Page 1

Page 2

Page 3

Contents

Safety

Emergency

Controls

Driving

Maintenance

Information

Index

1

2

3

4

5

6

7

Page 4

Contents

©2013 Paccar Inc - All Rights Reserved

This manual illustrates and describes the operation of features or equipment which may be either standard or optional on

this vehicle. This manual may also include a description of features and equipment which are no longer available or were

not ordered on this vehicle. Please disregard any illustrations or descriptions relating to features or equipment which are

not on this vehicle.

PACCAR reserves the right to discontinue, change specications, or change the design of its vehicles at any time without

notice and without incurring any obligation.

The information contained in this manual is proprietary to PACCAR. Reproduction, in whole or in part, by any means is strictly

prohibited without prior written authorization from PACCAR Inc.

Page 5

Safety

Introduction

Safety Alerts . . . . . . . . . . . . . . . . . . 1-3

Foreword . . . . . . . . . . . . . . . . . . . 1-5

Important Reference Number . . . . . . . . . . . 1-6

Illustrations. . . . . . . . . . . . . . . . . . . 1-7

General Safety Instructions. . . . . . . . . . . . 1-7

1

(07/19/2013) Y53-1181-1B1 1-1

Page 6

Page 7

Introduction

Introduction

Safety Alerts

Please read and follow all of the

safety alerts contained in this manual.

They are there for your protection

and information. These alerts can

help you avoid injury to yourself, your

passengers, and help prevent costly

damage to the vehicle. Safety alerts

are highlighted by safety alert symbols

and signal words such as "WARNING",

"CAUTION", or "NOTE". Please do not

ignore any of these alerts.

WARNING

WARNING!

The safety alert following this symbol

and signal word provides a warning

against operating procedures which

could cause death or injury. They could

also cause equipment or property

damage. The alert will identify the

hazard, how to avoid it, and the

probable consequence of not avoiding

the hazard.

Example:

WARNING!

Do not carry additional fuel containers

in your vehicle. Fuel containers, either

full or empty, may leak, explode, and

cause or feed a re. Do not carry extra fuel containers. Even empty ones

are dangerous. Failure to comply may

result in death, personal injury, equipment or property damage.

1

(07/19/2013) Y53-1181-1B1 1-3

Page 8

Introduction

CAUTION

1

CAUTION

The safety alert following this symbol

and signal word provides a caution

against operating procedures which

could cause equipment or property

damage. The alert will identify the

hazard, how to avoid it, and the

probable consequence of not avoiding

the hazard.

Example:

CAUTION

Continuing to operate your vehicle

with insufcient oil pressure will cause

serious engine damage. Failure to

comply may result in equipment or

property damage.

NOTE

NOTE

The alert following this symbol and

signal word provides important

information that is not safety related

but should be followed. The alert

will highlight things that may not be

obvious and is useful to your efcient

operation of the vehicle.

Example:

NOTE

Pumping the accelerator will not assist

in starting the engine.

1-4 Y53-1181-1B1 (07/19/2013)

Page 9

Introduction

Foreword

This manual contains information for

the correct operation and maintenance

of your PACCAR engine. Read and

follow all safety instructions. Refer

to the WARNING in the “General

Safety Instructions” beginning on

page 1-7. Keep this manual with

the equipment. If the equipment is

traded or sold, give the manual to

the new owner. The information,

specications, and recommended

maintenance guidelines in this manual

are based on information in effect

at the time of printing. PACCAR

reserves the right to make changes

at any time without obligation. If you

nd differences between your engine

and the information in this manual,

contact your local PACCAR Authorized

Repair Location or write to PACCAR

c/o PACCAR Engines, PO Box 1518,

Bellevue, WA 98009. The latest

technology and the highest quality

components were used to produce this

engine. When replacement parts are

needed, we recommend using only

genuine parts from PACCAR.

1

(07/19/2013) Y53-1181-1B1 1-5

Page 10

Introduction

Important Reference

1

Number

Fill in the part name and number in the blank spaces provided below. This will give you a reference whenever service or maintenance is required.

Part Name Number

Engine Model

Engine Serial Number (ESN)

Oil Type (Use API CJ-4 oil only)

Filter Part Numbers:

Air Cleaner Element

Lubricating Oil

Fuel (Use ultra-low sulfur diesel fuel only)

Coolant

Belt Part Numbers:

1-6 Y53-1181-1B1 (07/19/2013)

Page 11

Introduction

Illustrations

General Information

Some of the illustrations throughout

this manual are generic and will not

look exactly like the engine or parts

used in your application.

The illustrations are intended to show

repair or replacement procedures.

The procedure will be the same for all

applications, although the illustration

can differ.

General Safety Instructions

Important Safety Notice

WARNING!

Improper practices, carelessness, or

ignoring any warnings may cause

death, personal injury, equipment or

property damage.

Before performing any repair, read and

understand all of the safety precautions

and warnings. The following is a list of

general safety precautions that must

be followed to provide personal safety.

Failure to follow these instructions

may cause death or injury. Special

safety precautions are included in the

procedures when they apply.

• Use the proper tool for manually

rotating the engine. Do not attempt

to rotate the crankshaft by pulling

or prying on the fan. This practice

can cause death, personal injury,

equipment damage, or damage to

the fan blades, causing premature

fan failure.

• Work areas should be dry, well lit,

ventilated, free from clutter, loose

tools, parts, ignition sources and

hazardous substances.

• Wear protective glasses and

protective shoes when working.

• Do not wear loose-tting or torn

clothing. Remove all jewelry when

working.

• Before beginning any repair,

disconnect the battery (negative

[-] cable) and discharge any

capacitors.

• Put a "DO NOT OPERATE" tag in

the operator's compartment or on

the controls.

• Allow the engine to cool before

slowly loosening the coolant ller

cap to relieve the pressure from

the cooling system.

1

(07/19/2013) Y53-1181-1B1 1-7

Page 12

Introduction

1

stands to support the vehicle

or vehicle components before

performing any service work.

Do not work on anything that is

supported only by lifting jacks or

a hoist.

Always use blocks or proper

•

• Before removing or disconnecting

any lines, ttings, or related items,

relieve all pressure in the air, oil,

fuel, and cooling systems. Remain

alert for possible pressure when

disconnecting any device from a

system that contains pressure.

High pressure oil or fuel can cause

death or personal injury.

• Always wear protective clothing

when working on any refrigerant

lines and make sure that the

workplace is in a well ventilated

area. Inhalation of fumes can

cause death or personal injury.

To protect the environment,

liquid refrigerant systems must

be properly emptied and lled

using equipment that prevents

the release of refrigerant gas.

Federal law requires capturing

and recycling refrigerant.

• When moving or lifting any heavy

equipment or parts, make sure

to use proper techniques and

assistance. Ensure all lifting

devices such as chains, hooks, or

slings are in good condition and

are of the correct load capacity.

Make sure any lifting devices are

positioned correctly.

• Corrosion inhibitors and lubricating

oils may contain alkali. Do not get

the substance in eyes and avoid

prolonged or repeated contact

with skin. Do not swallow. In

case of contact, immediately wash

skin with soap and water. In case

of harmful contact, immediately

contact a physician. Always keep

any chemicals OUT OF REACH

OF CHILDREN.

• Naptha and Methyl Ethyl Ketone

(MEK) are ammable materials

and must be used with caution.

Follow the manufacturer's

instructions to ensure safety when

using these materials. Always

keep any chemicals OUT OF

REACH OF CHILDREN.

• When working on the vehicle,

be alert for hot parts on systems

that have just been turned off,

exhaust gas ow, and hot uids in

lines, tubes, and compartments.

Contact with any hot surface may

cause burns.

• Always use tools that are in good

condition. Make sure you have

the proper understanding of how

to use the tools before performing

any service work. Use only

genuine replacement parts from

PACCAR.

1-8

Y53-1181-1B1 (07/19/2013)

Page 13

Introduction

• Always use the same fastener

part number (or equivalent) when

replacing items. Do not use

a fastener of lesser quality if

replacements are necessary.

• Do not perform any repair when

impaired, tired, fatigued or after

consuming alcohol or drugs that

can impair your functioning.

• Some state and federal agencies

in the United States of America

have determined that used engine

oil can be carcinogenic and can

cause reproductive toxicity. Avoid

inhalation of vapors, ingestion,

and prolonged contact with used

engine oil.

• Coolant is toxic. If not reused,

dispose of coolant in accordance

with local environmental

regulations.

• California Proposition 65 Warning

- Diesel engine exhaust and some

of its constituents are known to

the State of California to cause

cancer, birth defects, and other

reproductive harm.

• The catalyst substrate located

in the Diesel Particulate Filter

contains Vanadium Pentoxide.

Vanadium Pentoxide has been

determined by the State of

California to cause cancer. Always

wear protective clothing and eye

protection when handling the

catalyst assembly. Dispose of the

catalyst in accordance with local

regulations. If catalyst material

gets into the eyes, immediately

ood eyes with water for a

minimum of 15 minutes. Avoid

prolonged contact with skin. In

case of contact, immediately wash

skin with soap and water. In case

of harmful contact, immediately

contact a physician.

CAUTION

Corrosive chemicals can damage the

engine. Do not use corrosive chemicals on the engine. Failure to comply may result in equipment or property

damage.

1

(07/19/2013) Y53-1181-1B1 1-9

Page 14

Page 15

WHAT TO DO IF...

You Need Roadside Assistance . . . . . . . . . . 2-3

Stop Engine Lamp Turns On . . . . . . . . . . . 2-3

Engine Oil Pressure Lamp Turns On. . . . . . . . 2-4

Check Engine Lamp Turns On . . . . . . . . . . 2-5

Engine is Overheating . . . . . . . . . . . . . . 2-5

EMERGENCY

2

(07/19/2013) Y53-1181-1B1 2-1

Page 16

Page 17

WHAT TO DO IF...

WHAT TO DO IF...

You Need Roadside Assistance

Call toll-FREE to talk to someone at

the PACCAR Customer Center:

• Kenworth customers,

call 1-800-KW-ASSIST

(1-800-592-7747).

• Peterbilt customers, call

1-800-4-PETERBILT

(1-800-473-8372).

• Open 24-7-365 days a year.

• They can help you get roadside

assistance.

• They have a custom mapping

system which locates authorized

PACCAR engine dealers and

Independent Service Providers

(ISPs) near you and lists types

of services offered, hours of

operation and contact information.

• They can assist with jump and

pull starts, tires, trailers, nes and

permits, chains, towing, hazardous

clean-up, out of fuel (roadside),

mechanical repairs and preventive

maintenance services.

• They have multilingual agents and

access to a translation service

to ensure quality assistance

for customers who speak any

language.

• They can’t answer your warranty

questions but can get you in

contact with an authorized dealer

who can.

• The PACCAR Customer Center

service is FREE.

Stop Engine Lamp Turns On

Stop Engine Lamp - If the

Stop Engine warning lamp

illuminates, it means you

have a serious engine system

problem.

WARNING!

This should be considered an emergency. You should stop the vehicle as

safely as possible and turn OFF the ignition. The vehicle must be serviced

and the problem corrected before driving again. Failure to do so may result

in personal injury, severe engine damage, equipment or property damage.

2

(07/19/2013) Y53-1181-1B1 2-3

Page 18

WHAT TO DO IF...

Engine Oil Pressure Lamp Turns On

Engine Oil Pressure Gauge

- It is important to maintain

2

Continuing to operate your vehicle

with insufcient oil pressure may

cause severe engine damage, equipment or property damage.

oil pressure within acceptable

limits. If oil pressure drops

below the minimum psi a

Red Warning Lamp on the oil

pressure gauge and the Stop

Engine Lamp will come ON.

CAUTION

• If the oil pressure fails to rise within

10 seconds after the engine starts,

stop the engine and determine the

cause.

• See Lubricating Oil System on

page 5-12, for the correct oil

pressure ranges for your vehicle's

engine.

• If the oil pressure suddenly drops,

or the audible alarm and engine

oil pressure warning light come on

while driving, do the following:

1. Slow down carefully.

2. Move a safe distance off the road

and stop.

3. Place the transmission in

neutral and set the parking

brake. (See Parking Brake

Valve and OPERATING THE

TRANSMISSION in your

vehicle Operator's Manual,

for transmission shifting and

parking brake information.)

4. Turn OFF the engine.

5. Turn ON the emergency asher

and use other warning devices to

alert other motorists.

6. Wait a few minutes to allow oil

to drain into the engine oil pan,

and then check the oil level. (See

Inspection of the Engine Oil Level

on page 5-4.)

7. Add oil if necessary. If the problem

persists, contact an authorized

PACCAR engine dealer as soon

as possible.

2-4

Y53-1181-1B1 (07/19/2013)

Page 19

WHAT TO DO IF...

Check Engine Lamp Turns On

Check Engine Lamp - Turns

on when a problem exists, but

the vehicle can still be safely

driven. Vehicle should be

serviced to correct the problem

but the situation should not be

considered an emergency.

Engine is Overheating

CAUTION

The cooling system may overheat

if the engine coolant is at the minimum level. A sudden loss of coolant,

caused by a split hose or broken hose

clamp could also lead to an overheat

condition. Always inspect to ensure

hoses and clamps are not cracked,

worn, or loose. Failure to comply may

result in equipment or property damage.

NOTE

The system may also temporarily overheat during severe operating conditions such as:

• Climbing a hill on a hot day.

• Stopping after high-speed/highload driving.

• Debris blocking air ow through

the cooling module (radiator).

If the engine coolant temperature

warning lamp comes on and the

audible alarm sounds showing an

overheat condition, or if you have any

other reason to suspect the engine

may be overheating, DO NOT TURN

OFF THE ENGINE unless a low water

warning device indicates a loss of

coolant. Follow these steps:

• Reduce engine speed or stop.

When stopped, place the

transmission in neutral and set the

parking brake. See the vehicle

operator's manual for instructions

on transmission shifting and

parking brake information.

• Check to ensure that the oil

pressure gauge reads normal.

• Increase the engine speed to

1,100 to 1,200 rpm maximum for

2-3 minutes.

2

(07/19/2013) Y53-1181-1B1 2-5

Page 20

WHAT TO DO IF...

• Monitor the engine temperature.

After the temperature returns to

normal, allow the engine to idle

3–5 minutes before shutting it off.

2

This allows the engine to cool

gradually and uniformly.

• If the overheating came from

severe operating conditions, the

temperature should have cooled

by this time.

• Check the coolant level at the

cooling module surge tank.

WARNING!

To reduce the chance of personal injury and/or vehicle damage caused by

engine overheating, never leave the

engine idling when the vehicle is unattended. If the engine overheats, immediate action is required to correct

the condition. Continued unattended

operation of the engine, even for a

short time, may result in serious engine damage or a re. Failure to comply may result in death, personal injury,

equipment or property damage.

WARNING!

Removing the ll cap on a hot engine

can cause scalding coolant to spray

out and burn you badly. If the engine has been in operation within the

previous 30 minutes, be very careful in removing the ll cap. Protect

face, hands, and arms against escaping uid and steam by covering the

cap with a large, thick rag. Do not

try to remove it until the surge tank

cools down or if you see any steam

or coolant escaping. In any situation,

remove the cap very slowly and carefully. Be ready to back off if any steam

or coolant begins to escape. See the

vehicle operator's manual for instructions on checking and lling the cooling module surge tank.

2-6 Y53-1181-1B1 (07/19/2013)

Page 21

WHAT TO DO IF...

CAUTION

Prolonged periods of idling after the

engine has reached operating temperatures can decrease engine temperature and could cause engine damage

from inadequate lubrication. The normal torsional vibrations generated can

also cause transmission wear. An idle

shutdown feature, available on PACCAR engines, can be programmed to

shut the engine down after a period of

low idle operation with no driver activity. A ashing warning lamp will inform

the driver of an impending shutdown.

Failure to comply may result in equipment or property damage.

CAUTION

If the truck is equipped with PTO

equipment, the engine shutdown system can be deactivated when the PTO

is operational; however, engine idle

periods should not exceed 5 minutes

whenever possible. Failure to comply

may result in equipment or property

damage.

2

(07/19/2013) Y53-1181-1B1 2-7

Page 22

Page 23

Operating Instructions

Engine Warning Lamps . . . . . . . . . . . . . 3-3

Engine Operating Range . . . . . . . . . . . . . 3-6

Engine Braking System . . . . . . . . . . . . . 3-7

Controls

3

(07/19/2013) Y53-1181-1B1 3-1

Page 24

Page 25

Operating Instructions

Operating Instructions

Engine Warning Lamps

General Information

The following engine warning lamps

cover only the lamps controlled by the

engine’s Electronic Control Module

(ECM). Please refer to the vehicle

Operator's and Engine Aftertreatement

Systems manual for additional warning

lamp information.

Check Engine Lamp

The check engine warning lamp will

illuminate when a problem exists,

but the vehicle can still be safely

driven. The vehicle should be serviced

to correct the problem, but the

situation should not be considered an

emergency.

The lamp will also illuminate when a

DPF regeneration or addition of Diesel

Exhaust Fluid is required. Another

function of the check engine lamp is to

warn the operator of an impending idle

shutdown. When the idle shutdown

timer is 30 seconds from expiring, the

engine ECM begins ashing the check

engine warning lamp once per second.

When the timer expires, the ECM will

turn off the warning lamp and shut

down the engine.

3

(07/19/2013) Y53-1181-1B1 3-3

Page 26

Operating Instructions

Stop Engine Lamp

The stop engine warning lamp will

3

illuminate, and an audible tone will

sound, when a major engine problem

exists.

WARNING!

This should be considered an emergency. You should stop the vehicle as

safely as possible and turn OFF the ignition. The vehicle must be serviced

and the problem corrected before driving again. Failure to comply may result

in personal injury, severe engine damage, equipment or property damage.

For engines with the engine protection

shutdown feature enabled, the

stop engine lamp will begin to

ash 30 seconds before the engine

automatically shuts down. The

warning lamp alerts the operator to the

impending shutdown.

The lamp will also illuminate when

the Diesel Exhaust Fluid (DEF) tank

is almost empty or the soot level in

the DPF is at full capacity. At this

level warning, regeneration cannot be

performed and engine power will be

derated.

Engine may automatically shut down

if the Check Engine light and Stop

Engine light are illuminated and the

operator does not correct the condition.

NOTE

The Malfunction Indicator Lamp

(MIL) will illuminate if the OBD (Onboard Diagnostics) system detects

a possible emissions system failure.

The vehicle should be brought in

for service at the next opportunity to

ensure the condition is corrected.

3-4 Y53-1181-1B1 (07/19/2013)

Page 27

Operating Instructions

Diesel Particulate Filter (DPF)

Warning Lamp

DPF Warning Lamp

Refer to Engine Aftertreatment

Systems Operator's Manual for

additional information.

High Exhaust System Temperature

(HEST) Warning Lamp

HEST Warning Lamp

Refer to Engine Aftertreatment

Systems Operator's Manual for

additional information.

Check Engine Lamp (CEL)

Check Engine Lamp

Refer to Engine Aftertreatment

Systems Operator's Manual for

additional information.

3

(07/19/2013) Y53-1181-1B1 3-5

Page 28

Operating Instructions

Diesel Exhaust Fluid (DEF) Lamp

Diesel Exhaust Fluid (DEF) Lamp

Refer to Engine Aftertreatment

3

Systems Operator's Manual for

additional information.

Engine Operating Range

General Information

CAUTION

Operating the engine at full throttle below peak torque will shorten engine

life to overhaul, can cause serious engine damage, and is considered engine abuse. Do not operate the engine

at full throttle operation below peak

torque rpm for more than 30 seconds.

Failure to comply may result in equipment or property damage.

PACCAR engines are designed to

operate at full throttle under momentary

conditions down to peak torque engine

speed. This is consistent with

recommended operating practices.

CAUTION

Operating the engine beyond the maximum engine speed can cause severe

engine damage. Use proper operating

techniques for the vehicle to prevent

engine overspeed. The maximum engine speed specication is listed in

the “General Engine Specications” on

page 5-12. Failure to comply may result in equipment or property damage.

NOTE

For applications with high idle time,

to help reduce soot loading in the aftertreatment system, avoid long periods of idling. If idling is required

increase idle speed using the cruise

control function.

3-6 Y53-1181-1B1 (07/19/2013)

Page 29

Operating Instructions

Engine Braking System

WARNING!

Do not operate the engine compression brake when driving/operating

your vehicle bobtail or with a loaded

or unloaded trailer on road surfaces

with poor traction (wet, icy, or snow

covered roads) or in heavy trafc.

Braking caused by the normal operation of the engine compression brake

could cause you to lose control of the

vehicle resulting in an injury accident.

Failure to comply may result in death,

personal injury, equipment or property

damage.

WARNING!

The service brakes must be used in

an emergency. The engine compression brake alone might not stop the vehicle fast enough to prevent an accident. The engine compression brake

is NOT intended as the primary brake

for the vehicle, nor is it an emergency

brake. The engine compression brake

only helps the service brakes by using

engine backpressure to slow the drivetrain. Use the service brakes for quick

stops. You could be seriously injured

if you relied only on the engine compression brake to stop the vehicle in

an emergency. Failure to comply may

result in death, personal injury, equipment or property damage.

WARNING!

Do not use the compression brake

when operating on road surfaces with

poor traction (such as wet, icy, or

snow covered roads or gravel). Compression brakes can cause the wheels

to skid on a slippery surface. You

could lose control of the vehicle and/or

jackknife if the wheels begin to skid,

resulting in an accident. Failure to

comply may result in death, personal

injury, equipment or property damage.

NOTE

If your vehicle is equipped with antilock brakes (ABS), operation of the

compression brake (if turned ON) may

be interrupted if the ABS system detects wheel slip due to operation on

slippery surfaces.

3

(07/19/2013) Y53-1181-1B1 3-7

Page 30

Operating Instructions

An engine compression brake is

standard on the PACCAR MX-13

engine. When activated, the engine

compression brake creates a braking

effect on the drive wheels. This

device uses engine power to slow

the vehicle down. Because it can

help keep your vehicle’s brakes from

3

overheating, it can save wear and tear

on the service brakes. However, the

engine compression brake is not an

emergency brake.

Ideally (on normal road surfaces),

you should slow your vehicle with the

compression brake (where permitted

by law) and use the service brakes only

for stopping completely. Operating this

way will greatly prolong the life of the

service brakes.

Compression Brake

With the compression brake switch

ON, the brake automatically creates its

braking effect when you remove your

foot from the accelerator pedal.

The brake switch is located on the

accessory dash panel. It controls

whether the brake is ON (ready to slow

the vehicle down) or OFF (no braking

action).

• Do not use the engine

compression brake to slow

the vehicle down when you are

bobtailing or pulling an empty

trailer.

• Make sure the brake is OFF before

starting the engine.

• After the engine is started, warmed

up, and you are ready to get under

way, turn the engine compression

brake switch ON for added braking

effect.

NOTE

If your vehicle is equipped with the

Eaton Vorad® system, operation of the

compression brake may be automatically activated.

3-8 Y53-1181-1B1 (07/19/2013)

Page 31

Operating Instructions

Compression Brake Controls

Two (2) switches on the dash panel

control the engine compression brake.

A master switch turns the system ON

or OFF. A second switch, located

next to the master switch, controls

the braking effect. This switch allows

you to choose progressively stronger

braking to slow the vehicle down.

Engine compression brake controls

include:

• On/Off switch.

• 3-position selector switch.

• Clutch switch.

• Throttle sensor.

• Service brake pressure switch.

• Eaton Vorad® Anti-Lock Braking

System.

Engaging conditions for the engine

compression brake are:

• Engine speed must be above

1,000 rpm.

• Coolant temperature must be

above 59°F (15°C).

Deactivation conditions for the engine

compression brake are:

• Accelerator pedal is depressed.

• Clutch pedal is depressed.

• Engine speed falls below 800 rpm.

• ABS control is active.

• Engine ECM recognizes a system

problem.

CAUTION

Operating the engine with a compression brake that will not automatically

deactivate (i.e. when the dash switch

is off, clutch pedal is depressed or

throttle is applied) will cause severe internal engine damage. Do not operate

the engine if the compression brake

will not deactivate. Failure to comply

may result in equipment or property

damage.

3

(07/19/2013) Y53-1181-1B1 3-9

Page 32

Operating Instructions

Engine Compression Brake Level

Switch Operation

There are 2 switches that control your

vehicle’s engine compression brake.

One switch turns the system on/off and

the second switch controls the braking

level. These switches are located on

the dash switch panel.

3

For the 3-position engine compression

brake level switch, there will be 100%

engine braking when the switch is in

the up (HIGH) position. In the middle

(MEDIUM) position, there will be 66%

engine braking. In the down (LOW)

position there will be 33% engine

braking.

With the compression brake switch

ON, the compression brake will be

engaged when the service brake is

applied.

If the cruise control is operated in

conjunction with the compression

brake, the compression brake will

engage to maintain the cruise set

speed.

On/Off Switch Symbol

Compression Brake Level Switch

Symbol

3-10 Y53-1181-1B1 (07/19/2013)

Page 33

Operating Instructions

General Information . . . . . . . . . . . . . . . 4-3

Normal Starting Procedure . . . . . . . . . . . . 4-4

Cold Weather Starting . . . . . . . . . . . . . . 4-5

Starting Procedure After Extended Shutdown or Oil

Change . . . . . . . . . . . . . . . . . . . 4-5

Operating the Engine . . . . . . . . . . . . . . 4-6

Engine Shutdown . . . . . . . . . . . . . . . . 4-6

Electromagnetic Interference (EMI) . . . . . . . . 4-6

Driving

4

(07/19/2013) Y53-1181-1B1 4-1

Page 34

Page 35

Operating Instructions

Operating Instructions

General Information

Correct care of your engine will result

in longer life, better performance, and

more economical operation.

Follow the daily maintenance checks

listed in “Maintenance Schedule” on

page 5-4.

Check the engine oil pressure and

engine coolant gauges, warning lights,

and other gauges daily to make sure

they are operational.

WARNING!

Combustible vapors near the air intake

system could be ingested into the engine, causing the engine to suddenly

accelerate and overspeed. This condition could result in operator losing control of the vehicle if an unexpected increase in engine rpm occurs. Combustible vapors could also cause a re.

Do not operate your vehicle in an area

where combustible chemicals or vapors may be present. Failure to comply may result in death, personal injury,

equipment or property damage.

IT IS THE RESPONSIBILITY OF

THE OWNER AND OPERATOR TO

OPERATE THE VEHICLE IN A SAFE

ENVIRONMENT.

4

(07/19/2013) Y53-1181-1B1 4-3

Page 36

Operating Instructions

Normal Starting Procedure

Starting

1. Ensure the parking brake is set

ON and the transmission shift

lever is in neutral. For automatic

transmissions that have park

position, place the shift lever in

park.

2. With the accelerator pedal in the

idle position, turn the ignition key

to the START position.

3. Release the key after 10 seconds

4

if the engine does not start. Then

wait 10 seconds and try again.

NOTE

If the engine is running, do not increase engine speed (rpm) or operate

the vehicle until the low oil pressure

warning lamp turns off.

CAUTION

Engaging the starter motor for more

than 30 seconds in any 5 minute period may cause it to overheat and can

damage the starter motor.

• If starter is engaged continuously

for 30 seconds, you must wait 5

minutes before trying to start the

engine to allow the starter motor

to cool down.

If the engine does not start, or runs

erratic, follow the procedure under

“Starting After the Fuel Tank Has Run

Dry”, see on page 5-30.

With the key in the ON position, the

engine warning lamps will come on

momentarily and then go out. The

engine warning lamps include:

1. Check engine lamp; yellow in

color.

2. STOP engine lamp; red in color.

3. Diesel Particulate Filter (DPF)

status indicator; yellow in color.

4. High Exhaust System Temperature

(HEST); amber in color.

4-4 Y53-1181-1B1 (07/19/2013)

Page 37

Operating Instructions

Cold Weather Starting

General Information

Follow the “Normal Starting Procedure”

on page 4-4.

Refer to the vehicle operator's manual

instructions for any additional cold

weather starting procedures.

If starting a cold engine, slowly

increase the engine speed. This

provides adequate lubrication to the

bearings and gives ample time to allow

the oil pressure to stabilize.

The use of cold starting aids are

not recommended for ambient

temperatures above 0° F (-18° C).

If an engine must idle for an extended

period of time, it should be done at

a fast idle (1000 rpm maximum) at

coolant temperatures below 150° F

(70° C).

For coolant temperatures below 150°

F (70° C), use a low gear and drive

at moderate engine speed until the

engine coolant has reached operating

temperature. Do not let the engine idle

longer than necessary.

CAUTION

Do not operate the engine at low idle

for long periods of time when the

coolant temperature is below the normal operating range. This could result

in the following:

• Fuel dilution of the lubricating oil

• Carbon buildup in the cylinder

• Sticking of the valves in the

cylinder head

• Reduced performance

• Damage to aftertreatment

components

Starting Procedure After

Extended Shutdown or Oil

Change

General Information

Follow the “Normal Starting Procedure”

on page 4-4.

4

(07/19/2013) Y53-1181-1B1 4-5

Page 38

Operating Instructions

Operating the Engine

Normal

Monitor the oil pressure and coolant

temperature gauges frequently. Refer

to “Lubricating Oil System” and

“Cooling System” for recommended

operating pressures and temperatures.

Shut off the engine if any pressure

or temperature does not meet the

specications.

4

Engine Shutdown

Before Stopping the Engine

NOTE

Do not shut off the engine immediately.

A hot engine stores a great amount of

heat and it does not cool down immediately after it is shut off. Always cool

the engine down before shutting it off.

You will greatly increase its service life.

Idle the engine at 1,000 rpm for 4

minutes. Then low idle for 30 seconds

before shutdown. This will allow

circulating coolant and lubricating oil

to carry heat away from the cylinder

head, valves, pistons, cylinder liners,

turbocharger, and bearings. This way

you can prevent engine damage that

may result from uneven cooling.

Electromagnetic Interference (EMI)

General Information

If not installed correctly, some vehicle

accessories (CB radios, mobile

transmitters, etc.) can generate and

use radio frequency energy that may

cause electromagnetic interference

(EMI) between the accessory and

the electronic controlled fuel system.

Under these conditions, PACCAR

is not liable for any performance

problems with either the fuel system or

the accessory. EMI is not considered

by PACCAR to be an engine failure

and therefore is not warrantable.

4-6 Y53-1181-1B1 (07/19/2013)

Page 39

Operating Instructions

System EMI Susceptibility

PACCAR products are designed

and tested for minimum sensitivity

to incoming electromagnetic energy.

The fuel system EMI susceptibility

has been designed with a high

tolerance against EMI and in most

normal circumstances, if not all,

electromagnetic energy-emitting

devices that meet the Federal

Communications Commission legal

requirements should cause no

interference.

System EMI Radiation Levels

Electronic components are required

to pass various PACCAR and industry

EMI specications. Our testing

has shown that when the engine is

properly installed and maintained, it

will not interfere with properly installed

onboard communication equipment.

If any interference condition is noticed,

follow these suggestions to reduce the

amount of EMI:

1. Locate the accessory receiving

antenna further away.

2. Check with the accessory supplier

representative in your area to:

° Accurately calibrate the

accessory for proper

frequency, power output,

and sensitivity.

° Determine the optimum

antenna location by obtaining

antenna reective energy data

measurements.

° Ensure that the optimum

antenna type and mounting

arrangement is being used.

° Ensure the accessory

equipment is properly

constructed for maximum

ltering to reject incoming

electromagnetic noise.

4

(07/19/2013) Y53-1181-1B1 4-7

Page 40

Page 41

Maintenance Guidelines

Overview . . . . . . . . . . . . . . . . . . . 5-3

Maintenance Schedule . . . . . . . . . . . . . 5-4

Maintenance Specications

General Engine Specications . . . . . . . . . 5-12

Lubricating Oil System . . . . . . . . . . . . . 5-12

Cooling System . . . . . . . . . . . . . . . . 5-13

Filter Specications . . . . . . . . . . . . . . 5-14

Fuel Recommendations . . . . . . . . . . . . 5-14

Warranty and the Use of Biodiesel Fuel . . . . . 5-16

Lubricating Oil Recommendations and Specications 5-17

Coolant Recommendations and Specications . . 5-18

Maintenance Procedures

Oil Pan Drain Plug . . . . . . . . . . . . . . 5-21

Inspection of the Engine Oil Level . . . . . . . . 5-21

Topping Up the Engine Oil . . . . . . . . . . . 5-22

Replacing Engine Oil Filters . . . . . . . . . . 5-23

Maintenance

5

(07/19/2013) Y53-1181-1B1 5-1

Page 42

5

Maintenance

Replacing Fuel Filter . . . . . . . . . . . . . 5-27

Replacing Coolant Filter . . . . . . . . . . . . 5-31

Emergency Repairs . . . . . . . . . . . . . . 5-35

5-2 Y53-1181-1B1 (07/19/2013)

Page 43

Maintenance Guidelines

Maintenance Guidelines

Overview

General Information

PACCAR recommends that the

engine be maintained according to the

maintenance schedule in this section.

If the engine is operating in ambient

temperatures below 0°F (-18°C)

or above 100°F (38°C), perform

maintenance at shorter intervals.

Shorter maintenance intervals are also

required if the engine is operated in a

dusty environment or if frequent stops

are made.

Some of these maintenance

procedures require special tools

or must be completed by qualied

personnel. Contact your local

PACCAR authorized repair location for

detailed information.

If your engine is equipped with

a component or accessory not

manufactured by PACCAR Inc, refer

to the component manufacturer's

maintenance recommendations.

Oil Drain Intervals

Oil drain interval recommendations are

based on vehicle application or engine

duty cycle. PACCAR recommends

the use of high quality lubricating oil

as indicated in the Lubricating Oil

Recommendations in the Maintenance

Specications Section.

5

(07/19/2013) Y53-1181-1B1 5-3

Page 44

Maintenance Guidelines

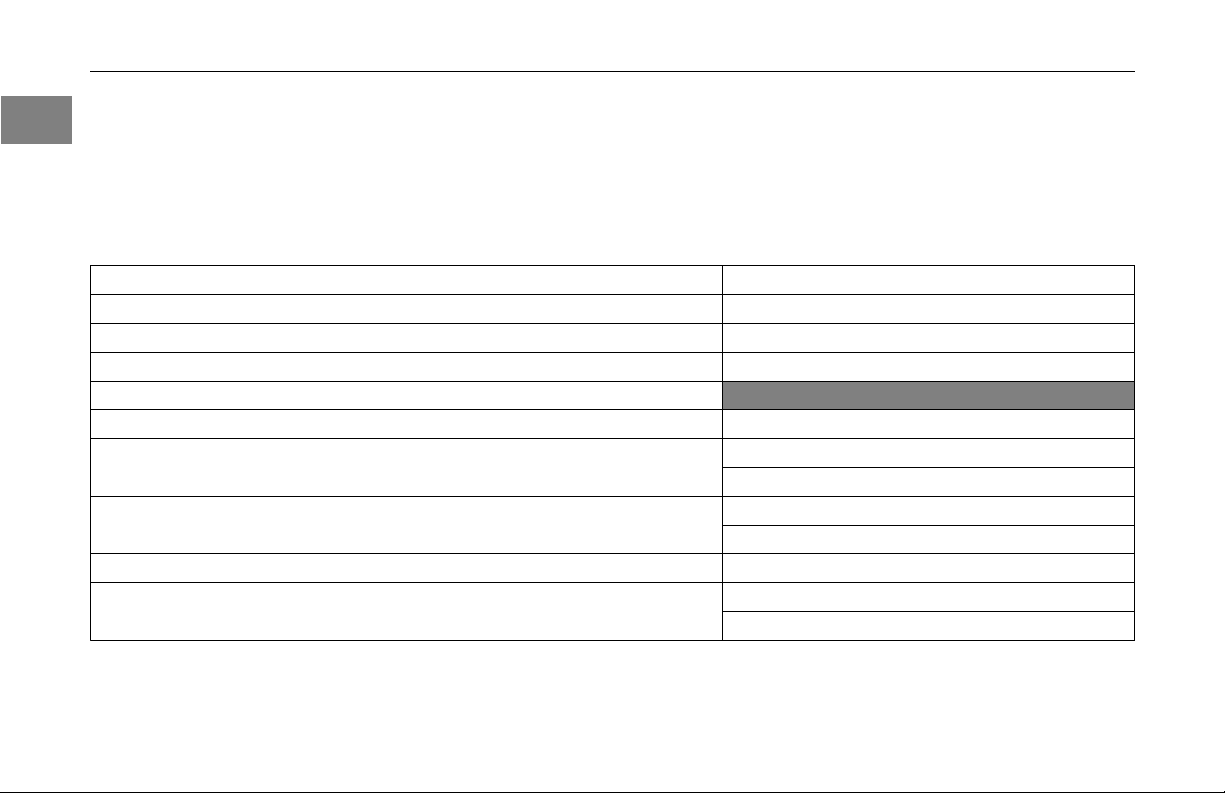

Severe Duty

Fuel Consumption

Miles per Gallon

Kilometers per Liter

Gross Vehicle Weight

Oil Drain and Filter Interval 25,000 miles/40,000 km

**Vocational vehicle applications include: Agriculture, Concrete Mixers, Construction, Crane, Dumps, Emergency/Fire, Heavy Equipment, Loggers,

Mining, Oil Field, Refuse, Pick-up & Delivery, Snowplows, and Wrecker

Vocational**

Less than 6 MPG

Less than 2.6 km/L

More than 80,000 lb

More than 36,300 kg

800 hours or 12 months

Normal Duty

Line Haul

6 MPG or greater

2.6 km/L or greater

80,000 lb or less

36,300 kg or less

Less than 20% idle time:

60,000 miles/96,000 km

1200 hours or 12 months

More than 20% idle time:

40,000 miles/64,000 km

1200 hours or 12 months

Maintenance Schedule

General Information

5

Perform maintenance at whichever

interval occurs rst. At each scheduled

maintenance interval, perform all

previous maintenance checks that are

due for scheduled maintenance.

This maintenance schedule is for a

Normal Duty Cycle engine operation.

Severe Duty / Vocational applications

will need to adjust mileage, kilometer,

hour, or time interval based on the Oil

Drain Interval Guidelines listed above.

NOTE

NOTE

The crankcase ventilation is good for

the life of the engine.

5-4 Y53-1181-1B1 (07/19/2013)

Page 45

Maintenance Guidelines

Daily or Refueling – Maintenance

Check

• Engine Lubrication Oil Level -

Check/Correct:

To check engine oil level, park

vehicle on level ground and wait 15

minutes after shutting off engine.

° Remove dipstick and wipe it

off with a clean, lint free rag.

° Reinsert dipstick all the way in

and pull it out again to check

oil level.

° Correct oil level is between

the low (L) and high (H) marks

on the dipstick.

• Engine Fuel Filter / Water

Separator – Automatic water

drain, no maintenance required

• Chassis Fuel Filter / Water

Separator – Drain trapped water

(if equipped)

• Air Intake Piping – Inspect:

° Hose/Pipe condition –

deterioration/signs of leaking

° Hose clamps for tightness

° Clearance to other

components

° Check Air Restriction Gauge

• Aftertreatment Exhaust Piping –

Inspect:

° Cracks

° Clearance to other

components (i.e. electrical

harnesses, etc.)

° Hose/pipe condition –

deterioration/signs of leaking

• Cooling Fan – Inspect:

° Cracks

° Clearance to other

components

5

(07/19/2013) Y53-1181-1B1 5-5

Page 46

Maintenance Guidelines

• Engine Coolant Level –

Check/Correct:

With the engine off and

temperature cool:

° Check coolant level. It should

be visible through the clear

plastic surge tank.

° Add coolant as necessary by

removing the pressure cap on

the neck of the surge tank or

sight glass.

° Replacement or top up

coolant should have the same

antifreeze concentration and

5

corrosion inhibitor content

as the original coolant in the

cooling system.

° Always dilute antifreeze to

the correct concentration

based on freeze protection

before adding it to the cooling

system. Adding or using 100%

antifreeze in a cooling system

may result in cooling system

plugging and overheating

problems.

• Diesel Exhaust Fluid (DEF) Level

– Check/Top Up:

NOTE

It is recommended to top up DEF when

refueling. See Engine Aftertreatment

Systems Operator’s Manual for DEF

information.

• Check for any signs of uid

leaks

• Ensure all access caps/covers are

installed and tight.

5-6 Y53-1181-1B1 (07/19/2013)

Page 47

Maintenance Schedule

Maintenance Guidelines

Maintenance Interval Miles Kilometers Hours Months

A 30,000 48,000 900 6

B 60,000 96,000 1,800 12

C

D 180,000 290,000 4,500 24

E 240,000 380,000 5,400 24

F 300,000 480,000 6,750 24

G

H 750,000 1,200,000 12,000

A 12,500 20,000 400 6

B 25,000 40,000 800 12

C

D 160,000 256,000 5,120 24

E 200,000 320,000 6,400 24

F 300,000 480,000 9,000 24

G

H 750,000 1,200,000 12,000

(07/19/2013) Y53-1181-1B1 5-7

120,000 190,000 3,600 24

480,000 770,000 13,500

40,000 64,000 1,280 24

480,000 770,000 13,500

Maintenance Schedule – Normal Duty/Line Haul

48 (4 years)

48 (4 years)

Maintenance Schedule – Severe Duty/Vocational

48 (4 years)

48 (4 years)

5

Page 48

Maintenance Guidelines

Perform maintenance at whichever previous maintenance checks that are

interval occurs rst. At each scheduled due for scheduled maintenance.

maintenance interval, perform all

Recommended Preventative Maintenance Interval

Component

Aftertreatment

System

Air System &

Compressor

5

Maintenance Task

• Aftertreatment Diesel Particulate Filter (DPF) – Clean using DPF cleaning machine.

NOTE

The aftertreatment DPF clean/replace interval is based on the use of lubricating oils that

meet the SAE 10W30 API CJ–4 oil specication.

• Aftertreatment Diesel Exhaust Fluid (DEF) Dosing Unit (DEF Module) Filter – Replace

Air Compressor – Check/Correct for carbon buildup

Air Cleaner – Check/Correct for restriction:

• Service lter element when air cleaner restriction gauge (option) locks in the extreme

high position.

• Hose/pipe condition – deterioration/ signs of leaking

• Hose clamp torque

Recommended Preventative

Maintenance Interval

A B

•

•

D E F

C

G

•

•

H

5-8 Y53-1181-1B1 (07/19/2013)

Page 49

Component

Charge Air System Charge Air Piping – Check/Correct:

Charging /

Cranking System

Cooling System Antifreeze – Check

Maintenance Task

• Hose/pipe condition – deterioration/signs of leaking

• Hose clamps for tightness

• Clearance to other components

Charge Air Cooler – Check/Correct:

• Cracked tubes or header

• Clogged ns/tubes

• Hose/pipe condition – deterioration/signs of leaking

• Hose clamp torque

Electrical Harness/Cables – Check:

• Inspect for loose connections, corrosion, chang, and broken retention clips.

Batteries, Cables, and Connections – Check:

• Condition – electrolyte level, cracks, signs of leaking, overcharging

• Hold–downs – Tightness

• Battery Box Mounting Bolt – Torque

• Coolant composition

• Coolant level

• Coolant protection

Radiator Hoses – Check

• Hose condition, deterioration/signs of leaking

• Hose clamp torque

• Replace Coolant Filter

• Change Extended Life Coolant*

See Extended Life Coolant on page 5-18.

Maintenance Guidelines

Recommended Preventative

Maintenance Interval

A B

•

•

•

•

•

D E F

C

•

H

G

•

•

5

(07/19/2013) Y53-1181-1B1 5-9

Page 50

Maintenance Guidelines

Component

Crankshaft Vibration Damper – Check:

Drive Belts

Engine Lubrication

– Line Haul

Engine Lubrication

– Severe Duty

5

Fuel System • Fuel Filter, Canister and Spin–on Type – Replace

Mounting Bolts Engine Mounting Bolts – Visual check

Valves – Initial

Service

Valves

Maintenance Task

• Inspect for cracks, nicks, leakage

• Check fastener torque

Belts – Check/Correct:

• Condition, signs of wear/ deterioration

• Alignment

Fan Belt Tensioner – Check/Correct:

• Mounting bolt torque

• Tensioner maintains proper belt tension

Poly-v Belts – Replace

Filters and Oil – Change:

• Oil lters

• Oil, less than 20% idle time – every 60,000 mi (96,000 km)

• Oil, greater than 20% idle time – every 40,000 mi (64,000 km)

Filters and Oil – Change:

• Oil lters

• Oil, every 25,000 mi (40,000 km; 800 hours or 12 months)

Valve Clearance:

• Inspect and adjust if necessary

• Valve cover gasket seal – Replace

(Next required service interval: D)

Valve Clearance:

• Adjust

• Valve cover gasket seal – Replace

Recommended Preventative

Maintenance Interval

A B

•

•

•

•

•

•

D E F

C

•

G

•

•

•

H

5-10 Y53-1181-1B1 (07/19/2013)

Page 51

Maintenance Guidelines

Recommended Preventative

Component

* Extended Life Coolant A heavy–duty extended life coolant (ELC) that meets ASTM D 6210 chemical composition specications must be used.

The change interval is 750,000 miles (1,200,000 km) or 12,000 hours on–road use (8 years or 15,000 hours off–highway use) on initial ll with

no extender added. The change interval is 1,000,000 miles (1,600,000 km)/20,000 hours/8 years with an extender addition at 500,000 miles

(800,000 km)/10,000 hours/4 years. Antifreeze is essential for freeze, overheat, and corrosion protection. The use of supplemental coolant

additives (SCAs) is not recommended.

Maintenance Task

NOTE

Follow the manufacturers' recommended maintenance procedures for the starter, alternator, batteries, electrical components, radiator, air compressor, air cleaner, refrigerant compressor, and fan clutch.

Maintenance Interval

A B

D E F

C

G

H

5

(07/19/2013) Y53-1181-1B1 5-11

Page 52

Maintenance Specications

Maintenance

Specications

General Engine

Specications

Horsepower

Firing Order

Crankshaft Rotation (viewed from front of engine) Clockwise

Displacement

Bore and Stroke 5.12 in. (130 mm) × 6.38 in. (162 mm)

Dry Weight (excludes Flywheel and Air Compressor) 2,600 lb. (1,179 kg.)

Idle Speed

Maximum Loaded Engine Speed

Maximum Governed No-Load Engine Speed

Maximum Engine Compression Brake Speed

Lubricating Oil System

5

Oil Pressure At Low Idle (minimum allowable) 27 psi (187 kPa) at 191°F (88°C) oil temperature

Regulated Oil Pressure 72 psi (496 kPa) at 223°F (106°C) oil temperature

Total System Capacity (Oil Pan and New Oil Filters) 42 qt (40.0 liters)

At Road Speed 900-1,900 rpm (minimum

allowable)

See EPA label on top of the valve cover or on the mixer manifold.

See EPA label on page 6-5.

1, 5, 3, 6, 2, 4

784 CID (12.9 liters)

Approximately 650 rpm

1,900 rpm

2,200 rpm

2,100 rpm

40 psi (276 kPa) at 215°F (102°C) oil temperature

5-12 Y53-1181-1B1 (07/19/2013)

Page 53

Cooling System

Maintenance Specications

Coolant Capacity Approximately 14 to 15 gallons (53 to 57 liters) depending on chassis

Minimum Recommended Pressure Cap 15 psi (103 kPa)

Maximum Top Tank Coolant Temperature 111°F (44°C) above outside temperature

WARNING!

Coolant is toxic. Do not get the uid

in eyes. If contact with the eyes occurs, ood eyes with large amounts

of water for 15 minutes. Avoid prolonged or repeated contact with skin.

In case of contact, immediately wash

skin with soap and water. Do not take

internally. If swallowed, seek immediate medical attention. Do not induce

vomiting. Failure to comply may result

in death, personal injury, equipment or

property damage.

Coolant is harmful to the environment.

Unused coolant must be stored as a

toxic hazardous material in leakproof

containers. Used coolant must be processed as industrial chemical waste.

Please follow HAZMAT guidelines with

both used and unused coolants.

model and cab/ sleeper heater options

NOTE

5

(07/19/2013) Y53-1181-1B1 5-13

Page 54

Maintenance Specications

Filter Specications Fuel Recommendations

General Information

WARNING!

PACCAR is not responsible for

problems caused by non-genuine lters

that do not meet PACCAR performance

or durability requirements.

Contact your local PACCAR authorized

repair location for specic part

numbers.

CAUTION

Use of non-genuine oil lters

cause severe engine damage.

can

The use of diesel fuel that has been

mixed with other fuels may cause an

explosion. Do not mix gasoline, alcohol, or gasohol with diesel fuel. Make

sure you know your fuel source and

use the recommended diesel fuel as

indicated in this section of the manual.

Failure to comply may result in death,

personal injury, equipment or property

damage.

5

CAUTION

Dirt or water in the fuel system can

cause severe damage to both the fuel

pump and the fuel injectors. Due to

the precise tolerances of diesel injection systems, it is extremely important

that the fuel be kept clean and free of

dirt or water. Know your fuel source

and make sure all steps are taken for

dispensing or using clean fuel in your

vehicle. Failure to comply may result

in equipment or property damage.

CAUTION

Lighter fuel can reduce economy or

possibly damage fuel system components. Lighter fuels typically do not

have enough lubricity elements in the

fuel to properly lubricate the fuel injection system. Be sure you follow

the fuel recommendations as indicated

in this section of the manual. Failure

to comply may result in equipment or

property damage.

5-14 Y53-1181-1B1 (07/19/2013)

Page 55

Maintenance Specications

CAUTION CAUTION

Using diesel fuels blended with lubri- If ultra-low-sulfur diesel fuel is not PACCAR recommends that the cetane

cants may cause damage to your ex- used, the engine may not meet emis- number of diesel fuel be a minimum

haust aftertreatment system. Service sion regulations, and damage may oc- of 45 for engines that are expected to

intervals for aftertreatment systems cur to the exhaust aftertreatment sys- operate at temperatures below 32°F

will be reduced. Do not use diesel fuel tem. The use of high-sulfur diesel fuel (0°C) and a minimum of 42 for enblended with lubricating oil in engines will damage the exhaust aftertreat- gines that are operated at temperaequipped with an aftertreatment sys- ment system and impact the engine tures above 32°F (0°C).

tem. Failure to comply may result in emission. Ultra-low-sulfur diesel fuel

equipment or property damage. is required for correct operation of

the aftertreatment system. The en-

CAUTION

Do not use high-sulfur diesel fuel as

it will damage the exhaust aftertreatment system. Also, the engine will

not meet emission regulations. Use

only ultra-low-sulfur diesel (ULSD)

fuel. Failure to comply may result in

equipment or property damage.

gine has been optimized for use with

an aftertreatment system to meet the

2013 U.S. Environmental Protection

Agency regulations. Failure to comply

may result in equipment or property

damage.

Using diesel fuel with a

lower-than-recommended cetane

number can cause hard starting,

instability, and excessive white smoke.

To maintain satisfactory operation

at low ambient temperatures, it is

important to specify diesel fuel of the

correct cetane number.

PACCAR requires all permissible

fuels to have adequate fuel lubricity.

Lubricity can be determined by ASTM,

specication D6079, ISO 12156, High

Frequency Reciprocating Rig (HFRR)

in which the fuel must have a wear scar

diameter of 0.02 in. (0.5 mm) or less.

NOTE

5

(07/19/2013) Y53-1181-1B1 5-15

Page 56

Maintenance Specications

The use of Ultra-Low-Sulfur diesel

fuel is required for this engine in

order to meet emission regulations

and to prevent damage to the engine

and exhaust system. The use of

other grades of diesel fuels other

than Ultra-Low-Sulfur diesel fuel will

be considered a use of incorrect

fuel for the engine. PACCAR is not

responsible for failures caused by the

use of incorrect fuel, oil or catalytic

reagent or by water, dirt or other

containments in the fuel or catalytic

reagent.

5

Warranty and the Use of Biodiesel Fuel

PACCAR Inc approves the use of

biodiesel fuel blends up to 5% by

volume in diesel fuel that meets all of

the following three conditions:

• The biodiesel used in the blend

meets ASTM Standard D 6751 or

EN 14214 specications.

• The biodiesel used in the blend

is sourced from a BQ-9000

Accredited Producer.

• The nished blend meets the fuel

properties of ASTM Standard D

975 or EN 590 specications.

The use of approved biodiesel fuel

does not affect the PACCAR engine

warranty. Failures caused by the use

of nonapproved biodiesel fuels or other

fuel additives that are of unacceptable

quality or do not meet specied

industry standards are not considered

as defects of parts or workmanship

by PACCAR and therefore will not

be covered by the PACCAR engine

warranty.

5-16

Y53-1181-1B1 (07/19/2013)

Page 57

Maintenance Specications

Lubricating Oil

Recommendations and

Specications

General Information

CAUTION

Extending the oil and lter change interval beyond the recommendations

will decrease the engine life due to

factors such as corrosion, deposits,

and wear. Engine oil lters capture

dirt and remove deposits from the oil

to prolong the life of internal moving

components. Follow the oil and lter

change intervals as recommended in

this section of the manual. Failure

to comply may result in equipment or

property damage.

A major factor in maintaining engine

performance and durability is the

proper use of quality engine lubricating

oils used in conjunction with the

appropriate oil drain and lter change

intervals. Attempting to extend the oil

and lter change interval beyond the

manufacturers recommendations may

decrease engine life.

NOTE

It is the operator’s responsibility to

abide by these recommendations to

ensure that the engine warranty does

not get affected.

PACCAR recommends the use of

high-quality SAE 10W30 API CJ-4

heavy-duty engine oil.

The primary PACCAR

recommendation is for the use of

10W30 multigrade lubricating oil

for normal operation at ambient

temperatures above 5°F (-15°C).

For ambient temperatures below

5°F (-15°C) SAE 5W30 may be

used, provided it meets API CJ-4

oil specications and biodiesel or

biodiesel blended fuel is not used as

fuel for the engine. Using a multigrade

oil helps improve engine cranking in

low-temperature conditions, reduces

deposit formation and increases

engine durability.

New Engine Break-In Oils

PACCAR does not approve the use of

special “break-in” engine lubricating

oils for new or rebuilt PACCAR

engines. It is recommended to use

the same lubricating oil for engine

break-in that will be used during normal

operation.

5

(07/19/2013) Y53-1181-1B1 5-17

Page 58

Maintenance Specications

Aftermarket Oil Additive Usage

PACCAR does not recommend the use

of aftermarket oil additives. Today's

high-quality engine lubricating oils are

very sophisticated. Most oils already

contain precise amounts of additives

blended into the lubricating oil to meet

stringent performance requirements.

These oils meet performance

characteristics that conform to the

lubricant industry standards and

are sufcient protection when used

according to the recommendations.

Aftermarket lubricating oil additives are

not necessary to enhance engine oil

5

performance and may in some cases

reduce the oil's capability to protect

the engine.

Coolant Recommendations

and Specications

The cooling system in your vehicle

was factory lled with Extended Life

Coolant (ELC) that meets or exceeds

all ASTM D 6210 requirements.

PACCAR recommends only using a

50/50 mixture of distilled water and

ELC when cooling system service

is required. A 50/50 mixture of ELC

and distilled water will provide freeze

protection down to -34°F (- 36.7°C),

which is adequate for most locations

in North America. For extremely cold

operating conditions, a 60/40 mixture

(coolant/water ratio) can be used to

provide freeze protection down to

-62°F (-52.2°C).

Your engine is also equipped with a

Coolant Filter designed to capture

and remove harmful deposits from the

cooling system to help prolong system

life.

CAUTION

Use of non-genuine coolant lters can

cause severe engine damage.

5-18 Y53-1181-1B1 (07/19/2013)

Page 59

Maintenance Specications

Checking Coolant Condition Recommended Extended Life Cooling System Sealing Additives

To ensure the Extended Life Coolant

(ELC) in your vehicle always provides

maximum freeze protection, perform

the following tests:

1. Check the coolant color at every

maintenance interval. It should be

a bright red with no signs of debris

or any oil.

2. Test the freeze point at least two

times a year. A refractometer or

test strips can be used to measure

the protection level.

Coolant Suppliers

Brand Name

TRP® Authorized PACCAR

Supplier

Engine Dealer

CAUTION

The use of sealing additives in the

cooling system can cause damage to

the engine. Sealing additives can plug

various areas of the radiator, EGR system and oil cooler. The plugging of

the cooling system can hamper heat

transfer, causing internal engine damage. Do not use sealing additives in

the cooling system. The use of sealing additives can:

• Build up in coolant low-ow areas.

3. Keep the cooling system at full

levels by topping-up using ELC

pre-diluted to 50/50 blend.

• Plug the radiator and oil cooler.

• Damage the water pump seal.

Failure to comply may result in equip-

ment or property damage.

(07/19/2013) Y53-1181-1B1 5-19

5

Page 60

Maintenance Specications

Cooling System Soluble Oils

CAUTION

The use of soluble oils in the cooling

system can cause damage to the engine. Soluble oils in the cooling system can:

• Damage heat transfer surfaces.

• Damage seals and hoses.

Failure to comply may result in equip-

ment or property damage.

5

5-20 Y53-1181-1B1 (07/19/2013)

Page 61

Maintenance Procedures

Maintenance

Procedures

Oil Pan Drain Plug

After draining the oil, discard the

washer and replace with a new copper

sealing washer, torque the bolt to 44

lb-ft (60 Nm).

Inspection of the Engine Oil Level

NOTE

It takes approximately 15 minutes for

all the oil to run into the sump when the

engine is ‘warm.’ If the level is checked

immediately after switching off the engine, the dipstick will show a low oil

level.

1. Make sure that the vehicle frame

rail is standing on a at and level

surface.

2. Make sure that the vehicle is

horizontal, both lengthwise and

crosswise. Check this carefully

on a vehicle with air suspension.

Note that the engine may be

inclined up to 4° depending on the

vehicle model and wheelbase.

3. Twist the dipstick handle to unlock

it, then pull the dipstick out of the

holder.

4. Wipe the dipstick clean with a

lint-free cloth.

5. Place the dipstick back into the

holder.

6. Pull the dipstick out again and

check the oil level. The oil level

should always be between the 2

marks on the dipstick.

5

(07/19/2013) Y53-1181-1B1 5-21

Page 62

Maintenance Procedures

7. Reinstall the dipstick and twist to

lock it in place.

5

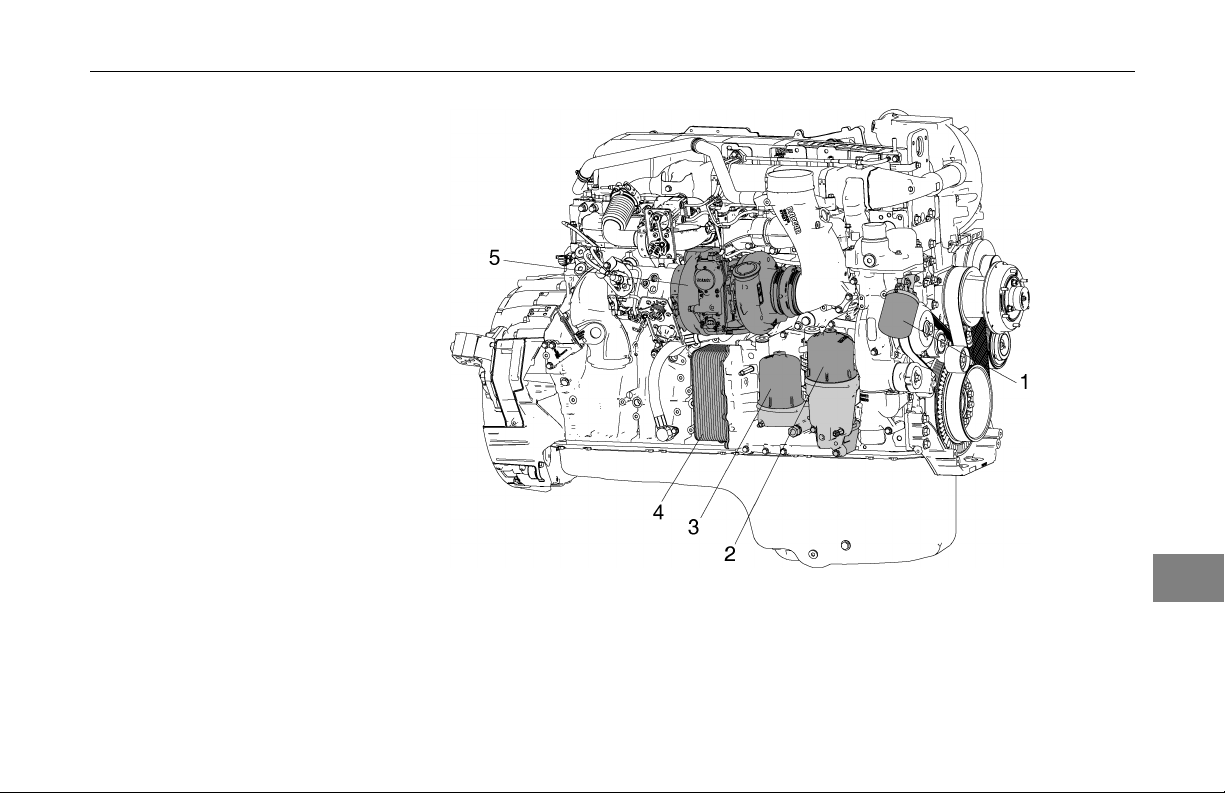

1. Engine Oil High Level

2. Engine Oil Low Level

Topping Up the Engine Oil

1. Top up with oil, if necessary, via

the ller opening. Use the correct

grade in the correct quantity.

2. After topping up, wait 1 minute and

check the oil level again.

3. Reinstall the oil ll cap and twist

to lock it in place.

NOTE

PACCAR recommends the use of

high-quality SAE 10W30 API CJ-4

heavy-duty engine oil.

5-22 Y53-1181-1B1 (07/19/2013)

Page 63

Maintenance Procedures

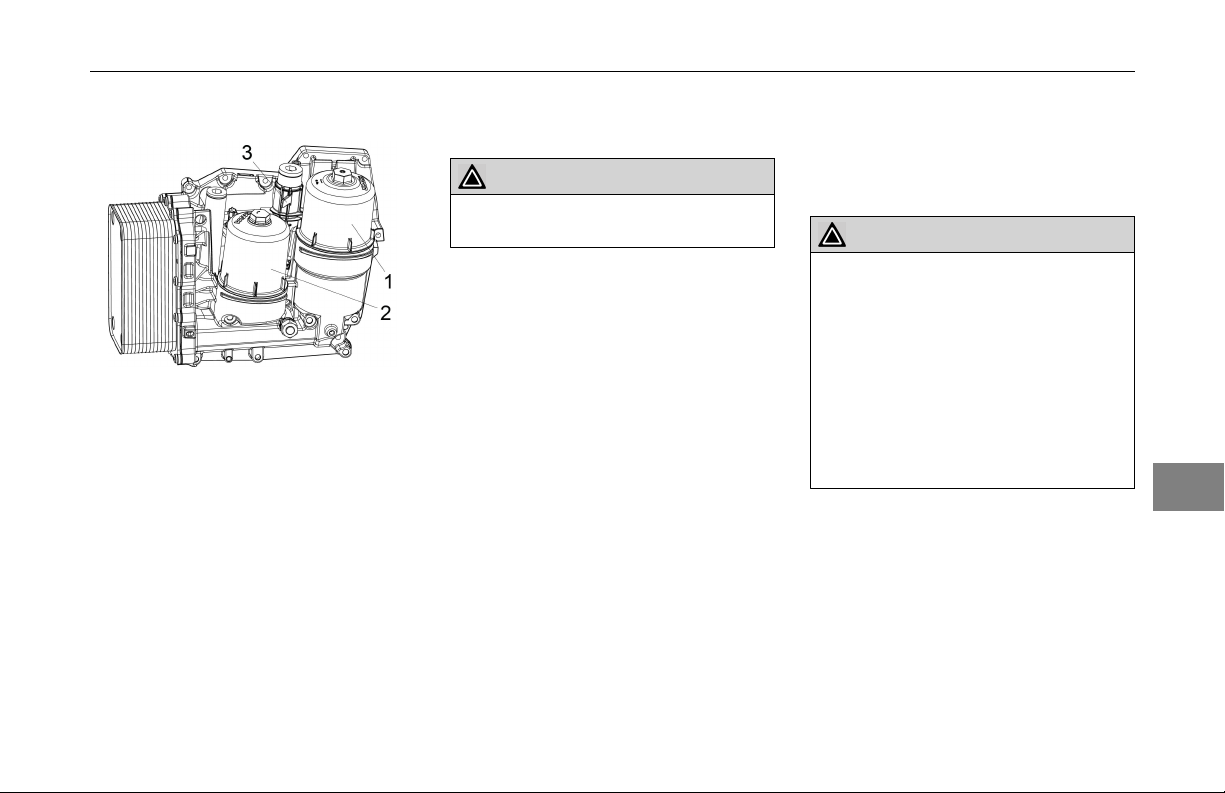

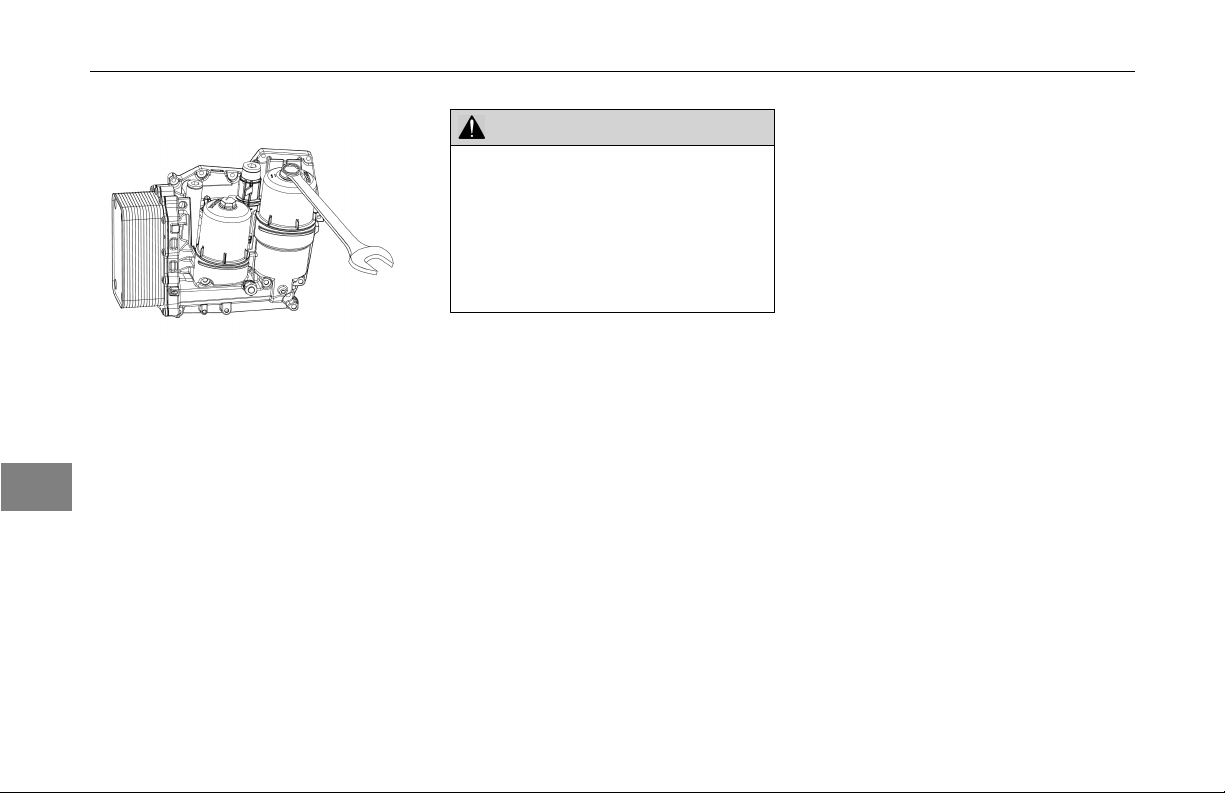

Replacing Engine Oil Filters

1. Full-Flow Oil Filter

2. Centrifugal Bypass Oil Filter

3. Oil Filter Cap Lock

Your engine is equipped with a full-ow

oil lter and centrifugal bypass oil lter.

Both lters are designed to capture

contaminants and remove deposits

from the oil to prolong the life of

internal moving components. Always

use quality engine lubricating oils in

conjunction with the appropriate oil

drain and lter change intervals. Refer

to “Maintenance Schedule” beginning,

on page 5-4, for the recommended oil Oil Filter Removal Preparation

and lter change service interval.

CAUTION

Use of non-genuine oil lters

cause severe engine damage.

can

1. Disconnect the chassis battery

cable at the negative battery

terminal.

CAUTION

Before beginning to remove and/or

disconnect any components, wait at

least 5 minutes after the key switch

is turned OFF for the aftertreatment

Diesel Exhaust Fluid (DEF) dosing

system to purge the DEF from the

system. The DEF system purges to

prevent damage from freezing. Failure to comply may result in equipment

or property damage.

5

(07/19/2013) Y53-1181-1B1 5-23

Page 64

Maintenance Procedures

WARNING!

Electrical shock hazard: Never disconnect the battery clamp when the

engine is running. Disconnecting the

battery clamps while the engine is running may result in death, personal injury or equipment damage from electrical arcing or damage to electrical components.

5

WARNING!

Turn off the engine and place the ignition switch in the OFF position before disconnecting the battery clamps.

Do not place any tools or other materials on top of or close to the batteries. This can cause a dangerous

high current short circuit and, in the

worst case, a battery explosion. Keep

all objects away from the battery terminals. Always break the contact between the battery clamp and the negative terminal before working on the

vehicle. Working on a vehicle while

the battery is connected may result in

electrical injury or damage. Always

disconnect the battery at the negative

terminal when performing service procedures. Failure to comply may result

in death, personal injury or equipment

damage.

Centrifugal Bypass Oil Filter

Removal

1. Remove the cap of the centrifugal

oil lter. Use a hexagonal socket

to avoid damaging the oil lter cap.

2. Remove the centrifugal lter.

3. Remove the O-ring from the screw

cap.

2. Place an oil collection pan directly

under the oil lter.

5-24 Y53-1181-1B1 (07/19/2013)

Page 65

Maintenance Procedures

WARNING!

Lubricating oil can cause skin irritation

or skin injury. To prevent skin injury,

avoid unnecessary contact with the lubricating oil. Wear protective clothing,

eye wear and gloves when handling lubricating oil. Failure to comply may result in personal injury.

Centrifugal Bypass Oil Filter

Installation

1. Lightly lubricate the O-ring (1) with

engine oil.

2. Fit the new O-ring (1) onto the cap

(2).

3. Mount the centrifugal lter (3) with

its top side in the bearing of the

screw cap (2).

4. Check to ensure the centrifugal

lter (3) can rotate freely.

5. Position the screw cap carefully

onto the oil module.

6. Tighten the screw cap by hand

until it reaches the end position.

7. Tighten the screw cap to 354 lb-in

(40 Nm). Use a hexagonal socket

to avoid damaging the oil lter cap.

5

(07/19/2013) Y53-1181-1B1 5-25

Page 66

Maintenance Procedures

Full-ow Oil Filter Removal

1. Unscrew the cap a few turns

and drain the lter housing. Use

a hexagonal socket to avoid

damaging the oil lter cap.

2. Remove the cap, with the oil lter

5

cartridge, from the lter housing.

Then remove the oil lter cartridge

from the screw cap.

3. Remove the O-ring from the screw

cap.

WARNING!

Lubricating oil can cause skin irritation

or skin injury. To prevent skin injury,

avoid unnecessary contact with the lubricating oil. Wear protective clothing,

eye wear and gloves when handling lubricating oil. Failure to comply may result in personal injury.

Full-ow Oil Filter Installation

1. Lightly oil the new O-ring.

2. Install a new O-ring onto the screw

cap.

3. Install the screw cap, with the

oil lter cartridge, onto the lter

housing. Tighten the screw

cap to 354 lb-in (40 Nm). Use

a hexagonal socket to avoid

damaging the oil lter cap.

5-26 Y53-1181-1B1 (07/19/2013)

Page 67

Maintenance Procedures

After Replacing Oil Filter(s)

1. Reconnect the chassis battery

cable at the negative battery

terminal. See Warnings at

Centrifugal oil lter removal

preparation.

2. Add approved engine oil SAE

10W30 API CJ-4 to the maximum

level marked on the dipstick.

3. Start and run the engine for ve

to ten minutes and check for any

oil leaks.

4. Remove oil collection pan and

dispose of any spillage properly.

5. Check engine oil level and top up

as necessary.

° chassis must be on level

surface

° wait at least ve minutes if the

engine has been hot

° pull the dipstick and wipe with

a clean, lint free cloth

° reinsert the dipstick, then

remove and check the oil level

° add approved engine oil

SAE 10W30 API CJ-4 to the

maximum level marked on the

dipstick

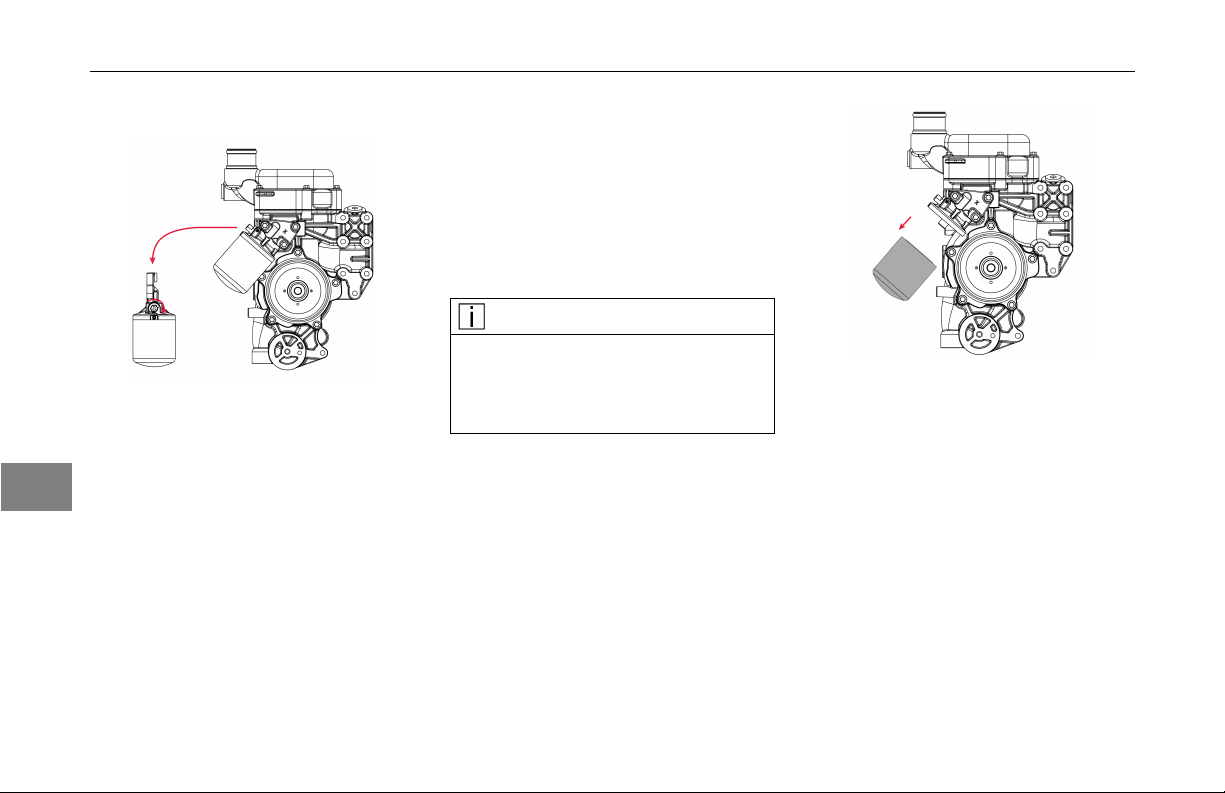

Replacing Fuel Filter

WARNING!

When removing the fuel lter, a quantity of fuel will escape. Do not smoke

or allow an open ame in close proximity. Failure to do so could ignite a re

or cause an explosion which could result in serious injury to you and/or bystanders. Failure to comply may result

in death, personal injury, equipment or

property damage.

NOTE

The fuel lter and the hand pump are

located on the left-hand side of the engine.

5

(07/19/2013) Y53-1181-1B1 5-27

Page 68

Maintenance Procedures

Description

The fuel lter / water separator module

provides ne particle ltration, water

separation, water in fuel sensing,

automatic water draining, lifetime

purication of drained water with a

charcoal lter, 12v preheating and

system manual priming in a singular

easy to service module.

NOTE

The engine and fuel module should be

operated in cold climates with acceptable cold climate fuel blends which noticeably reduces wax gelling of the fuel

lter cartridge. The fuel module in-

5

cludes a 12 - volt preheater to support

preheat of the fuel for initial start-up in

mild climates. Failure to operate with

acceptable cold climate fuel may result

in insufcient fuel ow to the fuel injection system.

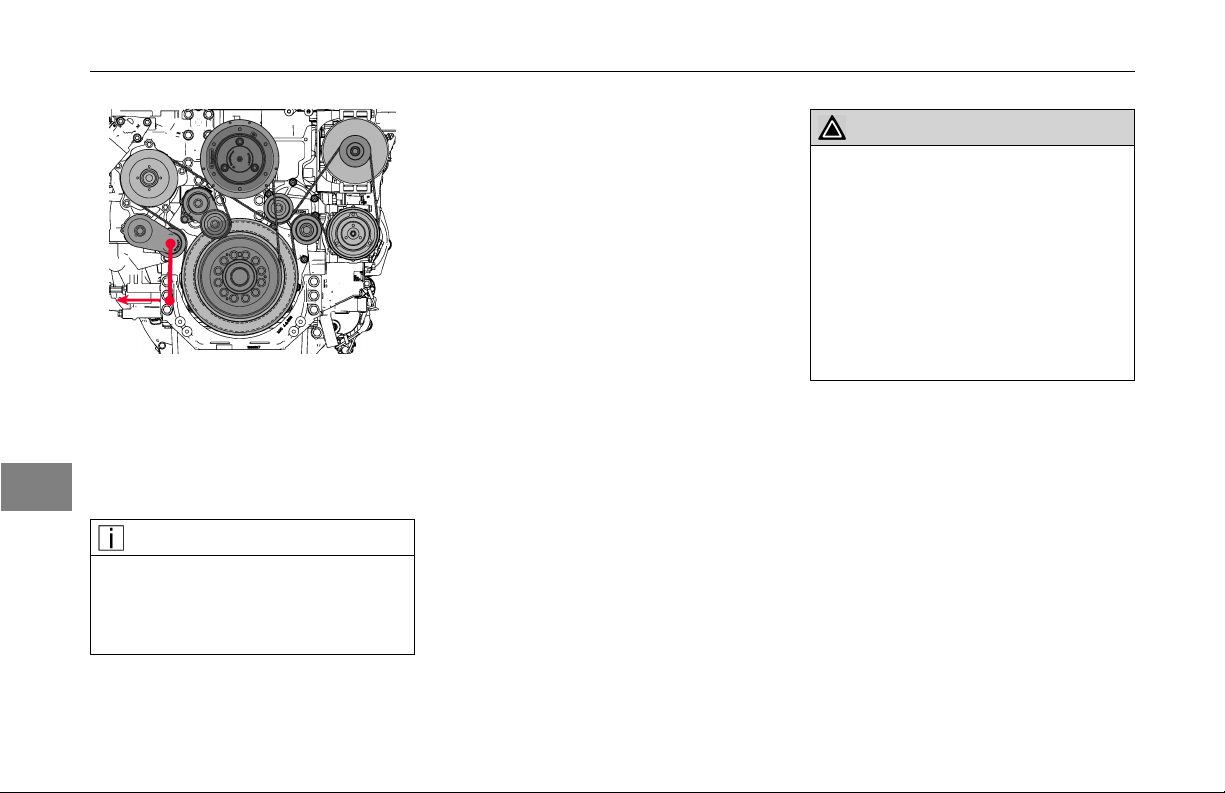

Removal

1. Fuel Filter Cap

2. Fuel Filter

3. Manual Priming Pump

4. Fuel Filter Housing

1. Loosen the fuel tank cap to relieve

any pressure in the fuel tank.

2. Clean the fuel lter cap and

surrounding area to ensure dirt

does not fall in to the fuel module.

CAUTION

Dirt in the fuel system can lead to signicant damage to the fuel system.

Failure to comply may result in equipment or property damage.

3. Remove the fuel lter cap by

rotating it counter-clockwise with a

wrench, automatic draining of fuel

will be initiated, wait 5 minutes for

complete fuel draining to prevent

fuel from leaking or dripping on the

starter motor

NOTE

The fuel lter cartridge is a disposable lter and may not be cleaned and

reused. Dispose of the lter as chemical waste.

4. Remove the fuel lter cartridge.

5-28 Y53-1181-1B1 (07/19/2013)

Page 69

Maintenance Procedures

Installation

1. Verify the sealing o-ring that

is supplied with the lter kit is

installed on the fuel lter cap and

lightly coat the o-ring with fuel.

2. Install the new fuel lter cartridge

to the cap, then insert in to the fuel

module.

3. Tighten the fuel lter cap by

rotating it clockwise until the lter

cap o-ring makes contact with the

fuel module. Then tighten the

lter cap to 29 ft-lbs (40 Nm) as

specied on the lter cap.

4. Loosen the fuel priming pump knob

by rotating it counter-clockwise.

5. Operate the priming pump by

moving the knob in and out until

pumping resistance increases

noticeably, may require up to 90

strokes. Then tighten the knob by

rotating it clockwise.

CAUTION

Operate priming pump at a maximum

rate of 30 strokes per minute to prevent damage to pump.

6. Check for leakage at the fuel lter