Pacific FURY 1500DCP Pars Manual

UHS BURNISHER

FURY 1500DCP

Parts Manual

OPERATING & MAINTENANCE

INTRODUCTION INSTRUCTIONS

READ THIS BOOK

This operator’s book has important information for the

use and safe operation of this machine. Read this book

carefully before starting the machine. Keep this book

and tell all operators to read the book. If you do not

follow the instructions, you can cause an injury or damage equipment, furniture or buildings.

For new books write to:

Pacific

2259 South Sheridan Road

Muskegon, MI 49442

Carefully inspect all components to ensure that there is

no concealed freight damage. If such damage is discovered, file a “CONCEALED DAMAGE REPORT” immediately with the delivering carrier.

The contents of this manual are based on the latest

product information available at the time of publication. Pacific reserves the right to make changes or

improvements to its machines without notice.

FOR YOUR CONVENIENCE, RECORD THE

FOLLOWING IMPORT ANT INFORMA TION:

MODEL_______________________________

SERIAL NUMBER______________________

P ART NUMBER _________________________

DA TE PURCHASED ____________________

IMPORT ANT SAFETY INSTRUCTIONS

T o assure the safe operation of this machine, you must read and understand all warnings and instructions in this book.

If you do not understand, ask your supervisor.

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE

WARNING

: To reduce the risk of fire, electric shock, or injury:

1. Y ou must be trained to operate this machine. This machine is to be operated for its intended use only.

2. Do not operate this machine unless it is completely assembled.

3. Always use a three-wire electrical system connected to the electrical ground. For maximum protection against

electrical shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical

contractor.

4. T o prevent electric shock, always remove the electrical plug from the electrical outlet before doing any rep airs or

maintenance and when leaving the machine unattended.

5. T o prevent electric shock, keep the machine surface dry . Do not subject to rain. S tore the machine in a dry building

area. Clean the machine with a dry cloth only .

6. Machines can cause an explosion when near flammable materials and vapors. Do not use this machine with or

near fuels, grain dust, solvents, thinners, or other flammable materials. Do not use flammables to clean this

machine.

7. A qualified or authorized person must do maintenance and repairs.

8. T o prevent damage to the power cord, do not move this machine over the power cord. Always lift the power cord over

the machine. Do not pull or carry cord, use cord as a handle, close a door on cord, or pull cord around sharp edges

or corners. Keep cord away from heated surfaces.

9. Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, left

outdoors, or dropped into water , return it to a service center.

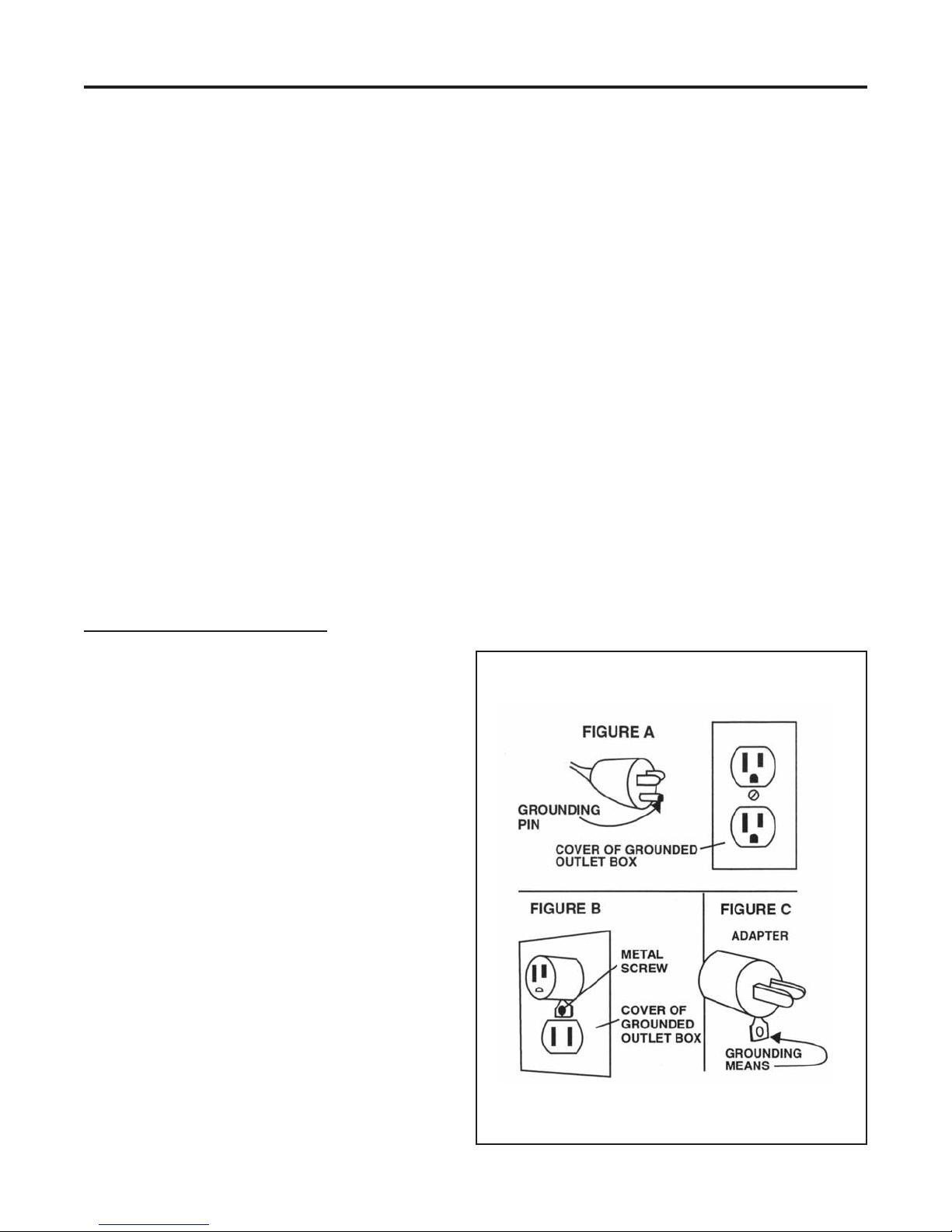

Grounding Instructions

This machine must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding plug. The plug must be inserted into an appropriate outlet that

is properly installed and grounded in accordance with all local

codes and ordinances.

WARNING - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as to whether the

outlet is properly grounded. Do not modify the plug provided with

the machine - if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

This machine is for use on a nominal 120-volt circuit, and has a

grounded plug that looks like the plug illustrated in figure A. A

temporary adapter that looks like the adapter illustrated in figures B

and C may be used to connect this plug to a 2-pole receptacle as

shown in figure B if a properly grounded outlet is not available.

The temporary adapter should be used only until a properly

grounded outlet (figure A) can be installed by a qualified electrician. The green colored rigid ear, lug, or the like extending from the

adapter must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adapter is

used, it must be held in place by a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted

by the Canadian Electrical Code

EXTENSION CORDS

Use only three-wire 12/3 or larger gauge approved extension

cords that have three-prong grounding type plugs and three-pole

receptacles that accept the appliance’s plug. Replace or repair

any damaged cords or plugs.

When servicing, refer to authorized person only. Use only identical replacement parts.

NOTE: Do not use adapters shown in figures B & C in Canada

2

OPERA TING & MAINTENANCE PROCEDURES

WARNING! For the safe operation of this machine follow the instructions given in this booklet

and the training given by your supervisor. Failure to do so can result in personal injury and/or

damage to machine and property!

DO NOT OPERA TE MACHINE IN AN EXPLOSIVE

ENVIRONMENT!

DO NOT USE THIS BURNISHER FOR SPRA Y BUFF

APPLICA TIONS. DOING SO WILL VOID WARRANTY

ON MOTOR.

The models shown in this manual are intended for commercial use.

PREPARATION

T o prepare the machine for operation, make sure it is of

correct voltage and properly assembled. If in doubt,

ask your supervisor.

Y our new floor machine operates in a straight-line forward motion, rather than the normal side to side motion

of a conventional single disc machine. Be prepared by

having your floor area cleared and ready for the fast

action of a burnisher.

Prepare the floor area by sweeping, dusting or mopping

as needed. Check the proper application recommendations and procedures found on the label of your finish

container . IF IN DOUBT , CALL YOUR SUPERVISOR .

WARNING! NEVER USE THIS MACHINE WITH FLAMMABLE OR EXPLOSIVE MA TERIAL!

For Burnishing: Select the correct clean floor pad

(your supplier can help you). The lighter color floor pads

(buff or white) are normally used for the burnishing procedure.

NEVER OPERATE THE MACHINE WITHOUT THE

FLOOR P AD INSTALLED!

It is very important to select clean, dry pads of uniform

thickness. Pads with high or low sections, or hard or

soft spots are unacceptable. Pads of open weave are

recommended; because close weaves tend to load up

fast, bog down the machines, cause circuits to overload and generally give poor results.

Tip the machine back to expose the pad driver. Remove the pad center lock ring. Carefully center the pad

onto the pad driver and secure with the locking ring.

Check for level, centering and flatness.

OPERATION

Set the machine upright onto the pad. Plug the

machine’s power cable into a properly grounded outlet

(see Safety Instructions). Next, release the handle locking knob and allow the handle to lower into a comfortable position. Then secure the handle locking knob. This

will allow the operator to easily control the brush pressure.

Depress the handle slightly to elevate the pad from the

floor. This is to avoid burning the floor on initial start up,

before the operator is ready to move forward. Pull out

on the “Watch Dog” Safety Lock button and start the

machine by depressing either the left or right switch

levers.

When you’re ready to move forward, lower the machine

head and pad to the floor and proceed forward in a straight

line, at a steady pace.

MAINTENANCE

AFTER EACH USE: Store the machine in a clean dry

area. Wipe the entire machine and cord down with a

clean cloth. Remove the pad and clean thoroughly . Wrap

the machine’s electrical cord onto the handles and the

cord hook provided. CHECK the cord and plug for nicks,

cuts or damage. Report these to your supervisor for

correction.

WARNING! Always disconnect the machine’s

electrical plug from the electrical outlet before

performing any service, maintenance, pad changing or inspection of the machine.

CIRCUIT BREAKER: A circuit breaker is used to pro-

tect the motor. If the motor draws high amperage the

circuit breaker will stop the motor. The reset button is

located in the front of the switch housing. Push the

reset button to restart the motor . If the motor continues

to stop, clean or change the floor pad. If this does not

correct the problem consult an authorized service person.

MOTOR: The motor is lubricated for life under normal

use. No oiling or greasing is necessary . However, if the

machine is used in dusty areas the motor should be

cleaned. Blowing the motor out with compressed air or

with the exhaust from a vacuum is suggested. Keeping

the motor clean will allow the clear passage of air for

ventilation and prevent overheating.

BELT TENSION: Proper belt tension is important for

smooth operation and belt life. Check the belt tension

and have no more than a 1/8-inch deflection. If adjustment is needed, loosen the four (4) motor mounting

bolts. Then tip the machine back onto its transport

wheels, slide the motor back and tighten the bolts.

CARBON BRUSH INSPECTION: Long life 3000-hour

carbon brushes are installed in the motor . The machine

is also equipped with a carbon brush wear indicator light

to signal when a carbon brush change is required.

3

Loading...

Loading...