Pacific GULPER 16SV Maintenance Manual

GULPER 16SV

16 GALLON WET/DRY

VACUUM WITH

FRONT MOUNT SQUEEGEE

OPERATING & MAINTENANCE

INTRODUCTION INSTRUCTIONS

READ THIS BOOK

This operator’s book has important information for the

use and safe operation of this machine. Read this book

carefully before starting the machine. Keep this book

and tell all operators to read the book. If you do not

follow the instructions, you can cause an injury or damage equipment, furniture or buildings.

For new books write to:

Pacific

2259 South Sheridan Road

Muskegon, MI 49442

Carefully inspect all components to ensure that there is

no concealed freight damage. If such damage is discovered, file a “CONCEALED DAMAGE REPORT” immediately with the delivering carrier.

The contents of this manual are based on the latest

product information available at the time of publication. Pacific reserves the right to make changes or

improvements to its machines without notice.

FOR YOUR CONVENIENCE, RECORD THE

FOLLOWING IMPORT ANT INFORMA TION:

MODEL_______________________________

SERIAL NUMBER______________________

P ART NUMBER _________________________

DA TE PURCHASED ____________________

IMPORT ANT SAFETY INSTRUCTIONS

T o assure the safe operation of this machine, you must read and understand all warnings and instructions in this book.

If you do not understand, ask your supervisor.

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE

WARNING

: To reduce the risk of fire, electric shock, or injury:

1. Y ou must be trained to operate this machine. This machine is to be operated for its intended use only.

2. Do not operate this machine unless it is completely assembled.

3. Always use a three-wire electrical system connected to the electrical ground. For maximum protection against

electrical shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical

contractor.

4. T o prevent electric shock, always remove the electrical plug from the electrical outlet before doing any rep airs or

maintenance and when leaving the machine unattended.

5. T o prevent electric shock, keep the machine surface dry . Do not subject to rain. S tore the machine in a dry building

area. Clean the machine with a dry cloth only .

6. Machines can cause an explosion when near flammable materials and vapors. Do not use this machine with or

near fuels, grain dust, solvents, thinners, or other flammable materials. Do not use flammables to clean this

machine.

7. A qualified or authorized person must do maintenance and repairs.

8. If the machine is not working as it should, has been dropped , damaged, left outdoors, or dropped into water , return

it to a service center

9. T o avoid damage to the machine’ s electrical cord, always lift the machine over the cord. Do not run the machine

over the electrical cord.

10. Make sure all labels, decals, warnings, cautions and instructions are fastened to the machine.

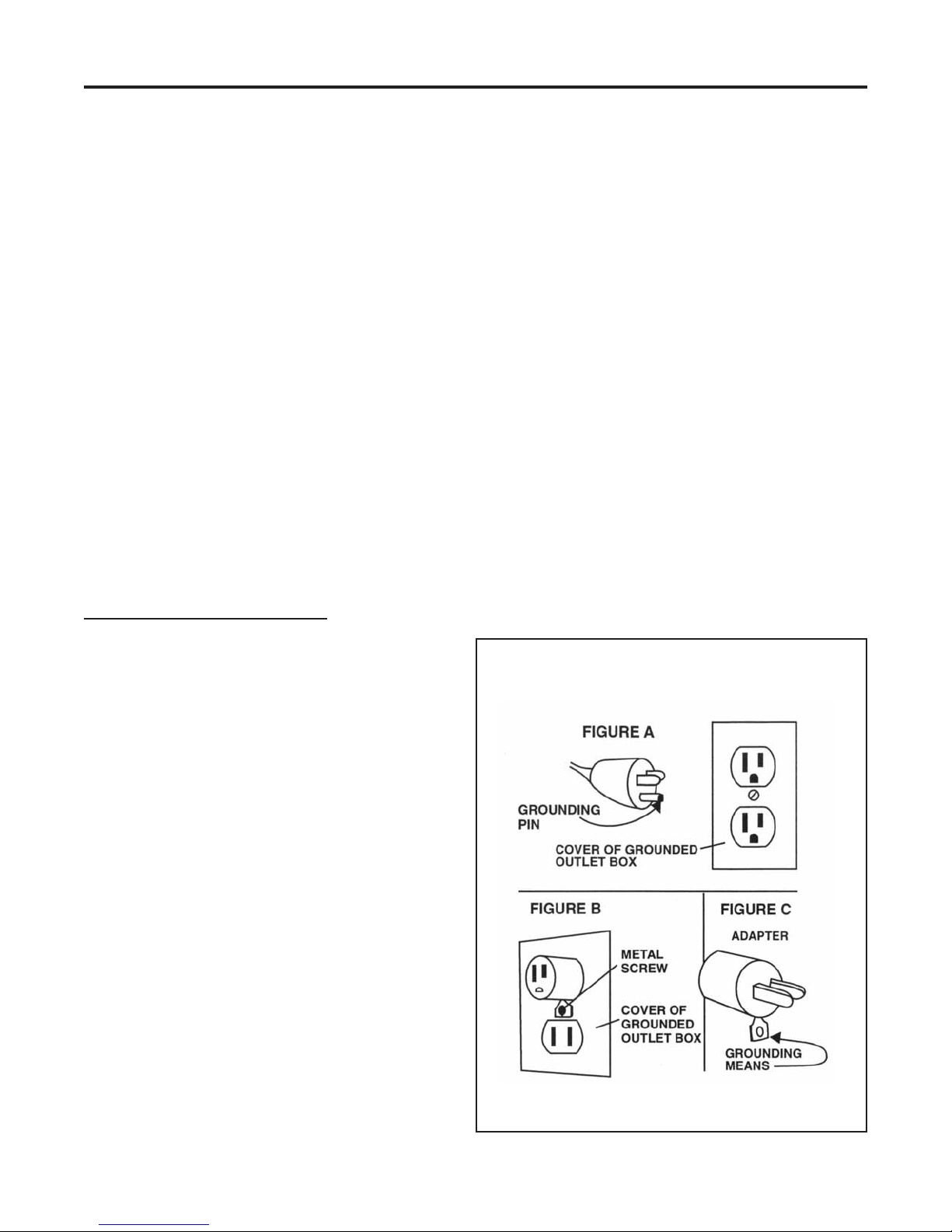

Grounding Instructions

This machine must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding plug. The plug must be inserted into an appropriate outlet that

is properly installed and grounded in accordance with all local

codes and ordinances.

WARNING - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug provided with

the machine - if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

This machine is for use on a nominal 120-volt circuit, and has a

grounded plug that looks like the plug illustrated in figure A. A

temporary adapter that looks like the adapter illustrated in figures B

and C may be used to connect this plug to a 2-pole receptacle as

shown in figure B if a properly grounded outlet is not available.

The temporary adapter should be used only until a properly

grounded outlet (figure A) can be installed by a qualified electrician. The green colored rigid ear, lug, or the like extending from the

adapter must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adapter is

used, it must be held in place by a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted

by the Canadian Electrical Code

EXTENSION CORDS

Use only three-wire 12/3 or larger gauge approved extension

cords that have three-prong grounding type plugs and three-pole

receptacles that accept the appliance’s plug. Replace or repair

any damaged cords or plugs.

When servicing, refer to authorized person only. Use only identical replacement parts.

NOTE: Do not use adapters shown in figures B & C in Canada

2

OPERA TING & MAINTENANCE PROCEDURES

WARNING! - For the safe operation of this ma-

chine follow instructions given in this booklet and

the training given by your supervisor. Failure to

do so can result in personal injury and/or damage

to machine and property!

DO NOT OPERATE MACHINE IN AN

EXPLOSIVE ENVIRONMENT!

WARNING! - NEVER USE THIS MACHINE TO PICK

UP VOLA TILE OR EXPLOSIVE MA TERIALS.

OPERATION

T o prepare the machine for operation, make sure it is of

the correct voltage and properly assembled. If in doubt,

ask your supervisor.

This machine in its original configuration is designed for

wet/pick up utilizing the front mount squeegee but for

convenience a dry filter bag has been included to enable you to use this unit for various functions. A tool kit

must be ordered as an accessory for dry pick up.

T o assemble your unit:

Unpack your unit from its shipping carton. Locate the

front mount squeegee assembly & hose assembly (see

page 8). The squeegee assembly mounts to the unit

by sliding the support bracket (item 15 on page 8) attached to the front mount squeegee onto the squeegee

mounting bracket located at the base of the tank at the

front of your unit. Position the front mount squeegee in

the center postion and then lock the assembly onto the

unit by turning the locking knob (item 8 on page 8) to

the right until firmly tightened. Depending on your

applicatiion, you can also offset the front mount squeegee further tot he right or left to get under toe kicks.

Attach the hose assembly by pushing the button on the

coupler located at the front of your tank (item 25 on

page 6) and inserting the vac end adapter (item 1 on

page 8) into the coupler and releasing the button to lock

it in. Then slide the other hose end into the port located

at the top of the front mount squeegee. You would reverse this process to remove the front mount squeegee

for transport.

To adjust the downward pressure on your front mount

squeegee you can turn the adjusting knob (item 9 on

page 8) to create more downward pressure (clockwise

turns) or less downward pressure (counter-clockwise

turns) until your squeegee is moving across the floor at

your preferred height.

Additional squeegee height adjustment can be made

by turning the caster knobs (item 19 on page 8) on the

front mount squeegee to increase or decrease the caster

height which would raise or lower the squeegee height .

FOR WET PICK UP:

“Wet” refers to liquids such as water, scrub solutions

and detergents, NOT volatile or explosive materials.

1. Release the clamps on the sides of the tank and

head assembly . Lift the head assembly of f and set

it aside.

2. Then lift the cloth filter assembly out of the collector

tank. Store the filter assembly for future, dry pick

up use. DO NOT RE-INSTALL.

3. Empty the collector tank of all dust and debris. Also

wipe the inside of the collector tank to remove cling

-ing dust.

4. Check the float shut-off device on the lower portion of

the head assembly . The float should have free move

-ment. When the recovered liquid soilage reaches

the collector tank capacity, the float will rise to shut

off the air flow , stopping the liquid recovery. This

prevents damaging over flow and signals the opera

-tor when to empty the collector tank.

5. Replace the head assembly and fasten the clamps.

Attach the short vacuum hose to both the coupler

on the tank and to the front mount squeegee.

6. Plug the power cord into a 120-volt grounded outlet.

7. Turn the machine’s motor on by pressing the rocker

switch that is located on the head assembly.

FOR DRY PICK UP:

“Dry” refers to material such as dust, dirt, debris and

dry foam shampoo.

1. Release the clamps on the sides of the tank and

head assembly . Lift the head assembly of f and set

it aside.

2. The lift the cloth filter assembly out of the collector

tank. Clean the cloth filter if needed (reference the

“Maintenance” section).

3. Empty the collector tank of all dust and debris. If the

debris is wet, empty and dry the inside of the tank

thoroughly .

4. Place the cloth filter assembly back into the

collector tank.

Check for a good seal around the outer filter lip and

tank rim.

5. Replace the head assembly and fasten the clamps.

Att ach the hose, wand and floor tool of choice. Note:

Tool kit must be ordered as an accessory for this

model.

6. Plug the power cord into a 120-volt grounded outlet.

7. Turn the machine’s motor on by pressing the rocker

switch that is located on the head of the assembly .

3

Loading...

Loading...