UTILITY RIG RACK

PACE EDWARDS RETRACTABLE HARD TRUCK BED COVER & UTILITY RACK SYSTEM

STANDARD INSTALLATION INSTRUCTIONS

IMPORTANT! The Pace Edwards truck bed cover and Explorer Series Rails

MUST be installed on the truck fi rst before attempting to install this rack system!

(800) 338-3697

www.paceedwards.com

Pace Edwards Company

2400 Commercial Blvd.

Centralia WA 98531

*Flip over for Contractor Rig Rack instructions

Tools Required for Assembly.........................................2

Before Y ou Start ...........................................................2

Utility Rack Illustration...................................................2

Packaging Contents .....................................................3

STEP 1: Install Side Stops ...........................................4

STEP 2: Assemble legs & gussets ..............................4

STEP 3: Assemble Crossmembers..............................4

STEP 4: Assemble Crossmembers, Legs & Braces.....5

STEP 5: Install Truss Mounts on Explrer Series Rails..5

STEP 6: Install Pickup Trusses on Truss mounts ........5

TABLE OF CONTENTS

Part #: UR-CR Rack-INSTALL 048

TOOLS REQUIRED FOR ASSEMBLY:

9/16” wrench or socket

1/2” open ended wrench

Flat clean surface (such as card board paper or plastic

Silicone sealant (if necessary)

BEFORE YOU START:

Read the instructions carefully before you start. These instructions are written for one-person installation. We

have noted where briefl y having an extra person’s assistance can make installation easier. If you have questions

regarding the installation please call our Technical Support Line at (800) 338-3697.

IMPORTANT! The Pace Edwards truck bed cover and Explorer Series Rails

MUST be installed on the truck fi rst before attempting to install this rack system!

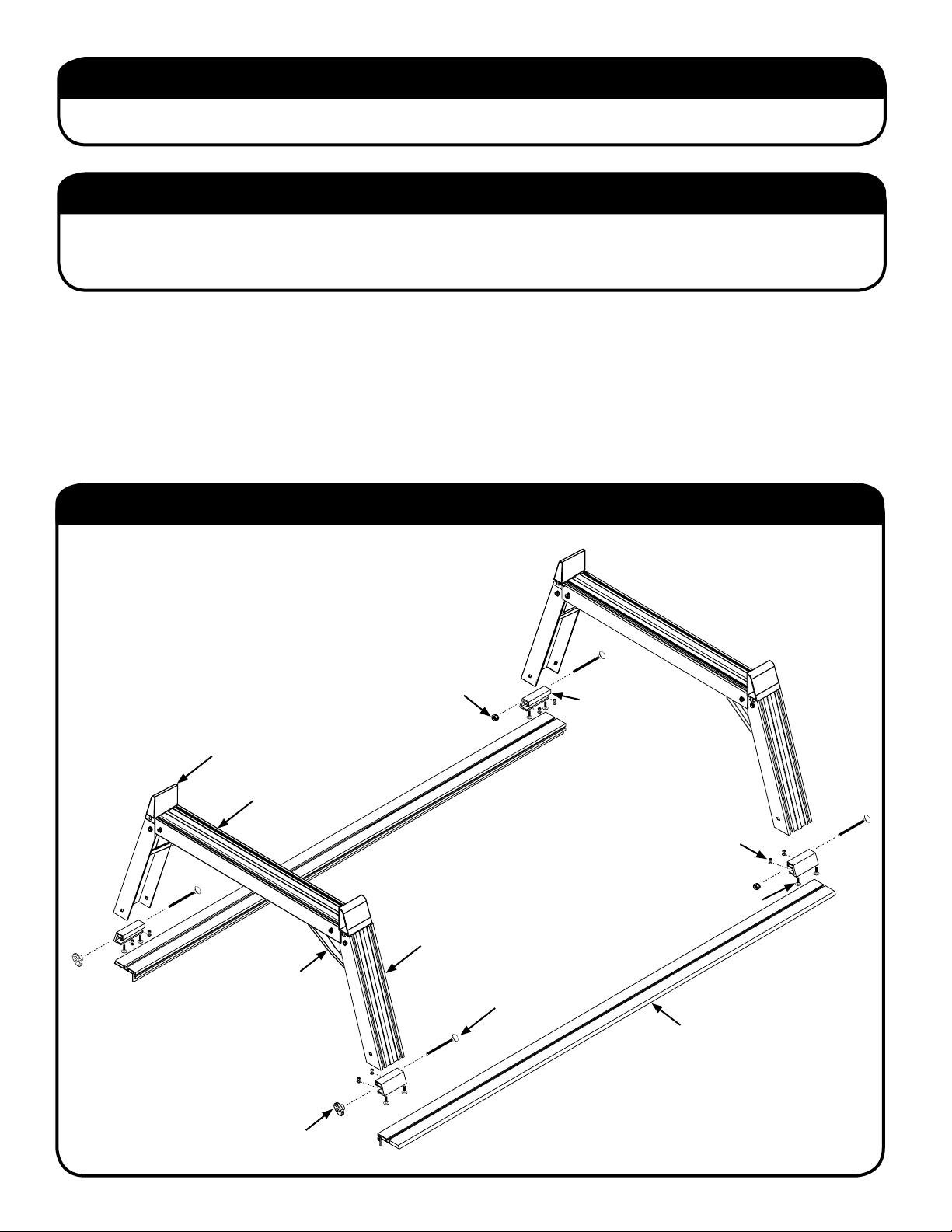

UTILITY RIG RACK ILLUSTRATION:

SIDE STOPS (x4)

TRUSS CROSSMEMBER (x2)

3/8” LOCK NUT (x12)

5/16” STAINLESS LOCK

WASHERS & NUTS (x16)

1” CARRIAGE BOLTS (x16)

LEGS (x4)

BRACES (x 4)

5” CARRIAGE BOLTS (x 12)

EXPLORER SERIES RAIL

(ORDERED SEPARATELY

WITH TRUCK BED COVER)

3/8” KNOB (x2)

2

UTILITY RIG RACK

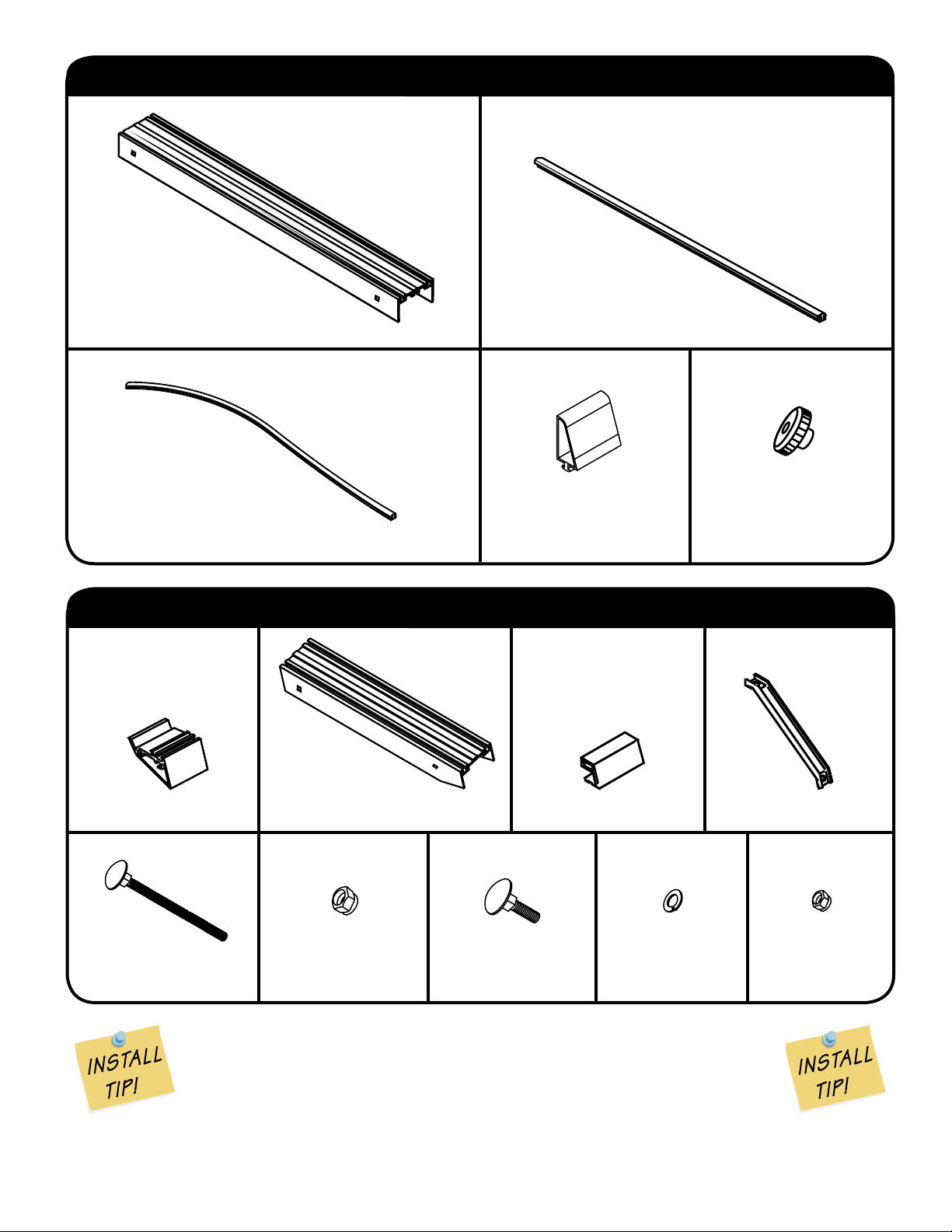

UTILITY RIG CROSSMEMBER BOX CONTENTS:

TRUSS CROSSMEMBER (x2) REAR CROSSMEMBER TRUSS

PLASTIC LOW FRICTION INSERT (x1)

CROSSMEMBER TRUSS RUBBER

ANTI-WEAR INSERTS (x2)

UTILITY RIG LEG BOX CONTENTS:

TRUSS MOUNTS (x4)

3/8” KNOB (x2)SIDE STOPS (x4)

5” CARRIAGE BOLTS (x 12)

A General Note on Assembly:

These parts have been precision cut to tolerances as close as one thousandth of an

inch. Some fi ts are designed to be press fi ts, others are designed to be sliding fi ts; but

nowhere should the use of great force be required for assembly. As with any piece

of machined equipment, if a part is not fi tting as it should, don’t use excessive force,

identify the problem and correct it. An initial misalignment of two parts can cause a burr

on one of them and make smooth assembly diffi cult.

INSTALLATION INSTRUCTIONS

LEGS (x4) BRACES (x 4)GUSSETS (x 4)

3/8” LOCK NUT (x12)

1” CARRIAGE

BOLTS (x16)

TRUSS MOUNTS (x4)

5/16” STAINLESS

LOCK WASHERS

(x16)

5/16” STAINLESS

LOCK NUTS (x16)

3

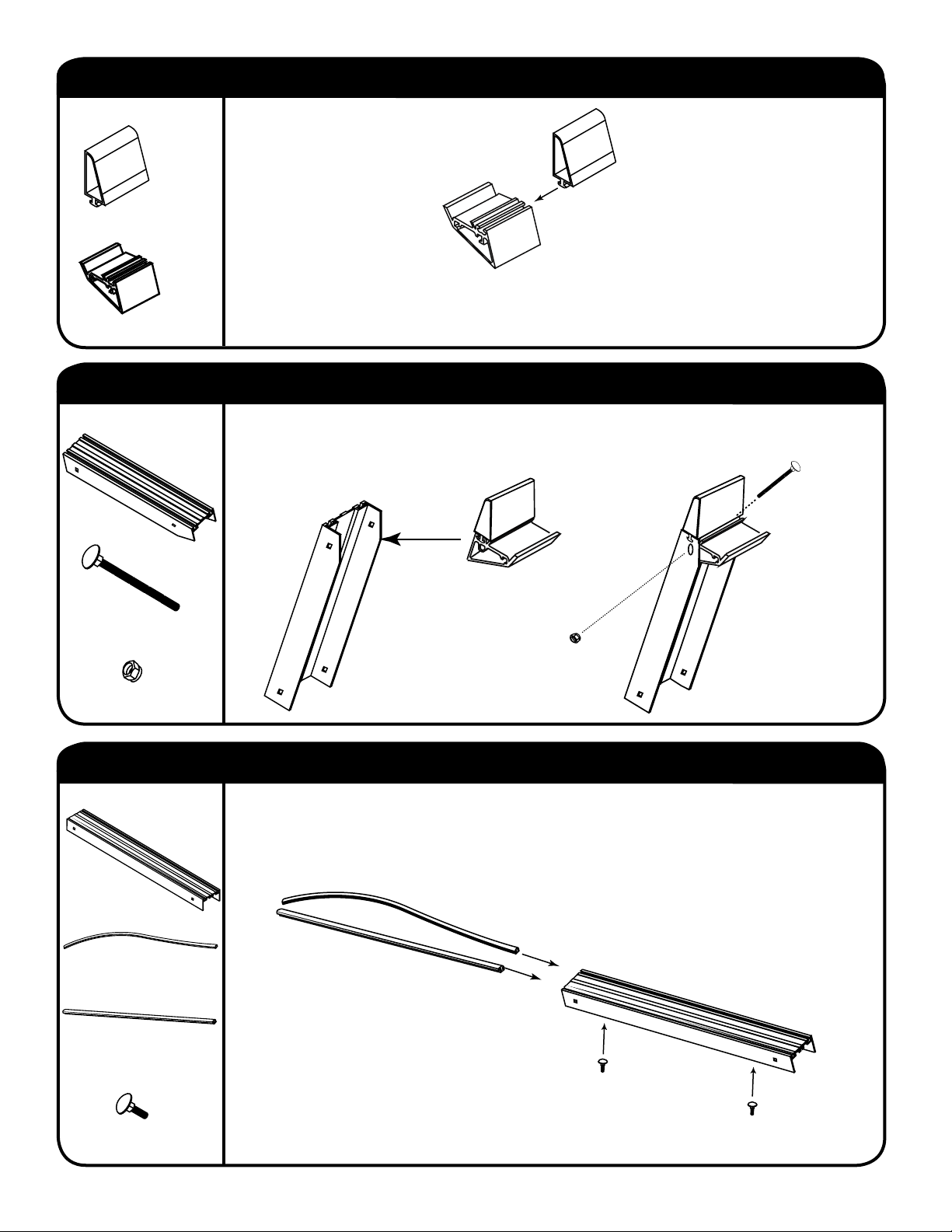

STEP 1: INSTALL SIDE STOPS

HARDWARE USED:

SIDE STOPS x 4

NOTE: To prevent Side Stops from the possibility of rattling, inject some silicone sealant

GUSSET x 4

into the T-slot of the gusset before inserting Side Stop.

STEP 2: ASSEMBLE LEGS & GUSSETS

HARDWARE USED:

Install gussets into legs as shown until holes align, then slide the 5” carriage bolts through

the holes. Install the 3/8” lock nuts on the 5” carriage bolts and tighten with a 9/16” wrench

until they bear lightly (do not tighten yet) on the aluminum surface.

LEGS x 4

5” CARRIAGE BOLTS x 4

3/8” LOCK NUTS x 4

STEP 3: ASSEMBLE CROSSMEMBERS

HARDWARE USED:

Slide a rubber anti-wear insert into the forward T -slot of each crossmember and slide a plastic

low-friction insert into the REAR T-slot on the REAR crossmember. Slide 2 small carriage

bolts (to be used for braces) into the T-slot on the underside of each crossmember.

TRUSS CROSSMEMBER (x2)

CROSSMEMBER

TRUSS RUBBER ANTIWEAR INSERTS (x2)

REAR CROSSMEMBER

TRUSS PLASTIC LOW

FRICTION INSERT (x1)

1” CARRIAGE BOLTS x 4

4

Plastic insert goes in REAR

T-slot of REAR truss ONLY!

UTILITY RIG RACK

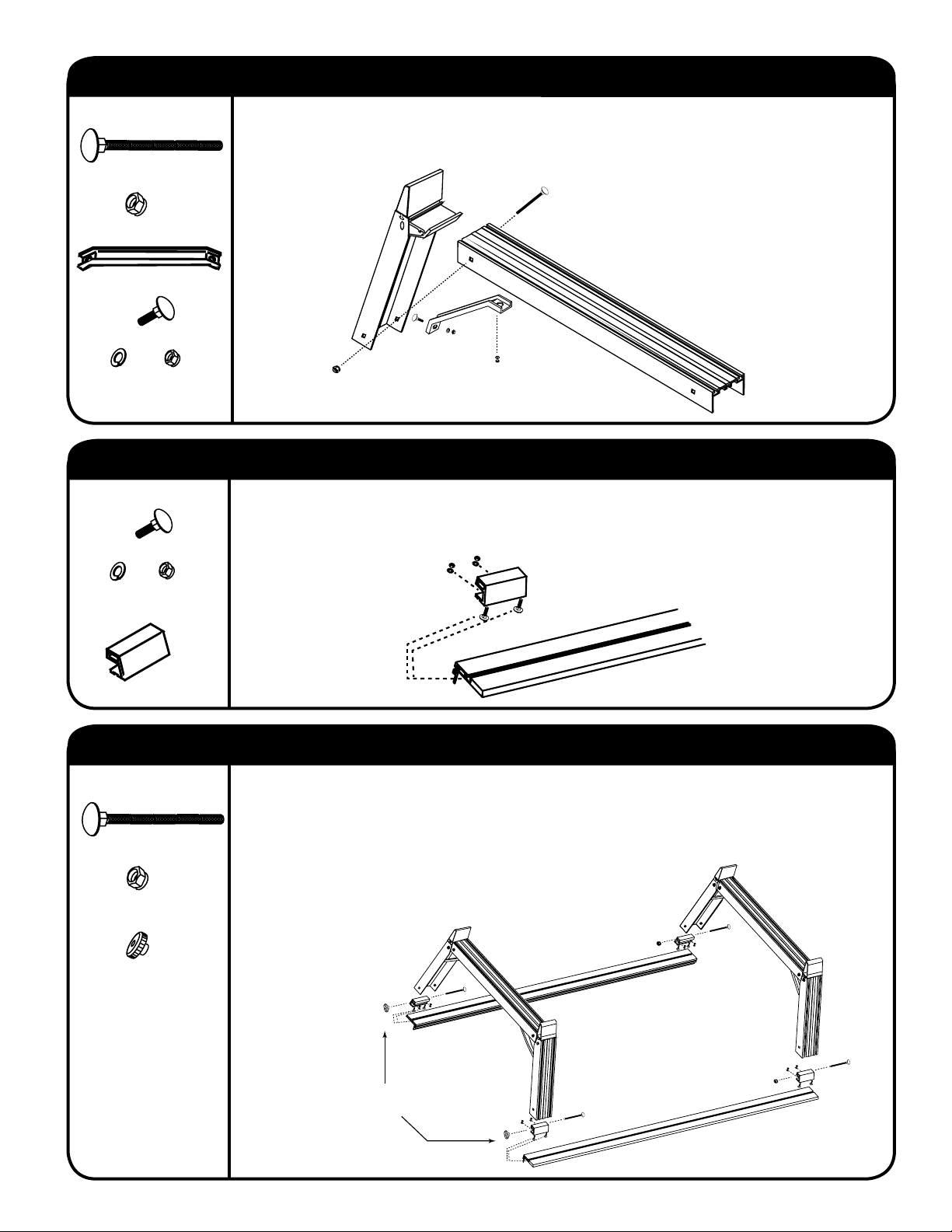

STEP 4: ASSEMBLE CROSSMEMBERS, LEGS & BRACES

HARDWARE USED:

Install crossmember on gusset as shown, and fasten loosely with 5” long carriage bolts and

3/8” locknuts. Slide a small carriage bolt into the inside T -slot of the leg and install the brace

between the leg and the crossmember using nuts and lock washers.

5” CARRIAGE BOLTS (x 4)

3/8” LOCK NUT (x 4)

BRACES (x 4)

1” CARRIAGE BOLTS (x 4)

5/16” STAINLESS LOCK

WASHERS & NUTS (x 8)

STEP 5: INSTALL TRUSS MOUNTS ON EXPLORER SERIES RAILS

HARDWARE USED:

1” CARRIAGE BOLTS (x 8)

Slide two 1” carriage bolts into the upper T-slots on each end of both Rails. Place a truss

mount on each of the bolt pairs (truss mount should be leaning inward as shown), positioning

the mounts 1/8” in from the ends of the rails. Install lock washers and nuts and tighten with

a 1/2” open end wrench.

5/16” STAINLESS LOCK

WASHERS & NUTS (x 8)

TRUSS MOUNTS (x4)

STEP 6: INSTALL PICKUP TRUSSES ON TRUSS MOUNTS

HARDWARE USED:

5” CARRIAGE BOLTS (x 4)

3/8” LOCK NUT (x 2)

3/8” KNOB (x2)

Lower the truss onto the truss mounts and slide the 5” long carriage bolts through the leg and

mount. Install nuts and tighten with a 9/16” wrench until they bear LIGHTL Y on the aluminum

surface. Make sure that the truss is centered on the rails and that the visible joint between the

leg and crossmember is as tight as possible, then tighten all 5” carriage bolts fi rmly. Note that

the truss mount has an elongated hole for side-to-side adjustment of the truss legs. Tighten

the nuts and knobs that secure the braces

INSTALLATION INSTRUCTIONS

UTILITY RIGS USE 3/8”

KNOBS ON REAR TRUSS

5

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK

2

INSTALLATION INSTRUCTIONS

height within the side rails of the rack

No warranty is made about the suitability of this product for any purpose other than securing ladders. Keep cargo

away from sharp or hot surfaces. CHECK TENSION FREQUENTLY - STRAPS STRETCH AND LOADS SETTLE.

washers are securely in place and that parts move freely . Keep at least 2 wraps of strap around mandrel. Keep strap

Inspect strap and winch assembly before each use and replace if worn or damaged. Make sure that the cotter pin and

It is a recommended industry standard that the working load not exceed 1/3 of the rated capacity or 400 lbs.

The Work Winch has a rated capacity of 1200 lbs. This is the load the complete assembly will withstand before failure.

REMEMBER TO CHECK STRAP TENSION FREQUENTLY BECAUSE STRAPS STRETCH AND LOADS SETTLE.

and tighten using the handle. Do not over tighten as the handle has been designed to slip on the hex if it is over-stressed.

engage the hook on the underside of the 2 1/2” tall lip of the crossmember. Take up the slack by rotating the hand wheel

To secure a load, let the handle hang freely, lift the pawl and pull out enough strap to go over the load. For pickup trucks,

OPERATION & CAUTIONS

STRAP AROUND MANDREL

KEEP AT LEAST 2 WRAPS OF

END THRU MANDREL

INSERT 6” OF STRAP

RIG GUSSET

CONTRACTOR

ORIENTATION

CORRECT STRAP

RIGHT HAND WINCH INSTALLATION

STRAP AROUND MANDREL

KEEP AT LEAST 2 WRAPS OF

END THRU MANDREL

INSERT 6” OF STRAP

RIG GUSSET

CONTRACTOR

ORIENTATION

CORRECT STRAP

LEFT HAND WINCH INSTALLATION

away from you. The hook end of the strap should come up on the outside of the coil from underneath.

careful attention to the orientation of both the pawl and the strap. The pawl looks like a dolphin and its nose faces

Work Winches can be installed form either the left side or the right side of Contractor Rig gussets and brackets. Pay

STEP 3: INSTALLATION DETAIL & DRAWING

WORK WINCH

Suggested park position for handle

1

the pawl.

within it). If the pawl is installed correctly, this is the only direction you will be able to turn the winch without lifting

you (If the handle has been installed, disengage it from its upper position and let it hang freely so the hex can rotate

Insert 6” of the strap end into the slot in the mandrel and wind in a direction so that the top of the spool comes toward

STEP 2: INSTALL THE STRAP

If handle is to be kept on winch shaft, engage as shown to prevent swinging and wear

the lynch pin and lock it.

over the hex, install the smaller washer and then insert

accessible place. If it is to be installed, place the handle

The handle can be installed or left in a tool box or other

with a pair of pliers.

onto the winch take-up wheel and spread the cotter pin

the other large washer and then the cotter pin. Hold

Slide the winch the rest of the way into the hole. Install

winch shaft.

pin through the pawl and into the small hole above the

its nose is facing away from you and slide the 2” clevis

Orient the pawl (which is shaped like a dolphin) so that

halfway into the hole in the gusset.

Then install the PVC bearing, then insert the assembly

Slide 1 of the 2 large washers onto the winch shaft.

LYNCH PIN (x 4)

STEP 1: INSTALL WORK WINCH IN GUSSET

SMALL WASHER (x4)HANDLE (x4)LARGE WASHER (x8)PVC BEARING (x 4)

PAWL (x4)

CLEVIS PIN (x4)

STRAP (x4) COTTER PIN (x 4)WINCH SHAFT (x 4)

WORK WINCH BOX CONTENTS:

or it can be installed with the winch on the left and the handle on the right (a mirror image).

Winches are included with the Contractor Rig Rack and can be installed with the winch on the right and handle on the left

The Work Winch is installed on Contractor Rig rack after the entire rack has been assembled and installed. 4 Work

STANDARD INSTALLATION INSTRUCTIONS

™

INTEGRATED TIE-DOWN SYSTEM (INCLUDED WITH CONTRACTOR RIG RACK)

WORK WINCH

INSTALLATION INSTRUCTIONS 7

CROSSMEMBER

EXTENSION BEAM TAB FITS INSIDE

REAR FRONT

NUTS (x 8)

5/16” STAINLESS

on some models due to a tapering truck body.

WASHERS (x 8)

5/16” STAINLESS LOCK

experience some degree of effort installing the Extension Beam over the bolt on the front truss

Complete the installation of the Extension Beam (which was left loose). It is normal to

install lock washers & nuts and tighten.

are seated and install a 1” carriage bolt downward through each end of the crossmember, then

1” CARRIAGE BOLTS (x 8)

is helpful in crossmember assembly). Make sure the Extension Beam and the crossmember

tab of the Extension Beam inside the crossmember (lifting unbolted end of the Extension Beam

side of the truck, hand the correct end of the crossmember over (see drawing) and insert the

Install the rubber wear strip in the crossmember. With the aid of another person on the opposite

HARDWARE USED:

STEP 9: INSTALL CROSSMEMBER

CONTRACTOR RIG RACK 6

assemble the crossmember.

the forward end slightly off the front truss to

on the rear Truss only, as you will need to lift

side and loosely install a lock washer and nut

Set the other Extension Beam on the opposite

NUTS (x 8)

5/16” STAINLESS

these two Extension Beam mounting bolts.

Install lock washers and nuts and tighten

Truss.

WASHERS (x 8)

5/16” STAINLESS LOCK

of the beam with the rear surface of the rear

(notched end goes in front), aligning the end

Mount one Extension Beam on the Trusses

HARDWARE USED:

STEP 9: INSTALL EXTENSION BEAMS ON TRUSSES

DECAL

bubbles, creases etc.

with just as much “grip” as the dry method would but without the risk of misalignment,

positioned, force out excess water with fi ngers or a sponge. The decal will ultimately adhere

wet method allows you to slide the decal around to position it correctly. When correctly

Extension Beam and apply the decal centered between holes over the splice joint. This

DECALS (x2)

PARALLELOGRAM

of dish washing liquid to a glass of water, pull off the decal backing, wet the decal and the

can be installed dry, the “wet method” makes the job much easier. Just add 10 or 12 drops

(800)338-3697

Position the decal accurately so that it repeats the punched hole pattern. Although the decal

holes do!

HARDWARE USED: Important! There are left and right decals! Decal leans forward just like Extension Beam

STEP 8: INSTALL DECAL OVER SPLICE JOINTS

3/8” STAINLESS NUT (x4)

WASHERS (x8)

3/8” STAINLESS LOCK

WASHERS (x4)

3/8” STAINLESS FLAT

then tighten nuts. Repeat the procedure for the remaining Extension Beam.

the other hole, align Extension Beam halves so that the outside surfaces meet smoothly, and

then install a fl at washer, then lock washer, then nut, in that order. Repeat the procedure for

blocks align. Slide a 3/8” fl at washer on the 4” bolt and insert the bolt through the splice blocks,

end to end so that the welded-in splice blocks touch each other and the holes in the splice

Locate a matching pair of Extension Beams (all holes leaning the same way) and place them

Beams (ie. cardboard, paper, plastic).

You will need a smooth clean surface where you can bolt together the halves of the Extension

BOLTS (x 4)

4-3/8” STAINLESS

HARDWARE USED:

STEP 7: ASSEMBLE EXTENSION BEAM HALVES

5

INSTALLATION INSTRUCTIONS

that secure the braces

the nuts and knobs

of the truss legs. Tighten

for side-to-side adjustment

mount has an elongated hole

3/8” LOCK NUT (x 4)

bolts fi rmly. Note that the truss

is as tight as possible, then tighten all 5” carriage

rails and that the visible joint between the leg and crossmember

5” CARRIAGE BOLTS (x 4)

aluminum surface. Make sure that the truss is centered on the

tighten with a 9/16” wrench until they bear LIGHTLY on the

carriage bolts through the leg and mount. Install nuts and

Lower the truss onto the truss mounts and slide the 5” long

HARDWARE USED:

STEP 6: INSTALL PICKUP TRUSSES ON TRUSS MOUNTS

open end wrench.

lock washers and nuts and tighten with a 1/2”

mounts 1/8” in from the ends of the rails. Install

be leaning inward as shown), positioning the

on each of the bolt pairs (truss mount should

on each end of both Rails. Place a truss mount

TRUSS MOUNTS (x4)

Slide two 1” carriage bolts into the upper T-slots

using nuts and lock washers.

into the inside T-slot of the leg and install the brace between the leg and the crossmember

Slide 2 small carriage bolts into the T -slot at the bottom of the gusset and slide 1 carriage bolt

CROSSMEMBER ONL Y!

HANDLE & KNOB ON REAR

WASHERS & NUTS (x 8)

5/16” STAINLESS LOCK

1” CARRIAGE BOLTS (x 8)

HARDWARE USED:

STEP 5: INSTALL TRUSS MOUNTS ON EXPLORER SERIES RAILS

5/16” KNOB (x2)

HANDLES (x2)

3/8” ADJUSTABLE

WASHERS & NUTS (x 12)

5/16” STAINLESS LOCK

1” CARRIAGE BOLTS (x 12)

BRACES (x 4)

3/8” LOCK NUT (x 2)

crossmember.

5” CARRIAGE BOLTS (x 4)

provided in the crossmember box. Use the 5/16” knob to fasten the brace under the rear

3/8” locknuts. For the rear crossmember of Contractor Rigs use the 2 adjustable handles

Install crossmember on gusset as shown, and fasten loosely with 5” long carriage bolts and

HARDWARE USED:

STEP 4: ASSEMBLE CROSSMEMBERS, LEGS & BRACES

CONTRACTOR RIG RACK

4

1” CARRIAGE BOLTS x 4

T-slot of REAR truss ONLY!

Plastic insert goes in REAR

bolts (to be used for braces) into the T-slot on the underside of each crossmember.

low-friction insert into the REAR T-slot on the REAR crossmember. Slide 2 small carriage

Slide a rubber anti-wear insert into the forward T -slot of each crossmember and slide a plastic

FRICTION INSERT (x1)

TRUSS PLASTIC LOW

REAR CROSSMEMBER

WEAR INSERTS (x2)

TRUSS RUBBER ANTICROSSMEMBER

MEMBER (x2)

TRUSS CROSS-

HARDWARE USED:

STEP 3: ASSEMBLE CROSSMEMBERS

3/8” LOCK NUTS x 4

5” CARRIAGE BOLTS x 4

LEGS x 4

until they bear lightly (do not tighten yet) on the aluminum surface.

the holes. Install the 3/8” lock nuts on the 5” carriage bolts and tighten with a 9/16” wrench

Install gussets into legs as shown until holes align, then slide the 5” carriage bolts through

HARDWARE USED:

STEP 2: ASSEMBLE LEGS & GUSSETS

Slide 1” Carriage bolt into the T-slot of the gusset as shown above.

HEAVY GUSSETS x 4

1” CARRIAGE BOLTS x 4

HARDWARE USED:

STEP 1: INSTALL EXTENSION BEAM MOUNTING BOLTS

3

INSTALLATION INSTRUCTIONS

on one of them and make smooth assembly diffi cult.

identify the problem and correct it. An initial misalignment of two parts can cause a burr

of machined equipment, if a part is not fi tting as it should, don’t use excessive force,

nowhere should the use of great force be required for assembly. As with any piece

inch. Some fi ts are designed to be press fi ts, others are designed to be sliding fi ts; but

These parts have been precision cut to tolerances as close as one thousandth of an

A General Note on Assembly:

DECALS (x2)

PARALLELOGRAM

(800)338-3697

LOCK NUTS (x24)

5/16” STAINLESS

BRACES (x 4)

WASHERS (x24)

5/16” STAINLESS LOCK

TRUSS MOUNTS (x4)

WASHERS (x4)

3/8” STAINLESS LOCK

WASHERS (x8)

3/8” STAINLESS FLAT

1” CARRIAGE BOLTS (x24)3/8” LOCK NUT (x12)5” CARRIAGE BOLTS (x 12)

LEGS (x4)

(x4)

3/8” STAINLESS NUT

BOLTS (x 4)

4-3/8” STAINLESS

EXTENSION BEAM HALVES (x4)

CONTRACTOR RIG EXTENSION BEAM BOX CONTENTS:

HEAVY GUSSETS (x 4)

5/16” KNOB (x2)3/8” ADJUSTABLE

HANDLES (x2)

LOCK NUTS (x6)

5/16” STAINLESS

ANTI-WEAR INSERTS (x3)

CROSSMEMBER TRUSS RUBBER

EXT. BEAM CROSSMEMBER (x1)

LOCK WASHERS (x6)

5/16” STAINLESS

CONTRACTOR RIG LEG BOX CONTENTS:

BOLTS (x6)

1” CARRIAGE

PLASTIC LOW FRICTION INSERT (x1)

REAR CROSSMEMBER TRUSS

TRUSS CROSSMEMBER (x2)

CONTRACTOR RIG CROSSMEMBER BOX CONTENTS:

CONTRACTOR RIG RACK

COVER)

WITH TRUCK BED

SEPARATELY

RAIL (ORDERED

EXPLORER SERIES

2

INSTALLATION

RIG GUSSET & BRACE

DETAIL OF CONTRACTOR

LEGS (x4)

GUSSETS (x 4)

HEAVY

BRACES (x 4)

CROSSMEMBER (x2)

TRUSS

WEAR INSERT (x3)

RUBBER ANTI-

CROSSMEMBER (x1)

REAR FRONT

CROSSMEMBER

THIS TAB FITS INSIDE

EXT. BEAM

EXTENSION BEAMS (x4-HALFS)

MOUNTS (x4)

TRUSS

REAR T-SLOT (x1)

PLASTIC INSERT IN

LADDER GLIDE

UTILITY RIG RACK ILLUSTRATION:

MUST be installed on the truck fi rst before attempting to install this rack system!

IMPORTANT! The Pace Edwards truck bed cover and Explorer Series Rails

regarding the installation please call our Technical Support Line at (800) 338-3697.

have noted where briefl y having an extra person’s assistance can make installation easier. If you have questions

Read the instructions carefully before you start. These instructions are written for one-person installation. We

BEFORE YOU START:

Silicone sealant (if necessary)

Flat clean surface (such as card board paper or plastic

1/2” open ended wrench

9/16” wrench or socket

TOOLS REQUIRED FOR ASSEMBLY:

Part #: UR-CR Rack-INSTALL 048

WORK WINCH INSTRUCTIONS ..............................8-9

STEP 10: Install Crossmember ..............................................7

STEP 9: Install Extension Beams on Trusses.........................6

STEP 8: install decal over splice joint .....................................6

STEP 7: Assemble extension beam halves ............................6

STEP 6: Install Pickup Trusses on Truss mounts ...................5

STEP 5: Install Truss Mounts on Explrer Series Rails.............5

STEP 4: Assemble Crossmembers, Legs & Braces................5

STEP 3: Assemble Crossmembers.........................................4

STEP 2: Assemble legs & gussets .........................................4

STEP 1: Install Side Stops ......................................................4

Packaging Contents ................................................................3

Utility Rack Illustration..............................................................2

Before Y ou Start ......................................................................2

Tools Required for Assembly....................................................2

Centralia WA 98531

2400 Commercial Blvd.

Pace Edwards Company

www.paceedwards.com

(800) 338-3697

*Flip over for Utility Rig Rack instructions

TABLE OF CONTENTS

MUST be installed on the truck fi rst before attempting to install this rack system!

IMPORTANT! The Pace Edwards truck bed cover and Explorer Series Rails

STANDARD INSTALLATION INSTRUCTIONS

PACE EDWARDS RETRACTABLE HARD TRUCK BED COVER & UTILITY RACK SYSTEM

CONTRACTOR RIG RACK

Loading...

Loading...