Pacific Triumph 1200 Maintenance Manual

Electronic Service

Manuals

This electronic document is provided as a service to our customers.

We do not create the contents of the information contained in this document. Should you have detailed questions pertaining to the information

contained in this document, you may contact Michco, or the manufacturer which provided the original information in this electronic deliverable. Michco’s only part in this electronic deliverable was the electronic

assembly process. By providing this manual on line we are not guaranteeing parts availability.

You may contact Michco through the following methods:

Phone (517) 484-9312 or (800) 331-3339

2011 N. High St. -- Lansing, Michigan -- 48906

Fax: (517) 484-9836

Email: CustServe@Michco.com

Web site: www.Michco.Com

Parts Web site: www.FloorMachineParts.Com

Order Parts on Line at:

www.FloorMachineParts.Com

Directly to Parts & Service:

By Email: Shop@Michco.com

By Fax: (517) 702-2041

By Voice: Use numbers above.

Serving the Cleaning Industry Since 1922

Notice: All copyrighted material remains property of original owners, all trademarks are property of respective owners.

Manuals are subject to Manufacturer’s reproduction limitations. Originals or reproductions were provided by manufacturers

through a request. We make no warranty as to the correctness of information provided in this document and you assume

all risk. By placing these manuals on line we are not declaring our corporation to be an manufacturer authorized dealer or

provider, please check our web site for authorized manufacturers we represent.

TRIUMPH 1200

12 Gallon

Box Extractor

OPERA TING & MAINTENANCE

INTRODUCTION INSTRUCTIONS

READ THIS BOOK

This operator’s book has important information for the use

and safe operation of this machine. Read this book carefully before starting the machine. Keep this book and tell all

operators to read the book. If you do not follow the instructions, you can cause an injury or damage equipment, furniture or buildings.

For new books write to:

Pacific Steamex, Inc.

2259 S. Sheridan

Muskegon, MI 49442-6252

Carefully inspect all components to ensure that there is no

concealed freight damage. If such damage is discovered,

file a “CONCEALED DAMAGE REPORT” immediately with

the delivering carrier.

The contents of this manual are based on the latest product

information available at the time of publication. Pacific

Steamex reserves the right to make changes or improvements

to its machines without notice.

FOR YOUR CONVENIENCE, RECORD THE

FOLLOWING IMPOR TANT INFORMA TION:

MODEL

SERIAL NUMBER

P ART NUMBER

DA TE PURCHASED

IMPORT ANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND INSTRUCTIONS

BEFORE USING THIS APPLIANCE!

WARNING! To reduce the risk of fire, electric shock, or injury:

1 . Unplug from outlet when not in use and before servicing.

2 . Do not use outdoors. Protect the machine from rain.

3. Do not allow to be used as a toy. Close attention is necessary when used by or near children.

4 . Use only as described in this manual.

5 . Never use this machine to pick up volatile or explosive materials!

6. Do not use this machine for pick up of dust or dry debris.

7. Do not use with damaged cord or plug. If appliance should not work as it should, has been dropped or

damaged, left outdoors, or dropped into water, return it to service center.

8. Do not pull or carry by cord, use cord as handle, close a door on cord or pull cord around sharp

edges or corners. Do not run appliance over cord. Keep cord away from heated surfaces.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord

10. Do not handle plug or appliance with wet hands. Do not immerse. Keep the machine in a dry building.

11. Do not put any objects into opening. Do not use with any opening blocked: keep free of dust, lint,

hair and anything that may reduce airflow.

12. Keep hair, loose clothing, fingers and all parts of the body away from openings and moving parts.

13. Turn off all controls before unplugging.

14. Do not use in areas where flammable or combustible liquids such as gasoline may be present.

15. Connect to a properly grounded outlet only.

16. Do not use water that is hotter than 82°C (180°F).

17. To prevent damage to the solution system, do not store in freezing temperatures without proper maintenance.

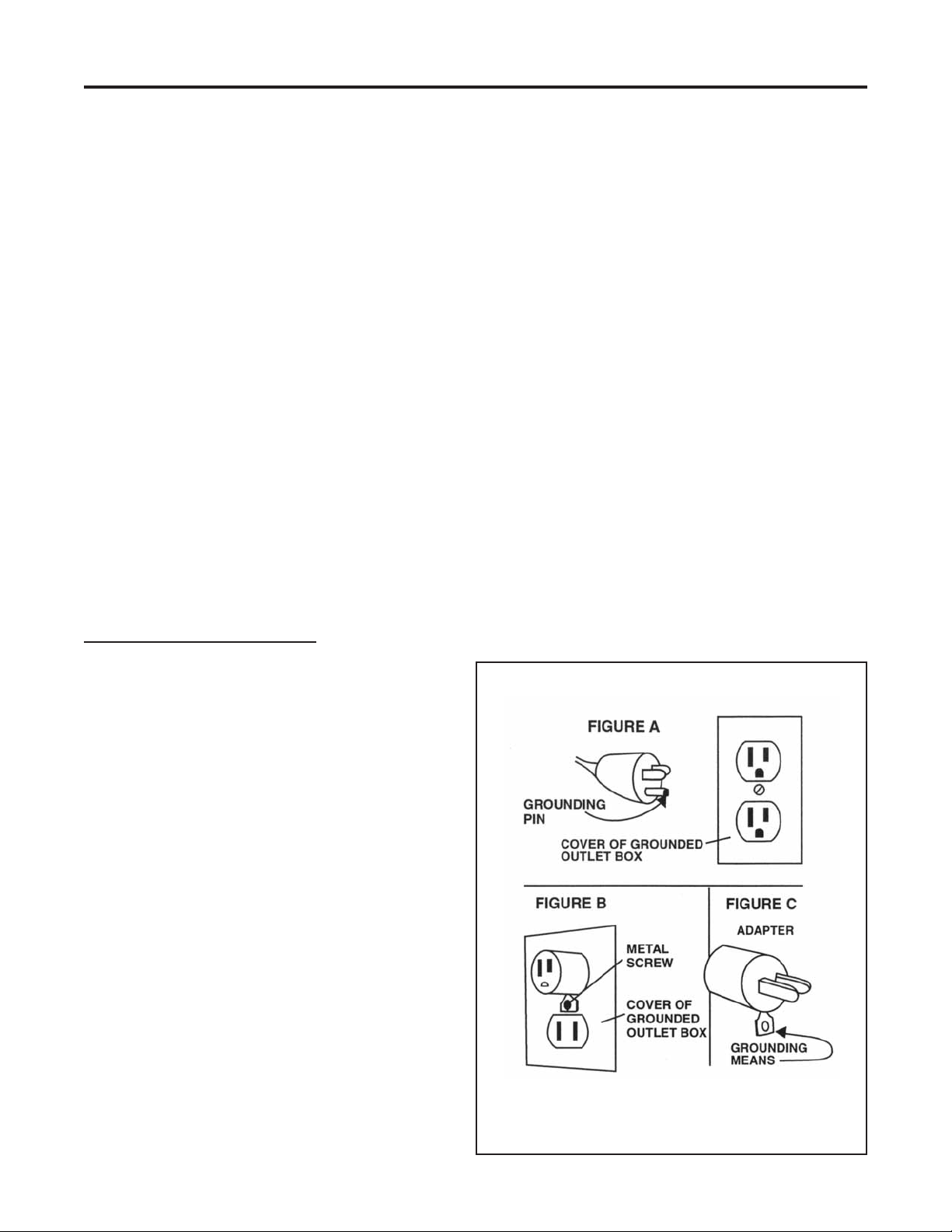

Grounding Instructions

This machine must be grounded. If it should malfunction or break down,

grounding provides a path of least resistance for electric current to reduce the

risk of electric shock. This machine is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be inserted

into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING - Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. Check with a qualified electrician or

service person if you are in doubt as to whether the outlet is properly grounded.

Do not modify the plug provided with the machine - if it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

This machine is for use on a nominal 120-volt circuit, and has a grounded

plug that looks like the plug illustrated in figure A. A temporary adapter that

looks like the adapter illustrated in figures B and C may be used to connect

this plug to a 2-pole receptacle as shown in figure B if a properly grounded

outlet is not available. The temporary adapter should be used only until a

properly grounded outlet (figure A) can be installed by a qualified electrician. The green colored rigid ear, lug, or the like extending from the adapter

must be connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by a metal

screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the

Canadian Electrical Code

EXTENSION CORDS

Use only three-wire 14/3 or larger gauge approved extension cords

that have three-prong grounding type plugs and three-pole receptacles that accept the appliance’s plug. Replace or repair any damaged cords or plugs.

When servicing, refer to authorized person only. Use only identical replacement parts.

NOTE: Do not use adapters shown in figures B & C in Canada

OPERA TING INSTRUCTIONS

W ARNING! For the safe operation of this machine follow

the instructions given in this booklet and the training given

by your supervisor . Failure to do so can r esult in personal

injury and/or damage to machine and property!

DO NOT OPERATE MACHINE IN AN EXPLOSIVE

ENVIRONMENT!

NEVER USE THIS MACHINE TO PICK UP VOLA TILE

OR EXPLOSIVE MA TERIALS!

The model shown in this manual is intended for commercial

use.

DO NOT OPERATE MACHINE IN AN EXPLOSIVE

ENVIRONMENT!

ASSEMBL Y & OPERA TION

1 . Connect one end of the vacuum hose to the intake port

of the extractor located on the top of the unit and the

other end to the wand.

2. Connect the one end of the solution hose to the brass

water discharge fitting on the lower front of the extractor and the other end to the valve connection on the

floor wand.

3. Fill the solution tank (the rectangular opening located

on the top of the machine that does not have a cover)

with warm or hot water, plus a commercial grade carpet

cleaning chemical. Use dilution recommendations located on the chemical bottle. This unit holds 12-gallons of liquid. NOTE: A low-foaming solution should

be used. If not a defoamer must be used to keep the

foam to a minimum during use to protect your vacuum

motor . Defoamer if used is placed in the recovery tank

prior to operating the unit.

of the carpet and pulling dirt embedded in the carpet up

while the suction created by the vacuum motor picks up

the water & dirt and empties it into the recovery tank.

8. Repeat step #7 without putting more solution down to

extract greater quanities of water from the carpet. Doing this extra times will shorten the drying time required

for your carpet.

9. After using all of the solution from the solution tank,

you should empty the recovery tank using the dump

valve located at the lower rear of the machine by bringing the unit to a janitor’s sink, commode, etc. and pulling up on the “T” handle on the top of the valve.

10 . Once the recovery tank is emptied, lower the “T” handle

and repeat steps 3-9 as needed to clean the remaining

carpet.

11 . The cover on the recovery tank must always be in place

while using the extractor. The suction from the unit

during operation holds this in place.

12. During recovery , note that 100% recovery of all liquid

will not be achieved.

DAIL Y OR REGULAR MAINTENANCE

1. Rinse solution and recovery tanks out after every use.

Never leave any liquid in the system after use during

storage. Store unit in a warm place. If unit is left in a

freezing environment with liquid left in the system, the

pump and pump housing could crack, requiring replacement of the pump.

2 . Twice a month, flush machine with a solution of white

vinegar (one quart vinegar to two gallons of water) or

anti-browning solution mixed as directed. This will prevent build up of alkaline residue in the machine.

4. Once you have completed all of the above and your

unit is plugged into a grounded outlet, turn on the pump

switch, which will start to pressurize the unit.

5. Turn on either one or both of the vacuum switches

depending on the amount of suction desired.

6 . Holding the wand with two hands, activate the solution

by squeezing the lever on the wand (located at the top

of the wand). Spray will start to flow from the jets located at the pick up end of the wand.

7 . With one hand squeezing the wand lever, the other hand

should be putting downward pressure on the wand and

dragging the wand backwards across the carpet towards

the operator. This is basically wringing the water out

3 . If spray jet on the wand becomes clogged, remove spray

tip, wash thoroughly and blow dry.

PERIODIC MAINTENANCE

1 . Periodically inspect all hoses, electrical cable and con-

nections on the machine. Frayed or cracked hoses

should be replaced to eliminate vacuum or water pressure loss. Check power cable for damage. Repair or

replace damaged cord to prevent fire or electric shock.

3

TRIUMPH 1200 FINAL ASSEMBLY

8

9

10

11

6

7

4

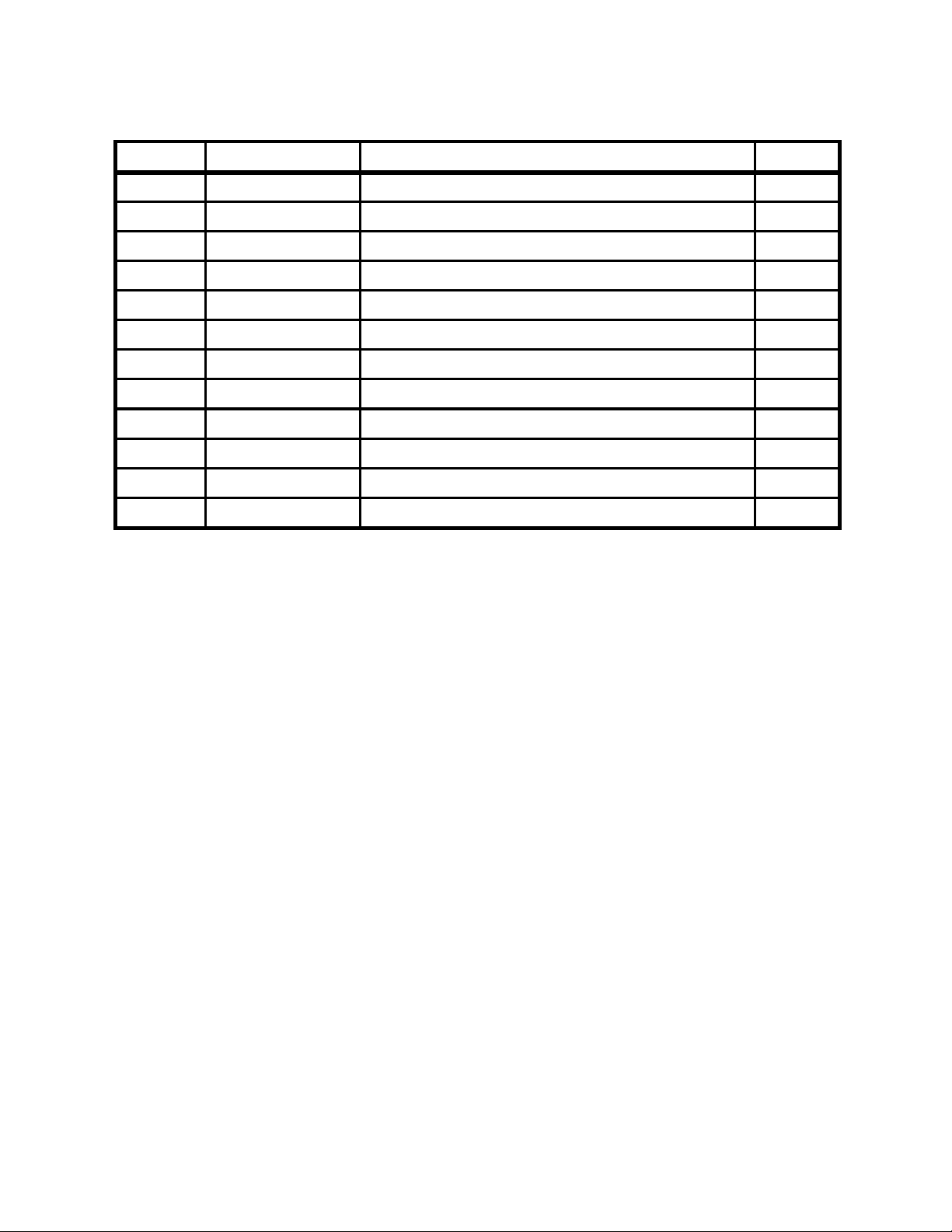

TRIUMPH 1200 FINAL ASSEMBLY P ARTS LIST

ITEM PART NO. DESCRIPTION QTY.

1 920665 Nut-Hex 1/4 SS Nyloc 1

2 254554 Hinge 1

3 911552 Cable-Steel Lanyard 1

4 962358 Screw-1/4-20x1-1/2 Hex SS 2

5 W104D Washer-Flat 4

6 252004 Clamp-Hose 5/8 Plastic 1

7 251804 Base-Black 1

8 255121 Lid Assembly 1

9

10

11

258626 Tank-Solution-Black 1

258627 Tank-Recovery-Black 1

255106 Latch-Rubber 2

980720 Washer-Flat (Not Shown) 8

5

Loading...

Loading...