Pacific FM-17DS, FM-20DS Installation Manual

PARTS & OPERATING MANUAL

FM-17DS & FM-20DS

FLOOR MACHINES

PLEASE READ THIS BOOK

This operator’s book has important informaon for the use and safe operaon of this machine. Read

this book carefully before using the machine. Keep this book and tell all operators to read the book. If

you do not follow the instrucons, you can cause an injury or damage equipment, furniture or buildings.

For new books, please download your copy from our website www.pacicoorcare.com or write to:

Pacic Floorcare

2259 S. Sheridan Drive

Muskegon, MI 49442-6252

Carefully inspect all components to ensure that there is no concealed freight damage. If such damage is

discovered, le a “CONCEALED DAMAGE REPORT” immediately with the delivering carrier.

The contents of this manual are based on the latest product informaon available at the me of

publicaon. Pacic reserves the right to make changes or improvements without noce.

Thank you for purchasing a Pacic Floorcare product. Warranty registraon will allow us to beer

serve you over the lifeme of the product. For quick and easy registraon, go to:

www.pacicoorcare.com/Register Product.

IMPORTANT SAFETY INSTRUCTIONS

To ensure the safe operaon of this machine, you must read and understand all warnings and instrucons in this book. If you

do not understand, ask your supervisor.

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE

WARNING: To reduce the risk of re, electric shock, or injury:

1. You must be trained to operate this machine. This machine is to be operated for its intended use only.

2. Do not operate this machine unless it is completely assembled.

3. Always use a three-wire electrical system connected to the electrical ground. For maximum protecon against electrical

shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical contractor.

4. To prevent electric shock, always remove the electrical plug from the electrical outlet before doing any repairs or maintenance and when leaving the machine unaended.

5. To prevent electric shock, keep the machine surface dry. Do not subject to rain. Store the machine in a dry building area.

Clean the machine with a dry cloth only.

6. Machines can cause an explosion when near ammable materials and vapors. Do not use this machine with or near fuels,

grain dust, solvents, thinners, or other ammable materials. Do not use ammables to clean this machine.

7. A qualied or authorized person must do maintenance and repairs.

8. To prevent damage to the power cord, do not move this machine over the power cord. Always li the power cord over

the machine. Do not pull or carry cord, use cord as a handle, close a door on cord, or pull cord around sharp edges or

corners. Keep cord away from heated surfaces.

9. Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, le outdoors, or dropped into water, return it to a service center.

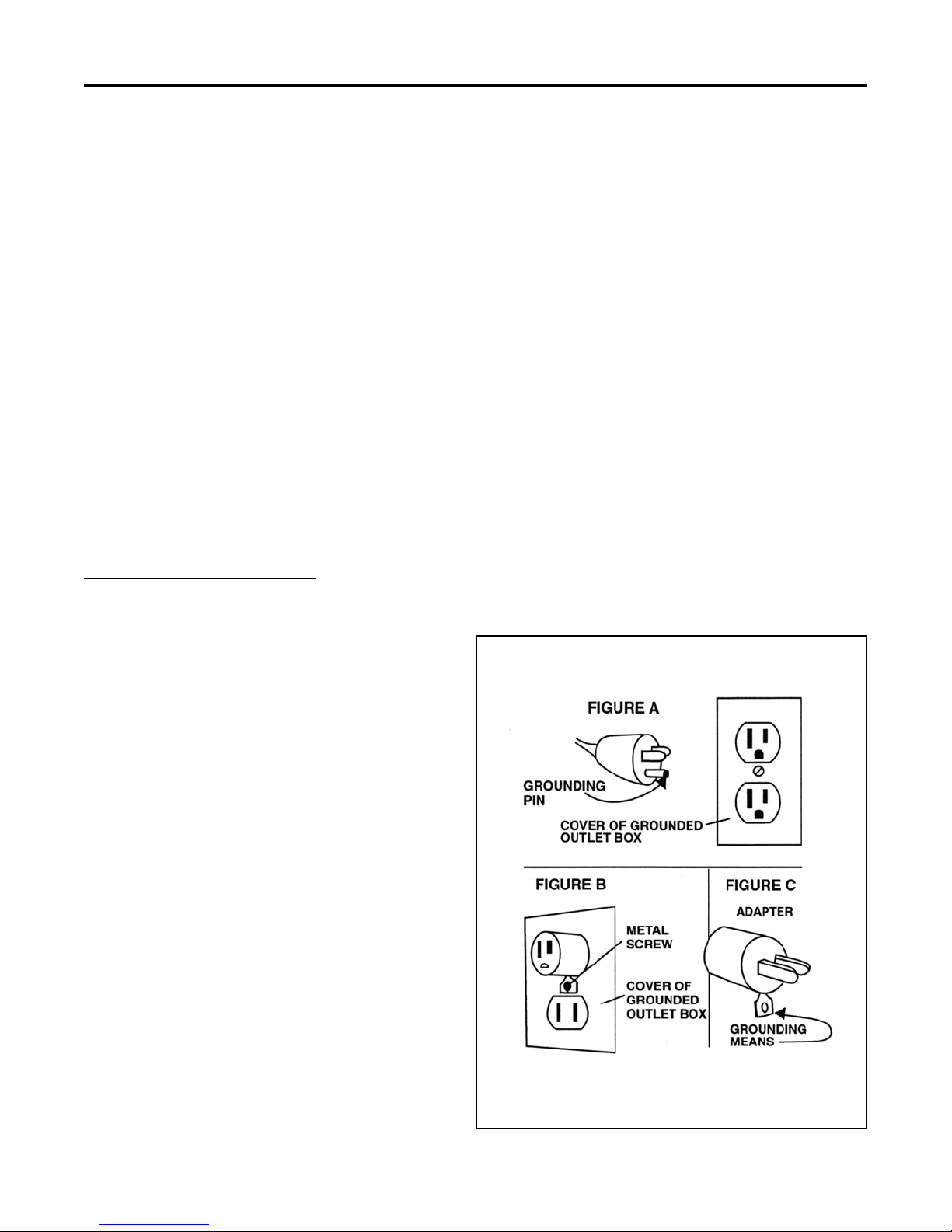

Grounding Instrucons

This machine must be grounded. If it should malfuncon or break down, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with a cord having an equipment-grounding conductor and grounding plug. The

plug must be inserted into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING - Improper connecon of the equipment-grounding

conductor can result in a risk of electric shock. Check with a qualied electrician or service person if you are in doubt as to whether

the outlet is properly grounded. Do not modify the plug provided

with the machine. If it will not t the outlet, have a proper outlet

installed by a qualied electrician.

This machine is for use on a nominal 120-volt circuit, and has a

grounded plug that looks like the plug illustrated in gure A. A

temporary adapter that looks like the adapter illustrated in gures

B and C may be used to connect this plug to a 2-pole receptacle

as shown in gure B if a properly grounded outlet is not available. The temporary adapter should be used only unl a properly

grounded outlet (gure A) can be installed by a qualied electrician. The green colored rigid ear, lug, or the like extending from

the adapter must be connected to a permanent ground such as

a properly grounded outlet box cover. Whenever the adapter is

used, it must be held in place by a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permied

by the Canadian Electrical Code

EXTENSION CORDS

Use only three-wire 12/3 or larger gauge approved extension

cords that have three-prong grounding type plugs and three-pole

receptacles that accept the appliance’s plug. Replace or repair any

damaged cords or plugs.

When servicing, refer to authorized person only. Use only idencal replacement parts.

NOTE: Do not use adapters shown in gures B & C in Canada

2

OPERATING PROCEDURES

WARNING! For the safe operaon of this machine follow the instrucons given in this manual and the training given by

your supervisor. Failure to do so can result in personal injury and/or damage to machine and property!

DO NOT OPERATE MACHINE IN AN EXPLOSIVE ENVIRONMENT!

This machine is intended for commercial use.

PREPARATION

To prepare the machine for operaon, make sure it is of correct voltage and properly assembled.

Your new oor machine operates in the normal side to side moon of a convenonal single disc machine. Be prepared before starng by

removing all obstrucons or other obstacles in the area to be cleaned. Check the proper applicaon recommendaons and procedures found

on the label of your cleaning or nish container. IF IN DOUBT, CALL

YOUR SUPERVISOR .

WARNING! NEVER USE THIS MACHINE WITH FLAMMABLE OR EXPLOSIVE MATERIAL!

For Scrubbing or Polishing: Select the correct oor pad or brush (your supplier can help you). If in doubt, ask your supervisor.

NEVER OPERATE THE MACHINE WITHOUT THE FLOOR PAD OR BRUSH INSTALLED!

To properly aach the brush, UNPLUG THE FLOOR MACHINE, place the handle in the vercal posion, then lt the machine back unl the

handle rests on the oor. Straddle the handle, facing the motor, and grasp the brush with the block toward you. Place the brush or pad

clutch plate over the three lugs on the motor drive adapter. Twist the brush right to lock it into posion. To remove the brush, UNPLUG

THE MACHINE and follow the same procedure as above, but by twisng the brush o with a rm jerk to the le. Remove the brush or pad

driver when the machine is not in use. This will help prevent brush damage and reduce wobble problems.

DUAL SPEED CONTROL: A rocker switch is located on the motor drip cover. Press the switch in on the side labeled LOW for 175 RPM pad

speed or to HIGH for 300 RPM pad speed.

OPERATION

Plug the machine’s power cable into a properly grounded outlet (see Safety Instrucons). Next, adjust the handle height to a comfortable

posion.

Pull out on the “Watch Dog” Safety Lock buon and start the machine by depressing either the le or right switch levers.

Both hands should be placed on the handle when the machine is in operaon. The machine will glide sideways over the oor by a slight

raising and lowering of the handle. Raise the handle slightly to go to the right. Lower the handle slightly to go le. Releasing the switch

lever stops the machine.

For Spray Bung: A diluted spray material of about one part water to one part soluon is recommended. Heavier spray bu soluons will

bog down the machine, load up the pad and adversely aect the machine’s eciency.

MAINTENANCE

AFTER EACH USE: Store the machine in a clean dry area. Wipe the enre machine and cord down with a clean cloth. Remove the pad or

brush and clean thoroughly. Wrap the machine’s electrical cord onto the handles and the cord hook provided. CHECK the cord and plug for

nicks, cuts or damage. Report these to your supervisor for correcon.

WARNING! Always disconnect the machine’s electrical plug from the electrical outlet before performing any service, maintenance, pad

changing or inspecon of the machine.

MOTOR: The motor is lubricated for life under normal use. No oiling or greasing is necessary. However, if the machine is used in dusty areas

or is used for spray bung, the motor should be cleaned. Blowing the motor out with compressed air or with the exhaust from a vacuum

is suggested. Keeping the motor clean will allow the clear passage of air for venlaon and prevent overheang. If you have any quesons

regarding the maintenance of your oor machine, ASK YOUR SUPERVISOR.

CARBON BRUSH INSPECTION: Long life 3000-hour carbon brushes are installed in the motor. The machine is also equipped with a carbon

brush wear indicator to signal when a carbon brush change is required.

Loading...

Loading...