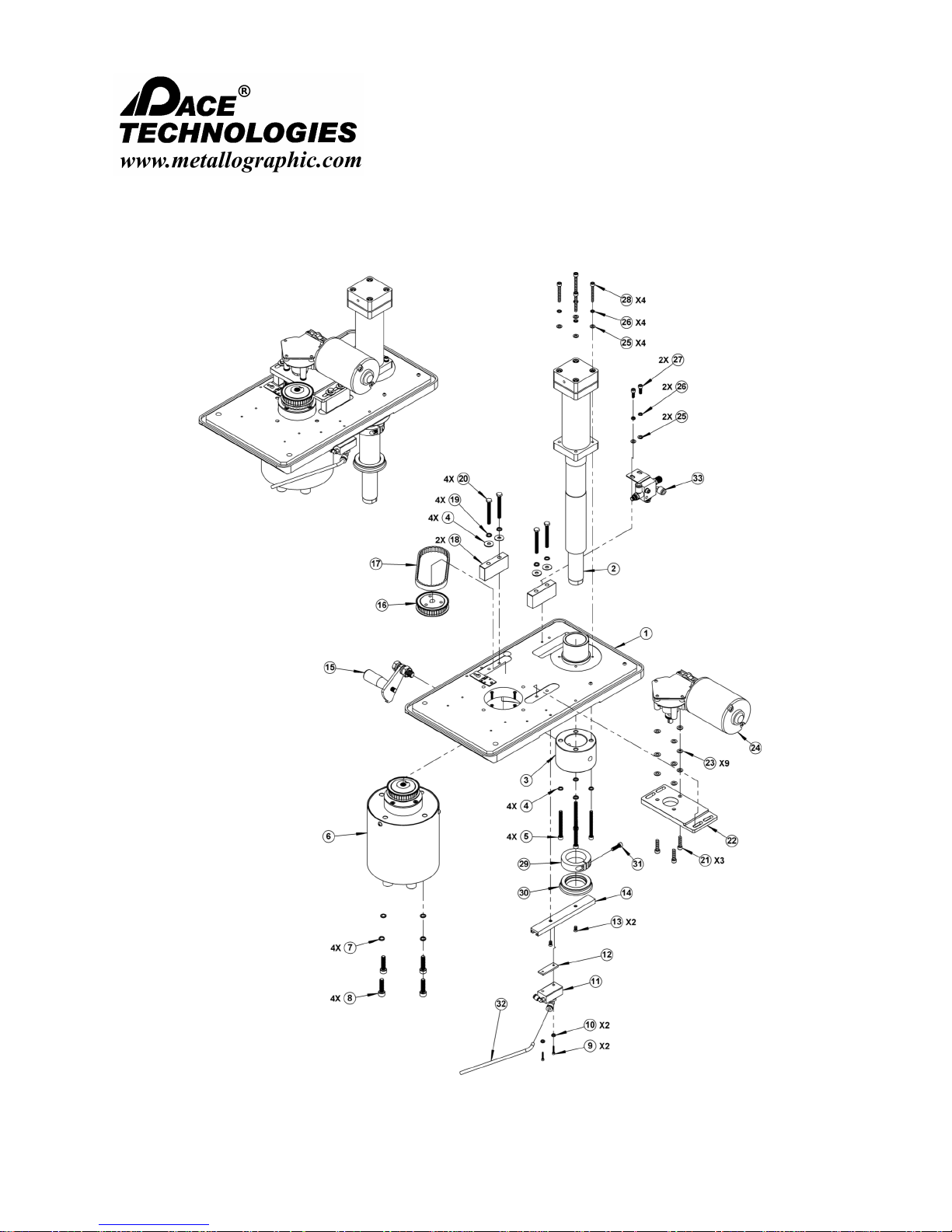

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Equipment Type: Semi-automated polishing head

Model:

Electrical

Requirements:

Frequency: 50/60 Hz

Motor Horsepower: 120W

Manual Revision

Date:

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

110 / 220 Volts (single-phase)

February 14, 2019

1

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

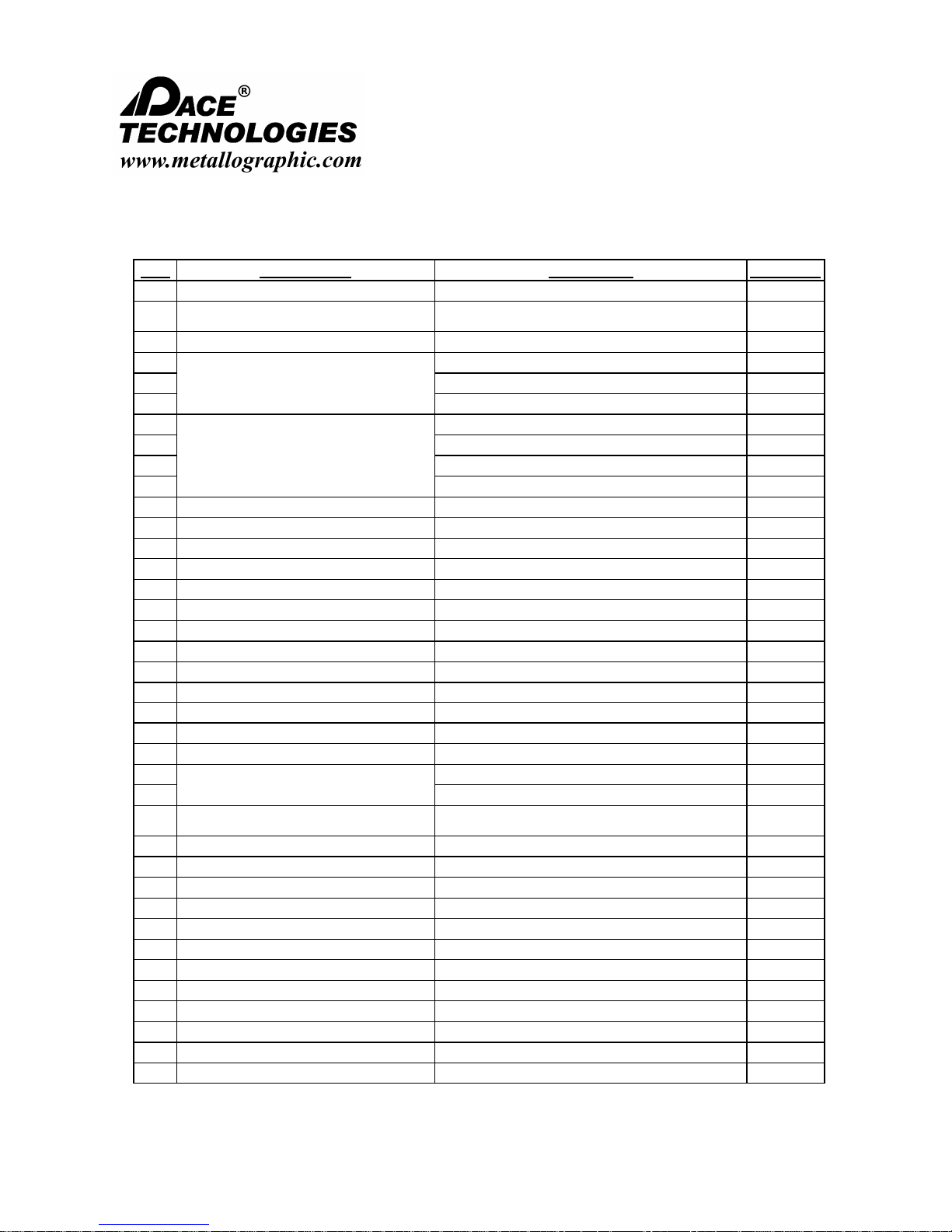

Contents

PAGE

Warranty

1.0 Product Description

2.0 Unpacking, Shipping and Installation

3.0 Installation

4.0 Safety

5.0 Start up

6.0 Maintenance

7.0 Trouble Shooting

ii

1

5

6

17

19

47

48

8.0 Metallographic Consumables

9.0 Spare Parts

10.0 Schematics

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

49

56

79

i

2

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

WARRANTY

Terms and Conditions applying to all PACE Technologies Products

1. LIMITED WARRANTY AND DISCLAIMER:

PACE Technologies Products are warranted for one year from the purchase date to be free from defects in

material and workmanship under correct use, normal operating conditions, and proper application. PACE

Technologies obligation under this warranty shall be limited to the repair or exchange, at PACE

Technologies option, of any PACE Technologies Product or part which proves to be defective as provided

herein. PACE Technologies reserves the right to either inspect the product at Buyer’s location or require it

to be returned to the factory for inspection. Buyer is responsible for freight to and from factory on all

warranty claims. The above warranty does not extend to goods damaged or subjected to accident, abuse or

misuse after release from PACE Technologies warehouse, nor goods altered or repaired by anyone other

than specifically authorized PACE Technologies representatives. PACE Technologies shall not in any way

be responsible for the consequences of any alteration, modification or misuse unless previously approved in

writing by an officer of PACE Technologies.

PACE TECHNOLOGIES MAKES NO EXPRESS WARRANTIES OTHER THAN THOSE WHICH ARE

SPECIFICALLY DESCRIBED HEREIN. Any description of the goods sold hereunder, including any

reference to Buyer’s specifications and any description in catalogs, circulars and other written material

published by PACE Technologies, is the sole purpose of identifying such goods and shall not create an

express warranty that the goods shall conform to such description.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED. THERE ARE NO IMPLIED WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR

PARTICULAR PURPOSE. THIS WARRANTY STATES PACE TECHNOLOGIES ENTIRE AND

EXCLUSIVE LIABILITY AND BUYER’S EXCLUSIVE REMEDY FOR ANY CLAIM FOR DAMAGES

IN CONNECTIONS WITH PACE TECHNOLOGIES PRODUCTS. PACE TECHNOLOGIES WILL IN

NO EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES WHATSOEVER,

NOR FOR ANY SUM IN EXCESS OF THE PURCHASE PRICE.

2. LIABILITY CAP:

PACE Technologies maximum aggregate liability for loss and damage arising under, resulting from or in

connection with the supply or use of the Equipment and Consumables provided under this purchase, or from

the performance or breach of any obligation (s) imposed hereunder, whether such liability arises from any

one or more claims or actions for breach of contract, tort, (including negligence), delayed completion,

warranty, indemnity, strict liability or otherwise, unless otherwise limited by the terms hereof, shall be

limited to one hundred percent (100%) of the purchase price.

3. DELIVERY:

Customer assumes and shall bear the risk of all loss or damage to the Products from every cause whatsoever,

whether or not insured, and title to such Products shall pass to Customer upon PACE Technologies delivery

of the Products to the common carrier of Pace Technologies choice, or the carrier specified in writing by

Customer, for shipment to Customer. Any claims for breakage, loss, delay, or damage shall be made to the

carrier by the Customer and Pace Technologies will render customer reasonable assistance in prosecuting

such claims.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

ii

3

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

4. ACCEPTANCE:

Customer shall inspect the Products promptly upon receipt of delivery. Unless customer objects in

writing within thirty (30) business days thereafter, customer shall be deemed to have accepted the

Products. All claims for damages, errors, or shortage in Products delivered shall be made by Customer

in writing within such five (5) business day period. Failure to make any claim timely shall constitute

acceptance of the Products.

5. PAYMENT:

Customer agrees to provide timely payment for the Products in accordance with the terms of payment

set forth on the reverse side hereof or in any proposal submitted herewith. If any payment is not paid

on or before its due date, Customer shall pay interest on such late payment from the due date until paid

at the lesser of 12% per annum or the maximum rate allowed by law.

6. DEFAULT:

If Buyer is in default (including, but not limited to, the failure by Buyer to pay all amounts due and

payable to Seller) under the work or purchase order or any other agreement between Buyer and Seller,

Buyer’s rights under the warranty shall be suspended during any period of such default and the original

warranty period will not be extended beyond its original expiration date despite such suspension of

warranty rights.

7. MISCELLANEOUS PROVISIONS:

This agreement has been made in and shall be governed by the laws of the State of Arizona. These

terms and conditions and the description of the Products on the reverse side hereof or in any proposal

submitted herewith constitute the entire agreement and understanding of the parties with respect to this

sale and supersede all prior and contemporaneous agreements or understandings, inducements or

representations, expressed or implied, written or oral, between the parties with respect hereto. Any

term or provision of this Agreement may be amended, and any observance of any term of this

Agreement may be waived, only by a writing signed by the party to be bounds. The waiver by a party

of any breach shall not be deemed to constitute a waiver of any other breach. Should suit be brought on

this Agreement, the prevailing party shall be entitled to recover its reasonable attorneys’ fees and other

costs of suit including costs and attorneys’ fees incurred on appeal or in collection of any judgment.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

iii

4

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

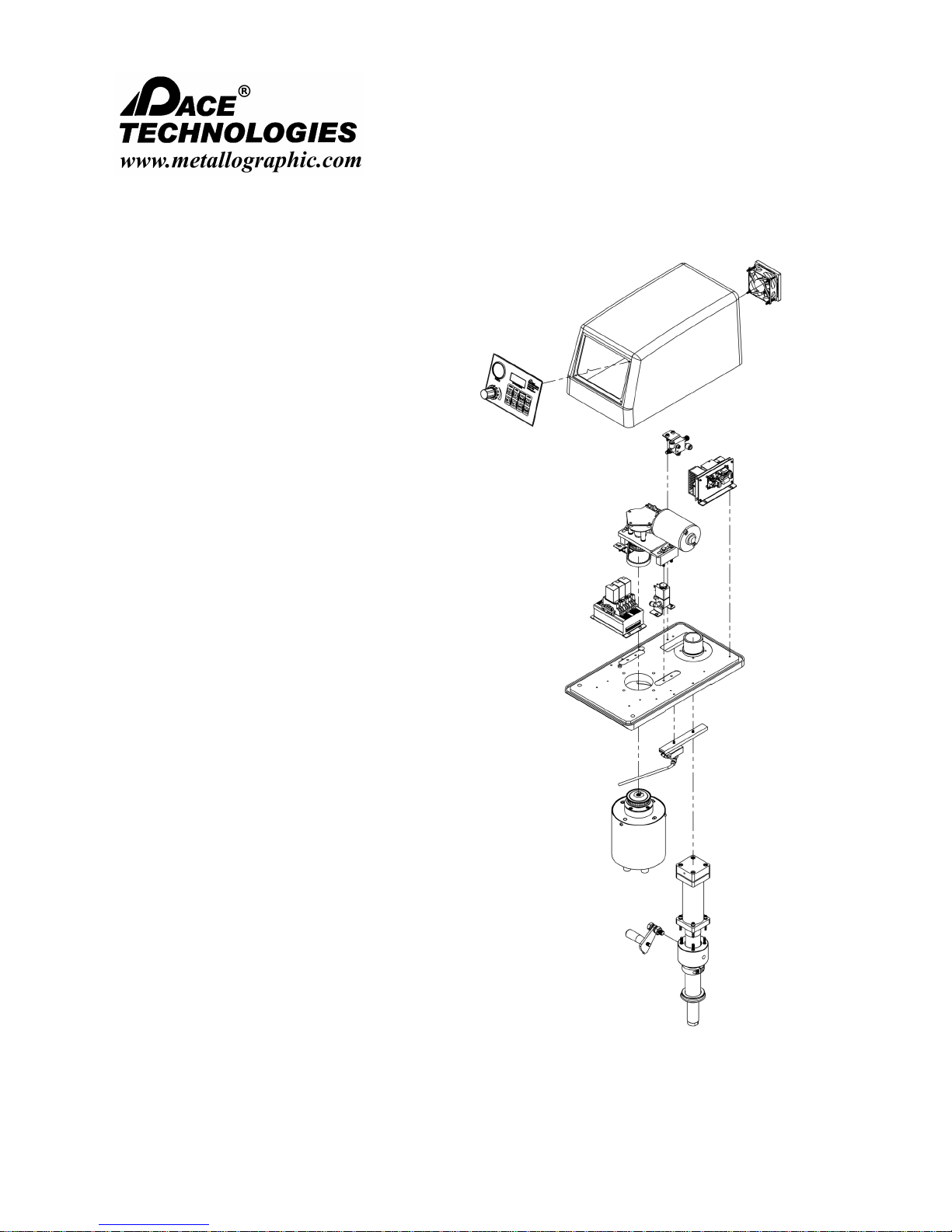

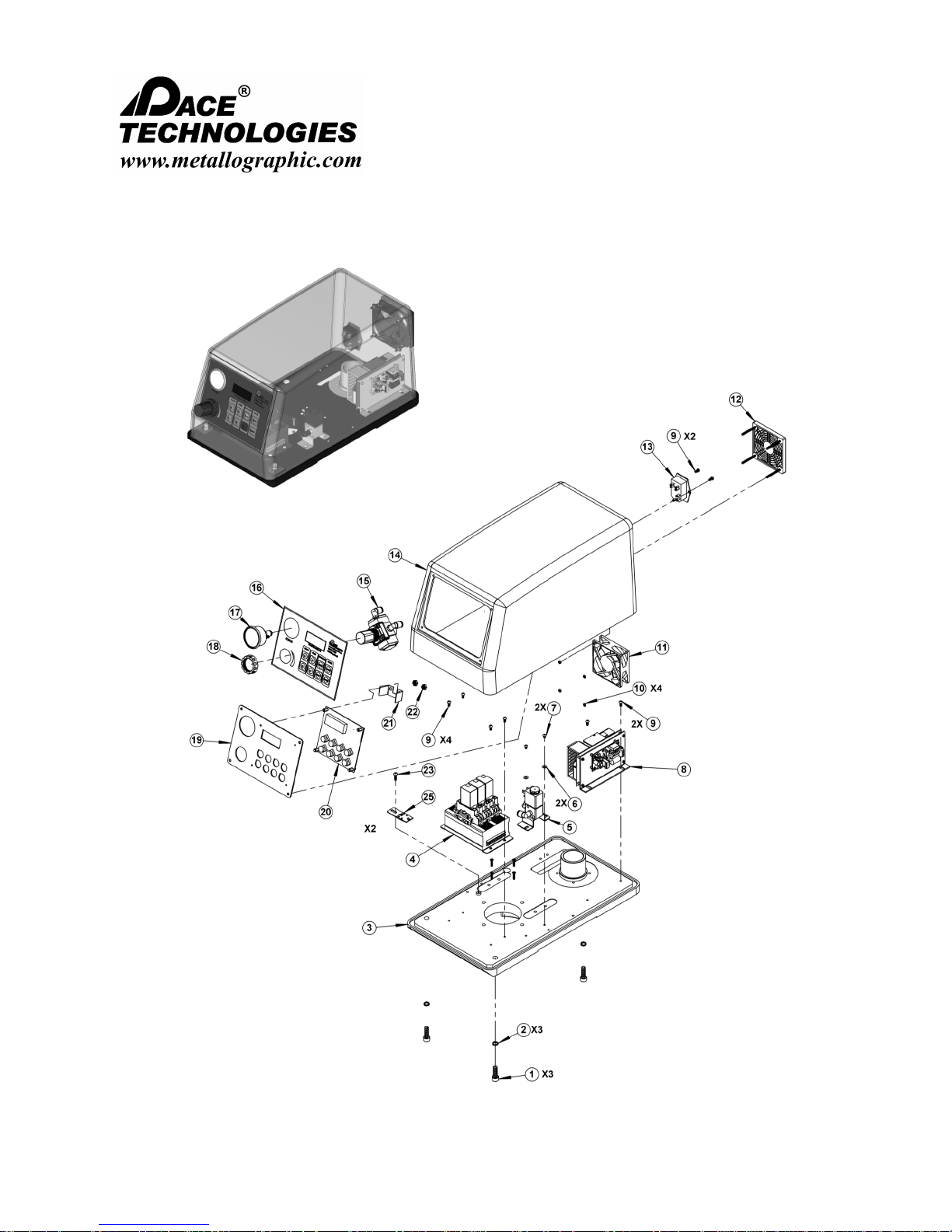

1.0 Product Description

1.1 General Description

Pressure

Adjustment

Dispenser ON/OFF

Dispenser

controller

Head release

lever / switch

Specimen

Pressure pistons

Pressure Gauge

Variable speed

display

Manual Start/Stop

AUTO/MANUAL

mode buttons

Pistons

UP/DOWN

Water Supply

Dispenser feed

Emergency

Stop button

Speed display

Timer display

Auto start button

The FEMTO 1500 is a variable speed polishing head (0-200 rpm) for use with the NANO 1000T

or NANO 2000T grinding/ polishing machine for semi-automated metallographic specimen

preparation. The FEMTO 1500 can also run either automatically with the NANO polishing base

or in a manual mode independently control from the NANO polisher.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Water

solenoid

switch

1

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

1.2 Technical Specifications

Electrical specifications: 110 / 220V single-phase

(50/60 Hz)

Number of specimens: Individual Force:

1-6 samples (1-inch to 1.5-inch

diameter.

1-3 samples 2-inch diameter

(holder and rings sold separately)

Force application: Individual piston

Motor power: 120 W

Polishing head speed:

Weight: Approx. 55 lbs (25 kg)

Dimensions (WxHxD): Approx. 13” x 18” x 18”

Working temperature: 32° - 100°F (0 - 40°C)

Shipping temperature: 32° - 100°F (0 - 40°C)

Storage temperature: 32° - 100°F (0 - 40°C)

Hook ups: Air - clean filter air with lubricator

EU Directives: Machinery Directive 2006/42/EC

Low Voltage Directive 2006/95/EC

Electromagnetic Compatibility Directive 2004/108/EC

EU Harmonized Standards: EN ISO 1200:2010

EN 61010-1:2010

EN 61326-1:2006

0 to 200 rpm variable speed

(330 mm x 450 mm x 450 mm)

(recommended)

Electrical - 110V or 220V, 50/60

Hz)

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

2

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

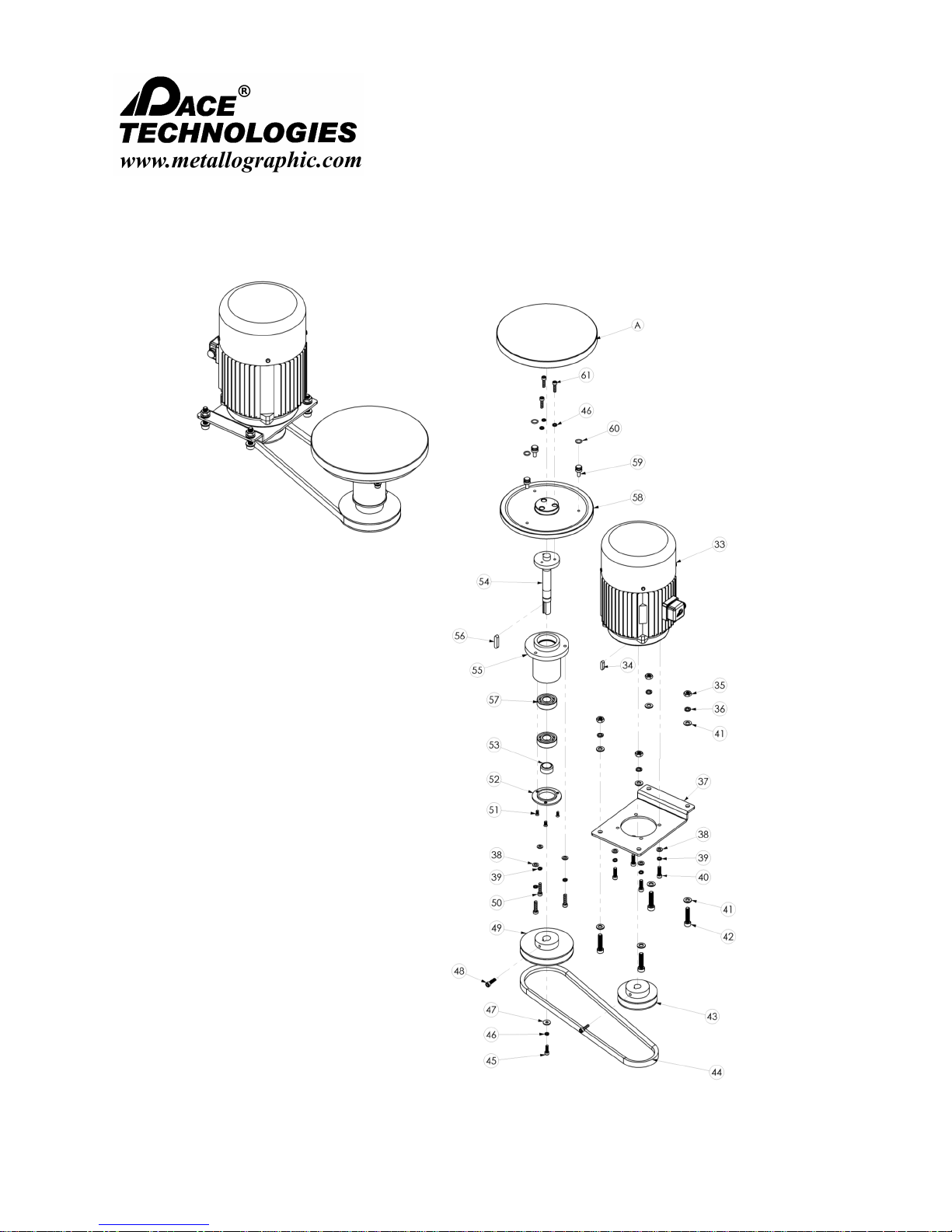

1.3 Features and Benefits

The FEMTO 1500 is equipped with a 120 W

variable 0-200 rpm speed motor. The drive

mechanism is connected to the motor via a

maintenance-free anti-slip polychain.

The FEMTO 1500 also has a lubricant

dispenser in addition to a high flow water

valve for hands free wet grinding with

abrasive papers and lubrication for polishing.

In addition, the FEMTO 1500 can be operated

either automatically or independently with the

NANO polishing base.

Note: Installation of the FEMTO 1500 /

NANO polishing base should be on a flat

sturdy surface, with easy access to drain,

water and electrical connections.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

3

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

1.4 Single Force vs. Central Force Comparison

Single Force vs. Central Force Polishing Machines

Metallographic semi-automated polishing machines are available with

individual/ single specimen loading or with a fixed central holder. The

main advantage for using a central force holder is that the overall

specimen flatness is better. The primary advantages for individual

specimen holders are fewer required grinding/ polishing steps and

the ability to re-polish samples without the need to re-planarize the

Central Force: The individual pistons apply the

polishing force to the landing pads and pushes

down the holder through the spring loaded

central male coupler. For central polishing a

minimum of three samples locked into the holder

is required; however, flatness is then fixed over

all the mounted specimens

Note: With independent pistons, initial grinding can be done with finer abrasives, thus reducing the

number of grinding steps. For flatter specimen preparation a central force polishing system (FEMTO

1500 or FEMTO 2500) are recommended.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Individual Force: Individual specimen force can

be applied using the Quick Release Chuck system

by screwing down the outside of the coupler so as

to lock the specimen mounting plate into a rigid

plane. This set-up allows for the individual holder

to be removed and cleaned. This holder also

eliminates the need to re-plane the samples if they

4

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

2.0 Unpacking, Shipping and Installation

2.1 Unpacking

2.2 Shipping

Unit is delivered in a box. Unpack and check for completeness of

parts.

Measures WxHxD: 20” x 30” x 37” (with NANO 1000T).

Weight: Varies, depending upon model

(approximately 55 lbs—FEMTO head).

When moving box, lift from bottom.

! Caution: Heavy sensitive electronic equipment. Take care to

avoid bodily injury and damage to the unit.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

5

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

3.0 Installation

Install unit carefully! Improper installation voids warranty.

!

The FEMTO 1500 / NANO 1000T polishing base should be placed on a flat stable

surface.

Requires air, water supply, drain and electrical connections.

After mounting on NANO polishing base (water, drain, electrical) and connection to an

air and electrical supply, the system is ready for operation by activating the main power

switches on both the NANO polisher and FEMTO head for Automatic operation.

NANO interface

cable

Head release

lever

Post locking

collar

Head release

switch

FEMTO post

Lubricant

Dispenser

Dispenser

Interface

Cable

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

6

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

Post

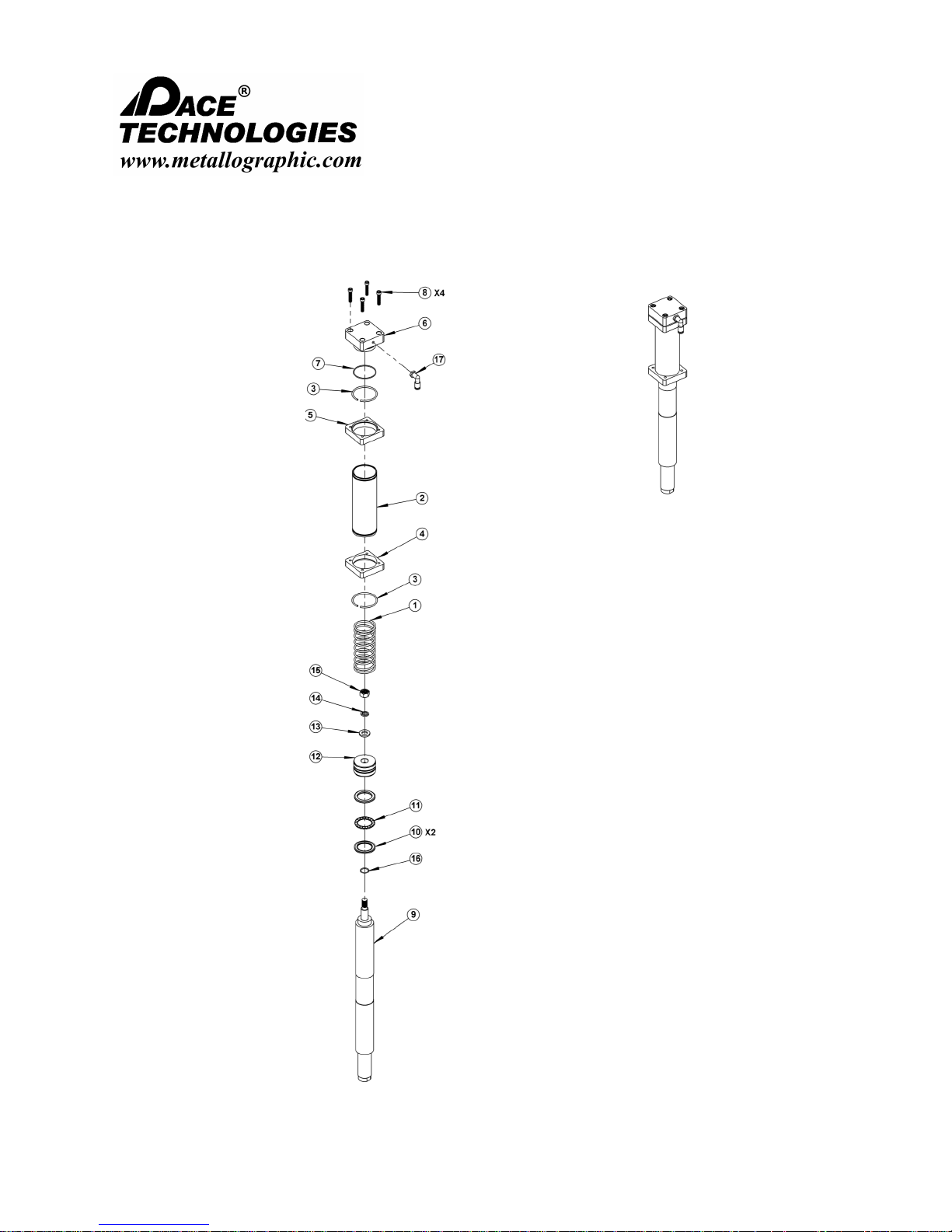

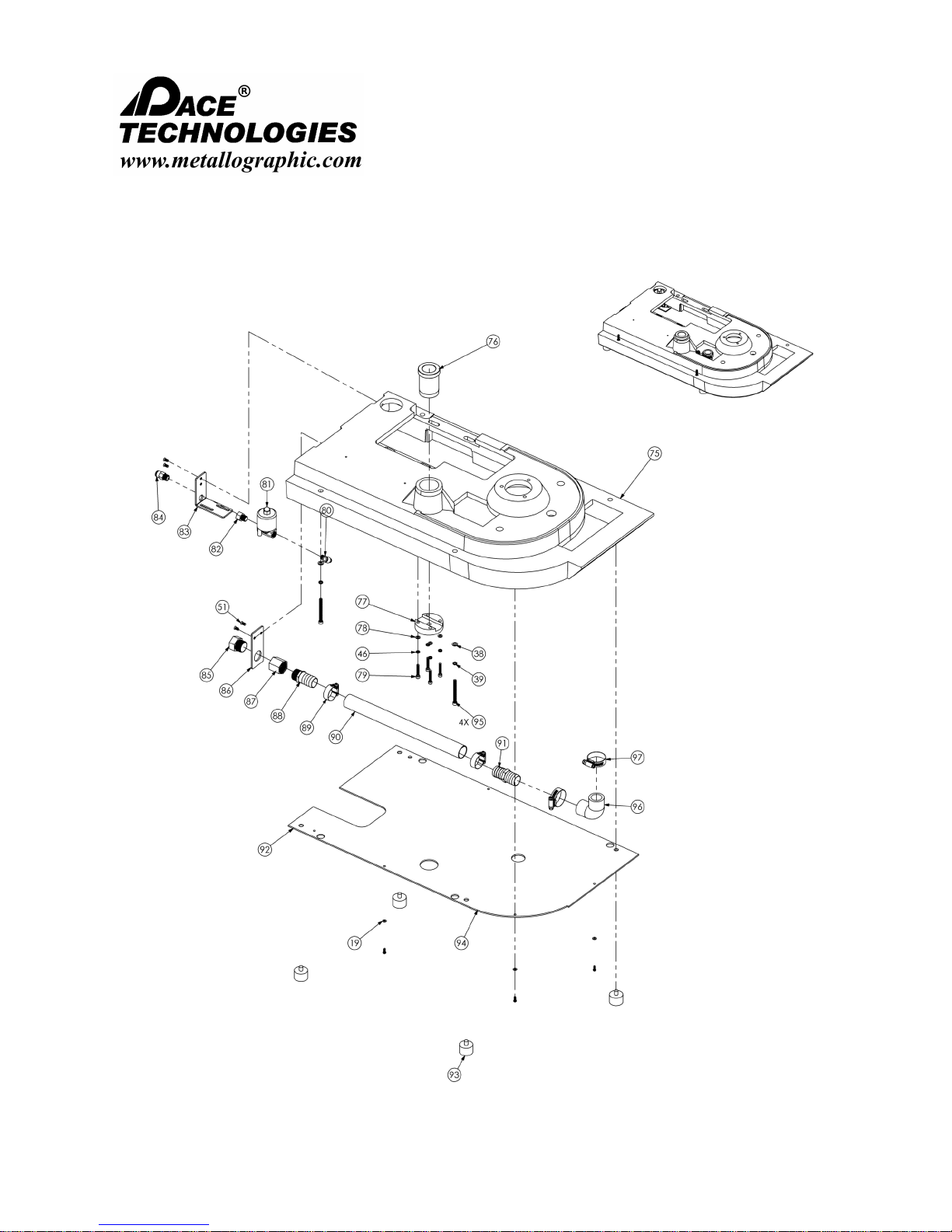

3.1 Post Connection

Bottom side post

location on

NANO polisher

positioning

Plate Groove

Post slot

Post

connection:

Loosen and swing the Plat Groove for the post so that you can see the post

Remove plastic cover from the top of the NANO polisher and lower the FEMTO post

IMPT: Securing the post is very important and must be done by tightening the bolt/

Remove the plastic cover plate from underneath the NANO polisher.

alignment notch. The post notch must fit into the groove in the brass plate.

into the hole. (note it is recommended to tighten the FEMTO post locking lever first).

Work the post down as far as possible.

The post notch should extend below the NANO casting base. If the post does not

go down all the way align the post with the plate groove and insert bolt/flat washer

and locking washer and tighten so that the post is fully down.

Replace plate and NANO plastic cover.

washer/locker washer from underneath the NANO polisher

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

7

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

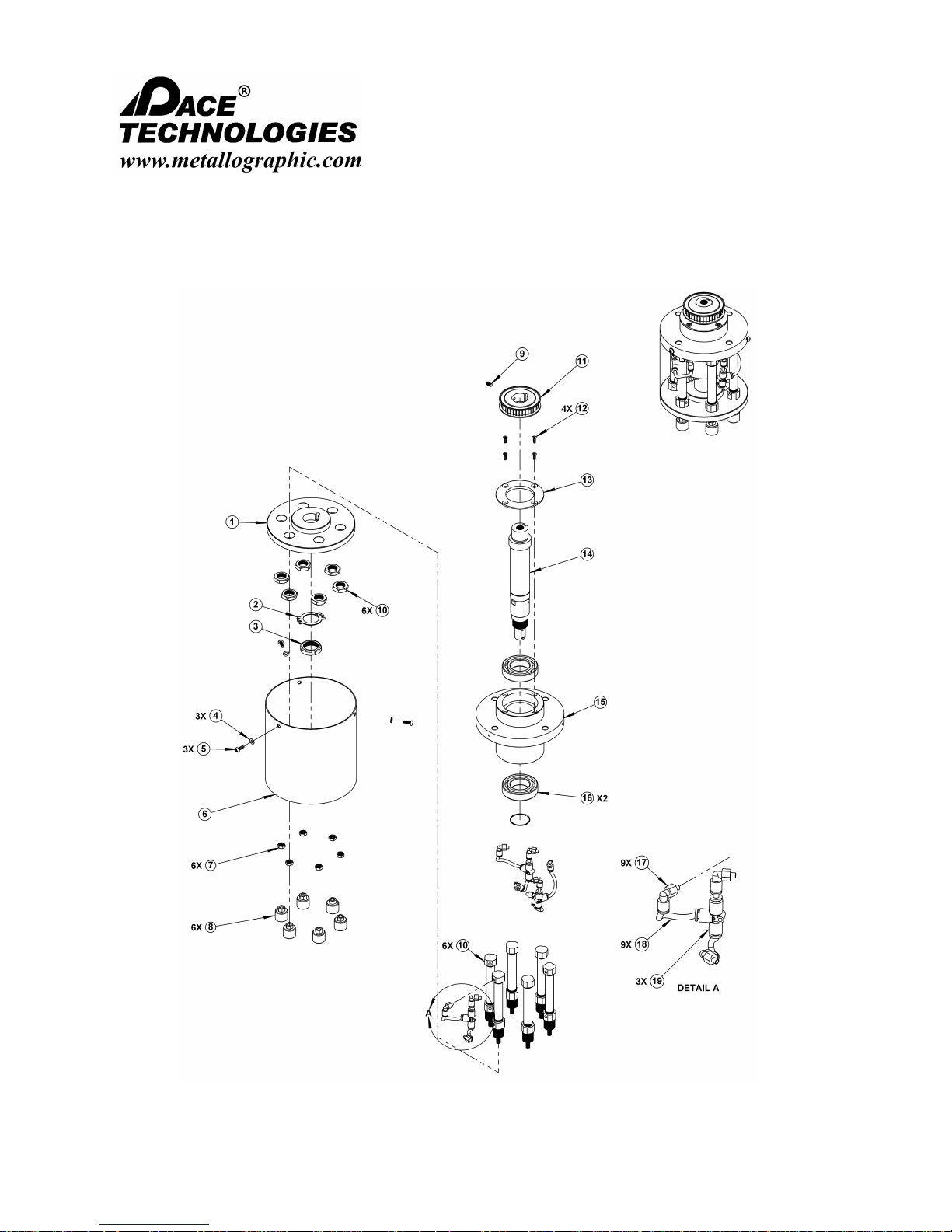

3.2 Quick Release Chuck Installation

The Quick Release Chuck is a system developed specifically for use in

the FEMTO 1500 polishing head. This systems purpose is to create a

fast and easy way of changing between our Central and Individual force

sample holders. With the Quick Release Chuck installed one polishing

head can be used to process and prepare samples with differing force

requirements. It is also possible to utilize both Individual and Central

force holders in the single procedure.

3.3 Installing a Central Force Sample Holder

To install the Central force sample holder simply

move the FEMTO head to the left of the NANO

bowl and lift the Quick Release Chuck sleeve

up. Now with your other hand push the “dogbone” male connector, on the sample holder, up

into the chuck until a click is heard. Push the

sleeve down then tighten the thump screw.

Tighten until a little bit of resistance is felt. The

Central force holder is ready to be used. Once

the procedure is completed, lift the sleeve back

up and pop off the sample holder to inspect the

samples. This system allows the sample holder

to be reinserted as many times as need

throughout the procedure.

Central Force Holder Part Number

1-inch / 25 mm central specimen holder (3-6 samples) QRC-SH100A-1500

1.25-inch / 30 mm central specimen holder (3-6 samples) QRC-SH125A-1500

1.5-inch / 40 mm central specimen holder (3-6 samples) QRC-SH150A-1500

2-inch / 50 mm central specimen holder (3 samples) QRC-SH200A-1500

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Central Force Loading plate CF-LP-1500

8

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

3.4 Installing Samples in Central Force Holder

Step 1: The loading plate is used to

mount samples into the Central

Force holder.

Step 3: Place samples into the holder as

shown below. The Central force

holder can hold either three or six

samples during a procedure.

Step 2: Place the Central Force holder onto the loading

plate as shown below. Make sure the sample

holder is flat against the rim of the Loading

Plate.

Step 4: Push each sample down using a thumb

and secure the setscrew located on the

edge of the sample holder. Do this for

each loaded sample.

Step 5: Remove the sample holder from the loading plate. It is now ready to be installed in

the Quick Release Chuck.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

9

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

3.5 Installing Individual Force Sample Holder

To install the Individual force holder move the FEMTO

head to the side of the NANO polisher. Lift the sleeve of

the Quick Release Chuck and push the sample holder

up into the chuck. Push the sleeve back down. Next,

turn the sleeve and thread the screw onto the holder.

This thread is reverse threaded. Therefore the normal

method of “lefty loose, righty tight” is not applicable here.

Instead it is “lefty tight, righty loose.” Once the sleeve is

secured around the threads turn the thumb screw on the

chuck. This greatly reduces the risk of the holder getting

loose during operation. Once finished with the Individual

force holder, simply unscrew the chuck from the sample

holder and then left the sleeve up again. The sample

holder is now able to be removed.

Specimen Holder FEMTO 1500

Single specimen holder mounting fixture for FEMTO 1100/1500, requires one set

of 3 plastic rings ranging from 1-inch up to 1.5-inch or 25mm up to 40 mm

(ordered separately)

1-in diameter rings SR-0100

1.25-in diameter rings SR-0125

1.5-in diameter rings SR-0150

25 mm diameter rings SR-25mm

30mm diameter rings SR-30mm

40 mm diameter rings SR-40mm

2-inch single specimen holder mounting fixture for FEMTO 1100/1500, requires

one set of 3, 2-inch or 50 mm plastic rings (ordered separately)

2-in diameter specimen rings SR-0200

50 mm diameter specimen rings SR-50mm

Individual specimen holder mounting fixture (for use with glass slide holders) SH-GHOLDER-1500

Glass slide holder for 27 x 47 mm and 1 x 3-inch slides (each) SR-G

SH-1150

SH-1250

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

10

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

3.6 Height Adjustment for FEMTO Head /Specimen Holder

Step 1: To lift the

FEMTO head, rotate

the lever to engage

the piston

Step 2: Lower the

FEMTO head onto a

Step 3: Loosen and

lower post the

holding collar

Specimen

holder height

adjustment:

Step 2: Place the working wheel with the highest profile abrasive/polishing pad

The specimen holder height needs to be adjusted to prevent the pistons from

grinding during the operation of the machine.

Step 1: Connect air and lift up head.

on the wheel. Using a single wall box as a spacer, place the cardboard on top of

the working wheel/abrasive combination.

Step 3: Loosen holding ring collar on the FEMTO post and slide down out of the

way.

cardboard spacer

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

11

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

3.7 Height Adjustment for FEMTO Head /Specimen Holder (continued)

Step 4: Rotate the

release lever to

disengage piston

button

Specimen

holder height

adjustment:

Step 5. Slide the

holding ring collar

up to the bottom of

the FEMTO head

and tighten.

Step 4. Rotate release lever slightly to lower the head.

Step 5. Slide the holding ring collar up to the bottom of the FEMTO head

and tighten.

Step 6. Lift head by rotating release lever to engage piston button on

bottom of FEMTO head. Remove cardboard spacer and lower the FEMTO

head.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

12

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

.8 Height Adjustment for FEMTO Head /Specimen Holder (continued)

Specimen

holder height

adjustment:

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Step 7. In the FEMTO manual mode, lower pistons with the down button.

Verify that the bottom of the piston is not rubbing against the abrasive

surface. (Note it is better to operate the specimen holder as close to the

working abrasive wheel as possible in order to get flatter specimens

13

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

3.9 Backside connections

External air supply: It is recommended that the air supply be clean, filtered and

lubricated to extend the life and performance of the systems.

Electrical connection: Connect electrical power cable and communications cable.

Note: Inspect the operating voltage on the name plate.

FEMTO 1500 HEAD

External air

supply

Communication

cable to NANO

polishing base

Electrical

supply

Power

switch

NANO 2000 POLISHER

External water

supply

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Water drain

FEMTO connections

Electrical connection

110V or 220V

Connect drain with the

best direction fitting

14

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

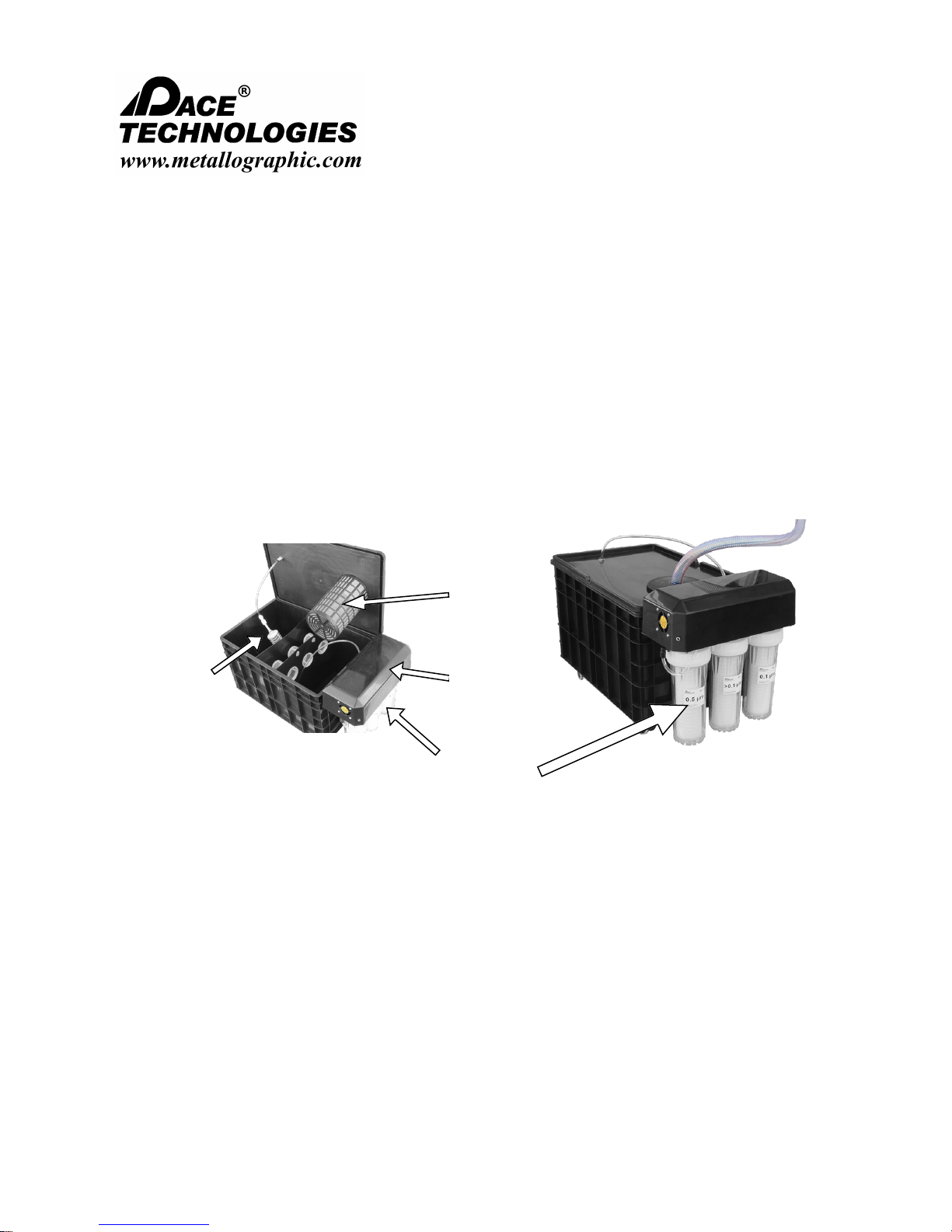

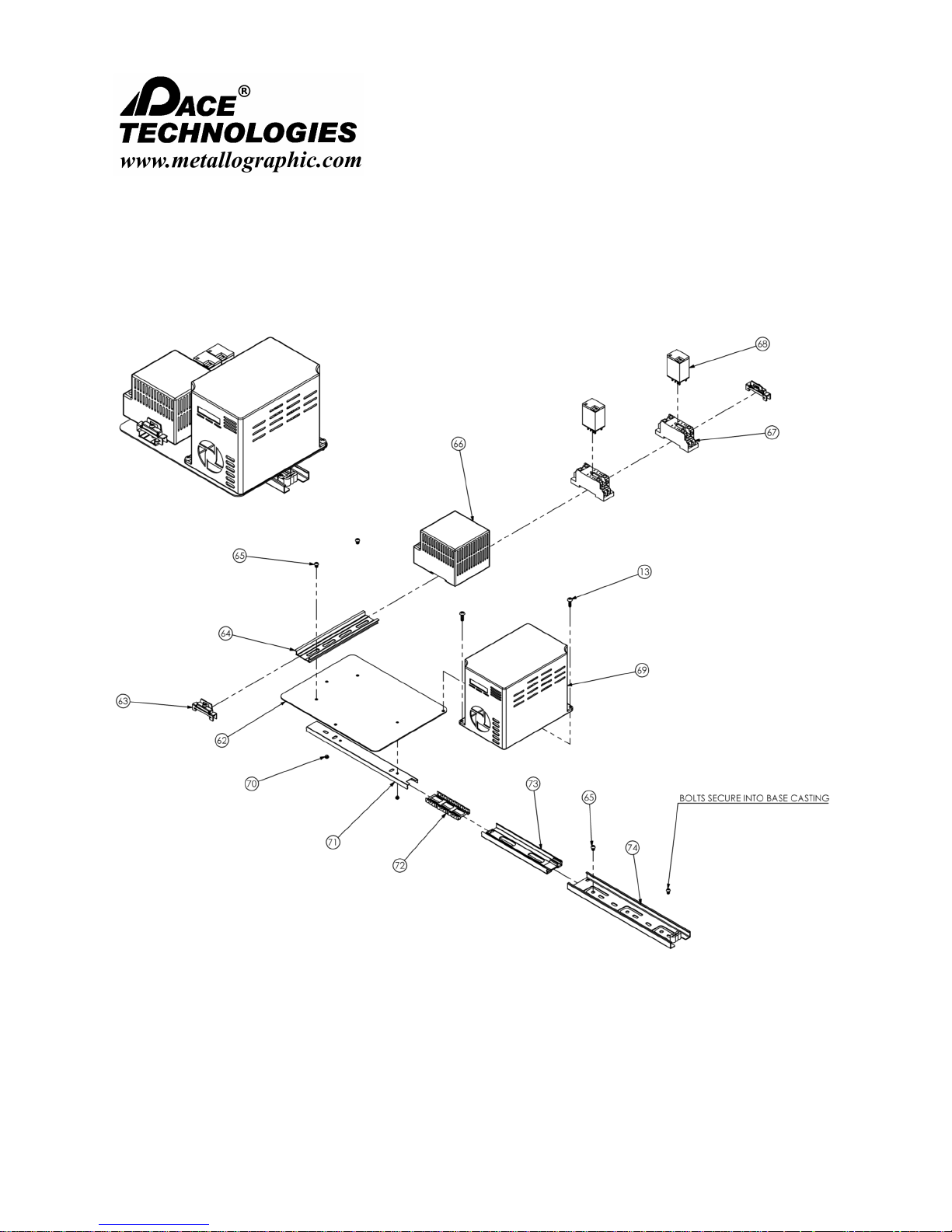

3.10 OPTIONAL Recirculating Filter System

Recirculating Filter System

The RC-1000 portable recirculating filter system allows for polishers to be mobile as well as to filter and

remove polishing swarf and abrasives generated from PACE Technologies NANO series polishers.

Utilizing a positive pressure pump, the recirculating filter system is able to provide clean water

containing <0.1 μm particles, thus eliminating waste flow to the building drainage system. The filtering

process begins with a coarse filter to eliminate coarse materials such as ripped polishing pads or torn

grinding papers. With a three chamber tank and counter current flow coarse abrasives can also settle

when the pump is not activated. As water is required, the pump will engage and pull the effluent

through a series of fine filters starting with a 0.5 μm filter, followed by a filter >0.1 μm and then to a sub

0.1 μm filter.

Pickup

screen

Coarse

Drain

Screen

Pump

Fine micron

exchangeable

filters

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

15

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Installation (continued)

3.11 Lubricator Connection

Lubricator set-up (Tube through cap)

Fasten lubricator to

FEMTO base casting

Connect communication

cable to FEMTO base

Position dispensing tube

by sliding along rail. To

lock into place tighten

screws located under the

holder

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Connect supply hose to

dispenser

16

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

4.0 Safety Guidelines

4.1 Warning Sign

4.2 Safety Precautions

This sign points to special safety features on the machine.

!

Careful attention to this instruction manual and the recommended safety guidelines is

!

essential for the safe operation of the FEMTO 1500.

Proper operator training is required for operation of the FEMTO 1500. Any unauthorized

mechanical and electrical change, as well as improper operation, voids all warranty

!

claims. All service issues need to be reported to the manufacturer / supplier.

Operate unit as specified in this manual.

!

Disconnect power before opening unit.

!

Do not leave any specimen or other parts on the working wheel.

!

Ensure that the air slots on polishing head are not obstructed.

!

When unit is not in use turn off water and air.

!

Keep hands clear of the specimen holder when the machine is running. Do not place or

position hands under specimen holder when it is in the raised position or when lowering

!

the head.

4.3 Emergency Statement

The FEMTO 1500 power head has been designed for polishing metallographic specimens up

to 2-inch diameter. Always follow proper operational guidelines and avoid contact with moving

parts, lubricants and abrasives. Seek appropriate medical care for cutting injuries.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

17

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

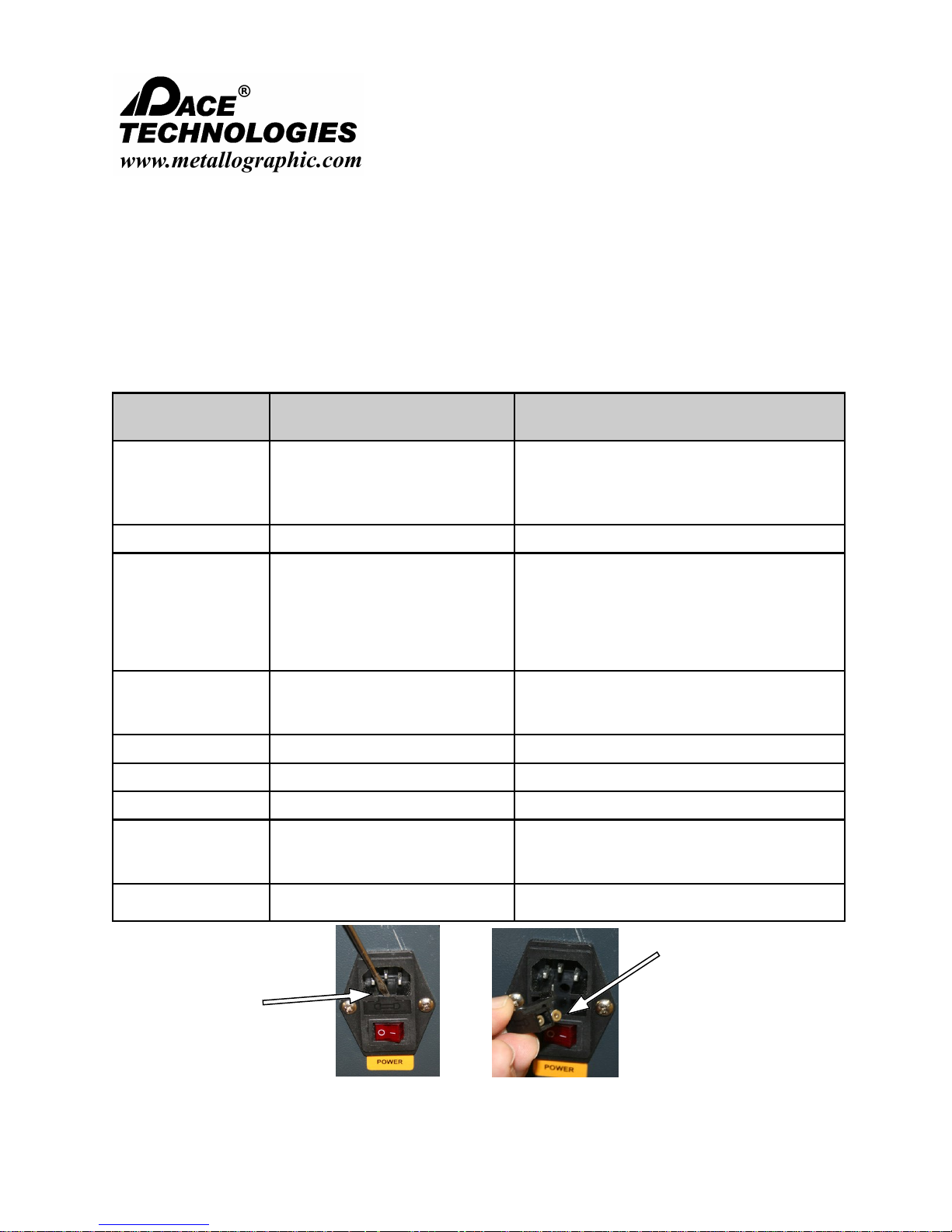

4.4 Safety Test

The emergency stop switch on the NANO polisher controls the operation of the FEMTO 1500

power head when operated in the AUTO mode. Test the emergency stop switch by running

!

the FEMTO 1500 head in the AUTO mode through the NANO polisher. The following safety

check is considered important:

Emergency stop switch

Test:

Proper

Response:

Malfunction:

Corrective

measure:

Activate main power switch.

Start NANO 1000T/ FEMTO 1500

machine in AUTO mode.

Depress emergency stop switch.

NANO 1000T and FEMTO 1500 head

stops.

NANO 1000T or FEMTO 1500 polisher

does not lose power.

If system does not power down,

disconnect power supply cord and call

service technician.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

18

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.0 Start-up and Operation

5.1 General

The FEMTO 1500 is an semi-automated grinding/ polishing accessory for the NANO polisher.

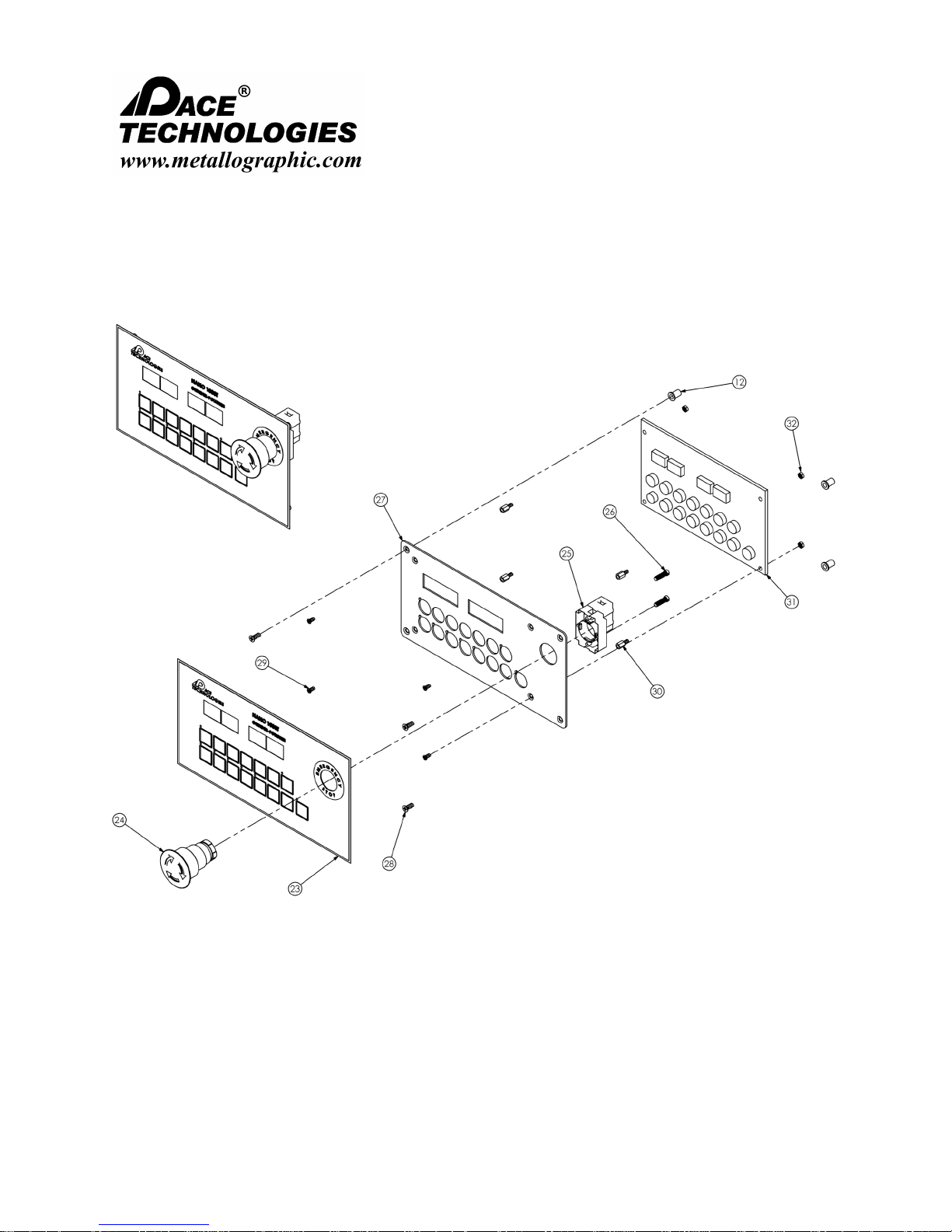

5.2 FEMTO 1500 Control Panel

Pressure

Gauge

Pressure

Adjustment

Pistons

Up/Down

Start / Stop buttons: Start/Stop the FEMTO head in the manual mode. Note the RUN/

STOP button on the NANO polisher controls the Automatic polishing

operation.

Motor

Speed

Controller

Wheel Speed

Indicator

Auto-mode for

timed grinding/

polishing

Manual Mode

Polishing

Start/Stop buttons

(manual mode)

Auto/ Manual buttons: Manual mode operates FEMTO independent of NANO polisher.

Pistons Up/Down: The UP/DOWN buttons control the pistons in the manual mode.

Motor Speed Controller: The FEMTO head has a variable speed motor (0-200 rpm).

Wheel Speed Indicator: Displays the motor speed (0-200 rpm)

Pressure Adjustment: Controls the pressure applied to the pistons.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Auto mode operates FEMTO in conjunction with NANO polisher.

19

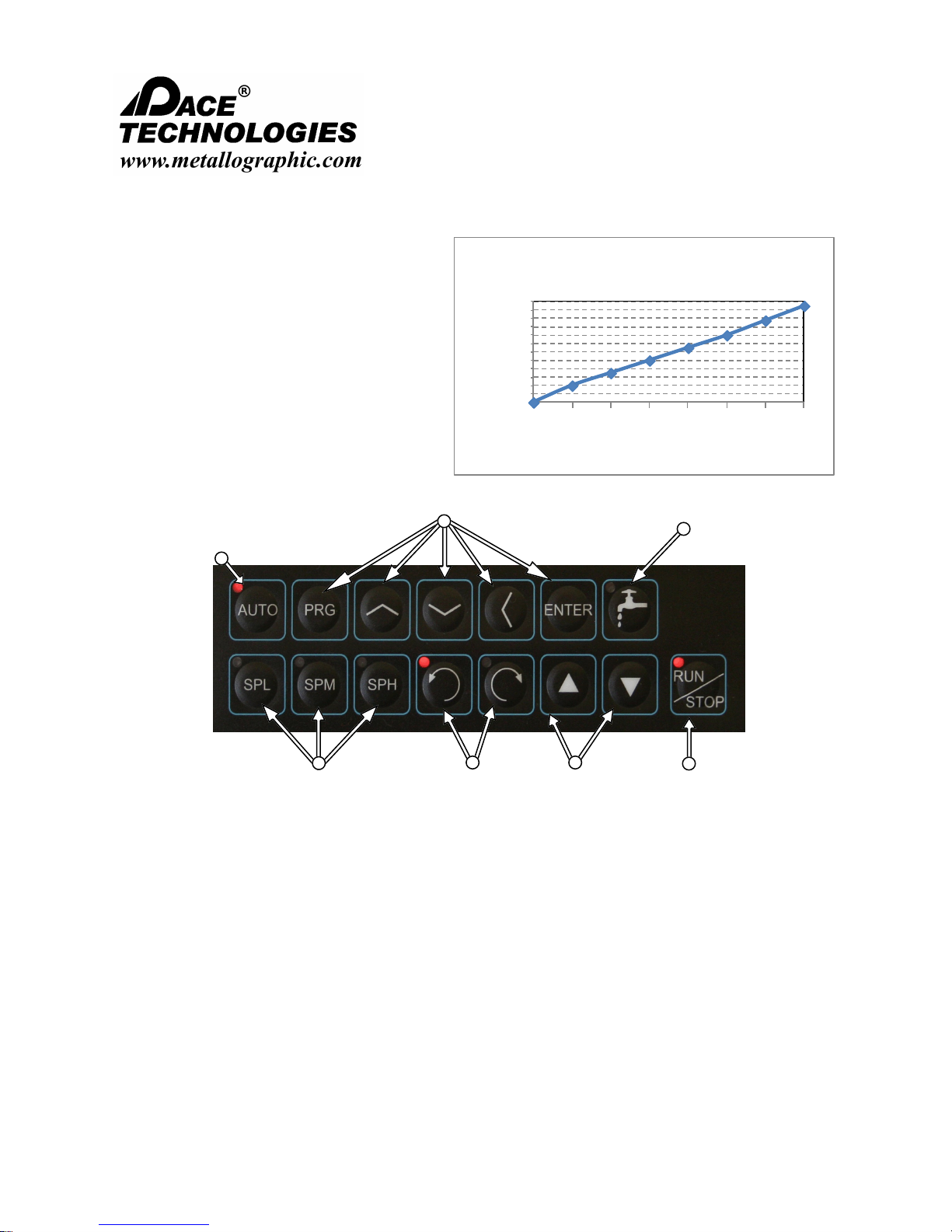

8

0

1

2

3

4

5

6

7

8

9

10

11

12

30 40 50 60 70 80 90 100

Applied Force per sample

(lbs)

Pressure gauge reading (PSI)

Applied Force per sample

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.2 FEMTO 1500 Control Panel

(applied force vs. pressure gauge)

5.3 NANO Polisher Control Panel

The NANO 1000T is a hand grinding/

polishing machine. By adding the FEMTO

power head, semi-automated polishing can

be accomplished.

Programming mode buttons

Auto-mode for timed

Water

button

grinding/ polishing

Preset speeds

(Low, medium, high)

Wheel

direction

Speed

control

RUN/STOP

Wheel direction: Clockwise rotation or counter clockwise rotation.

Run / Stop buttons: Start/stop the polishing wheel in both manual and auto mode.

Water button: Activates the water solenoid for the rinse bowl and rinse spout.

Preset speeds: Allows for faster speed control, SPL - low speed, SPM - medium

Auto-mode: Allows for running pre-programmed speeds and times (factory setting

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

speed, SPH - high speed (factory setting approx. 100, 200, 300 rpm.

approx. 200 rpm, FWD, 30 seconds).

20

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.4 AUTO Polishing Mode

1. Install working wheel and attach grinding papers /

polishing cloths.

Position the specimen holder so that the sample

tracks over the entire diameter of the grinding

papers in order to break the grinding papers

uniformly. Note positioning is not as significant

for polishing pads.

2. Power on the FEMTO and NANO machines

using the power switch located on the back of the

units.

Find and press the AUTO button on the FEMTO,

a light will illuminate when selected

Set an approximate pressure and head speed on

the FEMTO head.

Adjust

polishing

force

Adjust

head

speed

Set to

Auto mode

3. Set the base speed, time and direction on the

NANO controller (see next page for instructions)

4. Rotate water spout over working wheel. During

sample preparation adjust water flow by turning

water control knob as required. Note: Initial

operation of water valve may contain air in the

lines. Turn water on slowly to purge air from

system.

4. Depress AUTO mode button on the NANO,

ensure red light is illuminated. To start operation

press RUN/STOP button.

5. Adjust speed of the polishing head and the

applied pressure

Set to Auto

mode

Starts Auto

polishing

mode

TIP: It is recommended that the FEMTO head speed match or

exceed the NANO base speed and run in the same direction. This

provides flatter specimen samples, especially for coarse grinding.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

21

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.4.1 Programmable Mode

1. The programming mode can be used to pre-set the

polishing speed, direction and time for automated

polishing. It can also be used to change the Preset

speed buttons.

2. To change the speed of the wheel:

Press the PRG button and use the Up and Down

buttons to find SP1 and press ENTER. Use the up and

down < key to change the speed. Press ENTER to

save.

3. To program a grinding/ polishing time:

Press the PRG button and use the Up and Down

buttons to find t1 and press ENTER. Use the up and

down < key to change the time (enter in seconds displayed min-sec)

Preset speed buttons

4. To operate the pre-programmed conditions:

PRESS the AUTO button and then start the program

with the RUN/STOP button. The pre-programmed

conditions will be executed.

To change the speed setting for

the Preset speed buttons use

the following procedure:

Press the PRG button and use

the Up and Down buttons to SL

(slow speed) and press ENTER.

Use the up and down < key to

change the speed. Use Sn for

changing the medium speed

and SH for the fast speed.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

22

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.5 MANUAL NANO-FEMTO Polishing Mode

1. Install working wheel and attach grinding

papers / polishing cloths.

2. Power on the FEMTO and NANO machines

using the power switch located on the back of

the units.

Find and press the MANUAL button on the

FEMTO, a light will illuminate when selected

Set an approximate pressure and head speed on

the FEMTO head.

Load samples and lower the Pistons to the

DOWN position.

Press green Start button to start the FEMTO

head (NANO polisher will not start automatically

in this mode, it must be started separately).

Adjust the FEMTO speed and force.

Adjust

polishing

force

Press to

lower

pistons

Adjust

head

speed

Start/Stop

FEMTO head

Set to

Manual

3. Start the NANO head by using preset speeds

(SPL, SPM, SPH) and pressing RUN/STOP

button. Note speed can be adjusted with up and

down arrow keys.

4. Rotate water spout over working wheel. During

sample preparation adjust water flow by turning

water control knob as required. Note: Initial

operation of water valve may contain air in the

lines. Turn water on slowly to purge air from

system.

5. Both the NANO and FEMTO heads need to be

stopped by pressing the red STOP button on the

FEMTO head and also the RUN/STOP button on

the NANO controller.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Preset

Start/Stop

NANO

manually

23

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.6 SEMI-AUTO NANO-FEMTO Polishing Mode

1. Install working wheel and attach grinding papers /

polishing cloths.

2. Power on the FEMTO and NANO machines

using the power switch located on the back of the

units.

Find and press the AUTO button on the FEMTO

control panel

Set an approximate pressure and head speed on

the FEMTO head.

Load samples.

3. Start the NANO head by using preset speeds

(SPL, SPM, SPH) and pressing RUN/STOP

button. Note speed can be adjusted with up and

down arrow keys.

Adjust the FEMTO speed and force.

The FEMTO head and NANO polisher will start

automatically in this mode, however, it will run

until the RUN/STOP button is pressed.

Adjust

polishing

force

Adjust

head

speed

Set to

Auto

mode

4. Position flexible water spout over working wheel.

During sample preparation adjust water flow by

turning water control knob as required. Note:

Initial operation of water valve may contain air in

the lines. Turn water on slowly to purge air from

system.

5. Press the RUN/STOP button on the NANO

controller to stop the polishing operation.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Preset

Speeds

Start/Stop

NANO

manually

24

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

457 MANUAL Hand Polishing Mode (NANO ONLY)

To use the NANO polishing without the FEMTO head, turn off the power to the FEMTO head

using the main power switch on the back of the FEMTO head.

Swing the FEMTO head out of the way.

5.7.1 Grinding / polishing by hand

1. Install working wheel and attach grinding papers / polishing cloths.

2. Power on the machine in the back and set the mode, speed, and time (if required).

3. Rotate water spout over working wheel. During sample preparation adjust water flow by

turning water control knob as required. Note: Initial operation of water valve may contain

air in the lines. Turn water on slowly to purge air from system.

4. Press RUN/STOP start and stop the machine in the manual mode.

5.7.2 Direction and speed controller (manual)

1. To change direction of the wheel:

-Press FWD (clockwise) or REV (counter clockwise),

LED will light

2. To change the speed of the wheel:

Select one of the low, medium or high preset speed

buttons and use the Up and Down arrows to fine tune

speed if required

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

25

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.8 Manual Mode - Programming changes

1. The programming mode can be used to pre-set

the polishing speed, direction and time for

automated polishing. It can also be used to

change the Preset speed buttons.

2. To change the speed of the wheel:

Press the PRG button and use the Up and Down

buttons to find SP1 then press ENTER. Use the

Up and Down buttons to change the speed, press

ENTER to finalize the change.

3. To program a grinding/ polishing time:

Press the PRG button and use the Up and Down

buttons to find ST1 and press ENTER. Use the

Up and Down buttons to change the time

(seconds), press ENTER to finalize the change.

4. To operate the pre-programmed conditions:

Press the AUTO button and then start the

program with the RUN/STOP button. The preprogrammed conditions will be executed.

Preset

Speeds

To change the speed setting for

the Preset speed buttons use

the following procedure:

Press the PRG button and use

the Up and Down keys to find

SL (slow speed) then press

ENTER. Use the Up and Down

button to change the speed.

Use SN for changing the

medium speed and SH for the

fast speed presets.

Start/Stop

NANO

manually

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

26

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.9 Positioning and Loading FEMTO holder

1. For grinding with abrasive papers, the specimen holder

for the FEMTO head should be positioned so that the

specimen tracks over the entire radius of the grinding

paper.

Since grinding papers break down relatively fast, it is

recommended that the hardest part of the mount

(typically the specimen) track over the entire radius in

order to uniformly break down the grinding papers. If

the specimen does not break down the grinding papers

uniformly then the softer outside part of the mount will

grind more. The result is after polishing there will be a

portion of the mount which is not fully polished. This

portion of the mount will appear as a crescent shaped

moon and can cause issues when examining the edge

of the specimen.

TIP: If you have small samples, mount them toward

the outside edge of the mount for better tracking

Position holder so that the

specimen in the mount tracks over

then entire radius of the grinding

paper.

2. Individual specimen holders do not hold the specimen

in the holder. When the head is lifted, the specimens

will remain on the working wheel. In such a case they

will need to be reloaded after changing the abrasive.

TIP: By placing a rubber O-ring around the top of the

mount it can be lifted when the head is raised and held

in place. Note you most likely will not be able to do this

if you use the splash guards.

You can use O-rings to hold

specimens in place when

head is lifted

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

27

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

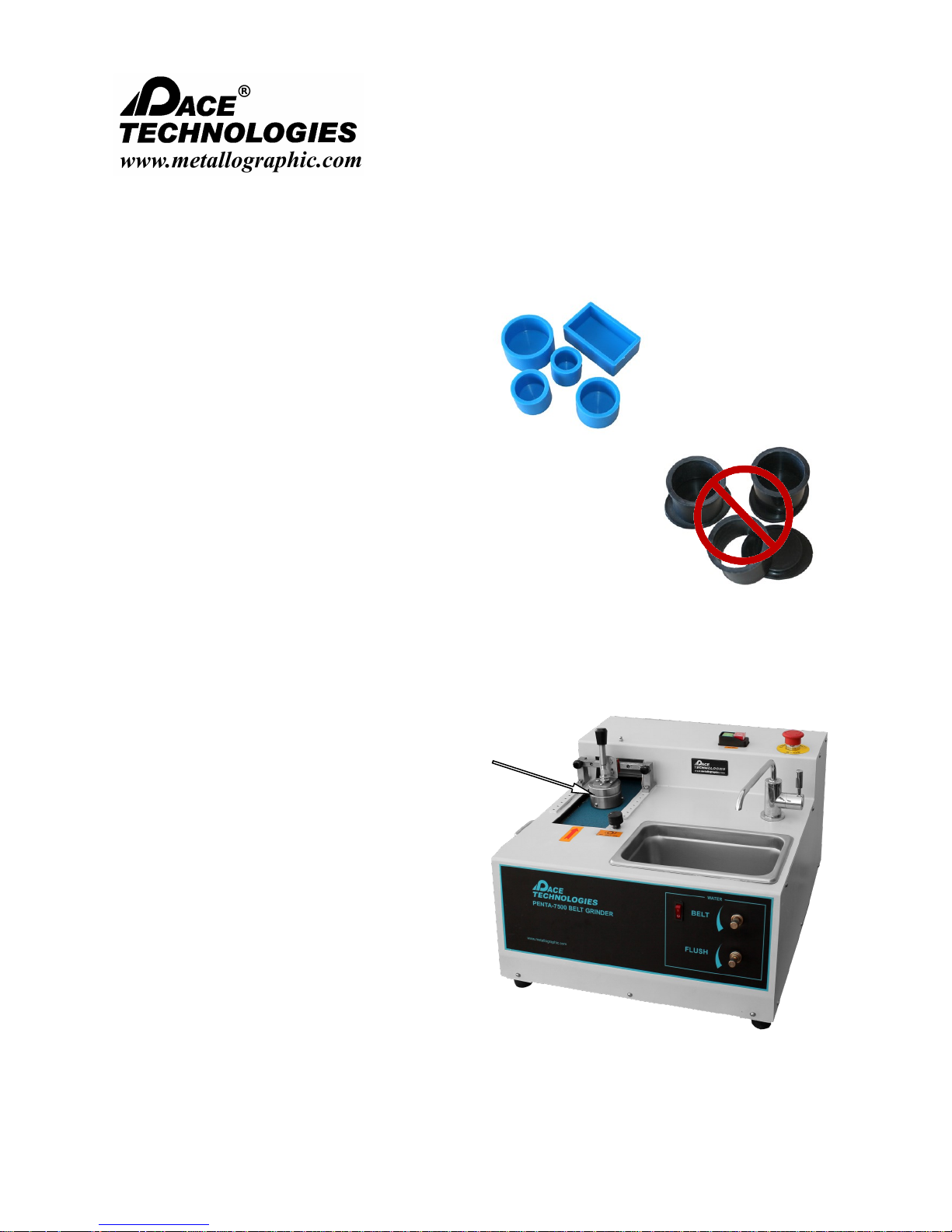

5.10 Metallographic Specimen Preparation Basics

TIP: To optimize individual polishing

Rubber molds produce

square mounts

machines, the specimen mounts need

to be square. It is recommended that

the specimen be mounted in either a

compression mounting press or with a

rubber mold for castable mounting.

DO NOT USE TAPERED 2-PIECE

MOLDING CUPS for Individual

Specimen Polishing machines.

2-piece molds produce

tapered mounts

USE A BELT GRINDER OR CENTRAL POLISHING FORCE

FIXTURE FOR COARSE GRINDING!!!

Square grinding

attachment

TIP: Individual polishing machines

DO NOT require coarse planar

grinding. In fact, extremely coarse

grinding with 60 grit down to 180 grit

is not recommended.

If coarse grinding is required, it is

recommended that the PENTA 7500

belt grinder, with its square grinding

attachment be used. The FEMTO

1500 with the central sample fixture

can also be used (see Section 1.5)

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

28

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.10 Metallographic Specimen Preparation Basics (continued)

A typical metallographic specimen preparation consists of the following basic steps:

Preparation Stage Purpose

Initial documentation:

Sectioning / cutting:

Rough, or planar grinding

(refer to Section 4.9.1):

Rough polishing (refer to

Section 4.9.2):

Final polishing (refer to

Section 4.9.1)::

Etching:

Examination:

To document the initial condition of the sample,

To map the sample surface,

To highlight the area of interest.

To reduce the size of large samples and to sample the

specimens close to the area of interest.

To obtain a planar surface,

To remove sectioning damage,

To approach the area of interest.

Ideally to remove all the subsurface damage and microstructural

damage produced during cutting and rough grinding (Superficial

scratches may still be present after this step).

Generally, more for cosmetic purposes than for removing

microstructural damage. In most cases, this stage should be

minimized to avoid over polishing and distorting the

microstructural features.

To enhance microstructural features such as grain boundaries,

grain size, phase differences, etc.

A variety of examination techniques are used in metallography,

including: optical microscopy, electron microscopy and hardness

testing.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

29

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.10.1 Rough / Planar Grinding

Rough or planar grinding, is required to produce flat specimens and to reduce the damage created by

sectioning. The planar grinding step is accomplished by decreasing the abrasive grit particle size

sequentially to obtain surface finishes that are ready for polishing. Care must be taken to avoid being

too abrasive in this step, and actually creating greater specimen damage than produced during cutting.

This is especially true for very brittle materials such as ceramics and silicon.

The machine parameters which affect the preparation of metallographic specimens include: grinding /

polishing pressure, grinding direction, and the relative velocity distribution between the specimen and

the polishing wheel.

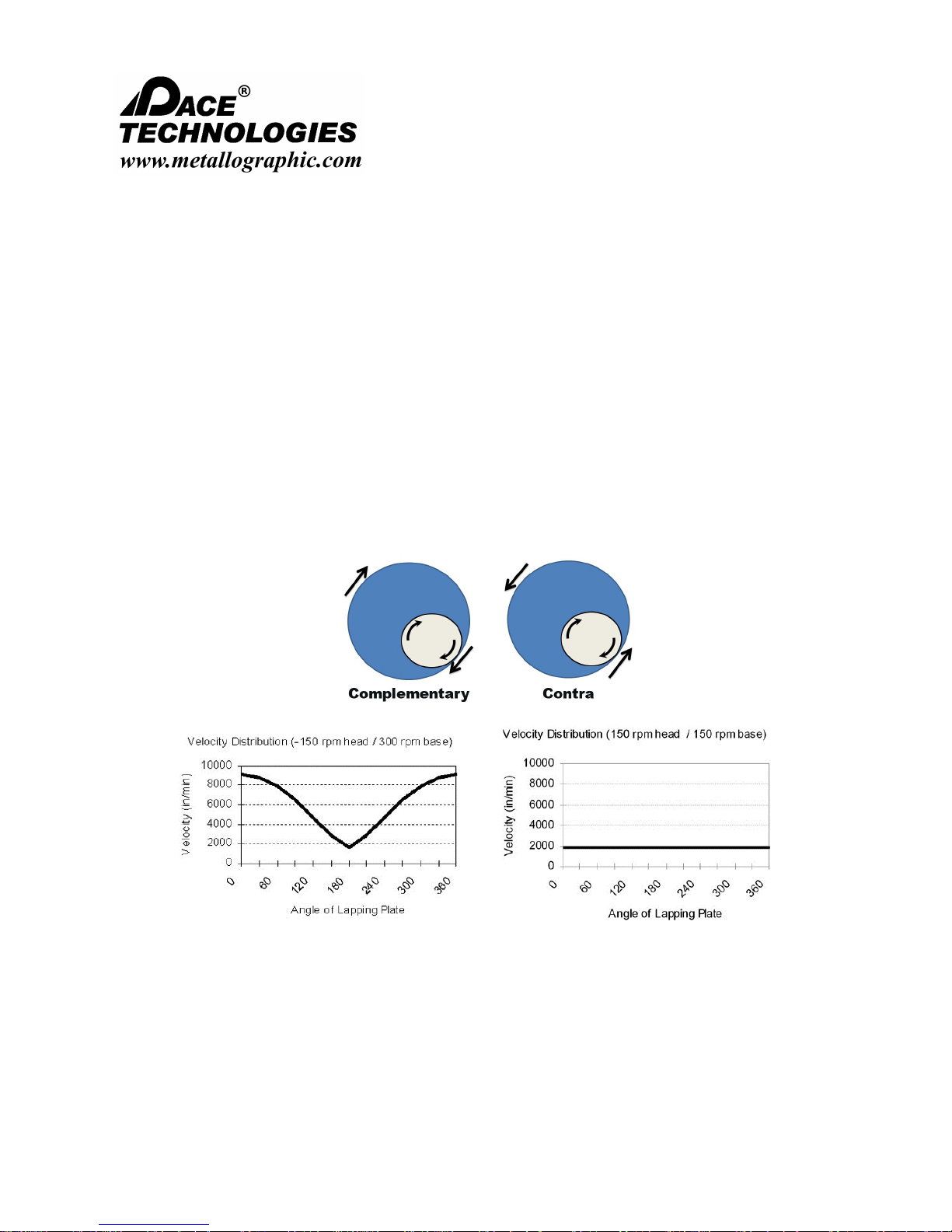

Grinding Speed

For automated polishing the relative speed between the polishing head and the polishing wheel has a

significant effect on the flatness of the mount, especially for grinding with coarse abrasives. As an

example, the following two conditions show the effect of running with the head and base speed in the

contra direction as well as running the head and base speeds in the same direction at the same speed.

High relative velocity difference (contra)

between the polishing head and polishing base

Low relative velocity difference

(complementary) between the polishing head

and polishing base

Based on the relative velocity distributions for grinding / polishing the best condition for maintaining a

uniform velocity across the specimen as it rotates around the polishing wheel is to run them in the

same direction at the same speed. In addition, changing the offset as well as the combination speed

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

30

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

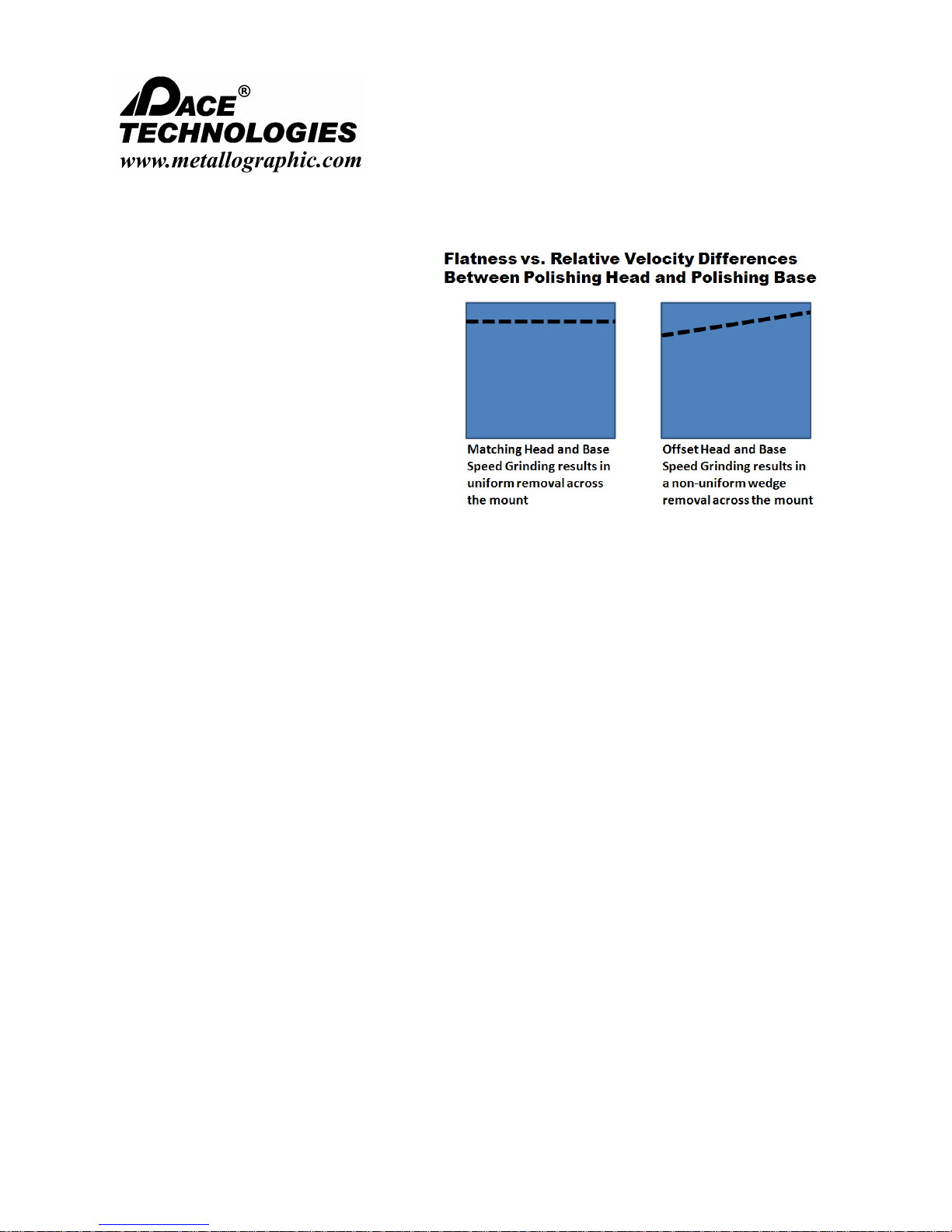

can control the aggressiveness of the

grinding/ polishing operation.

It is also very important for polishing

machines which use individual force

pistons for applying the polishing force to

run the power head and base at closely

matching speeds and in the

complementary direction. If these

machines are run with significantly different

speeds or direction the mount will have a

tendency to grind with a wedge and

therefore it will not be square.

Grinding Pressure

Grinding / polishing pressure is dependent upon the applied force (pounds or Newton's) and the area

of the specimen and mounting material. Pressure is defined as the Force/Area (psi, N/m2 or Pa). For

specimens significantly harder than the mounting compound, pressure is better defined as the force

divided by the specimen surface area. Thus, for larger hard specimens, higher grinding / polishing

pressures increase stock removal rates. However, higher pressure also increases the amount of

surface and subsurface damage produced in the specimen.

Note regarding SiC grinding papers: as the abrasive grains dull and cut rates decrease, increasing

grinding pressures can extend the life of the SiC paper.

Higher grinding / polishing pressures can also generate additional frictional heat which may be

beneficial for the chemical mechanical polishing (CMP) of ceramics, minerals and composites.

Likewise for extremely friable specimens (such as nodular cast iron), higher pressures and lower

relative velocity distributions can aid in retaining inclusions and secondary phases.

Grinding Direction

The orientation of the specimen can have a significant impact on the preparation results, especially for

specimens with coatings. In general, when grinding and polishing materials with coatings, the brittle

component should be kept in compression. In other words, for brittle coatings, the direction of the

abrasive should be through the coating and into the substrate. Conversely, for brittle substrates with

ductile coatings, the direction of the abrasive should be through the brittle substrate and into the

ductile coating.

Manual Preparation

In order to ensure that the previous rough grinding damage is removed when grinding by hand, the

specimen should be rotated 90 degrees and continually ground until all of the scratches from the

previous grinding direction are removed. When necessary, the abrasive paper should be replaced with

a newer paper to maintain cutting rates.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

31

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.10.2 Rough Polishing

The purpose of the rough polishing step is to remove the damage produced during cutting and planar

grinding. Proper rough polishing will maintain specimen flatness and retain all inclusions or

secondary phases. By eliminating the previous damage and maintaining the microstructural integrity

of the specimen at this step, a minimal amount of time is required to remove the cosmetic damage at

the final polishing step.

Rough polishing is accomplished primarily with diamond abrasives ranging from 9 micron to 1

micron. Polycrystalline diamond -- because of its multiple and small cutting edges -- produces high

cut rates with minimal surface damage. Therefore, polycrystalline diamond abrasives are

recommended for metallographic rough polishing on low-napped polishing cloths.

Rough Polishing Guidelines

Material Recommendations

Metals (ferrous, non-ferrous,

tool steels, superalloys, etc.)

Ceramics and ceramic matrix

composites (CMC)

Polymer matrix composites

(PMC)

Biomaterials

Microelectronic specimens Diamond-lapping films are recommended.

Plastics and polymers 800 and 1200 grit SiC abrasive paper are recommended.

Plasma spray materials

Rough polishing typically requires two polishing steps, e.g., a 6micron diamond followed by a 1-micron diamond on low-napped

polishing cloths.

Low-nap polishing pads using polycrystalline diamond, alternating

with colloidal silica. This provides a chemical mechanical

polishing (CMP) effect which results in a damage-free surface

Diamond-lapping films are recommended.

Low-napped polishing pads with polycrystalline diamond,

alternating with colloidal silica. Alternatively, diamond-lapping

films may work well.

Diamond-lapping films or low-napped polishing pads with

alternating diamond and colloidal silica abrasives.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

32

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.10.3 Final Polishing

The purpose of final polishing is to remove only the cosmetic surface damage. It should not be used

to remove any damage remaining from cutting and planar grinding. If the damage from these steps is

not completely removed, the rough polishing step should be repeated or continued.

Final Polishing Guidelines

Material Recommendation

Metals (ferrous, nonferrous, tool steels, super

alloys, etc.)

Ceramics and ceramic

matrix composites (CMC)

Polymer matrix composites

(PMC)

Biomaterials

Microelectronic specimens

Plastics and polymers Light polish with alumina on a high-napped polishing pad.

Plasma spray materials

High-napped polishing pads with a nanometer alumina polishing

abrasive. The polishing times should nominally be less than 30

seconds.

Low-napped polishing pads using 1-um polycrystalline diamond,

alternating with colloidal silica or colloidal silica alone.

Fine abrasive diamond-lapping films, followed by a very light polish

on a high-napped polishing pad.

Low-napped polishing pads with polycrystalline diamond, alternating

with colloidal silica.

Diamond-lapping films followed by a very light polish on a

high-napped polishing pad.

Diamond-lapping films followed by a very light and short alumina or

colloidal silica polish on a high-napped polishing pad.

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

33

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

5.11 Selected Polishing Procedures

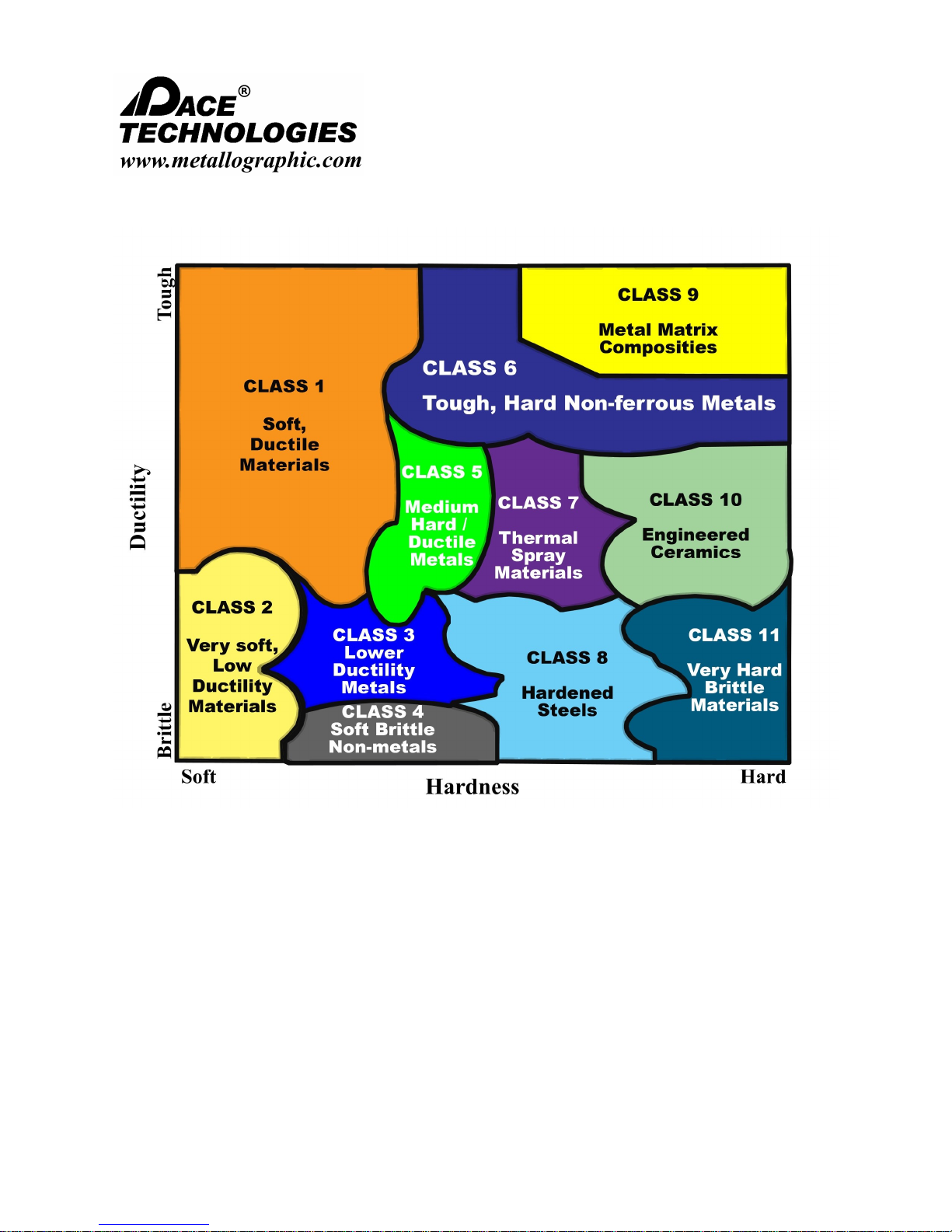

Metallographic specimen preparation requires knowledge of the specimen properties, the most

important characteristics are the hardness and ductility of the metallographic specimen. Based

on these material properties, the proper metallographic consumables and equipment parameters can be determined. The following chart shows the hardness and ductility for most metallographic material classes that are analyzed by metallographic techniques. Specimen procedures

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

34

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

35

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

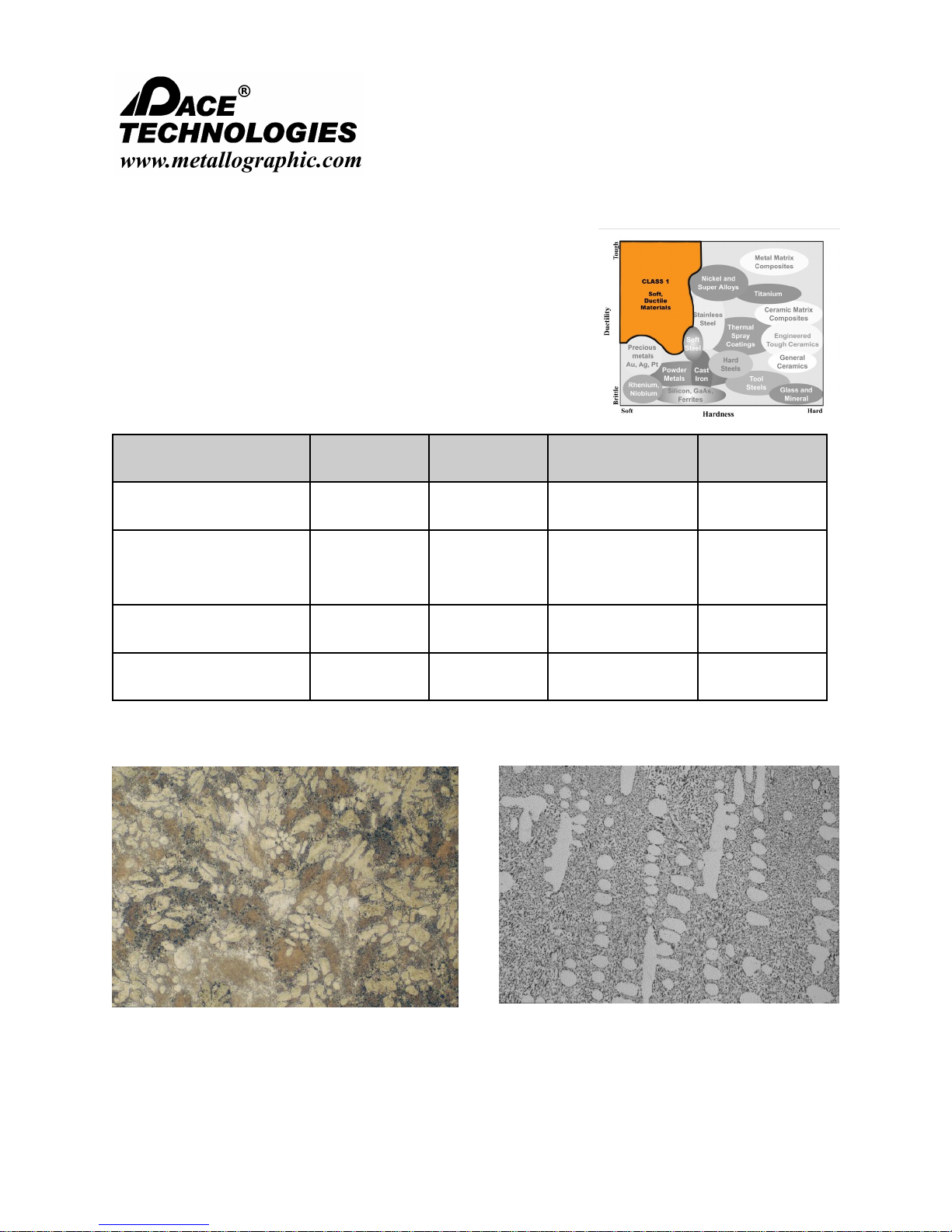

CLASS 1 Polishing Procedures

5.11.1 Aluminum and Aluminum Alloys

Aluminum and aluminum alloys are difficult to prepare because

they are soft and contain oxide particles which can become

dislodged and scratch the surface. The key to polishing aluminum

is to use very fine polishing abrasives (fine aggregates).

Abrasive/surface Lubricant

P120 grit ALO paper*

P220 grit ALO paper*

P220 grit ALO paper

P500 grit ALO paper

P1200 grit ALO paper

1 um DIAMAT diamond on

ATLANTIS pad

0.05 um Nanometer alumina on

NAPPAD pad

Water

Water

DIALUBE Purple

Extender

60-75 1 minute 100 rpm / 100 rpm

FEMTO pressure

setting (psi)

60-75 200 rpm / 200 rpm

60-75

60-75 2 minutes 200 rpm / 200 rpm

200 rpm / 200 rpm

* Recommended for Central Force holders (this step not required for Individual Force holders)

Time Head / Wheel speed

Until plane

1 minute

Until plane

1 minute

1 minute

Aluminum-Silicon Alloy, B.F. 200X

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Aluminum-Silicon Alloy, B.F. 200X

36

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

CLASS 2 Polishing Procedures

5.11.2 Rhenium and Refractory Alloys

Refractory metals such as Rhenium, Niobium, Tungsten and Molybdenum are

a very soft, and any loose or fracture abrasive particles can easily embed. This

makes specimen preparation very difficult because it gums up diamond

grinding disks or becomes embedded with fractured SiC particles when ground

with SiC papers. The key to preparation of this material is to use the tougher

alumina abrasive and to chemically etch the specimen between each grinding

step. The purpose of etching is to remove the embedded particles and not carry

them over as contamination.

Abrasive/surface Lubricant

P120 grit ALO paper*

P220 grit ALO paper*

P220 grit ALO paper

P500 grit ALO paper

P1200 grit ALO paper

1 um DIAMAT diamond on

ATLANTIS pad

Water

Water

DIALUBE Purple

Extender

FEMTO pressure

setting (psi)

60-75

60-75

60-75 2 minutes

100/100 rpm

100/100 rpm

100/100 rpm

Polishing with

10% Diluted

0.05 um acidic Nanometer

acid alumina on a

BLACKCHEM 2 pad

etchant below:

5-10 lbs 1 minute 100/100 rpm

Rhenium - 30 ml

lactic acid, 30 ml

HNO3, 1 ml HF

* Recommended for Central Force holders (this step not required for Individual Force holders)

Time Head / Wheel speed

Until plane

1 minute

Until plane

1 minute

1 minute

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Rhenium (BF), etched

37

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

CLASS 3 Polishing Procedures

5.11.3 Cast Irons

Cast irons are difficult materials to prepare properly because the

graphite nodules (or graphite flakes) are easily pulled out during

preparation. By minimizing the sectioning damage and by

starting with a modest-grit-size SiC paper, retaining these difficult

particles can be accomplished.

Abrasive/surface Lubricant

120 grit SiC paper*

240 grit SiC paper*

360 grit SiC paper

600 grit SiC paper

800 grit SiC paper

1200 grit SiC paper

1 um DIAMAT diamond on

GOLDPAD pad

0.05 um Nanometer alumina

on TRICOTE pad

* Recommended for Central Force holders (this step not required for Individual Force holders)

Water 5-10 lbs 200/200 rpm

Water 5-10 lbs 200/200 rpm

DIALUBE

Purple Extender

5-10 lbs 100/100 rpm 1 minute

FEMTO pressure

setting (psi)

5-10 lbs 200/200 rpm 2 minutes

Head / Wheel speed Time

Until plane

1 minute 1 minute

1 minute

1 minute

1 minute

1 minute

Nodular Cast Iron microstructure, Etchant 2%

Nital, Mag. 100X

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Graphite Cast Iron microstructure, Etchant 2%

Nital, Mag. 500X

38

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

CLASS 4 Polishing Procedures

5.11.4 Microelectronics

The microstructural preparation of electronic packages presents some very

difficult challenges, such as abrasives embedding in very soft solder joints,

edge rounding, polishing relief between very hard (ceramic) or brittle

(silicon) materials and the very soft plastic and metal solders. The use of

alumina lapping films are very useful for maintaining flatness and for

minimizing fractured abrasive embedding for non-ceramic substrates. For

specimens with ceramic substrates, diamond lapping films are recommended.

Abrasive/surface Lubricant

30 micron alumina lapping

film*

15 micron alumina lapping

film*

9 micron alumina lapping

film

6 micron alumina lapping

film

3 micron alumina lapping

film

1 um DIAMAT diamond on

ATLANTIS polishing pad

SIAMAT colloidal silica on a

MICROPAD polishing pad

* Recommended for Central Force holders (this step not required for Individual Force holders)

POLYLUBE

Extender

POLYLUBE

Extender

POLYLUBE

Extender

POLYLUBE

Extender

POLYLUBE

Extender

DIALUBE

Purple Extender

5-10 lbs 100/100 rpm 1 minute

FEMTO pressure

setting (psi)

5-10 lbs 100/100 rpm Until plane

5-10 lbs 100/100 rpm 1-2 minutes

5-10 lbs 100/100 rpm 1-2 minutes

5-10 lbs 100/100 rpm 1-2 minutes

5-10 lbs 100/100 rpm 1-2 minutes

5-10 lbs 100/100 rpm 1-2 minutes

Head / Wheel speed Time

Electronic die cross section

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Electronic die cross section

39

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

CLASS 5 Polishing Procedures

5.11.5 Stainless Steels

Stainless steels have high concentrations of chromium (>12%) and are

generally relatively soft as compared to heat treated steels. This makes

stainless steel more susceptible to smearing. Preparation is relatively

straight forward.

Abrasive/surface Lubricant

120 grit SiC paper*

240 grit SiC paper*

360 grit SiC paper

600 grit SiC paper

800 grit SiC paper

1200 grit SiC paper

1 um DIAMAT diamond on

GOLDPAD polishing pad

0.05 um Nanometer alumina

on TRICOTE polishing pad

* Recommended for Central Force holders (this step not required for Individual Force holders)

Water 5-10 lbs 200/200 rpm

Water 5-10 lbs 200/200 rpm

DIALUBE

Purple Extender

5-10 lbs 100/100 rpm 1 minute

FEMTO pressure

setting (psi)

5-10 lbs 200/200 rpm 2 minutes

Head / Wheel speed Time

Until plane

1 minute

1 minute

1 minute

1 minute

1 minute

431 Stainless Steel, mag. 400X, etched with Modified

Murakami's

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

300 Series Cast Stainless Steel, 200X (BF), Etchant

Oxalic Acid.

40

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

CLASS 6 Polishing Procedures

5.11.6 Super Alloys

Superalloys are high-performance alloys which exhibits excellent

mechanical strength and creep resistance at high temperatures,

good surface stability, and corrosion and oxidation resistance. The

base element in Superalloys are nickel, cobalt, nickel-iron.

Abrasive/surface Lubricant

120 grit SiC paper*

240 grit SiC paper*

360 grit SiC paper

600 grit SiC paper

9 um DIAMAT diamond on

POLYPAD polishing pad

6 um DIAMAT diamond on

TEXPAN polishing pad

1 um DIAMAT diamond on

GOLDPAD polishing pad

0.05 um Nanometer alumina

on TRICOTE polishing pad

* Recommended for Central Force holders (this step not required for Individual Force holders)

Water 5-10 lbs 200/200 rpm

Water 5-10 lbs 200/200 rpm

DIALUBE

Purple Extender

DIALUBE

Purple Extender

DIALUBE

Purple Extender

5-10 lbs 200/200 rpm 1 minute

FEMTO pressure

setting (psi)

5-10 lbs 200/200 rpm 2 minutes

5-10 lbs 200/200 rpm 2 minutes

5-10 lbs 200/200 rpm 2 minutes

Head / Wheel speed Time

Until plane

1 minute

1 minute

1 minute

Fe-Ni-Co-Al Alloy, 400X (Polarized Light)

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Nimonic 90, 400 X (DIC)

41

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

CLASS 7 Polishing Procedures

5.11.7 Thermal Spray Coatings

The metallographic specimen preparation of thermal spray coatings is

affected by the specimen composition and deposition conditions.

Microstructural features of interest include: porosity, flow, thickness and

inclusions. Proper metallurgical preparation takes into account that the

microstructure may be porous and perhaps somewhat brittle because of

inadequate processing.

Abrasive/surface Lubricant

180 grit SiC paper*

240 grit SiC paper*

320 grit SiC paper

400 grit SiC paper

600 grit SiC paper

800 grit SiC paper

1200 grit SiC paper

3 um DIAMAT diamond on

GOLDPAD polishing pad

1 um DIAMAT diamond on

ATLANTIS polishing pad

Final Polish on Vibratory Polisher using CMP polishing suspension and a MICROPAD polishing pad

* Recommended for Central Force holders (these steps are not required for Individual Force holders)

Water 5-10 lbs 200/200 rpm

Water 5 lbs 200/200 rpm

DIALUBE

Purple Extender

SIAMAT

Colloidal Silica

FEMTO pressure

setting (psi)

5 lbs 200/200 rpm 2 minutes

10 lbs 200/200 rpm 2 minutes

Head / Wheel speed Time

Until plane

1 minute

1 minute

1 minute

1 minute

1 minute

Nickel Chrome Coating, Mag 1000x (B.F.)

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

Nickel-Aluminum Coating, Mag 500x (B.F.)

42

NANO 1000T / FEMTO 1500

Polishing Head

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ INSTRUCTION MANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: pace@metallographic.com Web: http://www.metallographic.com

CLASS 8 Polishing Procedures

5.11.8 1095 Carbon Steel (Pearlite and Martensite

Phases) Preparation of high carbon steels is fairly straight-

forward. Depending upon the heat treatment, the grinding

and polishing times may increase for the harder martensite

phase.

Abrasive/surface Lubricant

120 grit SiC paper* Water 5 lbs 200/200 rpm Until plane

240 grit SiC paper

360 grit SiC paper

600 grit SiC paper

9 um DIAMAT diamond on

POLYPAD polishing pad

3 um DIAMAT diamond on

TEXPAN polishing pad

1 um DIAMAT diamond on

ATLANTIS polishing pad

0.05 um Nanometer alumina on

MICROPAD polishing pad

Water 5 lbs 200/200 rpm

DIALUBE

Purple Extender

DIALUBE

Purple Extender

DIALUBE

Purple Extender

5 lbs 100/100 rpm 30 seconds

FEMTO pressure

setting (psi)

5 lbs 200/200 rpm 3 minutes

5 lbs 200/200 rpm 3 minutes

5 lbs 200/200 rpm 2 minutes

Head / Wheel speed Time

1 minute

1 minute

1 minute

* Recommended for Central Force holders (this step not required for Individual Force holders)

1095 Steel, Furnace-Cooled, etched with

2% Nital, 400X B.F.

Microstructure: Pearlite structure