GENIUS 14

GENIUS 18

OPERATING & MAINTENANCE

INTRODUCTION INSTRUCTIONS

This operator’s book has important information for the use

and safe operation of this machine. Read this book carefully before starting the machine. Keep this book and tell

all operators to read the book. If you do not follow the

instructions, you can cause an injury or damage equipment,

furniture or buildings.

For new books write to:

Pacific

2259 S. Sheridan

Muskegon, MI 49442-6252

Carefully inspect all components to ensure that there is no

concealed freight damage. If such damage is discovered,

file a “CONCEALED DAMAGE REPORT” immediately

with the delivering carrier.

READ THIS BOOK

The contents of this manual are based on the latest product

information available at the time of publication. Pacific reserves the right to make changes or improvements to its

machines without notice.

FOR YOUR CONVENIENCE, RECORD THE FOLLOWING

INFORMATION:

MODEL_______________________________

SERIAL NUMBER_______________________

P ART NUMBER _________________________

DA TE PURCHASED ______________________

IMPORT ANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND INSTRUCTIONS

BEFORE USING THIS APPLIANCE!

WARNING! To reduce the risk of fire, electric shock, or injury:

1. Do not leave appliance when plugged in. Unplug from outlet when not in use and before servicing.

2. Do not use outdoors or on wet surfaces.

3. Do not allow to be used as a toy. Close attention is necessary when used by or near children.

4. Use only as described in this manual. Use only manufacturer’s attachments.

5. Do not use with damaged cord or plug. If appliance should not work as it should, has been dropped or

damaged, left outdoors, or dropped into water, return it to service center.

6. Do not pull or carry by cord, use cord as handle, close a door on cord or pull cord around sharp

edges or corners. Do not run appliance over cord. Keep cord away from heated surfaces.

7. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord

8. Do not handle plug or appliance with wet hands.

9. Do not put any objects into opening. Do not use with any opening blocked: keep free of dust, lint,

hair and anything that may reduce airflow.

10. Keep hair, loose clothing, fingers and all parts of the body away from openings and moving parts.

11. Turn off all controls before unplugging.

12. Use extra care when cleaning on stairs.

13. Do not use to pick up flammable or combustible liquids such as gasoline or use in areas where they

may be present.

14. Connect to a properly grounded outlet only.

15. Do not pick up anything that is burning or smoking, such as cigarettes, matches or hot ashes.

16. Do not use without dust bag and/or filters in place.

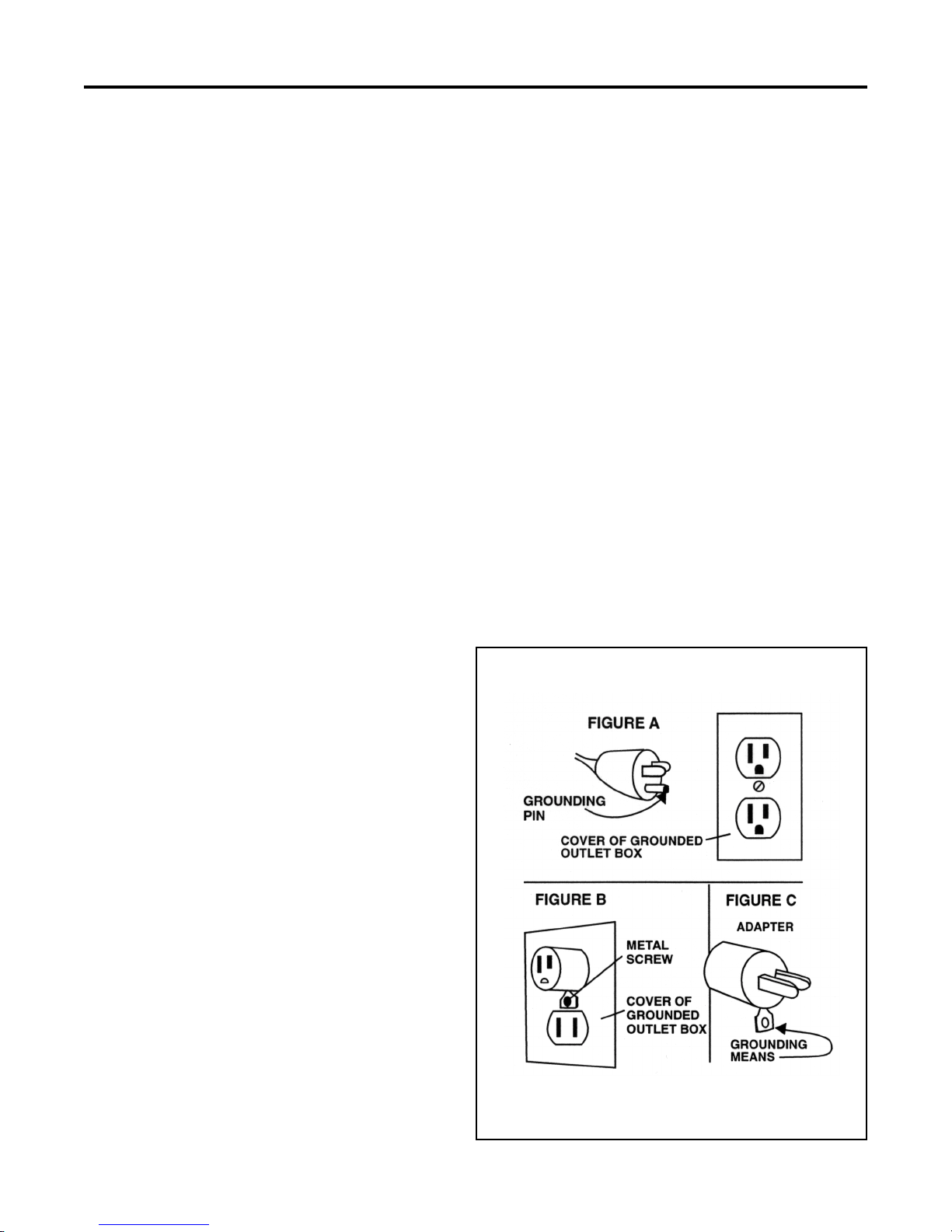

Grounding Instructions

This machine must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding

plug. The plug must be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and

ordinances.

WARNING - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug provided with

the machine - if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

This machine is for use on a nominal 120-volt circuit, and has a

grounded plug that looks like the plug illustrated in figure A. A

temporary adapter that looks like the adapter illustrated in figures B

and C may be used to connect this plug to a 2-pole receptacle as

shown in figure B if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly grounded

outlet (figure A) can be installed by a qualified electrician. The green

colored rigid ear, lug, or the like extending from the adapter must be

connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by

a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by

the Canadian Electrical Code

EXTENSION CORDS

Use only three-wire 16/3 or larger gauge approved extension cords that have

three-prong grounding type plugs and three-pole receptacles that accept the

appliance’s plug. Replace or repair any damaged cords or plugs.

When servicing, refer to authorized person only. Use only identical replacement parts.

NOTE: Do not use adapters shown in figures B & C in Canada

2

OPERATING PROCEDURES

W ARNING! For the safe operation of this

machine follow the instructions given in this

booklet and the training given by your supervisor . Failure to do so can r esult in personal

injury and/or damage to machine and property!

DO NOT OPERA TE MACHINE IN AN

EXPLOSIVE ENVIRONMENT!

W ARNING! NEVER USE THIS MACHINE

TO PICK UP VOLA TILE OR EXPLOSIVE

MA TERIALS.

W ARNING! DO NOT PICK UP WET

MA TERIAL WITH THIS MACHINE.

The model shown in this manual is intended for commercial

use and for vacuuming dry material only .

ASSEMBLY

OPERA TION AS AN UPRIGHT VACUUM

1. Properly install the filter bag in the vacuum:

Depress the two white buttons on the back of the vacuum

housing door (Drawing 1, Item 8), then swing it up and

open. Place the bag into the opening with the notched

portion next to the handle tube.

2. Plug the machine’s power cable into a properly

grounded outlet (see Safety Instructions).

3. Adjust the brush height to suit the thickness of the

carpet. The adjustment ranges from positions 1 through 4:

Position 1 for very low pile carpet and Position 4 for very

high pile carpet. Adjust the height adjustment knob

(Drawing 2, Item 39) to the lowest number position that

results in the green light being on and the red light off

(reference the “Electronic Power Brush Monitor” section).

4. Depress the foot pedal to lower the handle to the

operating position.

5. T urn ON the switch-the vacuum and brush motors

will start. Begin your DRY pick up vacuuming.

T o prepare the machine for operation, make sure it is of correct voltage and properly assembled. If in doubt, ask your

supervisor.

1. Place the brush head on a flat surface and latch the

swivel neck into the upright and locked position.

2 . Turn the knob (Drawing 1, Item 57) located on tank

assembly counterclockwise to the right. Insert the tank

assembly over the projection ears on the lower unit while

keeping the tank in the vertical position. Return the knob

to the locked position by turning it clockwise.

3 . Attach the flexible hose to the vacuum tank. The

long rigid portion of the flexible hose should be inserted

into the lower portion of the vacuum tank assembly.

OPERA TION with ACCESSORIES

1 . Properly install the filter bag in the vacuum.

2 . Plug the machine’s power cable into a properly

grounded outlet.

3 . Remove the rigid portion of the flexible hose from the

lower portion of the vacuum. The brush motor will

automatically stop when the hose is removed.

4. Attach the crevice or dusting tool to the wand, turn

the vacuum ON and begin.

5 . Upon completion, reinsert the rigid portion of the

hose into its’ retaining hole.

3

MAINTENANCE

AL WAYS turn the machine power switch OFF

and unplug the machine before performing any

service. Severe personal injury could result if

electrical power is not disconnected.

AFTER EACH USE:

1. Inspect the vacuum filter bag. If the bag is full or

damaged install a new one.

2. Check the cord and plug for nicks, cuts or damage.

Report these to your supervisor for correction. Wrap

the electrical cord on the hook provided.

3. Store the vacuum in a clean dry area.

FULL BAG INDICA TOR

Your machine is equipped with a device that senses when

airflow inside the vacuum chamber is restricted. The red

light located next to the on/off switch will come on when this

condition exists. Restricted airflow can be caused by the

following conditions:

A. If vacuum filter bag is full; install a new bag.

VACUUM INLET FIL TER

This machine has a vacuum inlet filter (Drawing 1, Item 69)

that will require periodic cleaning or replacement. The filter

is located below the paper bag cage in the housing.

To clean: Remove the filter and shake or vacuum it. If the

filter is worn or uncleanable, replace.

HEPA FIL TER

The hepa filter (Drawing 1, Item 49) will also require periodic

cleaning or replacement.

T o clean: Unlatch the cover (Drawing 1, Item 50) to access

the hepa filter, remove the filter and shake or vacuum it. If

the filter is worn or uncleanable, replace.

BRUSH STRIP REPLACEMENT

This machine has a removable brush strip. Replace it if it

becomes worn to the point where it no longer contacts the

carpet. To replace: First remove the three (3) screws that

hold the access plate on the bottom of the brush housing.

Once the brush roller is exposed, remove the R.H. Support.

The brush strip can now slide off - remove and replace with

a new one. Be sure the strip is pushed all the way in. Reassemble.

B. If the bag is not full, there is an obstruction in the

system. Remove the vacuum hose and hold it up to the

light; clean out any debris. Next, check the inlet to the power

brush housing and clear it of any debris.

ELECTRONIC POWER BRUSH MONITOR

The machine is equipped with a control system that alerts

the operator via indicator lights if a problem ooccurs within

the power brush housing. The lighting conditions and what

they mean are:

A. Green Light Illuminated & Red Light Off - The brush

assembly is working properly.

B. Both Red & Green Lights Illuminated - Lower the

brush, the drive belt may be broken, or change the brush

strip.

C. Red Light Illuminated & Green Light Off - The brush

roller is obstructed and cannot rotate. Turn the power switch

off and unplug the machine. Remove any string, debris or

other obstruction so that the brush turns freely.

VACUUM MOTOR MAINTENANCE

Have the vacuum motor inspected annually by a Factory

Authorized Service Technician. If the carbon brushes are

worn, they should be replaced. This service will prolong the

life of the vacuum motor.

The replacement of belts and other repairs to the machine

should be performed by a Factory Authorized Service T echnician.

4

NOTES

5

T ANK & VACUUM ASSEMBL Y

15a

15

6

26

29

19

7

20

3

4

27

8

5

9

10

12

28

33

11

68

13

1

73

72

71

18

21

22

23

24

75

76

30

31

32

2

16

17

25

48

35

36

56

34

55

54

57

37

58

59

60

38

74

61

63

64

47

45

44

14

39

69

40

41

42

43

46

70

50

49

51

52

53

62

65

66

67

6

P AR TS LIST - T ANK & V ACUUM ASSEMBLY

r

ITEM PART NO. DESCRIPTION QTY.

1 644120

2 908099

3 643920

4 964152

5

6 964153

7 648520

8 642320

9 648320

10 646620

11 964154

12 964155

13 640620

14 642420

15 649820

15a 649021

16 647501

17 964156

18 646621

19 642001

20 964155

21 911252

22 964158

23 964159

24 911253

25 964155

26 644520

27 642321

28 649020

29 964137

30 911193

31 645120

32 641320

33 643921

34 964158

35 911252

36 647220

37 644020

38 911254

39 964021

40 964138

Hose Assembly

Electric Cable

Handle Gr ip

Screw M3x20

Cable Cl a mp

Screw M4x12

Suction Hose Support

Top Cover

Closing C over Sp ring

Closing C over Plat e

Self-Threading Screw 3, 5x16

Self-Threading Screw 2, 9x13

Paper Bag, 10 Pack

Paper Bag Cage

Rigid Wand (no Inner Tube)

Tube, Rigid Wand Inner

Cable Retainer

Self-Threading Screw 3, 5x13

Support Plate

Cable Holder

Self-Threading Screw 2, 9x13

Microswitch

Self-Threading Screw 2, 9x16

Self-Threading Screw 2, 9x9, 5

Paper Bag Contr ol Card

Self-Threading Screw 2, 9x13

Cover H inge

Cover

Handle Tube

Screw M4x10

Switch

Lens

Upright Central Body/Housing

Lifting Handle

Self-Threading Screw 2, 9x16

Microswitch

Cable Retainer

Vacuum Motor Hol d e r

Micro Switch

Self-Threading Screw 3, 5x16

Self-Threading Screw 3, 9x13

1

1

1

2

1

1

1

1

1

1

4

4

1

1

1

1

1

2

1

1

2

1

1

2

1

4

2

1

1

2

1

1

1

1

1

1

1

1

1

2

1

ITEM PART NO. DESCRIPTION QTY.

41 642302

42 648301

43 649401

44 643403

45 625201

645208

46 620904

640910

47 643401

48 644820

49 643320

643307

50 642323

51 642020

52 964162

53 920630

54 964141

55 644220

56 964141

57 645103

58 645102

59 920631

60 646720

61 924065

62 647420

63 647202

64 964163

65 643601

66 642322

67 964021

68 643420

69 643321

70 964164

71 648120

72 649320

73 644121

74 980639

75 644122

76 647021

Safety Valve Cover

Safety Valve Cover Spring

Safety Valve

Vacuum Motor Ga sket

Vacuum Motor 115V

Vacuum Motor, 115V

Carbon Brush for 625201VacMt

CarbonBrush-645208 VacMtr

(Brown Holder)

Rubber Gasket

Sound Insulation

HEPA Filter

Foam Filter

Filter Cover

Filter Retaining Clamp

Screw M3x10

Nut M3

Screw M5x30

Motor Housing

Screw M5x30

Lockin g C atch /Knob

Locking Catch

Nut M4

Static Ground Pin

Self-Locking Nut M5

Locking-Rod

Latch

Self-Threading Screw 3, 5x13

Connection Protection

Vacuum Motor Cover

Self-Threading Screw 3, 5x16

Gasket

Vacuum Inlet Filter

Screw M3x8

Black Rotating Sleeve

Flexible Hose Union

Flexible Hose

Washer

Connection Hose Pressure Reg.

Post, Rubber

1

1

1

1

1

2

2

1

1

1

1

1

1

1

3

4

1

1

1

1

3

1

1

1

2

2

1

1

4

1

1

2

1

1

1

1

1

1

7

BRUSH HEAD ASSEMBL Y

13

14

30

31

15

32

20

33

16

21

34

35

55

37

1

12

11

17

36

43

19

18

40

2

10

28

29

41

6

57

3

7

24

42

38

8

52

25

26

4

5

9

51

22

23

39

46

47

48

49

44

45

56

50

8

P ARTS LIST - BRUSH HEAD ASSEMBLY

ITEM PART NO. DESCRIPTION QTY.

1 645121

2 642303

3 648502

4 641120

5 641121

6 642305

7 964136

8 911255

9 644901

10 647620

11 911256

12 641302

13 903017

14 646902

15 643322

16 643421

17 645201

645202

18 964157

19 980640

20 645105

21 648304

22 646901

23 648503

24 902034

25 642401

642404

26 640920

640921

28 964160

Lens

Base Cover

Swivel Neck Support Wiring

Bushing

Bushing

Joint Cover

Self-Threading Screw 3, 9x16

Wire on Swivel N eck

Swivel Neck

Felt Seal

Electronic Card Protection

Electronic Card 115V F350E

Belt

Pulley

Filter

Gasket

Brush Motor, 115V - 14"

Brush Motor, 115V - 18"

Self-Threading Screw 3, 9x19

Wash er D4

Support Lever

Spring

Brush Pulley

Brush Support

Bearing

Brush Core w/shaft - 14"

Brush Core w/shaft - 18"

Brush Strip - 14"

Brush Strip - 18"

Self-Threading Screw 3, 5x25

2

1

2

2

2

1

2

1

1

2

1

1

1

1

1

1

1

1

2

4

1

1

1

2

2

1

1

1

1

1

ITEM PART NO. DESCRIPTION QTY.

29 648305

30 647201

31 649701

32 980641

33 648302

34 647202

35 964138

36 647701

37 647020

38 644201

644202

39 645001

40 964138

41 964139

42 641201

641202

43 640502

44 647502

45 643408

46 643409

47 980636

48 647901

647902

49 964150

50 964149

51 644920

52 640904

55 640922

56 980637

57 648321

Spring

Retainer

Wheel

Wash er D6

Wheels Axle Spring

Latch

Self-Threading Screw 3, 9x13

Wheels Axle

Foot P edal

Chassis/Housing, Brush - 14"

Chassis/Housing, Brush - 18"

Brush Height Adjustment Knob

Self-Threading Screw 3, 9x13

Screw M5x45

Bumper - 14"

Bumper - 18"

Wheels Axle

Brush Adjustment Wheels

Gasket

Gasket

Washer

Shoe, Pick-Up - 14"

Shoe, Pick-Up - 18"

Screw M5x12

Screw M4x10

Complete Joint W/Support

Complete Brush, 14"

Carbon Brus h

Washer

Encl osing C over Spring

1

2

2

2

1

3

3

1

1

1

1

1

2

4

1

1

1

3

1

1

2

1

2

1

1

1

2

1

1

9

ACCESSORIES

1

4

2

3

ITEM PART NO. DESCRIPT ION QTY.

1 649001 Tube-Extension 1

2 648801 Crevice Tool 1

3 648802 Dusting Brush 1

4 640620 10 Pack Paper Bags 1

10

WIRING DIAGRAM

1

2

15

13

4

3

5

9

7

8

11

12

10

14

16

ITEM PART NO. DESCRIPT ION QTY.

1 908099

2 911193

3 911257

4 911252

5 911253

7 911258

8 911259

9 625201

10 911260

11 911201

Electric Cable

Switch

Lead Assembly

Microswitch

Control Card

Electric Cable Assembly

Terminal board Mannut

Vacuum Motor 115V

Grounding Lead

Elec.Lead Asm.-Microswitch

1

1

1

1

1

1

1

1

2

1

17

18

ITEM PART NO. DESCRIPT ION QTY.

12 911252

13 911264

14 911262

15 641302

641303

16 645201

645202

17 911255

18 648321

19 911263

Microswitch

Elec.Lead Asm.-Vacuum Motor

Contact Plug

Electronic Card 115V - 14"

Electronic Card 115V - 18"

Brush Motor 115V - 14"

Brush Motor 115V - 18"

Wire on Swivel N eck

Encl osing C over Spring

Antistatic Cable

11

1

2

1

1

1

1

1

1

1

1

WARRANTY POLICY

PACIFIC LIMITED WARRANTY

The Pacific Genius 14 and Genius 18 have been manufactured, tested and inspected in accordance with specific engineering requirements and

is WARRANTED to be free from defects in workmanship and materials as follows:

Three (3) years parts, one (1) year labor - Vacuum Motor and Brush Motor.

One (1) year parts & labor - All other components unless excluded below .

This warranty extends to the original user/purchaser and only when used, operated and maintained in accordance with Pacific Operating and

Maintenance instructions.

This warranty does not apply to the following wear parts and accessories of the machine including:

Part Number Part Name

908099

644121

640920

640921

903017

643321

643320

640620

641201

641202

640910

640922

Cord Assembly

Flexible Hose

Brush Strip-14”

Brush Strip-18”

Belt

Filter

Hepa Filter

Paper Bag Filters

Bumper-14”

Bumper-18”

Carbon Brush, Vac Motor

Carbon Brush, Brush Motor

Nor does it apply to damage or failure caused by improper use, abuse or neglect. Warranty credit or replacement of return parts including

motors, pumps, etc., is subject to incoming inspection of those items.

T o secure repair under this warranty, the following procedure should be taken:

• The inoperative machine or warranted parts must be delivered to the authorized dealer with shipping and delivery charges prepaid. If

unable to locate the Dealer, you may contact Pacific at the address listed herein for the location of the nearest Pacific repair center or agent

or for other instructions pertaining to your warranty difficulty.

• Upon compliance with the above warranty procedure, all warranted repairs would be completed at no additional charge or cost to the user .

• Only Pacific or its authorized dealers and agents may make no charge warranty repairs on this product. All others do so at their own risk.

This warranty limits Pacific’s liability to the repair of the product and/or warranted parts replacement and does not include incidental or

consequential damages arising from the use of a Pacific machine whether defective or not.

This warranty is in lieu of all other expressed or implied warranties and is extended to the original purchaser/user.

Ph: (800) 968-1332 Fax: (231) 773-1642

10/01 645620

2259 Sheridan

Muskegon, Michigan 49442

www.nextwaveofclean.com

Loading...

Loading...