WET/DRY VACUUMS

PWD 600

PWD 609

PWD 612

PWD 615

OPERATING & MAINTENANCE

INTRODUCTION INSTRUCTIONS

Gulper 600S

Gulper 609S

Gulper 612S

Gulper 615S

This operator’s book has important information for the use

and safe operation of this machine. Read this book carefully before starting the machine. Keep this book and tell

all operators to read the book. If you do not follow the

instructions, you can cause an injury or damage equipment,

furniture or buildings.

For new books write to:

Pacific

2259 S. Sheridan

Muskegon, MI 49442-6252

Carefully inspect all components to ensure that there is no

concealed freight damage. If such damage is discovered,

file a “CONCEALED DAMAGE REPORT” immediately

with the delivering carrier.

READ THIS BOOK

The contents of this manual are based on the latest product

information available at the time of publication. Pacific

Steamex reserves the right to make changes or improvements to its machines without notice.

FOR YOUR CONVENIENCE, RECORD THE

FOLLOWING IMPORTANT INFORMATION:

MODEL_______________________________

SERIAL NUMBER_______________________

PART NUMBER ________________________

DATE PURCHASED _____________________

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND INSTRUCTIONS

BEFORE USING THIS MACHINE!

WARNING! To reduce the risk of fire, electric shock, or injury:

1. You must be trained to operate this machine. This machine is to be operated for its intended use

only.

2. Do not operate this machine unless it is completely assembled.

3. Always use a three-wire electrical system connected to the electrical ground. For maximum protection against electrical shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical contractor.

4. To prevent electrical shock: Always remove the electrical plug from the electrical outlet before performing any repairs, maintenance or cleanup and when leaving the machine unattended.

5. To prevent electrical shock: Keep the machine surface dry; Do not subject to rain; Store the machine

in a dry building area; Clean the machine with a dry cloth only.

6. Machines can cause an explosion when near flammable materials and vapors. Do not use or store

this machine with or near fuels, grain dust, solvents, thinners, or other flammable materials. Do not

use flammables to clean this machine.

7. Maintenance and repairs must be done by a qualified or authorized person.

8. If the machine is not working as it should, has been dropped, damaged, left outdoors, or dropped into

water, return it to a service center.

9. To avoid damage to the machine’s electrical cord, always lift the machine over the cord. Do not run

the machine over the electircal cord.

10. Make sure all labels, decals, warnings, cautions and instructions are fastened to the machine.

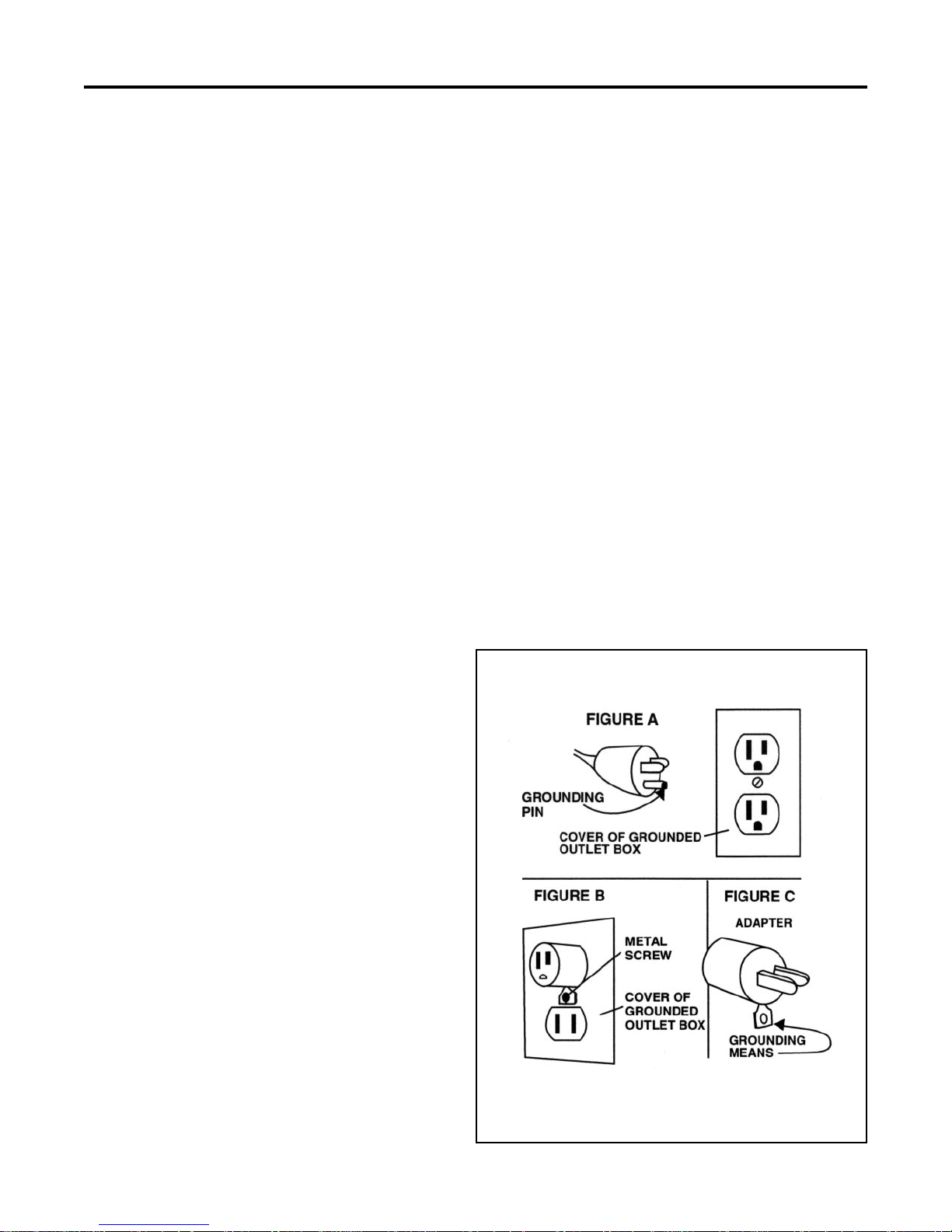

Grounding Instructions

This machine must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding

plug. The plug must be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and

ordinances.

WARNING - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug provided with

the machine - if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

This machine is for use on a nominal 120-volt circuit, and has a

grounded plug that looks like the plug illustrated in figure A. A

temporary adapter that looks like the adapter illustrated in figures B

and C may be used to connect this plug to a 2-pole receptacle as

shown in figure B if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly grounded

outlet (figure A) can be installed by a qualified electrician. The green

colored rigid ear, lug, or the like extending from the adapter must be

connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by

a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by

the Canadian Electrical Code

EXTENSION CORDS

Use only three-wire 16/3 or larger gauge approved extension cords that have

three-prong grounding type plugs and three-pole receptacles that accept the

appliance’s plug. Replace or repair any damaged cords or plugs.

When servicing, refer to authorized person only. Use only identical replacement parts.

NOTE: Do not use adapters shown in figures B & C in Canada

2

OPERATING PROCEDURES

WARNING! For the safe operation of this machine follow

the instructions given in this booklet and the training given

by your supervisor. Failure to do so can result in personal

injury and/or damage to machine and property!

DO NOT OPERATE MACHINE IN AN EXPLOSIVE

ENVIRONMENT!

To prepare the machine for operation, make sure it is of the correct

voltage and properly assembled. If in doubt, ask your supervisor.

FOR DRY PICK-UP:

“Dry” refers to material such as dust, dirt, debris and dry foam

shampoo.

1. Release the clamp on each side of the tank and head assembly.

Lift the head assembly off and set it aside.

2. Then lift the cloth filter assembly out of the collector tank.

Clean the cloth filter if needed (reference the “Maintenance”

section).

3. Empty the collector tank of all dust and debris. If the debris

is wet, empty and dry the inside of the tank thoroughly.

4. Place the cloth filter assembly back into the collector tank.

Check for a good seal around the outer filter lip and tank rim.

5. Replace the head assembly and fasten both clamps. Attach

the hose, wand and floor tool of choice (reference page 5).

6. Plug the power cord into a 115-volt, 60 cycle grounded outlet.

WARNING! NEVER USE THIS MACHINE TO PICK UP

VOLATILE OR EXPLOSIVE MATERIALS.

FOR WET PICK-UP:

“Wet” refers to liquids such as water, scrub solutions and detergents;

NOT VOLATILE OR EXPLOSIVE MATERIALS.

1. Release the clamp on each side of the tank and head assembly.

Lift the head assembly off and set it aside.

2. Then lift the cloth filter assembly out of the collector tank.

Store the filter assembly for future, dry pick-up use. DO

NOT REINSTALL.

3. Empty the collector tank of all dust and debris. Also wipe

the inside of the collector tank to remove clinging dust.

4. Check the float shut-off device on the lower portion of the

head assembly. The float should have free movement. When

the recovered liquid soilage reaches the collector tank capacity, the float will rise to shut off the air flow, stopping the

liquid recovery. This prevents damaging overflow and signals

the operator when to empty the collector tank.

5. Replace the head assembly and fasten both clamps. Attach

the hose, wand and floor tool of choice (reference page 5).

6. Plug the power cord into a 115-volt, 60 cycle grounded outlet.

7. Turn the machine’s motor on by pressing the rocker switch

which is located on the head assembly.

7. Turn the machine’s motor on by pressing the rocker switch

which is located on the head assembly.

MAINTENANCE

Good maintenance procedures assure better operation,

fewer repairs and longer life to your machine.

DISCONNECT THE ELECTRICAL PLUG OF THE MACHINE FROM THE ELECTRICAL OUTLET BEFORE

DOING ANY CLEANUP, REPAIRS OR MAINTENANCE

OF THE MACHINE AND WHEN LEAVING THE MACHINE

UNATTENDED.

CLEAN THE MACHINE AFTER EACH USE:

1. Wipe the outside with a clean cloth.

2. Clean the collector tank: Release the clamps on each side

of the tank and head assembly. Lift the head assembly off

and set aside. Lift the filter assembly out of the collector

tank and set aside. Then wipe the inside of the collector tank

with a clean cloth.

3. Empty and check the filter assembly: Empty the recovered

soilage into a suitable container and shake to remove clinging

dirt. Brush the outside of the filter bag to remove embedded

dirt. Check the filter assembly for tears or holes; repair or

replace if necessary. Install the clean filter assembly into the

clean collector tank.

ELECTRICAL CABLE:

Check the cord for any nicks, cuts or damage. Report these to

your supervisor for correction.

VACUUM HEAD ASSEMBLY:

1. Gaskets: Clean the vacuum head gasket and the float shut-off

gasket.

2. Float Shut-Off Device: This should move freely. Remove

any debris or strings from the float cage.

3. Head Assembly: Replace and leave ajar if the collector tank is

damp to prevent mildew.

WHEELS AND CASTERS:

Check these for cuts and nicks. Remove any strings or debris that

may restrict the free movement of the wheels. Wipe the treads

clean.

CARBON BRUSH INSPECTION:

Check for wear at six month intervals or every 600 hours of

operation. The carbon brushes must be replaced if worn shorter

than 3/8 inch.

3

12

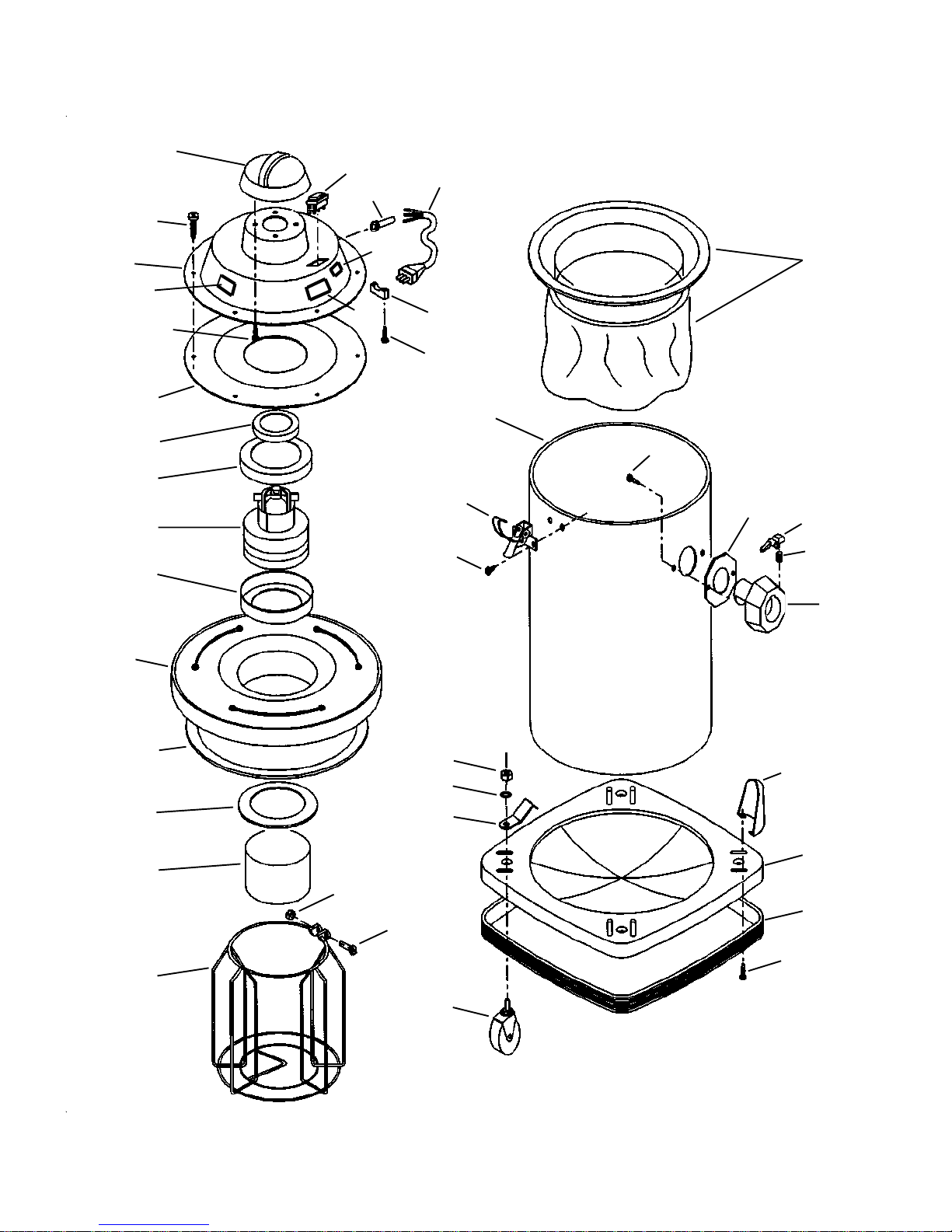

PWD 600 & 609

Gulper 600S & 609S

1

4

5

6

2

17

13

14

15

16

15

10

9

11

3

7

8

25

32

26

27

28

24

29

30

31

18

19

20

23

21

22

33

34

35

36

37

38

39

40

4

PWD 600 & 609

Gulper 600S & 609S

ITEM PART NO. DESCRIPTION QTY.

1 601510 Cap, Dome 1

2 602310 Cover, Motor 1

3 964020 Screw, Cap 4

4 608010 Switch 1

5 608530 Strain Relief 1

6 908010 Cord Assembly 1

7 607210 Retainer, Cord 1

8 964021 Screw, Cord Retainer 2

9 606310 Lab- Watts/Voltage 1

10 515150 Label - Warning 1

11 606314 Label - Serial Number 1

12 964022 Screw, Motor Cover 6

13 600211 Adapter, Upper Motor 1

14 602771 Duct, Air Vent 1

15 603410 Gasket, Vac Motor 2

16 605210 Motor, Vacuum 115V 1

605211 Motor, Vacuum 230V 1

600903 Carbon Brush, Vac Mtr. (2 req'd/mtr) 2

17 600212 Adapter, Lower Motor 1

18 603411 Gasket, Lower Adapter 1

19 603412 Gasket, Float Shut-Off 1

20 603312 Float, Shut-Off 1

21 W106D Nut, Float Cage 1

22 962120 Screw, Float Cage 1

23 602411 Cage, Float Shut-Off 1

24 600520 Adapter and Bag Assembly 1

25 608630 Tank, PWD-600 1

608640 Tank, PWD-609 1

26 602010 Clamp, Lid 2

27 930001 Rivet, Clamp Lid 4

28 603415 Gasket, Plastic Coupler 1

603425 Gasket, Foam Adaptor 1

29 607001 Pawl 1

30 608303 Spring 1

31 602415 Coupler, Tank 1

32 962112 Screw 2

33 924022 Nut, Caster 4

34 980008 Washer, Lock 4

35 607211 Retainer, Tank 4

36 609710 Caster 4

37 602311 Cover, Caster 4

38 601310 Base, Caster 1

39 601210 Bumper, Caster Base 1

40 964025 Screw, Caster Cover 8

5

PWD 612

Gulper 612S

1

4

5

12

2

9

3

13

14

15

16

17

18

10

11

45

6

26

7

8

27

32

28

29

31

30

33

34

35

36

19

20

21

22

23

24

25

37

38

39

40

41

42

43

44

6

PWD 612

Gulper 612S

ITEM PART NO. DESCRIPTION QTY.

1 601540 Cap, Dome 1

2 602340 Cover, Motor 1

3 964020 Screw, Cap 4

4 608010 Switch 1

5 608530 Strain Relief 1

6 908010 Cord Assembly 1

7 607210 Retainer, Cord 1

8 964021 Screw, Cord Retainer 2

9 606310 Lab- Watts/Voltage 1

10 515150 Label - Warning 1

11 606340 Label - Serial Number 1

12 964022 Screw, Motor Cover 8

13 600214 Adapter, Upper Motor 1

14 600216 Adapter, Middle Motor 1

15 603420 Gasket, Vac Motor 1

16 605210 Motor, Vacuum 115V 1

605211 Motor, Vacuum 230V 1

600903 Carbon Brush, Vac Mtr. (2 req'd/mtr) 2

17 603410 Gasket, Vac Motor 1

18 Gasket, Reduction 1

19 600215 Adapter, Lower Motor 1

20 603442 Gasket, Lower Adapter 1

21 603412 Gasket, Float Shut-Off 1

22 603312 Float, Shut-Off 1

23 602413 Cage, Float Shut-Off 1

24 W106D Nut, Float Cage 1

25 962120 Screw, Float Cage 1

26 600530 Adapter and Bag Assembly 1

27 608650 Tank, PWD-612 1

28 602010 Clamp, Lid 2

29 930001 Rivet, Clamp Lid 4

30 603910 Handle 2

31 964026 Screw, Handle 4

32 962112 Screw 2

33 603415 Gasket, Plastic Coupler 1

603425 Gasket, Foam Adaptor 1

34 607001 Pawl 1

35 608303 Spring 1

36 602415 Coupler, Tank 1

37 924022 Nut, Caster 4

38 980008 Washer, Lock 4

39 607211 Retainer, Tank 4

40 609720 Caster 4

41 602311 Cover, Caster 4

42 601320 Base, Caster 1

43 601220 Bumper, Caster Base 1

44 964025 Screw, Caster Cover 8

7

PWD 615

Gulper 615S

1

2

48

50

41

30

49

31

42

43

33

32

44

45

36

46

47

37

34

35

33

38

39

40

11

12

20

21

10

15

3

18

4

5

6

7

8

16

17

19

22

9

13

14

55

51

52

54

53

56

57

58

8

59

25

26

23

24

27

28

29

PWD 615 and Gulper 615S

ITEM PART NO. DESCRIPTION QTY.

1 601550 Cap, Dome 1

2 964022 Screw, Cap 4

3 964021 Screw, Strain Relief 1

4 607210 Retainer, Cord 1

5 608530 Strain Relief 1

6 908020 Cord Assembly 1

7 604610 Insert, Blank Switch 1

8 608010 Switch 2

9 604611 Insert, Blank Motor Cover 1

10 602350 Cover, Motor 1

11 964029 Screw, Motor Cover 8

12 606360 Label - Serial Number 1

13 606310 Lab- W atts/Voltage 1

14 515150 Label - Warning 1

15 964028 Screw, Upper Motor Adapter 4

16 600220 Adapter, Upper Motor 1

17 603410 Gasket, Vac Motor 1

18 605210 Motor, Vacuum 115V 2

605211 Motor, Vacuum 230V 2

600903 Carbon Brush, Vac Mtr. (2 req'd/mtr) 4

605212 Motor, Vac.Acustek-UC-115V 2

600904 Carbon Brush, 605212 Vac Mtr. (2 req'd/mtr) 4

19 604612 Spacer, Vac. Motor Intake 2

20 604613 Insert, Intake Blank 1

21 964020 Screw, Motor Adapter 6

22 600221 Adapter, Middle Motor 1

23 600222 Adapter, Lower Motor 1

24 603421 Gasket, Lower Adapter 1

25 603422 Gasket, Float Shut-Off 1

26 603312 Float Shut-Off 1

27 W106D Nut, Float Cage 1

28 962120 Screw, Float Cage 1

29 602420 Cage, Float Shut-Off 1

30 600540 Adapter and Bag Assembly 1

31 608660 Tank, PWD-615 1

32 964026 Screw, Handle 4

33 603910 Handle 3

34 602010 Clamp, Lid 2

35 930001 Rivet, Clamp Lid 4

36 962112 Screw 2

37 603415 Gasket, Plastic Coupler 1

38 607001 Pawl 1

39 608303 Spring 1

40 602415 Coupler, Tank 1

41 920004 Nut 2

42 600810 Bracket, Tilt 1

43 Gasket, Bracket 1

44 980009 W asher 4

45 W156D Screw, Tilt Bracket 2

46 964026 Screw, Handle 2

47 980010 W asher, Rubber-Handle 2

48 603920 Handle, Carriage 1

49 964031 Screw, Carriage Handle 2

50 924023 Nut-Wing 2

51 607710 Shaft, Wheel Axle 1

52 924022 Nut 2

53 507320 Snap Ring 2

54 609730 W heel, Carriage 2

55 964032 Screw, Tank Support 2

56 608540 Support, Tank 2

57 601330 Base, Carriage 1

58 924022 Nut, Caster 2

59 609720 W heel, Caster 2

18

19

DELUXE TOOL KIT

PART #608510

20

4

1

3

2

7

8

9

6

5

10

11

8

12

17

12

ITEM PART NO. DESCRIPTION QTY.

1 604110 Hose Asm, w/Adapters 1

2 600206 Adapter, 1-1/2 Hose, Vac End 1

3 600205 Adaptor, 1-1/2 Hose, Wand End 1

4 609810 Wand Asm., with Adapter & Pin 1

609813 Wand Half w/out Adapter (top half)

609809 Wand Half w/Adapter&Pin (bottom half)

5 606710 Disconnect Pin Assembly 1

6 600204 Adapter, Wand 1

7 608810 16" Bristle Floor Tool Asm. 1

8 601803 Top Casting with Adapter 1

9 601804 Base Casting, Bristle Tool 1

10 600901 Brush, Bristle Tool 1

11 602011 Clamp, Brush 2

12 964022 Screw 2

13 608812 16" Squeegee Floor Tool Asm. 1

14 601802 Base Casting-Squeegee Tool 1

15 600701 Blade, Squeegee Pickup 2

16 607212 Retainer 2

17 962115 10-24x3/8 Self-Tapping Screw 5

18 600210 Tool Adapter, 1-1/4 to 1-1/2 1

19 608816 1-1/2" Crevice Tool 1

20 608820 3" Round Dusting Tool 1

OPTIONAL:

21 608811 16" Carpet Tool Asm. 1

22 600902 Brush Strip 1

23 607901 Carpet Shoe 1

OPTIONAL ACCESSORY

CARPET TOOL- ITEM 21

8

9

13

22

14

12

23

15

16

TOOL KIT ASSEMBLY:

1. Connect the hose to the collector tank by inserting the

large, grooved hose adapter end into the tank adapter.

Pull the locking pin up to allow the hose adapter to slide

further in. Release the locking pin to engage the large

groove.

2. Insert the upper wand half firmly into the lower wand

assembly. The dimple on the lower wand aligns with the

groove of the upper half to assure a rigid fit.

3. Insert the wand end into the free end of the vacuum hose.

Then fasten the proper floor tool to the to the wand by

inserting the mating end of the floor tool into the adapter

collar of the wand assembly. Pull the tool locking pin to

allow total engagement of the adapter and tool. Release

the pin to lock the tool to the wand.

4. The hand tools may also be used by inserting their adapter

directly into the free end of the vacuum hose.

5. Tool Selection: Choosing the proper tool will give the

best results. To vacuum dust and debris from floors or

walls-select the bristle floor tool. To remove water, liquid

waste, strip solution, etc. from hard surfaced floors-use

the squeegee floor tool. When vacuuming carpets or

rugs-choose the carpet tool.

10

OPTIONAL SQUEEGEE ASSEMBLY

PART #608519

2

8

7

3

1

4

5

6

13

9

12

5

4

10

11

15

14

16

17

18

ITEM PART NO. DESCRIPTION QTY.

1 600206 Adapter, Hose 1

2 604112 Hose, without Cuffs 1

3 600205 Adapter, Hose 1

4 607213 Retainer, Squeegee Blade 2

5 600703 Blade, Squeegee 2

6 601805 Casting, Squeegee 1

7 605001 Knob, Adjusting Lower 1

8 605002 Knob, Adjusting Upper 1

9 600802 Bracket, Support 1

ITEM PART NO. DESCRIPTION QTY.

10 601101 Bushing 1

11 602101 Clip, Seeger 1

12 608302 Spring, Squeegee Tension 1

13 962128 Screw 14

14 605003 Knob, Caster Adjusting 2

15 W155D Screw 4

16 600803 Bracket, Caster 2

17 608301 Spring, Caster 2

18 609701 Caster 2

11

WARRANTY POLICY

WET/DRY VACUUMS

The Pacific Steamex Inc. Wet/Dry Vacuum has been manufactured, tested and inspected in accordance with specific engineering requirements and is WARRANTED to be free from defects in workmanship and materials as follows:

One (1) year parts & labor - All components unless excluded below.

This warranty extends to the original user/purchaser and only when used, operated and maintained in accordance with

Pacific Steamex Inc. Operating and Maintenance instructions.

This warranty does not apply to certain wear parts and accessories of the machine such as electrical cords, carbon motor

brushes, floor brushes, hoses, tools, filters, casters, wheels, etc. Nor does it apply to damage or failure caused by improper

use, abuse or neglect. Warranty credit or replacement of return parts including motors, etc., is subject to incoming inspection

of those items.

To secure repair under this warranty, the following procedure should be taken:

• The inoperative machine or warranted parts must be delivered to the authorized dealer with shipping and delivery

charges prepaid. If unable to locate the Dealer, you may contact Pacific Steamex Inc. at the address listed herein for the

location of the nearest Pacific Steamex Inc. repair center or agent or for other instructions pertaining to your warranty

difficulty.

• Upon compliance with the above warranty procedure, all warranted repairs would be completed at no additional charge

or cost to the user.

• Only Pacific Steamex Inc. or its authorized dealers and agents may make no charge warranty repairs on this product. All

others do so at their own risk.

This warranty limits Pacific Steamex Inc. liability to the repair of the product and/or warranted parts replacement and does not

include incidental or consequential damages arising from the use of a Pacific Steamex Inc. machine whether defective or not.

This warranty is in lieu of all other expressed or implied warranties and is extended to the original purchaser/user.

Ph: (800) 968-1332 Fax: (231) 773-1642

2259 Sheridan

Muskegon, Michigan 49442

www.nextwaveofclean.com

63002010/01

Loading...

Loading...