EXAMINED BY :

APPROVED BY

:

C

USTOMER

FILE NO

. CAS-0006502

EMERGING DISPLAY

ISSUE

: OCT.31, 2007

TECHNOLOGIES CORPORATION

TOTAL PAGE

VERSION

: 2

: 26

A

CCEPTANCE

S

PECIFICATIONS

MODEL NO. :

E T 0 2 4 0 0 6 D M U

FOR MESSRS :

(R oH S )

CUSTOMER'S APPROVAL

:

DATE

_____________________________

:

BY

_____________________________

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

R E C O R D S OF R E V I S I O N

D A T E

OCT.31, 2007 5 DELETE 5.2 PARALLEL INTERFACE CHARACTISTICS(6800-SERIES MPU)

11 8. BLOCK DIMENSION

REVISING THE ENTIRE PAGE

13,14 10. INTERFACE SIGNALS

REVISING THE ENTIRE PAGE

REVISED

PAGE

NO.

MODEL NO.

E T 0 2 4 0 0 6 D M U

DOC . FIRST ISSUE

S U M M A R Y

VERSION PAGE

2 0-1

OCT.23, 2007

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 0-2

T A B L E O F C O N T E N T S

NO. I T E M PAGE

===============================================================

1.

2. MECHANICAL SPECIFICATIONS

3.

4.

5. TIMING CHARACTERISTICS

6.

7.

8.

9. DETAIL DRAWING OF DOT MATRIX

10. INTERFACE SIGNAL

11. POWER SUPPLY

12. INSPECTION CRITERION

GENERAL SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

OPTICAL CHARACTERISTICS

OUTLINE DIMENSIONS

BLOCK DIMENSIONS

----------------------------------------------------

--------------------------------------------

---------------------------------------------

-------------------------------------------------

-------------------------------------------------------

------------------------------------------------

---------------------------------------

-------------------------------------

-------------------------------------

-------------------------------------

---------------------------------------

---------------------------------

1

1

2

3

4 ~ 6

7

8 , 9

10

11

12 , 13

14

15 ~ 26

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO.

E T 0 2 4 0 0 6 D M U

1. GENERAL SPECIFICATIONS

1 . 1 APPLICATION NOTES FOR CONTROLLER/DRIVER

PLEASE REFER TO :

H I M A X H X 8 3 4 7 - A

1 . 2 MATERIAL SAFETY DESCRIPTION

ASSEMBLIES SHALL COMPLY WITH EUROPEAN ROHS REQUIREMENTS,

INCLUDING PROHIBITED MATERIALS/COMPONENTS CONTAINING

LEAD,MERCURY, CADMIUM, HEXAVALENT CHROMIUM,

POLYBROMINATED BIPHENYLS (PBB) AND POLYBROMINATED

DIPHENYL ETHERS (PBDE)

2 . MECHANICAL SPECIFICATIONS

( 1 ) DISPLAY SIZE (inch)

( 2 ) NUMBER OF DOTS

( 3 ) MODULE SIZE

--------------------------------

---------------------------

--------------------------

2.4”

240W * (RGB) * 320H DOTS

42.72W * 60.26H * 3D mm

(WITHOUT FPC SIZE)

VERSION PAGE

2 1

( 4 ) ACTIVE AREA

( 5 ) DOT SIZE

( 6 ) PIXEL SIZE

( 7 ) LCD TYPE

( 8 ) COLOR

( 9 ) VIEWING DIRECTION

( 10 ) BACK LIGHT

---------------------------------

--------------------------------------

-------------------------------------

-----------------------------------

--------------------------------------

----------------------------------

-----------------------

36.72W * 48.96H mm (LCD)

0.051W * 0.153H mm

0.153W * 0.153H mm

TFT , TRANSMISSIVE

262K (18BIT)

12 O’CLOCK

LED , COLOR : WHITE

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 2

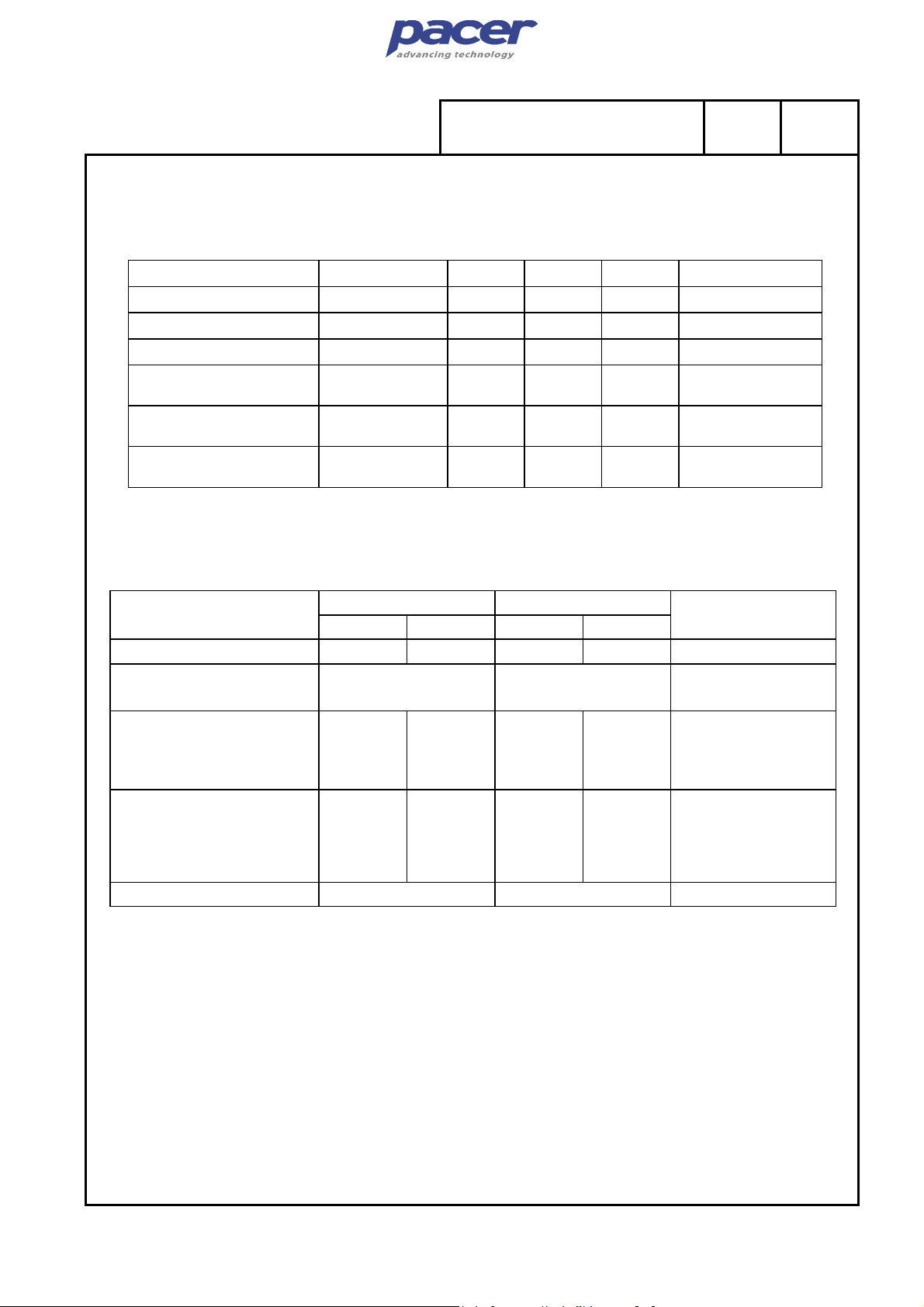

3 . ABSOLUTE MAXIMUM RATINGS

3 . 1 ELECTRICAL ABSOLUTE MAXIMUM RATINGS .

PARAMETER SYMBOL MIN. MAX. UNIT REMARK

INPUT POWER SUPPLY IOVCC/VCI -0.3 4.6 V

INPUT VOLTAGE V

STATIC ELECTRICITY

LED BACKLIGHT POWER

DISSIPATION

LED BACKLIGHT

FORWARD CURRENT

LED BACKLIGHT

REVERBE VOLTAGE

NOTE( 1 ) : LCM SHOULD BE GROUNDED DURING HANDING LCM.

- 0.3 VCI+0.3 V

I

⎯

PD

IF

VR

⎯

⎯

⎯

⎯

⎯

324 mW

90 mA

5 V

V NOTE ( 1 )

3 . 2 ENVIRONMENTAL ABSOLUTE MAXIMUM RATINGS .

OPERATING STORAGE

AMBIENT TEMPERATURE

HUMIDITY NOTE ( 4 ) NOTE ( 4 )

VIBRATION

SHOCK

CORROSIVE GAS NOT ACCEPTABLE NOT ACCEPTABLE

I T E M

MIN. MAX. MIN. MAX.

- 2 0 °C 7 0

⎯

⎯

C - 3 0 °C 8 0

°

( 3G)

2

2

⎯

⎯

2.45m/S

( 0.25G)

29.4 m/S

C

°

11.76m/S

( 1.2 G )

490m/S

( 50 G )

2

2

REMARK

NOTE ( 2 ), ( 3 )

WITHOUT

CONDENSATION

5~20Hz , 1HR

20~500Hz(20Hz) , 1HR

20~500Hz(500Hz) , 1HR

X,Y,Z,TOTAL 3HRS

10 m SECONDS

XYZ

DIRECTIONS

1 TIME EACH

NOTE ( 2 ) : Ta AT -30°C : 48HRS MAX .

80°C : 168HRS MAX .

NOTE ( 3 ) : BACKGROUND COLOR CHANGES SLIGHTLY DEPENDING ON AMBIENT

TEMPERATURE THIS PHENOMENON IS REVERSIBLE .

NOTE ( 4 ) : Ta ≤ 60°C : 90%RH (96HRS MAX .)

Ta > 60°C : ABSOLUTE HUMIDITY MUST BE LOWER THAN THE HUMIDITY OF

90%RH AT 60°C.(96 HRS MAX.)

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

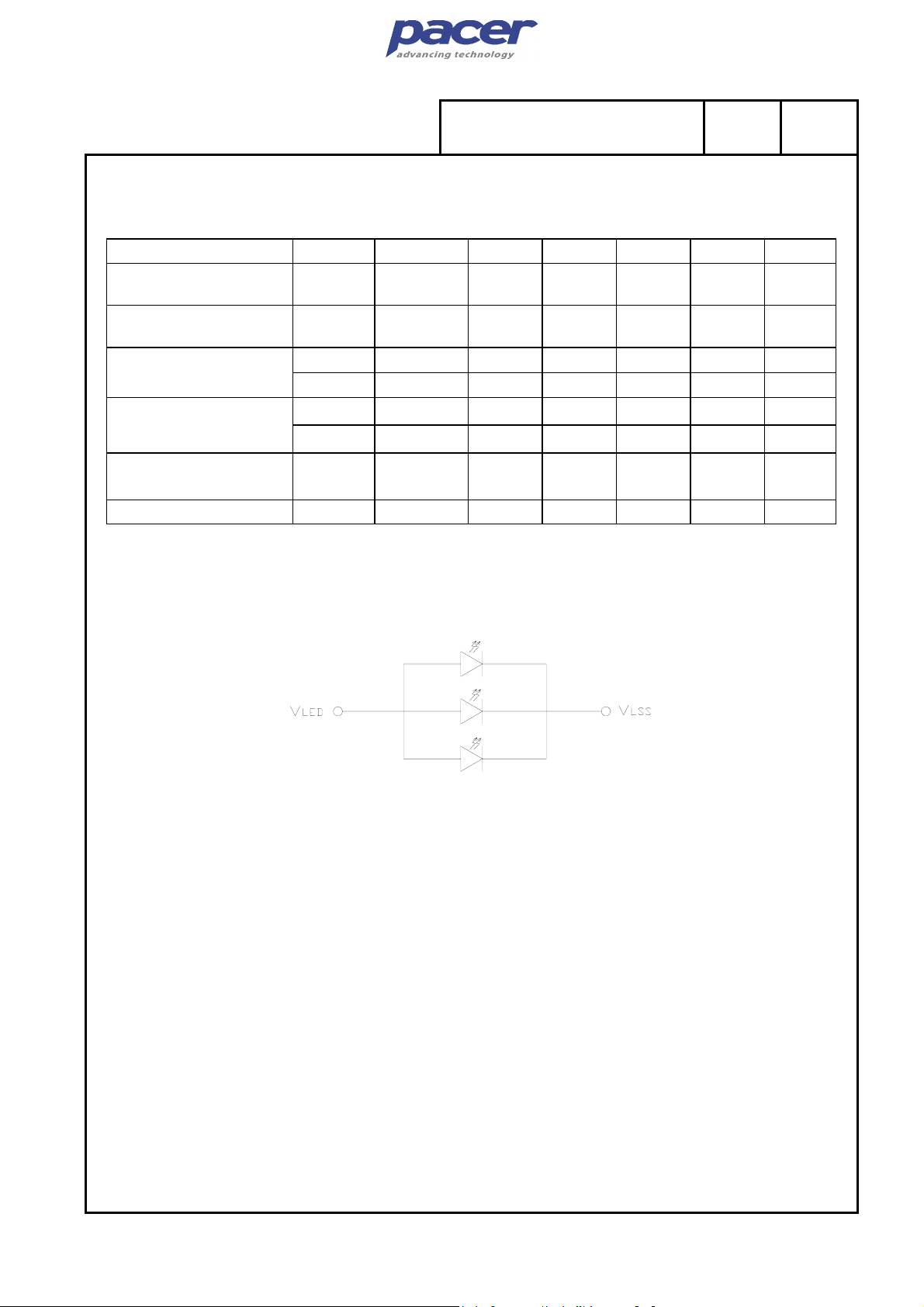

4 . ELECTRICAL CHARACTERISTICS

PARAMETER SYMBOL CONDITION MIN. TYP. MAX. UNIT REMARK

POWER SUPPLY FOR

ANALOG

POWER SUPPLY FOR

INTERFACE SIGNAL

V

INPUT VOLTAGE

NOTE ( 1 )

V

OUTPUT VOLTAGE

NOTE ( 1 )

OUTPUT CURRENT

NOTE (2)

VOLTAGE OF B/L VF IF = 60mA 3.0 3.3 3.6 V NOTE(3)

NOTE ( 1 ) : APPLIED TO TERMINALS , NRESET, D0~D17 , SDO ,SDI , RD_E , NWR_RNW ,

DNC_SCL ,TE.

NOTE ( 2 ) : IC : I

NOTE ( 3 ) : INTERNAL CIRCUIT DIAGRAM

VCI

+ I

IOVCC

VCI

I

OVCC

H LEVEL 0.8I

IH

VIL L LEVEL -0.3

H LEVEL 0.8I

OH

VOL L LEVEL

IC

MODEL NO.

⎯

⎯

⎯

E T 0 2 4 0 0 6 D M U

2.3 2.8 3.3 V

1.65 2.8 3.3 V

OVCC

OVCC

⎯

⎯

⎯

⎯

⎯

⎯

5 10 mA NOTE(2)

I

0.2 I

0.2 I

OVCC

OVCC

⎯

OVCC

VERSION PAGE

V

V

V

2 3

V

Ta = 25 °C

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

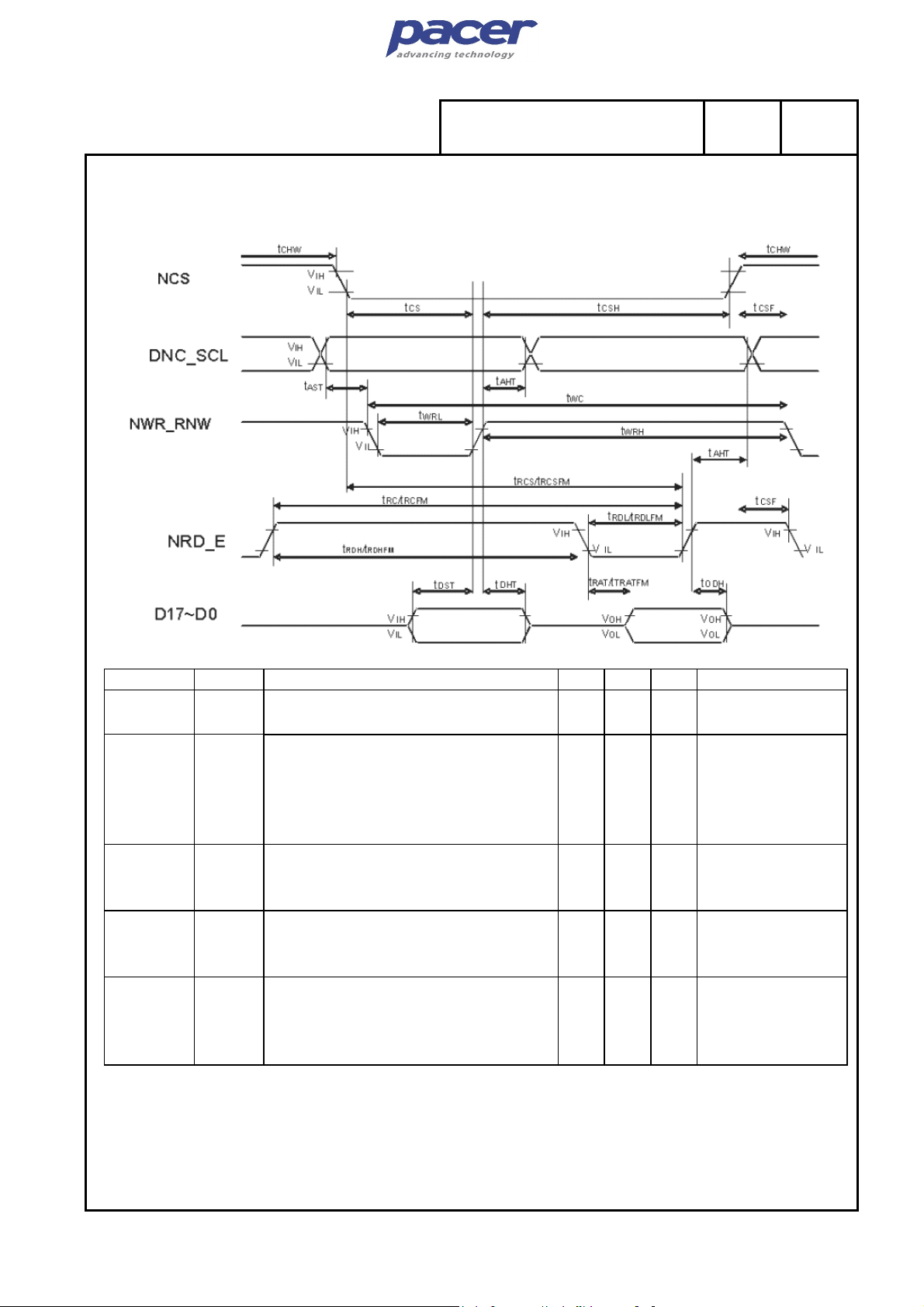

5 . TIMING CHARACTERISTICS

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 4

5.1 PARALLEL INTERFACE CHARACTISTICS (8080-SERIES MPU)

SIGNAL

DNC_SCL

NCS

NWR_RNW

NDR_E

D17 TO D0

SYMBOL

t

AST

t

AHT

t

CHW

t

CS

t

RCSFM

t

CSF

t

CSH

t

WC

t

WRH

t

WRL

t

DRCFM

t

RDHFM

t

RDLFM

t

DST

t

DHT

t

RATFM

t

ODH

PARAMETER

ADDRESS SETUP TIME

ADDRESS HOLD TIME (WRITE/READ)

CHIP SELECT “H” PULSE WIDTH

CHIP SELECT SETUP TIME(WRITE)

CHIP SELECT SETUP TIME

SHIP SELECT WAIT TIME(WRITE/READ)

CHIP SELECT HOLD TIME

WRITE CYCLE

CONTROL PULSE “H” DURATION

CONTROL PULSE “L“ DURATION

READ CYCLE

CONTROL PULSE “H“ DURATION

CONTROL PULSE ”L“ DURATION

DATA SETUP TIME

DATA HOLD TIME

READ ACCESS TIME

OUTPUT DISABLE TIME

MIN.

10

10

0

35

180

10

10

100

15

20

250

15

180

10

10

⎯

20

MAX.

TYP.

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

180

80

ns

ns

ns

ns

ns

DESCRIPTION

WHEN READ FROM

GRAM

FOR MAXIMUM

C

L = 30pF

FOR MINIMUM

L = 8pF

C

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 5

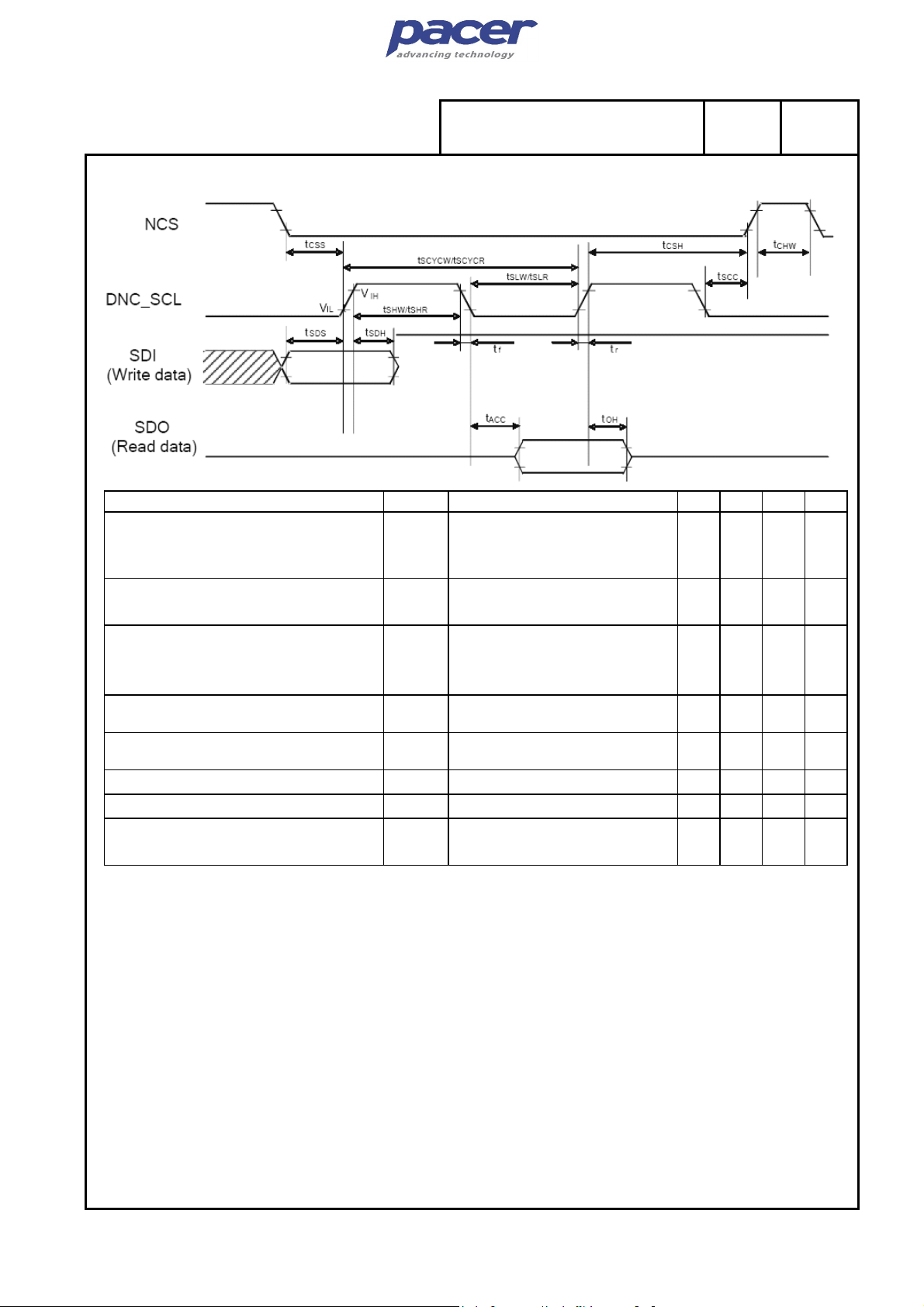

5.2 SERIAL INTERFACE CHARACTISTICS

SERIAL CLOCK CYCLE(WRITE)

DNC_SCL “H” PULSE WIDTH(WRITE)

DNC_SCL ”L” PULSE WIDTH ( WRITE)

DATA SETUP TIME(WRITE)

DATA HOLD TIME(WRITE)

SERIAL CLOCK CYCLE (READ)

DNC_SCL “H“ PULSE WIDTH (READ)

DNC_SCL ”L” PULSE WIDTH (READ)

ACCESS TIME

OUTPUT DISABLE TIME

DNC_SCL TO CHIP SELECT

NCS “H” PULSE WIDTH

CHIP SELECT SETUP TIME

CHIP SELECT HOLD TIME

PARAMETER

SYMBOL

t

SCYCW

t

SHW

t

SHW

t

SDS

t

SDH

t

SCYCR

t

SHR

t

SLR

t

ACC

tOH

t

SCC

t

CHW

t

CSS

t

CSH

CONDITIONS

DNC_SCL

SDI

DNC_SCL

SDO FOR MAXIMUM CL=30pF

FOR MINIMUM C

SDO FOR MAXIMUM CL=30pF

FOR MINIMUM C

DNC_SCL , NCS 50

NCS 45

NCS

L = 8pF

L = 8pF

MIN.

100

35

35

30

30

150

60

100

10

15

60

80

MAX.

TYP.

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯ ⎯

⎯ ⎯

⎯

⎯

UNIT

⎯

ns

⎯

⎯

⎯

ns

⎯

⎯

ns

⎯

⎯

100 ns

100 ns

ns

ns

⎯

ns

⎯

02101300-01-02

1

⎯

⎯

⎯

⎯

⎯

5

120

⎯

WHEN RESET

APPLIED DURING

STB MODE

WHEN RESET

APPLIED DURING

STB MODE

RESET GOES HIGH

LEVEL AFTER

POWER ON

VERSION PAGE

2 6

µ

⎯

UNIT

s

ms

ms

ms

⎯

⎯

MODEL NO.

E T 0 2 4 0 0 6 D M U

⎯

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

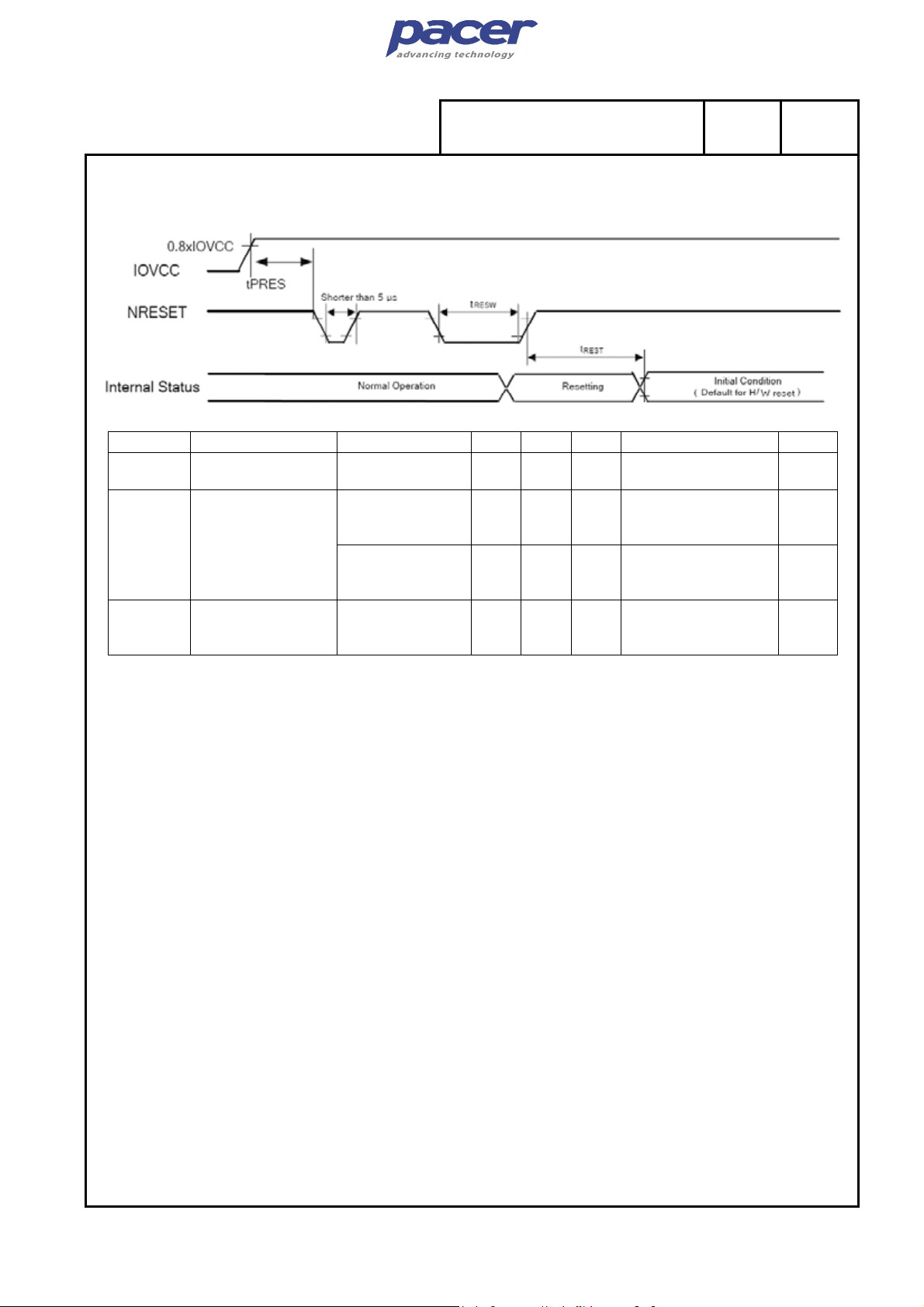

5.3 RESET INPUT TIMING

SYMBOL PARAMETER RELATED PINS MIN. TYP. MAX. NOTE

tRESW

tREST

tPRES

RESET LOW PULSE

WIDTH

RESET COMPLETE

RESET GOES HIGH

LEVEL AFTER

POWER ON TIME

TIME

(2)

(1)

NRESET 10

NRESET&

IOVCC

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

6 . OPTICAL CHARACTERISTICS NOTE ( 1 )

VIEWING

ANGLE

CONTRAST RATIO CR

t r ( rise )

RESPONSE TIME

THE BRIGHTNESS

OF MODULE

X

X

COLOR OF

CIE

X

COORDINATE

X

THE BRIGHTNESS OF

UNIFORMITY

NOTE (1) : TEST EQUIPMENT SETUP :

AFTER STABILIZING AND LEAVING THE PANEL ALONE AT A GIVEN TEMPERATURE FOR

30 MINUTES, THE MEASUREMENT SHOULD BE EXECUTED. MEASUREMENT SHOULD BE

EXECUTED IN A STABLE, WINDLESS , AND DARK ROOM. OPTICAL SPECIFICATIONS ARE

MEASURED BY TOPCON BM-7(FAST) WITH A VIEWING ANGLE OF 2° AT A DISTANCE OF

50cm AND NORMAL DIRECTION.

I T E M SYMBOL CONDITION MIN. TYP. MAX. UNIT REMARK

x+

HOR.

VER.

RED

GREEN

BLUE

WHITE

θ

x-

θ

y+

θ

y-

θ

t f ( fall )

B

0.587 0.617 0.647

R

YR 0.312 0.342 0.372

0.293 0.323 0.352

G

YG 0.571 0.601 0.631

0.112 0.142 0.172

B

YB 0.047 0.077 0.107

0.250 0.300 0.350

W

Y

W

⎯

MODEL NO

E T 0 2 4 0 0 6 D M U

y=0

CENTER

CR≥10

θ

θ

θ

IF = 60mA

θ

VIEWING

NORMAL ANGLE

θ

NTSC = 60%

θ

x=0

θ

x = θy = 0

x = θy = 0°

x = θy = 0°

x = θy = 0°

x = θy = 0°

⎯

.

60 65

°

35 40

60 65

°

25 30

200 250

°

⎯

⎯

250 300

0.270 0.320 0.370

70 75

10 20

20 30

VERSION PAGE

⎯

⎯

⎯

⎯

⎯

⎯

⎯

2 7

deg . NOTE(2)

NOTE(2)

ms NOTE(2)

2

cd/m

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

Ta = 2 5 °C

NOTE(3)

NOTE(3)

NOTE(4)

7)

NOTE (2) : PLEASE REFER TO 12.3 DEFINITION OF OPTICAL CHARACTERISTICS.

NOTE (3) : THE BRIGHTNESS TEST METHOD (BRIGHTNESS MEASURED WHEN LCD IS AT “ WHITE

STATE” )

○

ADD POWER TO LED, A、K PIN TEST POINT ARE

NOTE (4) : TNE BRIGHTNESS VNIFORMITY CALCULATE METHOD

⎡

−

1: UNIFORMITY ×

⎢

⎣

BRIGHTESS AVERAGE

BRIGHTESS MINIMUN - BRIGHTESS MAXIMUN

○

~

1

9

⎤

⎥

⎦

%100

02101300-01-02

E M E R G I N G D I S P L A Y

N

TECHNOLOGIES CORPORATION

7 . OUTLINE DIMENSIONS

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 8

UNIT : mm

SCALE : NTS

OT SPECIFIED TOLERANCE IS ± 0.3

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 9

DETAIL A

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

8 . BLOCK DIMENSION

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 10

02101300-01-02

N

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

9 . DETAIL DRAWING OF DOT MATRIX

MODEL NO

E T 0 2 4 0 0 6 D M U

36.72

0.153

0.051

R

G

B

0.153

R

G

B

.

VERSION PAGE

2 11

48.96

240(RGB)*320 DOTS

UNIT : mm

SCALE : NTS

OT SPECIFIED TOLERANCE IS ± 0.1

DOTS MATRIX TOLERANCE IS ± 0.01

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

10 . INTERFACE SIGNALS

MODEL NO

E T 0 2 4 0 0 6 D M U

.

PIN NO SYMBOL FUNCTION

1 VLED POWER SUPPLY FOR LED ( + )

2 VLSS POWER SUPPLY FOR LED ( - )

MAKER’S IDENTIFICATION(MAY ESTABLISH “H”, ”L” OR ”NC”)

IF THE CUSTOMER HAS MORE THAN TWO MAKERS WHO APPLIED

3 MAKER_ID

4 BS0

5 BS1

6 BS2

7 NRESET RESET

8 D17

9 D16

10 D15

11 D14

12 D13

13 D12

14 D11

15 D10

16 D9

17 D8

18 D7

19 D6

20 D5

21 D4

22 D3

23 D2

24 D1

25 D0

26 SDO

27 SDI

28 RD

29 WR

DIFFERENT S/W, CAN USE THIS PIN TO DETECT THE CODE BY THE MPU

AND DECIDE THE MAKER’S ID. MOST IMPORTANTLY, THE CUSTOMER

MUST DESIGN THIS PIN ON THE MAIN BOARD AS WELL AND LEAVE IT

OPEN AS NOT USED. NOTE:EDT MODULE’S SETTING IS “H”.

BS2 BS1 BS0 INTERFACE MODE

0 0 0 16-BIT BUS INTERFACE, 80-SYSTEM, 65K-COLOR

0 0 1

0 1 0

0 1 1 8-BIT BUS INTERFACE, 80-SYSTEM, 262K-COLOR

1 0 0

DATA BUS

8-BIT BUS:USE D7-D0 AND D17-D8 UNUSED

16-BIT BUS:USE D15-D0 AND D17-D16 UNUSED

18-BIT BUS:USE D17-D0

CONNECTED UNUSED PINS TO THE GND LEVEL

SERIAL INSTRUCTION DATA OUTPUT

IF NOT USE, LET IT TO OPEN

SERIAL INSTRUCTION DATA INPUT

IF NOT USE, LET IT CONNECTED TO IOVCC OR GND

READ SIGNAL AND READ DATA AT THE LOW LEVEL FIX IT TO IOVCC

OR GND WHEN USING SERIAL BUS INTERFACE

WRITE SIGNAL AND WRITES DATA AT RISING EDGE

FIX IT TO IOVCC OR GND WHEN USING SERIAL BUS INTERFACE

16-BIT BUS INTERFACE, 80-SYSTEM, 262KCOLOR

18-BIT BUS INTERFACE, 80-SYSTEM, 262KCOLOR

16-BIT BUS INTERFACE, 80-SYSTEM, 262KCOLOR

18-BIT BUS INTERFACE, 80-SYSTEM, 262K-

VERSION PAGE

2 12

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

E T 0 2 4 0 0 6 D M U

.

PIN NO SYMBOL FUNCTION

THE SIGNAL FOR COMMAND OR PARAMETER SELSECT NUDER PARALLEL

MOED(i.e. NOT SERIAL INTERFACE):

30 DNC_SCL

LOW:COMMAND

HIGH:PARAMETER

WHEN UNDER SERIAL INTERFACE, IT SERVERS AS SCL

31 NCS

32 TE

33 GND

34 IOVCC

35 VCI

36 NC

37 NC

38 NC

39 NC

40 NC

CHIP SELECT SIGNAL

TEARING EFFECT OUTPUT, IF NOT USED LET IT OPEN

GROUND

POWER SUPPLY FOR INTERFACE SIGAL

POWER SUPPLY FOR ANALOG

NOT CONNECTION

NOT CONNECTION

NOT CONNECTION

NOT CONNECTION

NOT CONNECTION

VERSION PAGE

2 13

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

1 1 . POWER SUPPLY

1 1 .1 POWER SUPPLY FOR LCM

VCI

MODEL NO.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 14

IOVCC

GND

VLED

VLSS

LCD MODULE

NOTE : IOVCC ≤ VCI

2.8V

2.8V

IF=60mA

VF=3.3V

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 15

12 . INSPECTION CRITERION

12.1 APPLICATION

THIS INSPECTION STANDARD IS TO BE APPLIED TO THE LCD MODULE

DELIVERED FROM EMERGING DISPLAY TECHNOLOGIES CORP.( E.D.T ) TO

CUSTOMERS

12.2 INSPECTION CONDITIONS

12.2.1

(2)VIEW ANGLE :

(1)OBSERVATION DISTANCE : 35CM±5CM

NON-OPERATION CONDITION:±5°

(PERPENDICULAR TO LCD PANEL SURFACE)

OPERATION CONDITION:±45°

(PERPENDICULAR TO LCD PANEL SURFACE)

12.2.2 ENVIRONMENT CONDITIONS :

ILLUMINATION

AMBIENT TEMPERATURE

AMBIENT HUMIDITY

AMBIENT

COSMETIC INSPECTION More than 600Lux

FUNCTIONAL INSPECTION 300~500 Lux

20°C~25°C

65±20%RH

12.2.3 INSPECTION LOT

QUANTITY PER DELIVERY LOT FOR EACH MODEL

12.2.4 INSPECTION METHOD

A SAMPLING INSPECTION SHALL BE MADE ACCORDING TO THE

FOLLOWING PROVISIONS TO JUDGE THE ACCEPTABILITY

(a)APPLICABLE STANDARD:MIL-STD-105E

NORMAL INSPECTION, SINGLE

SAMPLING LEVEL Ⅱ

(b)AQL:MAJOR DEFECT:AQL 0.65

MINOR DEFECT:AQL 2.5

TOTAL DEFFCTS:AQL 2.5

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

E T 0 2 4 0 0 6 D M U

.

12.3 DEFINITION OF OPTICAL CHARACTERISTICS

12.3.1

DEFINITION OF VIEWING ANGLE θx AND θy

VERSION PAGE

2 16

12.3.2 DEFINITION OF CONTRAST RATIO

"STATEWHITE"ATISLCDWHENMEASUREDBRIGHTNESS

)CR(RATIOCONTRAST =

"STATEBLACK"ATISLCDWHENMEASUREDBRIGHTNESS

12.3.3 DEFINITION OF RESPONSE TIME : (TR AND TF)

THE FIGURE BVELOW IS THE OUTPUT SIGNAL OF THE PHOTO

DETECTOR.

MEASURED AT THE CENTER AREA OF THE PANEL WHEN ALL THE INPUT

TERMINALS OF LCD PANEL ARE ELECTRICALLY OPENED.

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

E T 0 2 4 0 0 6 D M U

.

VERSION PAGE

2 17

12.4 INSPECTION STANDARDS

12.4.1 VISUAL DEFECTS CLASSIFICATION

TYPE OF DEFECT INSPECTION ITEM DEFECT FEATURE AQL

• DEFECT TO MISS SPECIFIED

DISPLAY FUNCTION , FOR ALL

1.DISPLAY ON

AND SPECIFIED DOTS

EX : DISCONNECTION , SHORT

CIRCUIT ETC

MAJOR DEFECT

2.BACKLIGHT

• NO LIGHT

• FLICKERING AND OTHER

0.65

ABNORMAL ILLUMINATION

3.DIMENSIONS

• SUBJECT TO INDIVIDUAL

ACCEPTANCE SPECIFICATIONS

• BLACK/WHITE SPOT

• BUBBLES ON POLARIZER

1.DISPLAY ZONE

• BLACK/WHITE LINE

• SCRATCH

• CONTAMINATION

• LEVER COLOR SPREED

2.BEZEL ZONE

• STAINS

• SCRATCHES

• FOREIGN MATTER

MINOR DEFECT

3.PCB

• CRACKS

• SCRATCHES

2.5

• STAINS

• INSUFFICIENT SOLDER

• SOLDERED IN INCORRECT

4.SOLDERING

POSITION

• CONVEX SOLDERING SPOT

• SOLDER BALLS

• SOLDER SCRAPS

5.DISPLAY ON

• LIGHT LINE

(ALL ON)

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 18

12.4.2 MODULE DEFECTS CLASSIFICATION

NO. ITEM CRITERIA

DISPLAY ON

1.

INSPECTION

(1)INCORRECT PATTERN

(2)MISSING SEGMENT

(3)DIM SEGMENT

(4)OPERATING VOLTAGE BEYOND SPEC

OVERALL

2.

DIMENSIONS

(1)OVERALL DIMENSION BEYOND SPEC

(1)INSPECTION PATTERN : FULL WHITE,FULL

BLACK,RED,GREEN AND BLUE SCREENS.

(2)

BLACK SPOT Ⅰ

3.

WHITE SPOT Ⅰ

ON-DISPLAY

DOT

DEFECT

BRIGHT DOT

DARK DOT

TOTAL DOT

MINIMUM DISTANCE

BETWEEN BRIGHT DOTS

MINIMUM DISTANCE

BETWEEN BRIGHT DOTS AND

DARK DOTS

MINIMUM DISTANCE

BETWEEN DARK DOTS

N≤3

N≤3

N≤3

L≥5mm

L≥5mm

L≥5mm

NOTE : THE DEFINITION OF DOT DEFECT:THE DOT

DEFECT WAS JUDGED AFTER REPAIR AND THE SIZE

OF A DEFECTIVE DOT OVER 1/2 OF WHOLE DOT IS

REGARDED AS ONE DEFECTIVE DOT.

(1)THE FOLLOWING BLACK LINE , WHITE LINE ARE

WITHIN THE VIEWING AREA .

LENGTH : L WIDTH : W PERMISSIBLE NO.

4.

WHITE LINE

ON-DISPLAY

3 < L

BLACK LINE

WIDTH : Wmm , LENGH : Lmm

L ≤ 0.5 W ≤ 0.1

0.5 < L ≤ 3 0.1 < W ≤ 0.5

0.5 ≤ W

IGNORE

3

NONE

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 19

NO. ITEM CRITERIA

BUBBLE

ON THE

POLARIZER

SURFACE STATUS

LINE SHAPE

L:LENGTH(mm)

DOT SHAPE

D:AVERAGE

DIAMETER(mm)

BUBBLES OF

POLARIZER

5.

/SURFACE STAINS

/DIRT/CF FAIL

/SPOT

CF FAIL / SPOT

NOTE : (1)POLARIZER BUBBLE IS DEFINED AS THE BUBBLE

APPEARS ON ACTIVE DISPLAY AREA. THE DEFECT OF

POLARIZER BUBBLE SHALL BE IGNORED IF THE

POLARIZER BUBBLE APPEARS ON THE OUTSIDE OF

ACTIVE DISPLAY AREA.

(2)THE EXTRANEOUS SUBSTANCE IS DEFINED AS IT CAN

BE OBSERVED WHEN THE MODULE IS POWER ON.

(3)THE DEFINITION OF AVERAGE DIAMETER ,D IS DEFINED

AS FOLLOWING.

AVERAGE DIAMETER(D)=(X+Y)/2 , WHERE

L ≤ 0.5, W ≤ 0.1

0.25 < D ≤ 0.5 N ≤ 5

0.1 < D ≤ 0.3mm N ≤ 3

0.1 < D ≤ 0.3mm N ≤ 3

X

0.5 < L ≤ 3

0.1< W ≤ 0.5

D ≤ 0.25

0.5 < D

D < 0.1 mm

D < 0.1 mm

NOTE

LGNORE

N ≤ 2

LGNORE

IGNORE

IGNORE

Y

SCRATCHES AND

6.

DENT ON GLASS

POLARIZER

UNEVEN COLOR

7.

SPREAD ,

COLORATION

BEZEL

8.

APPEARANCE

(1) PLS REFER TO THE ABOVE NO.3 AND 4 TO

DETERMINE SCRATCHES AND DENT ON POLARIZER

OR GLASS

(1)TO BE DETERMINED BASED UPON THE STANDARD

SAMPLE .

(1)BEZEL MAY NOT HAVE RUST ,BE DEFORMED OR HAVE

FINGER PRINTS STAINS OF OTHER CONTAMINATION .

(2)BEZEL MUST COMPLY WITH JOB SPECIFICATIONS .

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 20

NO. ITEM CRITERIA

(1)NO SOLDERING FOUND ON THE SPECIFIED PLACE

(2)INSUFFICENT SOLDER

(a)LSI , IC

A POOR WETTING OF SOLDER IS BETWEEN LOWER

BEND OR “HEEL” OF LEAD AND PAD

SOLDER FILLET

(b)CHIP COMPONENT

.SOLDER IS LESS THAN 50% OF SIDES AND FRONT

FACE WETTING

SOLDER FILLET

9. SOLDERING

1/2

• SOLDER WETS 3 SIDES OF TERMINAL , BUT LESS

THAN 25% OF SIDES AND FRONT SURFACE AREA ARE

COVERED

SOLDER

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 21

NO. ITEM CRITERIA

(3)PARTS ALIGMENT

(a)LSI , IC

LEAD WIDTH IS MORE THAN 50% BEYOND PAD

OUTLINE

9. SOLDERING

(b)CHIP COMPONENT

COMPONENT IS OFF CENTER , AND MORE THAN

50% OF THE LEADS IS OFF THE PAD OUTLINE

10. BACKLIGHT

(4)NO UNMELTED SOLDER PASTE MAY BE PRESENT

ON THE PCB.

(5)NO COLD SOLDER JOINTS , MISSING SOLDER

CONNECTIONS, OXIDATION OR ICICLE.

(6)NO RESIDUE OR SOLDER BALLS ON PCB.

(7)NO SHORT CIRCUITS IN COMPONENTS ON PCB.

(1)NO LIGHT

(2)FLICKERING AND OTHER ABNORMAL ILLUMINATION

(3)SPOTS OR SCRATCHES THAT APPEAR WHEN LIT

MUST BE JUDGED USING LCD SPOT , LINES AND

CONTAMINATION STANDARDS.

(4)BACKLIGHT DOESN’T LIGHT OR COLOR IS WRONG.

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

NO. ITEM CRITERIA

11. PCB , COB

GENERAL

12.

APPEARANCE

(1)COB SEAL MAY NOT HAVE PINHOLES LARGER THAN

0.2mm OR CONTAMINATION.

(2)COB SEAL SURFACE MAY NOT HAVE PINHOLES

THROUGH TO THE IC.

(3)THE HEIGHT OF THE COB SHOULD NOT EXCEED THE

HEIGHT INDICATED IN THE ASSEMBLY DIAGRAM.

(4)THERE MAY NOT BE MORE THAN 2mm OF SEALANT

OUTSIDE THE SEAL AREA ON THE PCB,AND THERE

SHOULD BE NO MORE THAN THREE PLACES.

(5)NO OXIDATION OR CONTAMINATION PCB TERMINALS

(6)PARTS ON PCB MUST BE THE SAME AS ON THE

PRODUCTION CHARACTERISTIC CHART.

THERE SHOULD BE NO WRONG PARTS , MISSING

PARTS OR EXCESS PARTS .

(7)THE JUMPER ON THE PCB SHOULD CONFORM TO THE

PRODUCT CHARACTERISTIC CHART.

(8)IF SOLDER GETS ON BEZEL TAB PADS,LED PAD,

ZEBRA PAD OR SCREW HOLD PAD,MAKE SURE IT IS

SMOOTHED DOWN .

(1)NO OXIDATION,CONTAMINATION,CURVES OR,BENDS

ON INTERFACE PIN (OLB) OF TCP.

(2)NO CRACKS ON INTERFACE PIN (OLB) OF TCP.

(3)NO CONTAMINATION, SOLDER RESIDUE OR SOLDER

BALLS ON PRODUCT.

(4)THE IC ON THE TCP MAY NOT BE DAMAGED, CIRCUITS.

(5)THE UPPERMOST EDGE OF THE PROTECTIVE STRIP ON

THE INTERFACE PIN MUST BE PRESENT OR LOOK AS

IF IT CAUSE THE INTERFACE PIN TO SEVER.

(6)THE RESIDUAL ROSIN OR TIN OIL OF SOLDERING

(COMPONENT OR CHIP COMPONENT) IS NOT BURNED

INTO BROWN OR BLACK COLOR.

(7)SEALANT ON TOP OF THE ITO CIRCUIT HAS NOT

HARDENED.

(8)PIN TYPE MUST MATCH TYPE IN SPECIFICATION

SHEET.

(9)LCD PIN LOOSE OR MISSING PINS.

(10)PRODUCT PACKAGING MUST THE SAME AS

SPECIFIED ON PACKAGING SPECIFICATION SHEET.

(11)PRODUCT DIMENSION AND STRUCTURE MUST

CONFORM TO PRODUCT SPECIFICATION SHEET.

(12)THE APPEARANCE OF HEAT SEAL SHOULD NOT

ADMIT ANY DIRT AND BREAK.

MODEL NO

E T 0 2 4 0 0 6 D M U

.

VERSION PAGE

2 22

02101300-01-02

b

b

b

b

b

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 23

NO. ITEM CRITERIA

THE LCD WITH EXTENSIVE CRACK IS NOT ACCEPTABLE

a b c

*W=DISTANCE BETWEEN

General glass chip :

a

c

≤ t/2 < VIEWING AREA ≤ 1/8X

t/2 > , ≤ 2t ≤ W/3 ≤ 1/8X

SEALANT AREA AND LCD

PANEL EDGE

w

c

X = LCD SIDE LENGTH

t = GLASS THICKNESS

a

c

a

a b c

13. CRACKED GLASS

Corner part :

c

b

≤ t/2 < VIEWING AREA ≤ 1/8X

> t/2 , ≤ 2t ≤ W/3 ≤ 1/8X

*W=DISTANCE BETWEEN

a

SEALANT AREA AND LCD

PANEL EDGE

X=LCD SIDE LENGTH

Y=GLASS THICKNESS

CHIP ON ELECTRODE PAD

a

c

a b c

≤ t ≤ 0.5mm ≤ 1/8X

* X=LCD SIDE WIDTH

t =GLASS THICKNESS

a b c

≤ t ≤ 1/8X ≤ L

*X=LCD SIDE WIDTH

t = GLASS THICKNESS

c

a

L=ELECTRODE PAD LENGTH

cIF GLASS CHIPPING THE ITO

TERMINAL , OVER 2/3 OF THE ITO

MUST REMAIN AND BE ,

INSPECTED ACCORDING TO

ELECTRODE TERMINAL

SPECIFICATIONS

dIF THE PRODUCT WILL BE HEAT

SEALED BY THE CUSTOMER , THE

ALIGNMENT MARK MUST NOT BE

DEMAGED

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

MODEL NO

E T 0 2 4 0 0 6 D M U

.

12.5 RELIABILITY TEST

12.5.1 STANDARD SPECIFICATIONS FOR RELIABILITY OF LCD MODULE

NO ITEM DESCRIPTION

HIGH TEMPERATURE

1

2

3

4

5

6

7

8

OPERATION

LOW TEMPERATURE

OPERATION

HIGH TEMPERATURE

STORAGE

LOW TEMPERATURE

STORAGE

HIGH TEMPERATURE /

HUMIDITY TEST

HIGH TEMPERATURE /

HIGH HUMIDITY

STORAGE

THERMAL SHOCK

( NOT OPERATED )

ESD

( ELECTROSTATIC

DISCHARGE )

THE SAMPLE SHOULD BE ALLOWED TO STAND AT +70°C FOR 240 hrs

THE SAMPLE SHOULD BE ALLOWED TO STAND AT -20°C FOR 240 hrs

THE SAMPLE SHOULD BE ALLOWED TO STAND AT +80°c FOR 240 hrs

THE SAMPLE SHOULD BE ALLOWED TO STAND AT -30°C FOR 240 hrs

THE SAMPLE SHOULD BE ALLOWED TO STAND AT 40°C, 90% RH

240 hrs

THE SAMPLE SHOULD BE ALLOWED TO STAND AT 40°C, 90% RH

240 hrs

THE SAMPLE SHOULD BE ALLOWED TO STAND THE FOLLOWING 10

CYCLES OF OPERATION :

-30°C FOR 30 MINUTES

+80°C FOR 30 MINUTES

AIR DISCHARGE ± 15KV

CONTACT DISCHARGE ± 8KV

VERSION PAGE

2 24

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

12.5.2 TESTING CONDITIONS AND INSPECTION CRITERIA

FOR THE FINAL TEST THE TESTING SAMPLE MUST BE STORED AT ROOM

TEMPERATURE FOR 24 HOURS, AFTER THE TESTS LISTED IN TABLE 6.2 ,

STANDARD SPECIFICATIONS FOR RELIABILITY HAVE BEEN EXECUTED IN

ORDER TO ENSURE STABILITY .

NO ITEM TEST MODEL INSPECTION CRITERIA

CURRENT

1

CONSUMPTION REFER TO SPECIFICATION

2 CONTRAST REFER TO SPECIFICATION

3 APPEARANCE VISUAL INSPECTION

12.5.3 LIFE TIME

FUNCTIONS , PERFORMANCE , APPEARANCE , ETC . SHALL BE FREE

FROM REMARKABLE DETERIORATION WITHIN 50,000 HOURS

UNDER ORDINARY OPERATING AND STORAGE CONDITIONS ROOM

LIFE TIME

NOTE : FROM OUR EXPERIENCE THE LIFE TIME OF HIGH HUMIDITY OPERATION AND HIGH

TEMPERATURE OPERATION AS ABOVE MENTIONED COULD BE ACHIEVED.

TEMPERATURE (25±10°C) , NORMAL HUMIDITY ( 45±20% RH ) , AND

IN AREA NOT EXPOSED TO DIRECT SUN LIGHT.

( LIFE TIME OF BACKLIGHT , PLEASE REFER TO DATA ABOUT

BACKLIGHT . )

MODEL NO

.

E T 0 2 4 0 0 6 D M U

THE CURRENT CONSUMPTION

SHOULD CONFORM TO THE PRODUCT

SPECIFICATION.

AFTER THE TESTS HAVE BEEN

EXECUTED , THE CONTRAST MUST BE

LARGER THAN HALF OF ITS INITIAL

VALUE PRIOR TO THE TESTS.

DEFECT FREE

VERSION PAGE

2 25

02101300-01-02

E M E R G I N G D I S P L A Y

TECHNOLOGIES CORPORATION

12.6 OPERATION

12.6.1 Do not connect or disconnect modules to or from the main system while

power is being supplied .

12.6.2 Use the module within specified temperature ; lower temperature causes the

retardation of blinking speed of the display ; higher temperature makes

overall display discolor . When the temperature returns to normality , the

display will operate normally .

12.6.3 Adjust the LC driving voltage to obtain the optimum contrast .

12.6.4 Power On Sequence input signals should not be supplied to LCD module

before power supply voltage is applied and reaches the specified value ( 5

±0.25v ) .

If above sequence is not followed , CMOS LSIs of LCD modules may be

damaged due to latch - up problem .

12.7 NOTICE

12.7.1 Use a grounded soldering iron when soldering connector I/O terminals . For

soldering or repairing , take precaution against the temperature of the soldering

iron and the soldering time to prevent peeling off the through-hole-pad .

12.7.2 Do not disassemble . EDT shall not be held responsible if the module is

disassembled and upon the reassembly the module failed .

12.7.3 Do not charge static electricity , as the circuit of this module

contains CMOS LSIs. A workman's body should always be static-protected by

use of an ESD STRAP . Working clothes for such personnel should be of

static-protected material .

12.7.4 Always ground the electrically-powered driver before using it to install the

LCD module . While cleaning the work station by vacuum cleaner , do not

bring the sucking mouth near the module ; static electricity of the electricallypowered driver or the vacuum cleaner may destroy the module .

12.7.5 Don’t give external shock.

12.7.6 Don’t apply excessive force on the surface.

12.7.7 Liquid in LCD is hazardous substance .Must not lick and swallow.

When the liquid is attach to your,skin,cloth etc.wash it out thoroughly and

immediately.

12.7.8 Don’t operate it above the absolute maximum rating.

12.7.9 Storage in a clean environment , free from dust,active gas,and

solvent.

12.7.10 Store without any physical load.

12.7.11 Rewiring : no more than 3 times .

MODEL NO

.

E T 0 2 4 0 0 6 D M U

VERSION PAGE

2 26

02101300-01-02

Loading...

Loading...