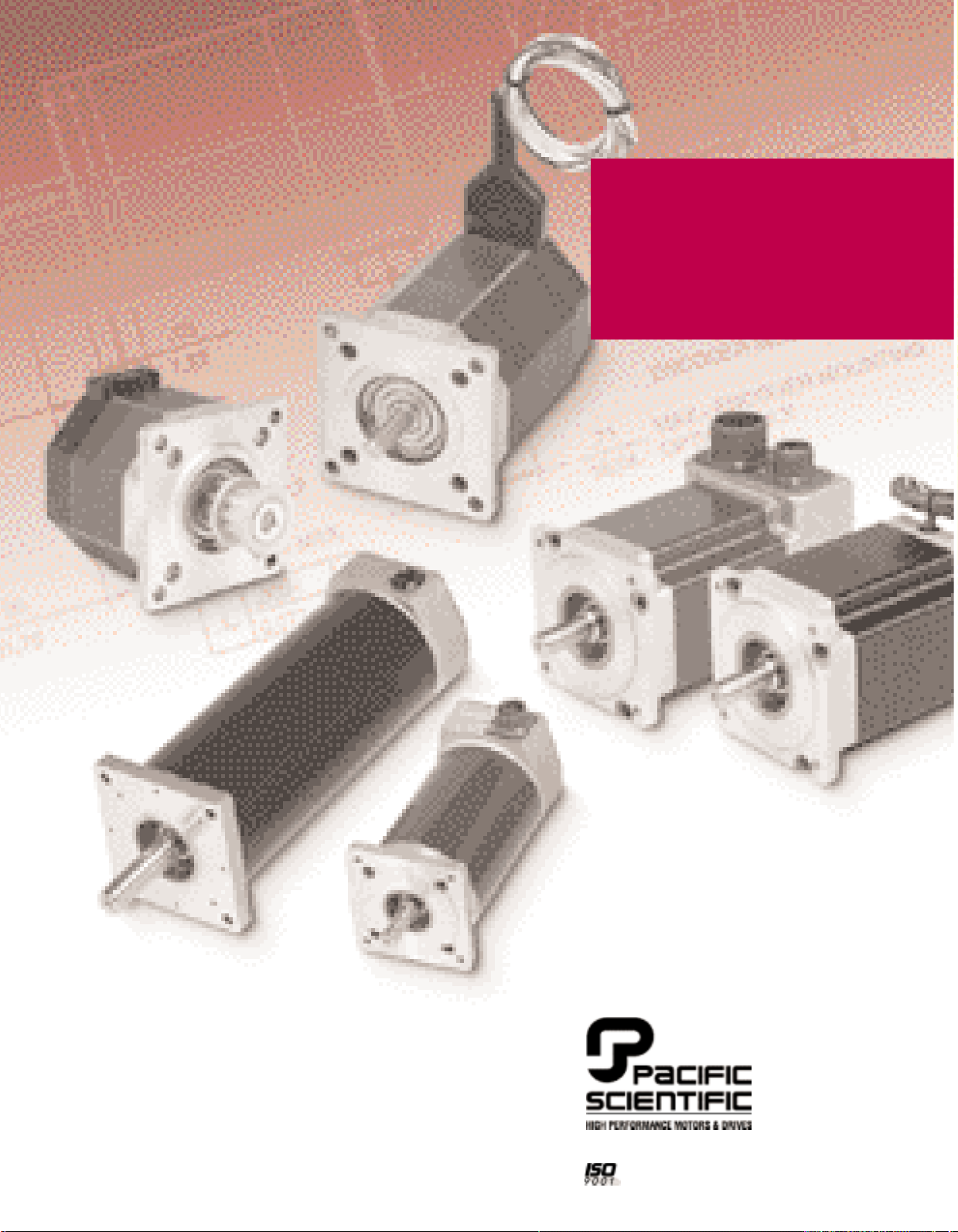

HYBRID

STEP MOTORS

■ NEMA 23, 34, 42 frame sizes

■ Custom models

■ 2 year warranty

November, 2000

PACIFIC SCIENTIFIC

STEPPER MOTORS

A Step Motor Range that

Offers You Choices

Pacific Scientific Steppers cover

a broad range of possible motion applications. High-quality, innovative

design is built into rugged, reliable

high-performance motors — from

the small to the very powerful. Add

a Pacific Scientific indexer or drive

for the pinnacle in stepper system performance.

POWERPAC

POWERPAC hybrid step motors offer

the highest torque-per-frame size of

any motor in the industry.

steppers are noted for their ruggedness and reliability.

POWERMAX II

POWERMAX II sets the performance

standard for NEMA 23 step motors.

With up to 253 oz-in. of holding

torque, you won’t find a more powerful two-inch stepper.

We can build POWERMAX II to your

specifications, in the volumes you

need, according to your JIT or other

delivery schedule.

Conventional Hybrid Step Motors

These high-efficiency, low loss hybrid

step motors are available in conventional

round-frame configurations.

Our general-purpose hybrid steppers

allow you to tailor a motor to your

in-plant or OEM specification.

Pacific Scientific Stepper

Drives and Indexers Complete

the Package

From the modular, flexible 6410

drive module through the fully-programmable powerful motion control of

the 5645 indexer/drive, Pacific

Scientific stepper drives offer highperformance features with exactly the

functionality you need. Ask for more

information on the Pac Sci line of

stepper drive products today.

Available in NEMA 34 and 42 frames,

these motors offer holding torques

to a staggering 5700 oz-in. Like all

Pacific Scientific motors, POWERPAC

1

TABLE OF

CONTENTS

Selection Overview

2

Hybrid Step Motor Technology

5

Application Assistance

6

POWERPAC Hybrid Step Motors-NEMA 34 & 42

10

• Sigmax

®

technology

• Standard Hybrid

POWERMAX II Hybrid Step Motors-NEMA 23

38

• Sigmax

®

technology

• Standard hybrid

• Sigmax Technology, low inertia rotor

• Standard hybrid, low inertia rotor

General Purpose Conventional Hybrids-NEMA 23, 34, & 42

54

• Sigmax technology

• Standard hybrid

Special Purpose Hybrid Step Motors-NEMA 23

73

• Sigmax

®

technology,low inertia rotor

• Standard hybrid, low inertia rotor

POWERSYNC AC Synchronous Motors-NEMA 34 & 42

82

P

acific Scientific

maintains a

worldwide network of support

resources to better serve our

customers as a global supplier of

motion control technology.

We are dedicated to quality in every

component manufactured. We are

committed to providing exceptional

customer service, unparalleled

product quality and reliable delivery

with short lead times. Techniques

such as data networking and

Benchmarking support our

commitment to quality and the

continuous improvement of

operations and products.

Our complete selection of high

performance components makes us a

single source of supply in many

motion control applications.

• brushless servo motors and drives

• adjustable speed motors and drives

• hybrid stepper motors and drives

• multi-axis programming software

• permanent magnet DC motors

• brushless servo motors

• low inertia servo motors

• hybrid stepper motors

• AC synchronous motors

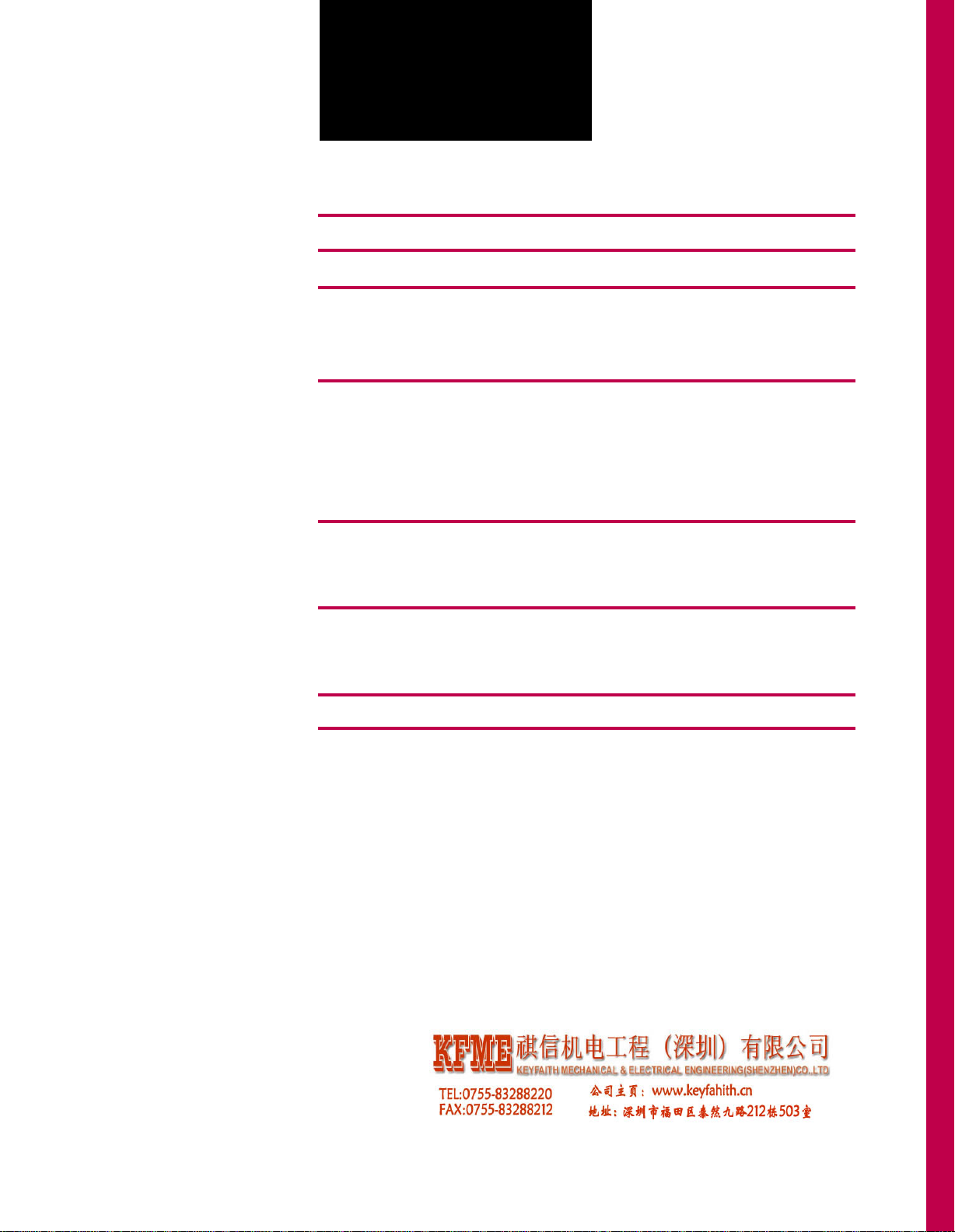

2

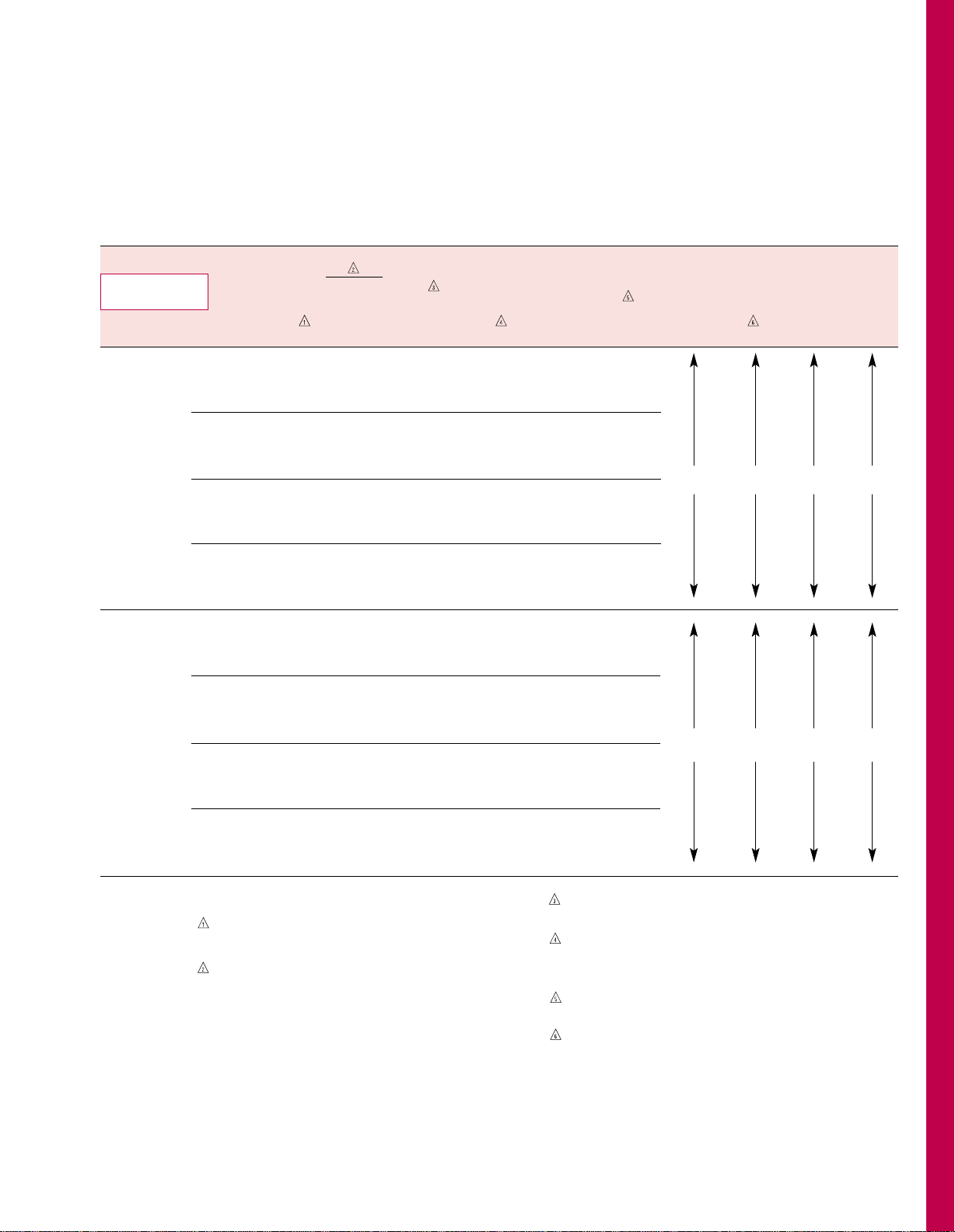

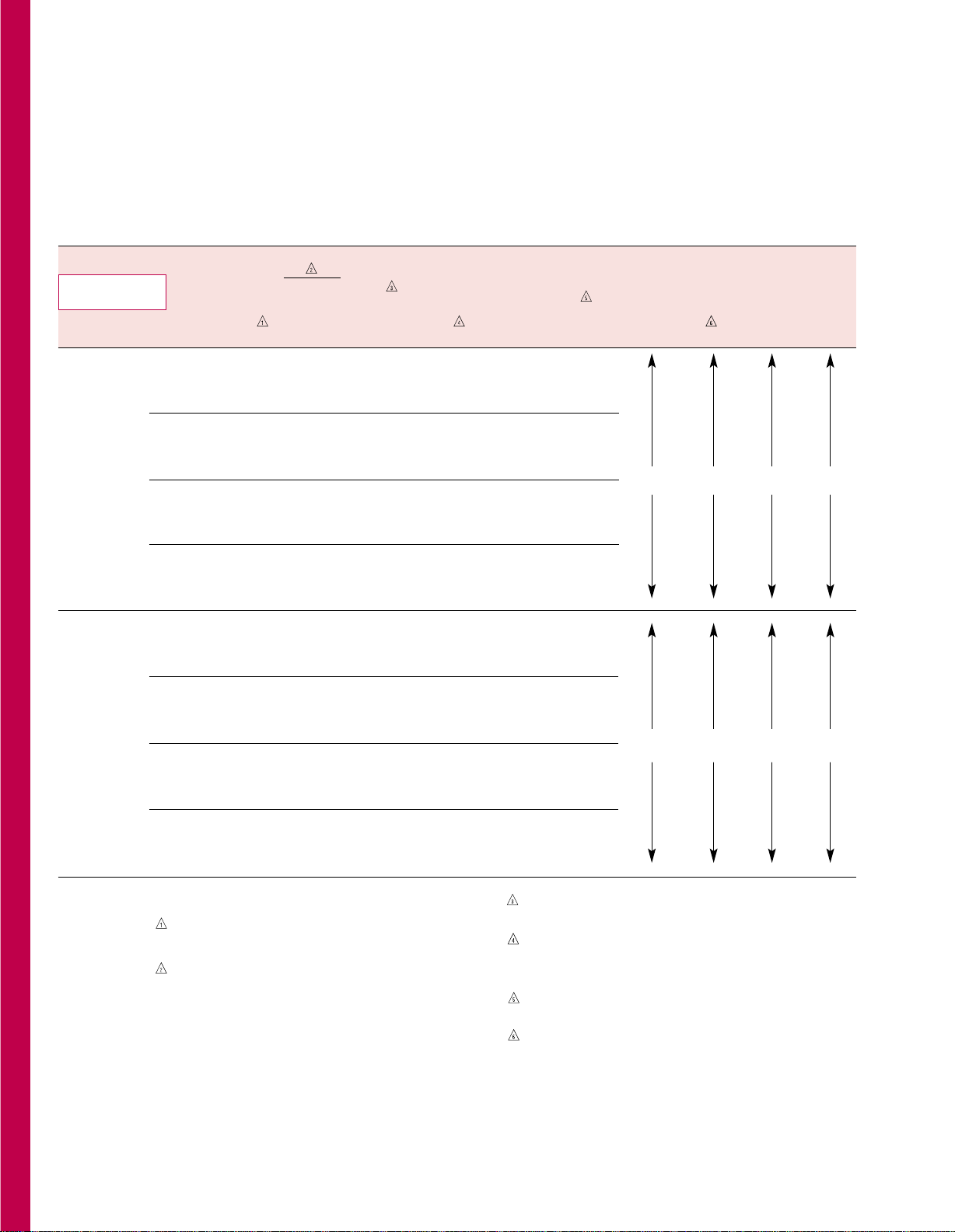

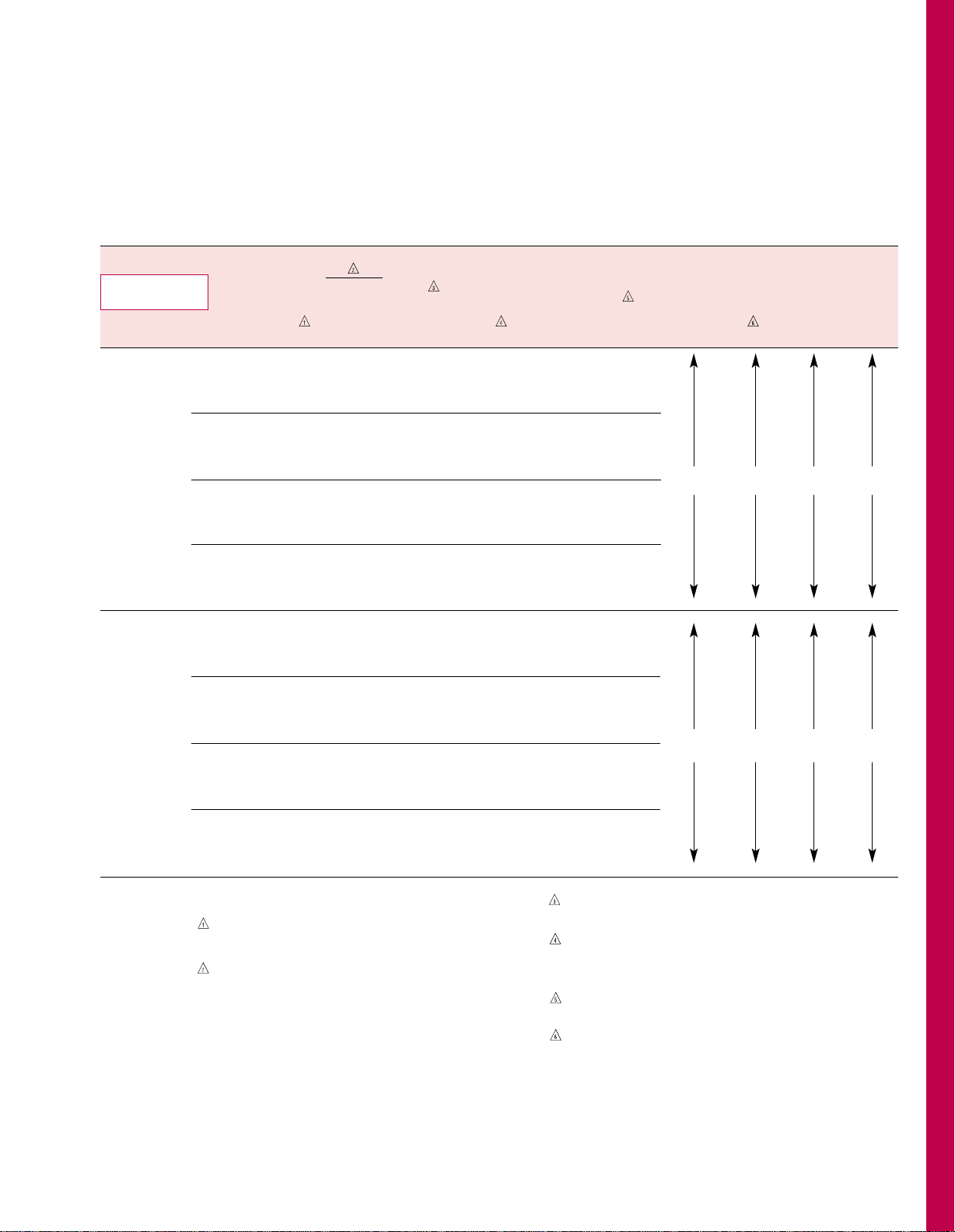

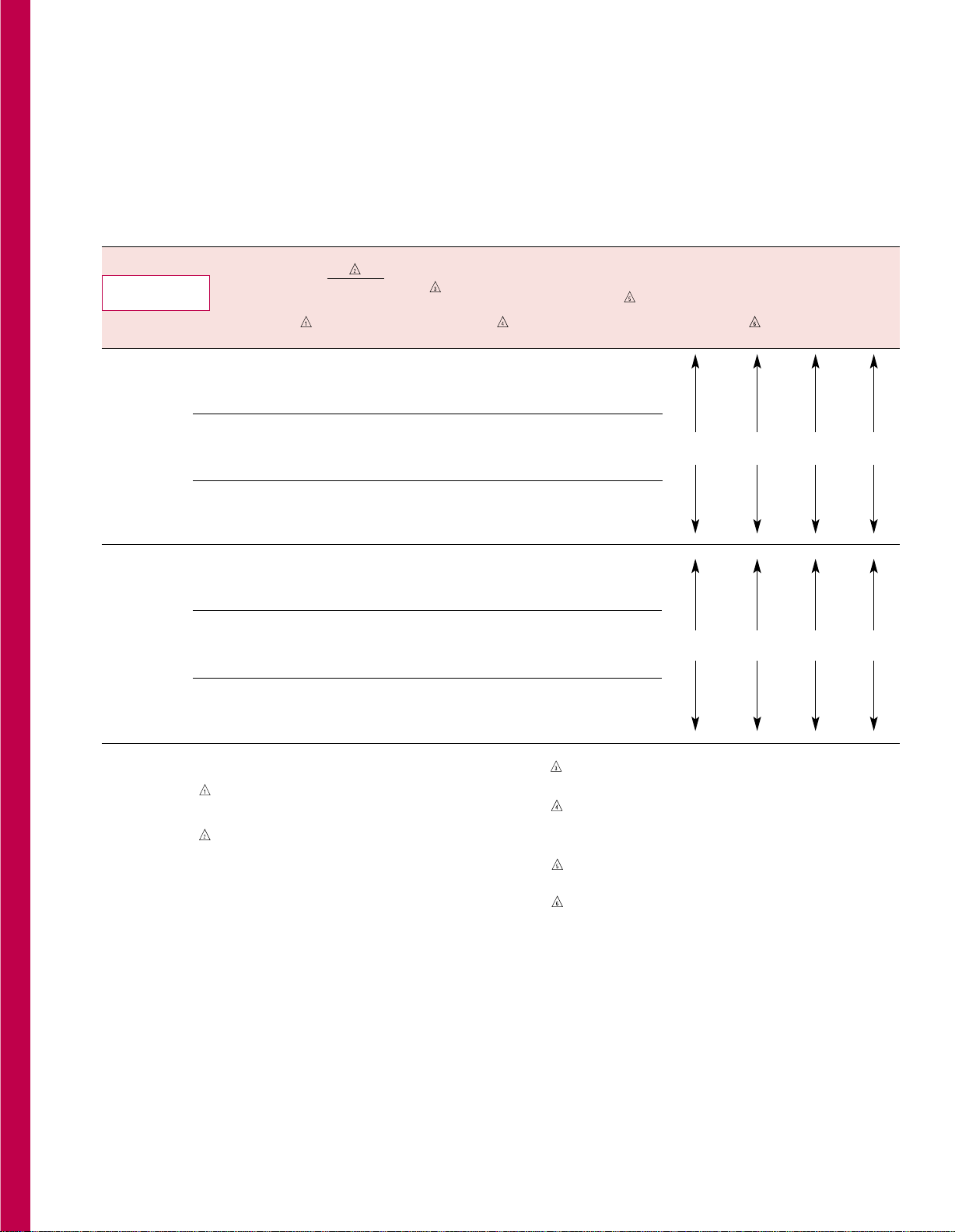

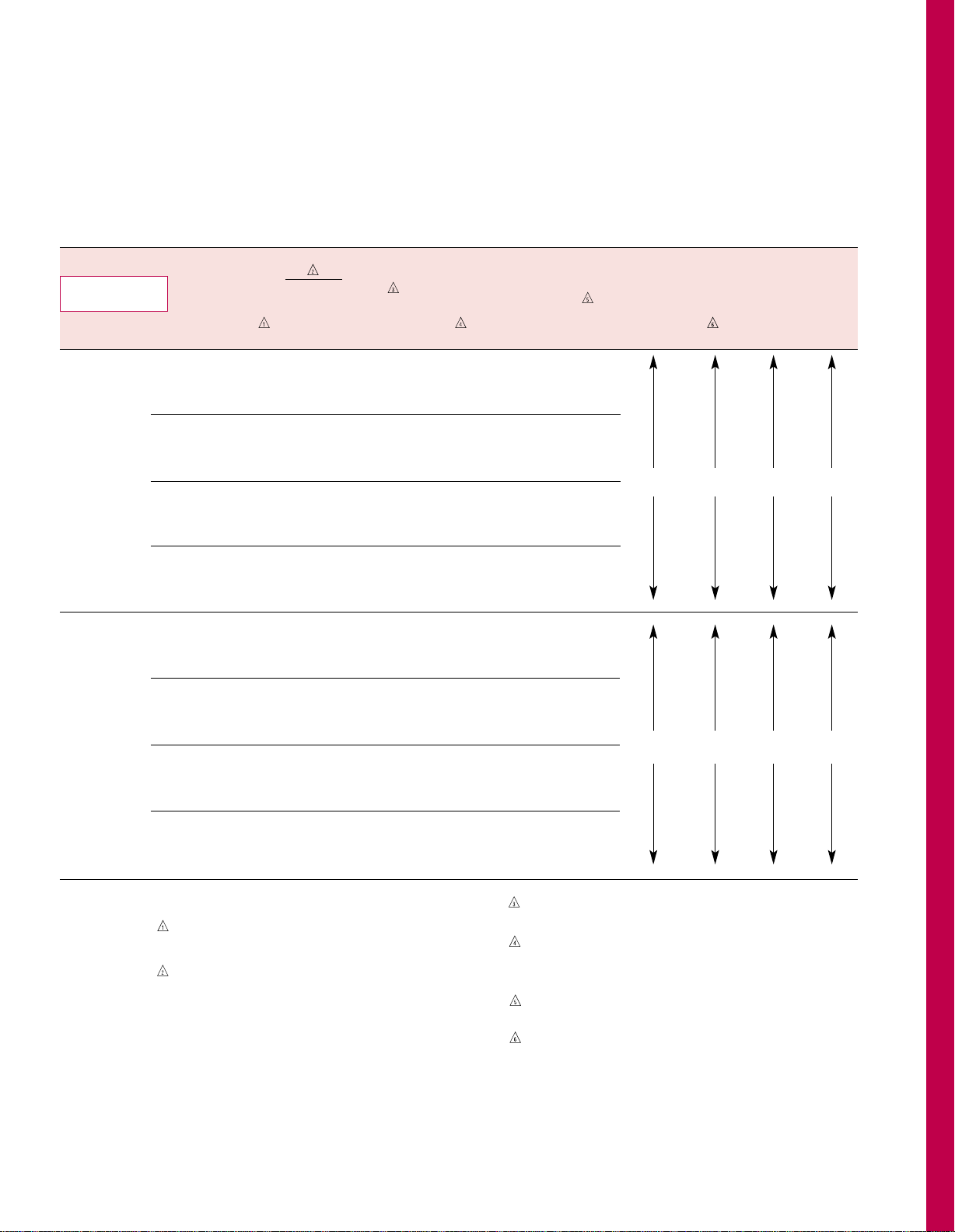

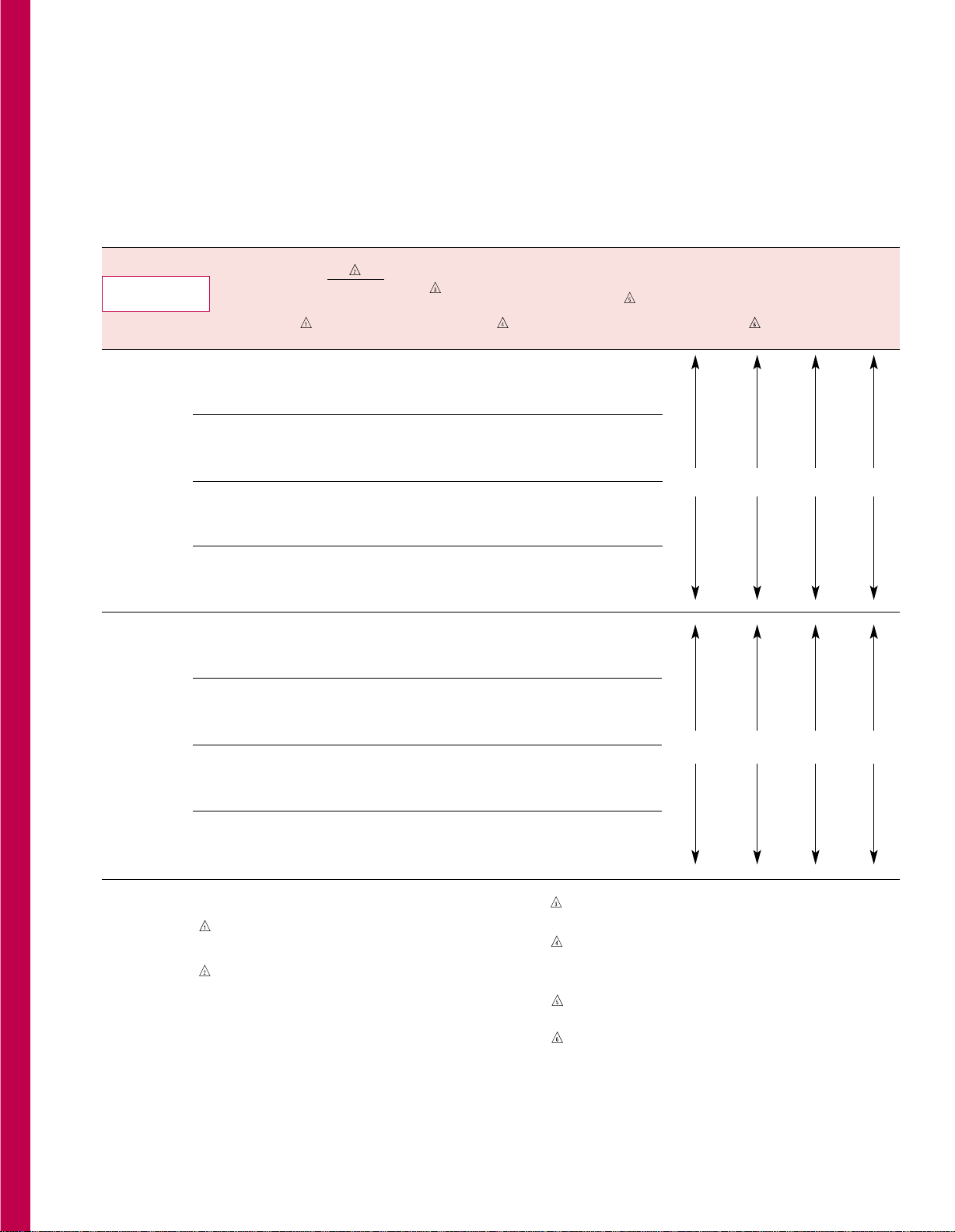

SELECTION

OVERVIEW

GENERAL PURPOSE MOTORS

POWERPAC™ HYBRIDS—

K Series – Sigmax®technology

N Series – standard hybrid

POWERMAX II®HYBRIDS

M Series—Sigmax®technology

P Series—standard hybrid

M “J” Series—Sigmax®technology—low inertia rotor

P “J”Series—standard hybrid—low inertia rotor

CONVENTIONAL HYBRIDS

E Series—Sigmax®technology

H Series—standard hybrid

SPECIAL PURPOSE HYBRIDS

E “J” Series—Sigmax®technology—low inertia rotor

H “J”Series—standard hybrid—low inertia rotor

POWERSYNC™ AC SYNCHRONOUS

MOTORS

SN Series—Synchronous motors

Step Motors

NEMA 23 Frame NEMA 34 Frame NEMA 42 Frame

2.3 3.4 4.2

Holding T orque Range (oz-in./Nm)

570-2790 oz-in. 1480-5700 oz-in.

(4.02-19.69 Nm) (10.45-40.23 Nm)

450-2180 oz-in. 1150-4365 oz-in.

(3.18-15.39 Nm) (8.12-30.81 Nm)

89-253 oz-in.

(.63-1.79 Nm)

42-214 oz-in.

(.29-1.51 Nm)

99-252 oz-in.

(.70-1.78 Nm)

79-201 oz-in.

(.55-1.42 Nm)

85-225 oz-in. 223-1300 oz-in. 957-3958 oz-in.

(.60-1.59 Nm) (1.58-9.18 Nm) (6.76-27.95 Nm)

36-156 oz.in. 158-916 oz-in. 585-2833 oz-in.

(.25-1.10 Nm) (1.12-6.47 Nm) (4.13-20.00 Nm)

77-196 oz-in.

(.54-1.39 Nm)

54-141 oz-in.

(.38-.99 Nm)

Maximum pull-out Maximum pull-out

torque to 900 oz-in. torque to 1550 oz-in.

(6.36 Nm) at 72 RPM (10.95 Nm) at 72 RPM

15

15

38

46

45

48

48

54

58

58

73

75

75

82

86

3

TECHNICAL OVERVIEW

(Con’t)

TYPES

POWERPAC K Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sigmax

®

hybrid construction

POWERPAC N Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Standard hybrid construction

POWERMAX II M Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sigmax hybrid construction

POWERMAX II P Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Standard hybrid construction

General Purpose Conventional hybrid E Series . . . . . . . . . . . .Sigmax hybrid construction

General Purpose Conventional hybrid H Series . . . . . . . . . . . .Standard hybrid construction

ROTOR CONSTRUCTION

POWERPAC N and K Series;

POWERSYNC AC Synchronous Motors . . . . . . . . . . . . . . . . .Laminated

POWERMAX II M and P Series;

Conventional E and H Series with “L” rotor designates . . . . . . . Laminated

(high speed efficiency)

POWERMAX II M and P Series;

Special purpose E and H Series with “J” rotor designates . . . . . Low mass/low inertia (fast start/stop,

high acceleration)

WINDINGS

H, J, K, L, M and N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard winding designations

T type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maximum torque at low speed

P type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maximum torque at high speed

A, B, C, D, E, F, G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Additional standard windings

PHASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FULL STEPS PER REVOLUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

FULL STEP ANGLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8°

ANGULAR ACCURACY

POWERPAC N Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±3% of one full step, no load

non-cumulative

POWERPAC K Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1.5% of one full step, no load

non-cumulative

POWERMAX II M and M “J”;

E and E “J” Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±1.5% of one full step, no load,

non-cumulative

POWERMAX II P and P “J”;

H and H “J”, H Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±3% of one full step, no load,

non-cumulative

OPERA TING TEMPERA TURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20 to 40°C

INSULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NEMA Class B, 130°C

AGENCY APPROVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . All NEMA 34 and 42 frame motors are

UL recognized; Class B motor

insulation (File E103510)

Construction (File E61960)

CE marked per EN60034-1

INSULATION RESISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Megohms @500V dc and 25°C

www.pacsci.com

TECHNICAL OVERVIEW

(CON’T)

4

SEALING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .POWERPAC N and K Series and Nema 34

and 42 with a “C”, “L” or “M” designation in

the model number have washdown

construction in accordance with NEMA MG1-

1.26, part E. With the addition of a shaft seal,

they meet IEC (International Electrotechnical

Commission) IP65 and are suitable for

washdown requirements.

ENCODER OPTIONS

POWERPAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .See page 36

POWERMAX II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .See page 53

Conventional & Special Purpose Hybrids . . . . . . . . . . . . . . . . . . .See page 79-80

POWERSYNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .See page 93

www.pacsci.com

HYBRID STEP MOTOR

TECHNOLOGY

GENERAL PURPOSE MOTORS

These motors offer torque, speed and acceleration

characteristics to fulfill commonly encountered applications.

All general purpose motors are available in both standard

and Sigmax

®

configurations.

This category includes:

• M and P Series POWERMAX II

®

hybrid motors, the

economical and high performance alternative to

conventional NEMA 23 step motors

• H and E Series conventional (round frame) hybrid motors

in a full range of frame sizes, with a broad selection of

windings to duplicate or exceed the performance of most

existing step motors

HIGH TORQUE

The POWERPAC N and K Series, in both NEMA34 and 42

frames, provide an impressive range of high torque output.

See the Ratings and Characteristics for the NEMA 34 frame

starting on page 15, followed by torque and acceleration

(torque to inertia ratio), and torque linearity comparisons.

Performance curves start on page 18. NEMA 42 information

starts on page 24.

HIGH ACCELERATION

Both the POWERPAC N and K Series have high torque-toinertia ratios that provide high acceleration rates to move loads

fast. The K Series, which incorporates the flux-focusing Sigmax

®

technology, provides the highest acceleration rates. Specify the

K Series for the most rapid load positioning. See the Ratings

and Characteristics for the NEMA 34 frame starting on page 15,

followed by torque and acceleration (torque-to-inertia ratio), and

torque linearity comparisons. Performance curves start on page

19. NEMA 42 information starts on page 24.

Patented Sigmax®technology*

redirects magnetic flux to inhibit

leakage and optimize torque production.

* Sigmax®technology is covered by U.S. patents

4,712,028, 4,713,470, 4,763,034 and 4,827,164.

SPECIAL PURPOSE MOTORS

Now and then, you’ll run into an application with special acceleration

requirements. With PacSci special purpose motors, you may not

need to order a customized motor or compromise performance.

All are offered in conventional (round frame) configurations:

• E “J” and H “J” Series motors, in NEMA 23 frame sizes, with

hollow, low mass rotors for rapid acceleration

Still don’t see it here? Just call. Or fax an application data form

(pages 8 and 9) to your Pacific Scientific distributor or the factory.

We have an extensive customization capability.

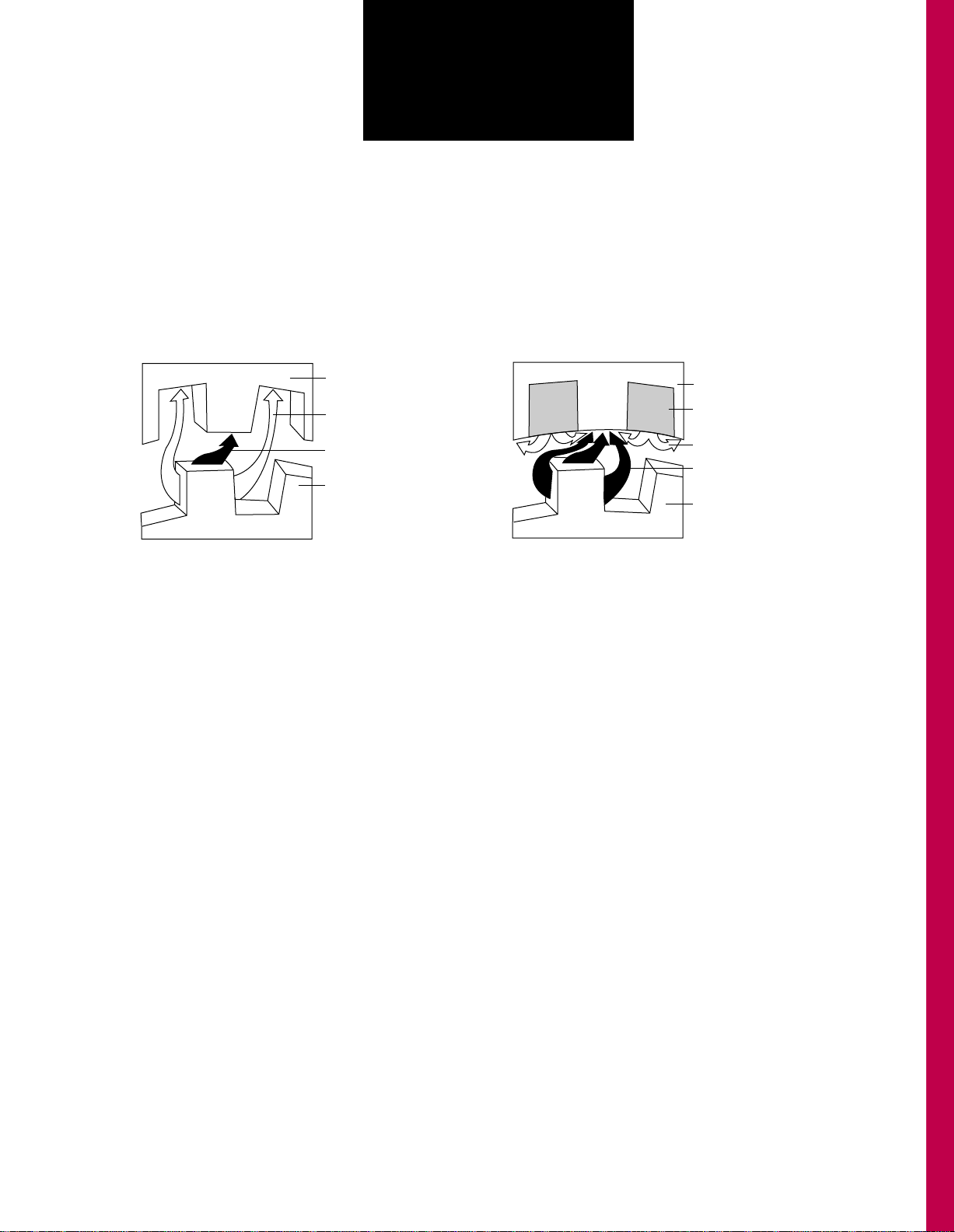

SIGMAX®TECHNOLOGY

SIGMAX

®

AND STANDARD

HYBRID STEP MOTORS

Here’s how Sigmax works.

• Stator mounted rare earth magnets concentrate

magnetic flux at desired points between the rotor and

stator

• Flux focusing action optimizes flux paths

• Produces higher torque and current utilization is better

than a comparably sized standard hybrid

Typical paths of flux transfer

in an energized conventional

hybrid step motor.Some flux

leakage occurs in normal

operation.

STANDARD HYBRID

S

N

Stator

Non-torque

producing flux

Torque producing

flux

Rotor

Stator

Rare earth magnet

inserts

Focusing flux

Concentrated torque

producing flux

Rotor

5

www.pacsci.com

S

N

S

S

N

N

www.pacsci.com

6

APPLICATION

ASSISTANCE

HOLDING TORQUE

Holding torque and rated current are leading

specifications for selection in the Ratings and

Characteristics tables for all motors. Holding torque is

often used as a figure of merit when comparing

motors. It specifies the maximum external torque that

can be applied to a stopped motor with rated current

applied without causing the motor to rotate

continuously.

Pacific Scientific hybrid step motors are used with

a variety of drivers from many different

manufacturers. These drivers have an extremely

broad range of voltage and current ratings. It is not

practical to show individual torque-speed curve

performance given the extensive combinations of

driver voltages and currents. Instead, holding torque

is shown for reference along with rated current.

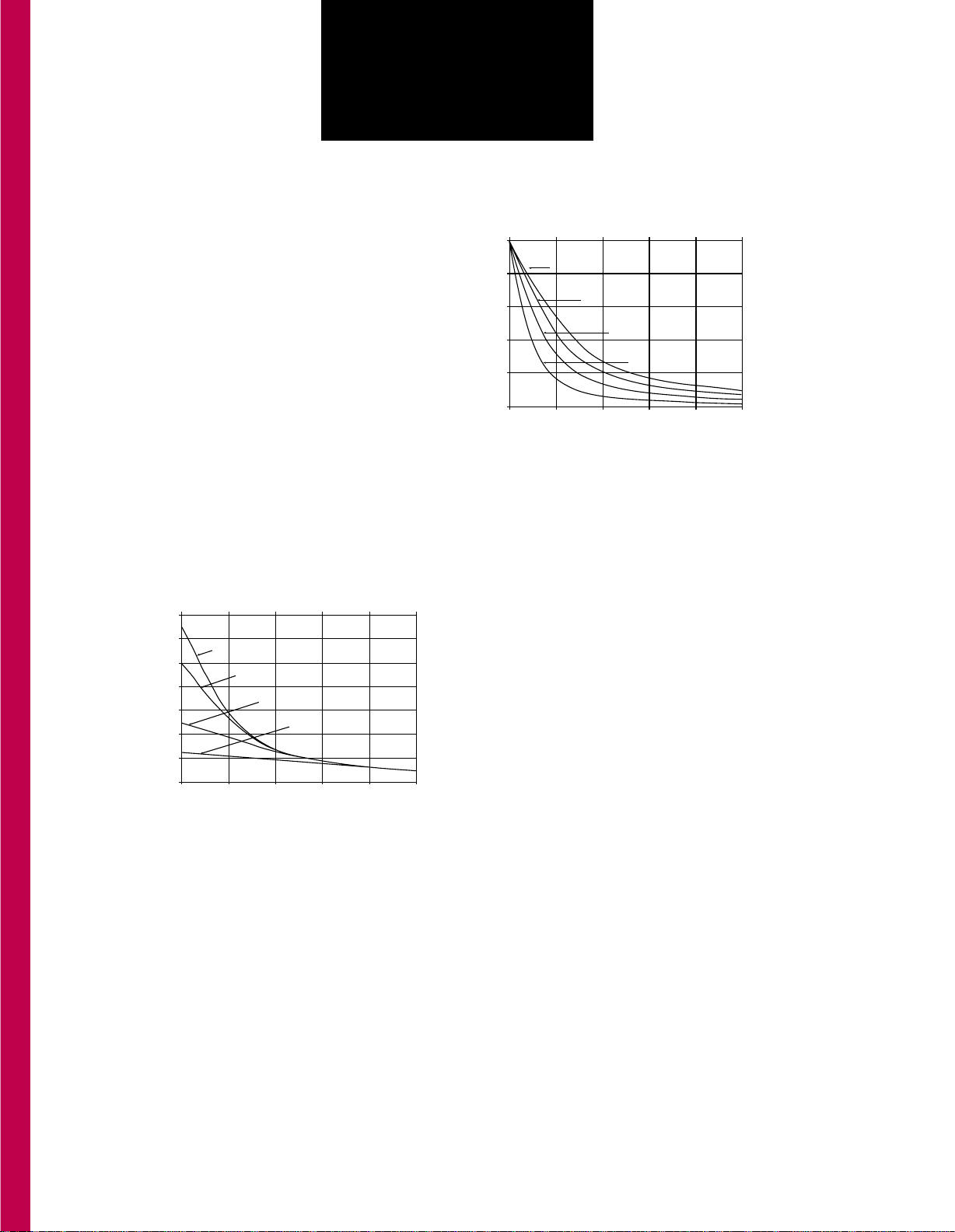

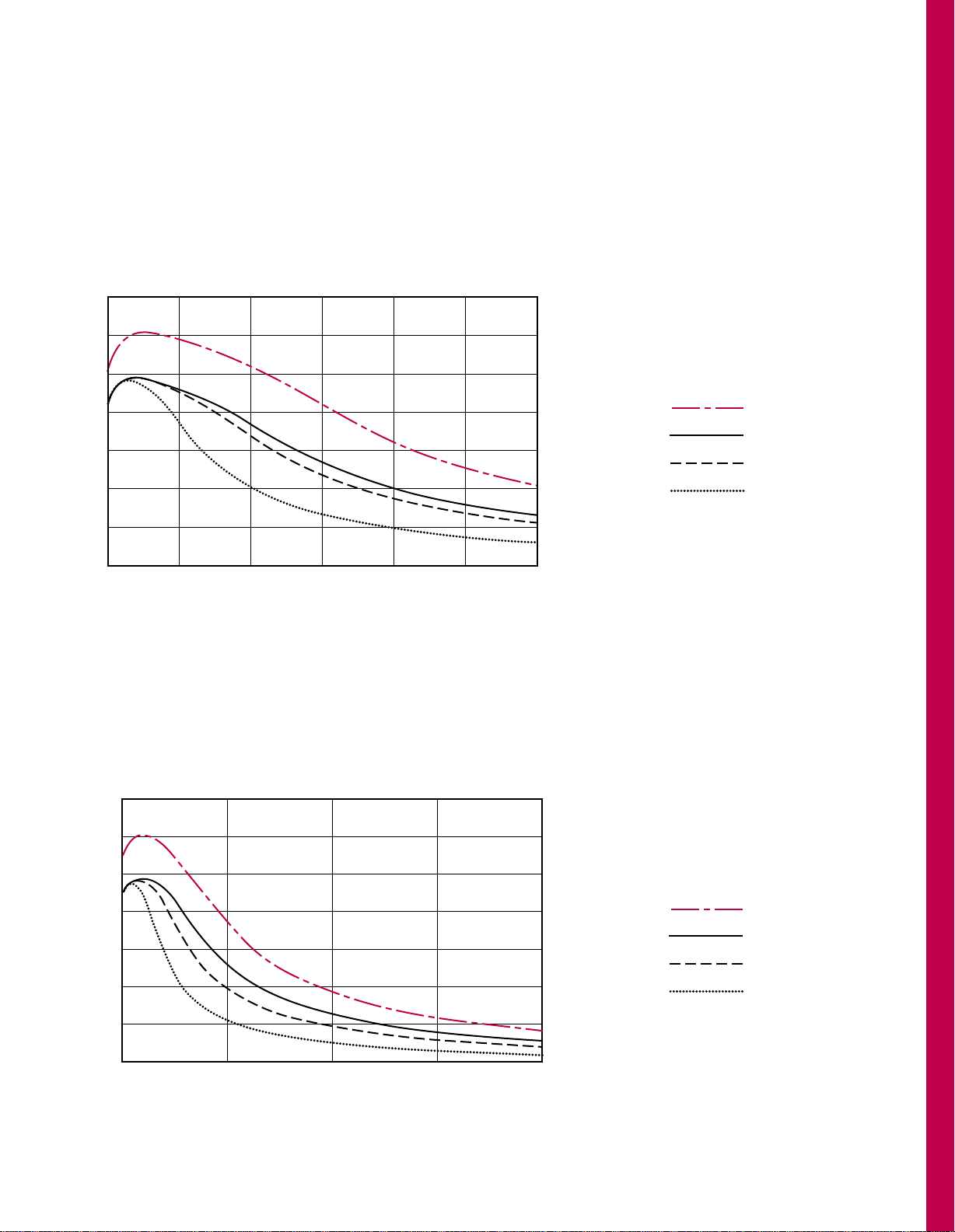

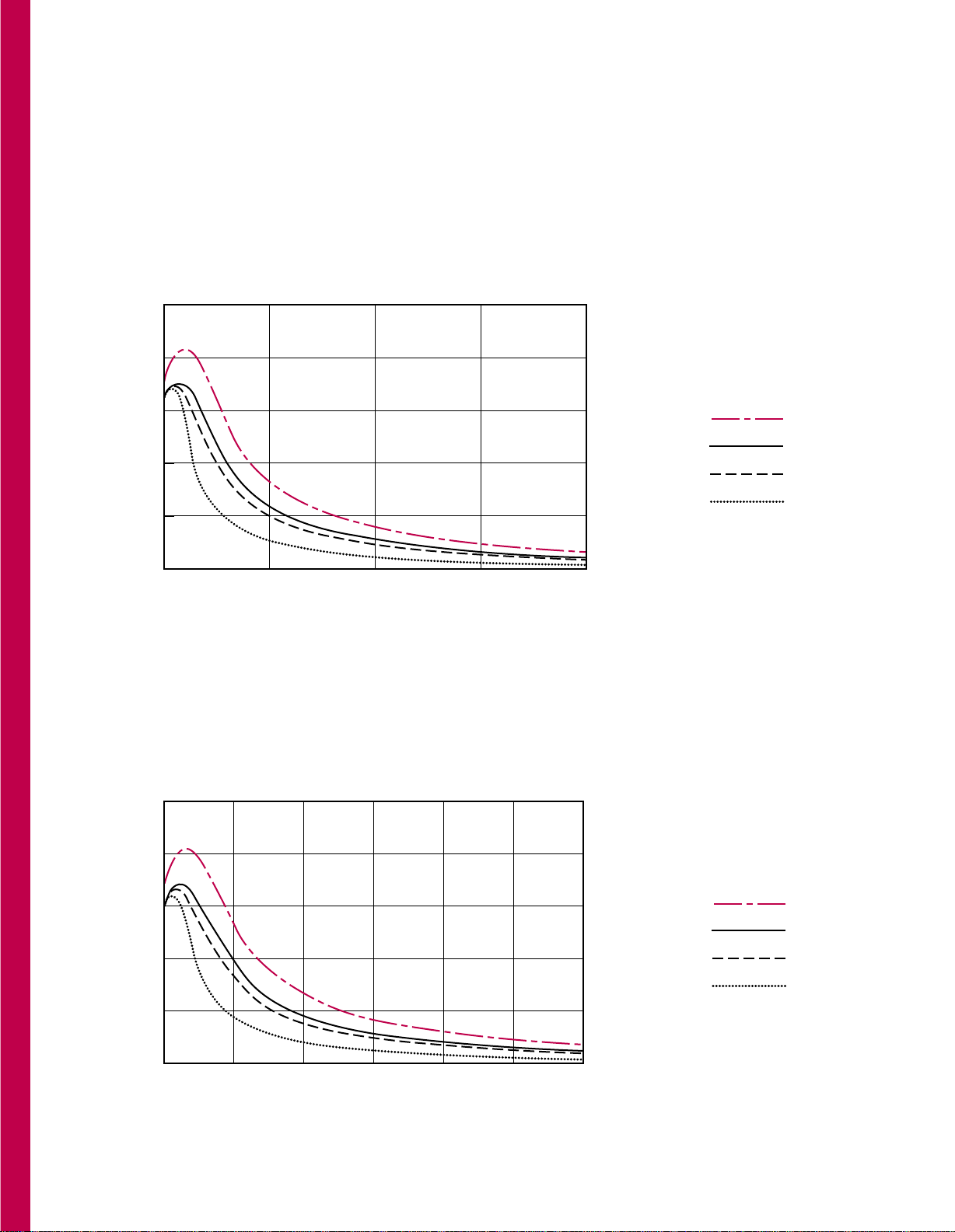

TORQUE-SPEED CURVES

As applied voltage and/or current to the motor is

changed, motor performance is altered. Figures 1

and 2 show typical torque-speed curves using a

bipolar chopper driver.

CURRENT CHANGES

VS. PERFORMANCE

Figure 1 shows the performance of the same motor

driven by bipolar chopper drivers with different

current ratings. All drivers have the same supply

voltage. Note that high speed performance is not

appreciably affected by the different current ratings.

Low speed running torque, however, varies

considerably with changes in the current rating. It is

important to understand that when current over the

rated current of the motor is applied, the increase in

torque will not be proportional to the increased

current. Furthermore, applied current levels

increasingly higher than rated current will likely result

in damage to the motor from demagnetization and/or

overheating.

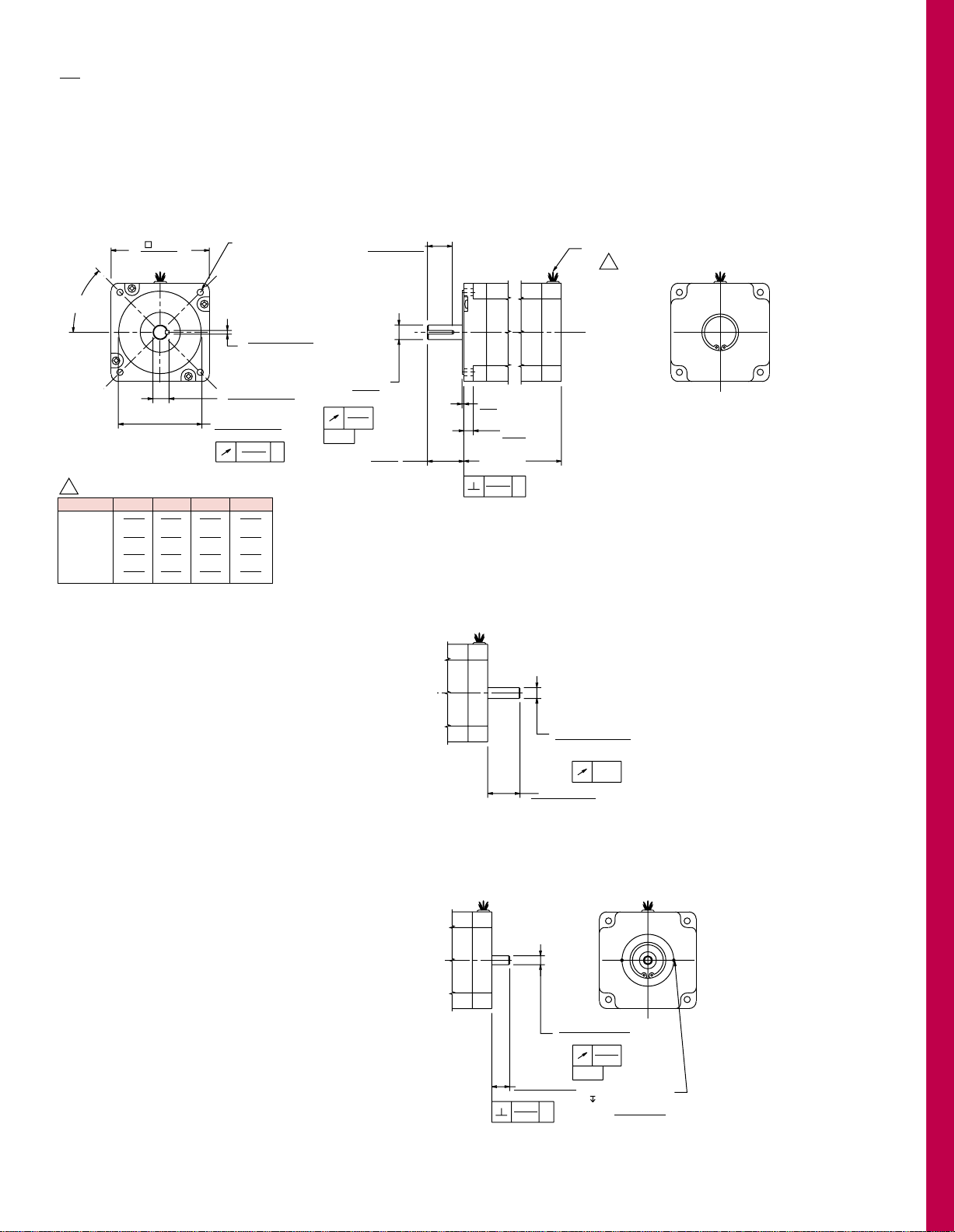

VOLTAGE CHANGES

VS. PERFORMANCE

Figure 2 shows the performance of the same motor

driven by bipolar chopper drivers with different

supply voltage ratings. All drivers have the same

current rating. Note that low speed running torque is

high and not appreciably affected by supply voltage

differences. High speed performance, however,

varies considerably with changes in supply voltage.

Caution must be exercised when increasing supply

voltage. Higher voltages will result in increased motor

heating regardless of motor speed.

APPLICATION ENGINEERING

Need help with your motor selection? We make it

simple and economical to apply step motors in your

designs. Application engineering assistance is only a

phone call or FAX away from your Pacific Scientific

distributor or the factory. To assist us in providing the

optimum motor for your application, please copy and

complete the STEP MOTOR APPLICATION DATA

form on pages 8 and 9. FAX it to our Application

Engineering Department at (815) 226-3148 and we

will provide a prompt reply.

Our response includes a comprehensive torquespeed performance curve of the recommended motor

at your voltage and current levels.

CUSTOM MOTORS

Even though we offer a broad spectrum of standard

motors, we recognize that you might need something

special. We routinely design custom windings to

provide the application specific characteristics you

need. Atypical modification such as a special shaft is

also a part of this service. Don’t hesitate to call us

and follow up with the application data form

described above.

1.0

0.8

0.6

0.4

0.2

0.0

0

0

600

2000

1200

4000

1800

6000

2400

8000

3000

10000

SPEED (FULL STEP/SEC)

SPEED (RPM)

NORMALIZED TORQUE (UNITLESS)

4 x V

3 x V

2 x V

1 x V (Reference curve)

Figure 2

1.4

0.0

0

0

600

2000

1200

4000

1800

6000

2400

8000

3000

10000

SPEED (FULL STEP/SEC)

SPEED (RPM)

NORMALIZED TORQUE (UNITLESS)

1.5 x Rated I

Figure 1

1.2

1.0

0.8

0.6

0.4

0.2

1.0 x Rated I (Reference curve)

.5 x Rated I

.25 x Rated I

www.pacsci.com

7

APPLICATION

ASSISTANCE

For a comprehensive analysis of your requirements,

just complete and FAX us the STEP MOTOR

APPLICATION DATA form on pages 8 and 9 (See

APPLICATION ASSISTANCE, previous page). An

application engineer will contact you promptly.

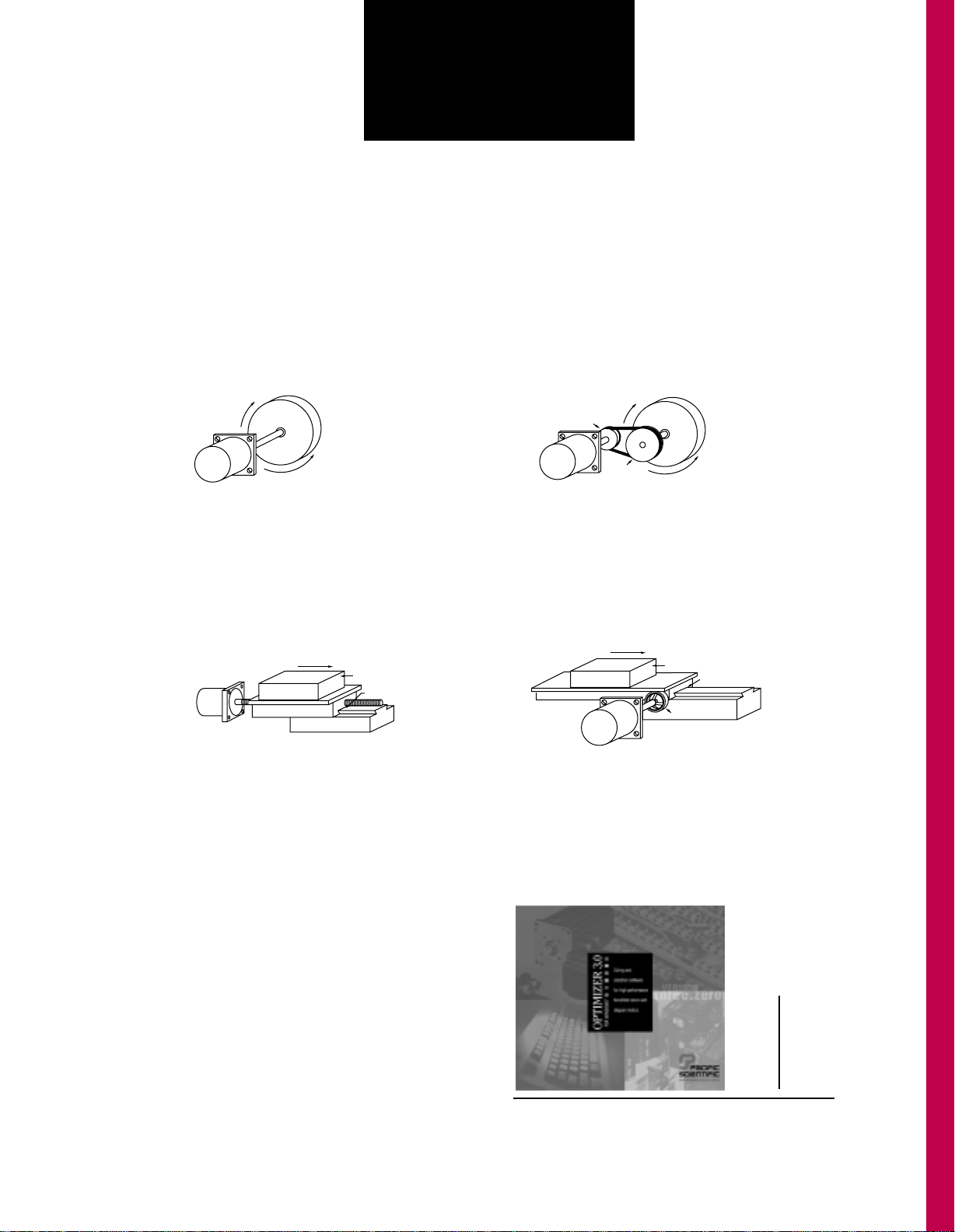

ROTARY MOTION—DIRECT DRIVE

Enhanced hybrid motor torque production, utilizing

Sigmax®technology, is ideal for direct drive applications. Benefits include elimination of mechanical

gear reduction. Be sure to use a flexible coupling.

LINEAR MOTION—LEADSCREW DRIVE

ROTARY MOTION—BELT DRIVE

Timing belt or band driven rotary motion is simple to

control, efficient and relatively free from backlash.

TANGENTIAL MOTION—DIRECT DRIVE

Step motors are well suited to table drives because

load remains constant. Leadscrew, rack and pinion,

or tangential systems can achieve the desired linear

motion and accuracy needed for many applications.

Ask us about Optimizer 3.0™ for Windows,™ our menu

driven sizing and selection software package. You’ll find

out how easy it can be to optimize your motor selection.

Request your free copy of Optimizer 3.0 in Windows™

compatible format on CD-ROM. Inquire at www.pacsci.com

Rotation

Load

Torque

Direction

Static

Force

Friction

Coefficient

LOAD

Rotation

Load

Torque

Driven

Pulley

Motor Pulley

Direction

Static

Force

Friction

Coefficient

LOAD

Motor

Tangential

Drive

VERSION

3.0

Tangential drives make use of the step motors high

torque-to-inertia ratios. In high speed tape and printhead drives, enhanced hybrid motors provide rapid

bidirectional accel/decel and critical position control.

SIZING/SELECTION SOFTWARE

www.pacsci.com

8

STEP MOTOR

APPLICATION DATA

FAX to 815-226-3148

Pacific Scientific

Application Engineering Dept.

Company

Date _

Address

City

State Zip

Name Title Phone

Product Description

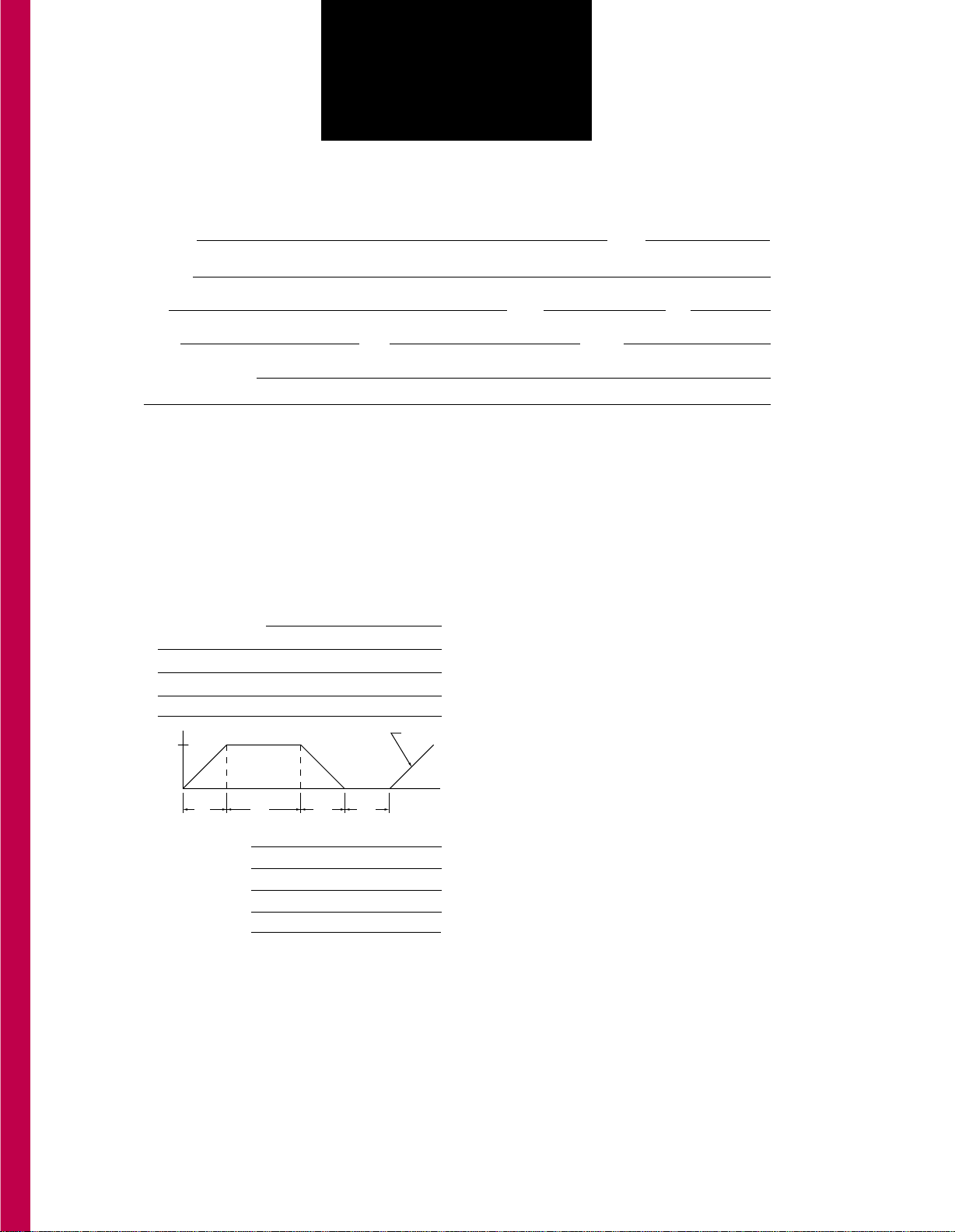

GENERAL

• APPLICATION DIAGRAM Draw below or fax

separately. Indicate key power transmission

details, e.g., pulley and gear ratios, lead screw pitch,

efficiencies, nut preload, etc.,. . .all this to size motor

and/or control properly.

• TYPICAL LOAD VELOCITY PROFILE Using the

diagram below as a guide, complete the values for

V through T

4

. Show worst case for proper sizing.

• PRODUCTS CURRENTLY USED List manufacturer

and model number

V = Velocity =

T1= Accel =

T2= Run =

T3= Decel =

T4= Dwell =

DRIVE INFORMATION

Bus Voltage_________ Phase Current_________

■■ Not Specified Yet

■■ Bipolar

■■ Unipolar

STATIC REQUIREMENTS

■■ Accuracy - Accurate to within ______________.

■■ Repeatability - Resolution = ______________.

■■ Holding Torque required = ____________oz in.

SYSTEM LOADING

■■ Friction loading _____________oz in.

■■ Total Load Inertia _________________oz in s

2

(include coupling and all power transmission inertias)

■■ Axial Load: Inward Load = ____________lb.

Outward Load = ___________lb.

■■ Radial Load _______________________lb.

COUPLING ■■ solid ■■ flex ■■ bellows

ELECTRICAL CHARACTERISTICS/FEEDBACK

■■ Inductance = ______ ■■ Number of Leads_____

■■ Resistance/phase = _________________ Ω

ENCODER

■■ Encoder Line Count =________ ppr

■■ Line Driver ■■ Non-Line Driver

ENVIRONMENT

■■ Ambient Temp. _____________ °Celcius

■■ Splashproof (IP65)

TIME

V

VELOCITY

NEXT CYCLE

T1 T2 T3 T4

www.pacsci.com

9

STEP MOTOR

APPLICATION DATA

(CON’T)

• STANDARD AND SPECIAL FEATURES

Motor model number from catalog

Circle whether you want standard or special features. If

special, indicate details. Note that special features may

result in increased price or leadtime.

• FRONT SHAFT (standard) (special)

D shaft length

±

(±.015)*

C shaft dia. ±

(+.0000/-.0005)*

run out

(.002 std. ext.)*

— Straight Key per electric motor standards

(standard option) (special)

Key: width height

length Other

Company Date

MOTOR

circle or specify

Note: All motors are 1.8°, 2 Phase.

• REAR END BELL (standard) (special)

mtg. hole B.C. ± (±.010)*

mtg. holes

hole pattern

other

• REAR SHAFT (standard) (special)

shaft length

±

(±.040)*

shaft dia.

±

(+.0000/-.0005)*

run out

(.002)*

other

— Flat See Fig. 1 (standard option) (special)

Min. usable length X

Dim. over flat Y ± (±.005)*

Corner radius R allowed

(±.060)*

Other

— Woodruff Key See Fig. 2

(standard option) (special)

ANSI std. key no.

(Example 303)

Key location Z

±

(±.020)*

Other

B - Pilot Diameter

A - Flange Width

E - Max Motor Length

F - Pilot Depth

.003 A

.002

-A-

.003 A

0,077

0,051

0,077

1

A

B

C

D

F

E

MOTOR LEADS

FIGURE 1

X

R

Y

FIGURE 2

Z

NOTES:

NEMA standard for shaft run out is .002" + .001"

for each additional inch of extension past the

standard length.

www.pacsci.com

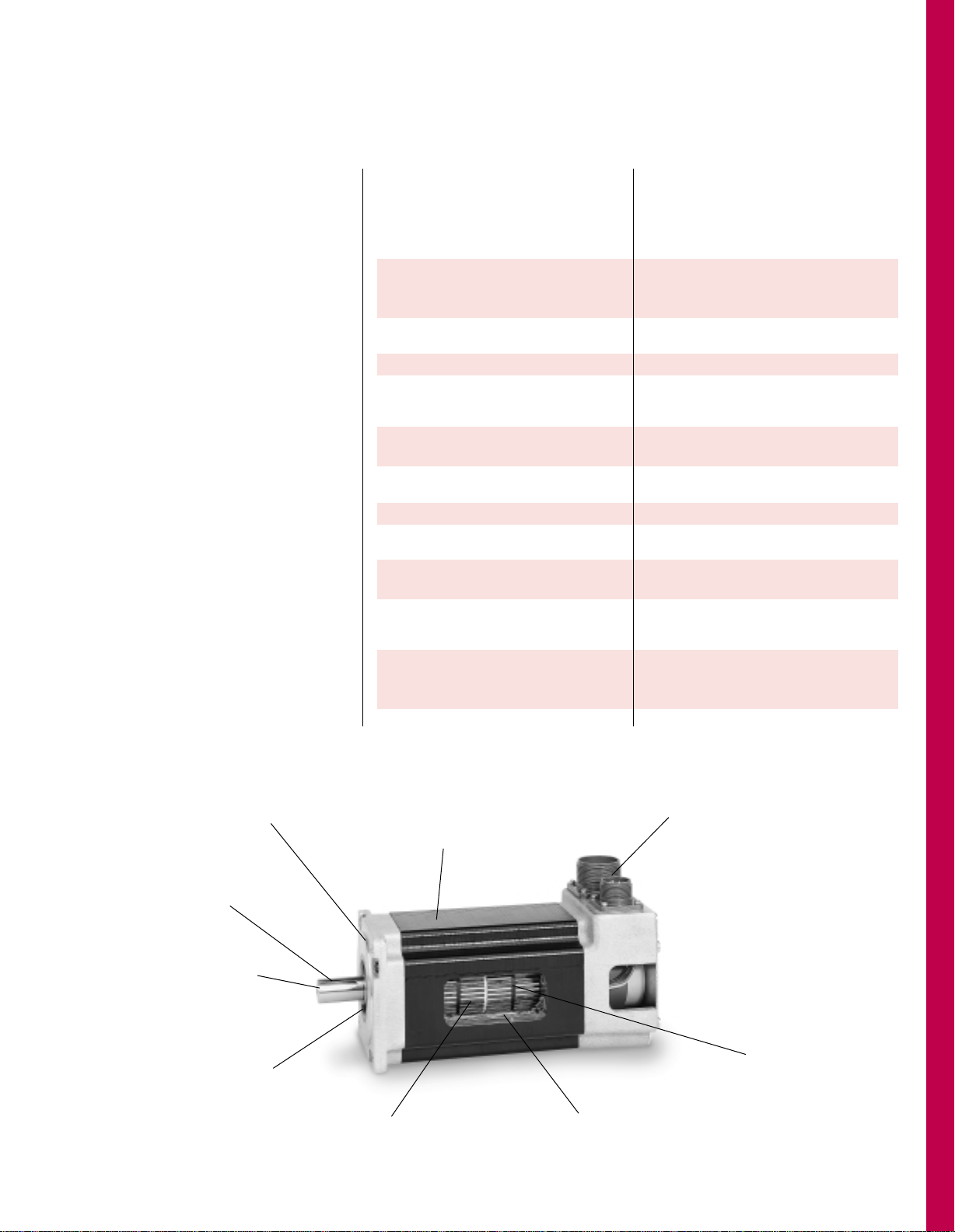

POWERPAC

™

HYBRID STEP MOTORS

Holding Torques to 5700

oz-in. (356 lb-in.)

New POWERPAC rugged NEMA 34 and

42 frame hybrid steppers provide the

highest torques per frame size in the

industry. Optimal magnetics in a

“housingless” frame combine with a

large diameter rotor and new rotor/

stator design to produce more torque

and provide high acceleration

capabilities. This unique design also

features low detent torque for

smoother microstepping. In addition,

POWERPAC runs cooler than

comparable size steppers.

N and K Series

POWERPAC is available in two

different designs; the N and K Series.

Both provide exceptionally high

holding torques. In addition, both

have high torque-to-inertia ratios and

therefore high acceleration

capabilities. The K Series incorporates

our patented Sigmax®flux focusing

technology and provides 25% more

torque than the N Series plus even

higher acceleration performance!

POWERPAC hybrid steppers

meet demanding motion

requirements, making

them cost effective

alternatives to

servo motors

in applications

with moderate

speed requirements.

Options

Combinations of standard options are

routinely provided to customize the

motor for your specific requirements.

For termination, select from terminal

board connections (via conduit sealed construction), MS connectors

(sealed construction) or flying leads.

Rear shaft extensions include one with

end bell mounting provisions for a

user installed encoder. Factory

mounted encoders are installed inside

the rear end bell in a sealed

construction...or outside, mounted

to the rear end bell. Front shaft

modifications may be specified. A

configuration such as an integral

spline is furnished as a special option.

Bipolar or unipolar phase sequencing

is readily available. In addition to

the standard selection of windings,

special windings are also provided.

Just call us!

10

www.pacsci.com

Sizing and Selection

Our OPTIMIZER™ Version 3.0

for Windows is a powerful motor

sizing and selection software program.

It provides a simple, time saving

method to specify the best POWERPAC

motor for your specific requirements.

Contact your Pacific Scientific

distributor for a copy or visit us

on the web at www.pacsci.com

BENEFITSFEATURES

With holding torques to 5700 oz-in. (356 lb-in.), Optimized magnetics provide maximum

the N and K Series provide the highest torques performance in small envelope, reducing space

per frame size in the industry— more than 3 required for the motor.

and 5 phase designs.

Improved torque linearity (above rated current) Acceleration boost to move loads even faster.

provides high peak torque capability Provides more torque for intermittent duty applications

(duty cycle dependent, contact factory)

High torque at moderate speeds Cost effective alternative to servo motors

Low detent torque harmonic Provides smoother microstepping performance

K Series uses patented Sigmax

®

technology Select from broad performance

to develop 25% more torque than N Series range to meet your requirement

Runs cooler than comparable steppers Longer, more reliable motor life— backed by a

using identical drive parameters two year warranty

Special rotor design for high acceleration Move/position loads fast

Rugged “housingless” square frame Efficient use of volume for optimal magnetic circuit

Sealed per IP65 For splashproof requirements

Outer bearing races won’t turn—front locked Long life bearings— also prevents

(in steel insert) and rear held by O-ring axial shaft movement for encoder applications

Extensive selection of shaft configurations, Match your requirements

terminations, standard and special windings

Two phase design Compatible with most drivers, smoother microstepping,

and lower input power required vs. three phase for

same torque

Optional encoder mounting provisions Optimizes control scheme

MORE POWER IN A SMALLER PACKAGE - POWERPAC

Optional shaft sizes and

special designs (spline, for

example) available

MS connector termination for motor and

optical encoder. Flying leads and terminal

board via conduit termination also

standard

Large diameter rotor coupled with optimum

magnetic design produces highest torque

and acceleration - both N and K Series

Rugged, square frame housingless

design provides NEMA and IP65

splashproof construction

Rare earth rotor magnets

provide high demagnetization

resistance

Standard NEMA mounting

Straight key. Other

options available

Long life bearings

withstand high radial

and axial forces

Sigmax®technology in K Series adds flux

concentrating rare earth stator magnets for even

higher torque and acceleration than N series

11

www.pacsci.com

12

POWERPAC

™

HYBRIDS INDEX

Product Overview

Inside front cover

How to use this Section

12

Features

11

Selection Overview

13

Technical Overview

3-4

Hybrid Step Motor Technology

5

Application Assistance

6-9

NEMA 34 Frame Motors

Model Number Code 14

Ratings and Characteristics 15-18

Torque and Acceleration Comparisons 19

Torque Linearity Curves 20

Performance (Torque/Speed) Curves 21-22

Drawings 23-24

NEMA 42 Frame Motors

Model Number Code 25

Ratings and Characteristics 26-28

Torque and Acceleration Comparisons 19, 29

Torque Linearity Curves 29

Performance (Torque/Speed) Curves 30-31

Drawings 32-33

Motor Technical Data

Power Connections 34-35

Phase Sequencing Tables 36

Encoder Mounting Options 36

Shaft Loading 37

Bearing Fatigue Life 37

How to use

this section

This guide covers the technical

information required to select and

order POWERPAC hybrid step

motors. Select the proper motor

using one of the following

procedures.

• If you’re already familiar with

these motors and the available

options, refer to the Model Number

Codes on pages 14 (NEMA 34)

and 25 (NEMA 42) to verify coded

information prior to ordering.

• If you’re not familiar with these

motors and the available options:

- refer to the Selection Overview,

p. 13, and Technical Overview,

p. 3-4. Ratings and Characteristics

for the NEMA 34 frame start on

p. 15 and p. 26 for the NEMA 42

frame. Both are followed by torque

and acceleration comparisons,

torque/speed curves and drawings

as shown in the index at the right.

Technical data common to both

NEMA 34 and 42 frames, including

connections, phasing diagrams,

encoder options, shaft loading

and bearing fatigue life starts on

page 34. To order, construct a

Model Number (pp. 14 and 25)

after all the technical parameters,

including options, are determined.

- If Application Assistance is

required, see the section starting

on page 6.

- Use OPTIMIZER

®

Version 3.0, our

Windows™compatible sizing and

selection software for both hybrid

steppers and brushless servomotors.

Optimizer will select a motor,

however, it may not include all

the options required. Construct

a model number after all the

technical parameters, including

options, are determined. Call

or fax us for your free disk

or visit us at www.pacsci.com

www.pacsci.com

13

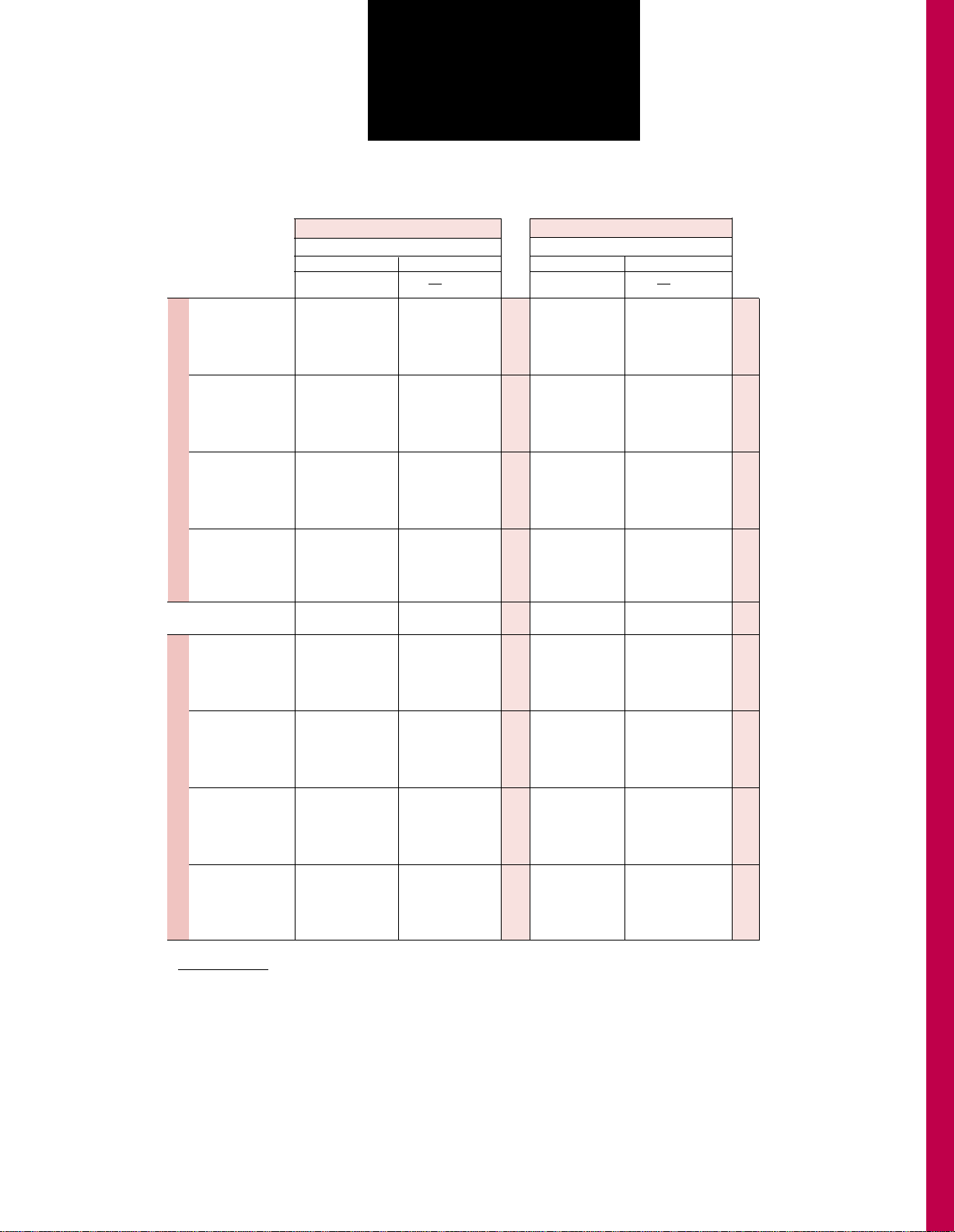

POWERPAC™HYBRIDS

SELECTION OVERVIEW

1 stack

2 stacks

3 stacks

4 stacks

1 stack

2 stacks

3 stacks

4 stacks

* Holding T

or

que

...a figure of merit for acceleration capability

Rotor Inertia

K Series - Sigmax

®

flux focusing technology

N Series - Standard

POWERPAC™ HYBRIDS

s

2

s

2

Page

Page

NEMA 34 NEMA 42

(3.38" square frame) (4.325" square frame)

Holding torque Torque-to-inertia ratio* Holding torque Torque-to-inertia ratio*

oz-in. (Nm)

rad

x 10

-3

oz-in. (Nm)

rad

x 10

-3

845(5.96) 41.8 15 2135(15.07) 27.3 26

1580(11.15) 41.6 16 4025(28.41) 26.0 27

2340(16.52) 41.3 17 5700(40.23) 24.9 28

2790(19.69) 37.2 18 NA NA

665(4.65) 32.9 15 1655(11.68) 21.1 26

1295(8.79) 32.8 16 3145(22.20) 20.3 27

1845(13.02) 32.5 17 4365(30.81) 19.0 28

2180(15.39) 29.1 18 NA NA

www.pacsci.com

14

POWERPAC™HYBRIDS

NEMA 34 Frame

(3.38" Square)

Basic Series

K=Sigmax

®

N=Standard

N3 3 HCHJ-LEK- M 2 -01

Number of

Rotor Stacks

1=1 Stacks

2=2 Stacks

3=3 Stacks

4=4 Stacks

Winding Type

H, J, K, L, and

M=Standards

M-(n/a on 1

stack)

H-(1 stack only)

S=Special, call

factory

Winding/Leads

F=8 Lead (n/a

C construction)

L=4 Lead series

H=4 Lead parallel

E=6 Lead (n/a

C construction)

Special Sequence

00=Standard motor–

no shaft seal

01=Standard motor

with shaft seal

Other #’s will be

assigned for special

motors

Construction/Hookup

R=Regular/leadwire

C=System

MS connector

L=Splashproof/to

terminal board via

conduit connector: 1/2"

NPSC pipe thread

M=Splashproof/to

terminal board via

conduit connector:

metric PG11 pipe thread

S=Special, call factory

Size

3=NEMA 34 frame size;

3.38" width/height,

square frame

Encoder Option

NS=No feedback

All of the configurations listed below

must use construction C or R and

shaft configuration E:

M2=Encoder mounting provisions

SS=Special, call factory

Shaft Modifications

K=Straight key

S=Special, call factory

Shaft Configuration

(Diameter & Length)

N=Single

D=Double (R or C

construction only)

E=Double ended for

encoder (R or C

construction only)

Rotor Type

L=Laminated

Mounting

Configuration

H=Heavy duty

NEMA

S=Special, call

factory

MODEL NUMBER CODE

HOW TO ORDER

Review the Motor Model Number Code to assure that all options are designated. Call your nearest Pacific

Scientific Motor Products Distributor to place orders and for application assistance. If you need to identify your

Distributor, call the Motor Products Division at (815) 226-3100.

The example model number above indicates a N series standard NEMA 34 frame motor with a three stack

rotor. This motor is equipped with a heavy duty front end bell and shaft, and a sealed system rear end

bell with MS connectors. It also has a bipolar parallel connection, a J winding, a straight keyway, encoder

mounting options and a shaft seal.

www.pacsci.com

15

POWERPAC

HYBRIDS

Also see:

• Torque and Acceleration Comparisons, p. 19

• Torque Linearity Curves, p. 20

• Performance Curves, p. 21-22

NEMA 34 FRAME (3.38" Square)—Ratings and Characteristics

Review the Model Number Code, page 14, to assure that all options are designated. Connections, encoders and

phasing diagrams start on page 34. Motor dimensions start on page 23. In addition to those below, motors with

characteristics for specific performance requirements are offered. Contact factory for more details.

Connection Holding

Torque Phase

Rated Inductance

Current/ Phase Thermal Rotor

Motor (2 phases on) Phase Resistance Detent Resistance Inertia

Model Number oz-in (Nm) (ohms) (mH) Torque oz-in-S2Weight

±10% (amps DC) ±10% Typical oz-in (Nm) (oC/watt) (kgm2x 10-3) lbs (kg)

K31HXHL-LXK-XX-XX • 830(5.86) 8.6 0.18 1.2

K31HXLL-LXK-XX-XX • 830(5.86) 4.3 0.72 4.7

K31HXEL-LXK-XX-XX • 590(4.16) 6.1 0.36 1.2

K31HXHK-LXK-XX-XX • 845(5.96) 6.6 0.29 2.1

K31HXLK-LXK-XX-XX • 845(5.96) 3.3 1.16 8.3

K31HXEK-LXK-XX-XX • 600(4.23) 4.7 0.58 2.1

K31HXHJ-LXK-XX-XX • 820(5.79) 5.5 0.42 2.8

K31HXLJ-LXK-XX-XX • 820(5.79) 2.7 1.69 11.4

K31HXEJ-LXK-XX-XX • 580(4.09) 3.9 0.84 2.8

K31HXHH-LXK-XX-XX • 805(5.68) 2.8 1.55 10.2

K31HXLH-LXK-XX-XX • 805(5.68) 1.4 6.21 40.7

K31HXEH-LXK-XX-XX • 570(4.02) 1.98 3.1 10.2

N31HXHL-LXK-XX-XX • 650(4.59) 8.6 0.18 1.4

N31HXLL-LXK-XX-XX • 650(4.59) 4.3 0.72 5.8

N31HXEL-LXK-XX-XX • 460(3.25) 6.1 0.36 1.4

N31HXHK-LXK-XX-XX • 665(4.69) 6.6 0.29 2.6

N31HXLK-LXK-XX-XX • 665(4.69) 3.3 1.16 10.3

N31HXEK-LXK-XX-XX • 470(3.32) 4.7 0.58 2.6

N31HXHJ-LXK-XX-XX • 645(4.55) 5.5 0.42 3.5

N31HXLJ-LXK-XX-XX • 645(4.55) 2.7 1.69 14

N31HXEJ-LXK-XX-XX • 455(3.21) 3.9 0.84 3.5

N31HXHH-LXK-XX-XX • 635(4.48) 2.8 1.55 12.5

N31HXLH-LXK-XX-XX • 635(4.48) 1.4 6.21 50.1

N31HXEH-LXK-XX-XX • 450(3.18) 1.98 3.1 12.5

Parallel

Series

Unipolar

Rated currents are in

descending order

Torque range:

570-845 oz-in.

35.6-52.8 lb-in.

4.02-5.96 Nm

K Series SIGMAX

®

1 rotor stack

25 2.7 0.0202 5

(0.18) (0.14) (2.27)

Torque range:

450-665 oz-in.

28.1-41.5 lb-in.

3.18-4.69 Nm

N Series Standard

1 rotor stack

18 2.7 0.0202 5

(0.13) (0.14) (2.27)

All ratings typical and at 25°C unless otherwise noted.

An ”X” in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 14.

Motor connections are determined by the Windings/Leads

designation in the Model Number Code on page 14. Note that

the F designation, although not shown in the above tables, is

an 8-lead option...see Terminations, page 34. In addition to the

lead wire termination, terminal board and MS connector hookup

for parallel, series or unipolar operation is also available.

With rated current applied. Windings at 130°C and motor

unmounted and in still air at 40°C.

Windings at 130°C and motor in still air at 40°C (without heat sink).

Motors may be operated up to 2 times rated current to provide

high peak torque with good torque linearity - duty cycle

dependant, contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

www.pacsci.com

16

Connection Holding

Torque Phase

Rated Inductance

Current/ Phase Thermal Rotor

Motor (2 phases on) Phase Resistance Detent Resistance Inertia

Model Number oz-in (Nm) (ohms) (mH) Torque oz-in-S

2

Weight

±10% (amps DC) ±10% Typical oz-in (Nm) (oC/watt) (kgm2x 10-3) lbs (kg)

K32HXHM-LXK-XX-XX • 1535(10.83) 10 0.18 1.4

K32HXLM-LXK-XX-XX • 1535(10.83) 5 0.7 5.5

K32HXEM-LXK-XX-XX • 1085(7.66) 7.1 0.35 1.4

K32HXHL-LXK-XX-XX • 1515(10.69) 8.1 0.26 2

K32HXLL-LXK-XX-XX • 1515(10.69) 4.1 1.03 8.1

K32HXEL-LXK-XX-XX • 1070(7.55) 5.8 0.52 2

K32HXHK-LXK-XX-XX • 1580(11.15) 6.1 0.45 4

K32HXLK-LXK-XX-XX • 1580(11.15) 3 1.8 16.2

K32HXEK-LXK-XX-XX • 1120(7.90) 4.3 0.9 4

K32HXHJ-LXK-XX-XX • 1510(10.66) 5.1 0.63 5.1

K32HXLJ-LXK-XX-XX • 1510(10.66) 2.5 2.53 20.5

K32HXEJ-LXK-XX-XX • 1065(7.52) 3.5 1.27 5.1

N32HXHM-LXK-XX-XX • 1215(8.58) 10 0.18 1.8

N32HXLM-LXK-XX-XX • 1215(8.58) 5 0.7 7

N32HXEM-LXK-XX-XX • 860(6.07) 7.1 0.35 1.8

N32HXHL-LXK-XX-XX • 1200(8.47) 8.1 0.26 2.6

N32HXLL-LXK-XX-XX • 1200(8.47) 4.1 1.03 10.3

N32HXEL-LXK-XX-XX • 850(6.00) 5.8 0.52 2.6

N32HXHK-LXK-XX-XX • 1245(8.79) 6.1 0.45 5.1

N32HXLK-LXK-XX-XX • 1245(8.79) 3 1.8 20.6

N32HXEK-LXK-XX-XX • 885(6.25) 4.3 0.9 5.1

N32HXHJ-LXK-XX-XX • 1195(8.43) 5.1 0.63 6.5

N32HXLJ-LXK-XX-XX • 1195(8.43) 2.5 2.53 26

N32HXEJ-LXK-XX-XX • 845(5.96) 3.5 1.27 6.5

Parallel

Series

Unipolar

Rated currents are in

descending order

Torque range:

1065-1580 oz-in.

66.5-98.7 lb-in.

7.52-11.15 Nm

K Series SIGMAX

®

2 rotor stacks

50 2 0.038 8.4

(0.35) (0.27) (3.81)

Torque range:

845-1245 oz-in.

52.8-77.8 lb-in.

5.96-8.79 Nm

N Series Standard

2 rotor stacks

36 2 0.038 8.4

(0.25) (0.27) (3.81)

All ratings typical and at 25°C unless otherwise noted.

An ”X” in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 14.

Motor connections are determined by the Windings/Leads

designation in the Model Number Code on page 14. Note that

the F designation, although not shown in the above tables, is

an 8-lead option...see Terminations, page 34. In addition to the

lead wire termination, terminal board and MS connector hookup

for parallel, series or unipolar operation is also available.

With rated current applied. Windings at 130°C and motor

unmounted and in still air at 40°C.

Windings at 130°C and motor in still air at 40°C (without heat sink).

Motors may be operated up to 2 times rated current to provide

high peak torque with good torque linearity - duty cycle

dependant, contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

POWERPAC

HYBRIDS

Also see:

• Torque and Acceleration Comparisons, p. 19

• Torque Linearity Curves, p. 20

• Performance Curves, p. 21-22

NEMA 34 FRAME (3.38" Square)—Ratings and Characteristics (Con’t)

Review the Model Number Code, page 14, to assure that all options are designated. Connections, encoders and

phasing diagrams start on page 34. Motor dimensions start on page 23. In addition to those below, motors with

characteristics for specific performance requirements are offered. Contact factory for more details.

www.pacsci.com

17

Connection Holding

Torque Phase

Rated Inductance

Current/ Phase Thermal Rotor

Motor (2 phases on) Phase Resistance Detent Resistance Inertia

Model Number oz-in (Nm) (ohms) (mH) Torque oz-in-S

2

Weight

±10% (amps DC) ±10% Typical oz-in (Nm) (oC/watt) (kgm2x 10-3) lbs (kg)

K33HXHM-LXK-XX-XX • 2150(15.17) 9.9 0.22 1.7

K33HXLM-LXK-XX-XX • 2150(15.17) 5 0.87 7

K33HXEM-LXK-XX-XX • 1520(10.73) 7 0.44 1.7

K33HXHL-LXK-XX-XX • 2340(16.52) 9 0.26 2.6

K33HXLL-LXK-XX-XX • 2340(16.52) 4.5 1.06 10.6

K33HXEL-LXK-XX-XX • 1655(11.68) 6.3 0.53 2.6

K33HXHK-LXK-XX-XX • 2205(15.56) 6.1 0.56 5

K33HXLK-LXK-XX-XX • 2205(15.56) 3 2.23 19.9

K33HXEK-LXK-XX-XX • 1560(11.01) 4.3 1.12 5

K33HXHJ-LXK-XX-XX • 2145(15.14) 5 0.83 7

K33HXLJ-LXK-XX-XX • 2145(15.14) 2.5 3.31 27.9

K33HXEJ-LXK-XX-XX • 1515(10.69) 3.5 1.65 7

N33HXHM-LXK-XX-XX • 1715(12.10) 9.9 0.22 2.3

N33HXLM-LXK-XX-XX • 1715(12.10) 5 0.87 9

N33HXEM-LXK-XX-XX • 1215(8.58) 7 0.44 2.3

N33HXHL-LXK-XX-XX • 1845(13.02) 9 0.26 3.4

N33HXLL-LXK-XX-XX • 1845(13.02) 4.5 1.06 13.6

N33HXEL-LXK-XX-XX • 1305(9.21) 6.3 0.53 3.4

N33HXHK-LXK-XX-XX • 1755(12.39) 6.1 0.56 6.4

N33HXLK-LXK-XX-XX • 1755(12.39) 3 2.23 25.8

N33HXEK-LXK-XX-XX • 1240(8.75) 4.3 1.12 6.4

N33HXHJ-LXK-XX-XX • 1710(12.07) 5 0.83 9

N33HXLJ-LXK-XX-XX • 1710(12.07) 2.5 3.31 36

N33HXEJ-LXK-XX-XX • 1210(8.54) 3.5 1.65 9

Parallel

Series

Unipolar

Rated currents are in

descending order

Torque range:

1515-2348 oz-in.

94.7-146.2 lb-in.

10.69-16.52 Nm

K Series SIGMAX

®

3 rotor stacks

75 1.6 0.0567 11.9

(0.53) (0.40) (5.39)

Torque range:

1210-1845 oz-in.

75.6-115.3 lb-in.

8.54-13.02 Nm

N Series Standard

3 rotor stacks

54 1.6 0.0567 11.9

(0.38) (0.40) (5.39)

All ratings typical and at 25°C unless otherwise noted.

An ”X” in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 14.

Motor connections are determined by the Windings/Leads

designation in the Model Number Code on page 14. Note that

the F designation, although not shown in the above tables, is

an 8-lead option...see Terminations, page 34. In addition to the

lead wire termination, terminal board and MS connector hookup

for parallel, series or unipolar operation is also available.

With rated current applied. Windings at 130°C and motor

unmounted and in still air at 40°C.

Windings at 130°C and motor in still air at 40°C (without heat sink).

Motors may be operated up to 2 times rated current to provide

high peak torque with good torque linearity - duty cycle

dependant, contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

POWERPAC

HYBRIDS

Also see:

• Torque and Acceleration Comparisons, p. 19

• Torque Linearity Curves, p. 20

• Performance Curves, p. 21-22

NEMA 34 FRAME (3.38" Square)—Ratings and Characteristics (Con’t)

Review the Model Number Code, page 14, to assure that all options are designated. Connections, encoders and

phasing diagrams start on page 34. Motor dimensions start on page 23. In addition to those below, motors with

characteristics for specific performance requirements are offered. Contact factory for more details.

www.pacsci.com

18

Connection Holding

Torque Phase

Rated Inductance

Current/ Phase Thermal Rotor

Motor (2 phases on) Phase Resistance Detent Resistance Inertia

Model Number oz-in (Nm) (ohms) (mH) Torque oz-in-S

2

Weight

±10% (amps DC) ±10% Typical oz-in (Nm) (oC/watt) (kgm2x 10-3) lbs (kg)

K34HXHM-LXK-XX-XX • 2725(19.23) 11.3 0.2 2

K34HXLM-LXK-XX-XX • 2725(19.23) 5.6 0.82 8.2

K34HXEM-LXK-XX-XX • 1930(13.62) 8 0.41 2

K34HXHL-LXK-XX-XX • 2790(19.69) 8.7 0.33 3.6

K34HXLL-LXK-XX-XX • 2790(19.69) 4.4 1.32 14.5

K34HXEL-LXK-XX-XX • 1975(13.94) 6.2 0.66 3.6

K34HXHK-LXK-XX-XX • 2580(18.21) 6 0.67 6.3

K34HXLK-LXK-XX-XX • 2580(18.21) 3 2.69 25.1

K34HXEK-LXK-XX-XX • 1825(12.88) 4.3 1.35 6.3

K34HXHJ-LXK-XX-XX • 2770(19.55) 5.5 0.8 8.9

K34HXLJ-LXK-XX-XX • 2770(19.55) 2.8 3.19 35.5

K34HXEJ-LXK-XX-XX • 1960(13.83) 3.9 1.6 8.9

N34HXHM-LXK-XX-XX • 2140(15.10) 11.3 0.2 2.6

N34HXLM-LXK-XX-XX • 2140(15.10) 5.6 0.82 10.6

N34HXEM-LXK-XX-XX • 1510(10.66) 8 0.41 2.6

N34HXHL-LXK-XX-XX • 2180(15.39) 8.7 0.33 4.7

N34HXLL-LXK-XX-XX • 2180(15.39) 4.4 1.32 18.8

N34HXEL-LXK-XX-XX • 1545(10.90) 6.2 0.66 4.7

N34HXHK-LXK-XX-XX • 2035(14.36) 6 0.67 8.1

N34HXLK-LXK-XX-XX • 2035(14.36) 3 2.69 32.4

N34HXEK-LXK-XX-XX • 1440(10.16) 4.3 1.35 8.1

N34HXHJ-LXK-XX-XX • 2170(15.32) 5.5 0.8 11.5

N34HXLJ-LXK-XX-XX • 2170(15.32) 2.8 3.19 45.9

N34HXEJ-LXK-XX-XX • 1535(10.83) 3.9 1.6 11.5

Parallel

Series

Unipolar

Rated currents are in

descending order

Torque range:

1825-2798 oz-in.

114.1-174.4 lb-in.

12.88-19.69 Nm

K Series SIGMAX

®

4 rotor stacks

65 1.3 0.075 15.1

(0.50) (0.53) (6.84)

Torque range:

1940-2180 oz-in.

90.0-136.2 lb-in.

10.16-15.39 Nm

N Series Standard

4 rotor stacks

57 1.3 0.075 15.1

(0.40) (0.53) (6.84)

All ratings typical and at 25°C unless otherwise noted.

An ”X” in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 14.

Motor connections are determined by the Windings/Leads

designation in the Model Number Code on page 14. Note that

the F designation, although not shown in the above tables, is

an 8-lead option...see Terminations, page 34. In addition to the

lead wire termination, terminal board and MS connector hookup

for parallel, series or unipolar operation is also available.

With rated current applied. Windings at 130°C and motor

unmounted and in still air at 40°C.

Windings at 130°C and motor in still air at 40°C (without heat sink).

Motors may be operated up to 2 times rated current to provide

high peak torque with good torque linearity - duty cycle

dependant, contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

POWERPAC

HYBRIDS

Also see:

• Torque and Acceleration Comparisons, p. 19

• Torque Linearity Curves, p. 20

• Performance Curves, p. 21-22

NEMA 34 FRAME (3.38" Square)—Ratings and Characteristics (Con’t)

Review the Model Number Code, page 14, to assure that all options are designated. Connections, encoders and

phasing diagrams start on page 34. Motor dimensions start on page 23. In addition to those below, motors with

characteristics for specific performance requirements are offered. Contact factory for more details.

www.pacsci.com

19

POWERPAC

HYBRIDS

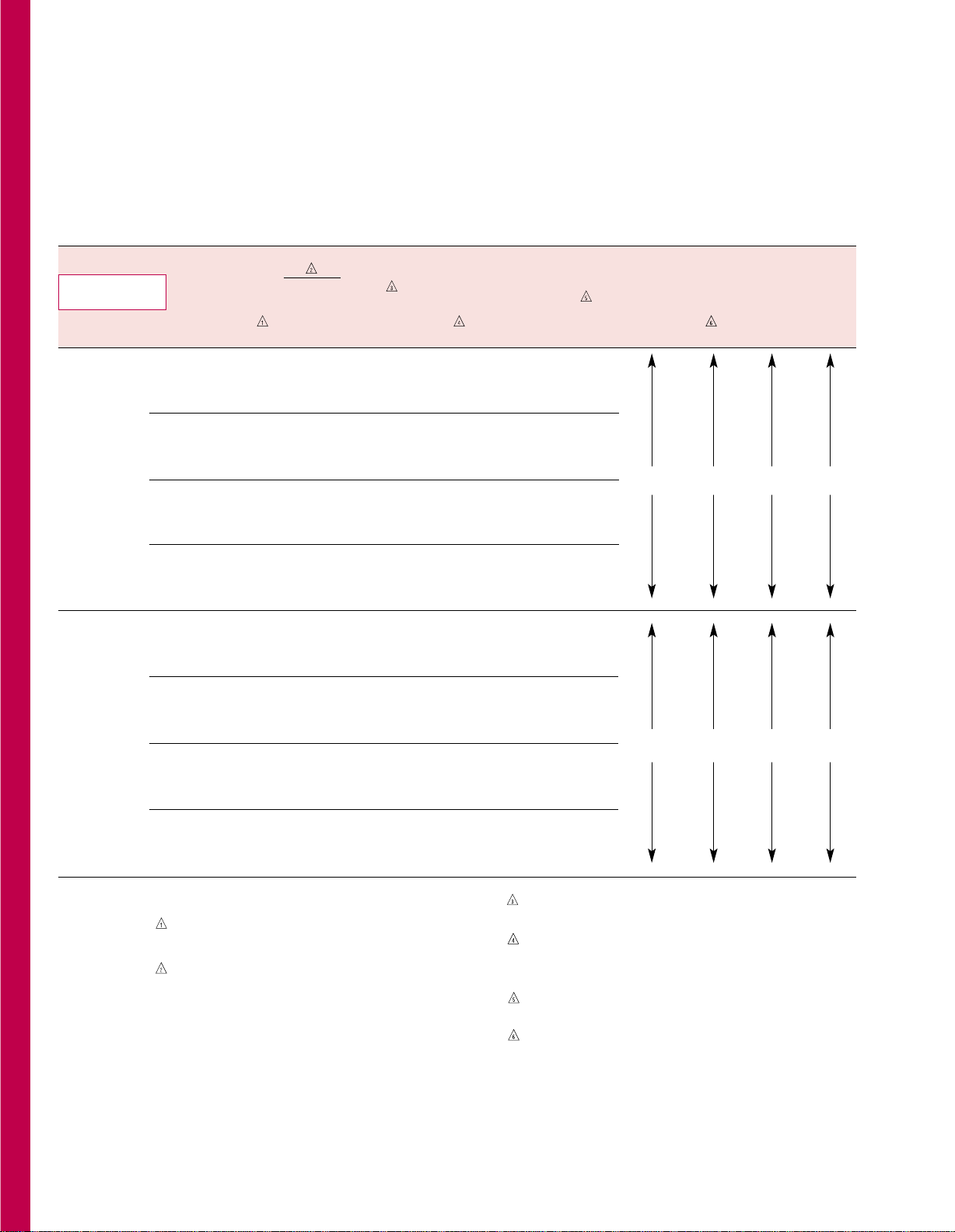

Torque and Acceleration Comparisons

Holding Torque

3000

2500

2000

1500

1000

665

845

1245

1580

1845

2180

2790

2340

500

0

N31

K31

N32

K32

K33

K34

N33

N34

Motor Model/Stack Length

Acceleration

rad

x 10 *

s

2

3

45.0

40.0

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0

N31

32.9

41.8

32.8

41.6

32.5

41.3

29.1

37.2

K31 N32

K32

N33 K33

N34

K34

Motor Model/Stack Length

* Holding Torque

...a figure of merit for acceleration capability

Rotor Inertia

NEMA 34 FRAME (3.38" Square)—

Torque and Acceleration Comparisons

NEMA 42** FRAME (4.325" Square)—

Torque and Acceleration Comparisons

Holding Torque

N41

0

1000

1655

2135

3145

4025

4365

5700

2000

3000

4000

5000

6000

K41

N42

K42

N43

K43

Motor Model/Stack Length

Acceleration

rad

x 10 *

s

2

3

30.0

25.0

20.0

21.1

27.3

20.3

K41N41 K42N42

Motor Model/Stack Length

K43N43

26.0

19.0

24.9

15.0

10.0

5.0

0

* Holding Torque

...a figure of merit for acceleration capability

Rotor Inertia

**Size 42 data shown here for comparison. NEMA 42 starts on

page 25.

www.pacsci.com

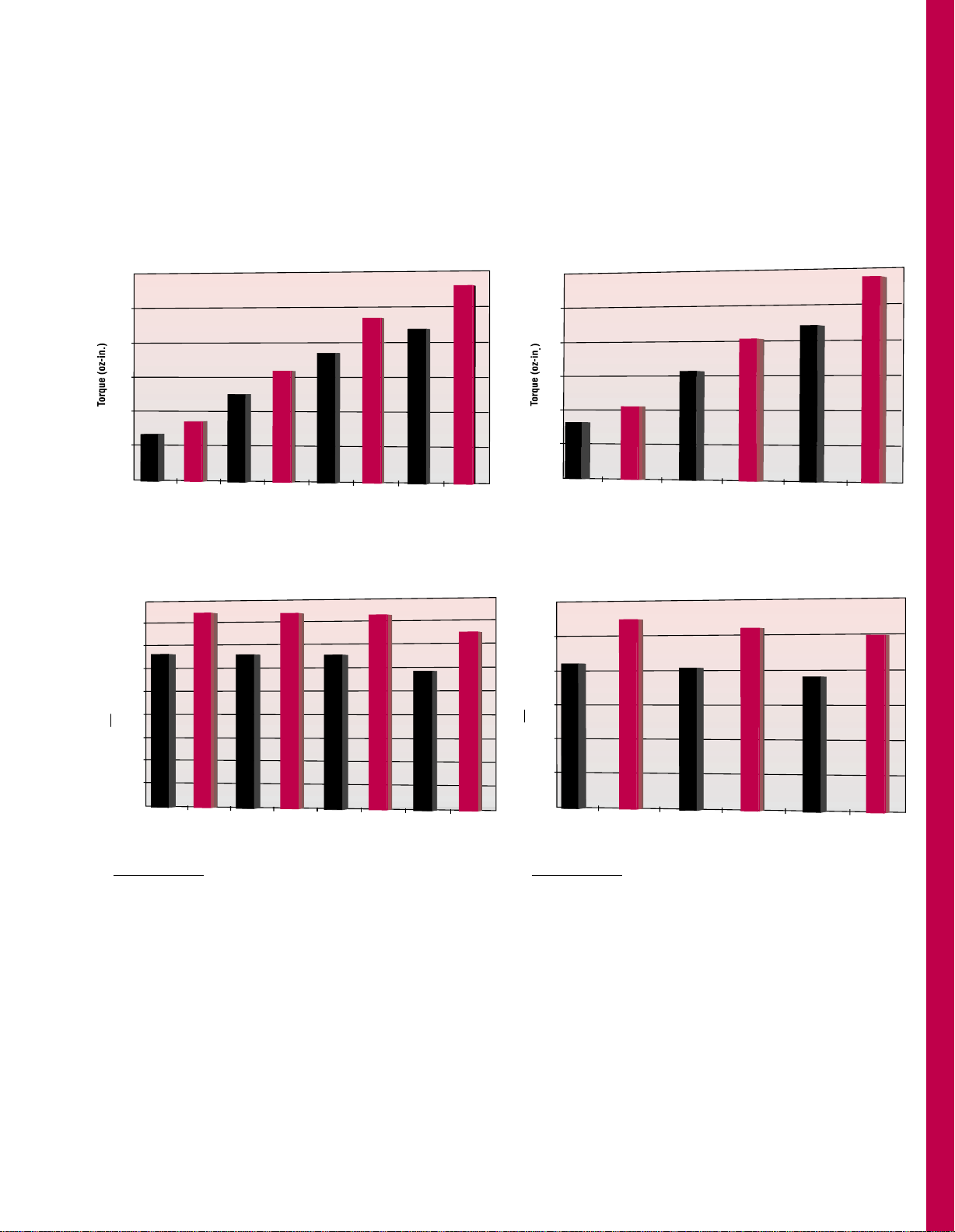

20

POWERPAC

HYBRIDS

NEMA 34 FRAME (3.38" Square)—Torque Linearity

A significant POWERPAC performance attribute is that when a current higher than rated current is applied, the increase in torque will be more

linear than other hybrids. Furthermore, current levels increasingly higher than rated current are less likely to cause demagnetization. Capitalize

on this performance characteristic which will provide an acceleration boost to move loads even faster. This technique is applicable to

intermittent duty applications in that the thermal limit of the motor cannot be exceeded. Driving the motor at higher than rated current is duty

cycle dependent. Contact the factory for application assistance.

These curves show the torque at rated current and the torque linearity up to two times rated current.

02.8

4500

5.6 8.4 11.3 14.1 16.9 19.7 22.6

4000

3500

3000

2000

1500

1000

2500

500

31.7

28.2

24.7

21.1

14.1

10.6

7.0

17.6

3.5

0

02.4

4000

4.9 7.4 9.9 12.3 14.8 17.3 19.8

3500

3000

2500

1500

1000

2000

500

28.2

24.7

21.1

17.6

10.6

7.0

14.1

3.5

0

02.5

2500

5 7.5 10 12.5 15 17.5 20

2000

1500

1000

500

17.6

14.1

10.6

7.0

3.5

0

02.1

1400

4.3 6.4 8.6 10.7 12.9 15.1 17.2

1200

1000

800

600

400

200

0

9.8

8.4

7.0

5.6

4.2

2.8

1.4

Holding Torque [Oz-in]

Holding Torque [Oz-in]

Current

[Amps]

Current

[Amps]

Holding Torque [Oz-in]

Current

[Amps]

Holding Torque [Oz-in]

Holding Torque [Nm]

Holding Torque [Nm]

Holding Torque [Nm]

Holding Torque [Nm]

Current

[Amps]

TORQUE LINEARITY

N & K 31 L-Winding

(bipolar parallel connection)

TORQUE LINEARITY

N & K 32 M-Winding

(bipolar parallel connection)

TORQUE LINEARITY

N & K 34 M-Winding

(bipolar parallel connection)

TORQUE LINEARITY

N & K 33 M-Winding

(bipolar parallel connection)

K34

N34

Rated Current

K33

N33

Rated Current

K32

N32

Rated Current

K31

N31

Rated Current

www.pacsci.com

21

POWERPAC

HYBRIDS

NEMA 34 FRAME (3.38" Square)—Performance

Motors will perform continuously as shown without the winding temperature exceeding 130°C when the motor is operated (without heat sink) in

an ambient temperature of up to 40°C. The curves do not reflect system resonance points, which will vary with motor coupling and system

parameters.

NEMA 34 FRAME – ONE ROTOR STACK

5A per phase; K31* and N31*

J winding, parallel connection, See Ratings and Characteristics, p. 15.

SPEED (RPM)

Model Numbers*/Voltage

5A per phase

K31HXHJ-...; 75V

N31HXHJ-...; 75V

N31HXHJ-...; 65V

N31HXHJ-...; 40V

SPEED (FULL STEP/SEC)

TORQUE (OZ-IN.)

TORQUE (Nm)

0

100

200

300

400

500

600

700

0 300 600 900 1200 1500 1800

0 1000 2000 3000 4000 5000 6000

0

0.7

1.4

2.1

2.8

3.5

4.2

4.9

NEMA 34 FRAME – TWO ROTOR STACKS

5A per phase; K32* and N32*

J winding, parallel connection, See Ratings and Characteristics, p. 16.

0 600 1200 1800 2400

0 2000 4000 6000 8000

0

200

400

600

800

1000

1200

1400

0

1.4

2.8

4.2

5.7

7.0

8.5

9.9

SPEED (RPM)

SPEED (FULL STEP/SEC)

TORQUE (OZ-IN.)

TORQUE (Nm)

K32HXHJ-...; 75V

N32HXHJ-...; 75V

N32HXHJ-...; 65V

N32HXHJ-...; 40V

Model Numbers*/Voltage

5A per phase

*See Model Number Code on page 14 for clarification.

www.pacsci.com

22

POWERPAC

HYBRIDS

NEMA 34 FRAME (3.38" Square)—Performance

Motors will perform continuously as shown without the winding temperature exceeding 130°C when the motor is operated (without heat sink) in

an ambient temperature of up to 40°C. The curves do not reflect system resonance points, which will vary with motor coupling and system

parameters.

NEMA 34 FRAME – THREE ROTOR STACKS

5A per phase; K33* and N33*

J winding, parallel connection, See Ratings and Characteristics, p. 17.

0 600 1200 1800 2400

0 2000 4000 6000 8000

0

800

1200

1600

2000

400

0

5.7

8.5

11.3

14.2

2.8

SPEED (RPM)

SPEED (FULL STEP/SEC)

TORQUE (OZ-IN.)

TORQUE (Nm)

K33HXHJ-...; 75V

N33HXHJ-...; 75V

N33HXHJ-...; 65V

N33HXHJ-...; 40V

Model Numbers*/Voltage

5A per phase

NEMA 34 FRAME – FOUR ROTOR STACKS

5A per phase; K34* and N34*

J winding, parallel connection, See Ratings and Characteristics, p. 18.

0

500

1000

1500

2000

2500

3.5

7.1

10.6

14.1

17.7

0 300 900 1500 1800

0 1000 3000

600

2000 5000

1200

4000 6000

0

SPEED (RPM)

SPEED (FULL STEP/SEC)

TORQUE (OZ-IN.)

TORQUE (Nm)

K34HXHJ-...; 75V

N34HXHJ-...; 75V

N34HXHJ-...; 65V

N34HXHJ-...; 40V

Model Numbers*/Voltage

5A per phase

*See Model Number Code on page 14 for clarification.

www.pacsci.com

23

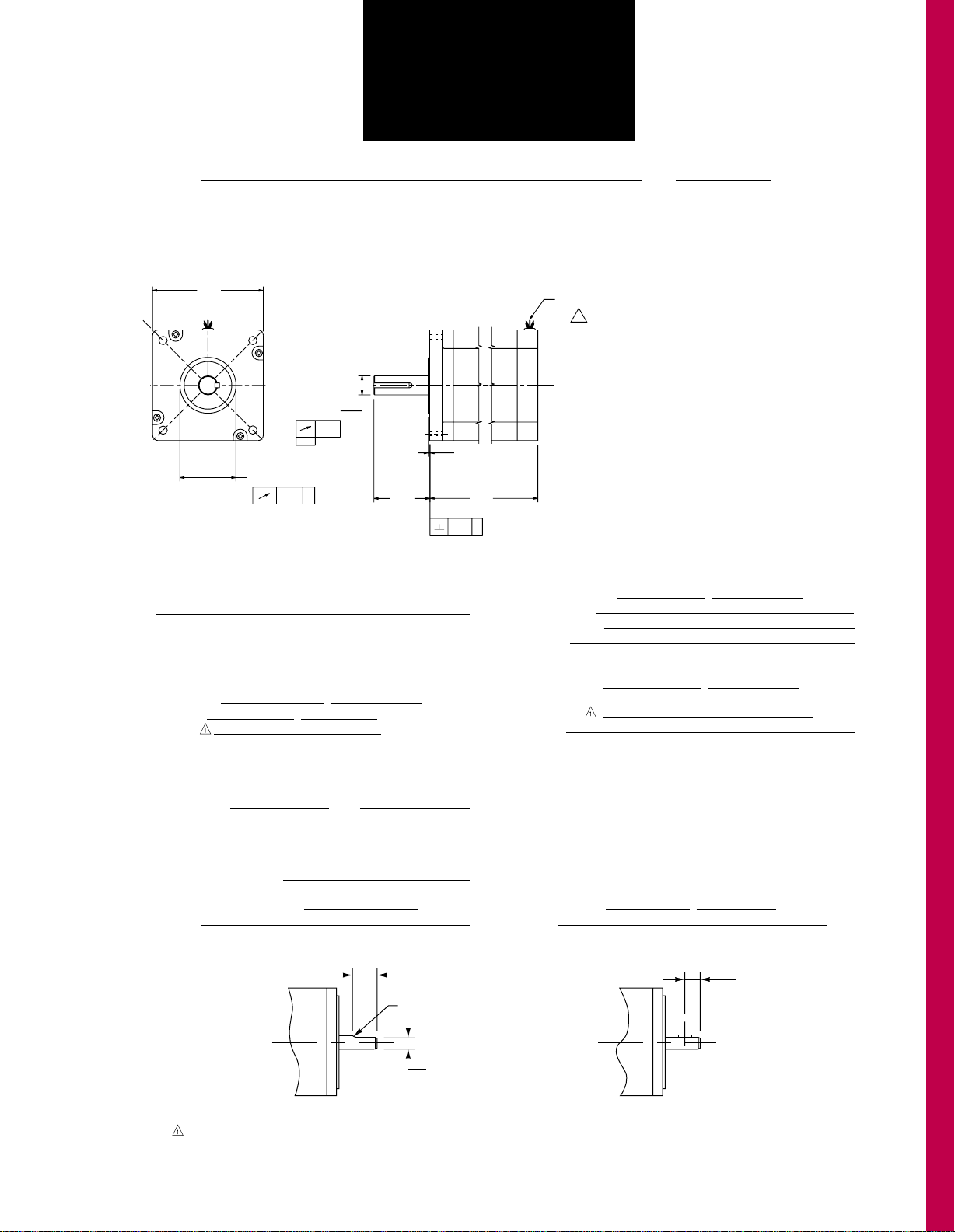

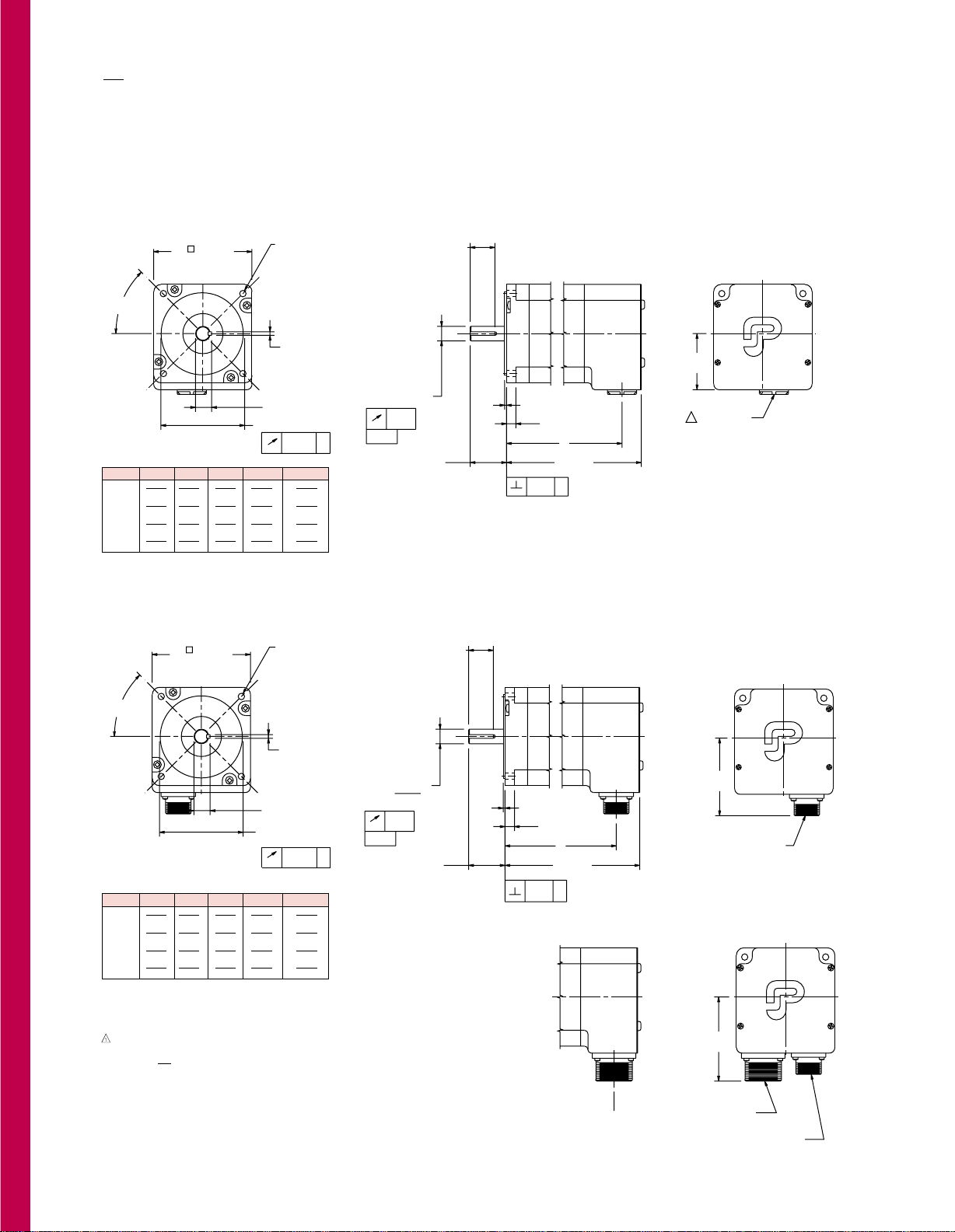

DIMENSIONS . . .

POWERPAC

HYBRIDS

in.

(metric dimensions for ref. only)

mm

NEMA 34 FRAME: All motors have a heavy duty NEMA front end bell and large diameter shaft to

support the higher output torques

LEADWIRE HOOKUP - ENCODER OPTIONS

Model Number Code designation R (Construction/Hookup), p. 14.

4X Ø .218 (5,537) THRU

EQUALLY SPACED ON

A Ø 3.875 (98,425) B.C.

.003

-A-

.003

0,051

0,077

0,077

Ø D

+.0000

(0,013)

-.0005

1

+.000

–.017 (-0,432)

K

+.0000

–.0020 (-0,051)

.002

( 3.38)

(85,852)

.06

1,52

L MAX.

Ø 2.875 ± .002

73,025 ± 0,051

(2X 45°)

1.25

31,750

MOTOR LEADS

.875 ± .010

22,23 ± 0,254

(.33)

(8,38)

T

NOTES:

1 MOTOR LEADS 12.0 MIN.

A

A

LEADWIRE HOOKUP

DOUBLE SHAFT CONFIGURATION

Model Number Code designation D (Shaft Configuration), p. 14.

LEADWIRE HOOKUP

ENCODER MOUNTING PROVISION

Model Number Code designation M2

(Encoder Mounting Options), p. 14.

Ø .3148

8,000

+.0000

–.0005

-B-

.002

0,051

.003

0,077

ON A Ø 1.812 B.C.

46,025

.625 ± .040

15,875 ± 1,016

2X 2-56 UNC-2B

.20 MIN.

-0,013

B

MOTOR D K T L MAX

.5000 .1250 .555 3.13

31 HR

12,700 3,175 14,097 79,502

.5000 .1250 .555 4.65

32 HR

12,700 3,175 14,097 118,11

.6250 .1875 .705 6.13

33 HR

15,875 4,763 17,907 155,70

.6250 .1875 .705 7.68

34 HR

15,875 4,763 17,907 195,07

Ø .3750

9,525

+.0000

–.0005

.002

0,051

1.12 ± .06

28,448 ± .1,520

-0,013

www.pacsci.com

24

ENCODER

MOUNTING OPTION

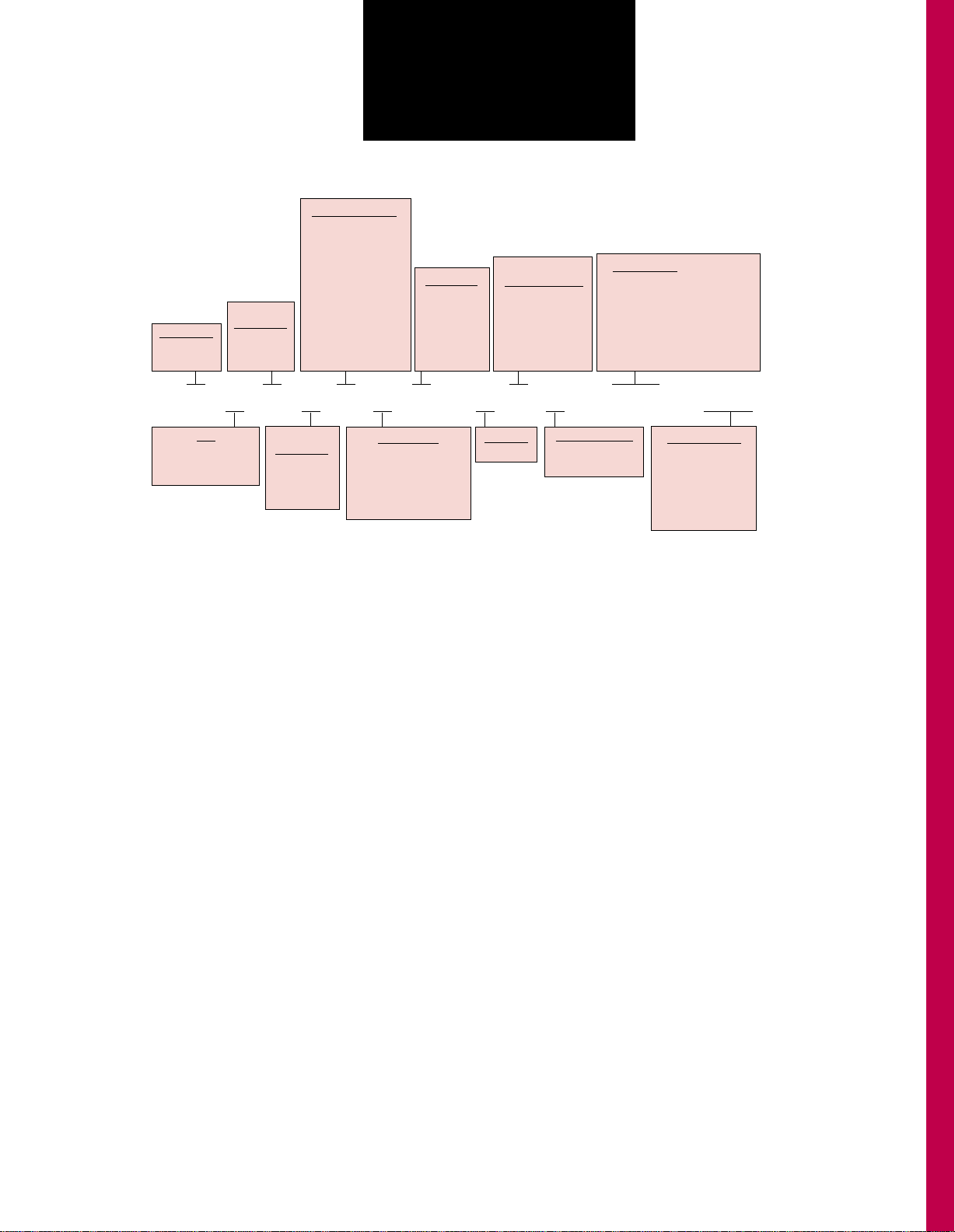

DIMENSIONS . . .

POWERPAC

HYBRIDS

in.

(metric dimensions for ref. only)

mm

NEMA 34 FRAME: All motors have a heavy duty NEMA front end bell and large diameter shaft to

support the higher output torques

SPLASHPROOF CONSTRUCTION/TERMINAL BOARD CONNECTIONS

(via English or Metric thread for conduit) Model Number Code designation L or M (Construction/Hookup), p 14.

SPLASHPROOF CONSTRUCTION/MS CONNECTOR(S)— ENCODER OPTION

Model Number Code designation C/System (Construction/Hookup) and Encoder Mounting Option, p 14.

4X Ø .218 (5,537) THRU

EQUALLY SPACED ON

A Ø 3.875 (98,425) B.C.

.003 A

0,077

-A-

.003 A

Ø D

+.0000

–.0005 (-0,013)

+.000

–.017 (0,432)

K

+.0000

–.0020 (-0,508)

.002

0,077

0,051

Removable

Insulating Bushing

( 3.38)

85,852

.06

Ø 2.875 ± .002

(2X 45°)

1.25

31,750

.875 ± .010

22,23 ± 0,254

(.33)

1,52

(8,38)

T

L MAX.

X

1.95 (49,53)

MAX.

1

Construction = Conduit

connection (1/2 NPSC TAP)

with

.56

I.D. removable

insulating bushing

Construction = Conduit

connection (PG 11 TAP).

(No insulating bushing

supplied)

L

M

14,2

.003 A

0,077

4X Ø .218 (5,537) THRU

EQUALLY SPACED ON

A Ø 3.875 (98,425) B.C.

.003 A

-A-

Ø D

+.0000

–.0005

-0,013

+.000

–.017 (-0,432)

K

+.0000

–.0020 (-0,508)

.002

0,077

0,051

.06

(.33)

1,52

8,38

L MAX.

( 3.38)

85,852

Ø 2.875 ± .002

73,025 ± 0,051

(2X 45°)

2.69 (68,33)

MAX.

X

MOTOR CONNECTOR

1.25

31,75

.875 ± .010

22,23 ± .0,254

T

ENCODER

CONNECTOR

MOTOR CONNECTOR

2.92 (74,17)

MAX.

X dimension same

as above

MOTOR D K T X L MAX

.5000 .1250 .555 3.70 4.44

31 HL

12,700 3,175 14,097 93,98 112,78

.5000 .1250 .555 5.22 5.96

32 HL

12,700 3,175 14,097 132,59 151,38

.6250 .1875 .705 6.74 7.48

33 HL

15,875 4,763 17,907 171,20 189,99

.6250 .1875 .705 8.25 8.99

34 HL

15,875 4,763 17,907 209,55 228,35

* See Model Number Code, p 14.

MOTOR D K T X L MAX

.5000 .1250 .555 3.56 4.44

31 HC

12,700 3,175 14,097 90,42 112,78

.5000 .1250 .555 5.07 5.96

32 HC

12,700 3,175 14,097 128,78 151,38

.6250 .1875 .705 6.59 7.48

33 HC

15,875 4,763 17,907 165,10 189,99

.6250 .1875 .705 8.11 8.99

34 HC

15,875 4,763 17,907 205,99 228,35

* See Model Number Code, p 14.

NOTES:

www.pacsci.com

25

POWERPAC™HYBRIDS

NEMA 42 Frame

(4.325" Square)

Basic Series

K=Sigmax

®

N=Standard

K4 3 HCHJ-LEK-M2 -01

Number of

Rotor Stacks

1=1 Stacks

2=2 Stacks

3=3 Stacks

Winding Type

J-(only on 1 stack),

K-(n/a on 1 stack),

L,

N-(n/a on 1 stack),

M=Standards

S=Special, call

factory

Winding/Leads

L=4 Lead series

H=4 Lead parallel

E=6 Lead (N/A

C construction)

F=8 Lead (N/A

C construction)

Special Sequence

00=Standard motor–

no shaft seal

01=Standard motor

with shaft seal.

Other #’s will be

assigned for special

motors

Construction/Hookup

R=Regular/leadwire

C=System

MS connector

L=Splashproof/to

terminal board via

conduit connector: 1/2"

NPSC pipe thread

M=Splashproof/to

terminal board via

conduit connector:

metric PG13,5 pipe

thread

S=Special, call factory

Size

4=NEMA 42 frame size;

4.325" width/height,

square frame

Encoder Option

NS=No feedback

All of the configurations listed below

must use construction C or R and

shaft configuration E:

M2=Encoder mounting provisions

SS=Special, call factory

Shaft Modifications

K=Straight key

S=Special, call factory

Shaft Configuration

(Diameter & Length)

N=Single

D=Double (R or C

construction only)

E=Double ended for

encoder (R or C

construction only)

S=Special, call factory

Rotor Type

L=Laminated

Mounting

Configuration

H=Heavy duty

NEMA

S=Special, call

factory

MODEL NUMBER CODE

HOW TO ORDER

Review the Motor Model Number Code to assure that all options are designated. Call your nearest Pacific

Scientific Motor Products Distributor to place orders and for application assistance. If you need to identify

your Distributor, call the Motor Products Division at (815) 226-3100.

The example model number above indicates a K series (Sigmax

®

) NEMA 42 frame motor with a three stack

rotor. This motor is equipped with a heavy duty front end bell and shaft, and a sealed system rear end bell

with MS connectors. It also has a bipolar parallel connection, a J winding, a straight keyway, a shaft seal

and encoder mounting provisions.

www.pacsci.com

26

POWERPAC

HYBRIDS

Also see:

• Torque and Acceleration Comparisons, p. 19, 29

• Torque Linearity, p. 29

• Performance Curves, p. 30-31

NEMA 42 FRAME (4.325" Square)—Ratings and Characteristics

Review the Model Number Code, page 25, to assure that all options are designated. Connections, encoders and

phasing diagrams start on page 34. Motor dimensions start on page 32. In addition to those below, motors with

characteristics for specific performance requirements are offered. Contact factory for more details.

Connection Holding

Torque Phase

Rated Inductance

Current/ Phase Thermal Rotor

Motor (2 phases on) Phase Resistance Detent Resistance Inertia

Model Number oz-in (Nm) (ohms) (mH) Torque oz-in-S

2

Weight

±10% (amps DC) ±10% Typical oz-in (Nm) (oC/watt) (kgm2x 10-3) lbs (kg)

K41HXHM-LXK-XX-XX • 2135(15.07) 10.7 0.16 2.2

K41HXLM-LXK-XX-XX • 2135(15.07) 5.3 0.63 8.7

K41HXEM-LXK-XX-XX • 1510(10.66) 7.5 0.31 2.2

K41HXHL-LXK-XX-XX • 2090(14.75) 8.7 0.23 3.1

K41HXLL-LXK-XX-XX • 2090(14.75) 4.4 0.93 12.3

K41HXEL-LXK-XX-XX • 1480(10.45) 6.2 0.47 3.1

K41HXHJ-LXK-XX-XX • 2095(14.79) 5.5 0.58 7.8

K41HXLJ-LXK-XX-XX • 2095(14.79) 2.7 2.33 31.4

K41HXEJ-LXK-XX-XX • 1480(10.45) 3.9 1.16 7.8

N41HXHM-LXK-XX-XX • 1655(11.68) 10.7 0.16 2.8

N41HXLM-LXK-XX-XX • 1655(11.68) 5.3 0.63 11.1

N41HXEM-LXK-XX-XX • 1170(8.26) 7.5 0.31 2.8

N41HXHL-LXK-XX-XX • 1625(11.47) 8.7 0.23 3.9

N41HXLL-LXK-XX-XX • 1625(11.47) 4.4 0.93 15.8

N41HXEL-LXK-XX-XX • 1150(8.12) 6.2 0.47 3.9

N41HXHJ-LXK-XX-XX • 1630(11.50) 5.5 0.58 10.1

N41HXLJ-LXK-XX-XX • 1630(11.50) 2.7 2.33 40.4

N41HXEJ-LXK-XX-XX • 1150(8.12) 3.9 1.16 10.1

Parallel

Series

Unipolar

Rated currents are in

descending order

Torque range:

1480-2135 oz-in.

92.5-133.4 lb-in.

10.45-15.07 Nm

K Series SIGMAX

®

1 rotor stack

65 1.9 0.0783 11

(0.46) (0.55) (4.98)

Torque range:

1150-1655 oz-in.

78.1-103.4 lb-in.

8.12-11.68 Nm

N Series Standard

1 rotor stack

42 1.9 0.0783 11

(0.30) (0.55) (4.98)

All ratings typical and at 25°C unless otherwise noted.

An ”X” in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 25.

Motor connections are determined by the Windings/Leads

designation in the Model Number Code on page 25. Note that

the F designation, although not shown in the above tables, is

an 8-lead option...see Terminations, page 34. In addition to the

lead wire termination, terminal board and MS connector hookup

for parallel, series or unipolar operation is also available.

With rated current applied. Windings at 130°C and motor

unmounted and in still air at 40°C.

Windings at 130°C and motor in still air at 40°C (without heat sink).

Motors may be operated up to 2 times rated current to provide

high peak torque with good torque linearity - duty cycle

dependant, contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

www.pacsci.com

27

Connection Holding

Torque Phase

Rated Inductance

Current/ Phase Thermal Rotor

Motor (2 phases on) Phase Resistance Detent Resistance Inertia

Model Number oz-in (Nm) (ohms) (mH) Torque oz-in-S

2

Weight

±10% (amps DC) ±10% Typical oz-in (Nm) (oC/watt) (kgm2x 10-3) lbs (kg)

K42HXHN-LXK-XX-XX • 4000(28.23) 15.8 0.1 1.6

K42HXLN-LXK-XX-XX • 4000(28.23) 7.9 0.41 6.5

K42HXEN-LXK-XX-XX • 2830(19.97) 11.2 0.21 1.6

K42HXHM-LXK-XX-XX • 4025(28.41) 9.9 0.25 4.2

K42HXLM-LXK-XX-XX • 4025(28.41) 4.9 1.02 16.9

K42HXEM-LXK-XX-XX • 2845(20.08) 7 0.51 4.2

K42HXHL-LXK-XX-XX • 3935(27.77) 8.1 0.38 6

K42HXLL-LXK-XX-XX • 3935(27.77) 4 1.51 23.9

K42HXEL-LXK-XX-XX • 2785(19.66) 5.7 0.75 6

K42HXHK-LXK-XX-XX • 3965(27.99) 6.4 0.6 9.8

K42HXLK-LXK-XX-XX • 3965(27.99) 3.2 2.41 39.2

K42HXEK-LXK-XX-XX • 2805(19.80) 4.5 1.2 9.8

N42HXHN-LXK-XX-XX • 3130(22.09) 15.8 0.1 2.1

N42HXLN-LXK-XX-XX • 3130(22.09) 7.9 0.41 8.4

N42HXEN-LXK-XX-XX • 2215(15.63) 11.2 0.21 2.1

N42HXHM-LXK-XX-XX • 3145(22.20) 9.9 0.25 5.5

N42HXLM-LXK-XX-XX • 3145(22.20) 4.9 1.02 22

N42HXEM-LXK-XX-XX • 2225(15.70) 7 0.51 5.5

N42HXHL-LXK-XX-XX • 3085(21.77) 8.1 0.38 7.8

N42HXLL-LXK-XX-XX • 3085(21.77) 4 1.51 31.2

N42HXEL-LXK-XX-XX • 2185(15.42) 5.7 0.75 7.8

N42HXHK-LXK-XX-XX • 3105(21.92) 6.4 0.6 12.8

N42HXLK-LXK-XX-XX • 3105(21.92) 3.2 2.41 51.1

N42HXEK-LXK-XX-XX • 2200(15.53) 4.5 1.2 12.8

Parallel

Series

Unipolar

Rated currents are in

descending order

Torque range:

2785-4025 oz-in.

174.0-251.5 lb-in.

19.66-28.41 Nm

K Series SIGMAX

®

2 rotor stacks

126 1.3 0.1546 18.4

(0.89) (1.09) (8.34)

Torque range:

2185-3145 oz-in.

136.5-196.5 lb-in.

15.42-22.2 Nm

N Series Standard

2 rotor stacks

84 1.3 0.1546 18.4

(0.59) (1.09) (8.34)

All ratings typical and at 25°C unless otherwise noted.

An ”X” in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 25.

Motor connections are determined by the Windings/Leads

designation in the Model Number Code on page 25. Note that

the F designation, although not shown in the above tables, is

an 8-lead option...see Terminations, page 34. In addition to the

lead wire termination, terminal board and MS connector hookup

for parallel, series or unipolar operation is also available.

With rated current applied. Windings at 130°C and motor

unmounted and in still air at 40°C.

Windings at 130°C and motor in still air at 40°C (without heat sink).

Motors may be operated up to 2 times rated current to provide

high peak torque with good torque linearity - duty cycle

dependant, contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

POWERPAC

HYBRIDS

Also see:

• Torque and Acceleration Comparisons, p. 19, 29

• Torque Linearity, p. 29

• Performance Curves, p. 30-31

NEMA 42 FRAME (4.325" Square)—Ratings and Characteristics (Con’t)

Review the Model Number Code, page 25, to assure that all options are designated. Connections, encoders and

phasing diagrams start on page 34. Motor dimensions start on page 32. In addition to those below, motors with

characteristics for specific performance requirements are offered. Contact factory for more details.

www.pacsci.com

28

Connection Holding

Torque Phase

Rated Inductance

Current/ Phase Thermal Rotor

Motor (2 phases on) Phase Resistance Detent Resistance Inertia

Model Number oz-in (Nm) (ohms) (mH) Torque oz-in-S

2

Weight

±10% (amps DC) ±10% Typical oz-in (Nm) (oC/watt) (kgm2x 10-3) lbs (kg)

K43HXHN-LXK-XX-XX • 5700(40.23) 15.4 0.14 2.5

K43HXLN-LXK-XX-XX • 5700(40.23) 7.7 0.55 10

K43HXEN-LXK-XX-XX • 4030(28.44) 10.9 0.28 2.5

K43HXHM-LXK-XX-XX • 5630(39.74) 9.9 0.33 5.9

K43HXLM-LXK-XX-XX • 5630(39.74) 4.9 1.32 23.7

K43HXEM-LXK-XX-XX • 3985(28.13) 7 0.66 5.9

K43HXHL-LXK-XX-XX • 5530(39.03) 8 0.5 8.5

K43HXLL-LXK-XX-XX • 5530(39.03) 4 1.98 34.1

K43HXEL-LXK-XX-XX • 3910(27.60) 5.7 0.99 8.5

K43HXHK-LXK-XX-XX • 5655(39.91) 6.2 0.82 15.2

K43HXLK-LXK-XX-XX • 5655(39.91) 3.1 3.29 60.7

K43HXEK-LXK-XX-XX • 4000(28.23) 4.4 1.65 15.2

N43HXHN-LXK-XX-XX • 4365(30.81) 15.4 0.14 3.2

N43HXLN-LXK-XX-XX • 4365(30.81) 7.7 0.55 13

N43HXEN-LXK-XX-XX • 3090(21.81) 10.9 0.28 3.2

N43HXHM-LXK-XX-XX • 4320(30.49) 9.9 0.33 7.7

N43HXLM-LXK-XX-XX • 4320(30.49) 4.9 1.32 30.7

N43HXEM-LXK-XX-XX • 3055(21.56) 7 0.66 7.7

N43HXHL-LXK-XX-XX • 4250(30.00) 8 0.5 11

N43HXLL-LXK-XX-XX • 4250(30.00) 4 1.98 44.2

N43HXEL-LXK-XX-XX • 3010(21.24) 5.7 0.99 11

N43HXHK-LXK-XX-XX • 4340(30.63) 6.2 0.82 19.6

N43HXLK-LXK-XX-XX • 4340(30.63) 3.1 3.29 78.5

N43HXEK-LXK-XX-XX • 3070(21.67) 4.4 1.65 19.6

Parallel

Series

Unipolar

Rated currents are in

descending order

Torque range:

3910-5700 oz-in.

244.3-356.0 lb-in.

27.60-40.23 Nm

K Series SIGMAX

®

3 rotor stacks

118 1 0.2293 25.7

(0.83) (1.62) (11.64)

Torque range:

3010-4365 oz-in.

188.1-272.8 lb-in.

21.24-30.81 Nm

N Series Standard

3 rotor stacks

106 1 0.2293 25.7

(0.75) (1.62) (11.64)

All ratings typical and at 25°C unless otherwise noted.

An ”X” in the Model Number Code indicates an undefined

option. Colored letter indicates winding. See Model Number

Code on page 25.

Motor connections are determined by the Windings/Leads

designation in the Model Number Code on page 25. Note that

the F designation, although not shown in the above tables, is

an 8-lead option...see Terminations, page 34. In addition to the

lead wire termination, terminal board and MS connector hookup

for parallel, series or unipolar operation is also available.

With rated current applied. Windings at 130°C and motor

unmounted and in still air at 40°C.

Windings at 130°C and motor in still air at 40°C (without heat sink).

Motors may be operated up to 2 times rated current to provide

high peak torque with good torque linearity - duty cycle

dependant, contact factory.

Small signal inductance as measured with impedance bridge at

1kHz, 1 amp.

Thermal resistance measured with motor hanging in still air

(unmounted).

POWERPAC

HYBRIDS

Also see:

• Torque and Acceleration Comparisons, p. 19, 29

• Torque Linearity, p. 29

• Performance Curves, p. 30-31

NEMA 42 FRAME (4.325" Square)—Ratings and Characteristics (Con’t)

Review the Model Number Code, page 25, to assure that all options are designated. Connections, encoders and

phasing diagrams start on page 34. Motor dimensions start on page 32. In addition to those below, motors with

characteristics for specific performance requirements are offered. Contact factory for more details.

www.pacsci.com

29

POWERPAC

HYBRIDS

NEMA 42 FRAME (4.325" Square)—Torque and Acceleration Comparisons

For comparison with size 34 motor, see page 19.

Holding Torque

N41

0

1000

1655

2135

3145

4025

4365

5700

2000

3000

4000

5000

6000

K41

N42

K42

N43

K43

Motor Model/Stack Length

Acceleration

rad

x 10 *

s

2

3

30.0

25.0

20.0

21.1

27.3

20.3

K41N41 K42N42

K43N43

26.0

19.0

24.9

15.0

10.0

5.0

0

* Holding Torque

...a figure of merit for acceleration capability

Rotor Inertia

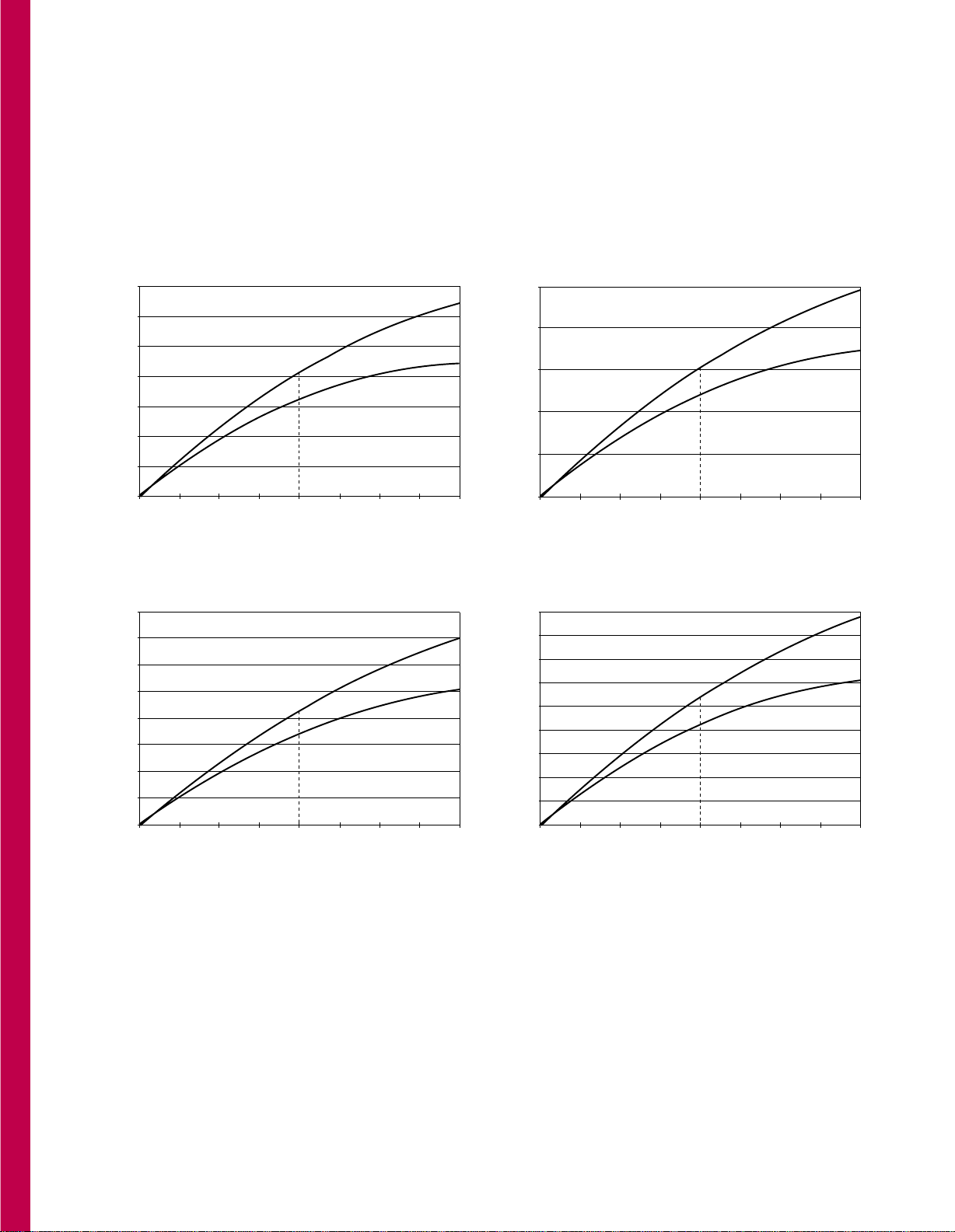

NEMA 42 FRAME (4.325" Square)—Torque Linearity

A significant POWERPAC performance attribute is that when a current higher than rated current is applied, the increase in torque will be more

linear than other hybrids. Furthermore, current levels increasingly higher than rated current are less likely to cause demagnetization. Capitalize

on this performance characteristic which will provide an acceleration boost to move loads even faster. This technique is applicable to

intermittent duty applications in that the thermal limit of the motor cannot be exceeded. Driving the motor at higher than rated current is duty

cycle dependent. Contact the factory for application assistance.

These curves show the torque at rated current and the torque linearity up to two times rated current.

Current

[Amps]

K43

N43

Rated Current

Current

[Amps]

K42

N42

Rated Current

0 3.8

9000

7.7 11.5 15.4 19.2 23.1 26.9 30.8

8000

7000

4000

3000

6000

5000

2000

1000

63.5

56.5

49.4

28.2

21.1

42.3

35.3

14.1

7.0

0

0 3.9

7000

7.9 11.8 15.8 19.7 23.7 27.6 31.6

6000

5000

3000

2000

4000

1000

49.4

42.3

35.3

21.1

14.1

28.2

7.0

0

0 2.6

3500

5.3 8.0 10.7 13.3 16.0 18.7 21.4

3000

2500

1500

1000

2000

500

24.7

21.1

17.6

10.6

7.0

14.1

3.5

0

Current

[Amps]

K41

N41

Rated Current

TORQUE LINEARITY

N & K 41 M-Winding

(bipolar parallel connection)

TORQUE LINEARITY