AMX-SERIES

OPERATION MANUAL

FOR THE

MODELS

105-AMX, 108-AMX,

112-AMX, 125-AMX,

140-AMX, 160-AMX,

305-AMX, 308-AMX,

312-AMX,320-AMX,

345-AMX,360-AMX,

390-AMX, 3120-AMX

AND THE

UMC-31

THIS MANUAL ASSIGNED TO:

MODEL_____________________

S/N______________________

THE INFORMATION CONTAINED

IN THIS MANUAL IS PROPRIETARY TO

PACIFIC POWER SOURCE.

MAY NOT BE COPIED OR REPRINTED

WITHOUT ITS EXPRESSED WRITTEN CONSENT.

PACIFIC POWER SOURCE, INC.

17692 FITCH

IRVINE, CALIF. 92614

PPS PART NO. 139250

REVISION A

October 2003

CERTIFICATION

Pacific Power Source certifies that this instrument was thoroughly tested and inspected and found to meet or

exceed its published specifications when it was shipped from the factory.

LIMITED WARRANTY

Pacific Power Source (PPS) warrants each unit to be free from defects in material and workmanship. For the

period of two (2) years from the date of shipment to the purchaser, PPS will either repair or replace, at its sole

discretion, any unit returned to its factory in Irvine, California. This warranty does not cover batteries. It does

not cover damage arising from mis-use of the unit or attempted field modifications or repairs. This warranty

specifically excludes damage to other equipment connected to this unit.

Upon notice from the purchaser within (30) days of shipment of units found to be defective in material or

workmanship, PPS will pay all shipping charges for the repair or replacement. If notice is received more than

thirty (30) days from shipment, all shipping charges shall be paid by the purchaser. Units returned on debit

memos will not be accepted and will be returned without repair.

This warranty is exclusive of all other warranties, express or implied.

TABLE OF CONTENTS

PAGE

1.0 GENERAL

1.1 USING THIS MANUAL ..................................................................................................................1

1.2 SAFETY NOTICES.......................................................................................................................... 2

1.3 GENERAL PRODUCT DESCRIPTION..........................................................................................5

2.0 SPECIFICATIONS

2.1 ELECTRICAL SPECIFICATIONS..................................................................................................7

2.1.1 INPUT POWER REQUIREMENTS ................................................................................................7

2.1.2 OUTPUT POWER..........................................................................................................................14

2.1.3 OUTPUT POWER FACTOR .........................................................................................................28

2.1.4 OUTPUT FREQUENCY ................................................................................................................ 28

2.1.5 OUTPUT DISTORTION ................................................................................................................ 28

2.1.6 OUTPUT LOAD REGULATION ..................................................................................................28

2.1.7 INPUT LINE REGULATION ........................................................................................................ 28

2.1.8 OUTPUT BANDWIDTH ...............................................................................................................29

2.1.9 LOAD TRANSIENT RESPONSE.................................................................................................. 29

2.1.10 OUTPUT DC OFFSET ................................................................................................................... 29

2.1.11 OUTPUT PROTECTION ............................................................................................................... 29

2.1.12 OUTPUT CONTROL CHARACTERISTICS ................................................................................ 29

2.1.13 OUTPUT ISOLATION................................................................................................................... 29

2.2 MECHANICAL SPECIFICATIONS.............................................................................................. 30

2.2.1 DIMENSIONS ................................................................................................................................ 30

2.2.2 INPUT POWER CONNECTION ...................................................................................................33

2.2.3 OUTPUT POWER CONNECTION ...............................................................................................38

2.2.4 CHASSIS SLIDE MOUNTS ..........................................................................................................38

2.3 ENVIRONMENTAL SPECIFICATIONS...................................................................................... 38

2.3.1 TEMPERATURE RANGE ............................................................................................................. 38

2.3.2 COOLING.......................................................................................................................................38

2.3.3 THERMAL PROTECTION............................................................................................................38

3.0 INSTALLATION

3.1 CHASSIS PLACEMENT ...............................................................................................................39

3.2 OUTPUT VOLTAGE RANGE CONFIGURATION ..................................................................... 41

3.2.1 OUTPUT VOLTAGE RANGE CONFIGURATION, MODELS 105 and 108-AMX.................... 43

3.2.2 OUTPUT VOLTAGE RANGE CONFIGURATION, MODEL 112-AMX....................................45

3.2.3 OUTPUT VOLTAGE RANGE CONFIGURATION, MODEL 125-AMX....................................47

3.2.4 OUTPUT VOLTAGE RANGE CONFIGURATION, MODELS 305 and 308-AMX.................... 49

3.2.5 OUTPUT VOLTAGE RANGE CONFIGURATION, MODEL 312-AMX....................................51

3.2.6 OUTPUT VOLTAGE RANGE CONFIGURATION, MODEL 320-AMX....................................53

3.2.7 OUTPUT VOLTAGE RANGE CONFIGURATION, MODELS 140, 160, 345, 360, 390, and

3120-AMX......................................................................................................................................55

3.3 INPUT POWER CONNECTION ...................................................................................................57

3.3.1 INPUT VOLTAGE CONFIGURATION, MODELS 105, 108, 305, and 308-AMX .....................57

3.3.4 INPUT VOLTAGE CONFIGURATION, MODELS 112 and 312-AMX ......................................59

3.3.5 INPUT VOLTAGE CONFIGURATION, MODEL 320-AMX ...................................................... 61

3.3.6 INPUT VOLTAGE CONFIGURATION, MODEL 125-AMX ...................................................... 63

3.3.7 INPUT VOLTAGE CONFIGURATION, MODELS 140, 160, 345, 360, 390, and 3120-

AMX ...............................................................................................................................................65

3.3.8 INPUT POWER WIRING REQUIREMENTS...............................................................................67

-i-

TABLE OF CONTENTS

3.4 OUTPUT POWER CONNECTION ...............................................................................................70

3.4.1 SINGLE PHASE OUTPUT ............................................................................................................70

3.4.2 SPLIT PHASE OUTPUT................................................................................................................ 74

3.4.3 THREE PHASE OUTPUT..............................................................................................................78

3.4.4 TRANSFORMER OUTPUTS - SPECIAL CONSIDERATIONS................................................. 79

3.4.5 MODELS 390-AMX and 3120-AMX CHASSIS INTERCONNECTIONS................................... 81

3.5 REMOTE INTERFACE .................................................................................................................82

3.6 AUX I/O INSTALLATION............................................................................................................82

3.7 EXTERNAL SENSE CONNECTION............................................................................................ 86

4.0 OPERATION

4.1 FRONT PANEL CONTROLS....................................................................................................... 89

4.2 INITIAL POWER-UP.................................................................................................................... 90

4.3 ROUTINE POWER-UP................................................................................................................. 91

4.3.1 ROUTINE POWER-UP, MODELS 390-AMX and 3120-AMX ................................................... 91

4.4 SYSTEM TURN-OFF ................................................................................................................... 92

4.4.1 SYSTEM TURN-OFF, MODELS 390-AMX and 3120-AMX.......................................................93

4.5 SYSTEM SHUTDOWN ................................................................................................................ 93

4.5.1 SHUTDOWN CONDITIONS........................................................................................................ 93

4.5.2 RESETTING SHUTDOWN FAULTS .......................................................................................... 94

4.6 OUTPUT VOLTAGE FORMS..................................................................................................... 94

4.6.1 SYSTEM ARCHITECTURE......................................................................................................... 97

5.0 MAINTENANCE

5.1 MAINTENANCE INTERVAL...................................................................................................... 99

5.2 MAINTENANCE REQUIREMENTS........................................................................................... 99

5.2.1 MODELS 105, 108, 112, 305, 308, and 312-AMX ....................................................................... 99

5.2.2 MODELS 125, 140, 160, 320, 345, 360, 390, and 3120-AMX ..................................................... 99

6.0 CALIBRATION

6.1 CALIBRATION INTERVAL...................................................................................................... 101

6.2 TEST EQUIPMENT REQUIREMENTS..................................................................................... 101

6.3 CALIBRATION PROCEDURE .................................................................................................. 102

6.3.1 CALIBRATE CONTROLLER ................................................................................................... 102

6.3.2 POWER SOURCE LOAD TEST................................................................................................. 103

PAGE

-ii-

TABLE OF CONTENTS

PAGE

7.0 SERVICE

7.1 SERVICE PROCEDURE .............................................................................................................105

7.2 ROSTER OF SYSTEM LEVEL PART NUMBERS....................................................................105

7.3 SUB-ASSEMBLY AND CHASSIS COMPONENT PART NUMBERS..................................... 106

7.3.1 FACTORY PART NUMBERS, MODEL 105-AMX ...................................................................106

7.3.2 FACTORY PART NUMBERS, MODEL 108-AMX ...................................................................107

7.3.3 FACTORY PART NUMBERS, MODEL 112-AMX ...................................................................107

7.3.4 FACTORY PART NUMBERS, MODEL 125-AMX ...................................................................108

7.3.5 FACTORY PART NUMBERS, MODEL 140-AMX ...................................................................108

7.3.5A FACTORY PART NUMBERS, MODEL 160-AMX ................................................................ 108A

7.3.6 FACTORY PART NUMBERS, MODEL 305-AMX ...................................................................109

7.3.7 FACTORY PART NUMBERS, MODEL 308-AMX ...................................................................109

7.3.8 FACTORY PART NUMBERS, MODEL 312-AMX ...................................................................110

7.3.9 FACTORY PART NUMBERS, MODEL 320-AMX ...................................................................110

7.3.10 FACTORY PART NUMBERS, MODEL 345-AMX ...................................................................111

7.3.11 FACTORY PART NUMBERS, MODEL 360-AMX ...................................................................112

7.3.12 FACTORY PART NUMBERS, MODEL 390-AMX ...................................................................113

7.3.13 FACTORY PART NUMBERS, MODEL 3120-AMX .................................................................114

8.0 UMC-31 CONTROLLER

8.1 GENERAL PRODUCT DESCRIPTION......................................................................................115

8.2 UMC-31 SPECIFICATIONS........................................................................................................ 116

8.2.1 OUTPUT FREQUENCY .............................................................................................................. 116

8.2.2 OUTPUT VOLTAGE ................................................................................................................... 117

8.2.3 OUTPUT WAVEFORM............................................................................................................... 117

8.2.4 OUTPUT FORMS ........................................................................................................................117

8.2.5 OUTPUT METERING .................................................................................................................118

8.2.6 ISOLATION .................................................................................................................................119

8.2.7 ENVIRONMENTAL .................................................................................................................... 119

8.3 UMC-31 INSTALLATION ..........................................................................................................119

8.3.1 REMOVE EXISTING CONTROLLER .......................................................................................119

8.3.2 CONFIGURE THE NEW CONTROLLER .................................................................................. 121

8.3.3 INSTALL THE NEW CONTROLLER ........................................................................................122

8.4 UMC-31 OPERATION................................................................................................................. 125

8.4.1 UMC-31 CONTROLS AND INDICATORS................................................................................ 125

8.4.2 UMC-31 AUXILIARY INPUTS ..................................................................................................127

8.4.3 UMC-31 DIGITAL OUTPUTS .................................................................................................... 127

8.5 UMC-31 CALIBRATION ............................................................................................................ 129

INDEX....................................................................................................................................................................... 132

9.0 MODIFICATIONS AND CHANGE NOTICES..................................................................... 135

-iii-

LIST OF ILLUSTRATIONS

FIGURE 1.3 AMX-SERIES POWER SOURCE - FRONT VIEW .........................................................4

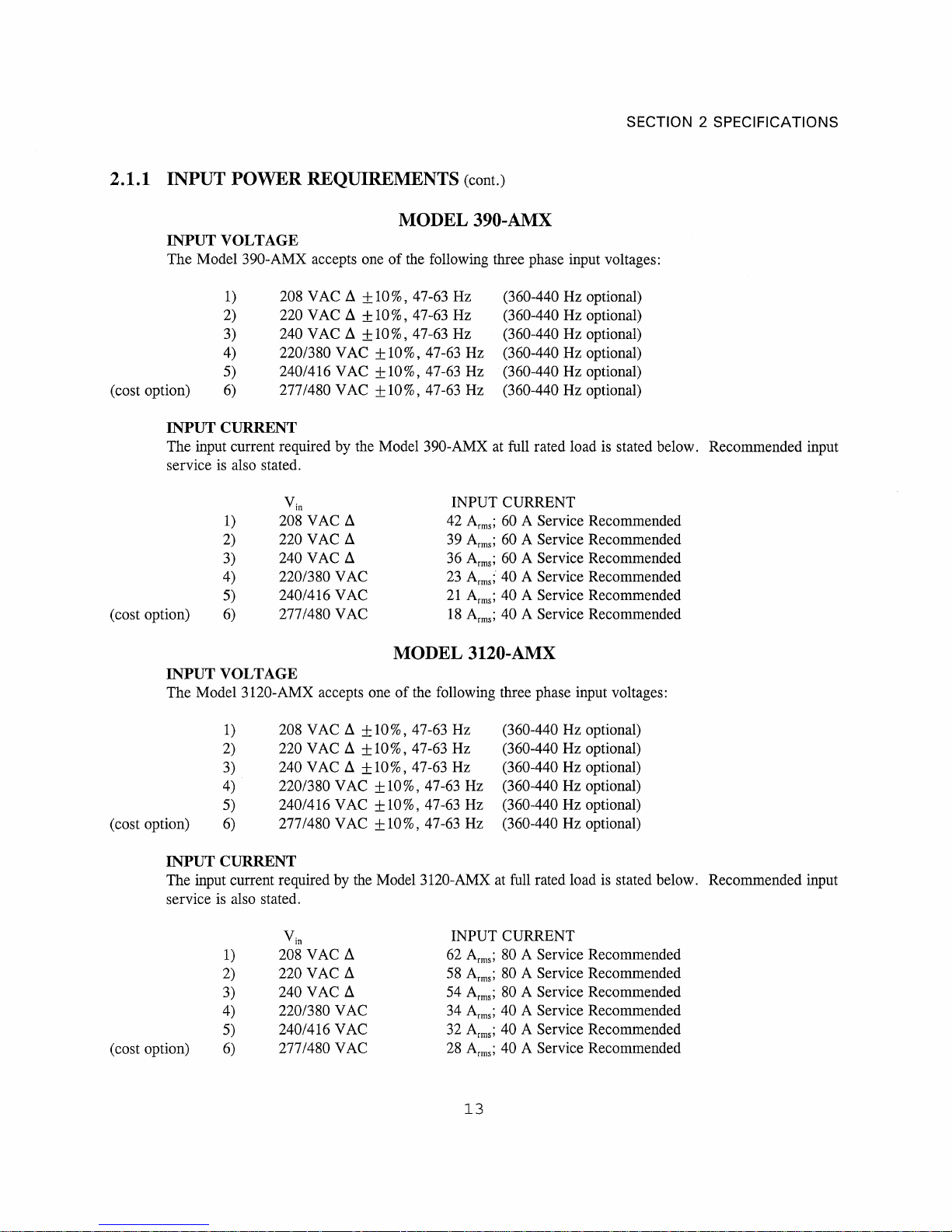

FIGURE 2.1.2(A) MODEL 105-AMX OUTPUT DERATING CURVES ....................................................15

FIGURE 2.1.2(B) MODEL 108-AMX OUTPUT DERATING CURVES ....................................................16

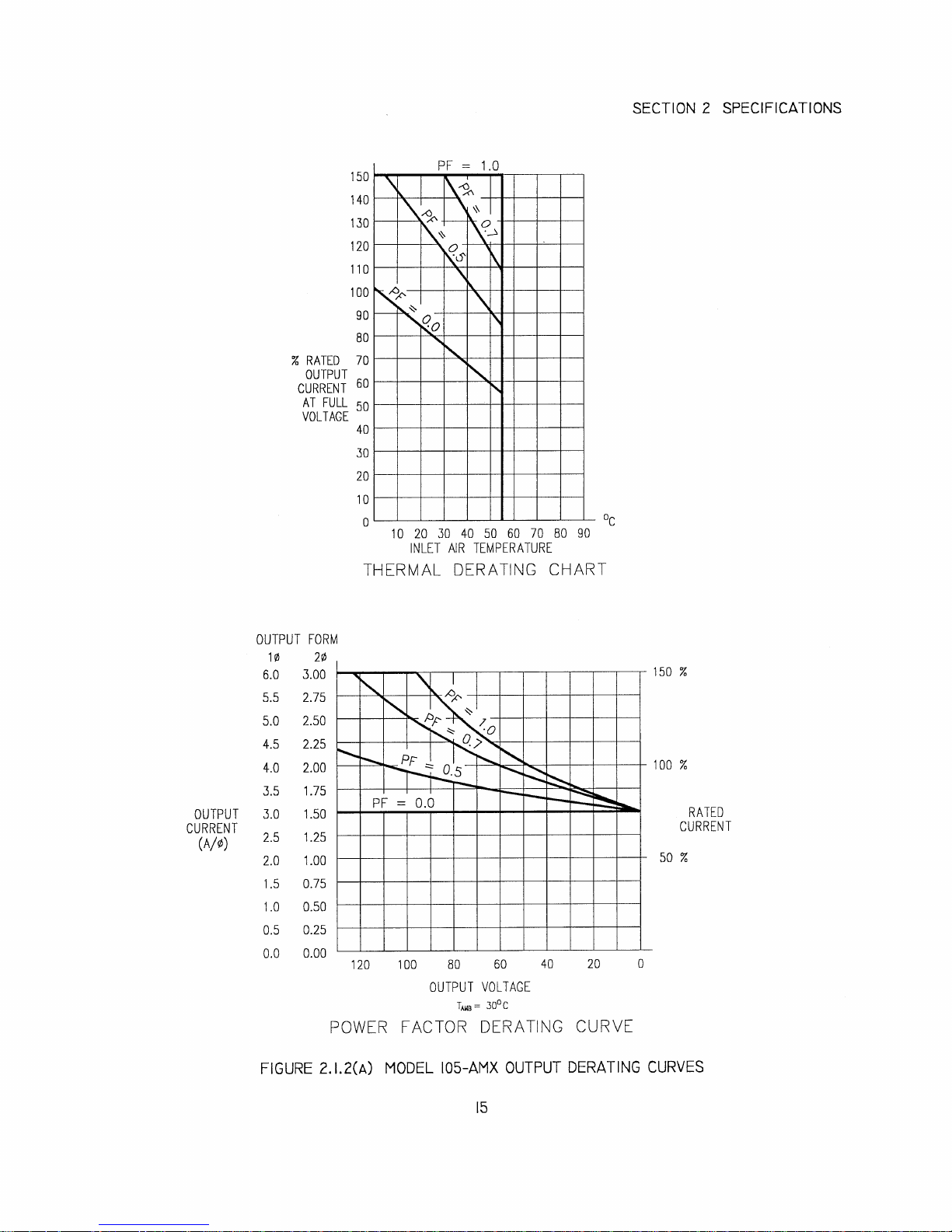

FIGURE 2.1.2(C) MODEL 112-AMX OUTPUT DERATING CURVES ....................................................17

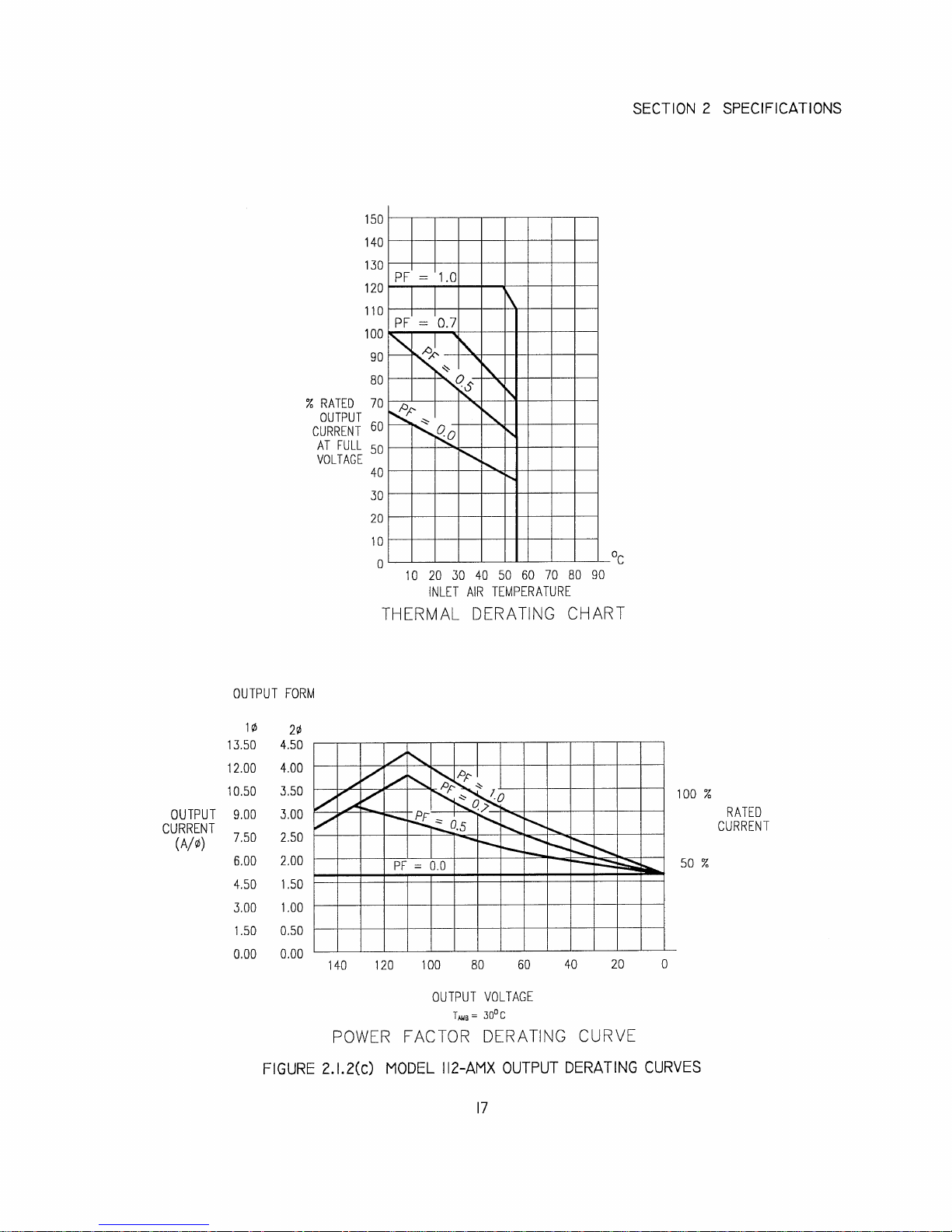

FIGURE 2.1.2(D) MODEL 125-AMX OUTPUT DERATING CURVES ....................................................18

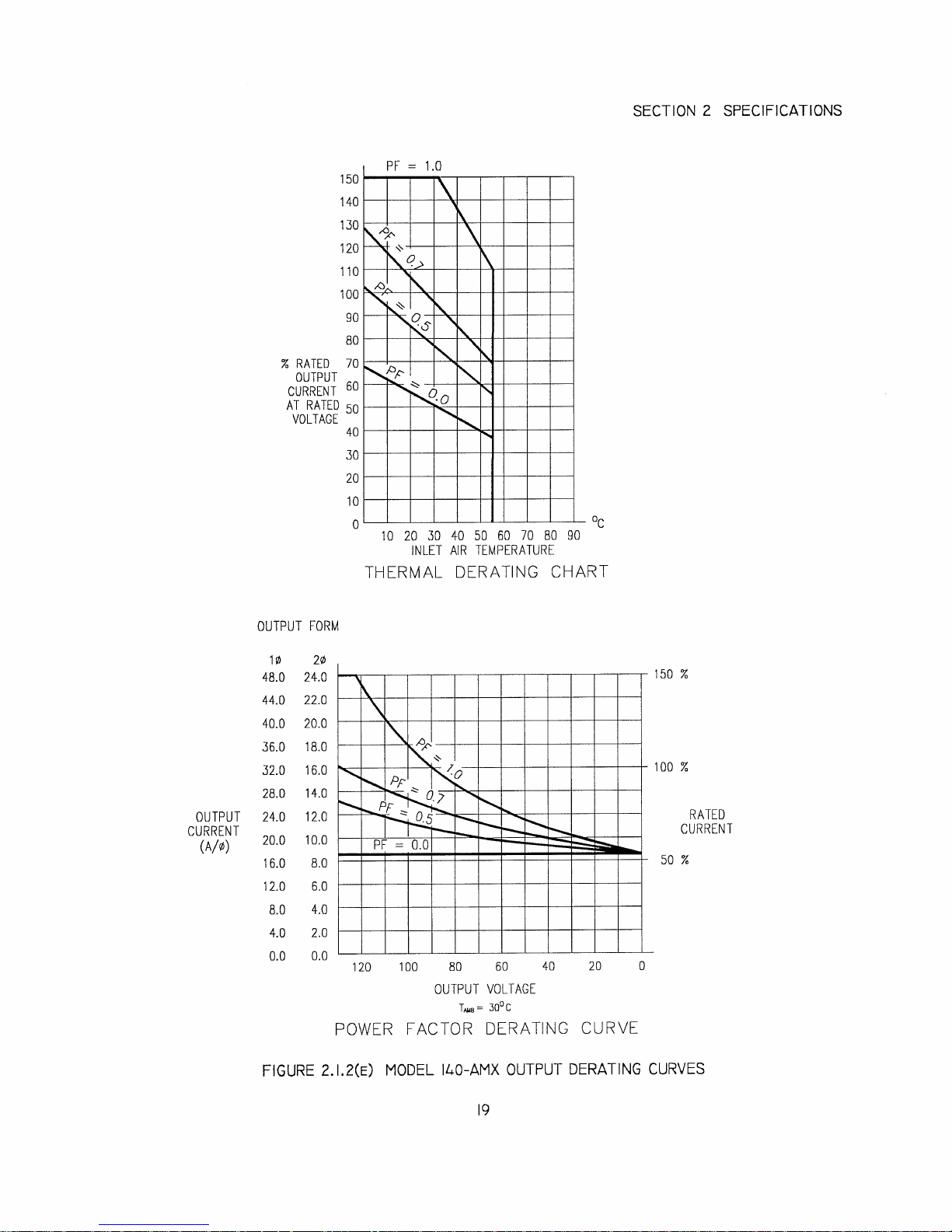

FIGURE 2.1.2(E) MODEL 140-AMX OUTPUT DERATING CURVES ....................................................19

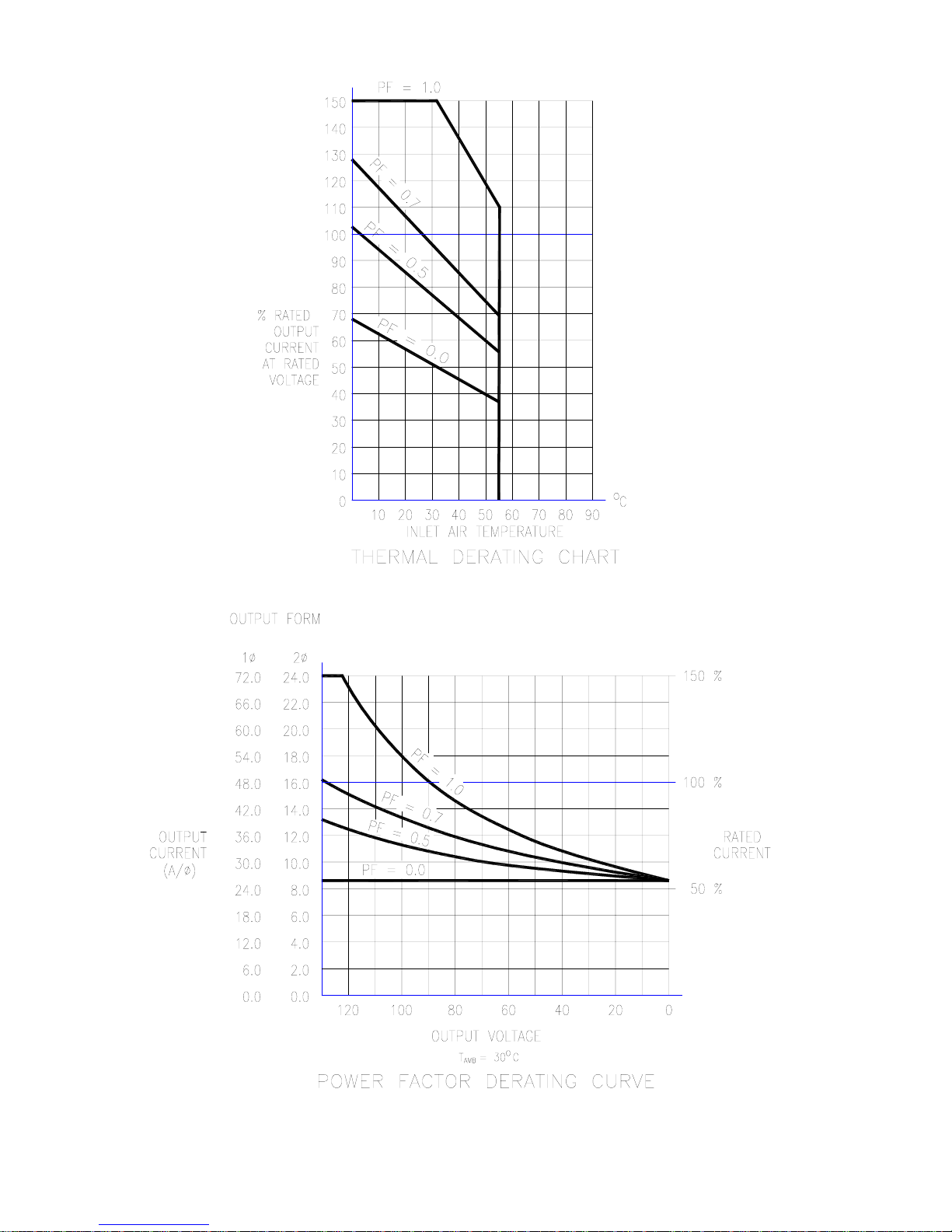

FIGURE 2.1.2(E2) MODEL 160-AMX OUTPUT DERATING CURVES ................................................. 19A

FIGURE 2.1.2(F) MODEL 305-AMX OUTPUT DERATING CURVES ....................................................20

FIGURE 2.1.2(G) MODEL 308-AMX OUTPUT DERATING CURVES ....................................................21

FIGURE 2.1.2(H) MODEL 312-AMX OUTPUT DERATING CURVES ....................................................22

FIGURE 2.1.2(J) MODEL 320-AMX OUTPUT DERATING CURVES ....................................................23

FIGURE 2.1.2(K) MODEL 345-AMX OUTPUT DERATING CURVES ....................................................24

FIGURE 2.1.2(L) MODEL 360-AMX OUTPUT DERATING CURVES ....................................................25

FIGURE 2.1.2(M) MODEL 390-AMX OUTPUT DERATING CURVES ....................................................26

FIGURE 2.1.2(N) MODEL 3120-AMX OUTPUT DERATING CURVES ..................................................27

FIGURE 2.2.1 OUTLINE DRAWING, MODELS 105, 108, 112, 305, 308, & 312-AMX .....................34

FIGURE 2.2.2 OUTLINE DRAWING, MODEL 320-AMX ...................................................................35

FIGURE 2.2.3 OUTLINE DRAWING, MODELS 125, 140, 160, 345, & 360-AMX .............................36

FIGURE 2.2.4 OUTLINE DRAWING, MODELS 390, 3120-AMX, & MAGNETICS MODULE ........37

FIGURE 3.2.1 MODELS 105 & 108-AMX OUTPUT VOLTAGE CONFIGURATION........................42

FIGURE 3.2.2(A) MODEL 112-AMX OUTPUT VOLTAGE CONFIGURATION TABLE .......................44

FIGURE 3.2.2(B) MODEL 112-AMX OUTPUT VOLT. RANGE JUMPER (E1) LOCATION ................. 45

FIGURE 3.2.4 MODELS 105 & 108-AMX OUTPUT VOLTAGE CONFIGURATION........................48

FIGURE 3.2.5(A) MODEL 312-AMX OUTPUT VOLTAGE CONFIGURATION TABLE .......................49

FIGURE 3.2.5(B) MODEL 312-AMX OUTPUT VOLT. RANGE JUMPER (E1) LOCATION ................. 50

FIGURE 3.2.7 MODELS 140, 160, 345, 360, 390, & 3120-AMX OUTPUT VOLTAGE

CONFIGURATION..........................................................................................................54

FIGURE 3.3.1 MODELS 105, 108, 305, 308-AMX INPUT VOLTAGE CONFIGURATION ............... 56

FIGURE 3.3.4 MODELS 112 & 312-AMX INPUT VOLTAGE CONFIGURATION............................ 58

FIGURE 3.3.5 MODEL 320-AMX INPUT VOLTAGE CONFIGURATION ......................................... 60

FIGURE 3.3.6 MODEL 125-AMX INPUT VOLTAGE CONFIGURATION ......................................... 62

FIGURE 3.3.7 MODELS 140, 160, 345, 360, 390, 3120-AMX INPUT VOLTAGE

CONFIGURATION..........................................................................................................64

FIGURE 3.3.8 AMX-SERIES INPUT WIRING DIAGRAM ..................................................................66

FIGURE 3.4.1.1 SINGLE PHASE OUTPUT CONNECTION ...................................................................68

FIGURE 3.4.1.2 SINGLE PHASE OUTPUT CONNECTION ...................................................................69

FIGURE 3.4.2.1 SPLIT PHASE OUTPUT CONNECTION ....................................................................... 72

FIGURE 3.4.2.2 SPLIT PHASE OUTPUT CONNECTION ....................................................................... 73

FIGURE 3.4.3.1 THREE PHASE OUTPUT CONNECTION.....................................................................76

FIGURE 3.4.3.2 THREE PHASE OUTPUT CONNECTION.....................................................................77

FIGURE 3.4.5 MODELS 390 AND 3120-AMX CHASSIS INTERCONNECTIONS ............................80

FIGURE 3.8.1 EXTERNAL SENSE CONNECTION, MODELS 125, 140, 160, 345, 360, 390, &

3120-AMX........................................................................................................................ 84

FIGURE 3.8.2 EXTERNAL SENSE CONNECTION, MODELS 105, 108, 305, 308, 112, 312, &

320-AMX..........................................................................................................................85

FIGURE 4.1 FRONT PANEL CONTROLS..........................................................................................88

FIGURE 4.6.1 AMX-SERIES SYSTEM ARCHITECTURE...................................................................96

FIGURE 8.3.2 UMC-31 CONFIGURATION JUMPER LOCATIONS................................................. 120

FIGURE 8.4.1 UMC-31 FRONT PANEL CONTROLS ........................................................................124

FIGURE 8.4.2 UMC-31 J5 AUX I/O CONNECTOR ............................................................................126

FIGURE 8.5 UMC-31 CALIBRATION ADJUSTMENT LOCATIONS............................................ 128

-

iv-

PAGE

SECTION 1 GENERAL

SECTION 1

GENERAL

1.0 GENERAL

This manual is written to provide the information required to use the AMX-Series AC Power Source. Operation

of the Models 105-AMX, 108-AMX, 112-AMX, 125-AMX, 140-AMX, 160-AMX, 305-AMX, 308-AMX, 312AMX, 320-AMX, 345-AMX, 360-AMX, 390-AMX, and 3120-AMX is described in this document.

This manual is an Operations Manual. Installation, operation, and calibration are the subjects covered by this

manual.

1.1 USING THIS MANUAL

This manual provides instructions for installation and use of the AMX-Series Power Source equipment. For this

reason, it is very important that the user reads sections 1, 3, and 4 prior to using this equipment. A thorough

understanding of these sections is required to properly operate this equipment.

Section 2 states the specifications of the equipment. Knowledge of this information is required to gain

maximum use of this equipment for a given application. The user is encouraged to read this section in order to

gain a deeper understanding of the capabilities of the AMX-Series Power Source.

Sections 5 and 6 list maintenance and calibration requirements of this equipment. Refer to these sections when

either maintenance or calibration is required.

Section 7 describes service methodology and provides system, sub-assembly, and component part numbers to

aid the user in making factory authorized field repairs.

This equipment is configured with a modular controller. This allows for the creation of systems with various

control characteristics and specifications. This manual describes the operation of the basic power source.

Detailed information relative to the UMC-31 Controller is also included is described in Section 8 of this

manual. The UPC controllers are described in a separate manual. Refer to the UPC-Series Operation Manual

for such information.

Section 9 contains product change notices, errata and data relative to customer specified modifications.

Always read this section before operating the equipment. This is especially true when modifications have been

installed, since these can change system operation.

If questions arise while reading this manual, the user is encouraged to call the Pacific Power Source. Pacific

maintains a toll-free number which is 1-800-854-2433.

- 1 -

SECTION 1 GENERAL

MODEL 305−AMX

w/ UMC−31 Controller

MODEL 360−AMX

w/ UPC−32 Controller

4

FIGURE 1.3

SECTION 1 GENERAL

1.3 GENERAL PRODUCT DESCRIPTION

The AMX-Series Power Source is high-performance AC power conversion equipment. This series of

equipment features models with power ratings from 500 VA to 12 kVA. All systems are designed to fit into the

standard 19 inch rack. These systems are suitable for use as frequency changers as well as sophisticated test

power generators.

All systems are configured with an interchangeable controller. Controller options range from the basic manual

type (UMC-Series) to the sophisticated programmable controller (UPC-Series). The manual controller allows

the user to adjust voltage and frequency. The programmable controller, on the other hand, not only allows

control of voltage and frequency, but also allows the user to simulate virtually any transient (including subcycle waveform disturbance) required for testing today's modern electronic equipment.

The standard output voltage range of the AMX-Series is 0-135 VAC

(0-150 VAC

l-n

Additionally, the Models 112-AMX and 312-AMX can be configured for several output voltage ranges

between and including 0-110 VAC

and 0-150 VAC

l-n

. Optional output transformers are available to provide

l-n

higher voltages. Voltage ratios up to 2.5:1 are available.

The AMX-Series consists of the basic models listed below:

1. Model 105-AMX - 500 VA Chassis capable of 1 or 2 Phase operation. Standard

Output voltage range is 0-135 VAC

, 1φ or 0-270 VAC, 2 Phase. Phase separation fixed at 180°

l-n

when operating in 2 Phase Mode.

2. Model 108-AMX - Same as 105-AMX, but rated for 750 VA output power.

3. Model 112-AMX - Same as 105-AMX, but rated for 1.2 kVA output power. Standard

Output voltage ranges are 0-110 VAC

through 0-150 VAC

l-n

, 1φ or 0-220 VAC through 0-300 VAC,

l-n

2 Phase.

4. Model 125-AMX - Same as 105-AMX, but rated for 2.5 kVA output power. Standard

Output voltage range is 0-150 VAC

, 1φ or 0-300 VAC, 2 Phase.

l-n

5. Model 140-AMX - Same as 105-AMX, but rated for 4.0 kVA output power.

6. Model 160-AMX - Same as 105-AMX, but rated for 6.0 kVA output power.

7. Model 305-AMX - 500 VA Chassis capable of 1, 2, or 3 Phase operation. Standard

Output voltage range is 0-135 VAC

. Phase separation fixed at 180° when operating in 2 Phase

l-n

Mode. In 3 Phase Mode, phase separation is fixed at 120° or programmable.

8. Model 308-AMX - Same as 305-AMX, but rated for 750 VA output power.

9. Model 312-AMX - Same as 305-AMX, but rated for 1.2 kVA output power. Standard

Output voltage ranges are 0-110 VAC

through 0-150 VAC

l-n

, 1φ or 0-220 VAC through 0-300 VAC,

l-n

2 Phase.

10. Model 320-AMX - Same as 305-AMX, but rated for 2.25 kVA output power.

for the Model 125-AMX).

l-n

5

SECTION 1 GENERAL

1.3 GENERAL PRODUCT DESCRIPTION (cont.)

11. Model 345-AMX - Same as 305-AMX, but rated for 4.5 kVA output power.

12. Model 360-AMX - Same as 305-AMX, but rated for 6.0 kVA output power.

13. Model 390-AMX - Same as 305-AMX, but rated for 9.0 kVA output power.

14. Model 3120-AMX - Same as 305-AMX, but rated for 12.0 kVA output power.

External voltage sense is provided on all systems. Systems configured with the programmable controller also

feature Continuous Self Calibration (CSC).

Output voltage and current metering is provided on all systems. Specifications of the metering functions vary

by controller type. Refer to Section 8 or the UPC-Series Operation Manual, as appropriate, for details relative

to the metering functions.

6

SECTION 2 SPECIFICATIONS

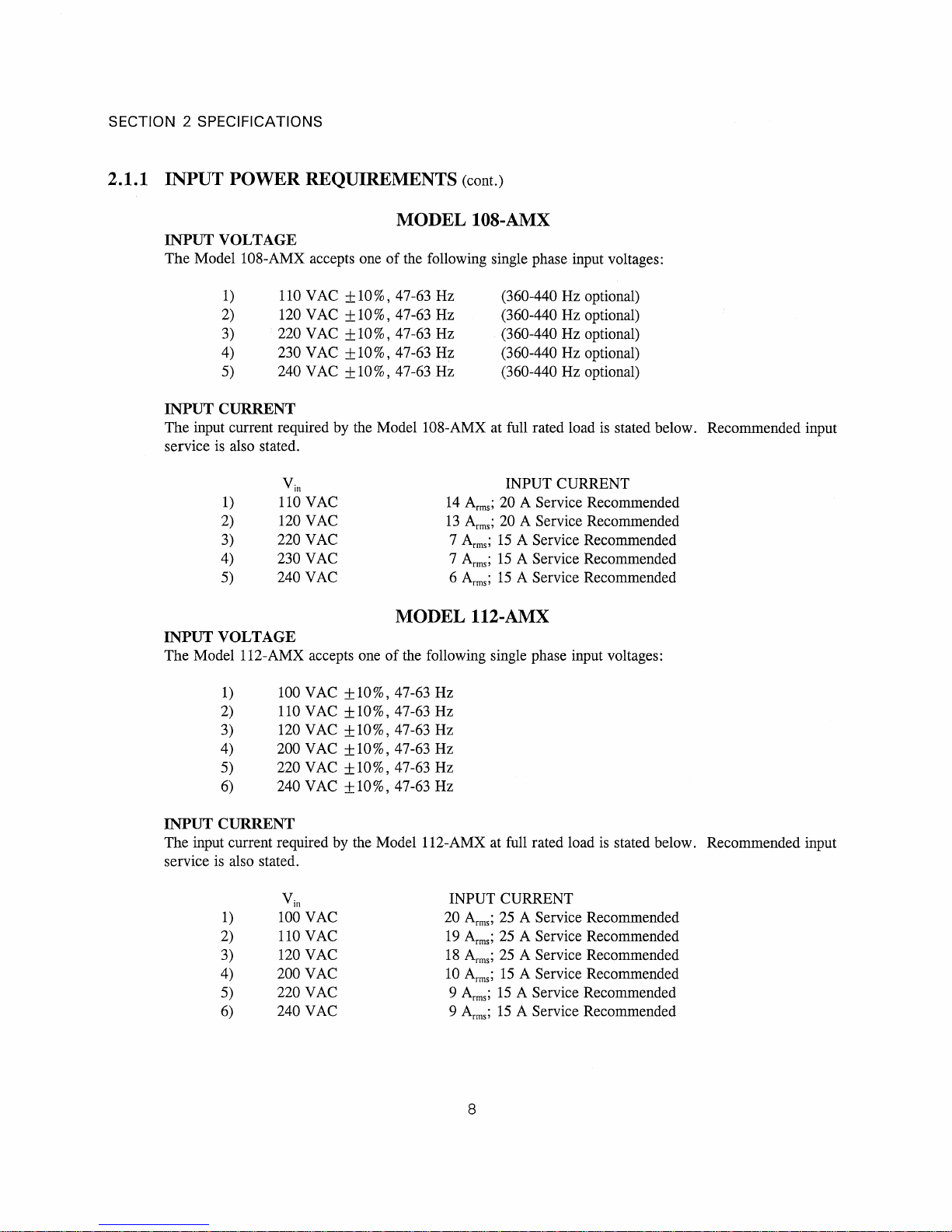

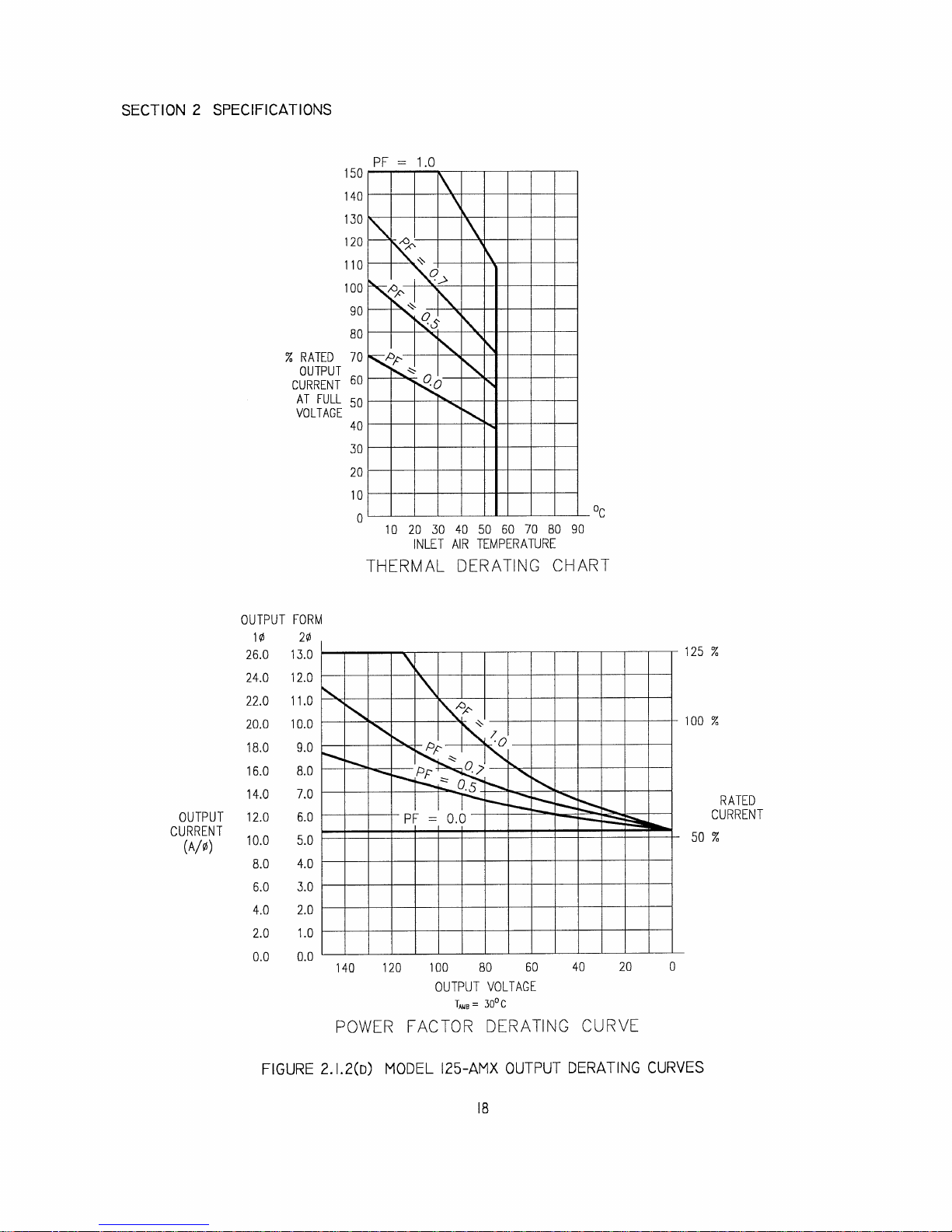

2.1.1 INPUT POWER REQUIREMENTS (cont.)

MODEL 125-AMX

INPUT VOLTAGE

The Model 125-AMX accepts one of the following three phase input voltages:

1) 208 VAC ∆ ±10%, 47-63 Hz (360-440 Hz optional)

2) 220 VAC ∆ ±10%, 47-63 Hz (360-440 Hz optional)

3) 240 VAC ∆ ±10%, 47-63 Hz (360-440 Hz optional)

4) 220/380 VAC ±10%, 47-63 Hz (360-440 Hz optional)

5) 240/416 VAC ±10%, 47-63 Hz (360-440 Hz optional)

(cost option) 6) 277/480 VAC ±10%, 47-63 Hz (360-440 Hz optional)

INPUT CURRENT

The input current required by the Model 125-AMX at full rated load is stated below. Recommended input

service is also stated.

INPUT CURRENT

V

1) 208 VAC ∆ 12 A

in

2) 220 VAC ∆ 11 A

3) 240 VAC ∆ 10 A

4) 220/380 VAC 6 A

5) 240/416 VAC 6 A

(cost option) 6) 277/480 VAC 5 A

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

; 10 A Service Recommended

rms

; 10 A Service Recommended

rms

; 10 A Service Recommended

rms

MODEL 140-AMX

INPUT VOLTAGE

The Model 140-AMX accepts one of the following three phase input voltages:

1) 208 VAC ∆ ±10%, 47-63 Hz (360-440 Hz cost option)

2) 220 VAC ∆ ±10%, 47-63 Hz (360-440 Hz cost option)

3) 240 VAC ∆ ±10%, 47-63 Hz (360-440 Hz cost option)

4) 220/380 VAC ±10%, 47-63 Hz (360-440 Hz cost option)

5) 240/416 VAC ±10%, 47-63 Hz (360-440 Hz cost option)

(cost option) 6) 277/480 VAC ±10%, 47-63 Hz (360-440 Hz cost option)

INPUT CURRENT

The input current required by the Model 140-AMX at full rated load is stated below. Recommended input

service is also stated.

INPUT CURRENT

V

1) 208 VAC ∆ 21 A

in

2) 220 VAC ∆ 19 A

3) 240 VAC ∆ 18 A

4) 220/380 VAC 12 A

5) 240/416 VAC 11 A

(cost option) 6) 277/480 VAC 9 A

; 30 A Service Recommended

rms

; 30 A Service Recommended

rms

; 30 A Service Recommended

rms

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

9

SECTION 2 SPECIFICATIONS

2.1.1 INPUT POWER REQUIREMENTS (cont.)

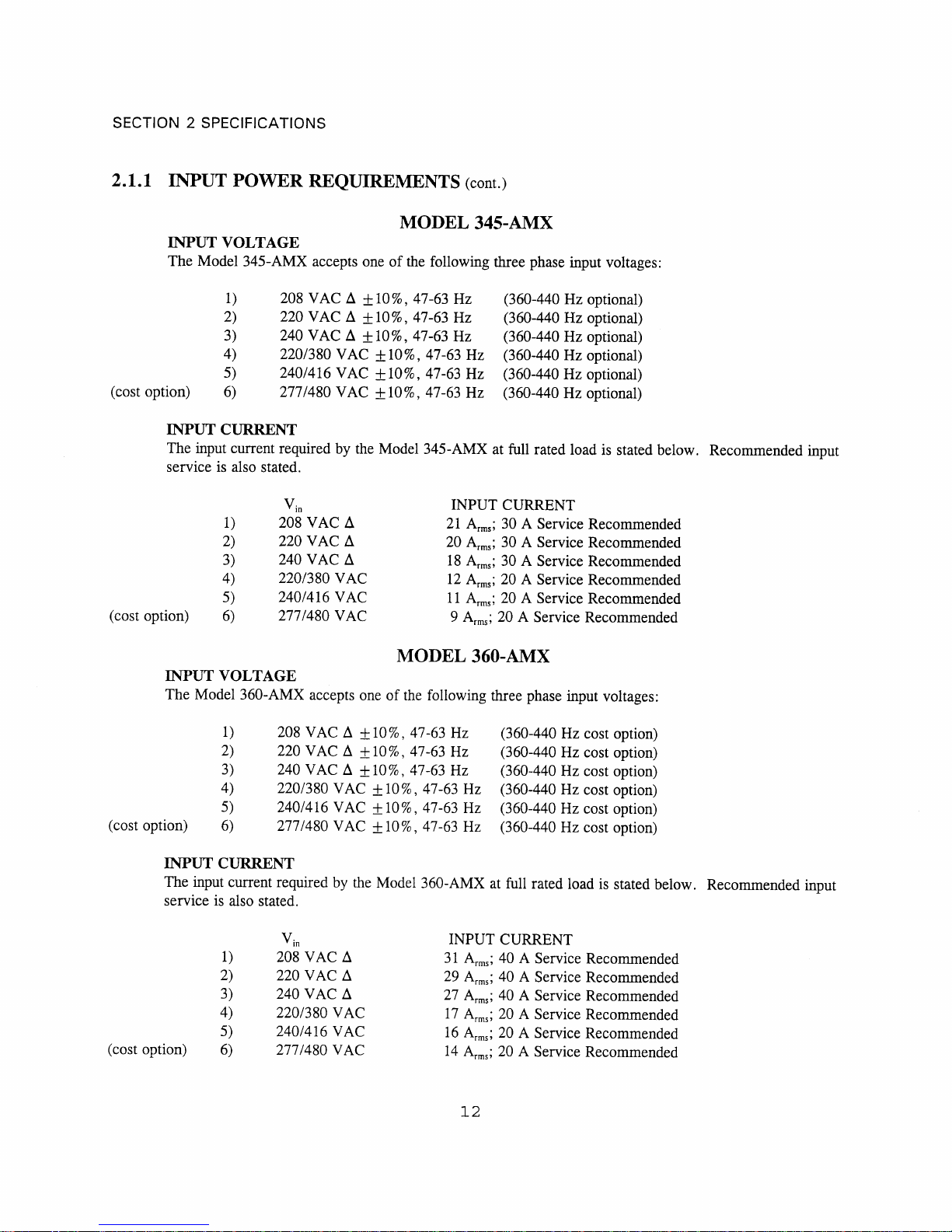

MODEL 160-AMX

INPUT VOLTAGE

The Model 160-AMX accepts one of the following three phase input voltages:

1) 208 VAC ∆ ±10%, 47-63 Hz (360-440 Hz cost option)

2) 220 VAC ∆ ±10%, 47-63 Hz (360-440 Hz cost option)

3) 240 VAC ∆ ±10%, 47-63 Hz (360-440 Hz cost option)

4) 220/380 VAC ±10%, 47-63 Hz (360-440 Hz cost option)

5) 240/416 VAC ±10%, 47-63 Hz (360-440 Hz cost option)

(cost option) 6) 277/480 VAC ±10%, 47-63 Hz (360-440 Hz cost option)

INPUT CURRENT

The input current required by the Model 360-AMX at full rated load is stated below. Recommended input

service is also stated.

INPUT CURRENT

V

1) 208 VAC ∆ 31 A

in

2) 220 VAC ∆ 29 A

3) 240 VAC ∆ 27 A

4) 220/380 VAC 17 A

5) 240/416 VAC 16 A

(cost option) 6) 277/480 VAC 14 A

; 40 A Service Recommended

rms

; 40 A Service Recommended

rms

; 40 A Service Recommended

rms

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

9A

SECTION 2 SPECIFICATIONS

(THIS PAGE INTENTIONALLY BLANK)

9B

SECTION 2 SPECIFICATIONS

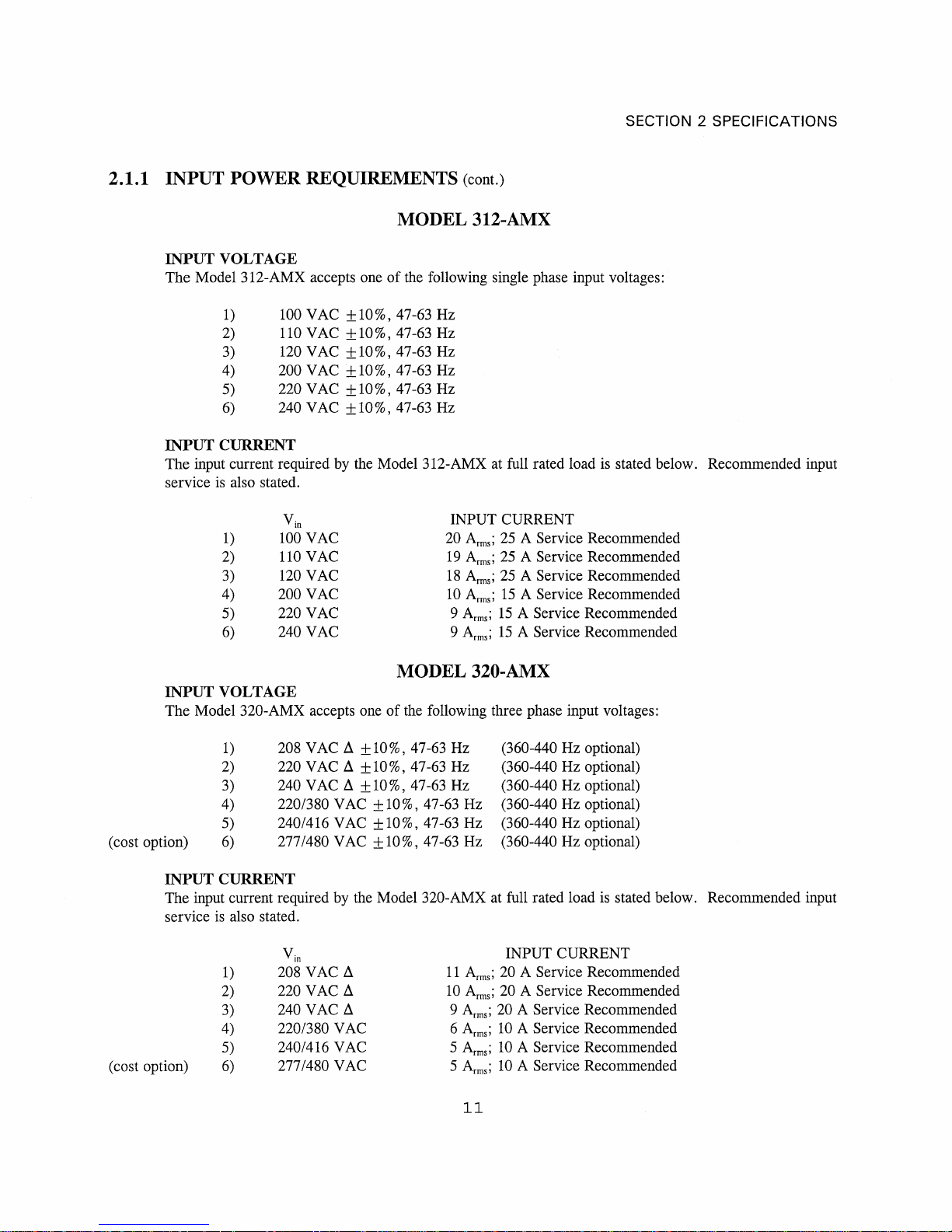

INPUT VOLTAGE

The Model 305-AMX accepts one of the following single phase input voltages:

1) 110 VAC ±10%, 47-63 Hz (360-440 Hz optional)

2) 120 VAC ±10%, 47-63 Hz (360-440 Hz optional)

3) 220 VAC ±10%, 47-63 Hz (360-440 Hz optional)

4) 230 VAC ±10%, 47-63 Hz (360-440 Hz optional)

5) 240 VAC ±10%, 47-63 Hz (360-440 Hz optional)

INPUT CURRENT

The input current required by the Model 305-AMX at full rated load is stated below. Recommended input

service is also stated.

INPUT CURRENT

V

in

1) 110 VAC 9 A

2) 120 VAC 8 A

3) 220 VAC 5 A

4) 230 VAC 4 A

5) 240 VAC 4 A

INPUT VOLTAGE

The Model 308-AMX accepts one of the following single phase input voltages:

1) 110 VAC ±10%, 47-63 Hz (360-440 Hz optional)

2) 120 VAC ±10%, 47-63 Hz (360-440 Hz optional)

3) 220 VAC ±10%, 47-63 Hz (360-440 Hz optional)

4) 230 VAC ±10%, 47-63 Hz (360-440 Hz optional)

5) 240 VAC ±10%, 47-63 Hz (360-440 Hz optional)

INPUT CURRENT

The input current required by the Model 308-AMX at full rated load is stated below. Recommended input

service is also stated.

INPUT CURRENT

V

in

1) 110 VAC 14 A

2) 120 VAC 13 A

3) 220 VAC 7 A

4) 230 VAC 7 A

5) 240 VAC 6 A

MODEL 305-AMX

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

; 15 A Service Recommended

rms

; 15 A Service Recommended

rms

; 15 A Service Recommended

rms

MODEL 308-AMX

; 20 A Service Recommended

rms

; 20 A Service Recommended

rms

; 15 A Service Recommended

rms

; 15 A Service Recommended

rms

; 15 A Service Recommended

rms

10

SECTION 2 SPECIFICATIONS

2.1.2 OUTPUT POWER

OUTPUT VOLTAGE RANGE

DIRECT-COUPLED

The standard output voltage range of the AMX-Series Power Source is 0-135 VAC

Model 125-AMX) when operated in the direct-coupled mode. Additionally, the Models 112-AMX and 312AMX can be configured for several direct-coupled output voltage ranges between and including 0-110 VAC

and 0-150 VAC

TRANSFORMER-COUPLED

The output voltage range of the AMX-Series Power Source varies when operated in the transformer-coupled

mode. Maximum output voltage is determined by the transformer turns ratio. See list below for maximum

output voltage vs. turns ratio.

TURNS RATIO MAXIMUM OUTPUT VOLTAGE (No Load)

1.5:1 204 VAC

2.0:1 273 VAC

2.5:1 341 VAC

OUTPUT CURRENT

FULL-RATED CURRENT

The full-rated output current the AMX-Series Power Source is listed below by model number. Current stated

for output voltage set to 125 VAC

maximum current at reduced voltage. Output current ratings are scaled appropriately when using transformercoupled outputs.

MODEL I

105-AMX 4 A 40 A 2 A 20 A N/A N/A

108-AMX 6 A 40 A 3 A 20 A N/A N/A

112-AMX 10 A 40 A 5 A 20 A N/A N/A

125-AMX 20 A 90 A 10 A 45 A N/A N/A

140-AMX 32 A 140 A 16 A 70 A N/A N/A

160-AMX 48 A 210 A 16 A 70 A N/A N/A

305-AMX 4 A 45 A 2 A 15 A 1.33 A 15 A

308-AMX 6 A 45 A 2 A 15 A 2 A 15 A

312-AMX 10 A 45 A 3 A 15 A 3 A 15 A

320-AMX 18 A 60 A 6 A 20 A 6 A 20 A

345-AMX 36 A 165 A 12 A 55 A 12 A 55 A

360-AMX 48 A 210 A 16 A 70 A 16 A 70 A

390-AMX 72 A 330 A 24 A 110 A 24 A 110 A

3120-AMX 96 A 410 A 32 A 140 A 32 A 140 A

OVERLOAD OPERATION

The AMX-Series Power Source will deliver up to 150% of rated rms output current into unity power factor

loads at full-rated output voltage. Low output power factor, reduced output voltage, and elevated ambient

temperatures will increase the internal dissipation of the power source and can cause overload shutdown due to

over-temperature conditions. Length of time to reach over-temperature varies with the models and the above

parameters.

. These voltages are stated for full rated load and nominal input voltage applied.

l-n

1φ 2φ 3φ

out, rms

I

I

out, pk

(0-150 VAC

l-n

l-n

l-n

l-n

. Refer to the Power Factor Derating chart of Figure 2.1.2(A-N) for

l-n

out, rms

I

I

out, pk

out, rms

I

out, pk

for the

l-n

l-n

14

SECTION 2 SPECIFICATIONS

FIGURE 2.1.2(E2) MODEL 160-AMX OUTPUT DERATING CURVES

19A

SECTION 2 SPECIFICATIONS

(THIS PAGE INTENTIONALLY BLANK)

19B

2.2.1 DIMENSIONS

Power Source:

Height: 14.00" [356 mm]

Width: 19.00" [483 mm] (front panel); 17.00" [432 mm] (chassis)

Depth: 23.50" [597 mm]

Weight: 170 lbs. [77 kg]

Refer to Figure 2.2.3 for the outline drawing of the Model 140-AMX.

Power Source:

Height: 14.00" [356 mm]

Width: 19.00" [483 mm] (front panel); 17.00" [432 mm] (chassis)

Depth: 23.50" [597 mm]

Weight: 180 lbs. [82 kg]

Refer to Figure 2.2.3 for the outline drawing of the Model 160-AMX.

Height: 5.25" [134 mm]

Width: 19.00" [483 mm] (front panel); 16.75" [426 mm] (chassis)

Depth: 23.00" [584 mm] (measured from back side of front panel, excludes terminal blocks)

Weight: 60 lbs. [27 kg] (w/o output transformers);

Refer to Figure 2.2.1 for the outline drawing of the Model 305-AMX.

Height: 5.25" [134 mm]

Width: 19.00" [483 mm] (front panel); 16.75" [426 mm] (chassis)

Depth: 23.00" [584 mm] (measured from back side of front panel, excludes terminal blocks)

Weight: 60 lbs. [27 kg] (w/o output transformers);

Refer to Figure 2.2.1 for the outline drawing of the Model 308-AMX.

SECTION 2 SPECIFICATIONS

(cont.)

MODEL 140-AMX

MODEL 160-AMX

MODEL 305-AMX

75 lbs. [34 kg] (with output transformers)

MODEL 308-AMX

75 lbs. [34 kg] (with output transformers)

31

SECTION 2 SPECIFICATIONS

Height: 5.25" [134 mm]

Width: 19.00" [483 mm] (front panel); 16.75" [426 mm] (chassis)

Depth: 23.00" [584 mm] (measured from back side of front panel, excludes terminal blocks)

Weight: 70 lbs. [32 kg]

Refer to Figure 2.2.1 for the outline drawing of the Model 312-AMX.

MODEL 312-AMX

31A

SECTION 2 SPECIFICATIONS

(THIS PAGE INTENTIONALLY BLANK)

31B

SECTION 2 SPECIFICATIONS

FIGURE 2.2.3 OUTLINE DRAWING, MODELS 125, 140, 160, 345, & 360-AMX

36

SECTION 2 SPECIFICATIONS

2.2.3 OUTPUT POWER CONNECTION

Output power is taken from the AMX-Series Power Source via rear panel mounted terminal blocks.

2.2.4 CHASSIS SLIDE MOUNTS

The chassis of the AMX-Series Power Source is designed to accept slide rails. These are provided as a cost

option. For more information, contact your local sales representative or the Pacific Power Source Sales Office.

2.3 ENVIRONMENTAL SPECIFICATIONS

This paragraph lists the environmental requirements of the AMX-Series Power Source.

2.3.1 TEMPERATURE RANGE

The AMX-Series Power Source is rated for full operation in ambient temperatures of 0 - 55°C and where the

relative humidity is in the range of 0 - 95%, non-condensing.

2.3.2 COOLING

The AMX-Series Power Source utilizes thermally regulated forced-air cooling to maintain proper temperatures

throughout. The maximum airflow of the Models 105-AMX, 108-AMX, 305-AMX, and 308-AMX is 100

CFM. The maximum airflow of the Models 112-AMX and 312-AMX is 200 CFM. The maximum airflow of

the Models 125-AMX and 320-AMX is 300 CFM. The maximum airflow of the Models 140-AMX, 160-AMX,

345-AMX, and 360-AMX is 600 CFM. The maximum airflow of the Models 390-AMX and 3120-AMX is

1200 CFM.

2.3.3 THERMAL PROTECTION

The input power transformer is configured with a thermocouple which senses its temperature. Additionally, the

power amplifier PCB assemblies are also configured with temperature sensors. When the transformer or any

power amplifier PCB exceeds maximum safe operating temperature, the output relays are opened and the

Shutdown Lamp, located on the front panel, is lighted.

The shutdown fault is implemented such that it must be manually reset. The fault can be reset after the overtemperature condition has ceased to exist and the Output Power Switch is placed in the "OFF" position.

Sending an Output Off command via the remote interface (applies to programmable systems only) also resets

the shutdown fault, provided that the condition which originally caused the shutdown has been cleared. If the

Output On/Off command is sent via the remote interface and the shutdown condition has not been cleared, the

power source will remain in the shutdown state until the offending condition has cleared.

38

SECTION 3

INSTALLATION

3.0 INSTALLATION

This section describes the installation of the AMX-Series AC Power Source.

3.1 CHASSIS PLACEMENT

The AMX-Series Power Source is designed to fit into the standard 19 inch rack. Provisions for mounting slide

rails are included in the chassis. The chassis can also be used as a bench-top unit, if desired.

* * * W A R N I N G * * *

• THE AMX-SERIES CHASSIS IS HEAVY !

(VARIOUS MODELS WEIGH APPROX 50-180 lbs PER ASSY)

USE EXTREME CARE WHEN MOVING THE UNIT.

• THE MAGNETICS MODULE, MODELS 125-AMX, 140-AMX, 160-AMX,

AND 320-AMX THROUGH 3120-AMX ARE NOT

UNIT MUST BE LIFTED BY TWO OR MORE INDIVIDUALS

IN ORDER TO REDUCE CHANCE OF PHYSICAL INJURY.

* * * W A R N I N G * * *

- - - - - - - - P A C K I N G N O T I C E - - - - - -

IT IS THE CUSTOMER'S RESPONSIBILITY TO ENSURE THAT UNITS ARE

ADEQUATELY PACKAGED WHEN THEY ARE MOVED TO A DIFFERENT

LOCATION. THE UNITS SHOULD ALWAYS BE PACKAGED IN THE

ORIGINAL SHIPPING CONTAINER WHEN MOVED OR RETURNED TO THE

FACTORY FOR SERVICE. INADEQUATE PACKAGING WILL RESULT IN

CHASSIS DAMAGE--INCURRING NON-WARRANTY SERVICE COSTS.

- - - - - - - - P A C K I N G N O T I C E - - - - - -

A ONE-PERSON LIFT.

39

SECTION 3 INSTALLATION

3.1 CHASSIS PLACEMENT

The first step in setting the chassis into place is to remove it from its shipping container. The next step is to

select an appropriate location for the unit. Key points to consider when locating the chassis are:

1. PROXIMITY TO THE LOAD - The power source should be located as close to the load as

possible. This helps to reduce distribution losses. These losses become more critical as the output

frequency increases.

2. VENTILATION - The chassis requires good ventilation to adequately cool the internal components.

Airflow ranges from 200 to 1200 CFM. A minimum of 12 inches front and back clearance is

recommended for proper operation of the Models 125-AMX, 140-AMX, 160-AMX, 320-AMX, 345AMX, 360-AMX, 390-AMX, and 3120-AMX. The air intake for the Models 105-AMX, 108-AMX,

112-AMX, 305-AMX, 308-AMX, 312-AMX, and 320-AMX is located on both sides near the front. A

minimum clearance of two inches on each side and 12 inches to the rear is required for proper

operation of these models.

When the chassis is placed in a 19 inch rack, it must be supported by either chassis slides or full depth angle

brackets. The front panel alone will not support the weight of the chassis. Chassis slides are available from

Pacific Power Source as a cost option. Call factory service for details.

After the location for the chassis is selected, verify that the input voltage of the power source is correct (Input

voltage is stated on the system ID label). If it requires changing, refer to Paragraph 3.3 for instructions.

Also check that the output voltage range is that which is desired. If not, reconfigure to the desired form as

directed by Paragraph 3.2.

After the input voltage form and output voltage range have been verified as correct, slide the chassis into the

rack or set it into its final position. Make input and output connections as stated in paragraphs 3.3 and 3.4,

respectively.

If either the Remote Interface (GPIB or RS-232) or External Sense feature is to be used, refer to paragraphs 3.5

and 3.7 for connection.

(cont.)

40

3.2 OUTPUT VOLTAGE RANGE CONFIGURATION

This paragraph describes the configuration of the Output Voltage Range for the AMX-Series Power Source.

The AMX-Series Power Source can be configured for several different Output Voltage Ranges. The standard

output configurations are:

1) - 0-110 VAC

0-125 VAC

0-135 VAC

0-150 VAC

2) VR1.5 0-204 VAC

3) VR2.0 0-273 VAC

4) VR2.5 0-341 VAC

The 0-110 through 0-150VAC output ranges are direct-coupled outputs and are always available. The

remaining output forms are transformer-coupled. Only one is available when output transformers are installed.

However, systems can be reconfigured for a different range, if required.

Configuration of the output voltage range is set at the time of order. Systems are configured at the factory as

ordered. The System ID label or Magnetics Module ID label will state the factory configured Voltage Range if

transformer-coupled outputs are present. If the output voltage range specified on the System ID label or

Magnetics Module ID label is that which is desired, no further action is required. Otherwise, reconfiguration is

required.

Also described in the following paragraphs are model specific controller details (Transformer Ratio and Amps

to Volts Ratio settings) that, although factory preset, must be set as described if inadvertantly changed or

otherwise modified.

Configuration of the Output voltage consists of

1) Verifying that the appropriate output transformer taps have been selected.

2) Verifying the proper setting of the Transformer Ratio Switch within the UPC.

3) Verifying the proper setting of the Amps to Volts Ratio Switch within the UPC

4) Calibration of the system.

Configuration varies from model to model. The following paragraphs describe the configuration settings of the

available standard output ranges. Refer to the appropriate paragraph for details. When custom output

transformers have been installed, refer to Section 9, Modifications. The instructions stated in Section 9 take

precedence over those listed in the following paragraphs.

Direct-Coupled Output on 112-AMX and 312-AMX

l-n

Direct-Coupled Output on 112-AMX and 312-AMX

l-n

Direct-coupled Output, standard on most models

l-n

Direct-Coupled Output on 112-AMX, 125-AMX, and

l-n

312-AMX

Models 105-AMX, 108-AMX, 140-AMX, 160-AMX,

l-n

305-AMX, 308-AMX, 320-AMX, 345-AMX, 360AMX, 390-AMX, & 3120-AMX equipped with

Magnetics Option

(Same as VR1.5 above)

l-n

(Same as VR1.5 above)

l-n

SECTION 3 INSTALLATION

41

SECTION 3 INSTALLATION

FIGURE 3.2.7 MODELS 140, 160, 345, 360, 390, & 3120-AMX OUTPUT VOLTAGE CONFIGURATION

54

SECTION 3 INSTALLATION

3.2.7 OUTPUT VOLTAGE RANGE CONFIGURATION, MODELS 140-AMX, 160-AMX,

345-AMX, 360-AMX, 390-AMX, and 3120-AMX

This paragraph describes the configuration of the Output Voltage Range for the Models 140, 160, 345, 360,

390, and 3120-AMX Power Sources. These models can be configured for either 0-135 VAC

273 VAC

, or 0-341 VAC

l-n

. The 0-204 VAC range is designated as the VR1.5 output form. The 0-273 VAC

l-n

, 0-204 VAC

l-n

range is defined to be the VR2.0 output form, and, finally, the 0-341 VAC range is defined to be the VR2.5

output form. A Magnetics Module (Assembly No. 134310) is required for the 204, 273 and 341 VAC output

forms.

Refer to Figure 3.2.7 for location of components referenced below and range tap selection information.

Conversion to the 204 VAC Output Range (VR1.5) is as follows:

1) Remove the top cover of the Magnetics Module.

2) Wire for 1.5:1 ratio as per wire table of Figure 3.2.7.

3) Replace top cover of Magnetics Module.

4) Connect Magnetics Module to the power source. The Magnetics Module is connected to the power

source by attaching P20 of the Magnetics Module to J20 of the power source. Also be sure to connect

the Chassis GND wire of the Magnetics Module to the CHS GND stud on the rear panel of the power

source.

5) Set the Transformer Ratio Switch of the UPC to 1.5. (Refer to the UPC-Series Operation Manual for

details. This step does not apply to systems equipped with the UMC controller.) The Transformer

Ratio switch is set to 0.0 on systems not equipped with output transformers.

6) Set the Amps to Volts Ratio Switch of the UPC to 15 for the Models 140-AMX, 160-AMX, 345-

AMX, and 360-AMX. Set the Amps to Volts Ratio Switch of the UPC to 30 for the Models 390AMX and 3120-AMX. (Refer to the UPC-Series Operation Manual for details. This step does not

apply to systems equipped with the UMC controller.)

7) Calibrate the power source as stated in Section 6 of this manual.

Conversion to the 273 VAC Output Range (VR2.0) proceeds as above, except that the Magnetics Module is

wired for 2.0:1 ratio and Transformer Ratio Switch of the UPC is set for 2.0.

Likewise, conversion to the 341 V Output Range (VR2.5) proceeds as above, except that the Magnetics Module

is wired for 2.5:1 ratio and Transformer Ratio Switch of the UPC is set for 2.5.

The Transformer Ratio Switch of the UPC is set to 0.0 on systems without transformer-coupled outputs.

While the above procedure can be performed in the field, Pacific Power Source recommends that the system be

returned to the factory when transformer-coupled outputs are to be added to the system. This insures proper

connection and calibration of the entire system.

, 0-

l-n

55

SECTION 3 INSTALLATION

FIGURE 3.3.7 MODELS 140/160/345/360/390/3120-AMX

INPUT VOLTAGE CONFIGURATION

64

SECTION 3 INSTALLATION

3.3.7 INPUT VOLTAGE CONFIGURATION, MODELS 140-AMX, 160-AMX, 345-AMX,

360-AMX, 390-AMX, & 3120-AMX

* * * W A R N I N G * * *

• DISCONNECT THIS UNIT FROM THE INPUT SERVICE BEFORE REMOVING TOP

COVER.

HIGH VOLTAGE HAZARD PRESENT INSIDE UNIT WHEN TOP COVER IS

REMOVED AND STILL CONNECTED TO INPUT SERVICE.

* * * W A R N I N G * * *

The 140-AMX, 160-AMX, 345-AMX, 360-AMX, 390-AMX, and 3120-AMX Power Sources have been

designed to accept most standard three phase input voltage forms. This is accomplished through the use of a

tapped input power transformer. Configuring the proper input form is simply a matter of setting jumpers in the

appropriate positions. The system is designed for use with input frequencies of 47 to 63 Hz. (Optionally, the

systems may be used with input frequencies of up to 440 Hz. Contact the factory for details.)

Figure 3.3.7 shows the location of the various jumpers which need attention relative to input voltage form. The

position of these jumpers is listed on the accompanying table.

The first step in configuring the input power form is to remove the top cover. Next, connect the jumpers as

stated in the table for the desired input voltage. Refer to the table in Figure 3.3.7 for the proper setting.

After configuring the input voltage form, check connections and insure that they are tight and in the correct

position. Replace the top cover.

- - - C A U T I O N - - -

• CONNECTION OF THIS UNIT TO IMPROPER INPUT VOLTAGES WILL CAUSE

CATASTROPHIC DAMAGE TO THE POWER SOURCE.

• READ THE INPUT VOLTAGE LABEL AND CONNECT TO THAT INPUT VOLTAGE

ONLY. IF THERE ARE ANY QUESTIONS, CONTACT THE FACTORY.

- - - C A U T I O N - - -

The AMX-Series Power Source is then connected to an appropriate distribution panel via an input power cord.

Refer to Paragraph 2.1.1 for minimum input service requirements of the various input voltage forms.

65

SECTION 3 INSTALLATION

FIGURE 3.3.8 AMX-SERIES INPUT WIRING DIAGRAM

66

3.3.8 INPUT POWER WIRING REQUIREMENTS

This paragraph describes the input wiring requirements for the AMX-Series Power Sources. Wire size and

connection techniques are discussed.

* * * W A R N I N G * * *

• LETHAL VOLTAGE PRESENT AT INPUT TERMINALS OF THIS MACHINE.

• ALWAYS CONNECT "CHS or GND" TERMINAL TO EARTH POTENTIAL.

FAILURE TO DO SO WILL CREATE A SHOCK HAZARD.

* * * W A R N I N G * * *

The Models 105-AMX, 108-AMX, 112-AMX, 305-AMX, 308-AMX, 312-AMX, and 320-AMX are supplied

with an input power cord. Install an appropriate plug onto the end of the power cord and connect to the proper

outlet. Refer to paragraph 2.1.1 for recommended input service of the configured input voltage form.

The input power of the Models 125-AMX, 140-AMX, 160-AMX, 345-AMX, 360-AMX, 390-AMX, and 3120AMX is connected to the Input Power Terminal Block located on the rear panel of the power source. In this

case the input wiring is brought to this terminal block from the distribution panel. The connection points are

labeled "A," "B," "C," "N," and "CHS." The input wiring is connected to these points in the appropriate order

with CHS being the safety ground or earth potential. The AMX-Series Power Source is not sensitive to phase

rotation of the input voltage. For all standard DELTA input voltage forms (208, 220, and 240 VAC) and WYE

input voltage forms (220/380 VAC, 240/416 VAC, and 277/480 VAC), the "N" terminal is not used. Refer to

Figure 3.3.8 for the proper wire size to be used with the configured input power form.

- - - C A U T I O N - - -

• CONNECTION OF THIS UNIT TO IMPROPER INPUT VOLTAGES WILL CAUSE

CATASTROPHIC DAMAGE TO THE POWER SOURCE.

• READ THE INPUT VOLTAGE LABEL AND CONNECT TO THAT INPUT VOLTAGE

ONLY.

IF THERE ARE ANY QUESTIONS, CONTACT THE FACTORY.

- - - C A U T I O N - - -

NOTE:

It is the user's responsibility to meet all local and national electrical codes when

installing this equipment.

SECTION 3 INSTALLATION

67

SECTION 3 INSTALLATION

FIGURE 3.4.1.1 SINGLE PHASE OUTPUT CONNECTION

68

SECTION 3 INSTALLATION

FIGURE 3.4.2.1 SPLIT PHASE OUTPUT CONNECTION

72

SECTION 3 INSTALLATION

FIGURE 3.8.1 EXTERNAL SENSE CONNECTION, MODELS 125, 140, 160, 345, 360, 390, & 3120-AMX

84

Loading...

Loading...