Paccar SM001-300, SmartAir eHVAC System Service Manual

HVAC

PM820010 Rev. 9 © 9/2016

SERVICE

M

ANUAL

Kenworth Idle Management System

Technical Information and Diagnostic Guide

Section

Title Idle Management System Service Manual

Number

Date Rev. 9 © 9/2016

Model All w/ Idle Management System

Page 1 of 39

HVAC

SM001-300

This guide will assist you in becoming more familiar with the working components

of the Kenworth Idle Management System and the proper steps and procedures to

completely diagnose the Kenworth Idle Management System unit.

©2016 PACCAR Corporation

Confidentiality Notice: This document and the information contained h

in whole or in part, or used for manufacture without the written permission of PACCAR. You are hereby notified that any dissemination of

this information is strictly prohibited.

erein is proprietary. It shall not be reproduced, copied or disclosed,

HVAC: Idle Management System

GENERAL SAFEY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Precautions for Working with HFC134a (R134a) Refrigerant and Po lyvinyl Ether

(PVE) Refrigerant Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Important Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EXTERNAL COMPONENT IDENTIFICATION AND LOCATION . . . . . . . . . . . . . . . 8

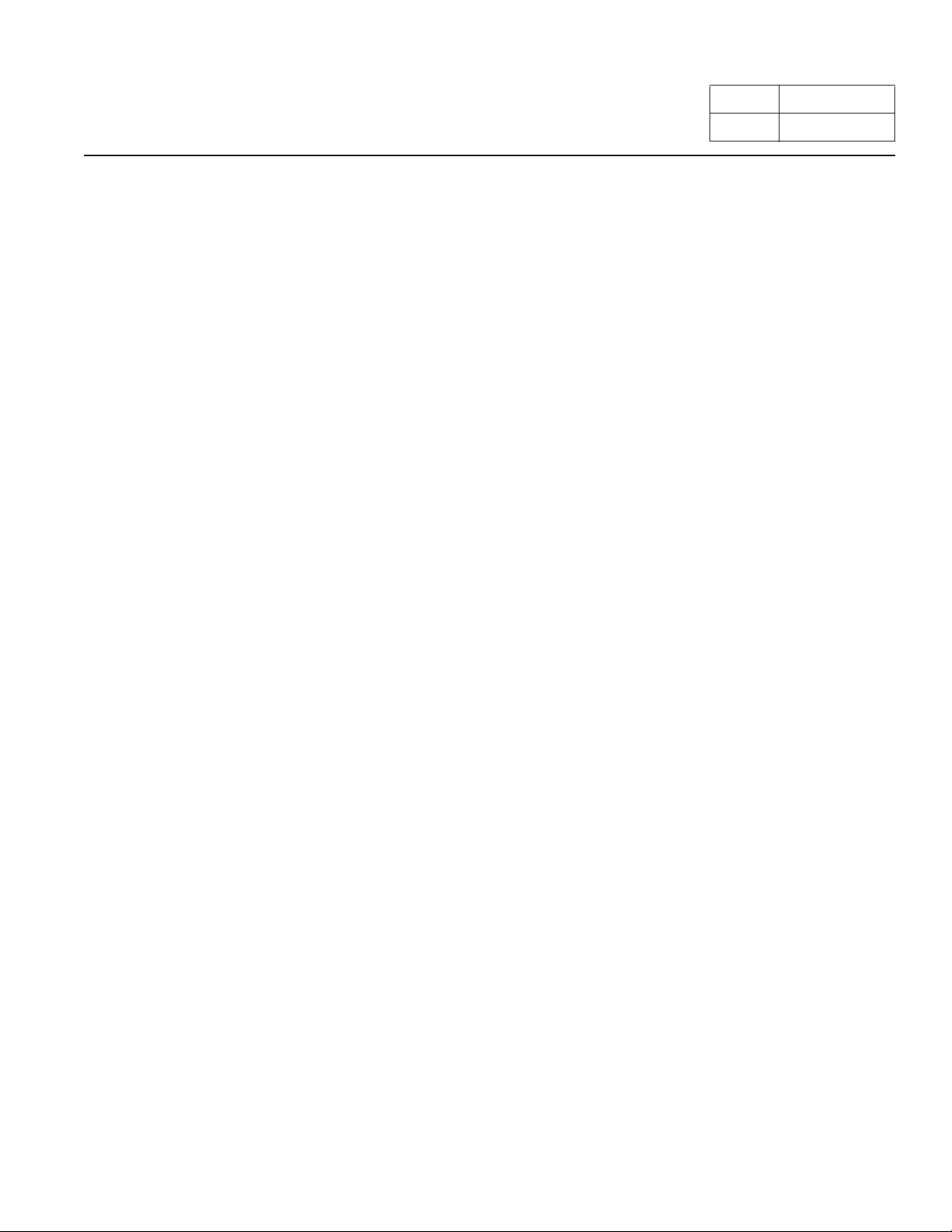

A. Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B. Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

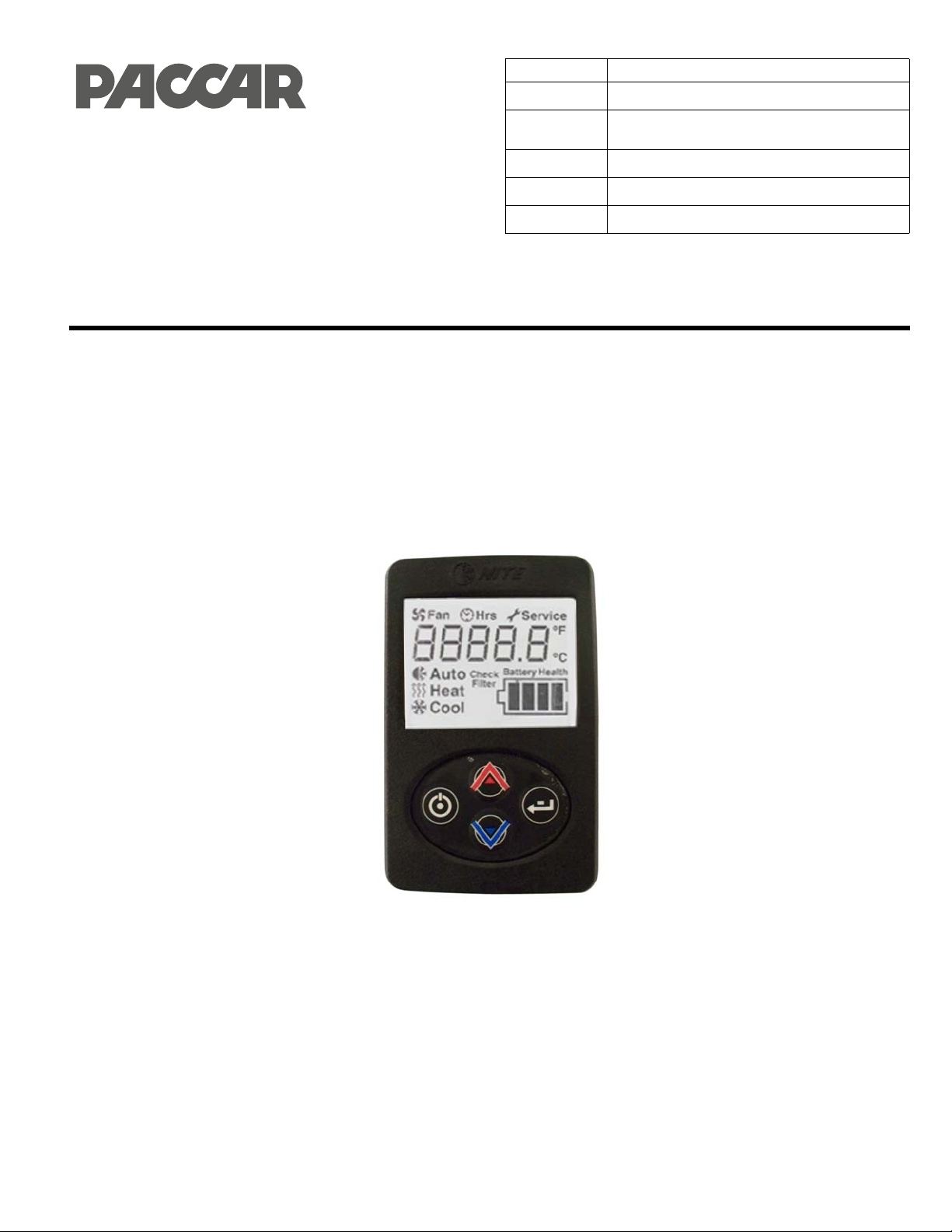

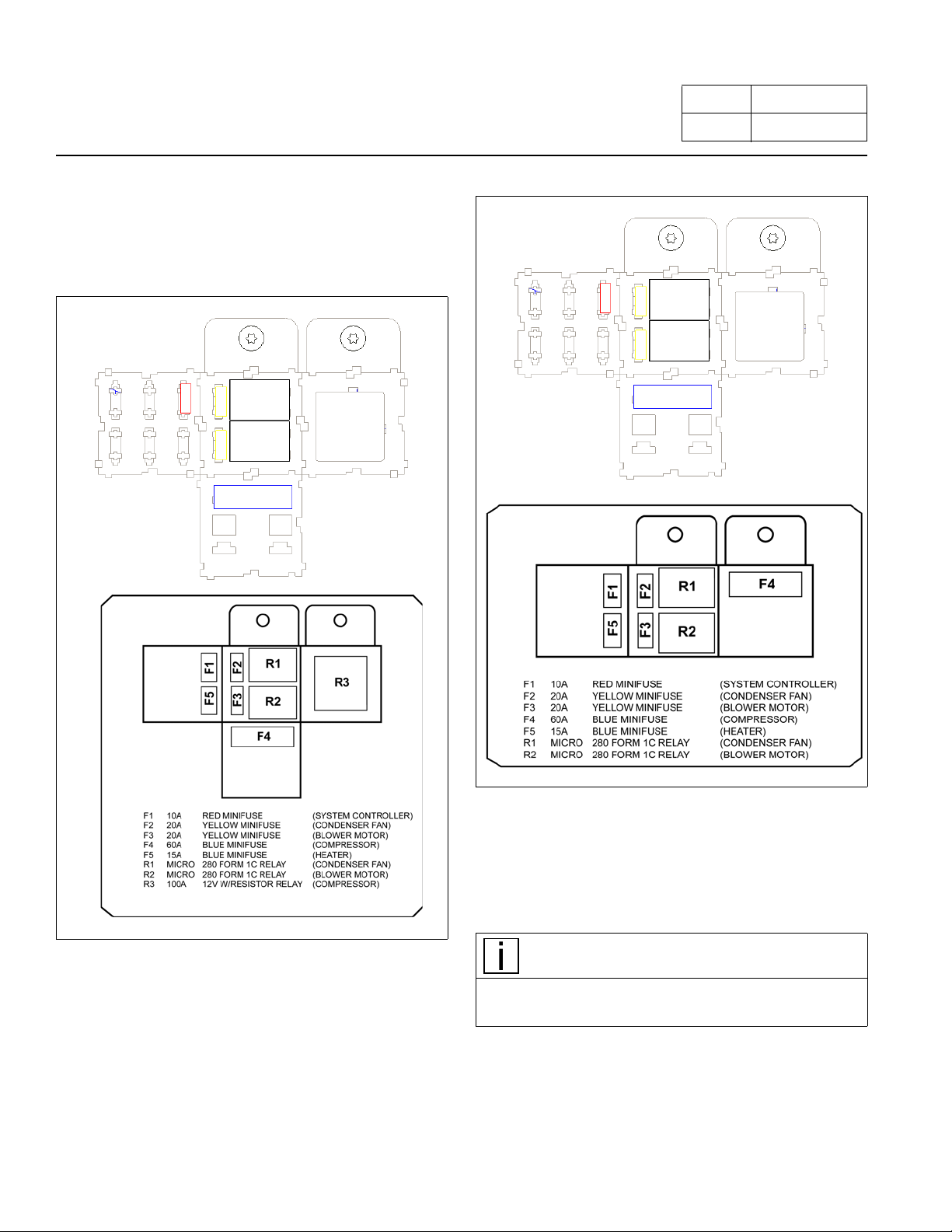

C. Fan and Temperature Control Display LED Display . . . . . . . . . . . . . . . . . 9

D. System and Compressor Con tro lle r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

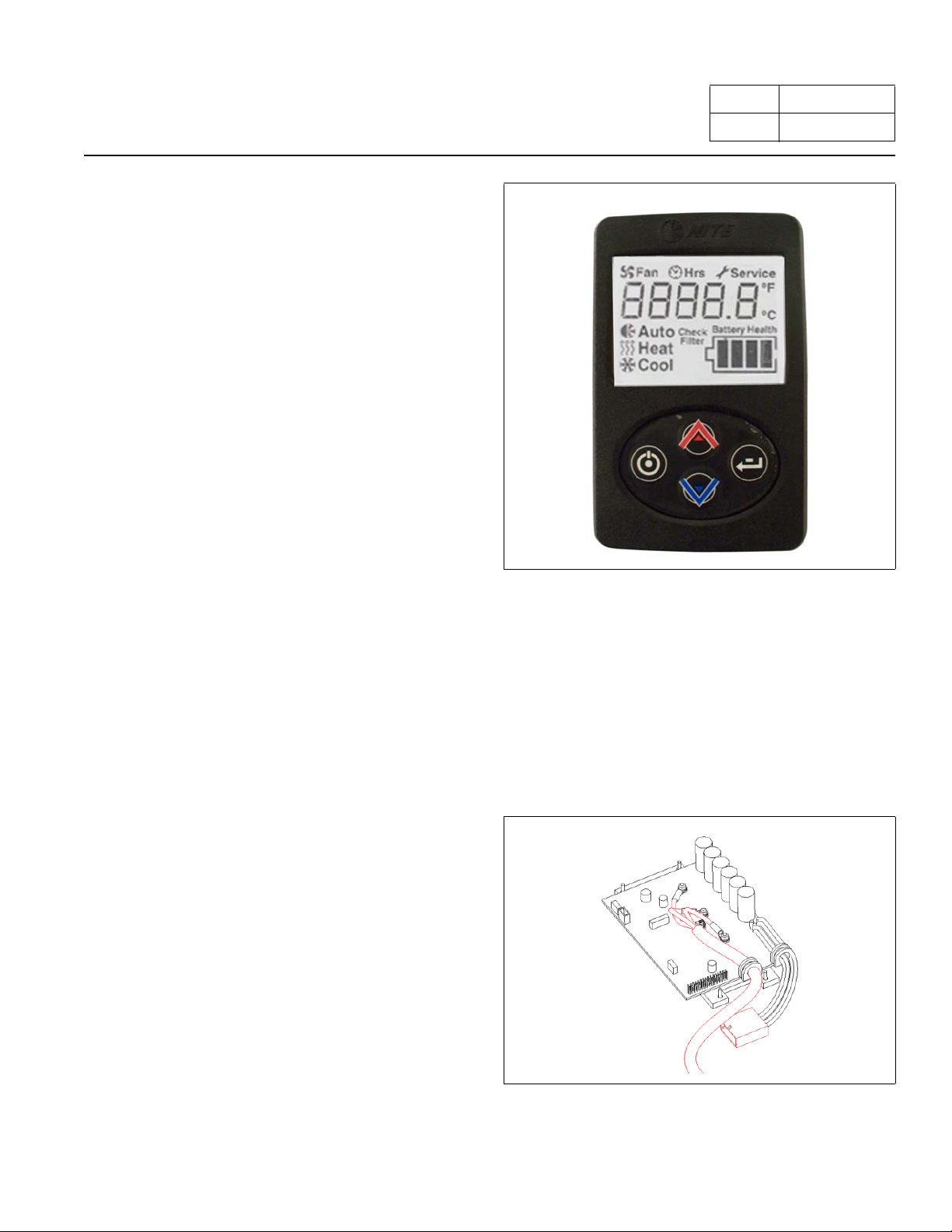

E. Linear Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

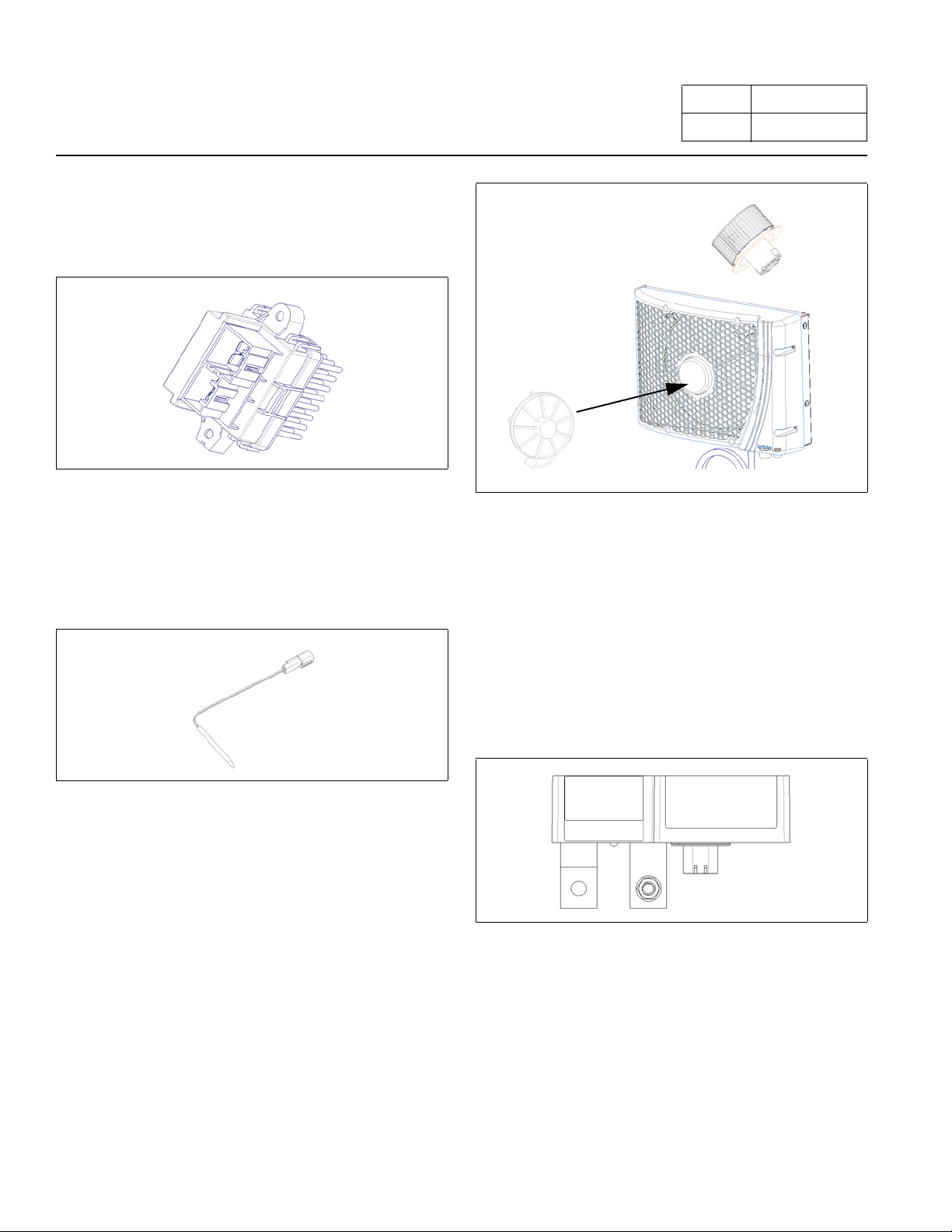

F. Discharge Temperature Sensor – Freeze Switch . . . . . . . . . . . . . . . . . . 10

Page 2 of 39

Number SM001-300

Contents

G. Evaporator Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

H. Condenser Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

I. Battery Management System (BMS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

J. Battery Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

INTERNAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A. High Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B. Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

C. Thermal Limit Switch on Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

D. Evaporator Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A/C System Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ESPAR Heating System Diagnostic Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

A. Battery Condition and Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

B. Fan and Temperature Control Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

C. Relay Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

D. Pressure Switch Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

E. Check Continuity Across Fuse Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

F. Discharg e Tem p er at ur e Se nso r /Fre ez e Switch Te stin g . . . . . . . . . . . . . 19

G. Compressor Thermal Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

H. Main Controller/Compressor Contro ller . . . . . . . . . . . . . . . . . . . . . . . . . . 19

HVAC: Idle Management System

I. Condenser Fan Motor Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

J. Evaporator Blower Motor and Linear Power Module Testing . . . . . . . . . .20

K. Compressor Rubber Mounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

L. Testing the Battery Management System (BMS) . . . . . . . . . . . . . . . . . . .21

M. Can Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

N. Testing the Espar Heater Connected to the EHVAC Digital Controller . . .22

O. Connecting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

P. Evacuating the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Q. Charging the Kenworth EHVAC System . . . . . . . . . . . . . . . . . . . . . . . . . .25

Service Instructions for Ring Terminal / Controller and Compressor . . . . . . . . . . . .33

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Page 3 of 39

Number SM001-300

HVAC: Idle Management System

Page 4 of 39

Number SM001-300

List of Figures

Figure 1. Fuses and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 12.

Figure 13.

Figure 14.

Figure 15.

Figure 16.

Figure 17.

Figure 18.

Figure 19.

Figure 20.

Figure 21.

Figure 22.

Figure 23.

Figure 24.

Figure 25.

Figure 26.

Figure 27.

Figure 28.

Figure 29.

Fuses and Relays (Units built 8/1/2016 to Present). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fan and Temperature Control Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System and Compressor Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Linear Power Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Discharge Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Evaporator Blower and Condenser Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Battery Management System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Battery Separator Solenoid, located in the battery box.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Automated Battery Disconnect Solenoid, located in the battery box. . . . . . . . . . . . . . . . . . . . . . . . . 11

High Pressure Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Thermal Limit Switch on Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Evaporator Inlet Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Relay Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Service Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service Recovery Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Internal Wiring Diagram (Before 8/1/2016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

External Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Wiring Diagram (8/1/2016 to Present) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

On/Off Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing Blower Speeds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

View System Runtime/Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Change from °F to °C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Enter Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Service Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EHVAC Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

HVAC: Idle Management System

GENERAL SAFEY INSTRUCTIONS

Page 5 of 39

Number SM001-300

A number of alerting messages are in this manual.

Please read and follow them. They are there for your protection and information. These

avoid injury to yourself or others and help prevent costly

damage to the vehicle.

messages can help you

Warnings, Cautions, and Notes

Key symbols and “signal words” are used to indicate

what kind of message is going to follow. Pay special

attention to instructions prefaced by symbols and signal

words “WARNING”, “CAUTION”, or “NOTE”. Please do

not ignore any of these alerts.

WARNING!

When you see this symbol and word, the messa g e th a t

follows is especially vital. This signals something that

can cause injury or even death. This message will tell

you what the hazard is, what can happen if you don’t

heed the warning, and/or how to avoid it.

CAUTION

• The air conditioning system uses HFC134a

(R134a) refrigerant and polyvinyl ether (PVE)

refrigerant oil, which are not compatible with

CFC-12 (R12) refrigerant, mineral oil, or PAG

oil. If the refrigerants or oils are mixed the compressor may fail.

• Do not attempt to use R-12 servicing equipment;

damage

ing equipment will result.

• Use only service equipment that is U.L. listed and

is

to remove HFC134a (R134a) from the air conditioning system.

• Verify the HFC134a (R134a ) refri gerant i n the vehi cle system and the recycling equipment/recovery

ank are contaminant free by using a refrigerant

t

identifier.

to the air condition system or your servic-

certified to meet the requirements of SAE J2210

NOTE

CAUTION

This symbol and word signals something that could

damage your vehicle.

NOTE

This symbol gives you information we believe to be

helpful. The information can be a service hint or something to assist with the r

epairing of the vehicle.

Precautions for Working with HFC134a

(R134a) Refrigerant and Polyvinyl Ether

(PVE) Refrigerant Oil

WARNING!

• DO NOT breathe A/C refrigerant and oil vapor or

mist. Exposure may irritate eyes, nose and throat.

• Additional health and safety information may be

btained from refrigerant and oil manufacturers.

o

• If accidental system disc

work area before resuming service.

harge occurs, ventilate

THIS SYSTEM MUST BE SERVICED BY QUALIFIED

PERSONNEL ONLY.

R134a service equipment or vehicle air conditioning

systems shou

with compressed air.

• This air conditioning system may contain R134a

orescent dye for leak detection. Inspect with a

flu

high intensity ultraviolet light system.

• A label on the unit will identify sy

cent dye.

ld not be pressure tested or leak tested

stems with fluores-

NOTE

The Air Conditioning system is designed for use only

with the specified polyvinyl ether (PVE) refrigerant oil

for HFC134a (R134a) A/C systems and HFC134a

(R134a) components. Idemitsu FVC68D PVE oil is the

ONLY recommended oil. The PVE oil is very Hygroscopic. Hygroscopic means that it

out proper sealing, oil will become moisture saturated

d should not be used.

an

absorbs water. With-

HVAC: Idle Management System

NOTE

Take care to follow the handling procedures below:

• Only use the specified FV

sealed container.

• Immediately reseal containers of oil.

• To avoid contamination, do not return oil to original

tainer once it is dispensed, and never mix it

con

with other refrigerant oils.

• Do not allow PVE oil to come in contact with Styrofoam parts. Damage may occur.

• Do not allow PVE oil to come in c

cle paint. Damage may occur.

• If any connection in the refrigerant loop is opened it

uld be closed as soon as possible in order to

sho

minimize the amount of moisture that enters the

system.

• Any components that are replaced should have

ust caps left in place until the component is ready

d

to be installed in the refrigerant loop.

• Any component removed from th e refrigerant loop

ould have dust caps in place as soon as possible

sh

in order to minimize moisture intrusion.

C68D PVE oil from a

ontact with vehi-

Important Safety Notices

WARNING!

Improper practices, carelessness, or ignoring any

warnings may cause death, personal injury, equipment

or property damage.

Read and understand all of the safety precautions and

nings before performing any repair. This list contains

war

the general safety precautions that must be followed to

provide personal safety. Special safety precautions are

included in the procedures when they apply.

Work areas should be dry, well lit, ventilated, and be free

m clutter, loose tools, parts, ignition sources and haz-

fro

ardous substances. Be aware of ha

that can exist.

• Wear protective glasses and protective shoes when

working.

• Rotating parts can cause cuts, mutilation or strangulation.

zardous conditions

Page 6 of 39

Number SM001-300

• Do not wear loose-fitting or torn clothing. Remove all

jewelry before

• Before beginning any repair, disconnect the battery

negative [-] cable) from both battery boxes and dis-

(

charge any capacitors.

• Disconnect the air starting motor, if equipped, to prevent accidental engine starting.

•Put a “DO N

compartment or on the controls.

• Allow the engine to cool before beginning any repair.

• Always use blocks or proper stands to support the

icle or vehicle components before performing any

veh

service work. Do not work on anything that is supported only by lifting jacks or a hoist.

• To reduce the possibility of personal injury, use a

ist or get assistance when lifting components that

ho

weigh 23 kg [50 lb] or more. Ensure all lifting devices

such as chains, hooks, or slings are in good condition and are of the correct load capacity. Make sure

y lifting devices are positioned correctly. Always

an

use a spreader bar when necessary. The lifting

hooks must not be side-loaded.

• Corrosion inhibitors and lubrica ting oils may contain

li. Do not get the substance in eyes and avoid

alka

prolonged or repeated contact with skin. Do n ot swallow. In case of contact, immediately wash

soap and water. In case of harmful contact, immediately contact a physician. Alway

cals OUT OF REACH OF CHILDREN.

• Naptha and Methyl Ethyl Ketone (MEK) are flammable materials and must be used with caution. Follow

the ma

when using these materials. Always keep any

chemicals OUT OF REACH OF CHILDREN.

• When working on the vehicle, be alert for hot part s on

systems

flow, and hot fluids in lines, tubes, and compartments. Contact with any hot surface may cause

rns.

bu

• Always use tools that are in good condition. Make

e you have the proper understanding of how to

sur

use the tools before performing any service work.

Use ONLY genuine replacement parts from PACCAR.

• Always use the same fastener part number (or equ ivalent) when replacing items. Do

lesser quality if replacements are necessary.

working.

OT OPERATE” tag in the operator's

skin with

s keep any chemi-

nufacturer's instructions to ensure safety

that have just been turned off, exhaust gas

not use a fastener of

HVAC: Idle Management System

Page 7 of 39

Number SM001-300

• Do not perform any repair when impaired, tired,

fatigued or after consuming alcohol or drugs that can

impair your functioning.

• Some state and federal agencies in the United States

of America have determined that used engine oil can

be carcinogenic and can cause reproductive toxicity.

Avoid inhalation of vapors, ingestion, and prolonged

contact with used engine oil.

• Liquefied petroleum gas is heavier than air and can

accumulate near the floor, in sumps, and low-lying

areas.

• Close the manual fuel valves prior to performing

maintenance and repairs, and when storing the vehi

cle inside.

• California Proposition 65 Warning – Diesel engine

exhaust and some of its constituents are known to

the State of California to cause cancer, birth defects,

and other reproductive harm.

• DO NOT breathe A/C refrigerant and oil vapor or

mist. Exposure may irritate eyes, nose and throat.

• Additional health and safety information may be

obtained from refrigerant and oil manufacturers.

• If accidental system discharge occurs, ventilate work

area before resuming service.

-

HVAC: Idle Management System

EXTERNAL COMPONENT

IDENTIFICATION AND LOCATION

A. Fuses

Page 8 of 39

Number SM001-300

Figure 1. Fuses and Relays

Figure 2. Fuses and Relays (Units built 8/1/2016 to

Present)

F1 Fuse 10 Amp (Mini)

This fuse provides short circuit prot ection for the System

rol.

cont

NOTE

Removing fuse F1 for 10-15 seconds will reset the system controller to factory default settings.

Location: on the control center.

F2 Fuse 10 Amp (Mini)

This fuse provides short circuit protection for the condenser fan.

HVAC: Idle Management System

Location: on the control center.

F3 Fuse 20 Amp (Mini)

This fuse provides short circuit protect ion for the evaporator blower.

Location: on the control center.

F4 Fuse 60 Amp (Maxi)

This fuse provides short circuit protection for the compressor.

Location: on the control center.

B. Relays

Location: on the control center.

R1. This relay controls the voltage to the condenser fan.

Page 9 of 39

Number SM001-300

R2. This relay controls the vo

module and evaporator blower.

R3. This relay controls the v

controller.

ltage to the linear power

oltage to the compressor

C. Fan and Temperature Control Display

LED Display

Allows for temperature and Blower speed adjustment of

the EHVAC (Electrical Heating and Ventilation Air Conditioning) unit when operating in Auto, cool or heat mode.

Unit – stops when unit is shut off or batteries are

A/C

depleted.

Figure 3. Fan and Temperature Control Display

Auxiliary heater will shut down when batteries are

depleted but will continue to run through the cool down

cycle. Also displays hours of service, battery health and

service items.

D. System and Compressor Controller

This device controls the unit and the output voltage to the

variable speed compressor. It is located under the large

access cover.

Figure 4. System and Compressor Controller

HVAC: Idle Management System

E. Linear Power Module

This module controls the amount of voltage delivered to

the evaporator blower creating variable blower speeds. It

is located in the return air in front of the evaporator coil.

Figure 5. Linear Power Module

F. Discharge Temperature Sensor – Freeze

Switch

Page 10 of 39

Number SM001-300

Figure 7. Evaporator Blower and Condenser Fan

I. Battery Management System (BMS)

This sensor monitors the evaporator outlet temperature

as it enters the vehicle duct system.

Figure 6. Discharge Temperature Sensor

G. Evaporator Blower

This blower pulls air through the evaporator coil and

blows conditioned air into the interior of the sleeper.

H. Condenser Fan

This blower draws air through the condenser coil to cool

the refrigerant flowing through the system.

This device monitors the auxiliary batteries for state of

charge, communicates with the EHVAC system and controls the battery separator solenoid. LED light on this

vice indicates power to the device and does not pro-

de

vide diagnostics. Power inputs to this device are fuse

otected.

pr

If one of the BMS fuses blows, the solenoid will disen-

gage.

Figure 8. Battery Management System

J. Battery Separator

This device connects the truck batteries to the EHVAC

batteries. When the starting batteries are at or above

13.2 volts, the battery management device will engage

the solenoid to allow the alternator to charge the auxiliary

batteries. When the voltage drops to or below 12.5 vo lts

the battery management system will disengage the solenoid to prevent the truck starting batteries from being dis charged below the engine start level.

HVAC: Idle Management System

Figure 9. Battery Separator Solenoid, located in the

battery box.

Page 11 of 39

Number SM001-300

Automated Battery Disconnect (Option)

This device disconnects the EHVAC batteries from the

AC unit when the cab disconnect switch is set to

EHV

OFF. The cab disconnect switch must be set to ON for

the EHVAC unit to operate.

Figure 10. Automated Battery Disconnect Solenoid,

located in the battery box.

HVAC: Idle Management System

INTERNAL COMPONENTS

A. High Pressure Switch

This normally closed brazed pressure switch will open

and prevent the operation of the compressor due to high

internal pressure. It is NOT serviceable.

Figure 11. High Pressure Switch

Page 12 of 39

Number SM001-300

B. Compressor

This unit is part of the hermetically sealed refrigeration

system.

Figure 12. Compressor

C. Thermal Limit Switch on Compressor

This is a normally closed (auto reset) switch to protect

the compressor from high temperature.

Figure 13. Thermal Limit Switch on Compressor

D. Evaporator Inlet Filter

This filter protects the evaporator coil from dust and

debris. It is washable and should be serviced periodically

during routine maintenance.

Figure 14. Evaporator Inlet Filter

When necessary, the Check Filter indicator will notify you

that the EHVAC filter must be cleaned or changed. To

reset “Check Filter” – at screen 1 press and hold enter

button for 3 seconds.

Loading...

Loading...