steadily at

all times.

vi. Never allow the power cable to come into

contact with the sanding disc.

7. When the dust in the dust bag reaches the ‘MAX’

line stop sanding. Switch OFF (O) and

disconnect the power cable from the power

supply and remove the paper dust bag. Turn the

top of the paper dust bag over to stop the escape

of dust and dispose of into a suitable container.

Never reuse the paper dust bag or empty it.

Never dispose of it into a fire. If the cloth bag is

used empty into a suitable container being

careful to contain the dust. Do not dispose of the

contents into a fire.

CAUTION - the

is a powerful machine.

Always ensure you have a firm grip

before switching on.

CAUTION - to prevent damage to the

floor surface, work piece or machine

follow these rules.

Pacific Wolverine PF7

Edger Sander

3

8. Fit a new paper dust bag, or refit the cloth bag.

Reconnect the floor sander to the power supply

and continue sanding.

9. When taking a break from work switch OFF ‘O’

and disconnect the power cable from the supply,

remove and dispose of the paper dust bag, or

empty the cloth bag as detailed in 7. above.

Never leave the floor sander unattended with a

dust bag in place containing dust.

10. On completion disconnect the power cable from

the supply. Remove and dispose of the paper

dust bag, or empty the cloth bag as detailed in 7.

above. Replace the bag frame in its up position

and stow the power cable. Leave the old abrasive

disc inplace to protect the sandingdisc. Carry out

maintenance as recommended in Maintenance

and Servicing.

DANGER - never leave the floor sander

unattended with dust in the dust bag.

Always remove the dust bag and dispose

of into asuitable container.

Loading...

Loading...