Contents

Safety

Emergency

Controls

Driving

Maintenance

Information

Index

1

2

3

4

5

6

7

Contents

©2011PaccarInc-AllRightsReserved

Thismanualillustratesanddescribestheoperationoffeaturesorequipmentwhichmaybeeitherstandardoroptionalon

thisvehicle.Thismanualmayalsoincludeadescriptionoffeaturesandequipmentwhicharenolongeravailableorwere

notorderedonthisvehicle.Pleasedisregardanyillustrationsordescriptionsrelatingtofeaturesorequipmentwhichare

notonthisvehicle.

PACCARreservestherighttodiscontinue,changespecications,orchangethedesignofitsvehiclesatanytimewithout

noticeandwithoutincurringanyobligation.

TheinformationcontainedinthismanualisproprietarytoPACCAR.Reproduction,inwholeorinpart,byanymeansisstrictly

prohibitedwithoutpriorwrittenauthorizationfromP ACCARInc.

Safety

Introduction

SafetyAlerts..............1-3

Foreword...............1-5

ImportantReferenceNumber.......1-6

Illustrations...............1-7

GeneralSafetyInstructions........1-7

1

1-1

Introduction

Introduction

SafetyAlerts

Pleasereadandfollowallofthe

safetyalertscontainedinthismanual.

Theyarethereforyourprotection

andinformation.Thesealertscan

helpyouavoidinjurytoyourself,your

passengers,andhelppreventcostly

damagetothevehicle.Safetyalerts

arehighlightedbysafetyalertsymbols

andsignalwordssuchas"WARNING",

"CAUTION",or"NOTE".Pleasedonot

ignoreanyofthesealerts.

WARNING

WARNING:

Thesafetyalertfollowingthissymbol

andsignalwordprovidesawarning

againstoperatingprocedureswhich

couldcausedeathorinjury .Theycould

alsocauseequipmentorproperty

damage.Thealertwillidentifythe

hazard,howtoavoidit,andthe

probableconsequenceofnotavoiding

thehazard.

Example:

WARNING:Donotcarry

additionalfuelcontainersin

yourvehicle.Fuelcontainers,

eitherfullorempty,mayleak,

explode,andcauseorfeeda

re.Donotcarryextrafuel

containers.Evenemptyones

aredangerous.Failureto

complymayresultindeath,

personalinjury,equipmentor

propertydamage.

1

1-

3

Introduction

CAUTION

1

CAUTION:

Thesafetyalertfollowingthissymbol

andsignalwordprovidesacaution

againstoperatingprocedureswhich

couldcauseequipmentorproperty

damage.Thealertwillidentifythe

hazard,howtoavoidit,andthe

probableconsequenceofnotavoiding

thehazard.

Example:

CAUTION:Continuingto

operateyourvehiclewith

insufcientoilpressure

willcauseseriousengine

damage.Failuretocomply

mayresultinequipmentor

propertydamage.

NOTE

NOTE:

Thealertfollowingthissymboland

signalwordprovidesimportant

informationthatisnotsafetyrelated

butshouldbefollowed.Thealert

willhighlightthingsthatmaynotbe

obviousandisusefultoyourefcient

operationofthevehicle.

Example:

NOTE:Pumpingtheaccelerator

willnotassistinstartingthe

engine.

1-4

Introduction

Foreword

Thismanualcontainsinformationfor

thecorrectoperationandmaintenance

ofyourPACCARengine.Readand

followallsafetyinstructions.Refer

totheWARNINGinthe“General

SafetyInstructions”beginningon

page1-7.Keepthismanualwith

theequipment.Iftheequipmentis

tradedorsold,givethemanualto

thenewowner.Theinformation,

specications,andrecommended

maintenanceguidelinesinthismanual

arebasedoninformationineffect

atthetimeofprinting.PACCAR

reservestherighttomakechanges

atanytimewithoutobligation.Ifyou

nddifferencesbetweenyourengine

andtheinformationinthismanual,

contactyourlocalPACCARAuthorized

RepairLocationorwritetoPACCAR

c/oP ACCAREngines,POBox1518,

Bellevue,WA98009.Thelatest

technologyandthehighestquality

componentswereusedtoproducethis

engine.Whenreplacementpartsare

needed,werecommendusingonly

genuinepartsfromPACCAR.

1

1-5

Introduction

ImportantReference

1

Number

Fillinthepartnameandnumberintheblankspacesprovidedbelow .Thiswillgiveyouareferencewheneverserviceormaintenanceisrequired.

PartNameNumber

EngineModel

EngineSerialNumber(ESN)

OilType(UseAPICJ-4oilonly)

FilterPartNumbers:

AirCleanerElement

LubricatingOil

Fuel(Useultra-lowsulfurdieselfuelonly)

Coolant

BeltPartNumbers:

1-6

Introduction

Illustrations

GeneralInformation

Someoftheillustrationsthroughout

thismanualaregenericandwillnot

lookexactlyliketheengineorparts

usedinyourapplication.

Theillustrationsareintendedtoshow

repairorreplacementprocedures.

Theprocedurewillbethesameforall

applications,althoughtheillustration

candiffer.

GeneralSafetyInstructions

ImportantSafetyNotice

WARNING:Improper

practices,carelessness,

orignoringanywarnings

maycausedeath,personal

injury,equipmentorproperty

damage.

Beforeperforminganyrepair,readand

understandallofthesafetyprecautions

andwarnings.Thefollowingisalistof

generalsafetyprecautionsthatmust

befollowedtoprovidepersonalsafety .

Failuretofollowtheseinstructions

maycausedeathorinjury.Special

safetyprecautionsareincludedinthe

procedureswhentheyapply.

•Usethepropertoolformanually

rotatingtheengine.Donotattempt

torotatethecrankshaftbypulling

orpryingonthefan.Thispractice

cancausedeath,personalinjury,

equipmentdamage,ordamageto

thefanblades,causingpremature

fanfailure.

•Workareasshouldbedry,welllit,

ventilated,freefromclutter,loose

tools,parts,ignitionsourcesand

hazardoussubstances.

•Wearprotectiveglassesand

protectiveshoeswhenworking.

•Donotwearloose-ttingortorn

clothing.Removealljewelrywhen

working.

•Beforebeginninganyrepair,

disconnectthebattery(negative

[-]cable)anddischargeany

capacitors.

•Puta"DONOTOPERATE"tagin

theoperator’scompartmentoron

thecontrols.

•Allowtheenginetocoolbefore

slowlylooseningthecoolantller

captorelievethepressurefrom

thecoolingsystem.

1

1-

7

Introduction

•Alwaysuseblocksorproper

1

standstosupportthevehicle

orvehiclecomponentsbefore

performinganyservicework.

Donotworkonanythingthatis

supportedonlybyliftingjacksor

ahoist.

•Beforeremovingordisconnecting

anylines,ttings,orrelateditems,

relieveallpressureintheair,oil,

fuel,andcoolingsystems.Remain

alertforpossiblepressurewhen

disconnectinganydevicefroma

systemthatcontainspressure.

Highpressureoilorfuelcancause

deathorpersonalinjury .

•Alwayswearprotectiveclothing

whenworkingonanyrefrigerant

(Freon)linesandmakesurethat

theworkplaceisinawellventilated

area.Inhalationoffumescan

causedeathorpersonalinjury.

Toprotecttheenvironment,

liquidrefrigerantsystemsmust

beproperlyemptiedandlled

usingequipmentthatprevents

thereleaseofrefrigerantgas.

Federallawrequirescapturing

andrecyclingrefrigerant.

•Whenmovingorliftinganyheavy

equipmentorparts,makesure

tousepropertechniquesand

assistance.Ensurealllifting

devicessuchaschains,hooks,or

slingsareingoodconditionand

areofthecorrectloadcapacity.

Makesureanyliftingdevicesare

positionedcorrectly .

•Corrosioninhibitorsandlubricating

oilsmaycontainalkali.Donotget

thesubstanceineyesandavoid

prolongedorrepeatedcontact

withskin.Donotswallow.In

caseofcontact,immediatelywash

skinwithsoapandwater.Incase

ofharmfulcontact,immediately

contactaphysician.Alwayskeep

anychemicalsOUTOFREACH

OFCHILDREN.

•NapthaandMethylEthylKetone

(MEK)areammablematerials

andmustbeusedwithcaution.

Followthemanufacturer’s

instructionstoensuresafetywhen

usingthesematerials.Always

keepanychemicalsOUTOF

REACHOFCHILDREN.

•Whenworkingonthevehicle,

bealertforhotpartsonsystems

thathavejustbeenturnedoff,

exhaustgasow,andhotuidsin

lines,tubes,andcompartments.

Contactwithanyhotsurfacemay

causeburns.

•Alwaysusetoolsthatareingood

condition.Makesureyouhave

theproperunderstandingofhow

tousethetoolsbeforeperforming

anyservicework.Useonly

genuinereplacementpartsfrom

PACCAR.

1-

8

Introduction

•Alwaysusethesamefastener

partnumber(orequivalent)when

replacingitems.Donotuse

afasteneroflesserqualityif

replacementsarenecessary.

•Donotperformanyrepairwhen

impaired,tired,fatiguedorafter

consumingalcoholordrugsthat

canimpairyourfunctioning.

•Somestateandfederalagencies

intheUnitedStatesofAmerica

havedeterminedthatusedengine

oilcanbecarcinogenicandcan

causereproductivetoxicity.Avoid

inhalationofvapors,ingestion,

andprolongedcontactwithused

engineoil.

•Coolantistoxic.Ifnotreused,

disposeofcoolantinaccordance

withlocalenvironmental

regulations.

•CaliforniaProposition65Warning

-Dieselengineexhaustandsome

ofitsconstituentsareknownto

theStateofCaliforniatocause

cancer,birthdefects,andother

reproductiveharm.

•Thecatalystsubstratelocated

intheDieselParticulateFilter

containsVanadiumPentoxide.

VanadiumPentoxidehasbeen

determinedbytheStateof

Californiatocausecancer.Always

wearprotectiveclothingandeye

protectionwhenhandlingthe

catalystassembly.Disposeofthe

catalystinaccordancewithlocal

regulations.Ifcatalystmaterial

getsintotheeyes,immediately

oodeyeswithwaterfora

minimumof15minutes.Avoid

prolongedcontactwithskin.In

caseofcontact,immediatelywash

skinwithsoapandwater.Incase

ofharmfulcontact,immediately

contactaphysician.

CAUTION:Corrosive

chemicalscandamage

theengine.Donotuse

corrosivechemicalsonthe

engine.Failuretocomply

mayresultinequipmentor

propertydamage.

1

1-9

WHATTODOIF...

YouNeedRoadsideAssistance......2-3

StopEngineLampTurnsOn.......2-3

EngineOilPressureLampTurnsOn....2-4

CheckEngineLampTurnsOn......2-5

EngineisOverheating..........2-5

EMERGENCY

2

2-1

WHATTODOIF...

WHATTODOIF ...

YouNeedRoadside Assistance

Calltoll-FREEtotalktosomeoneat

theP ACCARCustomerCenter.The

toll-FREEtelephonenumberislocated

onthewindshielddecal.

•Open24-7-365daysayear

•Theycanhelpyougetroadside

assistance.

•Theyhaveacustommapping

systemwhichlocatesauthorized

PACCARenginedealersand

IndependentServiceProviders

(ISPs)nearyouandliststypes

ofservicesoffered,hoursof

operationandcontactinformation.

•Theycanassistwithjumpand

pullstarts,tires,trailers,nesand

permits,chains,towing,hazardous

clean-up,outoffuel(roadside),

mechanicalrepairsandpreventive

maintenanceservices.

•Theyhavemultilingualagentsand

accesstoatranslationservice

toensurequalityassistance

forcustomerswhospeakany

language.

•Theycan’tansweryourwarranty

questionsbutcangetyouin

contactwithanauthorizeddealer

whocan.

•ThePACCARCustomerCenter

serviceisFREE.

StopEngineLampTurnsOn

StopEngineLamp-Ifthe

StopEnginewarninglamp

illuminates,itmeansyou

haveaseriousenginesystem

problem.

WARNING:Thisshouldbe

consideredanemergency.

Youshouldstopthevehicle

assafelyaspossibleand

turnOFFtheignition.The

vehiclemustbeservicedand

theproblemcorrectedbefore

drivingagain.Failuretodo

somayresultinpersonal

injury,severeenginedamage,

equipmentorproperty

damage.

2

2-

3

WHATTODOIF...

EngineOilPressureLamp TurnsOn

2

CAUTION:Continuingto

operateyourvehiclewith

insufcientoilpressuremay

causesevereenginedamage,

equipmentorproperty

damage.

•Iftheoilpressurefailsto

•SeeLubricatingOil

EngineOilPressureGauge

-Itisimportanttomaintain

oilpressurewithinacceptable

limits.Ifoilpressuredrops

belowtheminimumpsia

RedWarningLampontheoil

pressuregaugeandtheStop

EngineLampwillcomeON.

risewithin10seconds

aftertheenginestarts,

stoptheengineand

determinethecause.

Systemonpage5-1 1,for

thecorrectoilpressure

rangesforyourvehicle’s

engine.

•Iftheoilpressure

suddenlydrops,orthe

audiblealarmandengine

oilpressurewarninglight

comeonwhiledriving,do

thefollowing:

1.Slowdowncarefully.

2.Moveasafedistanceoff

theroadandstop.

3.Placethetransmission

inneutralandsetthe

parkingbrake.(See

ParkingBrakeValve

andOPERATINGTHE

TRANSMISSIONin

yourvehicleOperator’s

Manual,fortransmission

shiftingandparkingbrake

information.)

4.TurnOFFtheengine.

5.TurnONtheemergency

asheranduseother

warningdevicestoalert

othermotorists.

6.Waitafewminutesto

allowoiltodrainintothe

engineoilpan,andthen

checktheoillevel.(See

InspectionoftheEngine

OilLevelonpage5-4.)

7.Addoilifnecessary.Ifthe

problempersists,contact

anauthorizedP ACCAR

enginedealerassoonas

possible.

2-

4

WHATTODOIF...

CheckEngineLampTurns On

CheckEngineLamp-Turns

onwhenaproblemexists,but

thevehiclecanstillbesafely

driven.Vehicleshouldbe

servicedtocorrecttheproblem

butthesituationshouldnotbe

consideredanemergency.

EngineisOverheating

CAUTION:Thecooling

systemmayoverheatifthe

enginecoolantisatthe

minimumlevel.Asudden

lossofcoolant,causedby

asplithoseorbrokenhose

clampcouldalsoleadtoan

overheatcondition.Always

inspecttoensurehosesand

clampsarenotcracked,worn,

orloose.Failuretocomply

mayresultinequipmentor

propertydamage.

NOTE:Thesystemmayalso

temporarilyoverheatduring

severeoperatingconditions

suchas:

•Climbingahillonahotday.

•Stoppingafter

high-speed/high-load

driving.

•Debrisblockingairow

throughthecoolingmodule

(radiator).

NOTE:Iftheenginecoolant

temperaturewarninglamp

comesonandtheaudiblealarm

soundsshowinganoverheat

condition,orifyouhaveany

otherreasontosuspectthe

enginemaybeoverheating,

DONOTTURNOFFTHE

ENGINEunlessalowwater

warningdeviceindicatesaloss

ofcoolant.Followthesesteps:

•Reduceenginespeedor

stop.Whenstopped,place

thetransmissioninneutral

andsettheparkingbrake.

Seethevehicleoperator’s

manualforinstructionson

transmissionshiftingand

parkingbrakeinformation.

2

2-

5

WHATTODOIF...

•Checktoensurethatthe

oilpressuregaugereads

normal.

•Increasetheenginespeed

2

to1,100to1,200rpm

maximumfor2-3minutes.

•Monitortheengine

temperature.Afterthe

temperaturereturnsto

normal,allowtheengine

toidle3–5minutesbefore

shuttingitoff.Thisallows

theenginetocoolgradually

anduniformly .

•Iftheoverheatingcame

fromsevereoperating

conditions,thetemperature

shouldhavecooledbythis

time.

•Checkthecoolantlevelat

thecoolingmodulesurge

tank.

WARNING:Toreduce

thechanceofpersonal

injuryand/orvehicle

damagecausedbyengine

overheating,neverleave

theengineidlingwhenthe

vehicleisunattended.Ifthe

engineoverheats,immediate

actionisrequiredtocorrect

thecondition.Continued

unattendedoperationofthe

engine,evenforashorttime,

mayresultinseriousengine

damageorare.Failureto

complymayresultindeath,

personalinjury,equipmentor

propertydamage.

WARNING:Removingthe

surgetankllcapwhile

theengineishotcanbe

dangerous.Neverremove

thesurgetankcapwhilethe

engineisstillhot;youcould

bebadlyburned.Failureto

complymayresultindeath,

personalinjury,equipmentor

propertydamage.

•Scaldingsteamanduid

underpressuremay

escapeandcauseserious

personalinjuries.

•Waituntilthecoolant

temperatureisbelow

122°F(50°C).

•Protectyourface,hands,

andarmsbycoveringthe

capwithalarge,thick

ragtoprotectagainst

escapinguidandsteam.

•Carefullyandslowly

turnthecaponeturnto

allowexcesspressureto

escape,thenpushdown

andturnfornalremoval.

Seethevehicleoperator’s

manualforinstructions

oncheckingandlling

thecoolingmodulesurge

tank.

2-

6

WHATTODOIF...

CAUTION:Donotallow

yourenginetoidle,atlow

RPMs(400–600rpm),longer

than5minutes.Prolonged

periodsofidlingafterthe

enginehasreachedoperating

temperaturescandecrease

enginetemperatureandcould

causeenginedamagefrom

inadequatelubrication.The

normaltorsionalvibrations

generatedcanalsocause

transmissionwear.Anidle

shutdownfeature,available

onPACCARengines,can

beprogrammedtoshut

theenginedownaftera

periodoflowidleoperation

withnodriveractivity.A

ashingwarninglampwill

informthedriverofan

impendingshutdown.If

thetruckisequippedwith

PTOequipment,theengine

shutdownsystemcanbe

deactivatedwhenthePTOis

operational;however ,engine

idleperiodsshouldnot

exceed5minuteswhenever

possible.Failuretocomply

mayresultinequipmentor

propertydamage.

2

2-7

Controls

OperatingInstructions

EngineWarningLamps.........3-3

EngineOperatingRange.........3-6

EngineBrakingSystem.........3-6

3

3-1

OperatingInstructions

OperatingInstructions

EngineWarningLamps

GeneralInformation

Thefollowingenginewarninglamps

coveronlythelampscontrolledbythe

engine’sElectronicControlModule

(ECM).Pleaserefertothevehicle

operator’smanualforadditional

warninglampinformation.

CheckEngineLamp

Thecheckenginewarninglampwill

illuminatewhenaproblemexists,

butthevehiclecanstillbesafely

driven.Thevehicleshouldbeserviced

tocorrecttheproblem,butthe

situationshouldnotbeconsideredan

emergency.

Thelampwillalsoilluminatewhena

DPFregenerationoradditionofDiesel

ExhaustFluidisrequired.Another

functionofthecheckenginelampisto

warntheoperatorofanimpendingidle

shutdown.Whentheidleshutdown

timeris30secondsfromexpiring,the

engineECMbeginsashingthecheck

enginewarninglamponcepersecond.

Whenthetimerexpires,theECMwill

turnoffthewarninglampandshut

downtheengine.

3

3-

3

OperatingInstructions

StopEngineLamp

Thestopenginewarninglampwill

3

illuminate,andanaudibletonewill

sound,whenamajorengineproblem

exists.

WARNING:Thisshouldbe

consideredanemergency.

Youshouldstopthevehicle

assafelyaspossibleand

turnOFFtheignition.The

vehiclemustbeserviced

andtheproblemcorrected

beforedrivingagain.Failure

tocomplymayresultin

personalinjury,severe

enginedamage,equipmentor

propertydamage.

Forengineswiththeengineprotection

shutdownfeatureenabled,the

stopenginelampwillbeginto

ash30secondsbeforetheengine

automaticallyshutsdown.The

warninglampalertstheoperatortothe

impendingshutdown.

Thelampwillalsoilluminatewhen

theDieselExhaustFluid(DEF)tank

isalmostemptyorthesootlevelin

theDPFisatfullcapacity .Atthis

levelwarning,regenerationcannotbe

performedandenginepowerwillbe

derated.

DieselParticulateFilter(DPF)

WarningLamp

DPFWarningLamp

RefertoEngineAftertreatment

SystemsOperator’sManualfor

additionalinformation.

3-

4

OperatingInstructions

HighExhaustSystemT emperature

(HEST)WarningLamp

HESTWarningLamp

RefertoEngineAftertreatment

SystemsOperator’sManualfor

additionalinformation.

CheckEngineLamp(CEL)

CheckEngineLamp

RefertoEngineAftertreatment

SystemsOperator’sManualfor

additionalinformation.

DieselEmissionFluid(DEF)Lamp

DieselEmissionFluid(DEF)Lamp

RefertoEngineAftertreatment

SystemsOperator’sManualfor

additionalinformation.

3

3-

5

OperatingInstructions

EngineOperatingRange

GeneralInformation

CAUTION:Operatingthe

engineatfullthrottlebelow

peaktorquewillshorten

enginelifetooverhaul,

cancauseseriousengine

3

damage,andisconsidered

engineabuse.Donot

operatetheengineatfull

throttleoperationbelowpeak

torquerpmformorethan30

seconds.Failuretocomply

mayresultinequipmentor

propertydamage.

PACCARenginesaredesignedto

operateatfullthrottleundermomentary

conditionsdowntopeaktorqueengine

speed.Thisisconsistentwith

recommendedoperatingpractices.

CAUTION:Operatingthe

enginebeyondthemaximum

enginespeedcancause

severeenginedamage.Use

properoperatingtechniques

forthevehicletoprevent

engineoverspeed.The

maximumenginespeed

specicationislisted

inthe“GeneralEngine

Specications”onpage5-10.

Failuretocomplymayresult

inequipmentorproperty

damage.

EngineBrakingSystem

WARNING:Donotoperate

theenginecompression

brakewhendriving/operating

yourvehiclebobtailorwith

aloadedorunloadedtrailer

onroadsurfaceswithpoor

traction(wet,icy,orsnow

coveredroads)orinheavy

trafc.Brakingcausedby

thenormaloperationof

theenginecompression

brakecouldcauseyouto

losecontrolofthevehicle

resultinginaninjuryaccident.

Failuretocomplymayresult

indeath,personalinjury,

equipmentorproperty

damage.

WARNING:Theservice

brakesmustbeusedinan

emergency.Theengine

compressionbrakealone

mightnotstopthevehicle

3-

6

OperatingInstructions

fastenoughtoprevent

anaccident.Theengine

compressionbrakeisNOT

intendedastheprimarybrake

forthevehicle,norisitan

emergencybrake.Theengine

compressionbrakeonly

helpstheservicebrakesby

usingenginebackpressure

toslowthedrivetrain.Use

theservicebrakesforquick

stops.Youcouldbeseriously

injuredifyoureliedonly

ontheenginecompression

braketostopthevehicleinan

emergency.Failuretocomply

mayresultindeath,personal

injury,equipmentorproperty

damage.

WARNING:Donotuse

thecompressionbrake

whenoperatingonroad

surfaceswithpoortraction

(suchaswet,icy,orsnow

coveredroadsorgravel).

Compressionbrakescan

causethewheelstoskidon

aslipperysurface.Youcould

losecontrolofthevehicle

and/orjackknifeifthewheels

begintoskid,resultinginan

accident.Failuretocomply

mayresultindeath,personal

injury,equipmentorproperty

damage.

NOTE:Ifyourvehicleis

equippedwithanti-lock

brakes(ABS),operationof

thecompressionbrake(ifturned

ON)maybeinterruptedifthe

ABSsystemdetectswheelslip

duetooperationonslippery

surfaces.

Anenginecompressionbrakeis

standardonthePACCARMX

engine.Whenactivated,theengine

compressionbrakecreatesabraking

effectonthedrivewheels.This

deviceusesenginepowertoslow

thevehicledown.Becauseitcan

helpkeepyourvehicle’sbrakesfrom

overheating,itcansavewearandtear

ontheservicebrakes.However,the

enginecompressionbrakeisnotan

emergencybrake.

Ideally(onnormalroadsurfaces),

youshouldslowyourvehiclewiththe

compressionbrake(wherepermitted

bylaw)andusetheservicebrakesonly

forstoppingcompletely.Operatingthis

waywillgreatlyprolongthelifeofthe

servicebrakes.

3

3-

7

OperatingInstructions

CompressionBrake

Withthecompressionbrakeswitch

ON,thebrakeautomaticallycreatesits

brakingeffectwhenyouremoveyour

footfromtheacceleratorpedal.

Thebrakeswitchislocatedonthe

accessorydashpanel.Itcontrols

3

whetherthebrakeisON(readytoslow

thevehicledown)orOFF(nobraking

action).

•Donotusetheengine

compressionbraketoslow

thevehicledownwhenyouare

bobtailingorpullinganempty

trailer.

•MakesurethebrakeisOFFbefore

startingtheengine.

•Aftertheengineisstarted,warmed

up,andyouarereadytogetunder

way,turntheenginecompression

brakeswitchONforaddedbraking

effect.

NOTE:Ifyourvehicleis

equippedwiththeEaton

Vorad®system,operationof

thecompressionbrakemaybe

automaticallyactivated.

CompressionBrakeControls

Two(2)switchesonthedashpanel

controltheenginecompressionbrake.

AmasterswitchturnsthesystemON

orOFF .Asecondswitch,located

nexttothemasterswitch,controls

thebrakingeffect.Thisswitchallows

youtochooseprogressivelystronger

brakingtoslowthevehicledown.

Enginecompressionbrakecontrols

include:

•On/Offswitch.

•3-positionselectorswitch.

•Clutchswitch.

•Throttlesensor.

•Servicebrakepressureswitch.

•EatonVorad®Anti-LockBraking

System

Engagingconditionsfortheengine

compressionbrakeare:

3-

8

OperatingInstructions

•Enginespeedmustbeabove

1,000rpm.

•Coolanttemperaturemustbe

above59°F(15°C).

Deactivationconditionsfortheengine

compressionbrakeare:

•Acceleratorpedalisdepressed.

•Clutchpedalisdepressed.

•Enginespeedfallsbelow800rpm.

•ABScontrolisactive.

•EngineECMrecognizesasystem

problem.

CAUTION:Operatingthe

enginewithacompression

brakethatwillnot

automaticallydeactivate

(i.e.whenthedashswitchis

off,clutchpedalisdepressed

orthrottleisapplied)will

causesevereinternalengine

damage.Donotoperatethe

engineifthecompression

brakewillnotdeactivate.

Failuretocomplymayresult

inequipmentorproperty

damage.

3

3-

9

OperatingInstructions

EngineCompressionBrakeLevel

SwitchOperation

Thereare2switchesthatcontrolyour

vehicle’senginecompressionbrake.

Oneswitchturnsthesystemon/offand

thesecondswitchcontrolsthebraking

level.Theseswitchesarelocatedon

thedashswitchpanel.

3

Forthe3-positionenginecompression

brakelevelswitch,therewillbe100%

enginebrakingwhentheswitchisin

theup(HIGH)position.Inthemiddle

(MEDIUM)position,therewillbe66%

enginebraking.Inthedown(LOW)

positiontherewillbe33%engine

braking.

Withthecompressionbrakeswitch

ON,thecompressionbrakewillbe

engagedwhentheservicebrakeis

applied.

Ifthecruisecontrolisoperatedin

conjunctionwiththecompression

brake,thecompressionbrakewill

engagetomaintainthecruiseset

speed.

On/OffSwitchSymbol

CompressionBrakeLevelSwitch

Symbol

3-10

Driving

OperatingInstructions

GeneralInformation...........4-3

NormalStartingProcedure........4-4

ColdWeatherStarting..........4-5

StartingProcedureAfterExtended

ShutdownorOilChange........4-5

OperatingtheEngine..........4-6

EngineShutdown............4-6

ElectromagneticInterference(EMI)....4-6

4

4-1

OperatingInstructions

OperatingInstructions

GeneralInformation

Correctcareofyourenginewillresult

inlongerlife,betterperformance,and

moreeconomicaloperation.

Followthedailymaintenancechecks

listedin“MaintenanceSchedule”on

page5-4.

Checktheengineoilpressureand

enginecoolantgauges,warninglights,

andothergaugesdailytomakesure

theyareoperational.

WARNING:Combustible

vaporsneartheairintake

systemcouldbeingested

intotheengine,causing

theenginetosuddenly

accelerateandoverspeed.

Thisconditioncouldresult

inoperatorlosingcontrolof

thevehicleifanunexpected

increaseinenginerpm

occurs.Combustiblevapors

couldalsocauseare.Do

notoperateyourvehiclein

anareawherecombustible

chemicalsorvaporsmaybe

present.Failuretocomply

mayresultindeath,personal

injury,equipmentorproperty

damage.

ITISTHERESPONSIBILITYOF

THEOWNERANDOPERATORTO

OPERATETHEVEHICLEINASAFE

ENVIRONMENT.

4

4-

3

OperatingInstructions

NormalStartingProcedure

Starting

EnsuretheparkingbrakeissetON

andthetransmissionshiftleverisin

neutral.Forautomatictransmissions

thathaveparkposition,placetheshift

leverinpark.

Withtheacceleratorpedalintheidle

position,turntheignitionkeytothe

STARTposition.

4

NOTE:Releasethekeyafter10

secondsiftheenginedoesnot

start.Thenwait10secondsand

tryagain.

NOTE:Iftheengineisrunning,

donotincreaseenginespeed

(rpm)oroperatethevehicleuntil

thelowoilpressurewarning

lampturnsoff.

overheatandcandamagethe

startermotor.

WiththekeyintheONposition,the

enginewarninglampswillcomeon

momentarilyandthengoout.The

enginewarninglampsinclude:

1.Checkenginelamp;yellowin

color.

2.STOPenginelamp;redincolor.

3.DieselParticulateFilter(DPF)

statusindicator;yellowincolor.

4.HighExhaustSystemTemperature

(HEST);amberincolor.

CAUTION:Engagingthe

startermotorformorethan

30secondsinanyfteen

minuteperiodmaycauseitto

4-

4

OperatingInstructions

ColdWeatherStarting

GeneralInformation

Followthe“NormalStartingProcedure”

onpage4-4.

Refertothevehicleoperator’smanual

instructionsforanyadditionalcold

weatherstartingprocedures.

Ifstartingacoldengine,slowly

increasetheenginespeed.This

providesadequatelubricationtothe

bearingsandgivesampletimetoallow

theoilpressuretostabilize.

Theuseofcoldstartingaidsare

notrecommendedforambient

temperaturesabove0°F(-18°C).

Ifanenginemustidleforanextended

periodoftime,itshouldbedoneat

afastidle(1000rpmmaximum)at

coolanttemperaturesbelow150°F

(70°C).

Forcoolanttemperaturesabove150°

F(70°C),usealowgearanddrive

atmoderateenginespeeduntilthe

enginecoolanthasreachedoperating

temperature.Donotlettheengineidle

longerthannecessary .

CAUTION:Donotoperate

theengineatlowidlefor

longperiodsoftimewhen

thecoolanttemperatureis

belowthenormaloperating

range.Thiscouldresultin

thefollowing:

•Fueldilutionofthe

lubricatingoil

•Carbonbuildupinthe

cylinder

•Stickingofthevalvesin

thecylinderhead

•Reducedperformance

•Damagetoaftertreatment

components

StartingProcedureAfter ExtendedShutdownorOil Change

GeneralInformation

Followthe“NormalStartingProcedure”

onpage4-4.

4

4-5

OperatingInstructions

OperatingtheEngine

Normal

Monitortheoilpressureandcoolant

temperaturegaugesfrequently.Refer

to“LubricatingOilSystem”onpage

5-11and“CoolingSystem”onpage

5-12forrecommendedoperating

pressuresandtemperatures.Shut

offtheengineifanypressureor

temperaturedoesnotmeetthe

specications.

4

EngineShutdown

BeforeStoppingtheEngine

NOTE:Donotshutoffthe

engineimmediately.Ahot

enginestoresagreatamountof

heatanditdoesnotcooldown

immediatelyafteritisshutoff.

Alwayscooltheenginedown

beforeshuttingitoff.Youwill

greatlyincreaseitsservicelife.

Idletheengineat1,000rpmfor4

minutes.Thenlowidlefor30seconds

beforeshutdown.Thiswillallow

circulatingcoolantandlubricatingoil

tocarryheatawayfromthecylinder

head,valves,pistons,cylinderliners,

turbocharger,andbearings.Thisway

youcanpreventenginedamagethat

mayresultfromunevencooling.

Electromagnetic Interference(EMI)

GeneralInformation

Ifnotinstalledcorrectly,somevehicle

accessories(CBradios,mobile

transmitters,etc.)cangenerateand

useradiofrequencyenergythatmay

causeelectromagneticinterference

(EMI)betweentheaccessoryand

theelectroniccontrolledfuelsystem.

Undertheseconditions,P ACCAR

isnotliableforanyperformance

problemswitheitherthefuelsystemor

theaccessory .EMIisnotconsidered

byPACCARtobeanenginefailure

andthereforeisnotwarrantable.

4-

6

OperatingInstructions

SystemEMISusceptibility

PACCARproductsaredesigned

andtestedforminimumsensitivity

toincomingelectromagneticenergy.

ThefuelsystemEMIsusceptibility

hasbeendesignedwithahigh

toleranceagainstEMIandinmost

normalcircumstances,ifnotall,

electromagneticenergy-emitting

devicesthatmeettheFederal

CommunicationsCommissionlegal

requirementsshouldcauseno

interference.

SystemEMIRadiationLevels

Electroniccomponentsarerequired

topassvariousPACCARandindustry

EMIspecications.Ourtesting

hasshownthatwhentheengineis

properlyinstalledandmaintained,it

willnotinterferewithproperlyinstalled

onboardcommunicationequipment.

Ifanyinterferenceconditionisnoticed,

followthesesuggestionstoreducethe

amountofEMI:

1.Locatetheaccessoryreceiving

antennafurtheraway .

2.Checkwiththeaccessorysupplier

representativeinyourareato:

°Accuratelycalibratethe

accessoryforproper

frequency,poweroutput,

andsensitivity .

°Determinetheoptimum

antennalocationbyobtaining

antennareectiveenergydata

measurements.

°Ensurethattheoptimum

antennatypeandmounting

arrangementisbeingused.

°Ensuretheaccessory

equipmentisproperly

constructedformaximum

lteringtorejectincoming

electromagneticnoise.

4

4-7

MaintenanceGuidelines

MaintenanceSpecications

MaintenanceProcedures

Overview...............5-3

MaintenanceSchedule.........5-4

GeneralEngineSpecications.....5-10

LubricatingOilSystem.........5-11

CoolingSystem............5-12

FilterSpecications..........5-13

FuelRecommendations........5-13

WarrantyandtheUseofBiodieselFuel.5-15

LubricatingOilRecommendationsand

Specications...........5-16

CoolantRecommendationsand

Specications...........5-17

OilPanDrainPlug..........5-20

InspectionoftheEngineOilLevel....5-20

ToppingUptheEngineOil.......5-21

Maintenance

5

5-

1

Maintenance

ReplacingEngineOilFilters......5-22

ReplacingFuelFilter.........5-26

ReplacingCoolantFilter........5-29

EmergencyRepairs..........5-30

5

5-2

MaintenanceGuidelines

MaintenanceGuidelines

dustyenvironmentoriffrequentstops

OilDrainIntervals

aremade.

Overview

GeneralInformation

PACCARrecommendsthatthe

enginebemaintainedaccordingtothe

maintenancescheduleinthissection.

Someofthesemaintenance

proceduresrequirespecialtools

ormustbecompletedbyqualied

personnel.Contactyourlocal

PACCARauthorizedrepairlocationfor

detailedinformation.

Oildrainintervalrecommendationsare

basedonvehicleapplicationorengine

dutycycle.PACCARrecommends

theuseofhighqualitylubricatingoil

asindicatedintheLubricatingOil

Recommendationsonpage5-16inthe

MaintenanceSpecicationsSection.

Iftheengineisoperatinginambient

temperaturesbelow0°F(-18°C)

orabove100°F(38°C),perform

maintenanceatshorterintervals.

Shortermaintenanceintervalsarealso

requirediftheengineisoperatedina

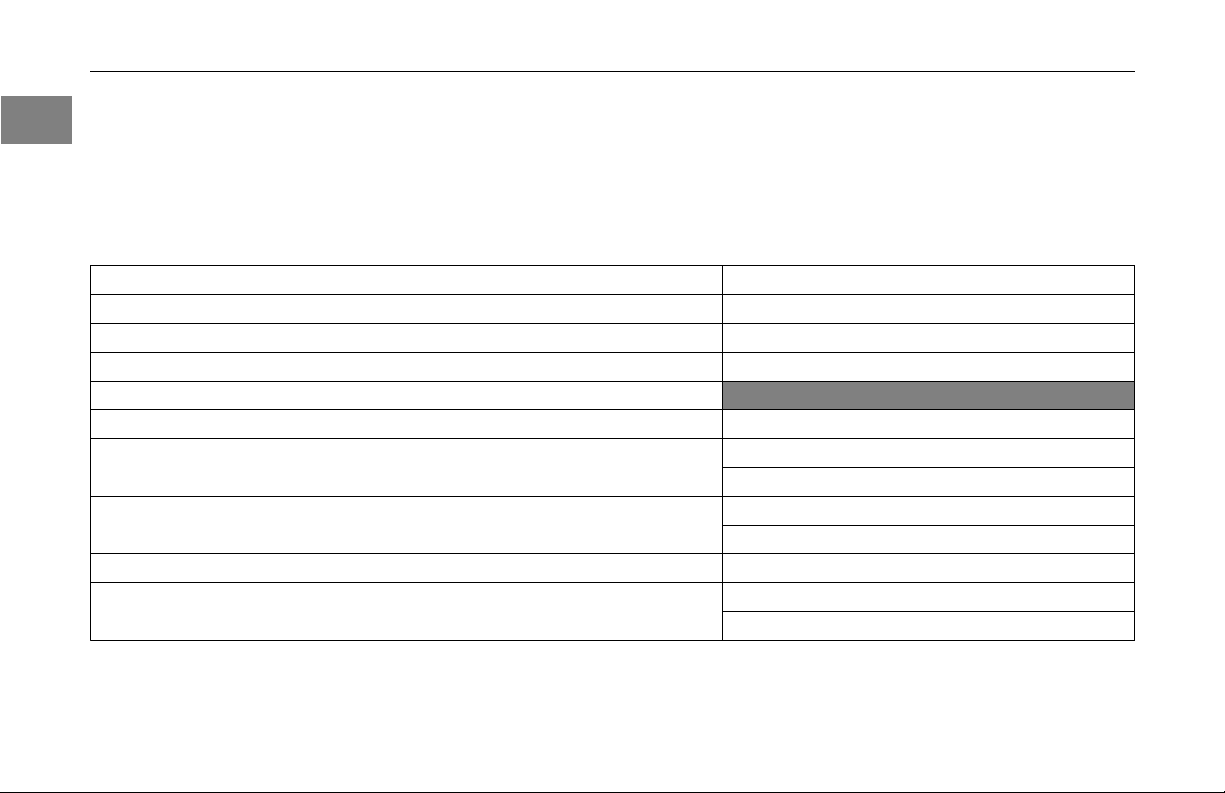

OilDrainIntervalGuidelines

FuelConsumption

MilesperGallon

KilometersperLiter

GrossVehicleWeight

OilDrainInterval25,000miles/40,000km

**Vocationalvehicleapplicationsinclude:Agriculture,ConcreteMixers,Construction,Crane,Dumps,Emergency/Fire,HeavyEquipment,Loggers,

Mining,OilField,Refuse,Pick-up&Delivery,Snowplows,andWrecker

Ifyourengineisequippedwith

acomponentoraccessorynot

manufacturedbyPACCARInc,refer

tothecomponentmanufacturer’s

maintenancerecommendations.

Lessthan6MPG

Lessthan2.6km/L

Morethan80,000lb

Morethan36,300kg

800hoursor12months

SevereDuty

Vocational**

NormalDuty

LineHaul

6MPGorgreater

2.6km/Lorgreater

80,000lborless

36,300kgorless

40,000miles/64,000km

1200hoursor12months

5

5-3

MaintenanceGuidelines

MaintenanceSchedule

GeneralInformation

Performmaintenanceatwhichever

intervaloccursrst.Ateachscheduled

maintenanceinterval,performall

previousmaintenancechecksthatare

dueforscheduledmaintenance.

NOTE:Thismaintenance

scheduleisforaNormalDuty

Cycleengineoperation.Severe

Duty/Vocationalapplications

willneedtoadjustmileage,

kilometer,hour,ortimeinterval

basedontheOilDrainInterval

Guidelineslistedabove.

5

DailyorRefueling–Maintenance

Check

•EngineLubricationOilLevel-

Check/Correct

Tocheckengineoillevel,park

vehicleonlevelgroundandwait15

minutesaftershuttingoffengine.

°Removedipstickandwipeit

offwithaclean,lintfreerag.

°Reinsertdipstickallthewayin

andpullitoutagaintocheck

oillevel.

°Correctoillevelisbetween

thelow(L)andhigh(H)marks

onthedipstick.

•Fuel–WaterSeparator(if

installed)–Draintrappedwater

•AirIntakePiping–Inspect

°Hose/Pipecondition–

deterioration/signsofleaking

°Clearancetoother

components

°CheckAirRestrictionGauge

•AftertreatmentExhaustPiping–

Inspect

°Cracks

°Clearancetoother

components(i.e.electrical

harnesses,etc.)

°Hose/pipecondition–

deterioration/signsofleaking

•CoolingFan–Inspect

°Cracks

°Clearancetoother

components

°Hoseclampsfortightness

5-

4

MaintenanceGuidelines

•EngineCoolantLevel–

Check/Correct

Withtheengineoffand

temperaturecool:

°Checkcoolantlevel.Itshould

bevisiblethroughtheclear

plasticsurgetank.

°Addcoolantasnecessaryby

removingthepressurecapon

theneckofthesurgetankor

sightglass.

°Replacementortopup

coolantshouldhavethesame

antifreezeconcentrationand

corrosioninhibitorcontent

astheoriginalcoolantinthe

coolingsystem.

°Alwaysdiluteantifreezeto

thecorrectconcentration

basedonfreezeprotection

beforeaddingittothecooling

system.Addingorusing100%

antifreezeinacoolingsystem

mayresultincoolingsystem

pluggingandoverheating

problems.

•DieselEmissionFluid(DEF)level

–Check/T opUp:

NOTE:Itisrecommended

totopupDEFwhen

refueling.SeeEngine

AftertreatmentSystems

Operator’sManualforDEF

information.

•Checkforanysignsofuid

leaks

•Ensureallaccesscaps/coversare

installedandtight.

Every20,000mi(32,000km),600

Hours,or6Months-Maintenance

Check

•AirCleanerRestriction-

Check/Correct

°Servicelterelementwhen

aircleanerrestrictiongauge

(option)locksintheextreme

highposition.

°Hose/pipecondition-

deterioration/signsofleaking

°Hoseclamptorque

•Charging/CrankingSystem-

Check

°Inspectelectrical

harness/cablesforloose

connections,corrosion,

chang,andbrokenretention

clips.

•ChargeAirPiping-Check/Correct

°Hose/pipecondition-

deterioration/signsofleaking

5

5-

5

MaintenanceGuidelines

°Hoseclampsfortightness

°Clearancetoother

components

•ChargeAirCooler-Check/Correct

°Crackedtubesorheader

°Cloggedns/tubes

°Hose/pipecondition-

deterioration/signsofleaking

°Hoseclamptorque

**InitialOnly40,000mi(64,000

km),1,200Hours,or12monthsMaintenanceCheck

•ValveClearance-Adjust

**(Seenote3below)

•ValveCoverGasketSeal-

Replace

•DriveBelts-Check/Correct

°Beltcondition-signsof

wear/deterioration

°Beltalignment

•FanBeltT ensioner-

5

Check/Correct

°Mountingbolttorque

°T ensionermaintainsproper

belttension

5-6

MaintenanceGuidelines

Every40,000mi(64,000km),1,200

Hours,or12months-Maintenance

Check

•FuelFilter,CanisterandSpin-on

Type-Replace

•LubricatingOil-Change

•LubricatingOilFilters-Change

•CoolingSystemAntifreezeCheck

°Coolantlevel

°CoolantProtection

•Batteries-Check

°BatteryCablesand

Connections–Check

°Batterycondition–electrolyte

level,cracks,signsofleaking,

overcharging

°Batteryhold-downsfor

tightness

°Batteryboxmountingbolt

torque

Every80,000mi(128,000km),2,400

Hours,or2Years-Maintenance

Check

•RadiatorHoses-Check

°Hosecondition-

deterioration/signsofleaking

°Hoseclamptorque

•CrankshaftVibrationDamper-

Check

°Damperforcracks,nicks,

Leakage

°Damperfastenertorque

•AirCompressorCarbonBuildup-

Check/Correct

Every160,000mi(256,000km),

4,800Hours–MaintenanceCheck

•Coolingsystemantifreezecheck

°Coolantlevel

°Coolantprotection

°Replacecoolantlter

•AftertreatmentFuelInjector–

Clean

•ExhaustSystem-Change

°Replaceexhaustexpipe(s)

•ValveClearance-adjust

•Valvecovergasketseal-replace

•Enginemountingbolts-check

°Checkbolttorque

5

7

5-

MaintenanceGuidelines

Every200,000mi(320,000km),

4,500Hours–MaintenanceCheck

•AftertreatmentDieselExhaust

Fluid(DEF)DosingUnit(DEF

Module)Filter–Replace

•AftertreatmentDieselParticulate

Filter(DPF)cleaning,using

DPFcleaningmachine

**(Seenote4below)

5

Every500,000mi(800,000km),

15,000Hours–MaintenanceCheck

•CrankcaseVentilation–Replace

Every750,000mi(1,200,000

km),22,000Hours,or6years–

MaintenanceCheck

•Changeextendedlifecoolant

**(Seenote1below)

NOTE:

1.Aheavy-dutyextendedlife

coolant(ELC)thatmeets

ASTMD6210chemical

compositionspecications

mustbeused.Thechange

intervalis750,000miles

(1,200,000km)or22,000

hourson-roaduse(8

yearsor15,000hours

off-highwayuse)oninitial

llwithnoextenderadded.

Thechangeintervalis

1,000,000miles(1,600,000

km)/20,000hours/8years

withanextenderaddition

at500,000miles(800,000

km)/10,000hours/4years.

Antifreezeisessential

5-

8

forfreeze,overheat,and

corrosionprotection.The

useofsupplementalcoolant

additives(SCAs)isnot

recommended.

2.Followthemanufacturers’

recommended

maintenanceprocedures

forthestarter ,alternator,

batteries,electrical

components,radiator,

aircompressor,aircleaner ,

refrigerantcompressor,and

fanclutch.

3.Resetvalvelash,ifneeded,

tonominalspecications.

4.TheaftertreatmentDPF

clean/replaceinterval

isbasedontheuseof

lubricatingoilsthatmeetthe

SAE15W40(APICJ-4)oil

specication.

MaintenanceGuidelines

5

5-9

MaintenanceSpecications

Maintenance

Specications

GeneralEngine

Specications

Horsepower

FiringOrder

CrankshaftRotation(viewedfromfrontofengine)Clockwise

Displacement

BoreandStroke5.12in.(130mm)×6.38in.(162mm)

DryWeight2,640lb

IdleSpeed

MaximumLoadedEngineSpeed

MaximumGovernedNo-LoadEngineSpeed

5

MaximumEngineCompressionBrakeSpeed

SeeEPALabelontopofthevalvecover

1,5,3,6,2,4

784CID(12.9liters)

Approximately650rpm

1,900rpm

2,200rpm

2,100rpm

5-10

MaintenanceSpecications

LubricatingOilSystem

AtLowIdle(minimumallowable)27psi(187kPa)at191°F(88°C)oiltemperature OilPressure

AtRoadSpeed900-1,900rpm(minimum

allowable)

RegulatedOilPressure72psi(496kPa)at223°F(106°C)oiltemperature

TotalSystemCapacity(OilPanandNewOilFilters)42qt(40.0liters)

40psi(276kPa)at215°F(102°C)oiltemperature

5

5-11

MaintenanceSpecications

CoolingSystem

CoolantCapacityApproximately14to15gallons(53to57liters)dependingonchassis

MinimumRecommendedPressureCap15psi(103kPa)

MaximumT opT ankCoolantT emperature121°F(49°C)aboveoutsidetemperature

WARNING:Coolantistoxic.

Donotgettheuidineyes.If

contactwiththeeyesoccurs,

oodeyeswithlargeamounts

ofwaterfor15minutes.

Avoidprolongedorrepeated

contactwithskin.Incaseof

contact,immediatelywash

skinwithsoapandwater .

Donottakeinternally.If

5

swallowed,seekimmediate

medicalattention.Donot

inducevomiting.Failureto

complymayresultindeath,

personalinjury,equipmentor

propertydamage.

NOTE:Coolantisharmfultothe

environment.Unusedcoolant

mustbestoredasatoxic

hazardousmaterialinleakproof

containers.Usedcoolantmust

beprocessedasindustrial

chemicalwaste.Pleasefollow

HAZMATguidelineswithboth

usedandunusedcoolants.

modelandcab/sleeperheateroptions

5-12

MaintenanceSpecications

FilterSpecications

GeneralInformation

PACCARisnotresponsiblefor

problemscausedbynon-genuinelters

thatdonotmeetP ACCARperformance

ordurabilityrequirements.

ContactyourlocalPACCARauthorized

repairlocationforspecicpart

numbers.

FuelRecommendations

WARNING:Theuseofdiesel

fuelthathasbeenmixed

withotherfuelsmaycause

anexplosion.Donotmix

gasoline,alcohol,orgasohol

withdieselfuel.Makesure

youknowyourfuelsource

andusetherecommended

dieselfuelasindicatedinthis

sectionofthemanual.Failure

tocomplymayresultindeath,

personalinjury,equipmentor

propertydamage.

CAUTION:Dirtorwaterinthe

fuelsystemcancausesevere

damagetoboththefuelpump

andthefuelinjectors.Due

totheprecisetolerancesof

dieselinjectionsystems,itis

extremelyimportantthatthe

fuelbekeptcleanandfree

ofdirtorwater.Knowyour

fuelsourceandmakesureall

stepsaretakenfordispensing

orusingcleanfuelinyour

vehicle.Failuretocomply

mayresultinequipmentor

propertydamage.

CAUTION:Lighterfuel

canreduceeconomyor

possiblydamagefuelsystem

components.Lighterfuels

typicallydonothaveenough

lubricityelementsinthe

fueltoproperlylubricate

thefuelinjectionsystem.

Besureyoufollowthe

fuelrecommendationsas

indicatedinthissectionof

themanual.Failuretocomply

mayresultinequipmentor

propertydamage.

CAUTION:Usingdieselfuels

blendedwithlubricants

maycausedamagetoyour

exhaustaftertreatment

system.Serviceintervalsfor

5

5-

13

MaintenanceSpecications

aftertreatmentsystemswill

bereduced.Donotusediesel

fuelblendedwithlubricating

oilinenginesequippedwith

anaftertreatmentsystem.

Failuretocomplymayresult

inequipmentorproperty

damage.

CAUTION:Donotuse

high-sulfurdieselfuelas

itwilldamagetheexhaust

aftertreatmentsystem.Also,

theenginewillnotmeet

emissionregulations.Use

onlyultra-low-sulfurdiesel

5

(ULSD)fuel.Failuretocomply

mayresultinequipmentor

propertydamage.

CAUTION:Ifultra-low-sulfur

dieselfuelisnotused,

theenginemaynotmeet

emissionregulations,and

damagemayoccurtothe

exhaustaftertreatment

system.Theuseof

high-sulfurdieselfuel

willdamagetheexhaust

aftertreatmentsystem

andimpacttheengine

emission.Ultra-low-sulfur

dieselfuelisrequiredfor

correctoperationofthe

aftertreatmentsystem.The

enginehasbeenoptimized

forusewithanaftertreatment

systemtomeetthe2010U.S.

EnvironmentalProtection

Agencyregulations.Failure

tocomplymayresultin

equipmentorproperty

damage.

NOTE:P ACCARrecommends

thatthecetanenumberofdiesel

fuelbeaminimumof45for

enginesthatareexpectedto

operateattemperaturesbelow

32°F(0°C)andaminimumof42

forenginesthatareoperatedat

temperaturesabove32°F(0°C).

NOTE:Usingdieselfuelwith

alower-than-recommended

cetanenumbercancause

hardstarting,instability,and

excessivewhitesmoke.To

maintainsatisfactoryoperation

atlowambienttemperatures,it

isimportanttospecifydieselfuel

ofthecorrectcetanenumber.

NOTE:PACCARrequires

allpermissiblefuelstohave

adequatefuellubricity.Lubricity

canbedeterminedbyASTM,

specicationD6079,ISO12156,

HighFrequencyReciprocating

Rig(HFRR)inwhichthefuel

musthaveawearscardiameter

of0.02in.(0.5mm)orless.

NOTE:Theuseof

Ultra-Low-Sulfurdieselfuel

isrequiredforthisengine

inordertomeetemission

regulationsandtoprevent

damagetotheengineand

5-

14

MaintenanceSpecications

exhaustsystem.Theuseof

othergradesofdieselfuels

otherthanUltra-Low-Sulfur

dieselfuelwillbeconsidered

auseofincorrectfuelfor

theengine.PACCARisnot

responsibleforfailurescaused

bytheuseofincorrectfuel,oil

orcatalyticreagentorbywater,

dirtorothercontainmentsinthe

fuelorcatalyticreagent.

WarrantyandtheUseof BiodieselFuel

PACCARIncapprovestheuseof

biodieselfuelblendsupto5%by

volumeindieselfuelthatmeetsallof

thefollowingthreeconditions:

•Thebiodieselusedintheblend

meetsASTMStandardD6751or

EN14214specications.

•Thebiodieselusedintheblend

issourcedfromaBQ-9000

AccreditedProducer.

•Thenishedblendmeetsthefuel

propertiesofASTMStandardD

975orEN590specications.

Theuseofapprovedbiodieselfuel

doesnotaffectthePACCARengine

warranty.Failurescausedbytheuse

ofnonapprovedbiodieselfuelsorother

fueladditivesthatareofunacceptable

qualityordonotmeetspecied

industrystandardsarenotconsidered

asdefectsofpartsorworkmanship

byPACCARandthereforewillnot

becoveredbythePACCARengine

warranty.

5

5-

15

MaintenanceSpecications

LubricatingOil

Recommendationsand

Specications

GeneralInformation

CAUTION:Extendingtheoil

andlterchangeinterval

beyondtherecommendations

willdecreasetheengine

lifeduetofactorssuchas

corrosion,deposits,and

wear.Engineoillters

capturedirtandremove

depositsfromtheoilto

prolongthelifeofinternal

movingcomponents.Follow

5

theoilandlterchange

intervalsasrecommendedin

thissectionofthemanual.

Failuretocomplymayresult

inequipmentorproperty

damage.

Amajorfactorinmaintainingengine

performanceanddurabilityisthe

properuseofqualityenginelubricating

oilsusedinconjunctionwiththe

appropriateoildrainandlterchange

intervals.Attemptingtoextendtheoil

andlterchangeintervalbeyondthe

manufacturersrecommendationsmay

decreaseenginelife.

NOTE:Itistheowners

responsibilitytocorrectlyfollow

lubricatingoilrecommendations.

Ifrecommendationsareignored,

theenginewarrantycouldbe

affected.

PACCARrecommendstheuseof

high-qualitySAE15W40(APICJ-4)

heavy-dutyengineoil.

TheprimaryPACCAR

recommendationisfortheuseof

15W-40multigradelubricatingoil

fornormaloperationatambient

temperaturesabove5°F(-15°C).

Forambienttemperaturesbelow

5°F(-15°C)SAE5W30maybe

used,provideditmeetsAPICJ-4

oilspecicationsandbiodieselor

biodieselblendedfuelisnotusedas

fuelfortheengine.Usingamultigrade

oilhelpsimproveenginecrankingin

low-temperatureconditions,reduces

depositformationandincreases

enginedurability .

5-

16

MaintenanceSpecications

NewEngineBreak-InOils

PACCARdoesnotapprovetheuseof

special“break-in”enginelubricating

oilsforneworrebuiltPACCAR

engines.Itisrecommendedtouse

thesamelubricatingoilforengine

break-inthatwillbeusedduringnormal

operation.

AftermarketOilAdditiveUsage

PACCARdoesnotrecommendtheuse

ofaftermarketoiladditives.T oday’s

high-qualityenginelubricatingoilsare

verysophisticated.Mostoilsalready

containpreciseamountsofadditives

blendedintothelubricatingoiltomeet

stringentperformancerequirements.

Theseoilsmeetperformance

characteristicsthatconformtothe

lubricantindustrystandardsand

aresufcientprotectionwhenused

accordingtotherecommendations.

Aftermarketlubricatingoiladditivesare

notnecessarytoenhanceengineoil

performanceandmayinsomecases

reducetheoil’scapabilitytoprotect

theengine.

CoolantRecommendations

andSpecications

Thecoolingsysteminyourvehicle

wasfactorylledwithExtendedLife

Coolant(ELC)thatmeetsorexceeds

allASTMD6210requirements.

PACCARrecommendsonlyusinga

50/50mixtureofdistilledwaterand

ELCwhencoolingsystemservice

isrequired.A50/50mixtureofELC

anddistilledwaterwillprovidefreeze

protectiondownto-34°F(-36.7°C),

whichisadequateformostlocations

inNorthAmerica.Forextremelycold

operatingconditions,a60/40mixture

(coolant/waterratio)canbeusedto

providefreezeprotectiondownto

-62°F(-52.2°C).

Yourengineisalsoequippedwitha

CoolantFilterdesignedtocapture

andremoveharmfuldepositsfromthe

coolingsystemtohelpprolongsystem

life.

5

5-

17

MaintenanceSpecications

CheckingCoolantCondition

ToensuretheExtendedLifeCoolant

(ELC)inyourvehiclealwaysprovides

maximumfreezeprotection,perform

thefollowingtests:

1.Checkthecoolantcoloratevery

maintenanceinterval.Itshouldbe

abrightredwithnosignsofdebris

oranyoil.

2.T estthefreezepointatleasttwo

timesayear.Arefractometeror

teststripscanbeusedtomeasure

theprotectionlevel.

3.Keepthecoolingsystematfull

5

levelsbytopping-upusingELC

pre-dilutedto50/50blend.

5-

18

RecommendedExtendedLife

CoolantSuppliers

BrandName

TRP

MaintenanceSpecications

Supplier

AuthorizedPACCAREngineDealer

CoolingSystemSealingAdditives

CAUTION:Theuseofsealing

additivesinthecooling

systemcancausedamageto

theengine.Sealingadditives

canplugvariousareasof

theradiator,EGRsystem

andoilcooler.Theplugging

ofthecoolingsystemcan

hamperheattransfer,causing

internalenginedamage.Do

notusesealingadditivesin

thecoolingsystem.Theuse

ofsealingadditivescan:

•Buildupincoolant

low-owareas.

•Plugtheradiatorandoil

cooler.

•Damagethewaterpump

seal.

Failuretocomplymayresult

inequipmentorproperty

damage.

CoolingSystemSolubleOils

CAUTION:Theuseofsoluble

oilsinthecoolingsystemcan

causedamagetotheengine.

Solubleoilsinthecooling

systemcan:

•Damageheattransfer

surfaces.

•Damagesealsandhoses.

Failuretocomplymayresult

inequipmentorproperty

damage.

5

5-19

MaintenanceProcedures

Maintenance

Procedures

OilPanDrainPlug

Afterdrainingtheoil,discardthe

washerandreplacewithanewcopper

sealingwasher,torquetheboltto44

lb-ft(60Nm).

5

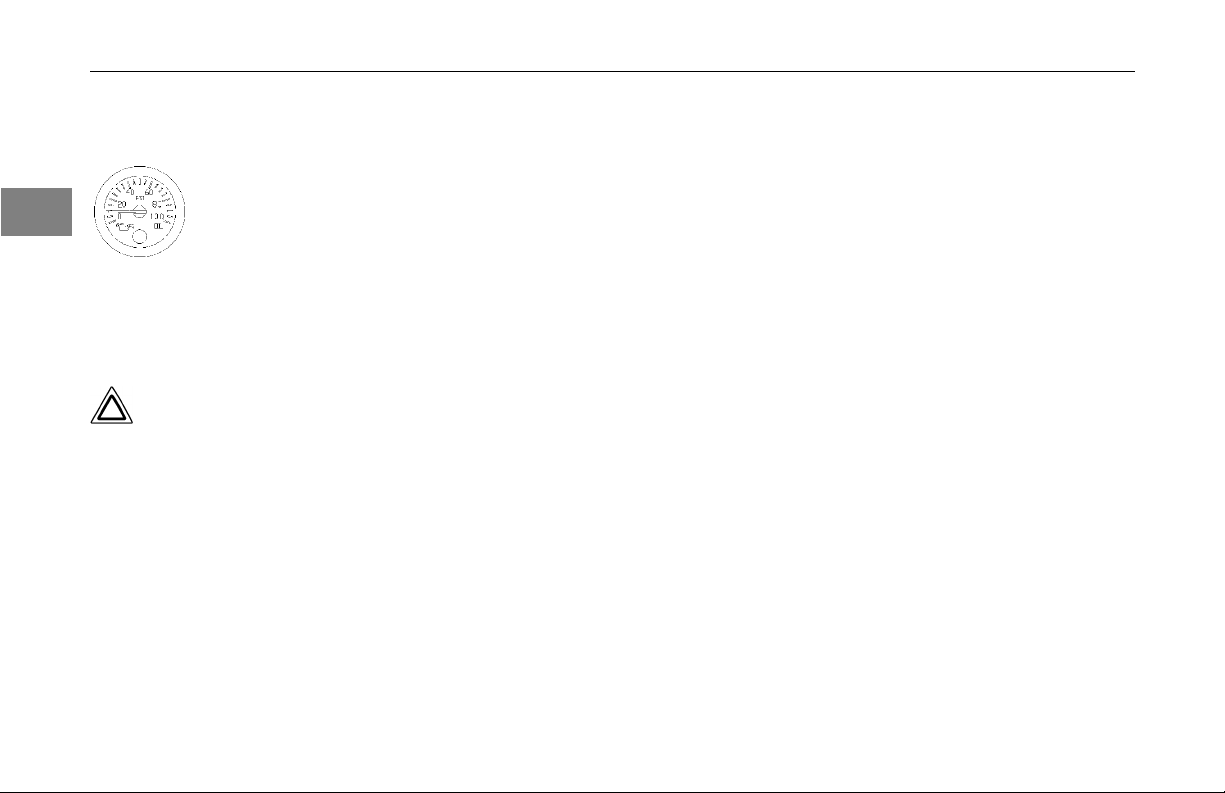

InspectionoftheEngineOil Level

NOTE:Ittakesapproximately

15minutesforalltheoiltorun

intothesumpwhentheengine

is‘warm.’Ifthelevelischecked

immediatelyafterswitchingoff

theengine,thedipstickwill

showalowoillevel.

1.Makesurethatthevehicleframe

railisstandingonaatandlevel

surface.

2.Makesurethatthevehicleis

horizontal,bothlengthwiseand

crosswise.Checkthiscarefully

onavehiclewithairsuspension.

Notethattheenginemaybe

inclinedupto4°dependingonthe

vehiclemodelandwheelbase.

3.Twistthedipstickhandletounlock

it,thenpullthedipstickoutofthe

holder.

4.Wipethedipstickcleanwitha

lint-freecloth.

5.Placethedipstickbackintothe

holder.

6.Pullthedipstickoutagainand

checktheoillevel.Theoillevel

shouldalwaysbebetweenthe2

marksonthedipstick.

7.Reinstallthedipstickandtwistto

lockitinplace.

5-

20

1.EngineOilHighLevel

2.EngineOilLowLevel

MaintenanceProcedures

ToppingUptheEngineOil

1.T opupwithoil,ifnecessary,via

thelleropening.Usethecorrect

gradeinthecorrectquantity.

2.Aftertoppingup,wait1minuteand

checktheoillevelagain.

3.Reinstalltheoilllcapandtwist

tolockitinplace.

NOTE:P ACCARrecommends

theuseofhigh-qualitySAE

15W40(APICJ-4)heavy-duty

engineoil.

5

5-21

MaintenanceProcedures

ReplacingEngineOilFilters

1.full-owOilFilter

2.centrifugalbypassOilFilter

Yourengineisequippedwithafull-ow

oillterandcentrifugalbypassoillter.

Bothltersaredesignedtocapture

5

contaminantsandremovedeposits

fromtheoiltoprolongthelifeof

internalmovingcomponents.Always

usequalityenginelubricatingoilsin

conjunctionwiththeappropriateoil

drainandlterchangeintervals.Refer

to“MaintenanceSchedule”beginning

onpage5-4fortherecommendedoil

andlterchangeserviceinterval.

OilFilterRemovalPreparation

1.Disconnectthechassisbattery

cableatthenegativebattery

terminal.

CAUTION:Before

beginningtoremove

and/ordisconnectany

components,waitatleast

5minutesafterthekey

switchisturnedOFF

fortheaftertreatment

DieselEmissionFluid

(DEF)dosingsystem

topurgetheDEFfrom

thesystem.TheDEF

systempurgestoprevent

damagefromfreezing.

Failuretocomplymay

resultinequipmentor

propertydamage.

WARNING:Electrical

shockhazard:Never

disconnectthebattery

clampwhentheengineis

running.Disconnecting

thebatteryclampswhile

theengineisrunningmay

resultindeath,personal

injuryorequipment

damagefromelectrical

archingordamageto

electricalcomponents.

Turnofftheengineand

placetheignitionswitch

intheOFFpositionbefore

disconnectingthebattery

clamps.Donotplaceany

toolsorothermaterials

ontopoforcloseto

thebatteries.Thiscan

causeadangeroushigh

currentshortcircuit

and,intheworstcase,a

batteryexplosion.Keep

allobjectsawayfrom

thebatteryterminals.

Alwaysbreakthecontact

betweenthebattery

clampandthenegative

terminalbeforeworking

5-

22

MaintenanceProcedures

onthevehicle.Working

onavehiclewhilethe

batteryisconnected

mayresultinelectrical

injuryordamage.Always

disconnectthebattery

atthenegativeterminal

whenperformingservice

procedures.

2.Placeanoilcollectionpandirectly

undertheoillter.

CentrifugalBypassOilFilter

Removal

1.Removethecapofthecentrifugal

oillter.Useahexagonalsocket

toavoiddamagingtheoilltercap.

2.RemovetheO-ringfromthescrew

cap.

WARNING:Lubricatingoil

cancauseskinirritationor

skininjury.Topreventskin

injury,avoidunnecessary

contactwiththelubricating

oil.Wearprotectiveclothing,

eyewearandgloveswhen

handlinglubricatingoil.

Failuretocomplymayresult

inpersonalinjury.

5

5-

23

MaintenanceProcedures

CentrifugalBypassOilFilter

Installation

1.LightlylubricatetheO-ring(1)with

engineoil.

2.FitthenewO-ring(1)ontothecap

(2).

3.Mountthecentrifugallter(3)with

5

itstopsideinthebearingofthe

screwcap(2).

4.Checktoensurethecentrifugal

lter(3)canrotatefreely .

5.Positionthescrewcapcarefully

ontotheoilmodule.

6.Tightenthescrewcapbyhand

untilitreachestheendposition.

7.Tightenthescrewcapto354lb-in

(40Nm).Useahexagonalsocket

toavoiddamagingtheoilltercap.

Full-owOilFilterRemoval

1.Unscrewthecapafewturns

anddrainthelterhousing.Use

ahexagonalsockettoavoid

damagingtheoilltercap.

2.Removethecap,withtheoillter

cartridge,fromthelterhousing.

Thenremovetheoilltercartridge

fromthescrewcap.

3.RemovetheO-ringfromthescrew

cap.

4.Removethecentrifugallter.

WARNING:Lubricatingoil

cancauseskinirritationor

skininjury.Topreventskin

5-

24

MaintenanceProcedures

injury,avoidunnecessary

contactwiththelubricating

oil.Wearprotectiveclothing,

eyewearandgloveswhen

handlinglubricatingoil.

Failuretocomplymayresult

inpersonalinjury.

Full-owOilFilterInstallation

1.LightlyoilthenewO-ring.

2.InstallanewO-ringontothescrew

cap.

3.Installthescrewcap,withthe

oilltercartridge,ontothelter

housing.Tightenthescrew

capto354lb-in(40Nm).Use

ahexagonalsockettoavoid

damagingtheoilltercap.

AfterReplacingOilFilter(s)

1.Reconnectthechassisbattery

cableatthenegativebattery

terminal.SeeWarningsat

Centrifugaloillterremoval

preparation.

2.AddapprovedengineoilSAE

15W40(APICJ-4)tothemaximum

levelmarkedonthedipstick.

3.Startandruntheengineforve

totenminutesandcheckforany

oilleaks.

4.Removeoilcollectionpanand

disposeofanyspillageproperly.

5.Checkengineoillevelandtopup

asnecessary .

°chassismustbeonlevel

surface

°waitatleastveminutesifthe

enginehasbeenhot

°pullthedipstickandwipewith

aclean,lintfreecloth

5

5-

25

MaintenanceProcedures

°reinsertthedipstick,then

removeandchecktheoillevel

°addapprovedengineoilSAE

15W40(APICJ-4)tothe

maximumlevelmarkedonthe

dipstick

5

ReplacingFuelFilter

WARNING:Whenremoving

thefuellter ,aquantityoffuel

willescape.Donotsmokeor

allowanopenameinclose

proximity.Failuretodoso

couldigniteareorcausean

explosionwhichcouldresult

inseriousinjurytoyouand/or

bystanders.Failuretocomply

mayresultindeath,personal

injury,equipmentorproperty

damage.

NOTE:Thefuellterandthe

handpumparelocatedonthe

left-handsideoftheengine.

Removal

1.Airbleedscrew

2.Fuellterhousing

3.Fuellter

1.Loosenthefueltankcaptorelieve

anypressureinthefueltank.

2.Cleanthefuellterhousing(2)

andsurroundingarea.

CAUTION:Dirtinthe

fuelsystemcanleadto

signicantdamageto

thefuelsystem.Failure

tocomplymayresultin

equipmentorproperty

damage.

5-

26

MaintenanceProcedures

3.Removethefuellter(3)by

rotatingitcounter-clockwise.Use

alterwrenchtoremove.

NOTE:Preventfuelfrom

leakingordrippingonthe

startermotor.

NOTE:Thefuellter

cartridgeisadisposable

lterandmaynotbe

cleanedandreused.

Disposeofthelteras

chemicalwaste.

Installation

4.Fuelprimerpumpknob

5.Fuelprimerpump

1.Beforeinstallingthenewfuellter,

lllterwithcleandieselfueland

lightlyoiltheltero-ringwithfuel

orengineoil.

2.Installthenewfuellter(3),

rotatingitclockwiseuntilthelter

o-ringmakescontactwiththelter

housing(2).Thentightenthelter

byhand¾ofarevolution.

3.Loosenthefuellterhousing

airbleedscrew(1)byrotatingit

counter-clockwise.

4.Loosenthefuelprimerpumpknob

(5)byrotatingitcounter-clockwise.

5.Operatetheprimerpump(4)by

movingtheknob(5)inandout

untilfuel(withoutairbubbles)

bleedsoutofthefuellterhousing

airbleedscrew(1).

6.Withtheprimerpumpknob(5)

pushedin,tightenthefuellter

housingairbleedscrew(1).

7.Next,operatetheprimerpump(4)

bymovingtheknob(5)inandout

untilpumpingresistanceincreases

noticeably.Thentightentheknob

byrotatingitclockwise.

8.Checkforleakageattheairbleed

screw(1)andfuellter(3).Tighten

ifnecessary.

WARNING:Checkthefuel

lterandairbleedscrew

forsignsofleakage.

Donotsmokeorallow

anopenameinclose

5

5-

27

MaintenanceProcedures

proximity.Failuretodo

socouldigniteareor

causeanexplosionwhich

couldresultinserious

injurytoyouand/or

bystanders.Failureto

complymayresultin

death,personalinjury,

equipmentorproperty

damage.

9.Starttheengineandrunitatidle

speedforseveralminutes.This

willallowanyairinthesystemto

escape.Thenturntheengineoff

andcheckthesystemforleakage.

10.Re-starttheengine.Iftheengine

5

doesnotstart,orrunserratic,

followtheprocedureunder

“StartingAftertheFuelT ankHas

RunDry”.

StartingAftertheFuelT ankHas

RunDry

Thefollowinginstructionsshouldonly

beusedinemergencysituationswhen

thefueltankhasrundry.Failureto

followthestartinginstructionsbelow

maydamagethestartermotor.

4.Fuelprimerpumpknob

5.Fuelprimerpump

1.Loosenthefuelprimerpumpknob

(5)byrotatingitcounter-clockwise.

2.Next,operatetheprimerpump(4)

bymovingtheknob(5)inandout

untilpumpingresistanceincreases

noticeably.Thentightentheknob

byrotatingitclockwise.

3.Operatethestartermotoruntilthe

enginestarts.

NOTE:Themaximumtime

thestartermotorcanbe

switchedonatanygiven

timeis30seconds.

4.Iftheenginedoesnotstartwithin

thistime,allowthestartermotor

tocooldownforatleast1minute

beforerepeatingtheprocedure.

WARNING:Donotloosen

anyfuellinettingsinorder

tobleedthefuelsystemof

air.Thesystemisunder

highpressurewhich,when

relieved,couldcausedeath,

personalinjury,equipmentor

propertydamage.

5-

28

MaintenanceProcedures

ReplacingCoolantFilter

Yourengineisequippedwitha

CoolantFilterdesignedtocapture

andremoveharmfuldepositsfrom

thecoolingsystemtohelpprolong

systemlife.Refertothe“Maintenance

Schedule”beginningonpage5-4for

therecommendedcoolantlterchange

serviceinterval.

WARNING:Donotremove

theradiatorcaponahot

engine.Itcancausescalding

coolanttosprayoutand

youcouldbeburned.Ifthe

enginehasbeenoperated

withinthelast30minutes,

beverycarefulinremoving

theradiatorcap.Failureto

complymayresultindeath,

personalinjury,equipmentor

propertydamage.

•Protectface,hands,and

armsagainstescaping

uidandsteamby

coveringthecapwith

alarge,thickrag.

WARNING:Handlecoolant

andantifreezecarefully.

Ethyleneglycolantifreezeis

poisonous.Storeinoriginal

uidcontaineronly,and

alwayskeepoutofthereach

ofchildren.Failuretocomply

mayresultindeath,personal

injury,equipmentorproperty

damage.

•Also,neverremovethe

caponthesurgetank

whiletheengineisstill

hot.Waituntilthecoolant

temperatureisbelow

120°F(50°C).Scalding

steamanduidunder

pressuremayescapeand

causeseriouspersonal

injuries.

Removal

1.Slowlyloosentheradiatorcapto

relieveanypressureinthecooling

system.

2.Closethecoolantltershutoff

valvebyrotatingittothe“C”

position.

3.Cleanthecoolantlterand

surroundingarea.

4.Removethecoolantlterby

rotatingitcounter-clockwise.Use

alterwrenchtoremove.

5

5-

29

MaintenanceProcedures

NOTE:Asmallamountof

coolantcouldleakoutwhen

thelterisloosened.Usea

suitablecontainertocatch

anydrips.

NOTE:Thecoolantlter

cartridgeisadisposable

lterandmaynotbe

cleanedandreused.

Disposeofthelteras

chemicalwaste.

5.RemovetheO-ringfromthe

coolantlterhousing,ifithasnot

beenremovedalready .

5

Installation

1.Applyasmallamountofcoolantto

thesealingringofthenewcoolant

lter.

2.Installthelter,rotatingit

clockwiseuntilthesealingring

makescontactwiththelter

housing.Thentightenbyhand½¾ofarevolution.

3.TurntheshutoffvalvetotheOpen

position.

4.Reinstalltheradiatorcap.

5.Starttheengineandrunatidle

speedforseveralminutes.Check

forleaks.

EmergencyRepairs

ReplacingBelts

NOTE:IMPORT ANT :Always

tthesametypeofbeltsas

theonesreplaced.

5-

30

MaintenanceProcedures

PolyV-belt,CoolantPumpDriveand

FanDrive

Removal

1.Disconnecttheelectricalground

wirefromthebattery.

2.Placeaex-barwitha15-mm

socketontheautomaticbelt

tensionerrollerfastenerasshown.

Rotatetheex-barasshownin

thediagramtorelievebelttension.

3.Withthebelttensionerpressure

relieved,removethepolyV-belt

fromthepulleys.

NOTE:Thetensionercan

betemporarilyblocked

witha0.16-0.2inch(4-5

mm)thickpin(bore).This

facilitatesremovaland

installationofthepoly

V-belt.

4.Afterremovingthebelt,carefully

allowthebelttensionertospring

backtothestop(ifithadnotbeen

temporarilyblocked).

5.Inspectthepulleysfordamage,

rust,andgreasedeposits.Clean

orreplaceasnecessary .

Installation

1.PlacethenewpolyV-beltoverthe

pulleys,makingcertainthebelt

fallsintoallthebeltpulleygrooves.

2.Afterinstallingthebelt,carefully

allowthebelttensionertospring

backtoitsnormalposition.Ifthe

tensionerhadbeentemporarily

blocked,relievetensioner

pressureenoughtoremove

thelockingpin,thenallowthe

tensionertospringbacktoits

normalposition.

3.Reconnecttheelectricalground

wiretothebattery.

5

5-

31

MaintenanceProcedures

RemovalandInstallation—Poly

V-belt,Alternatorand

Air-ConditioningCompressor

Drive

Removal

1.RemovethepolyV-beltfromthe

fanandcoolantpumpdriveas

describedin“PolyV-belt,Coolant

PumpDriveandFanDrive”

“Removal”.

2.Next,placeaex-barwitha

15mmsocketonthealternator

andairconditioningcompressor

drivebelttensionerrollerfastener

asshown.Movethebarinthe

5

directionshowntorelievepressure

onthebelttensioner.

3.Withthebelttensionerpressure

relieved,removethepolyV-belt

fromthepulleys.

NOTE:Thetensionercan

betemporarilyblocked

witha0.16-0.2inch(4-5

mm)thickpin(bore).This

facilitatesremovaland

installationofthepoly

V-belt.

4.Afterremovingthebelt,carefully

allowthebelttensionertospring

backtothestop(ifithadnotbeen

temporarilyblocked).

5.Inspectthepulleysfordamage,

rustandgreasedeposits.Clean

orreplaceasnecessary .

Installation

1.PlacethenewpolyV-beltoverthe

pulleys,positioningthenewbelt

sothatitfallsintoallthebeltpulley

grooves.

2.Afterinstallingthebelt,carefully

allowthebelttensionertospring

backtoitsnormalposition.Ifthe

tensionerhadbeentemporarily

blocked,relievetensioner

pressureenoughtoremove

thelockingpin,thenallowthe

tensionertospringbacktoits

normalposition.

3.Reinstallthecoolantpumpand

fandrivepolyV-beltaspreviously

describedin“PolyV-belt,Coolant

PumpDriveandFanDrive”

“Installation”.

4.Reconnecttheelectricalground

wiretothebattery.

CleaningtheEngine

Whencleaningtheengine,follow

theinstructionsfromthevehicle

manufacturerOperator’sManualand

observeallenvironmentalprotection

regulations.

5-

32

CAUTION:Donotdirectwater

ontoelectricalcomponents,

plugconnectors,sealsor

exiblehosesontheengine.

Watermayenterthepart

causingelectricaldamage

orcontaminatingoil.To

preventdamagetoengine

components,keepthewater

movingatalltimeswhile

cleaningtheengine.Failure

tocomplymayresultin

equipmentdamage.

MaintenanceProcedures

5

5-33

Information

EngineIdentication

EngineComponentLocations......6-3

EPALabel...............6-4

Warranty

UnitedStatesandCanadaPACCARMX

EngineCoverage...........6-5

UnitedStatesandCanadaFireApparatus

TruckApplicationsCoverage......6-9

EmissionWarranty..........6-13

CaliforniaEmissionControlSystem

Warranty,On-Highway........6-15

6

6-1

EngineIdentication

EngineIdentication

RightSideofEngine

LeftSideofEngine

EngineComponent Locations

1.CoolantFilter

2.Full-owOilFilter

3.CentrifugalBypassOilFilter

4.OilCooler

5.Turbocharger

1.FuelFilter

2.AirCompressor

3.PowerSteeringPump

4.Starter

5.FuelPump

6.ElectronicControlModule(ECM)

7.CrankcaseVent

8.Alternator

9.A/CCompressor

6

6-3

EngineIdentication

EPALabel

TheEPAlabelprovidesimportantfacts

abouttheengine.TheEPAlabelis

locatedontopoftheenginevalve

cover.TheengineEP Alabelmust

notbechangedunlessapprovedby

PACCAR.

1.EPALabelLocation

6

TheEP Alabelprovidesmanydetails

regardingtheengine.Somefactsthat

arefoundontheEPAlabelincludethe

following:

•Fuelrate

•Idlespeed

•Maximumratedspeed

•Valvelash

•Maximumpowerrating

•Dateofmanufacture

•Enginedisplacement

6-4

Warranty

Warranty

UnitedStatesandCanada PACCARMXEngine Coverage

ProductsWarranted

ThiswarrantyappliestonewP ACCAR

MXEnginessoldandusedinthe

UnitedStatesorCanadaandoperated

inon-highwayapplicationswithone

exception–thereisdifferentwarranty

coverageforenginesusedinthere

apparatustruckapplications.

ThePACCARMXEngineiswarranted

directlytotherstpurchaserby

PACCAR.

BaseEngineWarranty

Thiswarrantycoversanyfailuresofthe

Enginewhichresult,undernormaluse

andservice,fromadefectinmaterial

orfactoryworkmanship(Warrantable

Failure).Thiscoveragebeginsonthe

dateofdeliveryandendstwoyearsor

250,000miles(400,000kilometers)or

6,250hours,whicheveroccursrst,

afterthedateofdeliveryoftheEngine

totherstpurchaser.

Additionalcoverageisoutlinedinthe

EmissionWarrantysection.

MajorEngineComponentsWarranty

ThereisanEngineWarrantyperiod

of60months,500,000miles(800,000

kilometers)or12,500hours,whichever

occursrst,afterthedateofdelivery

oftheEnginetotherstpurchaserfor

thefollowingEngineparts:

•CylinderBlockCasting

•MainBearingBolts

•CylinderHeadCasting

•CylinderHeadBolts

•Crankshaft

•Camshaft

•CamFollowerAssemblies

•ConnectingRodAssemblies

•CrankshaftGear

•CamshaftGear

•CamshaftIdlerGear

6

•LubePumpGear

5

6-

Warranty

6

•FlywheelHousing

•WaterPumpHousing

•ThermostatHousing

PACCARResponsibilities

PACCARwillpayforallpartsandlabor

neededtorepairthedamagetothe